Oil-in-water type emulsion demulsifying agent and preparation method thereof

A technology of oil-in-water emulsion and demulsifier, which is applied in separation methods, liquid separation, mining wastewater treatment, etc. It can solve the problems of limited types and unsatisfactory performance, and achieve low equipment requirements, high oil removal efficiency, and low oil content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

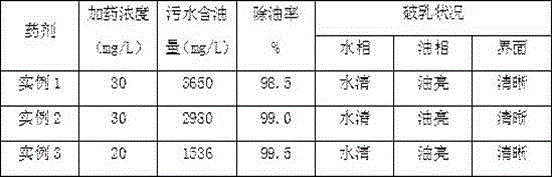

Examples

Embodiment 1

[0021] Add 340g of acetic acid into a 500mL four-necked bottle equipped with a thermometer and agitator, blow in nitrogen gas, raise the temperature to 50°C, add 103g of diethylenetriamine dropwise, and the reaction is exothermic. ℃, reacted for 12h, and the by-product water was removed to obtain a yellow viscous liquid——bisamide.

[0022] Add 50g of organic solvent ethanol, 2g of tin tetrachloride and 25g of the bisamide synthesized above to a 500mL four-necked bottle equipped with a thermometer, agitator and condenser in sequence. Propane 235g, stirred for 5h, cooled to obtain a brown-red viscous liquid—chlorinated polyether.

[0023] Add 350g of the chlorinated polyether synthesized above to a 500mL four-necked bottle equipped with a thermometer, agitator and condenser tube, raise the temperature to 50°C, blow in nitrogen gas, add 80g of dimethylamine aqueous solution dropwise, after the dropwise addition is completed, at 80°C Keep the temperature constant for 3 hours, rai...

Embodiment 2

[0025] Add 340g of acetic acid into a 500mL four-necked bottle equipped with a thermometer and agitator, blow in nitrogen gas, raise the temperature to 50°C, add 189g of tetraethylenepentamine dropwise, the reaction is exothermic, and the dropping time is controlled for about 2h, and the temperature continues to rise to 180°C ℃, reacted for 12h, and the by-product water was removed to obtain a yellow viscous liquid——bisamide.

[0026] Add 50g of organic solvent ethanol, 2g of tin tetrachloride and 25g of the bisamide synthesized above to a 500mL four-necked bottle equipped with a thermometer, agitator and condenser in sequence. 318g of propane, stirred for 5h, and cooled to obtain brown-red viscous liquid—chlorinated polyether.

[0027] Add 350 g of the above-synthesized chlorinated polyether to a 500 mL four-necked bottle equipped with a thermometer, agitator and condenser tube, raise the temperature to 50 ° C, blow in nitrogen gas, add 96 g of dimethylamine aqueous solution ...

Embodiment 3

[0029] Add 146g of adipic acid and 50g of water into a 500mL four-necked bottle with a thermometer and agitator, blow in nitrogen, raise the temperature to 50°C, add 103g of diethylenetriamine dropwise, the reaction is exothermic, and the dropping time is controlled for about 2h , continue to heat up to 160 ° C, react for 12 hours, remove the by-product water to obtain a yellow viscous liquid - bisamide.

[0030] Add 50g of organic solvent ethanol, 2g of tin tetrachloride and 20g of the bisamide synthesized above to a 500mL four-necked bottle equipped with a thermometer, agitator and condenser in sequence. Propane 315g, stirred for 5h, cooled to obtain a brown-red viscous liquid—chlorinated polyether.

[0031]Add 300g of the chlorinated polyether synthesized above to a 500mL four-necked bottle equipped with a thermometer, agitator and condenser tube, raise the temperature to 50°C, blow in nitrogen gas, add 98g of dimethylamine aqueous solution dropwise, after the dropwise addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com