Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

582results about How to "Easy entry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

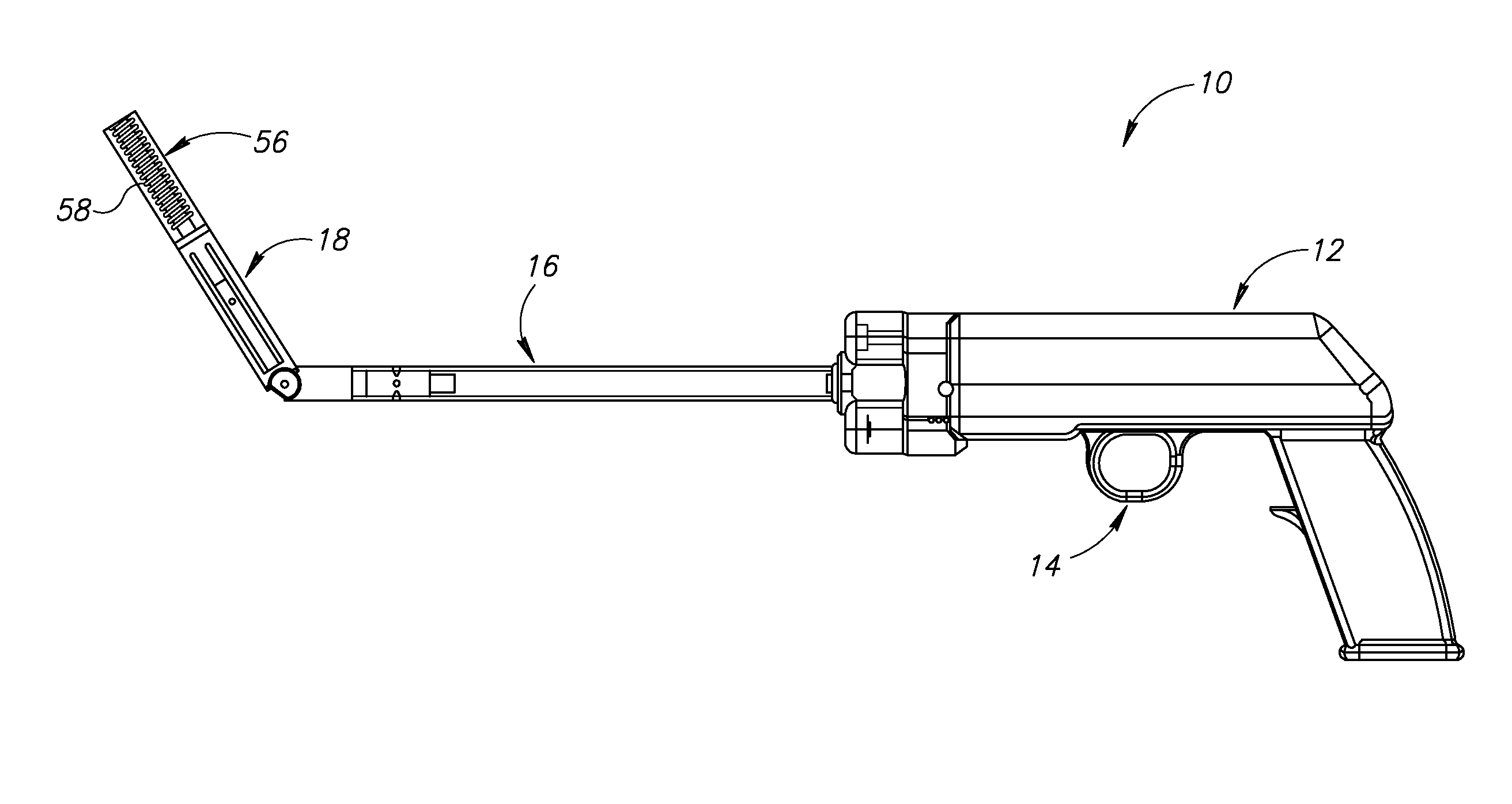

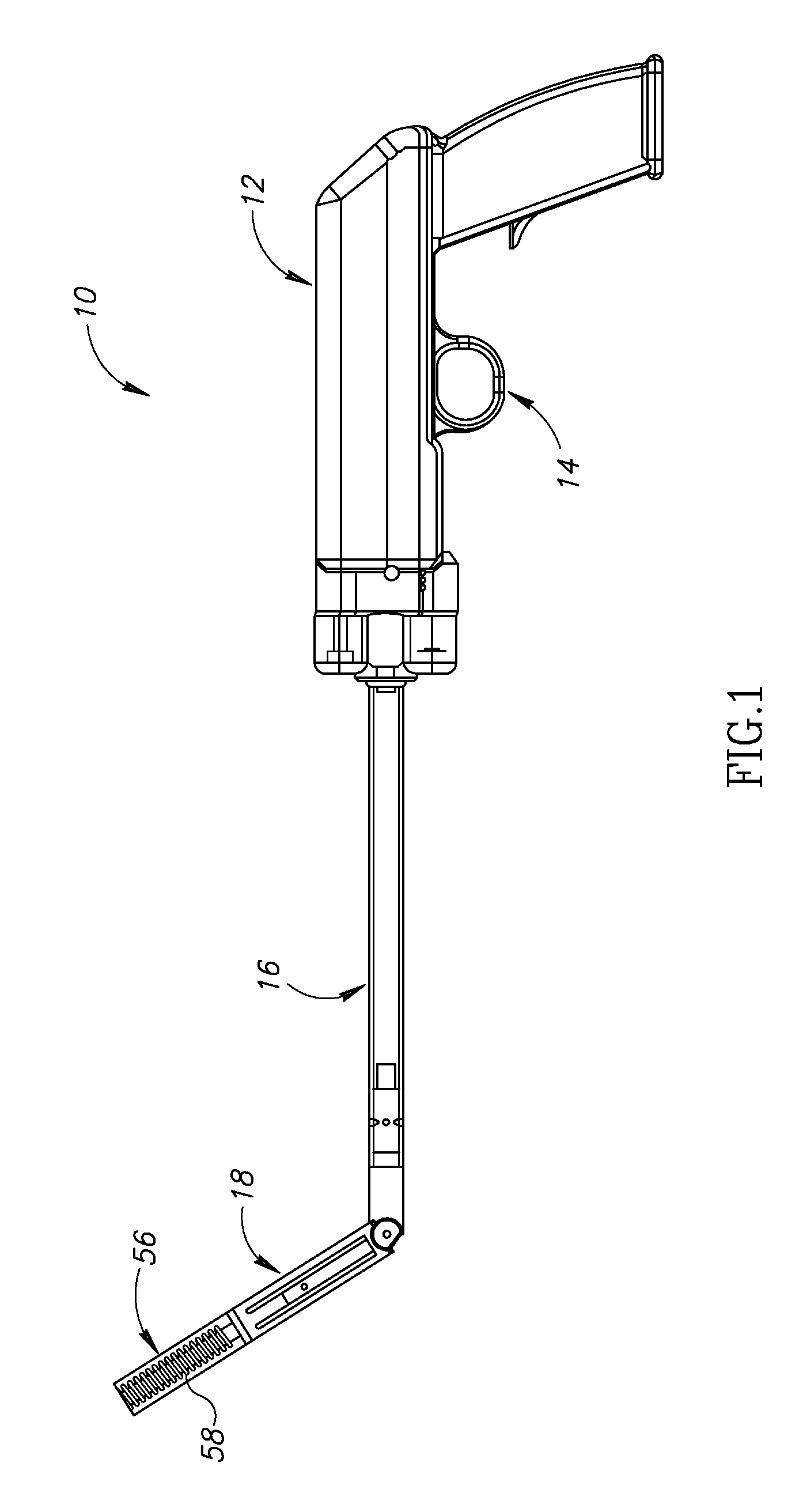

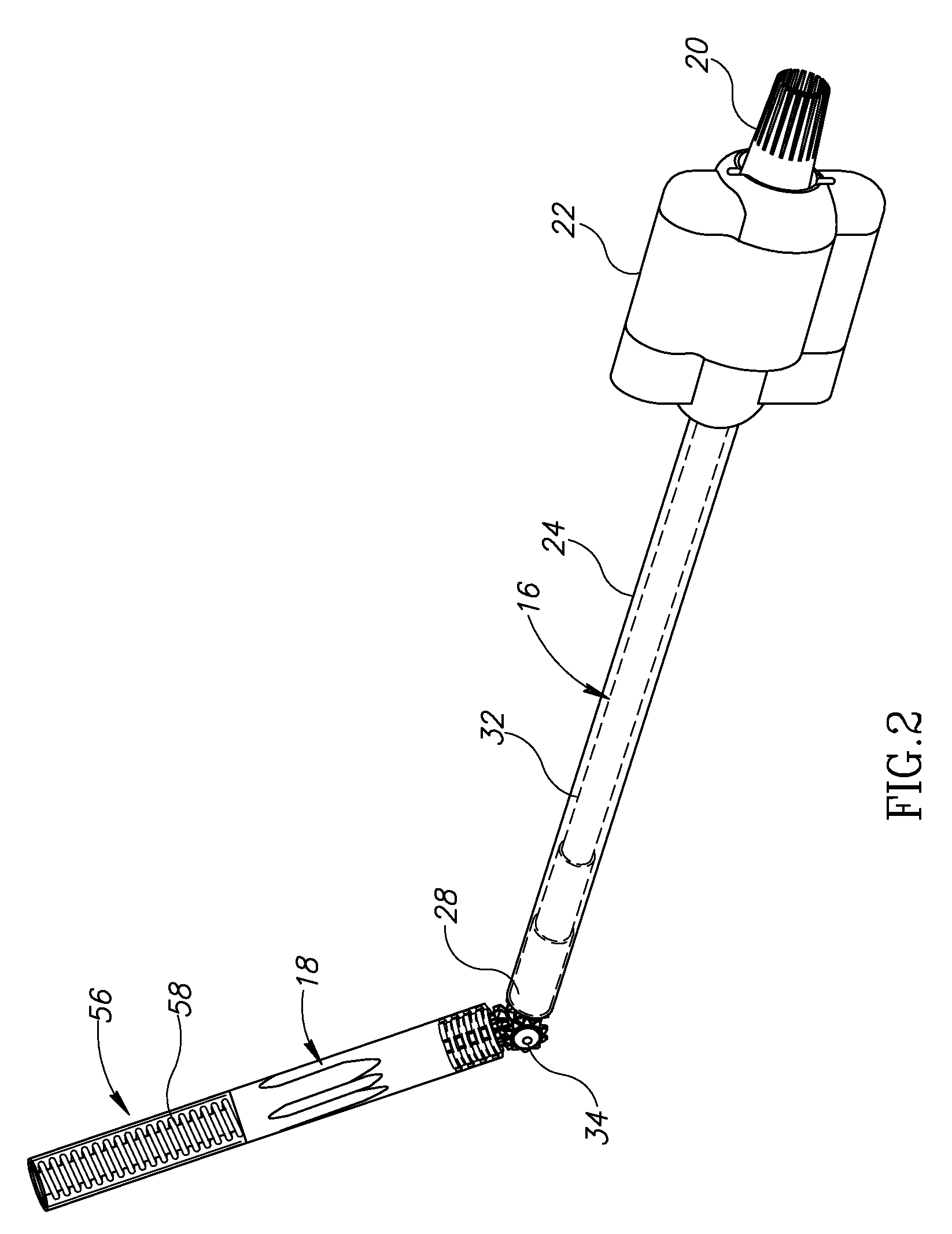

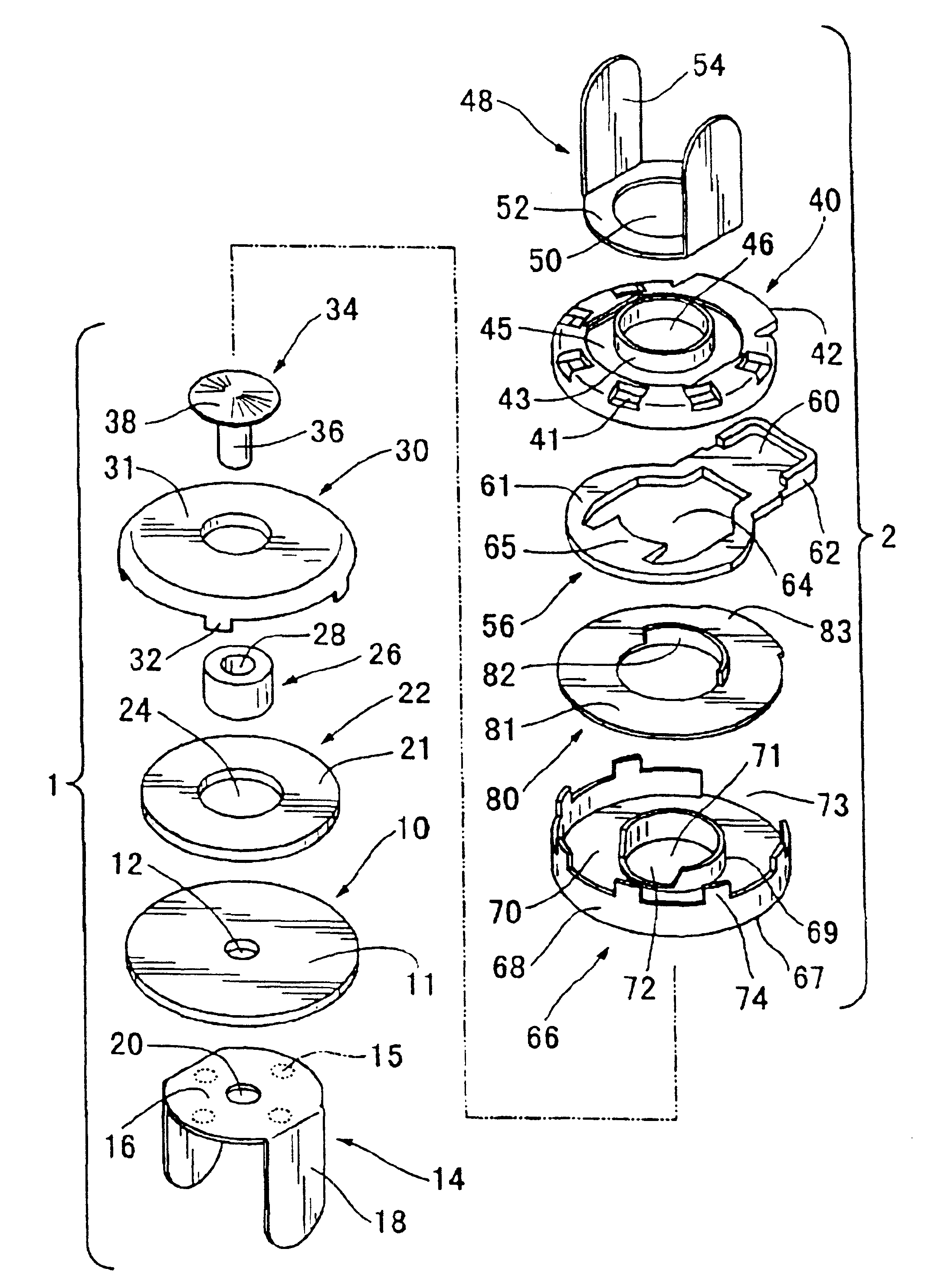

Device and method for applying rotary tacks

A tacker for applying a rotary tack, including a drive shaft coupled to a trigger, wherein operating the trigger causes rotation of the drive shaft, an articulated applicator arm pivotally connected to the drive shaft at a pivot, the articulated applicator arm including a rotatable output shaft connected to a magazine that holds a rotary tack, and a clutch mechanism which, at initial movement of the trigger, has a first orientation that causes the articulated applicator arm to pivot about the pivot until reaching a stop, and has a second orientation wherein upon continued movement of the trigger, the clutch mechanism permits the drive shaft to rotate the output shaft and cause application of the rotary tack from the magazine.

