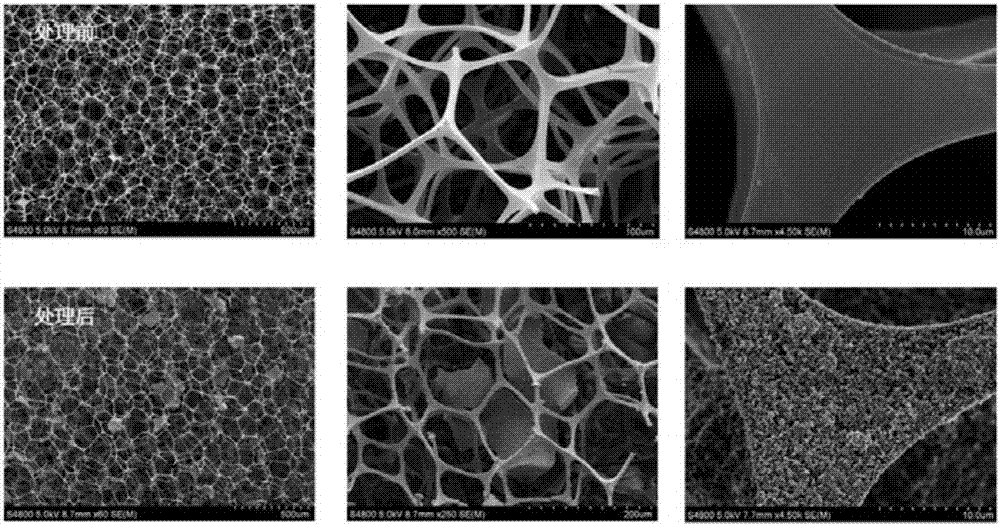

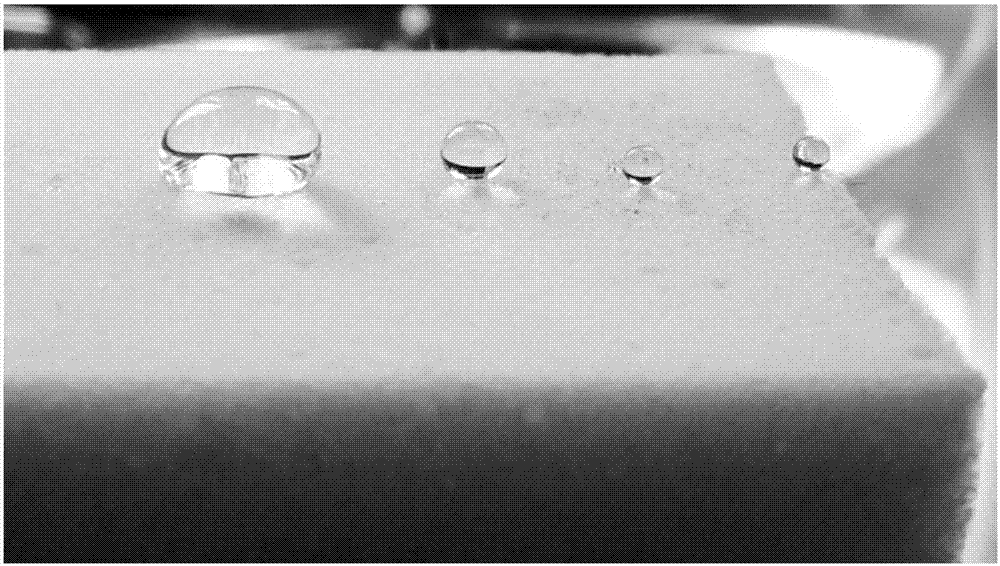

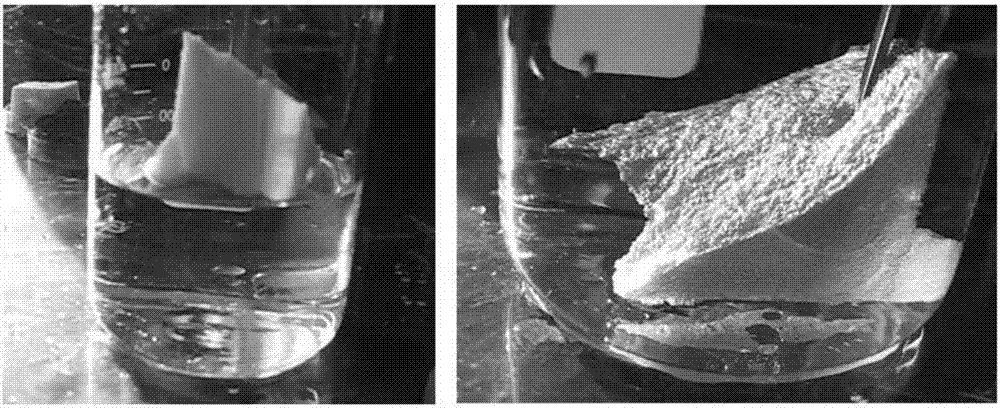

Superhydrophobic sponge body and preparation method thereof

A technology of super-hydrophobic sponge and sponge body is applied in the field of super-hydrophobic sponge body and its preparation, which can solve the problems of poor hydrophobic effect of adsorption and recovery materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) First, the melamine sponge was ultrasonically washed in deionized water and absolute ethanol for 15 minutes, placed in a stainless steel tray and dried in an oven at 80°C for 1 hour, then cut into 4×4×4cm 3 Small piece spare;

[0027] (2) Then soak the sponge body in 1M hydrochloric acid solution for 30 minutes, then wash it with deionized water until pH=7, take it out and dry it in an oven at 80°C for 3 hours;

[0028] (3) Weigh 2 grams of hydrophobic fumed silica nanoparticles, 7 grams of PDMS, and dissolve 1.2 grams of OMCTS curing agent in 200 milliliters of n-hexane, place in a single-necked flask and mechanically stir with a stirring rod for 6 hours until dissolved;

[0029] (4) Take out the prepared solution and pour it into a beaker, and soak the small pieces of sponge therein for 30 minutes;

[0030] (5) Put the small pieces of sponge in a stainless steel tray, and ventilate and dry at room temperature for 3 hours;

[0031] (6) The small pieces of sponge ...

Embodiment 2

[0039] (1) First, the melamine sponge was ultrasonically washed in deionized water and absolute ethanol for 20 minutes, placed in a stainless steel tray and dried in an oven at 60°C for 1 hour, then cut into 1×1×1 cm 3 Small piece spare;

