Feeding system of food packaging barrel injection molding machine

A technology of food packaging and feeding system, applied in the field of machinery, can solve the problems of easy occurrence of loopholes, easy air involvement, and reduction of air bubble content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

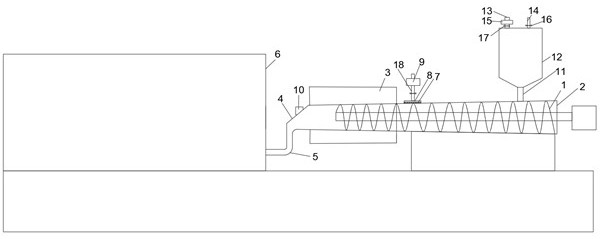

[0017] Such as figure 1 The feeding system of a food packaging barrel injection molding machine shown includes a screw feeder 1, a housing 2, a heater 3, an inclined baffle 4, an L-shaped feeding pipe 5, an injection molding machine body 6, micropores 7, negative Pressure chamber 8, first negative pressure pump 9, vibrator 10, feed port 11, storage tank 12, suction port 13, feed port 14, second negative pressure pump 15, valve 16, one-way valve 17, Connecting pipe 18.

[0018] Wherein, the top of the feeding port 11 of the screw feeder 1 is connected with a storage tank 12, and the storage tank 12 is formed with a suction port 13 and a feeding port 14; the suction port 13 is connected with a second negative pressure pump 15; The feed port 14 is equipped with a valve 16 . The shell 2 is conical; the end of the shell 2 is wrapped and fixed with a heater 3; the end of the shell 2 is formed with an inclined baffle 4 that gradually slopes downward along the feeding direction, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com