Owner:EASYLAP LTD

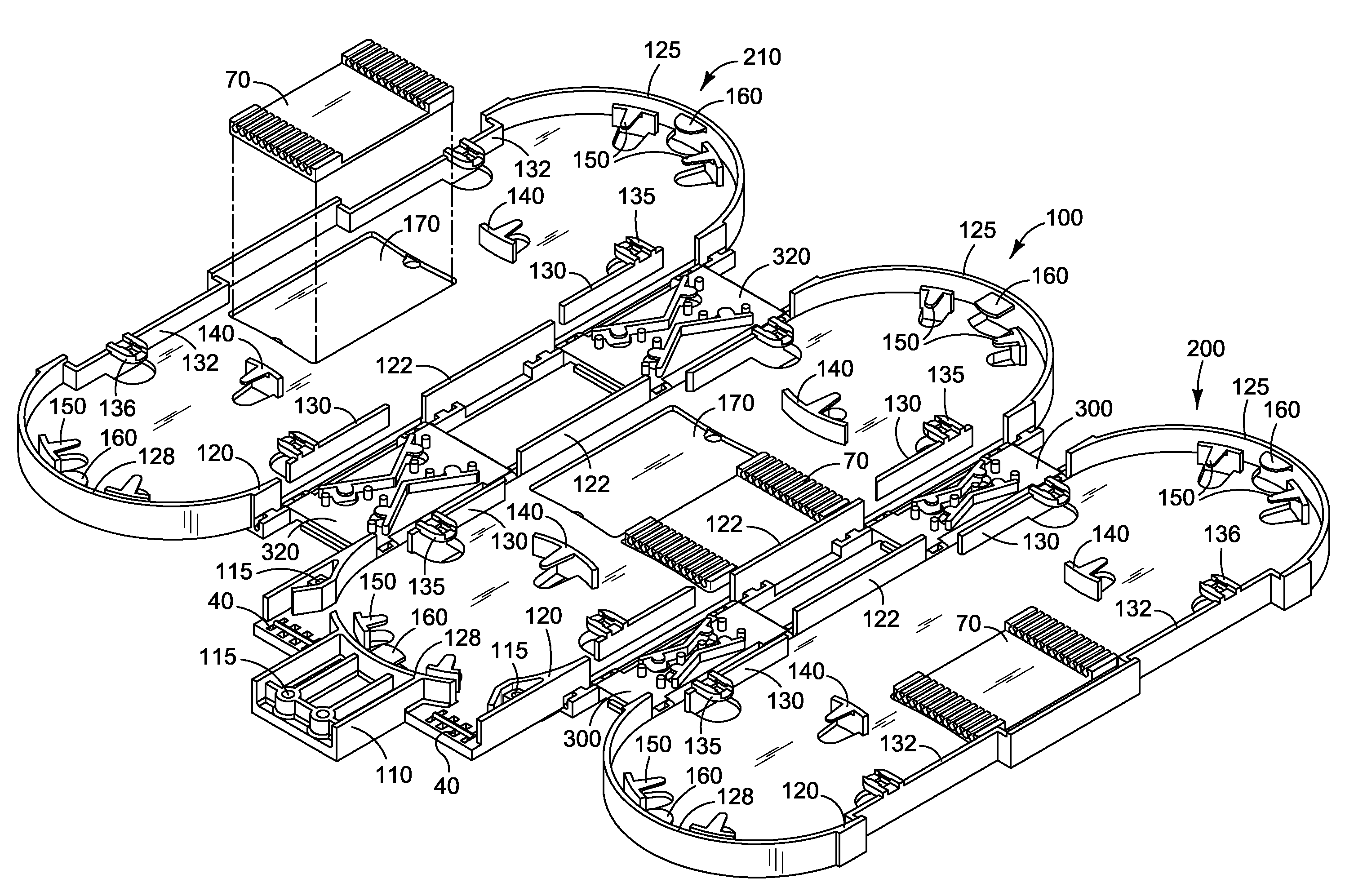

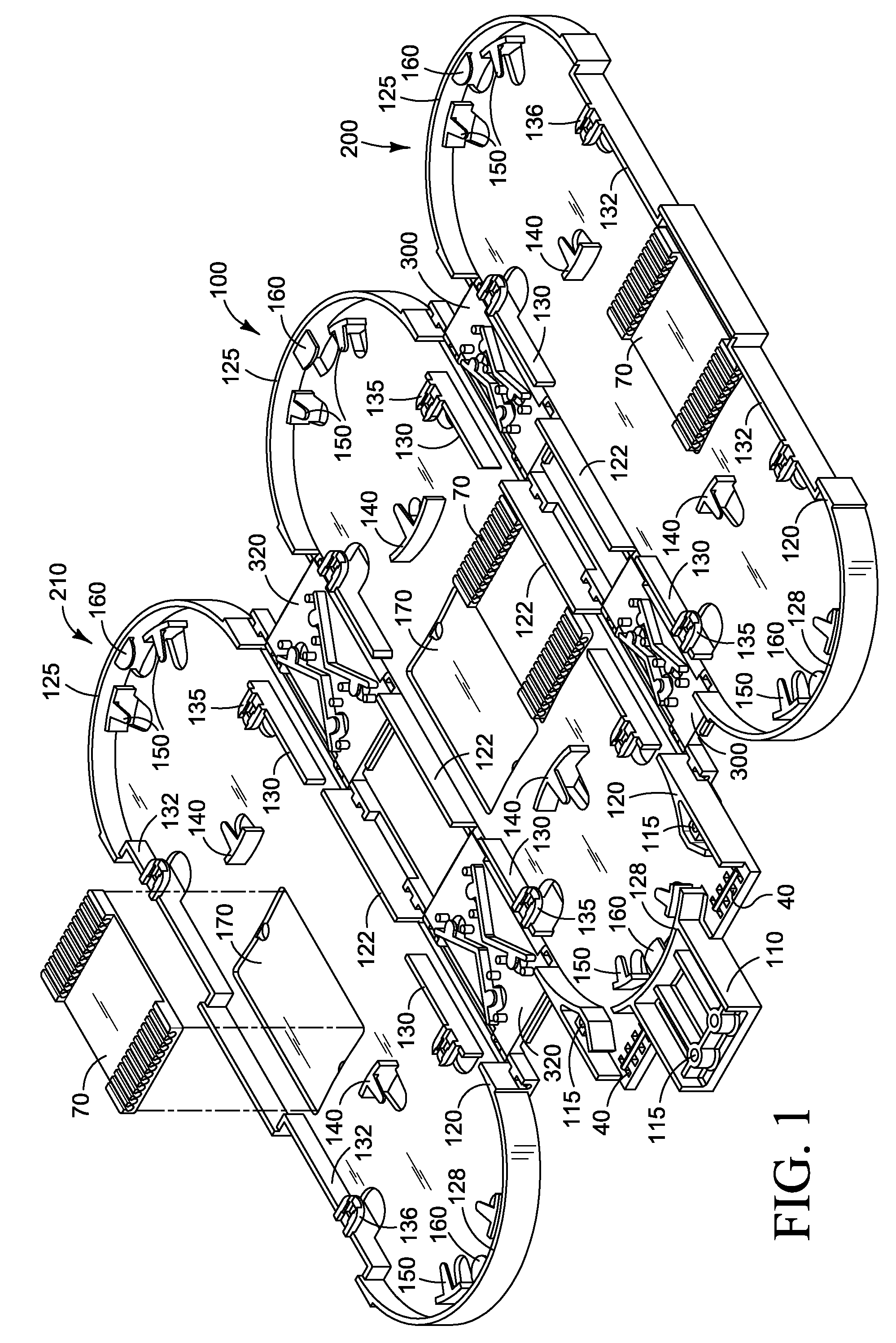

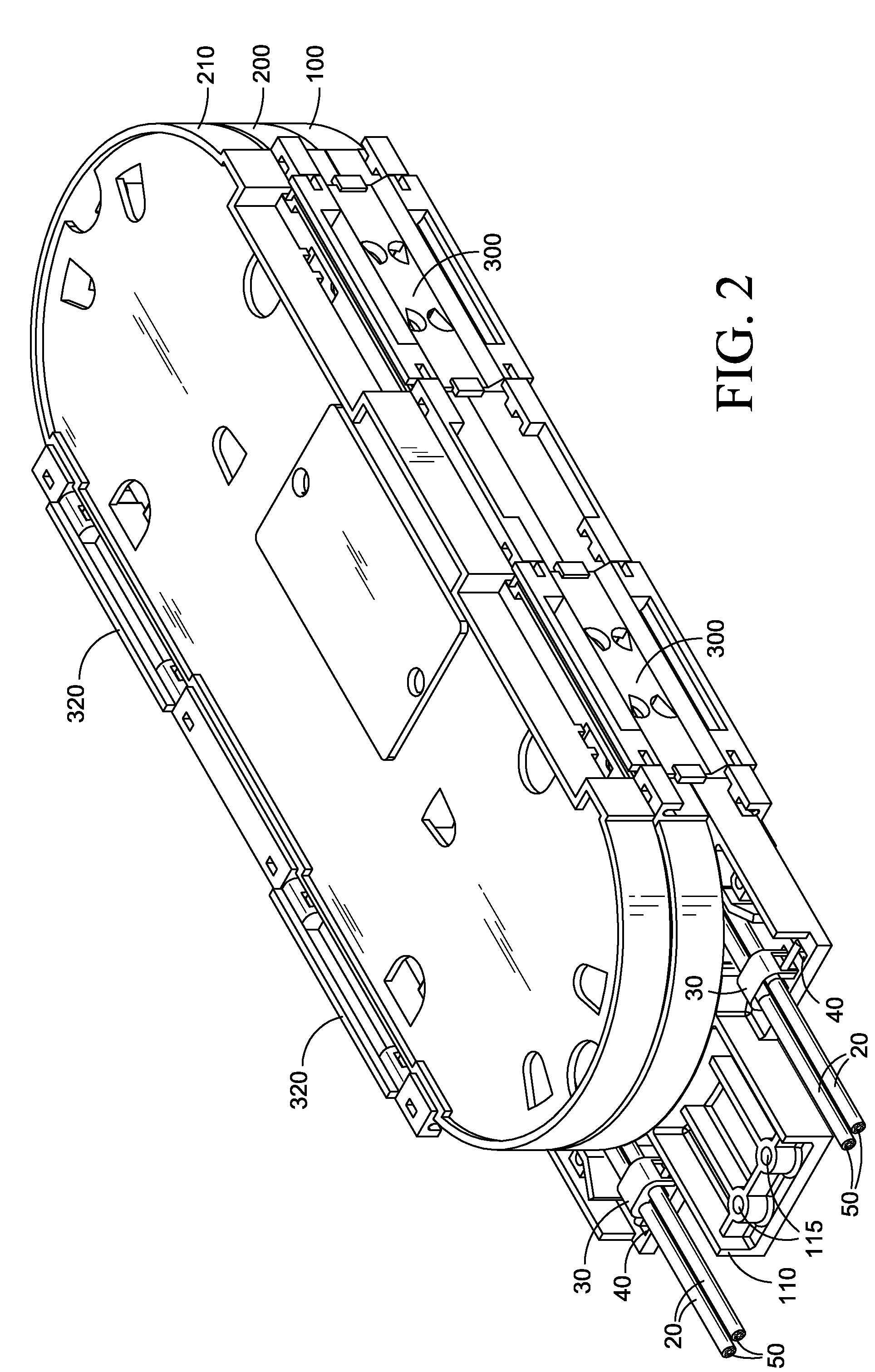

Fiber optic categorization and management tray

A fiber optic splice organizer stores optical fiber splices and sufficient slack to permit the fibers to be readily separated, such as for reorganization or to remake a splice. Multiple hinges connect a plurality of fiber trays side by side to provide pivotable connections between trays. A flat orientation of the trays enables splicing and coiling of fibers as they are loaded into a tray. The trays then pivot into a fiber storage position. Special features of the hinges provide support for fibers and splices as they are loaded into the trays. The hinges protect the fibers as the trays are pivoted as well as when the trays are in their folded position for storage without requiring buffer tubes. Multiple architectures for the organization of fibers are enabled without violating minimal bend radii, and while providing for ease of separation of individual fibers or groups of fibers.

Owner:GONZALES CURTIS PAUL +1

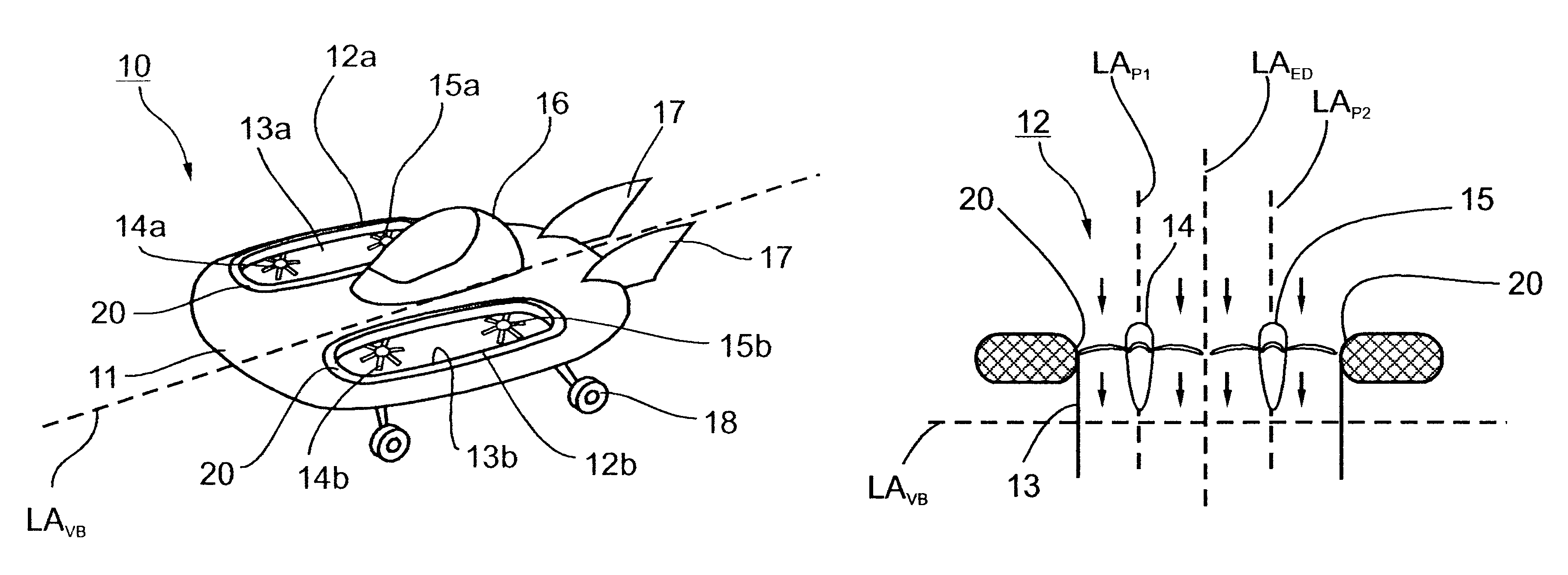

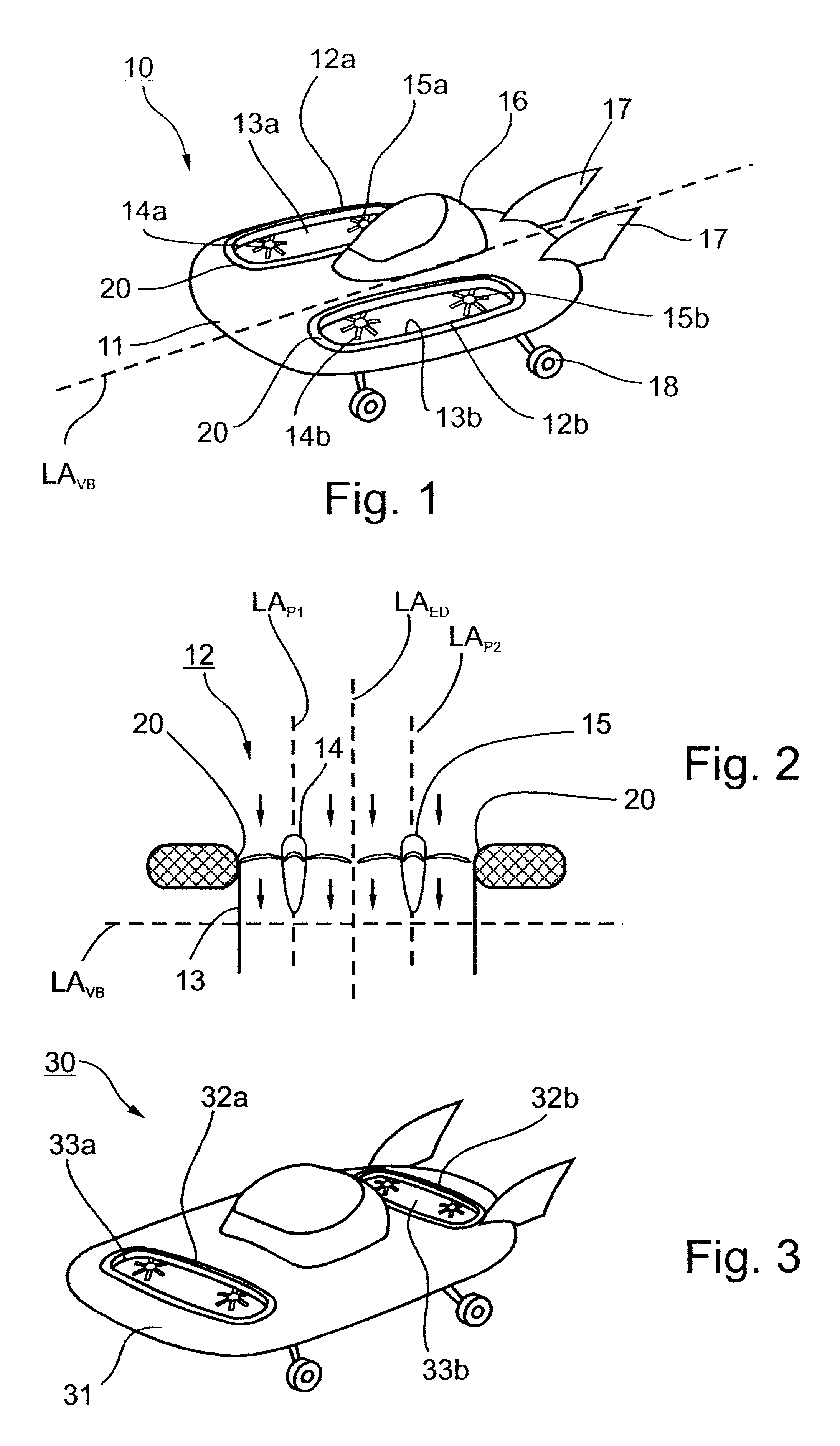

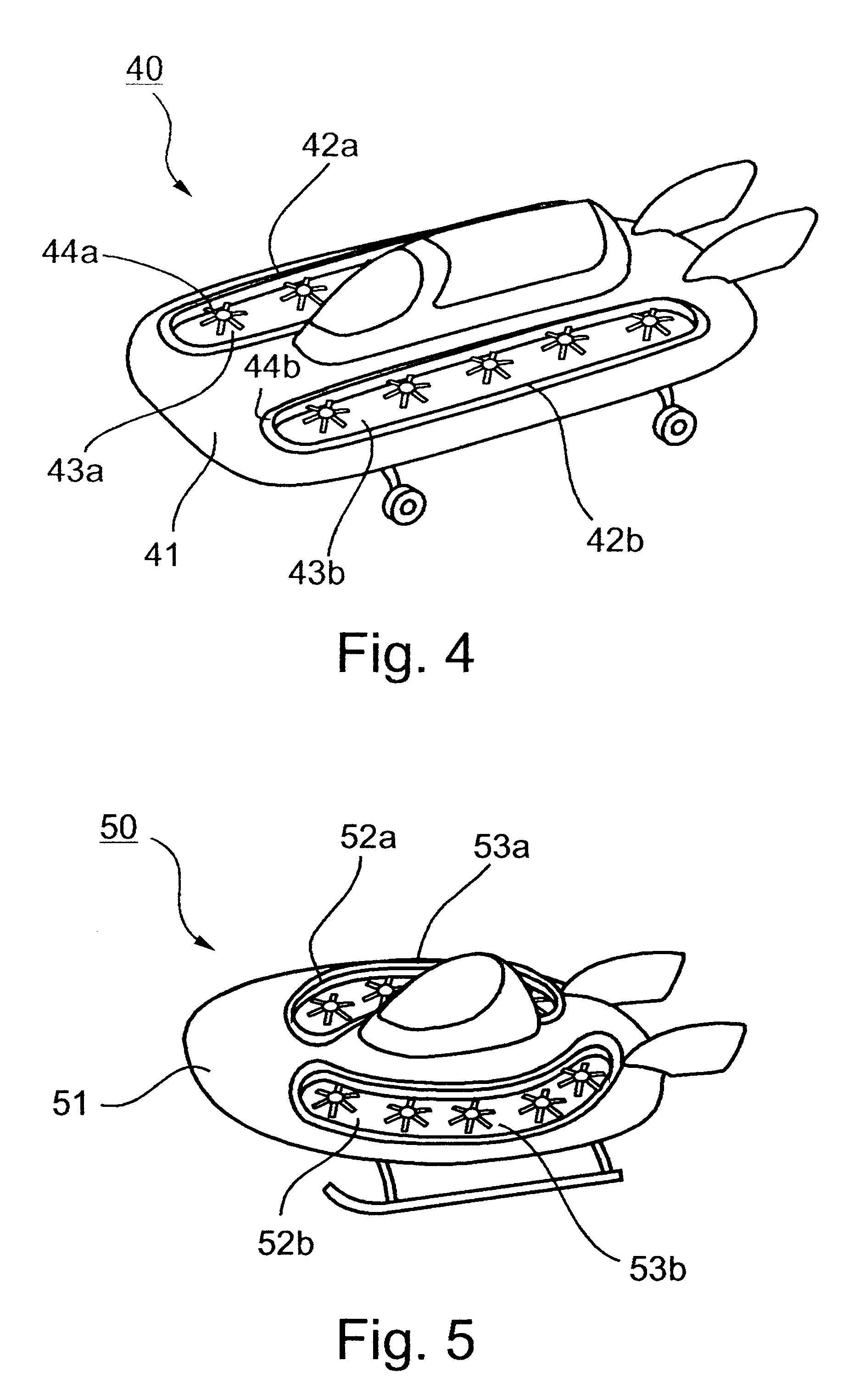

Ducted vehicles particularly useful as VTOL aircraft

InactiveUS6568630B2Easy entryEasy exitAircraft navigation controlFlying saucersJet aeroplaneJet engine

A VTOL aircraft (or other vehicle such as a sea vehicle) includes a pair of elongated ducts on opposite sides of the vehicle body, and a plurality of powered propellers (or other propulsion units such as jet engines) mounted within and enclosed by each of the elongated ducts, such as to produce an upward lift force to the vehicle. Each of the elongated ducts has a short transverse dimension slightly larger than the diameter of the blades of each propeller enclosed thereby, and a large transverse dimension slightly larger than the sum of the diameters of the blades of all the propellers enclosed thereby.