[0040] (2) Subsequently immerse the sponge body in 1M chromic acid solution for 30 minutes, then wash it with deionized water until pH=7 of the lotion, take it out and dry it in an oven at 80°C for 3 hours;

[0041] (3) Weigh 0.4 grams of silica nanowires, 2 grams of PDMS, and 0.4 grams of curing agent dissolved in 60 milliliters of ethyl acetate, place in a single-necked flask and mechanically stir with a stirring rod for 4 hours until dissolved;

[0042] (4) Soak the small pieces of sponge in the modified solution for 2 hours, and place them in an ultrasonic cleaner for ultrasonic dispersion;

[0043] (5) Put the small pieces of sponge in a stainless steel tray, and ventilate and dry at room temperature for 3 hours;

[0044] (6) The smal...

Embodiment 3

[0047] (1) First, the polyurethane sponge was ultrasonically washed in deionized water and absolute ethanol for 15 minutes, placed in a stainless steel tray and dried in an oven at 70°C for 1 hour, then cut into 4×4×4cm 3 Small piece spare;

[0048] (2) Subsequently immerse the sponge body in 1M chromic acid / sulfuric acid solution for 1 hour, then wash with deionized water until pH=7 of the lotion, take it out and dry it in an oven at 80°C for 3 hours;

[0049] (3) Weigh 2 grams of hydrophobic fumed silica nanoparticles, 12 grams of PDMS, and dissolve 1.2 grams of curing agent in 200 milliliters of n-hexane, place in a single-necked flask and mechanically stir with a stirring rod for 5 hours until dissolved;

[0050] (4) Take out the prepared solution and pour it into a beaker, soak the small piece of sponge in it for 30 minutes, take it out and dry it at room temperature for 3 hours, and repeat this process 3 times;

[0051] (5) Put the small piece of sponge after the last w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com