Premixed concrete and production method thereof

A technology of ready-mixed concrete and tailings, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of land occupation, environmental pollution, etc., achieve small water consumption, reduce costs, and reduce management costs and running cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

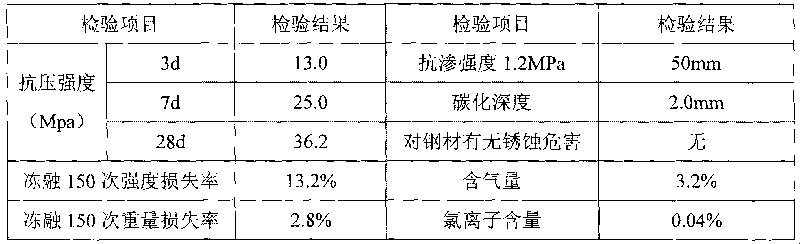

Embodiment 1

[0021] A kind of C35 ready-mixed concrete, each raw material ratio is (unit Kg / m 3 ): p.s32.5 cement 330-350, grade III fly ash 90-120, river sand 530-630, gravel 950-1050, tailings powder 170-180, water 170-180, tailings modifier 9.2~9.8.

[0022] The method for producing C35 ready-mixed concrete, the steps of the method are:

[0023] 1) Naturally air-dry the waste tailings to lose moisture;

[0024] 2) Prepare various raw materials according to the above ratio, and the order of feeding when stirring is: river sand, tailings powder, cement, fly ash, first stir for 20 seconds, then add gravel and stir for 20 seconds, and finally add water and tailings Blend the ore modifier for 60 seconds and tap out the blender.

Embodiment 2

[0026] A kind of C30 concrete, each raw material ratio is (unit Kg / m 3 ): p.s32.5 cement 290-310, grade III fly ash 90-120, river sand 550-650, gravel 970-1070, tailings powder 180-300, water 170-180, tailings modifier 8.1-8.7.

[0027] The method of producing C30 concrete is the same as embodiment one.

Embodiment 3

[0029] A kind of C25 concrete, each raw material ratio is (unit Kg / m 3 ): p.s32.5 cement 240-260, grade III fly ash 90-120, river sand 570-670, gravel 1010-1110, tailings powder 180-300, water 170-180, tailings modifier 6.7-7.3.

[0030] The method of producing C25 concrete is the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com