Owner:URBAN AERONAUTICS

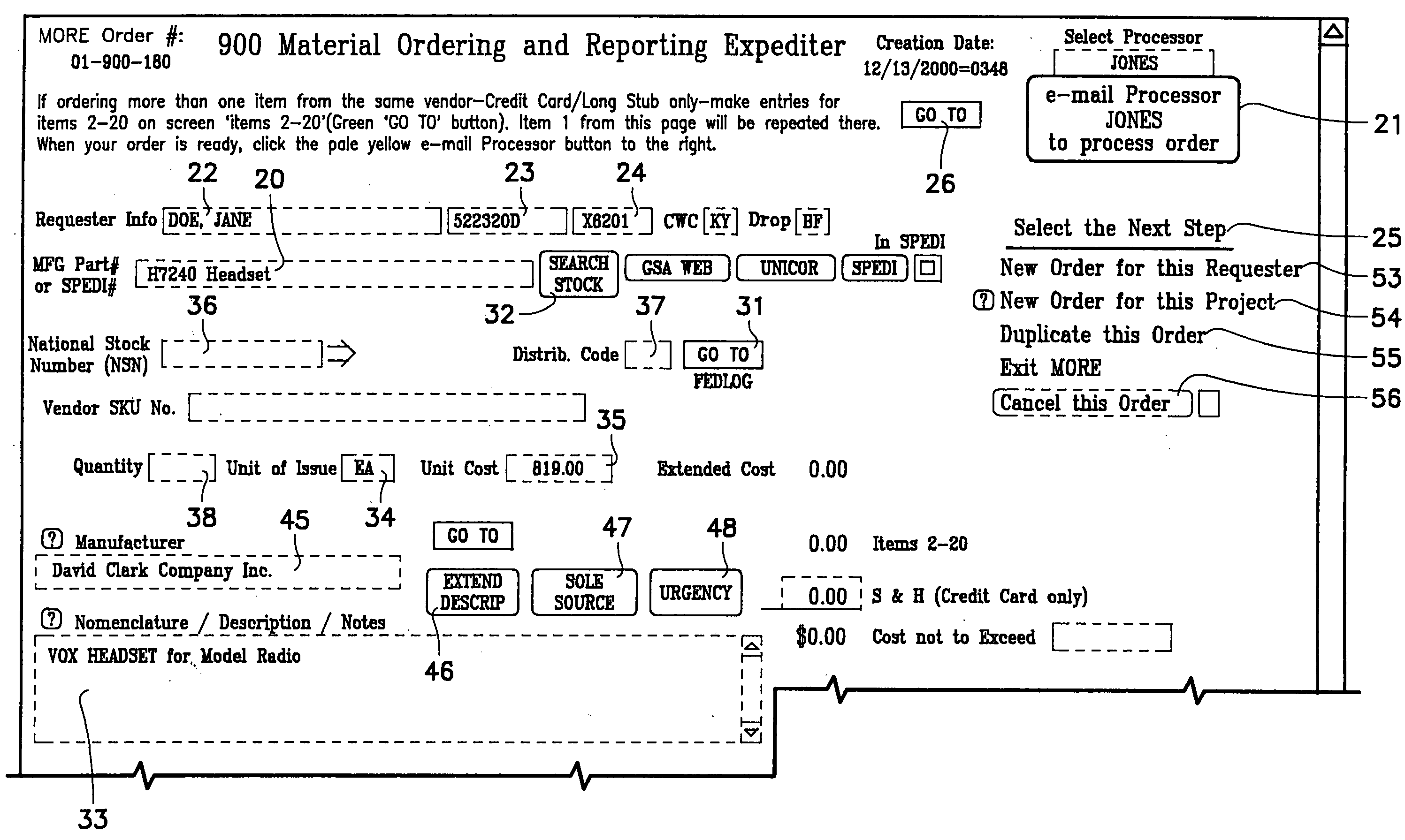

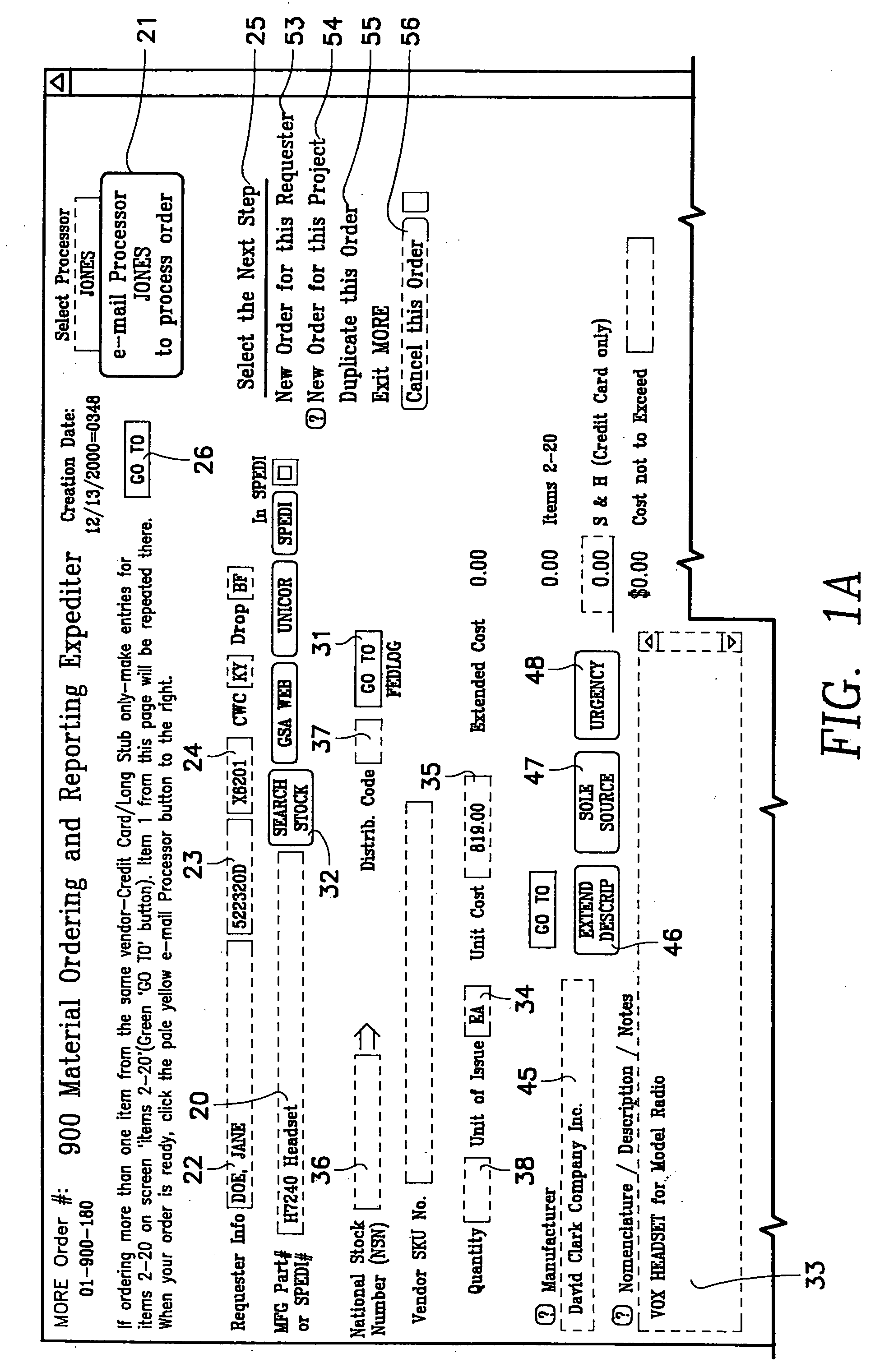

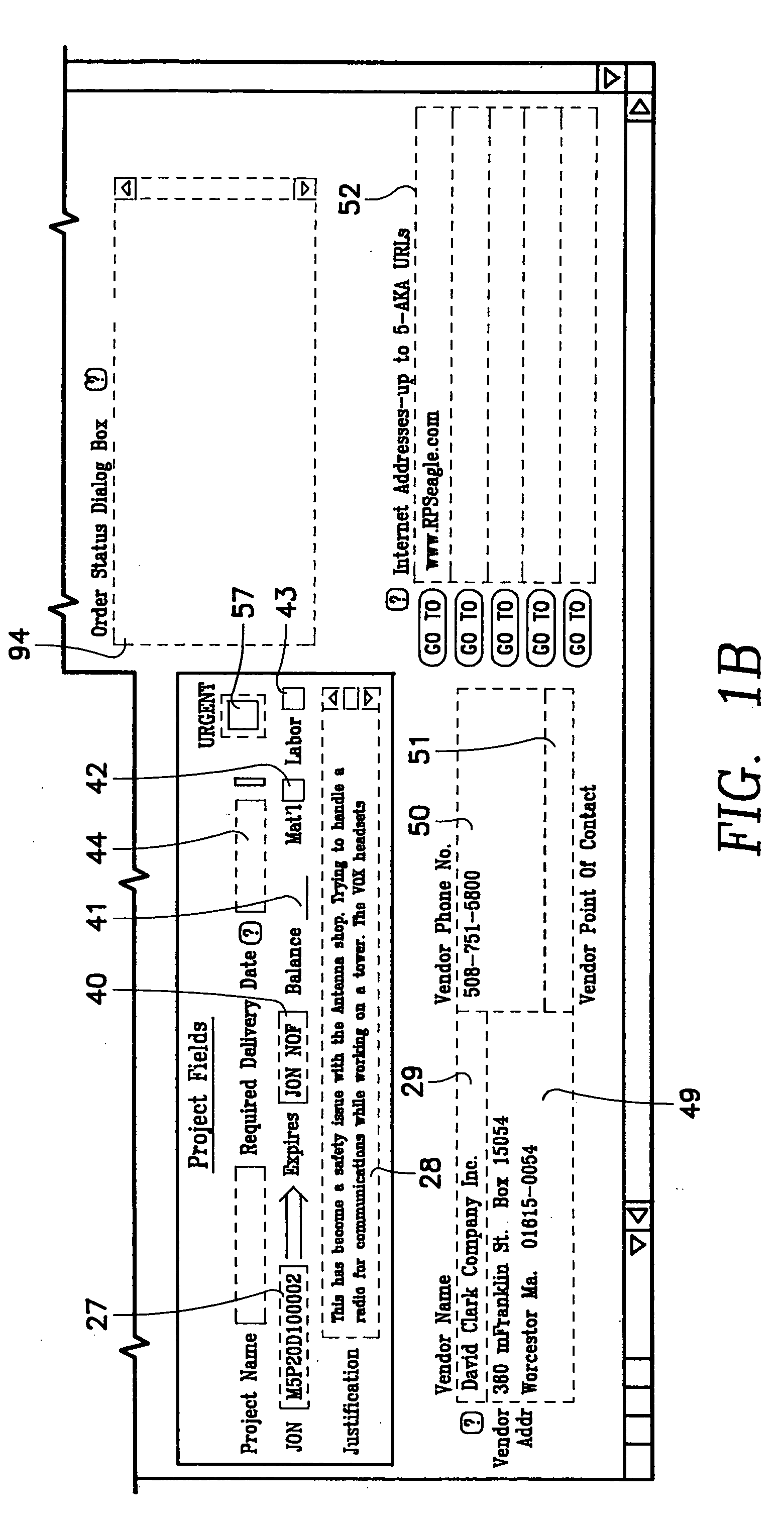

Material ordering and reporting expediter (MORE)

InactiveUS20050165659A1Easy to cutEasy to pasteFinanceBuying/selling/leasing transactionsPaper documentDocument preparation

A computer program which automates and assist various members of an order and approval chain in preparing purchase documents. A requester using the program enters a part number and other information in the purchase document and forwards the document to a processor. The processor checks the purchase document for accuracy and completeness and forwards the document to the approval chain. When each member of the approval chain electronically signs the purchase document is returned to the processor who fills the purchase order.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

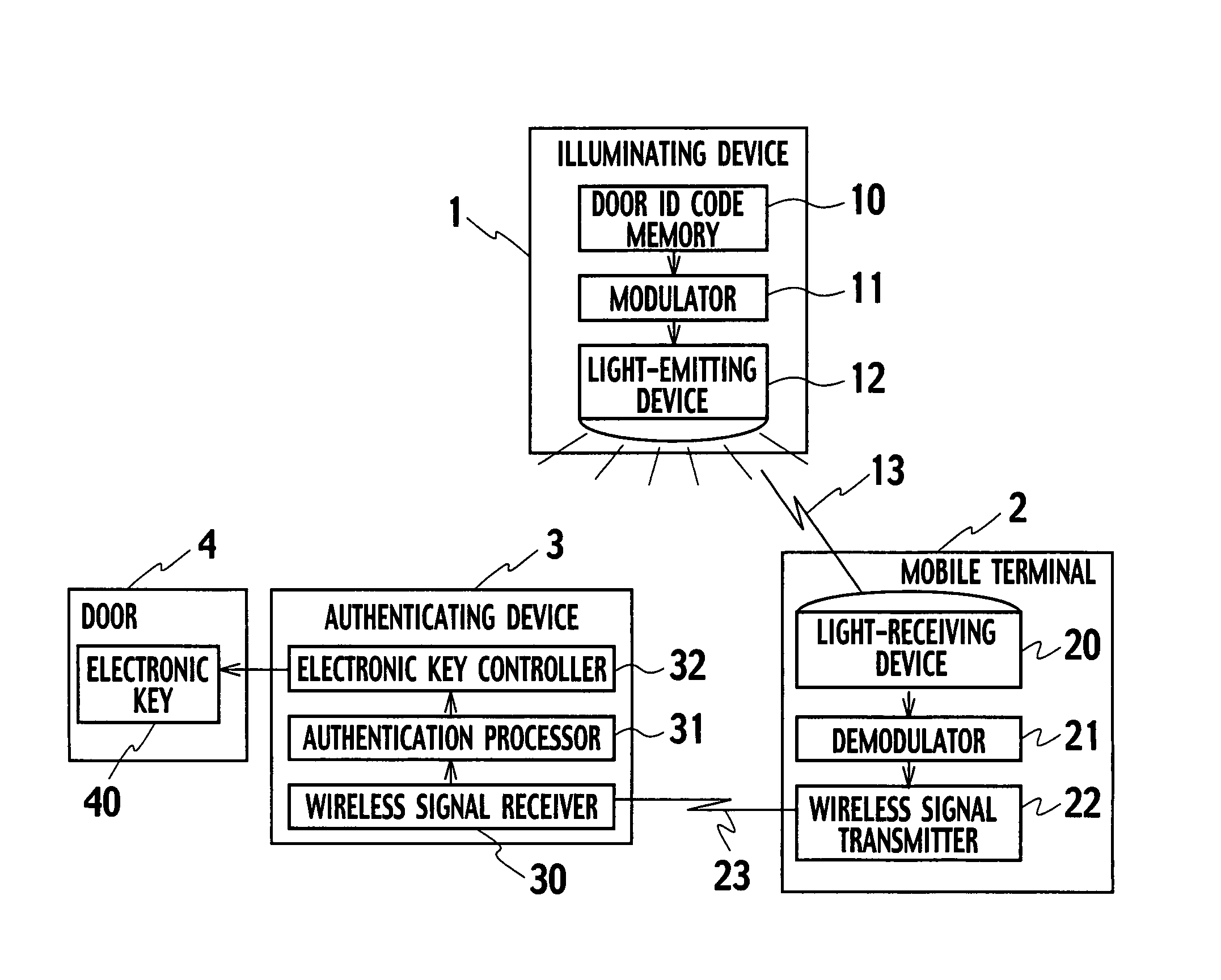

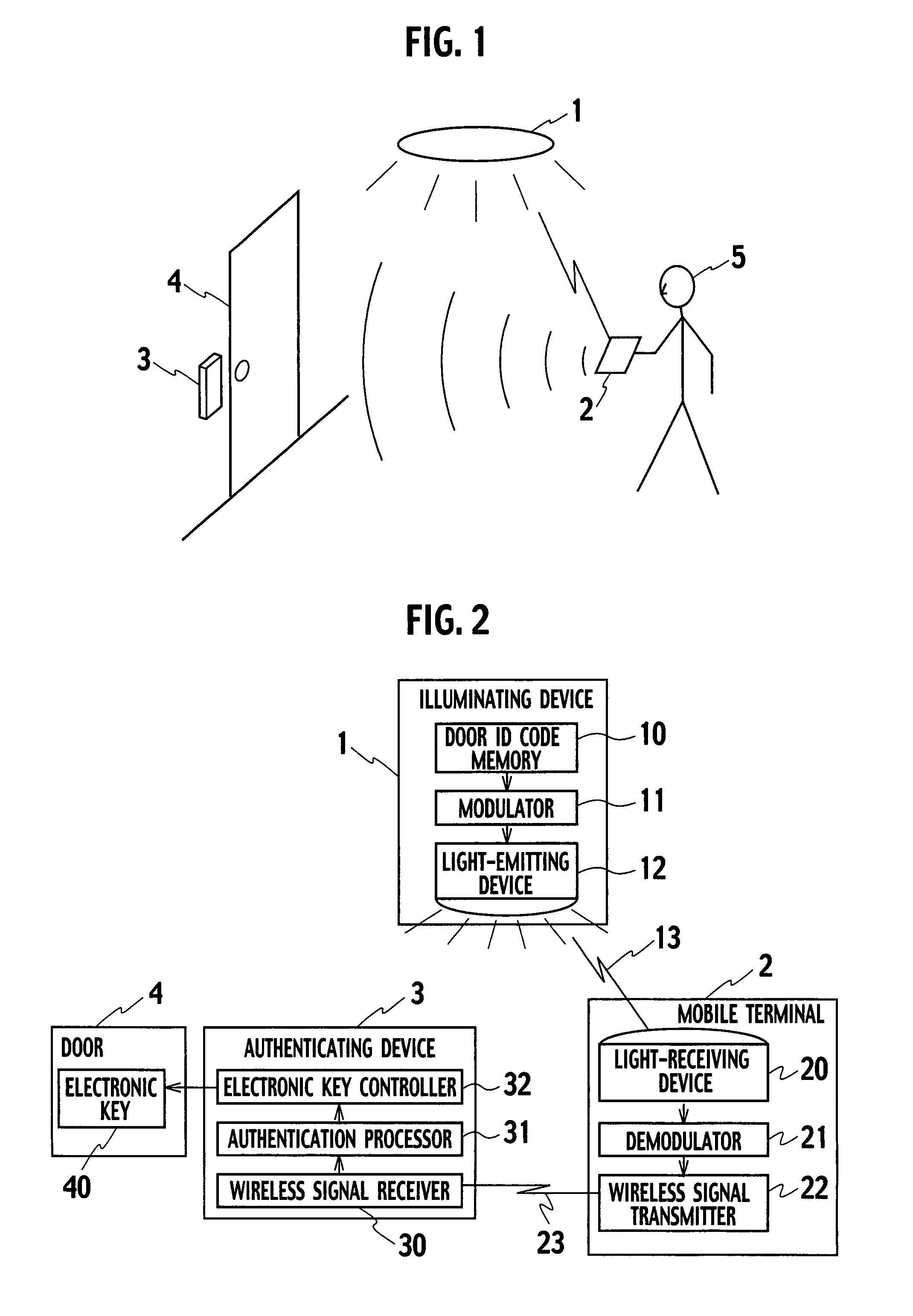

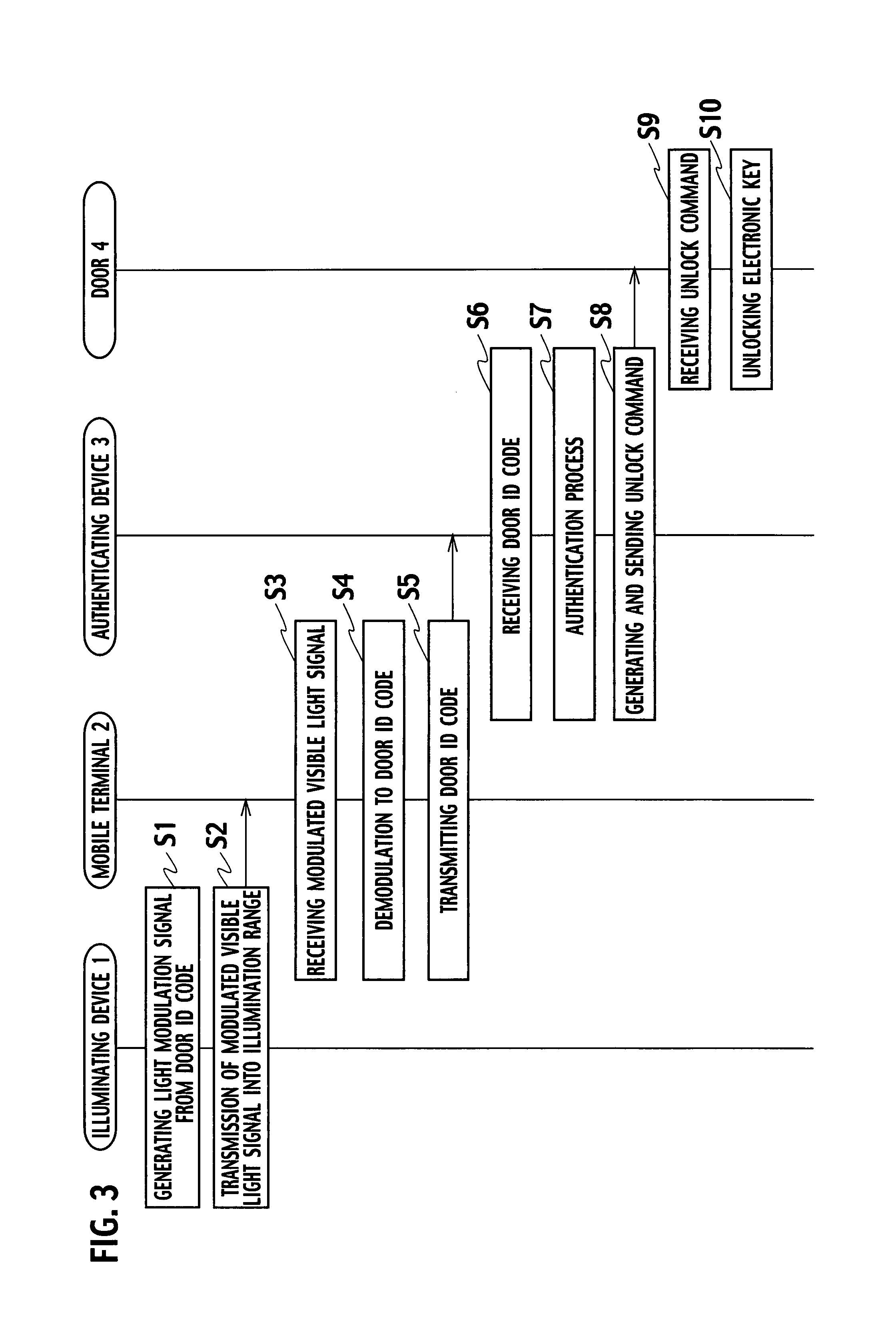

Entry control system and entry control method

InactiveUS8093988B2Easy entryLimited facilityElectric signal transmission systemsDigital data processing detailsControl systemLight signal

To provide an entry control system as well as an entry control method allowing for an easy entry of user, permitting a restriction to persons who have a legitimate right to enter a facility, an illuminating device (1) emits a modulated visible light signal 13 modulated by use of a door ID code into a preset illumination range, the modulated visible light signal 13 from the illuminating device (1) is received by a mobile terminal (2) portable by the user, where it is demodulated for wireless signal transmission, and the door ID code transmitted from the mobile terminal (2) is received by an authentication device (3), which judges whether or not the door ID code is legitimate, and generates an unlock command when the door ID code is judged to be legitimate, and a door (4) for a facility controlled of entry receives the unlock command from the authentication device (3), whereby it is unlocked.

