Special-purpose waterproof bonding layer for drainage asphalt pavement and design method thereof

A technology of waterproof adhesive layer and drainage asphalt, which can be applied to cohesive pavement, roads, roads and other directions paved on site. It can solve the problems of large void ratio, water damage, and easy water seepage, so as to improve service life and enhance durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

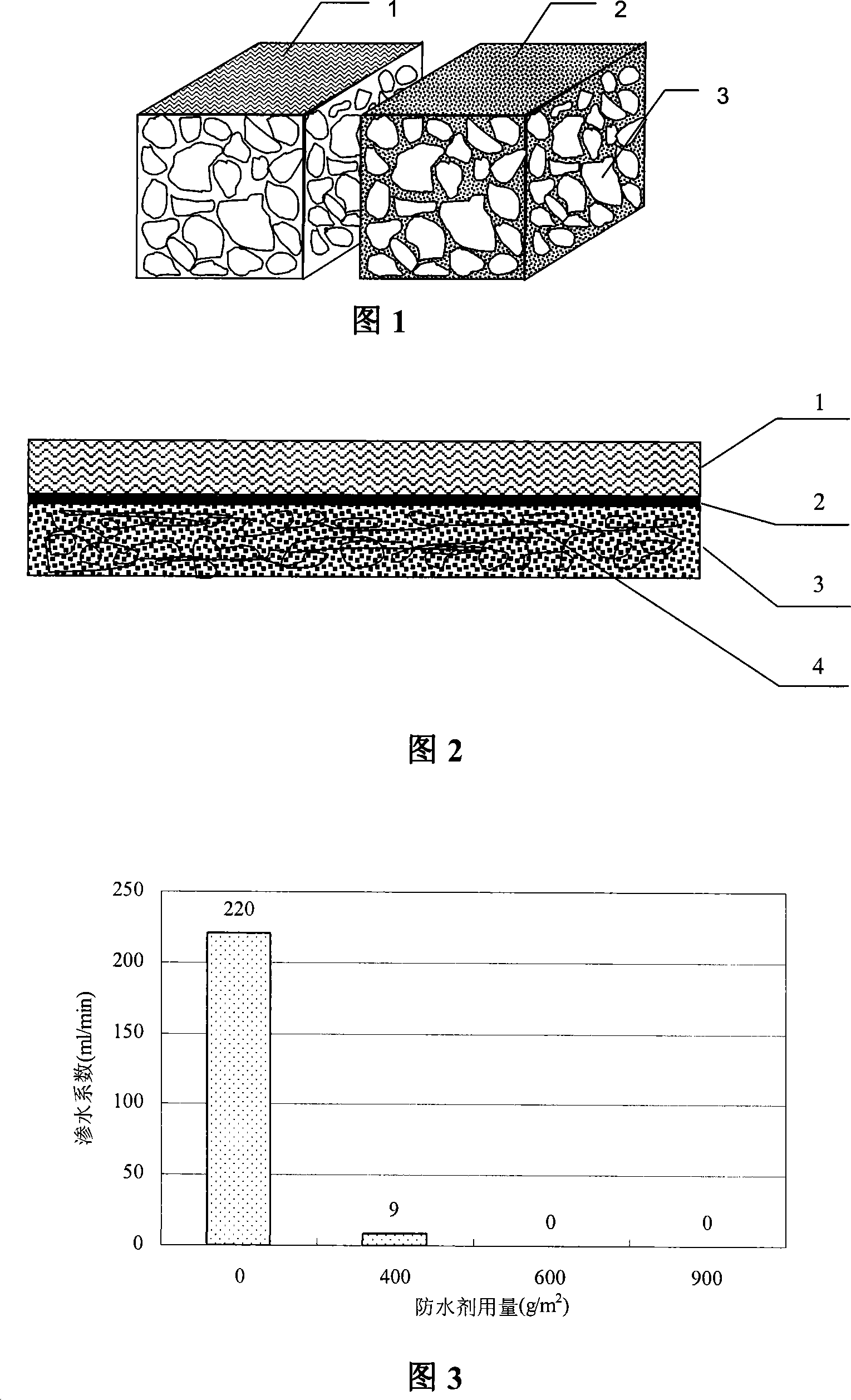

[0038] The structural layer of the special waterproof adhesive layer for drainage asphalt pavement embodiment 1 is laid as follows:

[0039] 1. Clean the AC-20 densely graded asphalt concrete pavement, and use a sprinkler to clean the pavement in a large area to remove the residual mud and dust in the depth of the pavement structure. After the pavement is dry, keep the construction section of the drainage asphalt pavement from being polluted.

[0040] 2. Spray the silicone rubber waterproofing agent in three times by manual spraying, the first time spraying along the driving direction, the dosage is 100g~200g / square meter, the silicone rubber waterproofing agent first solidifies and forms a film at the bottom; every 2~6 hours Finally, spray along the reverse direction of the vehicle for the second time, with an amount of 100g-200g / square meter, so that the silicone rubber waterproofing agent can be cured to form a film in the middle. After another 2 to 6 hours, spray along the...

Embodiment 2

[0044] According to the T0703-1993 wheel rolling method in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", four groups of rutting plate-shaped specimens of densely graded asphalt concrete AC-20 were produced. Its porosity is 6-8%. The first group of specimens were not treated, and the second, third and fourth groups of specimens were sprayed with 0.4kg / m 2 、0.6kg / m 2 and 0.9kg / m 2 Silicone rubber waterproofing agent, and then according to the provisions of T 0730-2000, conduct water penetration test on all test pieces. The test results are shown in Figure 3. When the amount of silicone rubber waterproofing agent exceeds 400g / m 2 When above, the water seepage coefficient of AC-20 densely graded asphalt mixture can be reduced to zero; the water seepage coefficient before and after artificial spraying of the silicone rubber waterproofing agent in Example 1 is listed in Table 1.

Embodiment 3

[0046] Asphalt Pavement Construction Depth Test

[0047] This test adopts the sand laying method to measure the change of the structure depth before and after spraying the anti-seepage agent. The operation steps are as follows: spread the known volume of standard sand on the asphalt road surface, and push the sand as flat as possible with a push plate with a rubber sheet attached to the bottom. For a circle, measure the diameter of the circle in the vertical direction and take the average value. The ratio of the volume of sand to the average area of the paved circle is the structural depth of the pavement. The surface texture depth TD is calculated as follows:

[0048] TD=1000V / (πD 2 / 4)

[0049] In the formula: TD-surface structure depth of mixture, mm

[0050] V - volume of sand, 25cm 3

[0051] D-average diameter of flattened sand, mm

[0052] According to the wheel rolling method of T0703-1993 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Eng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com