Backboard of solar battery with seven-layer structure

A solar cell and layer structure technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of fluoroplastic layer peeling, low bonding strength, and backplane loss of weather resistance, so as to improve reliability and enhance bonding Strength, the effect of improving the bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this case, the same components are provided with the same reference numerals.

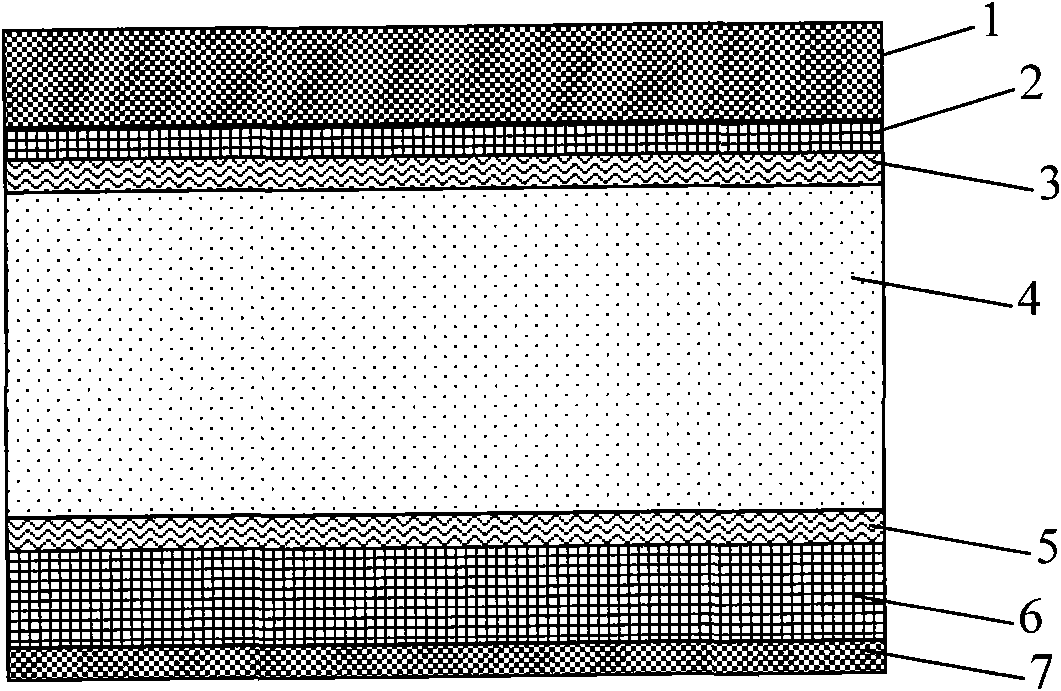

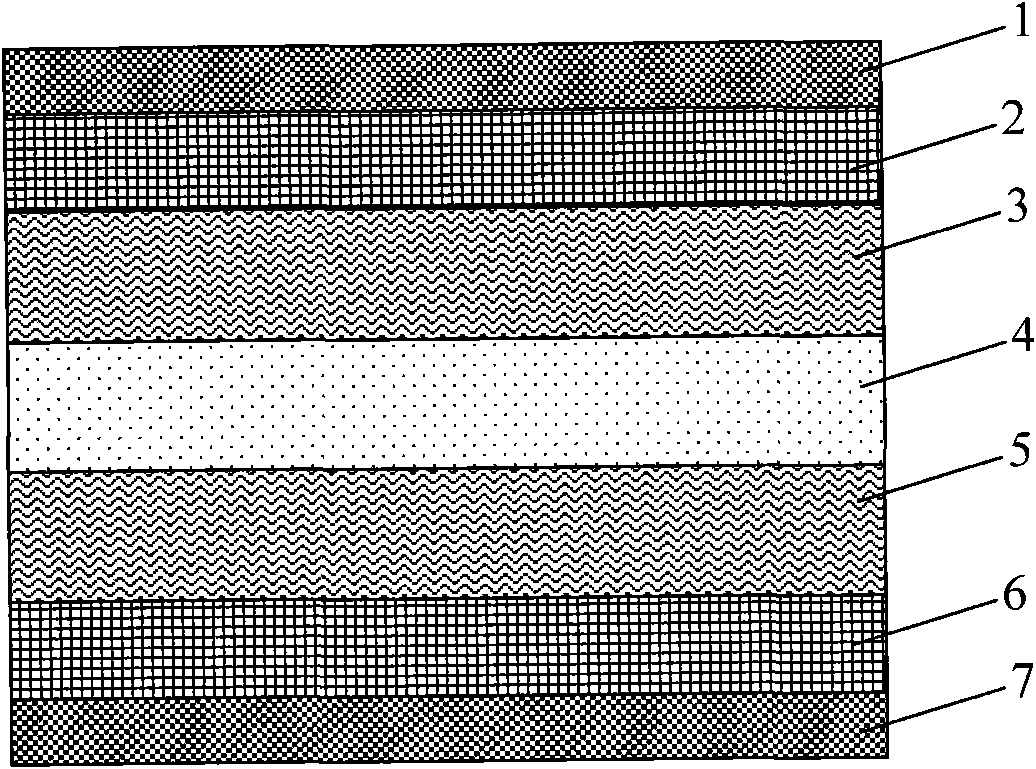

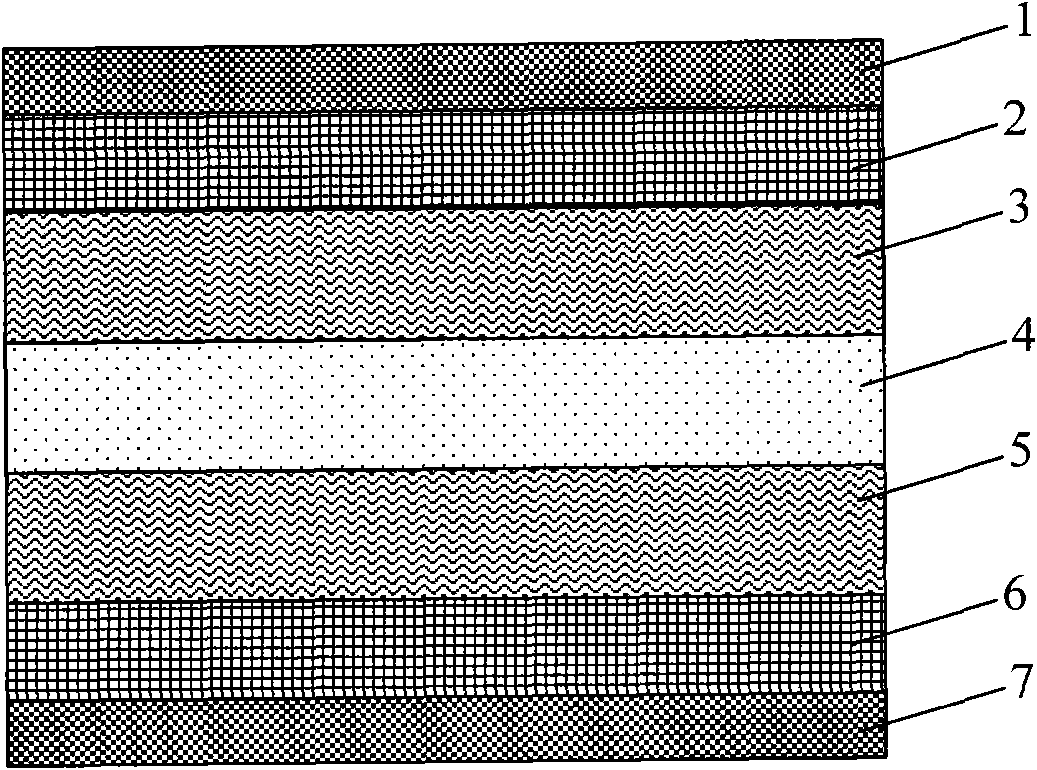

[0027] See figure 1 and figure 2 As shown, the solar battery back sheet of the seven-layer structure of the present invention includes a first fluoroplastic weather-resistant layer 1, a first transition layer 2, a first adhesive layer 3, a structural reinforcement layer 4, and a second adhesive layer from top to bottom. Layer 5, the second transition layer 6 and the second fluoroplastic weather-resistant layer 7, the first fluoroplastic weather-resistant layer 1 is attached to the first transition layer 2, and the first transition layer 2 is bonded by the first Layer 3 is bonded to the structural reinforcement layer 4, and the structural reinforcement layer 4 is bonded to the second transition layer 6 through the second adhesive layer 5, and the second transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com