Owner:KK TOSHIBA

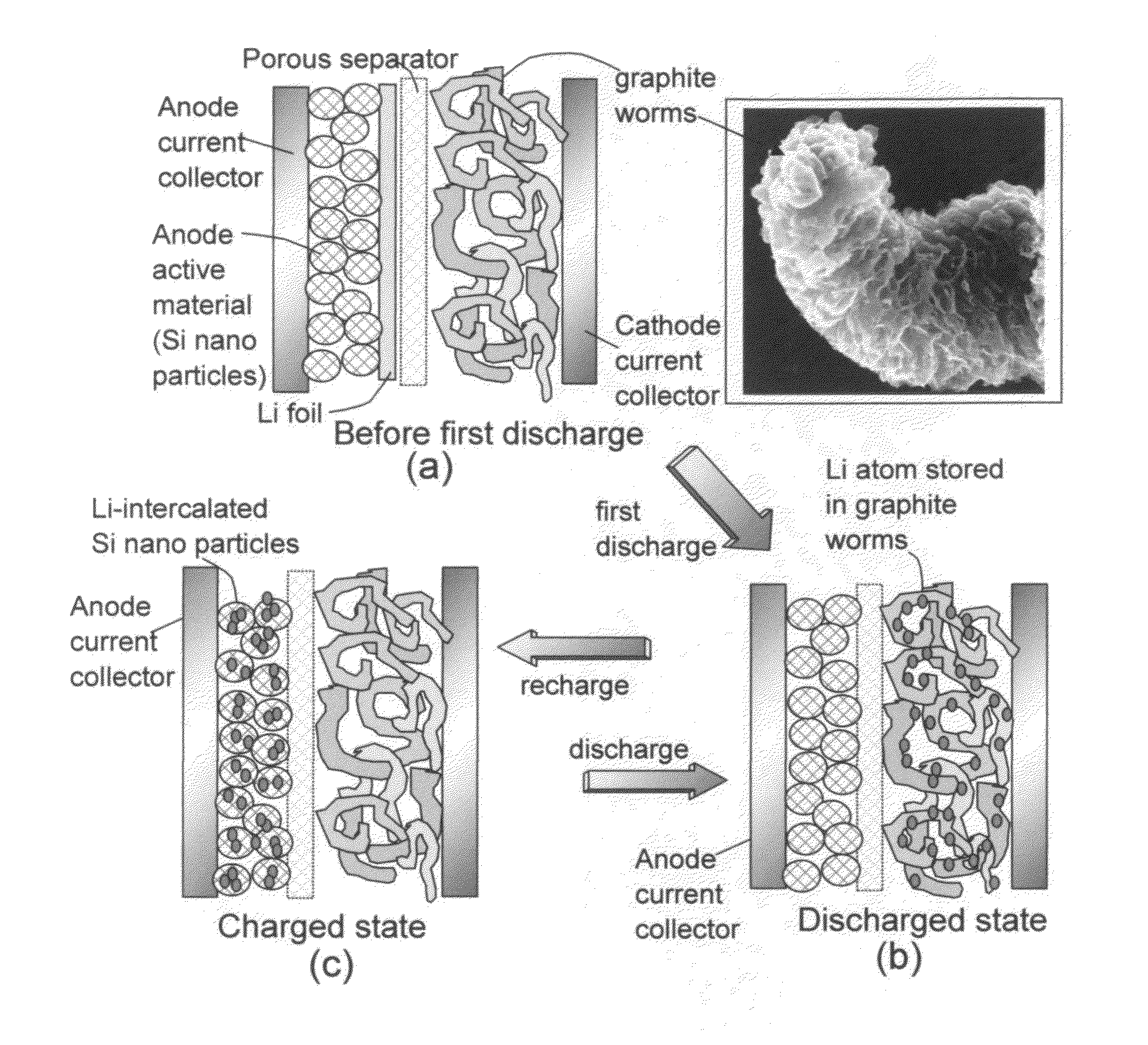

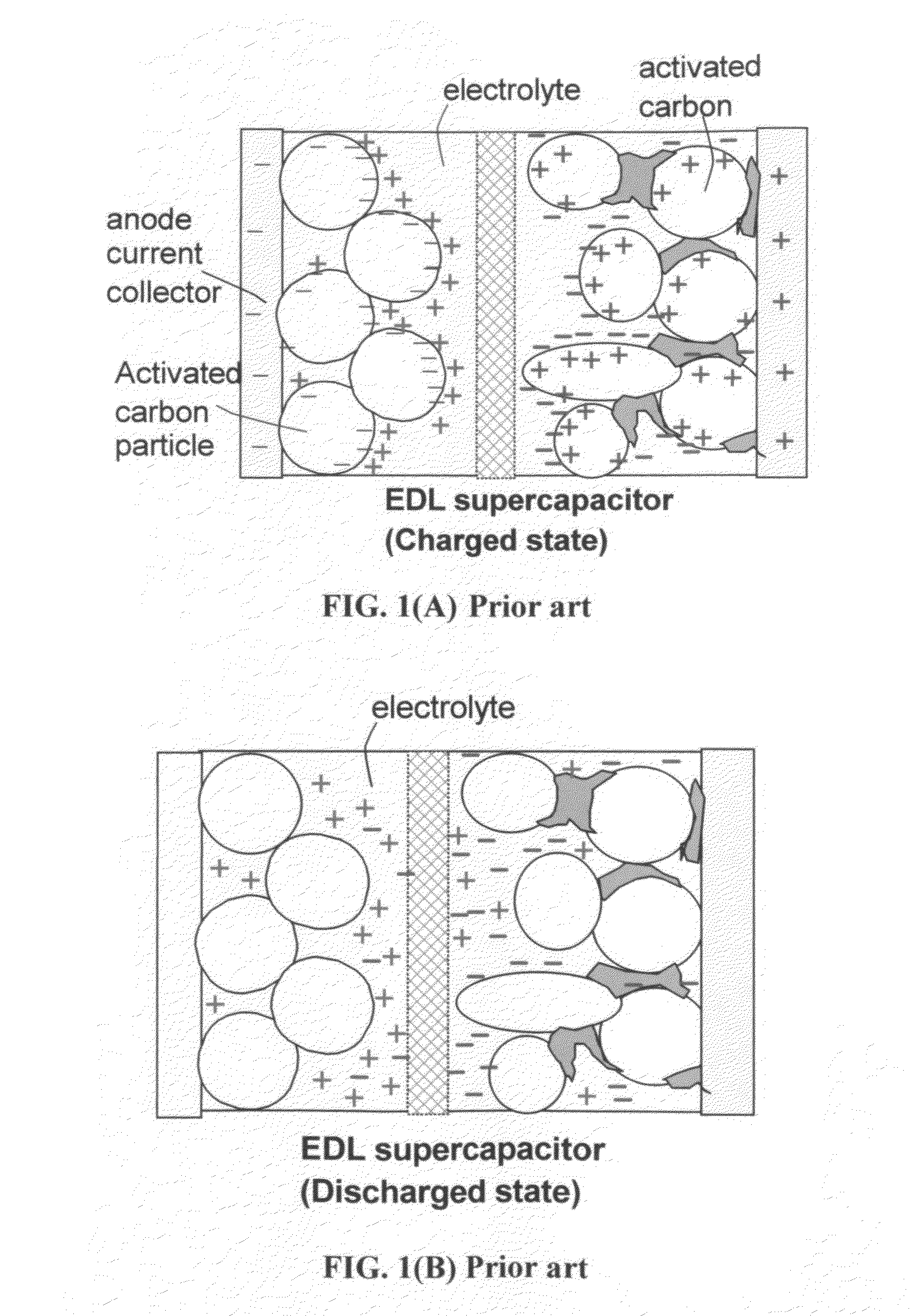

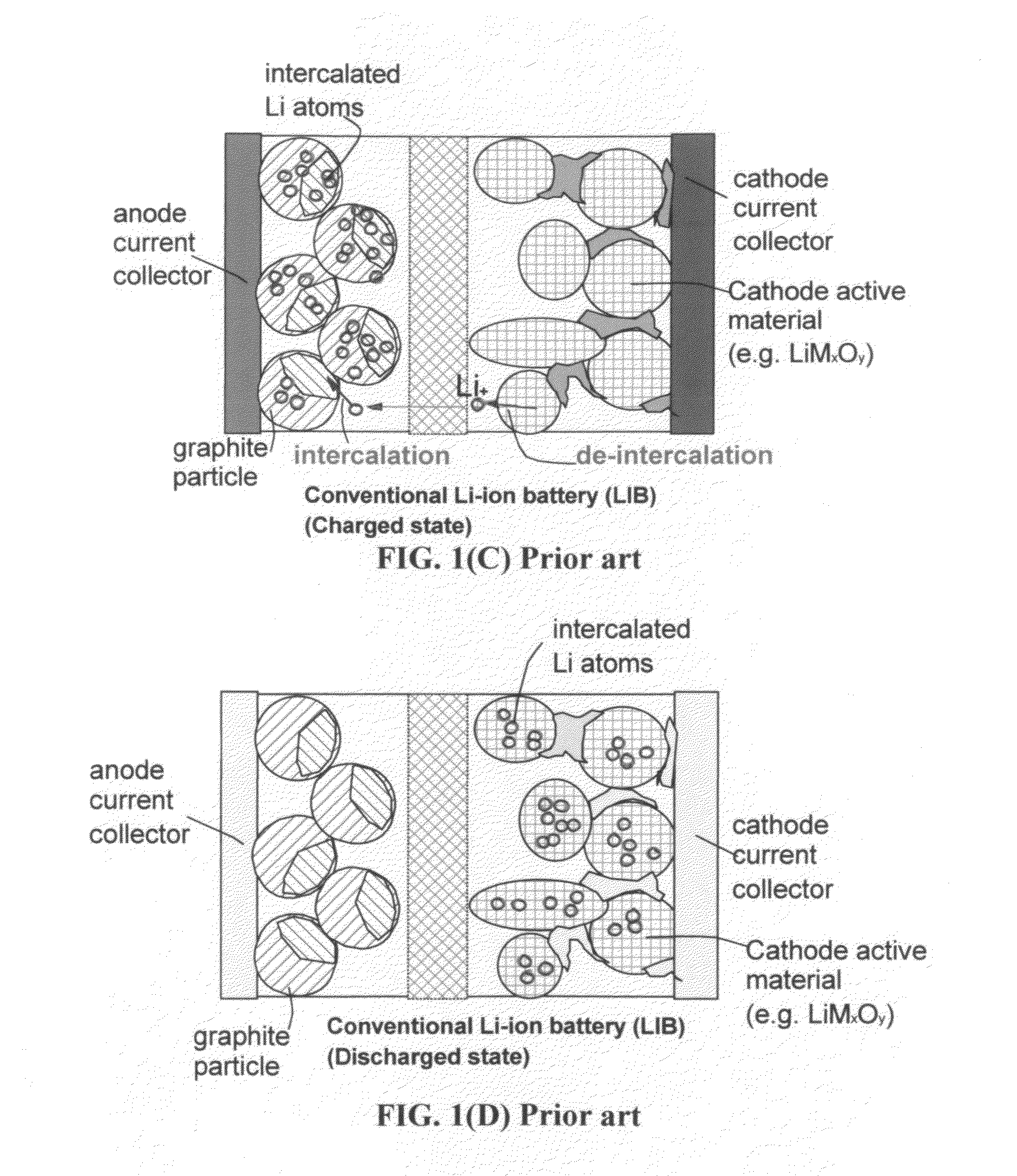

Method of operating a lithium-ion cell having a high-capacity cathode

ActiveUS20130271085A1Improvement factorImprove diffusivityMaterial nanotechnologyBatteries circuit arrangementsLithiumLow voltage

A method of operating a lithium-ion cell comprising (a) a cathode comprising a carbon or graphitic material having a surface area to capture and store lithium thereon; (b) an anode comprising an anode active material; (c) a porous separator disposed between the two electrodes; (d) an electrolyte in ionic contact with the two electrodes; and (e) a lithium source disposed in at least one of the two electrodes to obtain an open circuit voltage (OCV) from 0.5 volts to 2.8 volts when the cell is made; wherein the method comprises: (A) electrochemically forming the cell from the OCV to either a first lower voltage limit (LVL) or a first upper voltage limit (UVL), wherein the first LVL is no lower than 0.1 volts and the first UVL is no higher than 4.6 volts; and (B) cycling the cell between a second LVL and a second UVL.

Owner:GLOBAL GRAPHENE GRP INC

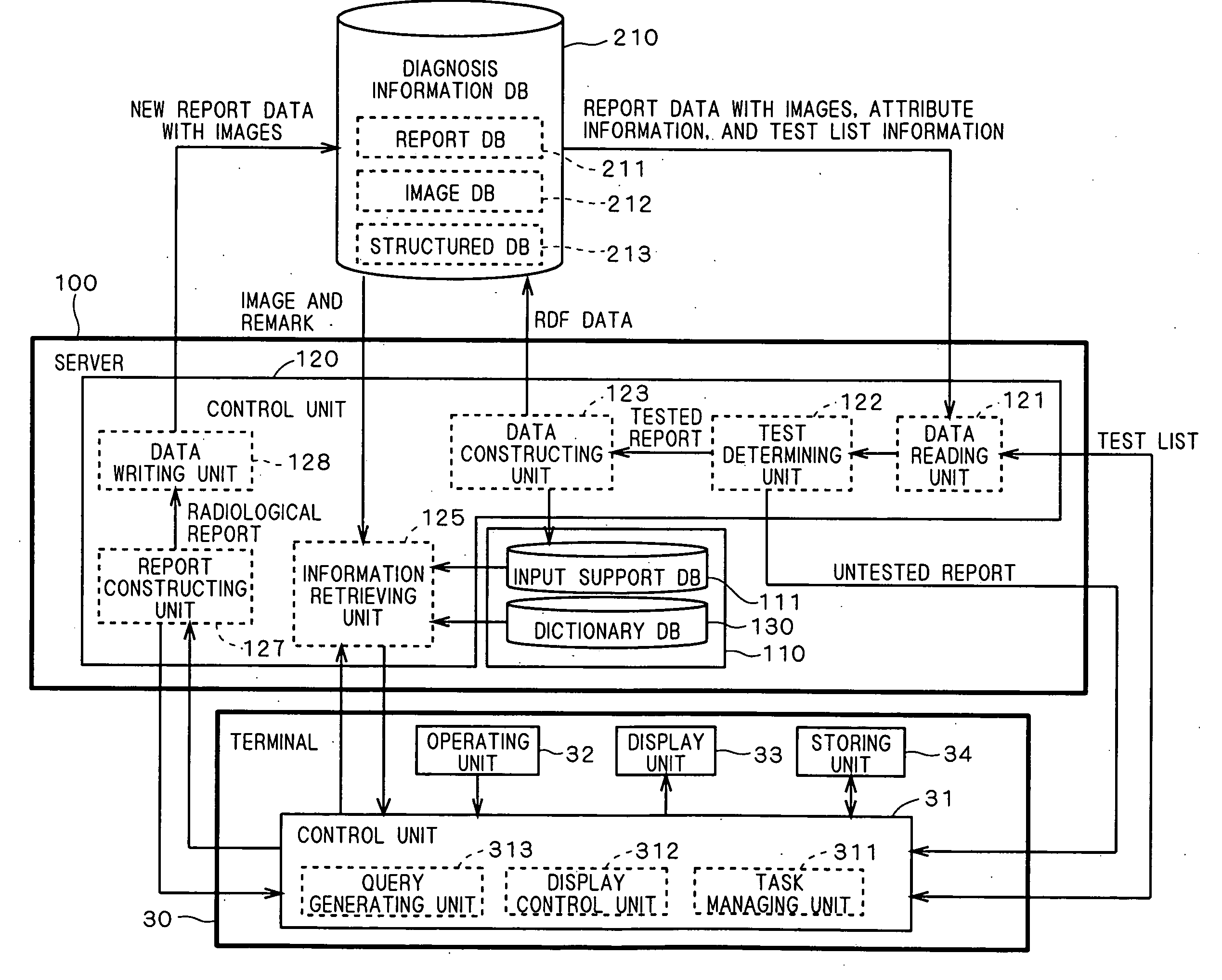

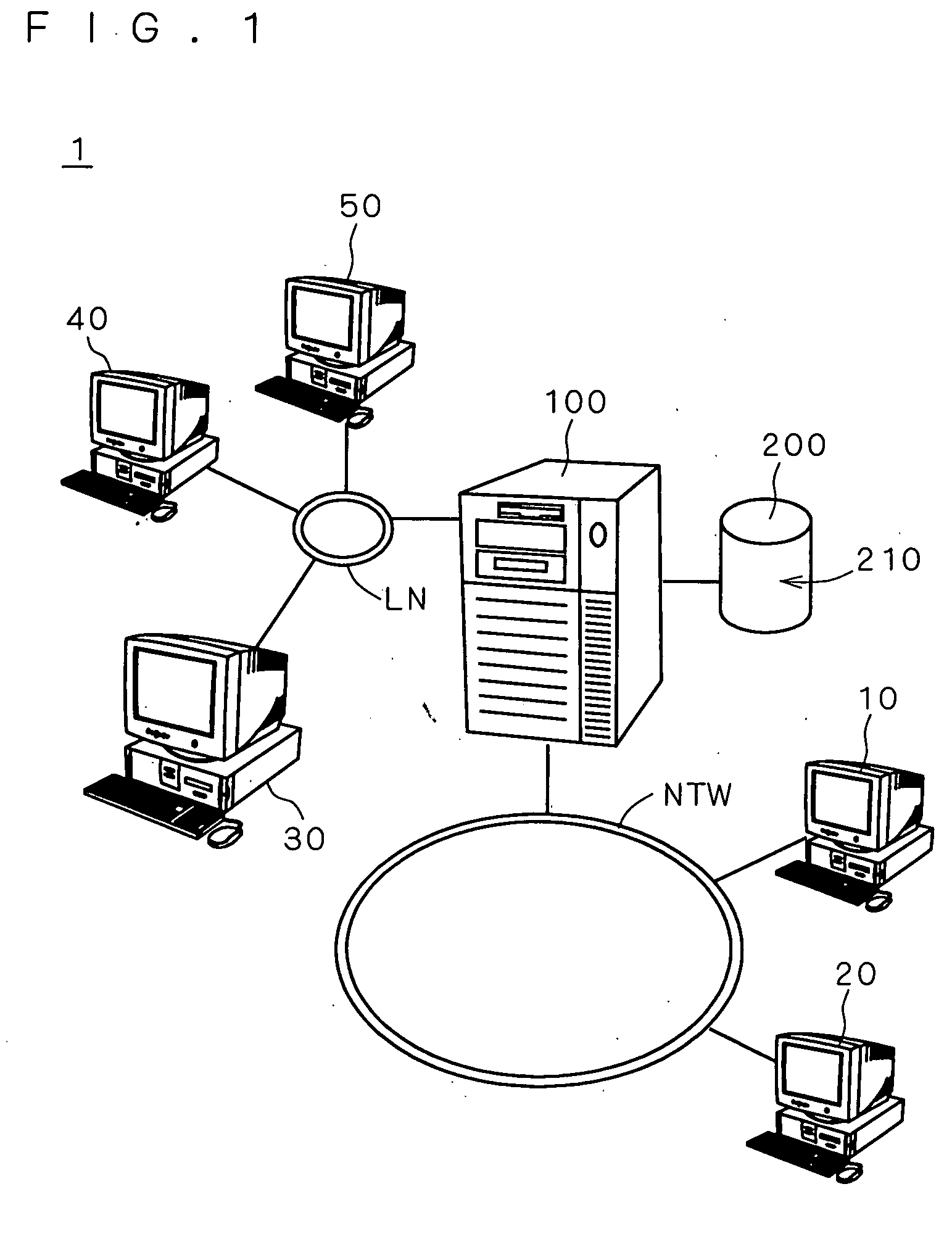

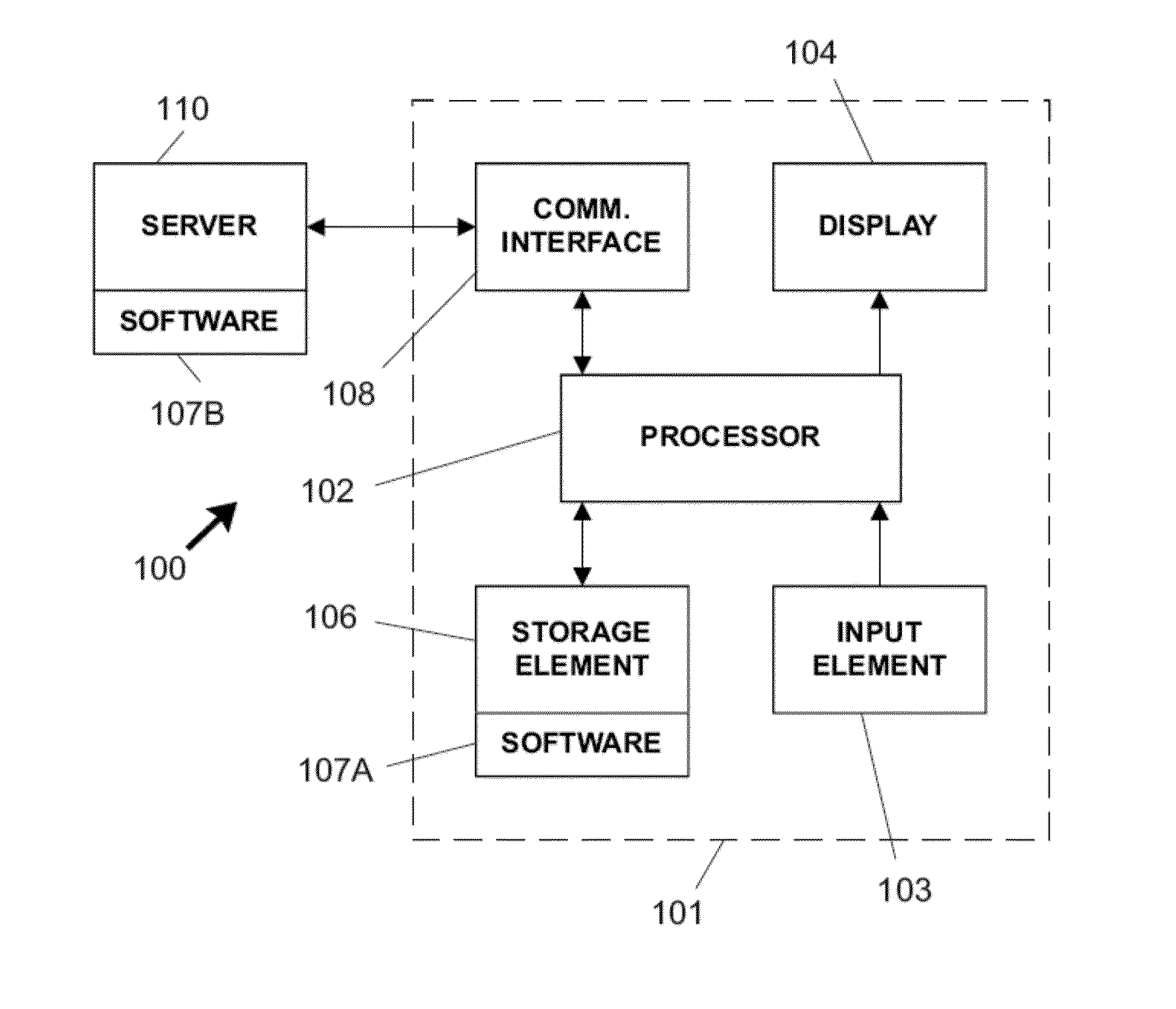

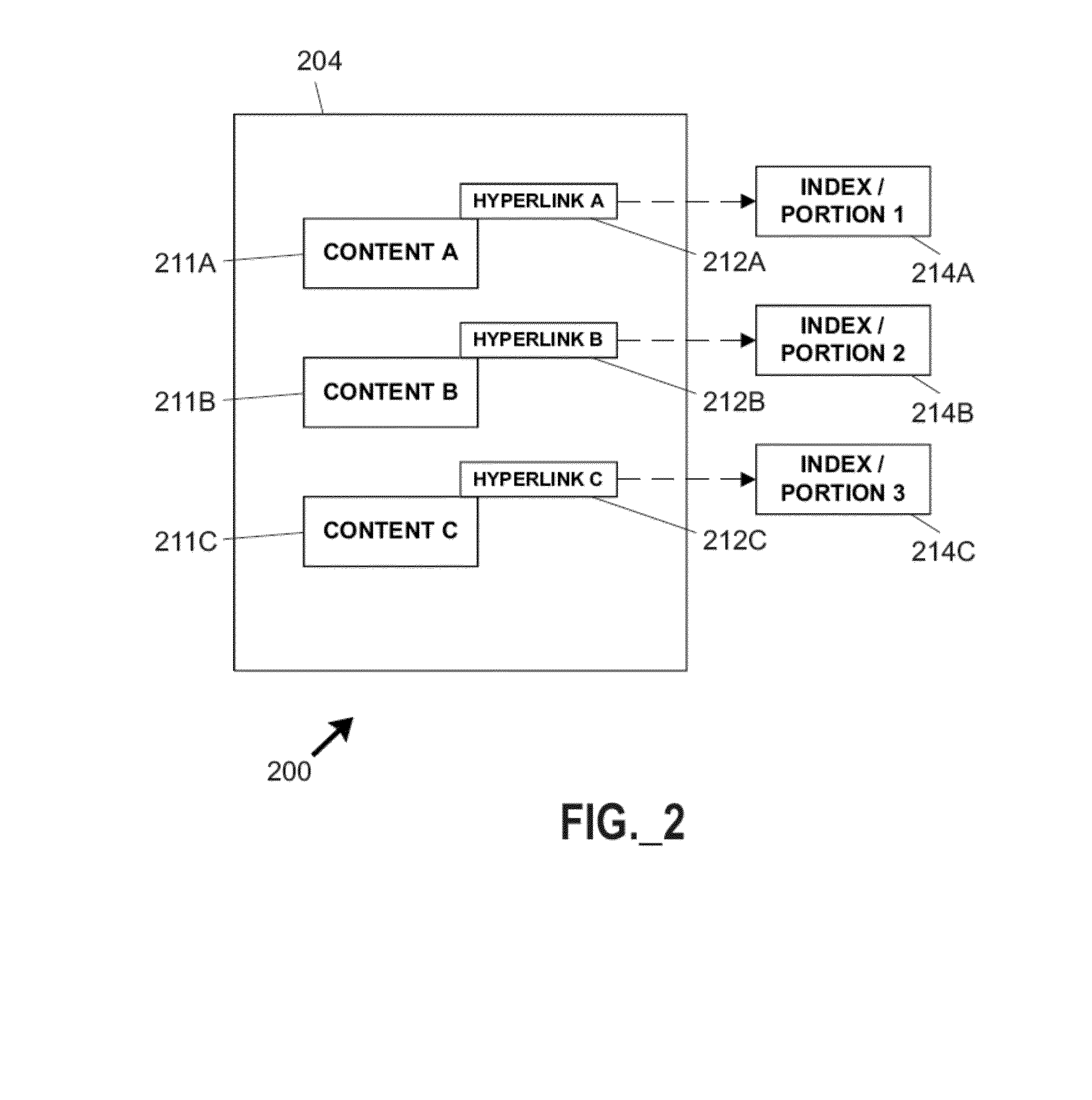

Database system, program, image retrieving method, and report retrieving method

ActiveUS20080052126A1High precision of retrievalEasy to addData processing applicationsDigital data processing detailsRadiology reportReference image

In a plurality of pieces of single report structured data that is stored in a structured database in a diagnosis information database, character information constructing a radiological report describing detailed information of image data is added as metadata for search to the image data. For example, only by designating image data to be read as image (retrieval reference image) data as a reference of retrieval by a reading physician as the user during radiological operation, the character information already added to the retrieval reference image data is set as a keyword. By a keyword search using the metadata, data of a similar image and a related report of the retrieval reference image data are detected from the structured DB.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

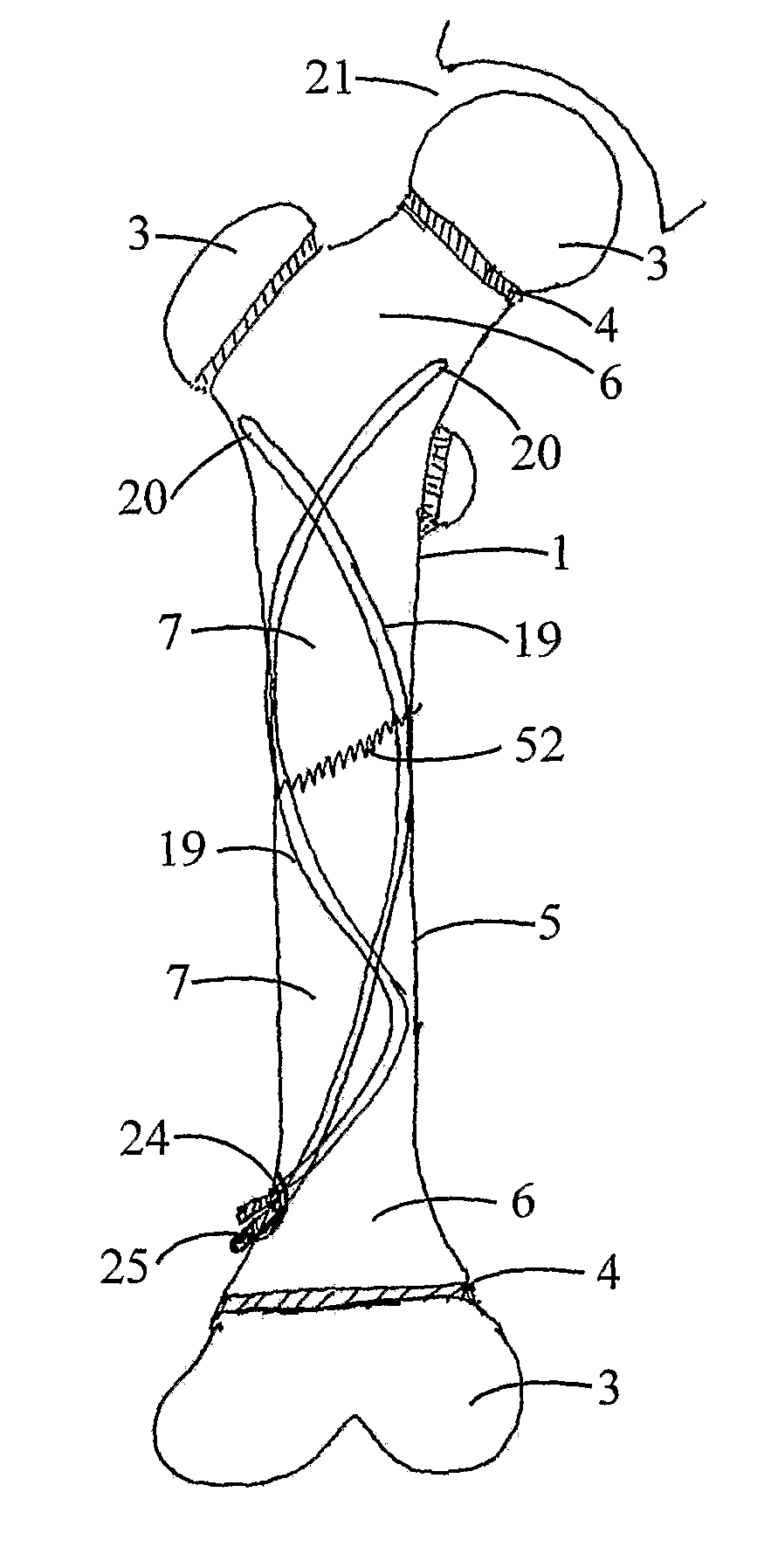

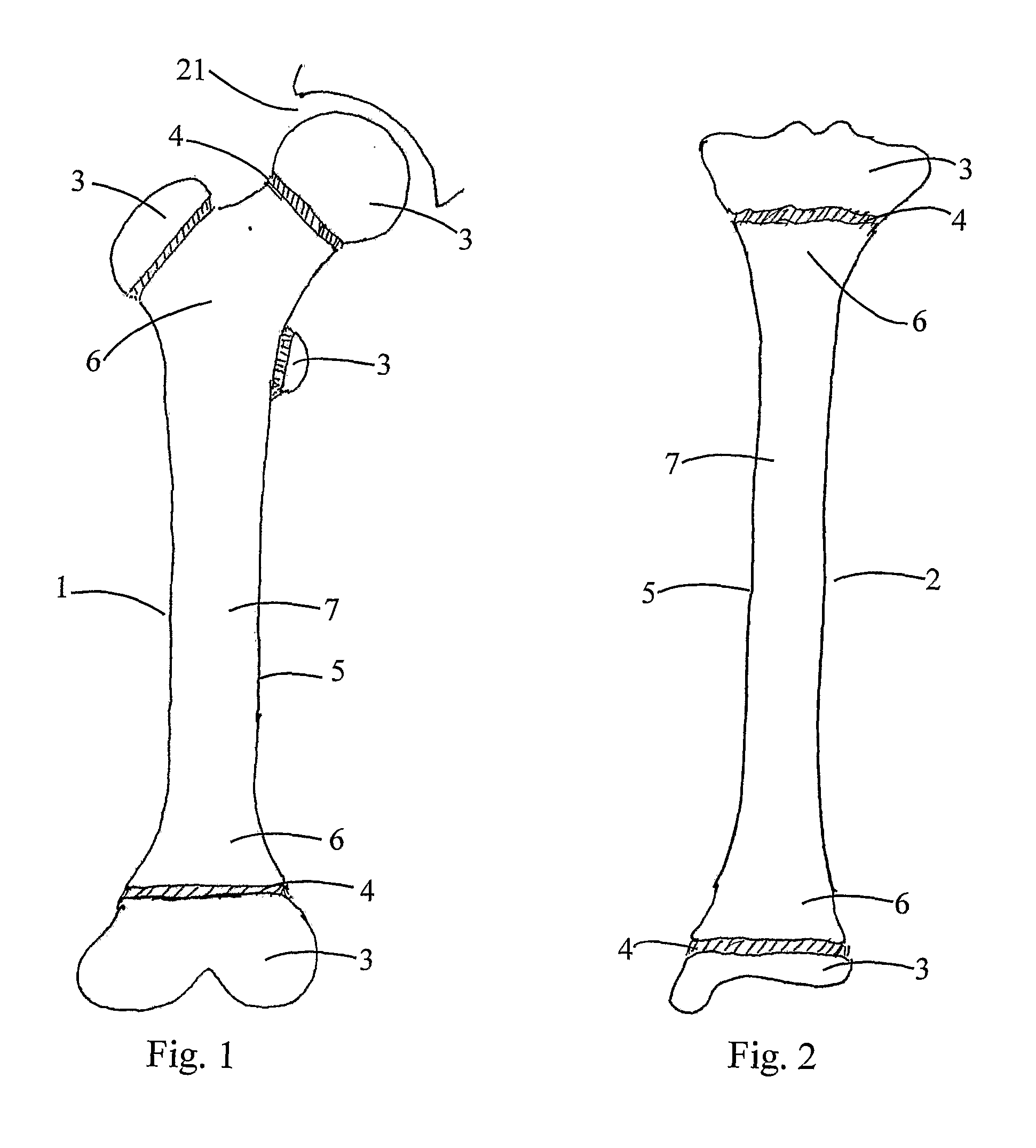

Flexible Nail Assembly For Fractures Of Long Bones

InactiveUS20070173834A1Prevents mal-relationEarly weight bearingInternal osteosythesisJoint implantsLONG BONE FRACTURECombined use

An implant assembly of flexible nails (19) for fractures of long bones comprises of a straight universal length flexible nails having properties of ductility as 15% to 25% of elongation of nail and ultimate tensile strength of 600 to 800 Mega Pascal on testing, having an identical pathfinder blunt conical tip (20) at both ends, an optional proximal fixation device (27) with optional plural holes for interlocking screws (28) to be used in combination with said flexible nails having peripheral equally spaced plural grooves deep less than diameter of one said flexible nail, a end cap with plural holes to be used in combination with said proximal fixation device to anchor cut hooked ends of said flexible nails and a tool plier_knurler cum cutter temporarily applied when said flexible nails are alone in use.

Owner:THAKKAR NAVIN N

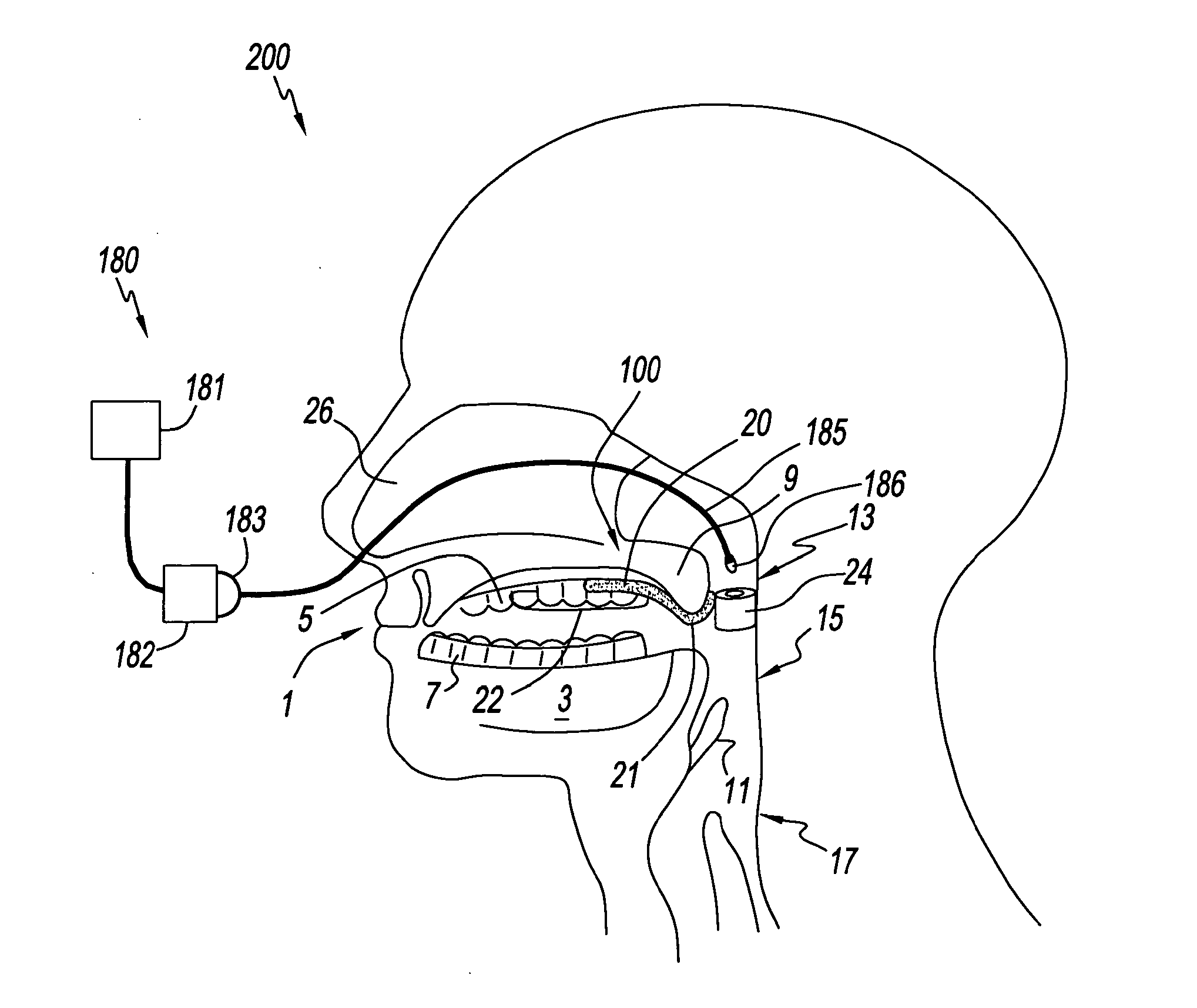

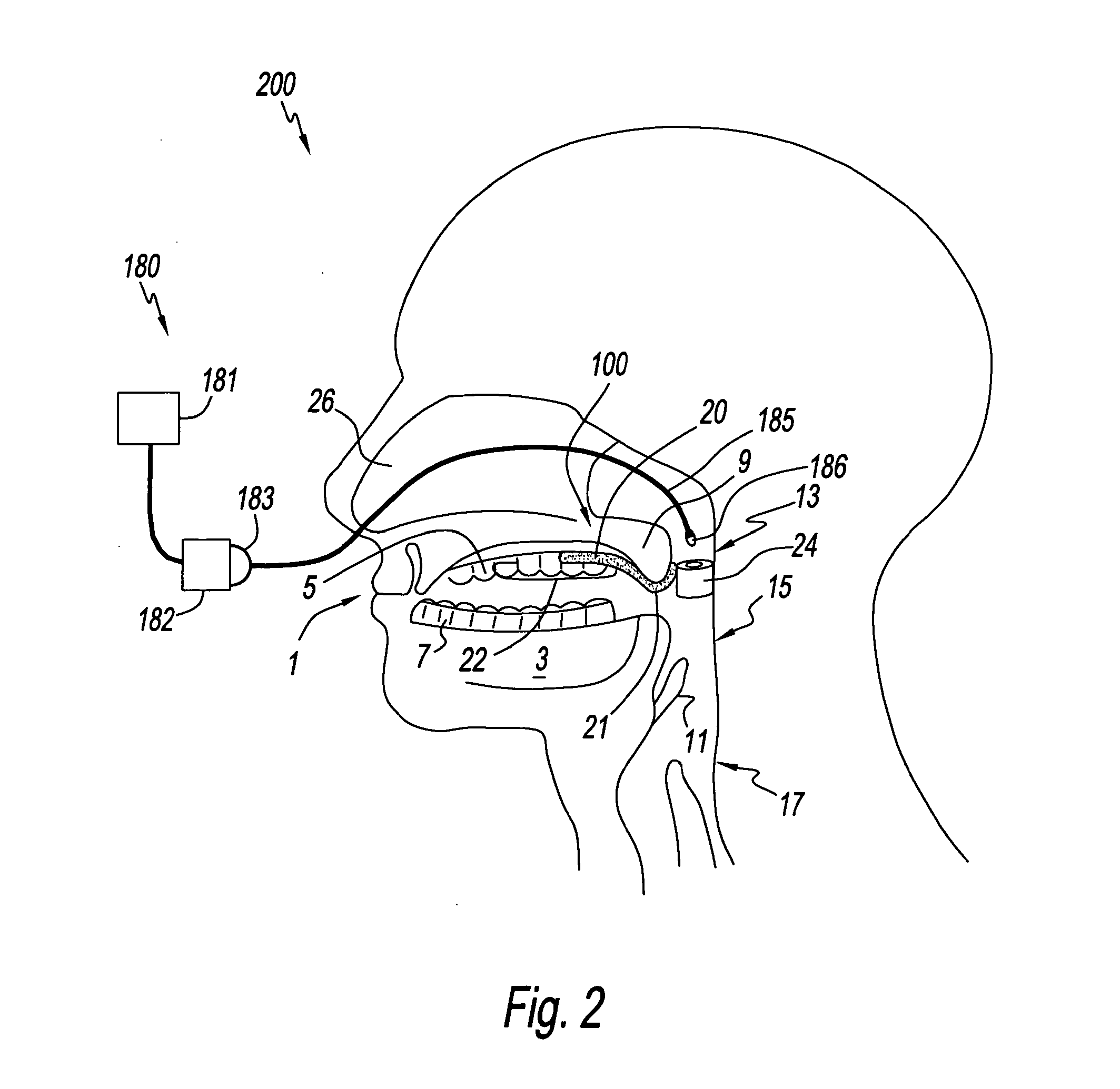

A palate retainer with attached nasopharyngeal airway extender for use in the treatment of obstructive sleep apnea

ActiveUS20110178439A1Minimizes triggering gag reflexPrevent the palate from falling backSurgeryPerson identificationTongue rootRetainer

A medical appliance for the treatment of obstructive sleep apnea in a patient, the appliance comprising: a securing device configured to be removably affixed to the patient's jaw; and a biasing member which is insertable behind the soft palate and / or the base of the patient's tongue, thereby providing for the flow of air in the nasopharyngeal airway; wherein the securing device is connected to the biasing member to allow insertion and / or removal of the biasing member from the nasopharyngeal airway.

Owner:LUMEN DEVICES

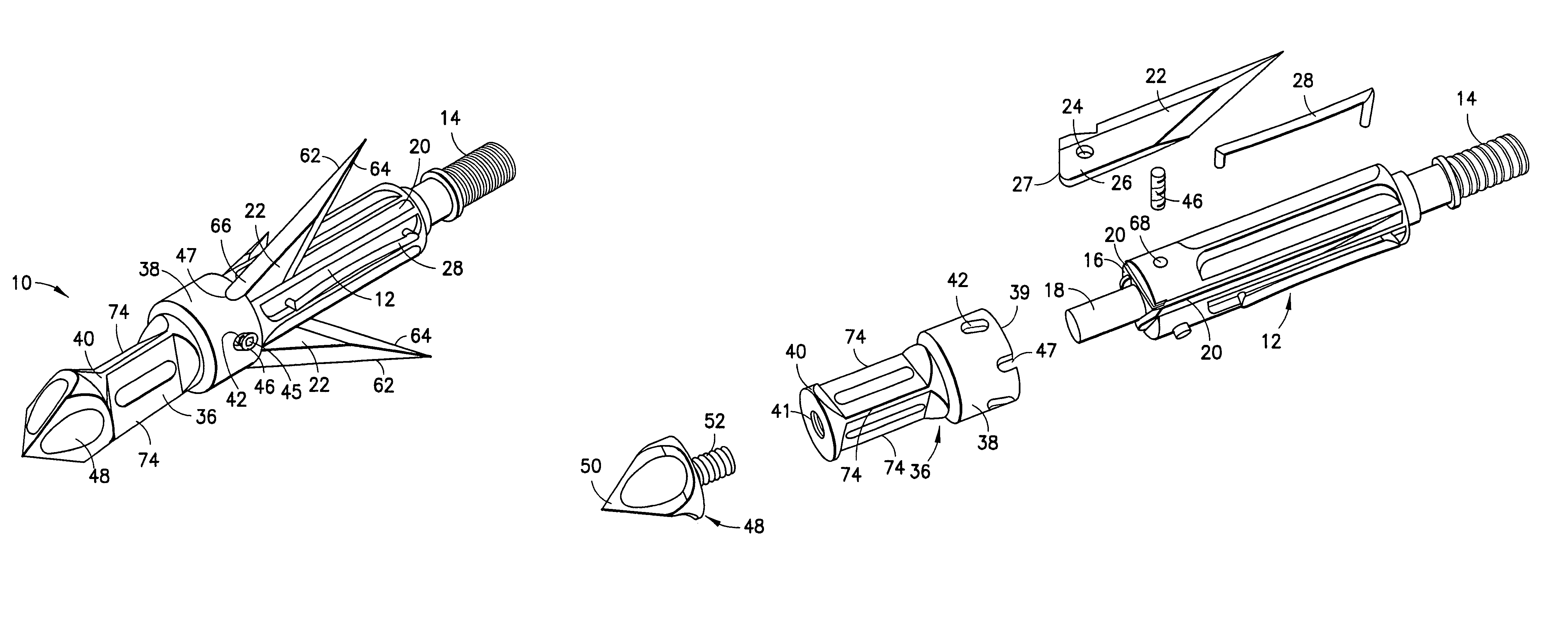

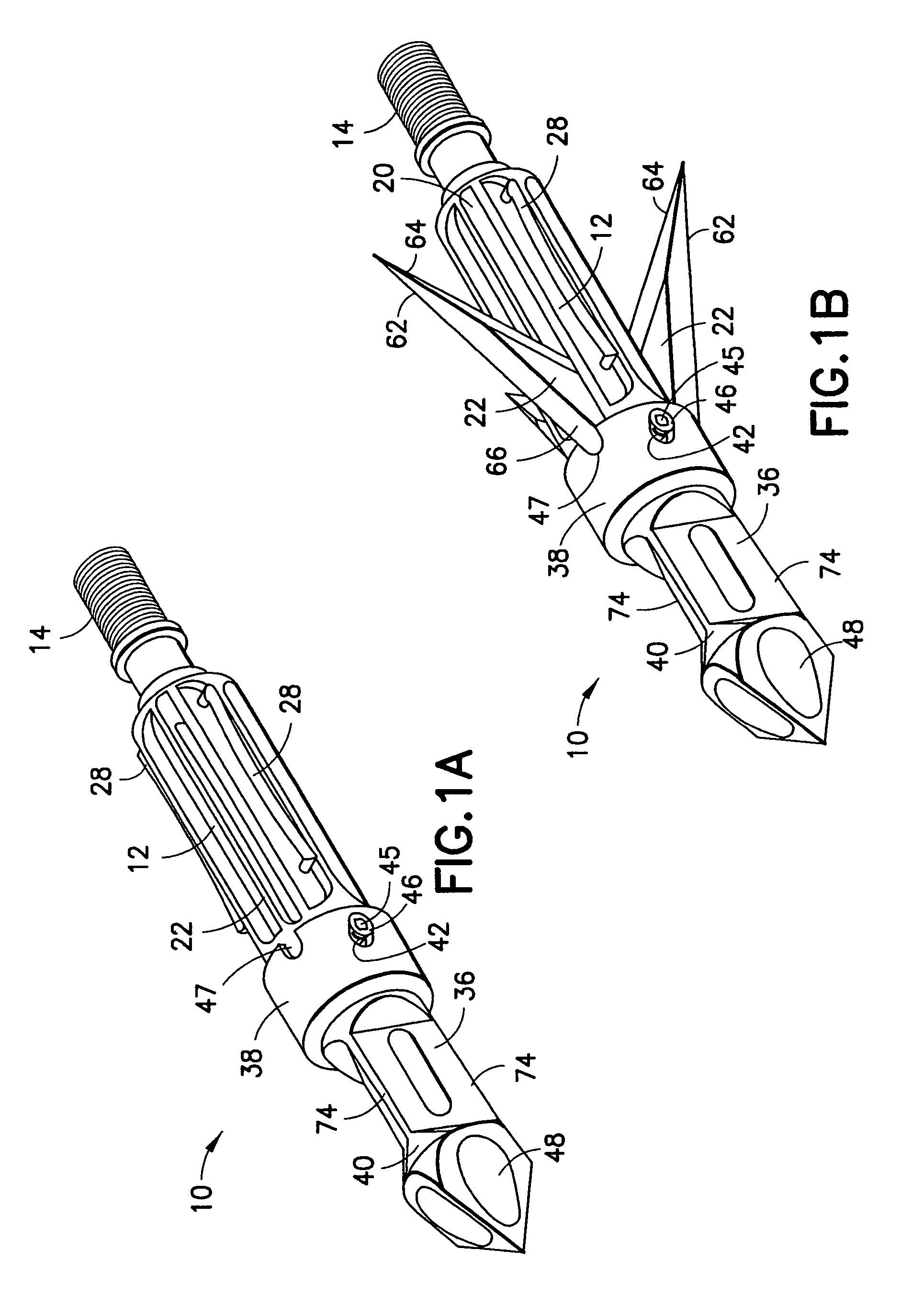

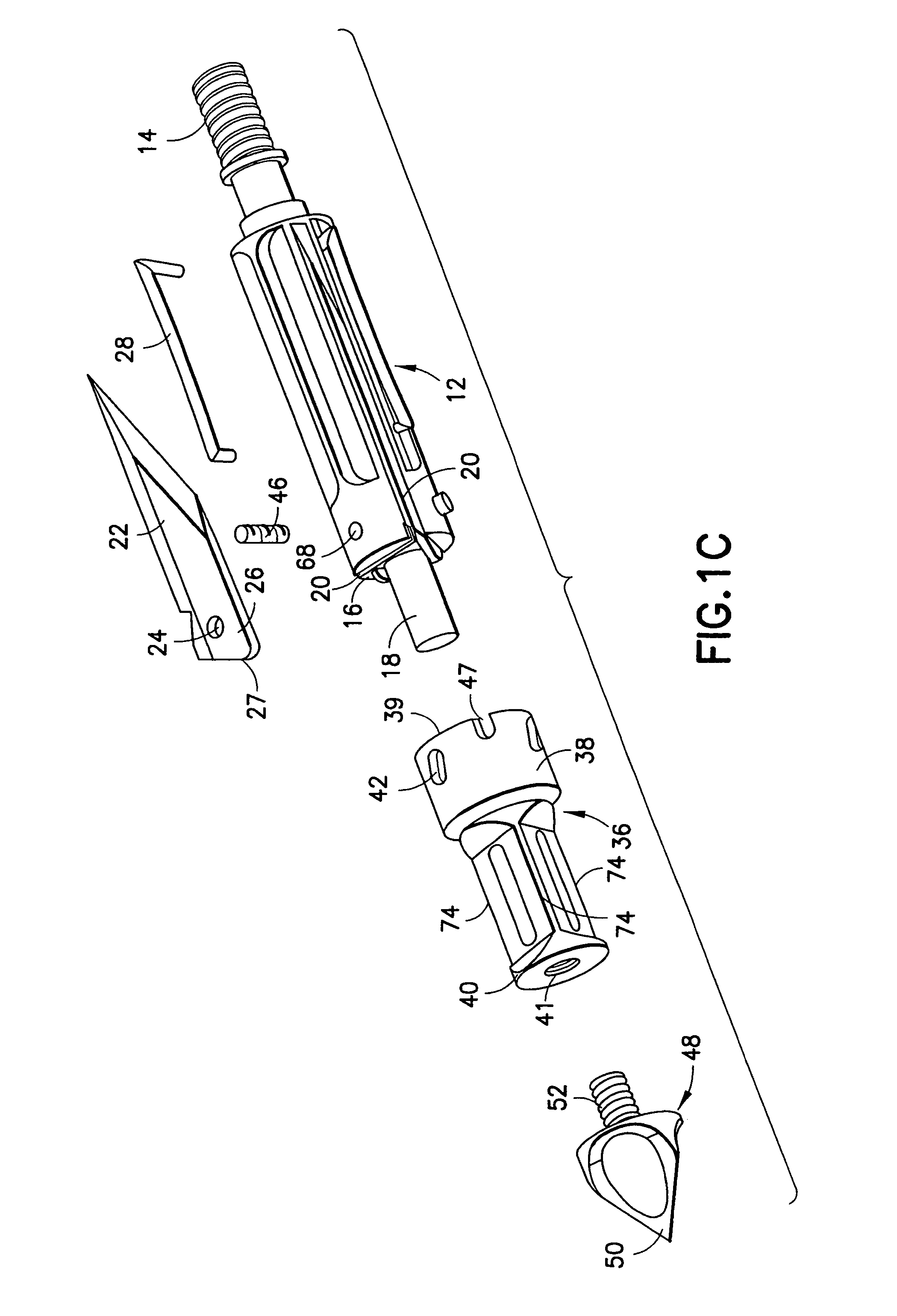

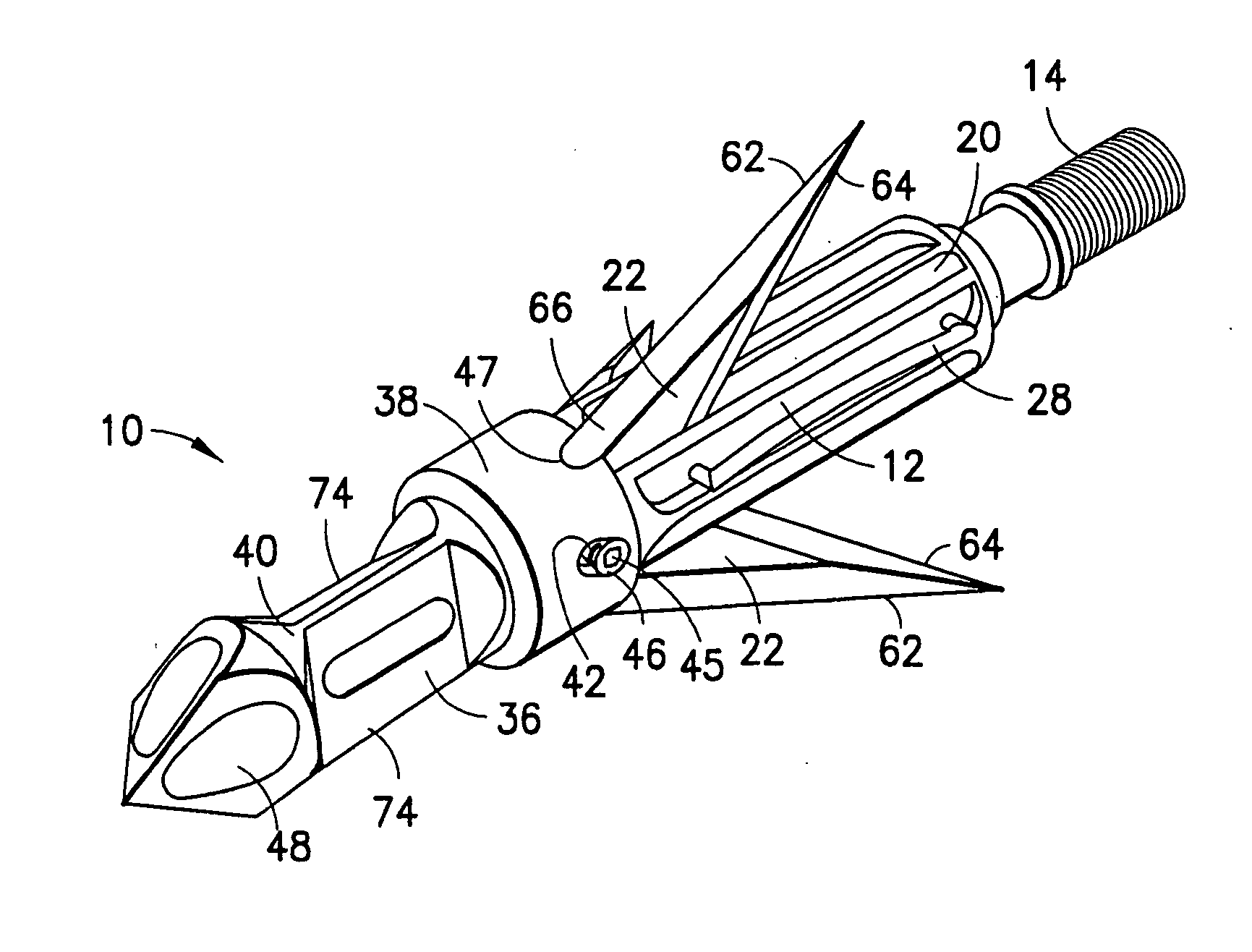

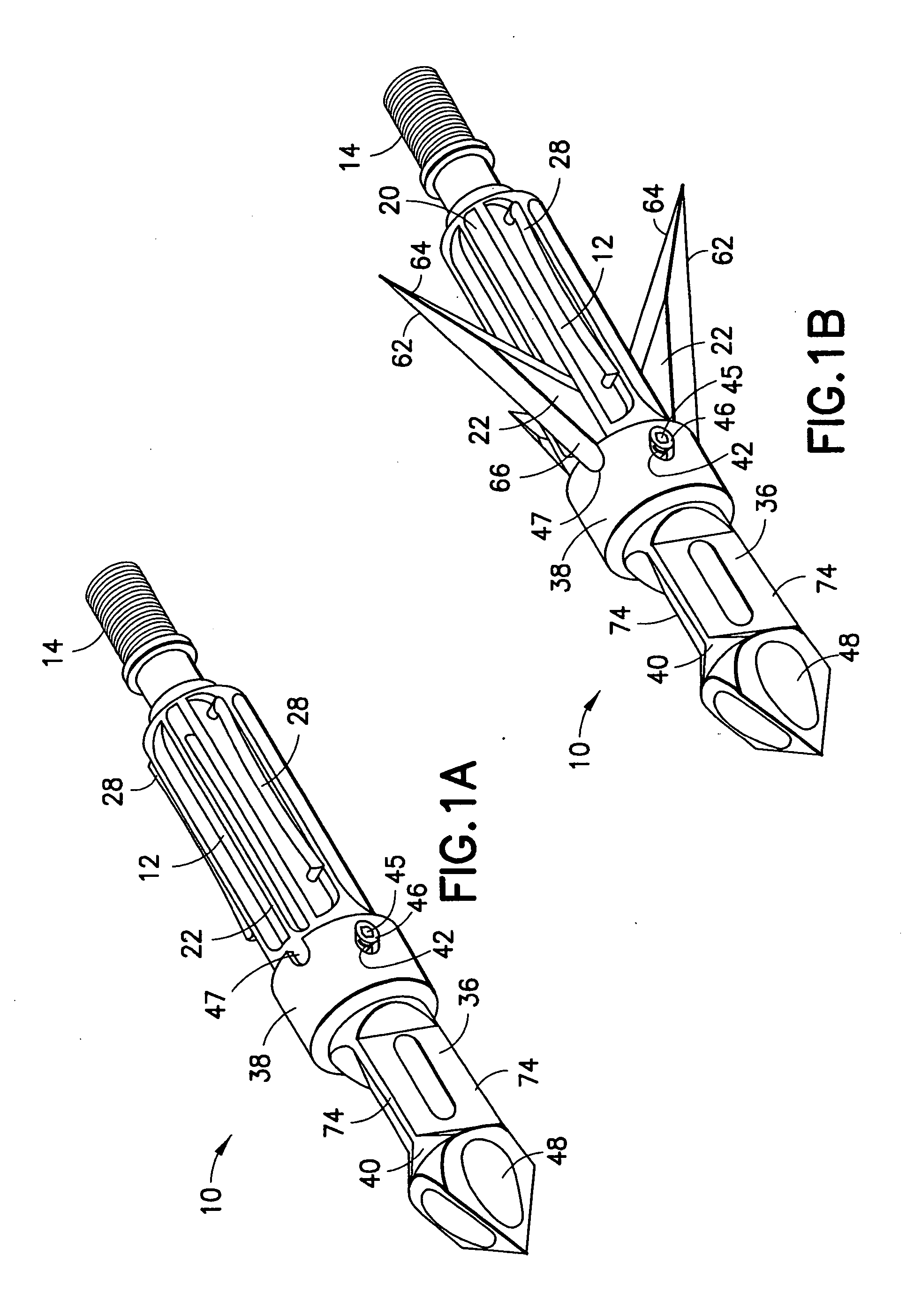

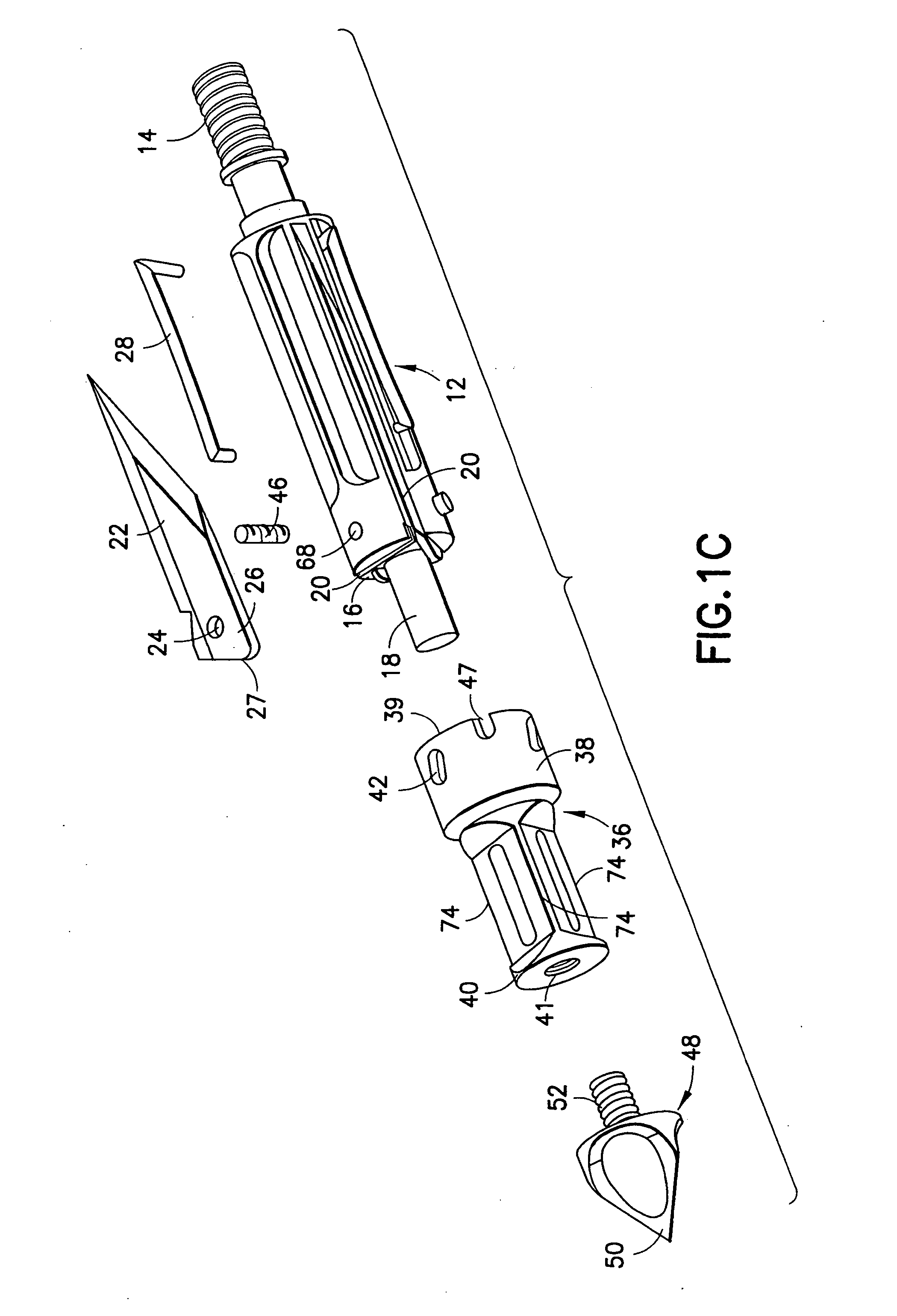

Mechanical broadhead with expandable blades

ActiveUS7713151B2Rule out the possibilityStrong materialThrow gamesArrowsEngineeringMechanical engineering

A mechanical broadhead for attachment to an arrow having a broadhead body including a plurality of blade windows formed therein, a geometrically angled retractable blade attached within each of the blade windows, retaining springs for retaining the blades in a retracted position during flight, a front body slidably mounted onto the broadhead body, and a front tip secured to the front body. Upon contact with a target, the front tip and front body slide rearwardly into an end of the geometrically angled blades, thus pushing each of the blades through the blade windows into a deployed position. The blades of the broadhead are reset by inserting a sharp point underneath an end portion of the retaining springs and applying a slight twisting motion allowing the blades to retract back into the broadhead body into a loaded position.

Owner:RAMCAT LLC

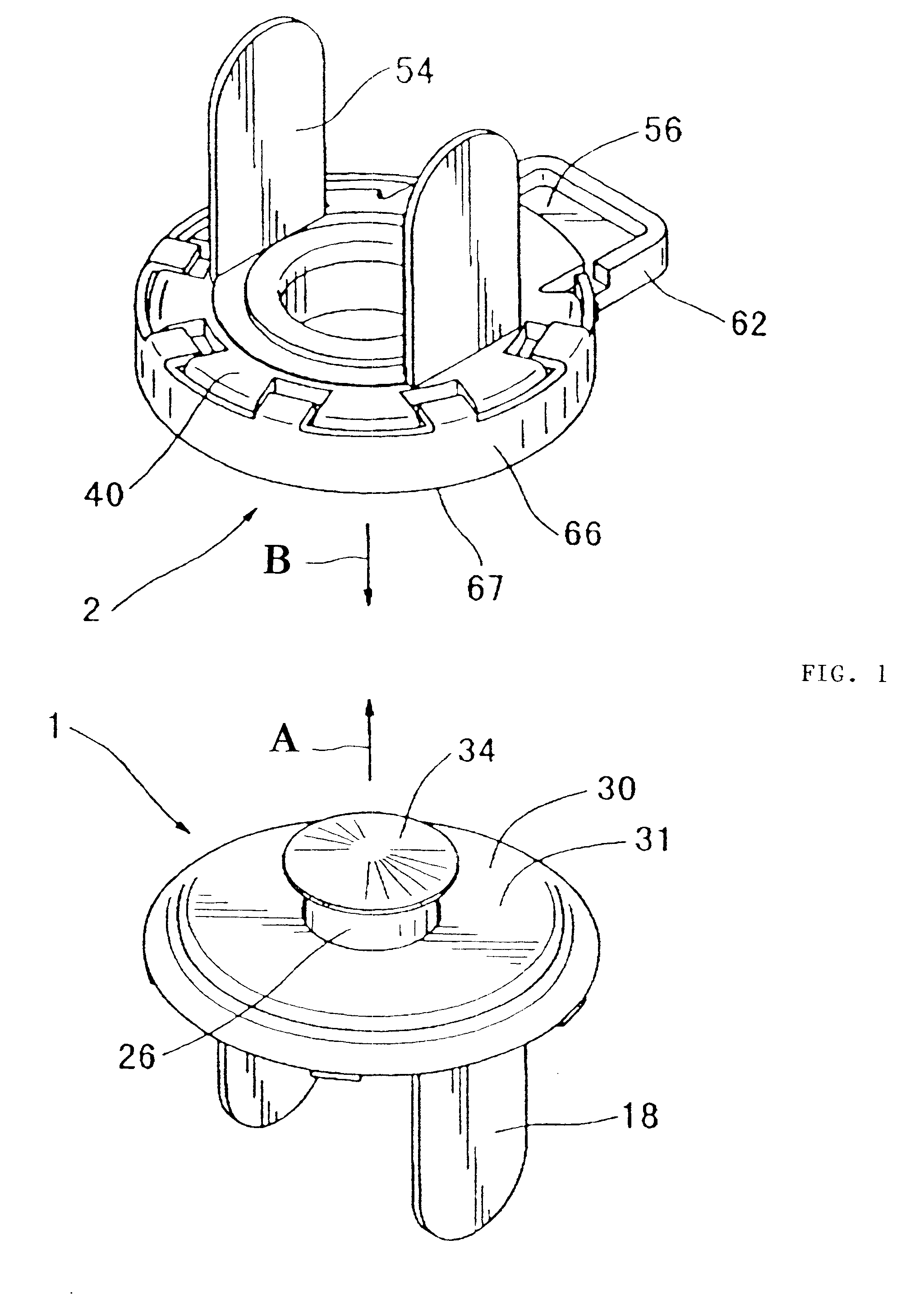

Magnetic fixing unit

InactiveUS6564434B1Easy to operateImprove assembly strengthSnap fastenersCollar-studsMagnetic tension forceEngineering

A magnetic fixing unit having a first and second sub-assembly with cooperative structure for increased strength of assembly and prevention of mutual shifting between the first and the second assemblies. The magnetic fixing unit further includes a guide structure on one of the first and second assemblies to effect cooperative locking engagement with an engaging member on the other of the assemblies.

Owner:MORITA TAMAO

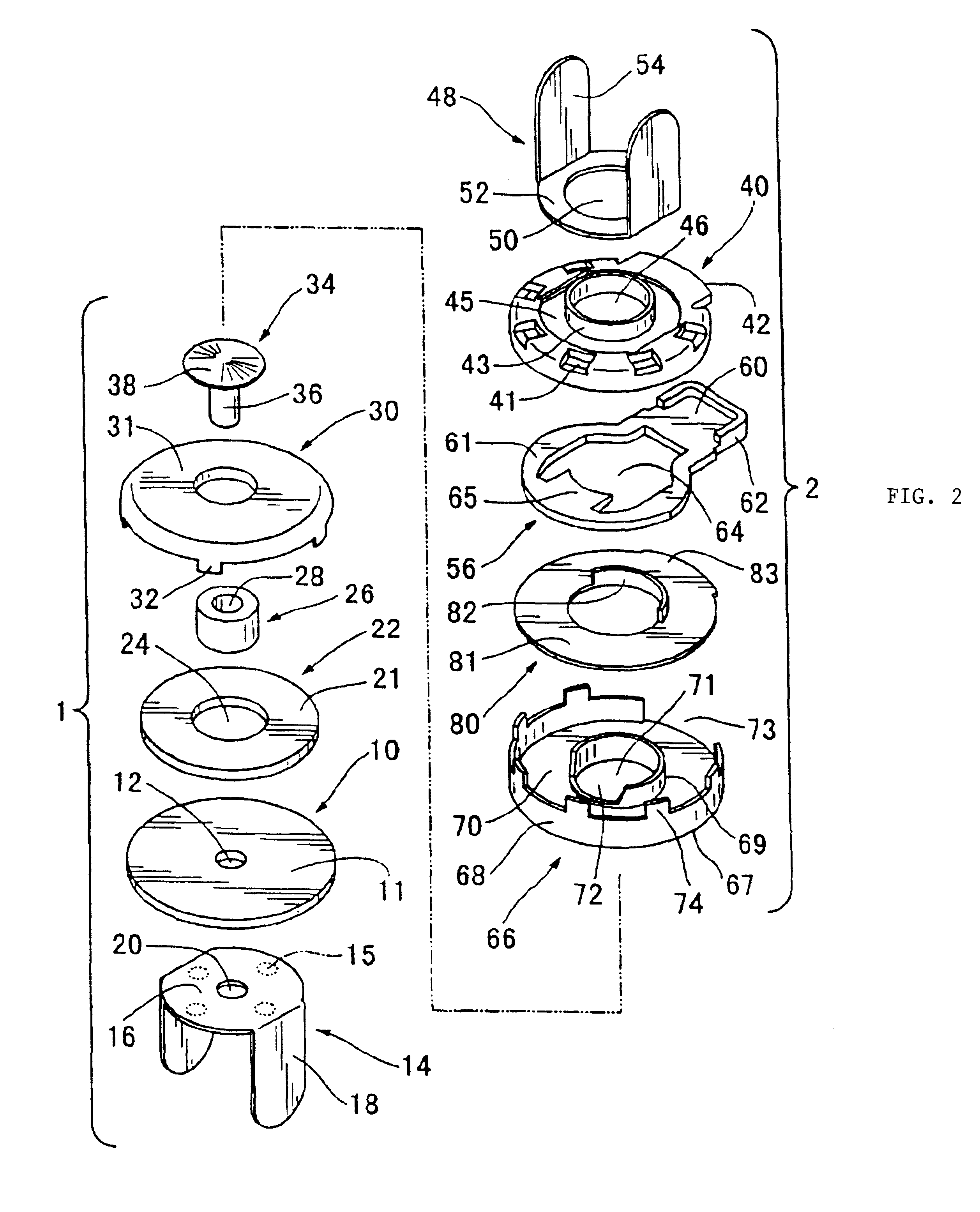

Vehicle and structure shield with a cable frame

ActiveUS20120011993A1Prevent hour glassingLight weightDefensive equipmentArmoured vehiclesRocketMechanical engineering

An ordinance, such as a rocket propelled grenade, shield includes a net with hard points at select nodes of the net and cable guides on the side of the net. Cables under tension extend through the cable guides supporting the net typically in conjunction with a top cross bar, spaced top struts, and spaced bottom struts. This framis design facilitates entering and exiting the vehicle or structure.

Owner:FOSTER-MILLER

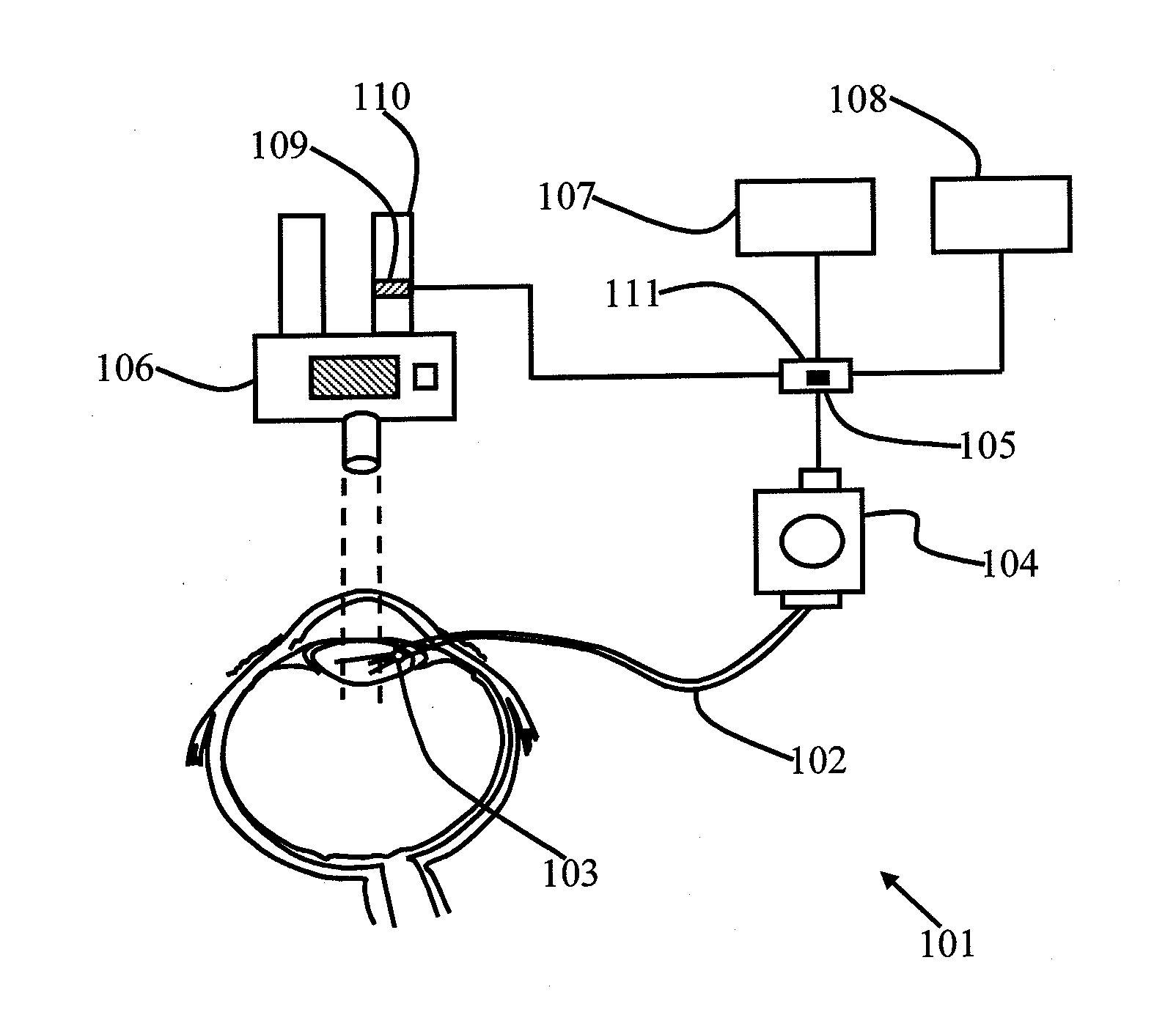

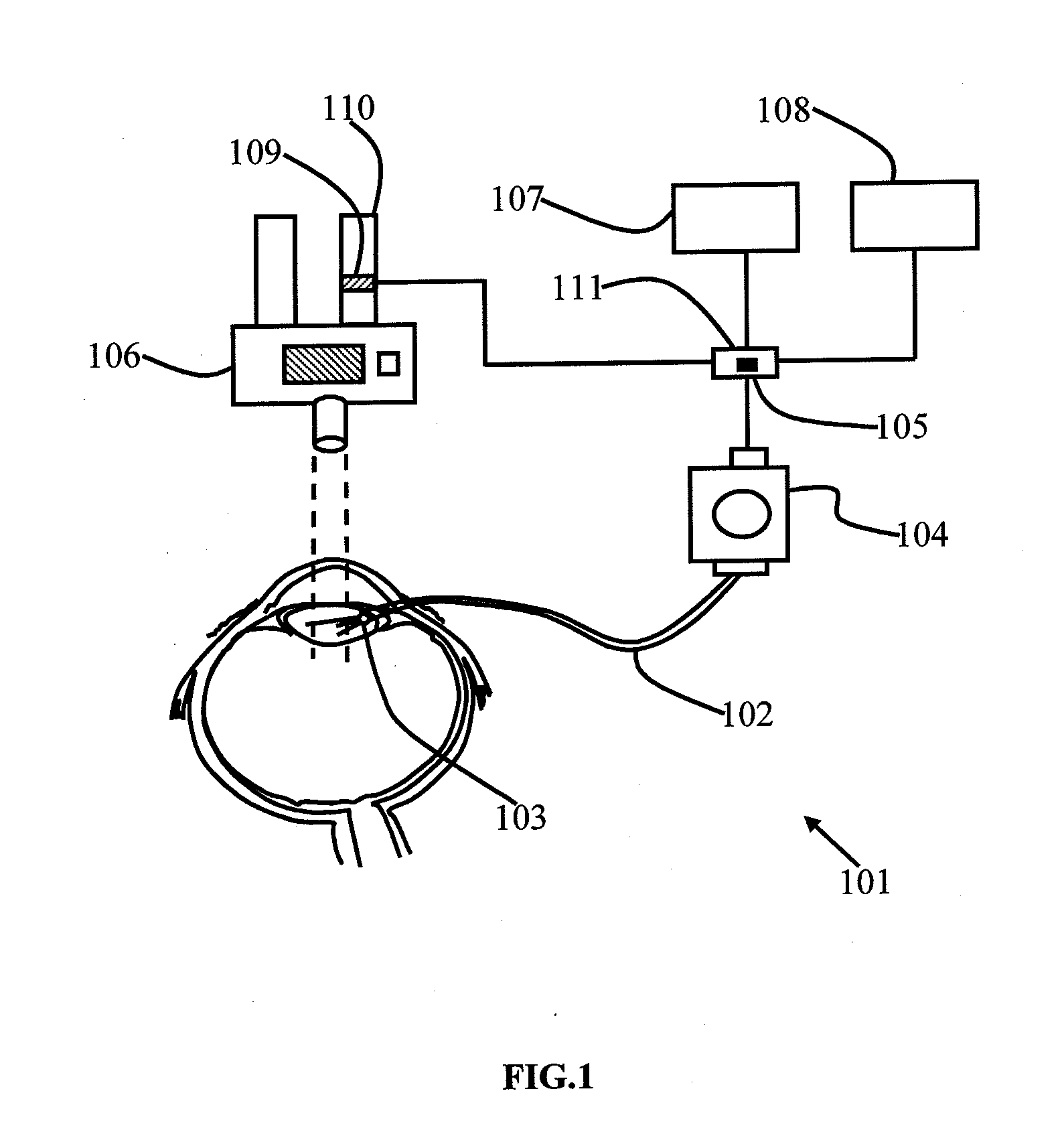

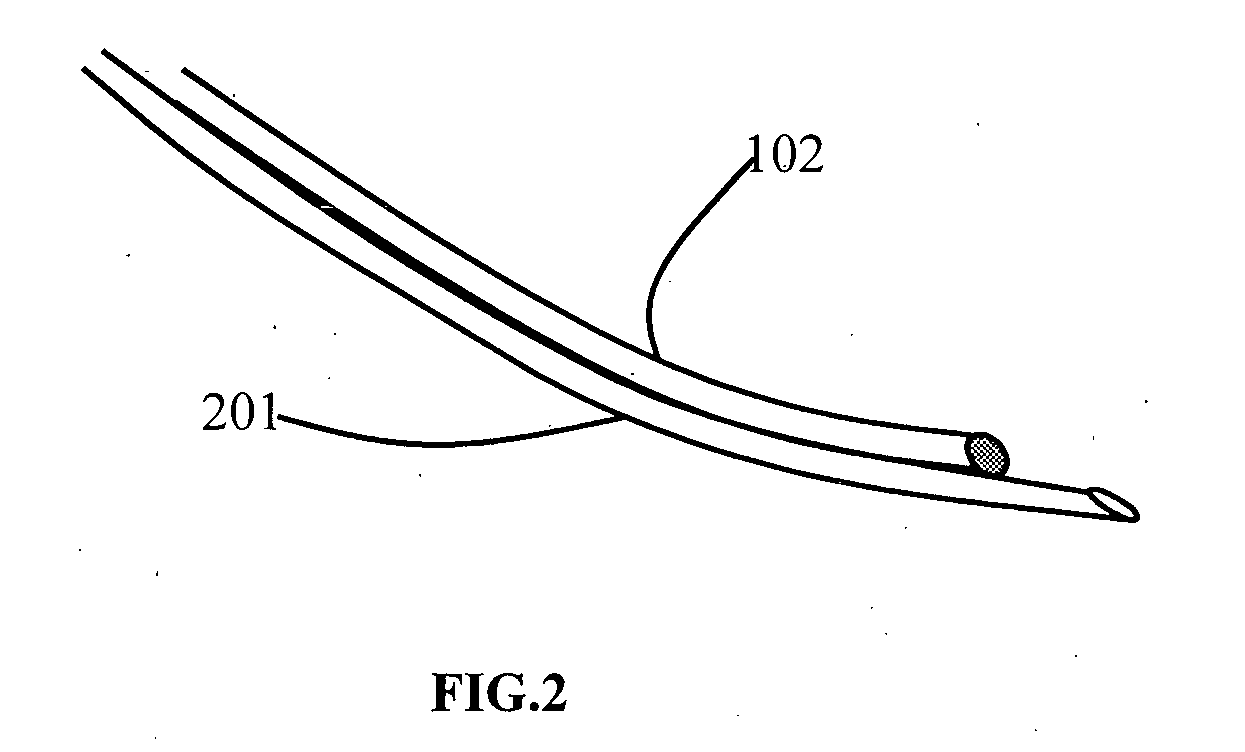

Integrated fiber optic ophthalmic intraocular surgical device with camera

A fiber optic ophthalmic surgical microscope with camera assembly comprises a fiber optic cable (102), a micro lens unit (103), a surgical instrument attached with the fiber optic cable (102), a signal splitter (105), a surgical operating microscope (106), a switch-over mechanism (111) and at least a device for viewing the images. The surgical instrument includes a chopper, a dialer, sinsky's hooks, a manipulator, micro forceps, a coaxial irrigation and aspiration (Infusion Aspiration) canula, bimanual Infusion Aspiration canula or combination thereof. The switch-over mechanism is a button. The button is provided on the signal splitter. The device for viewing the images is selected from a group comprising TV monitor and VCR.

Owner:MIRLAY RAM SRIKANTH

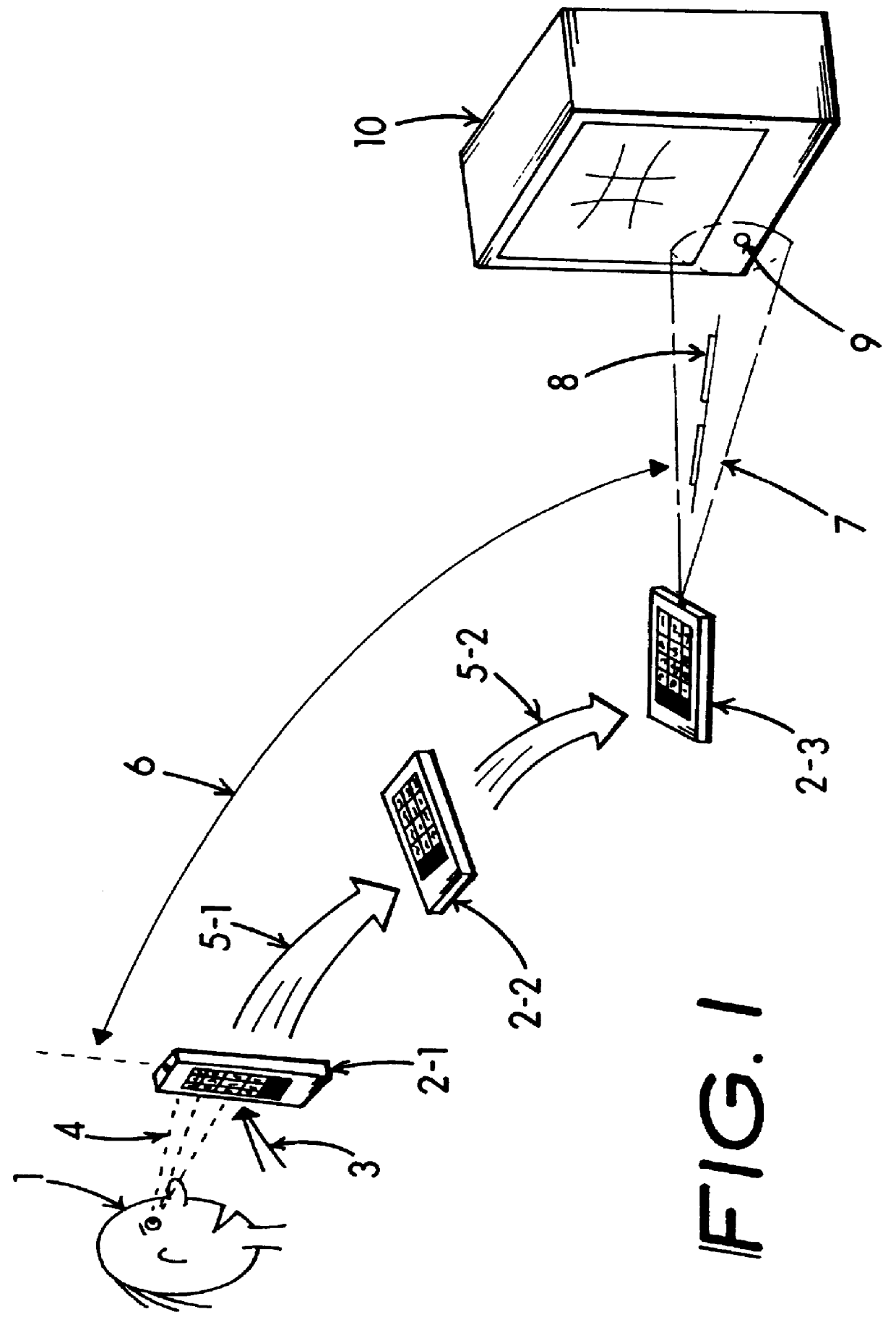

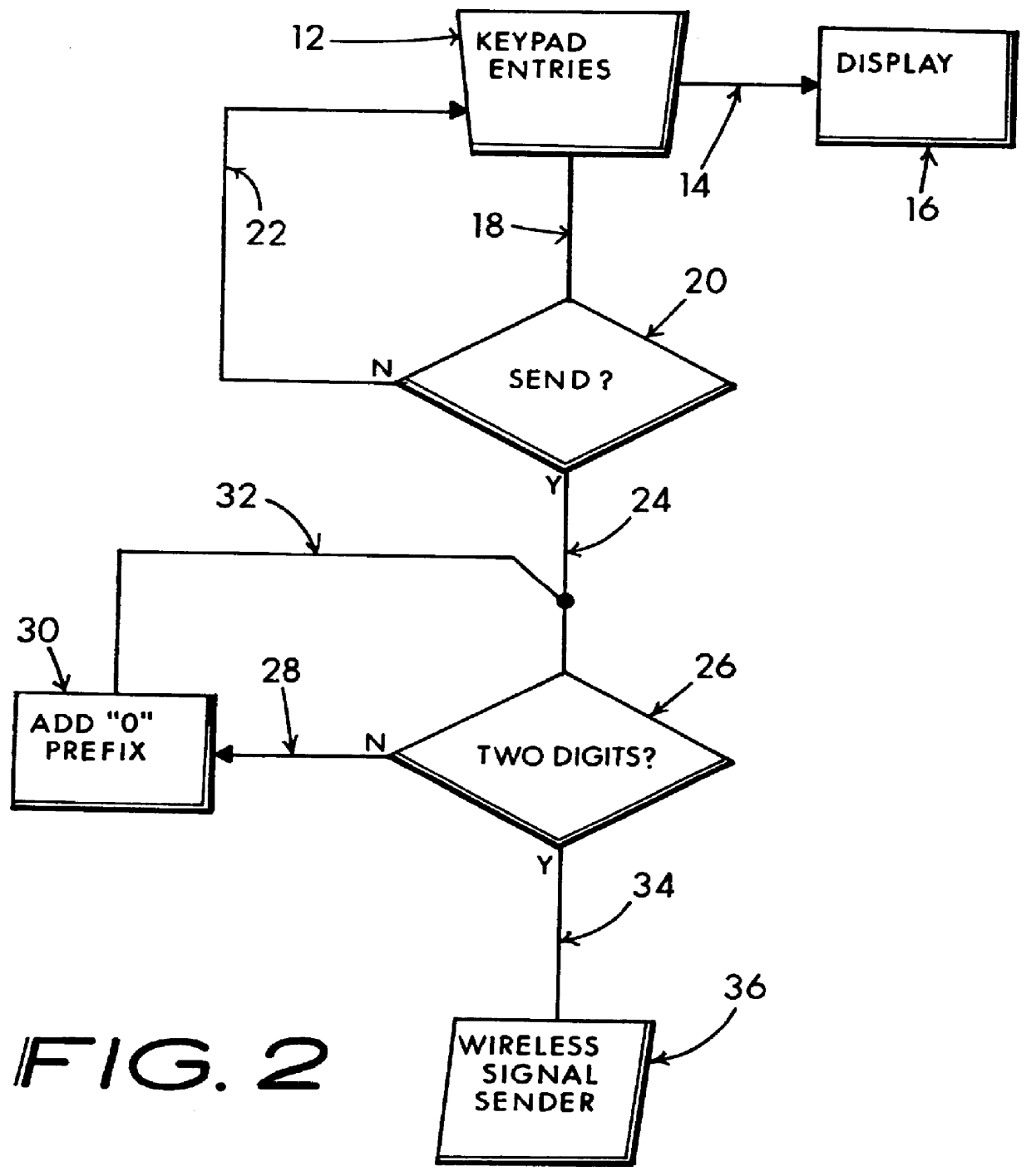

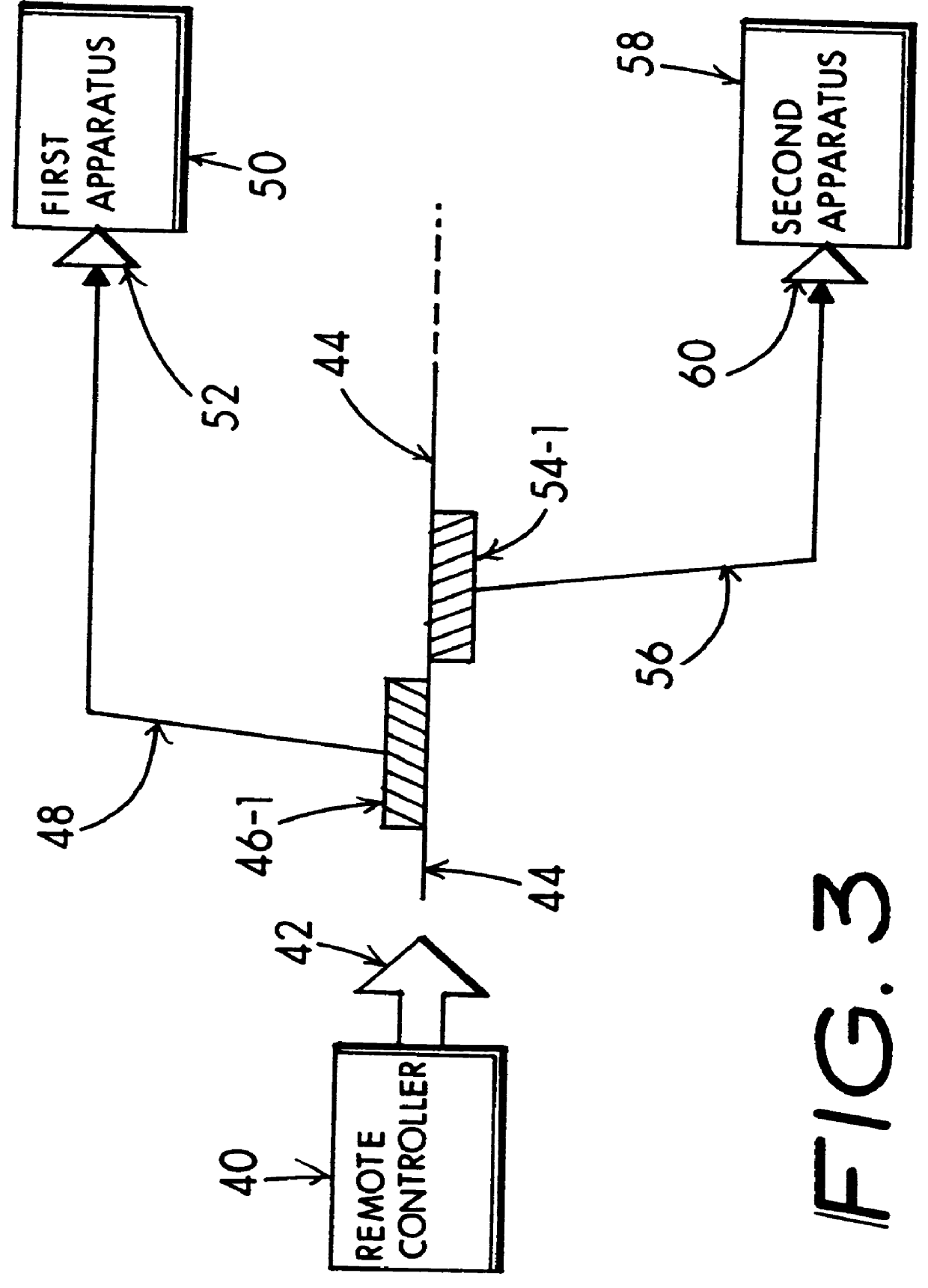

Remote control for a television enabling a user to enter and review a channel selection choice immediately prior to sending an encoded channel selection command to the television

InactiveUS6094239AEasy entryPreventing irritating switchingTelevision system detailsResonant circuit detailsNetwork packetRemote control

A handheld remote controller device that may be manually programmed while the keypad is conveniently supported in an easy to actuate and readily viewable position in front of a user. Individual keybutton entries are temporarily stored until the entry sequence is complete. Each keybutton entry may be visually displayed for review by the user. When the entry sequence is completed the remote controller device is then aimed at a remotely controlled television set, video tape or video disk player, cable or satellite signal converter. The user initiates a SEND command and the stored entries are retrieved and transmitted from the remote controller device to the receptor of the remotely controlled device as a packet of data which acts to change channel selection or accomplish other tasks in the remotely controlled device. A keybutton entry filter reduces a likelihood for accidental multiple entries which may be caused by tremors and other physical or mental maladies. In this way, physically challenged persons, or elderly persons in particular, may be enabled to utilize a remote control function with less chance for error. When only a single number channel, such as channel 5 is selected, a necessitous leading zero is automatically added to the SEND dispatched command.

Owner:HANGER SOLUTIONS LLC +1

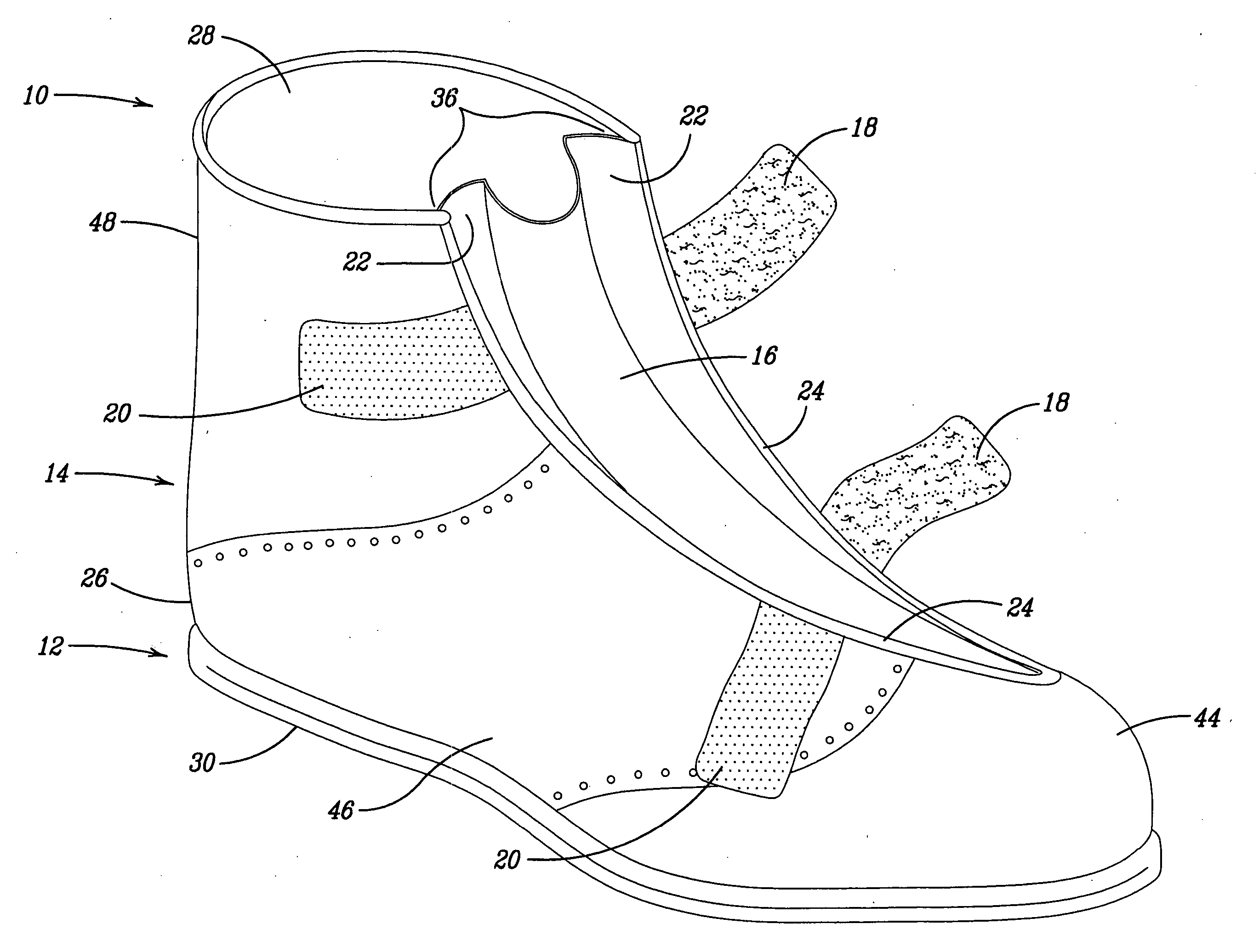

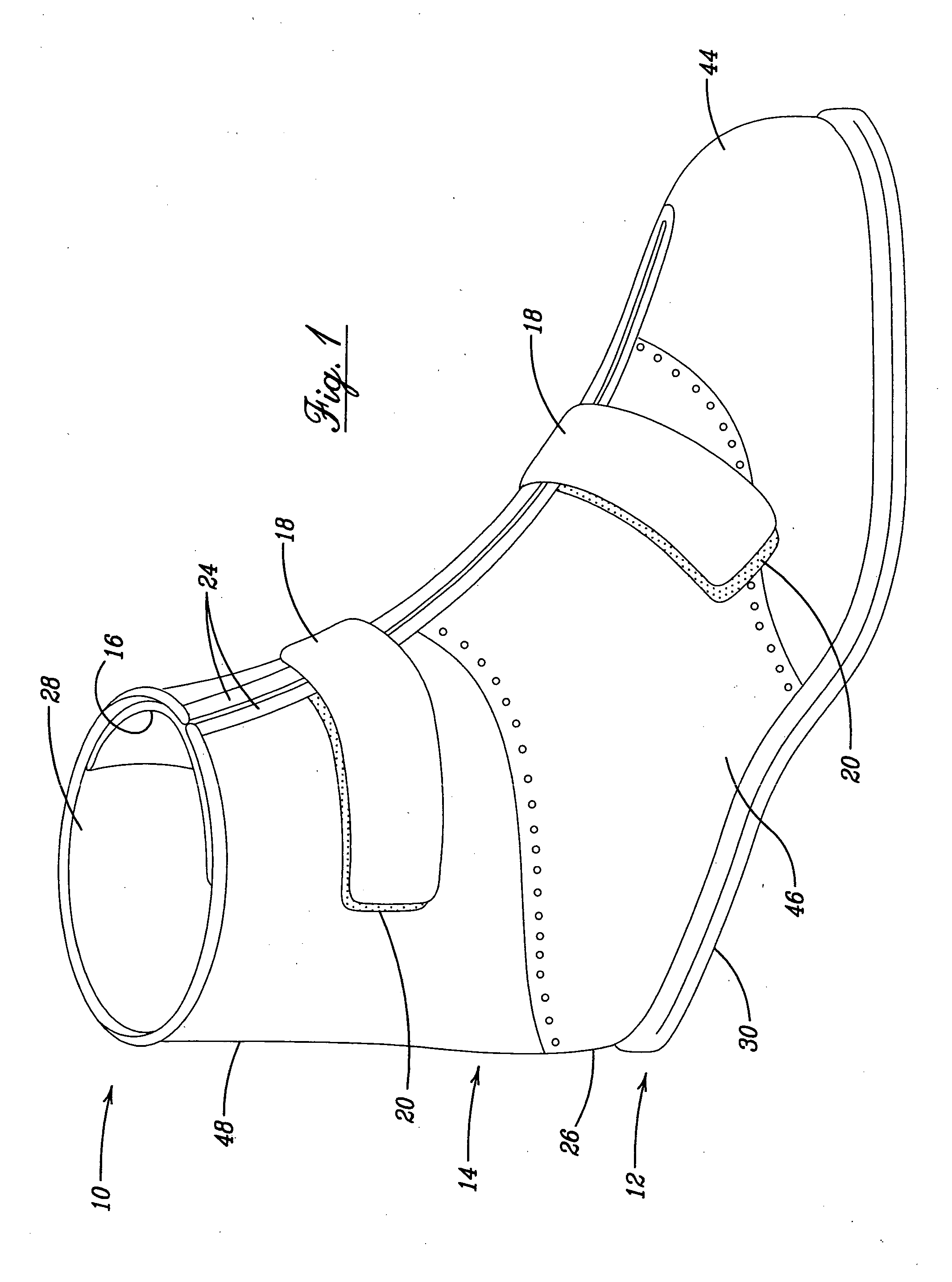

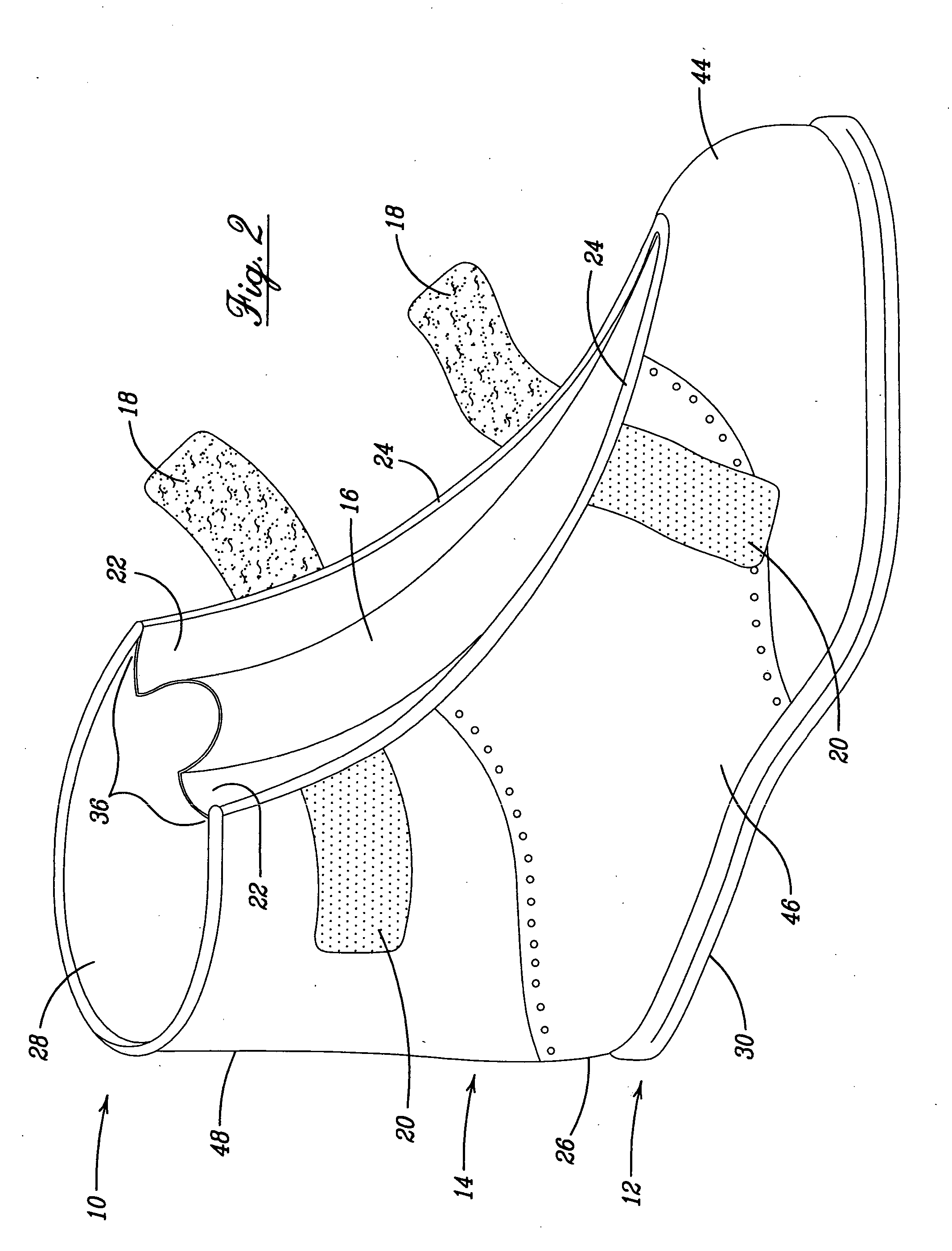

Waterproof protective overshoe for golf shoes

A waterproof protective overshoe or boot adapted to be worn over a standard rubber or plastic blunted smooth bottom cleated golf shoe, the overshoe having a rugged outsole with a protruding patterned grid tread, a smooth resilient compressible flexible conforming insole for receiving the rubber or plastic cleats of a golf shoe into a corresponding number of recesses formed by the compression of the insole by the cleats locking the golf shoe in place within the protective overshoe, a double gusseted front creating a wide opening mouth for ease of putting on or taking off the boot, and a plurality of adjustable fasteners for securing the boot to the shoe clad foot of a golfer, the boot being of unitary construction and extending above the ankle of a golfer so as to be impervious to water intrusion, particularly when worn in combination with rain pants.

Owner:CULTON DALE M +1

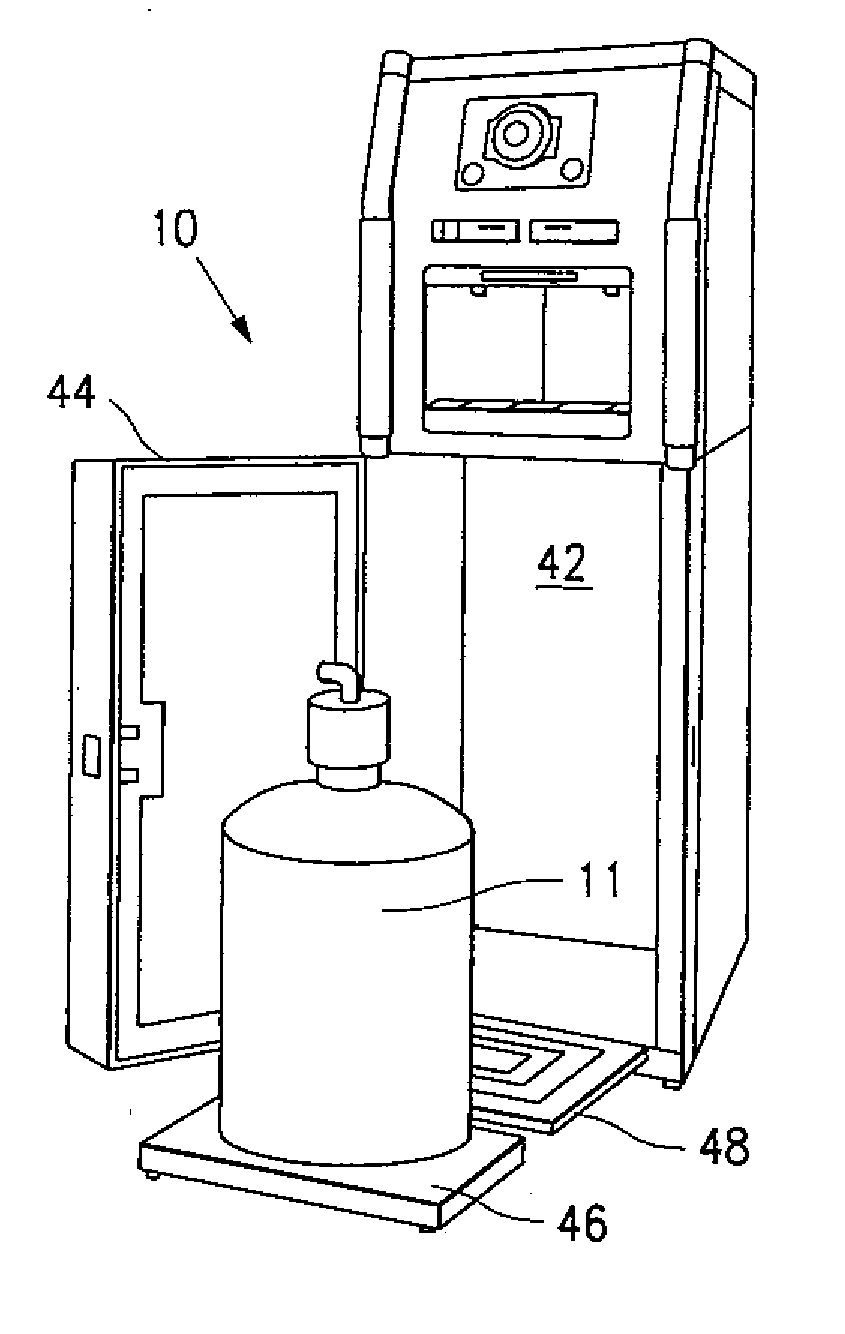

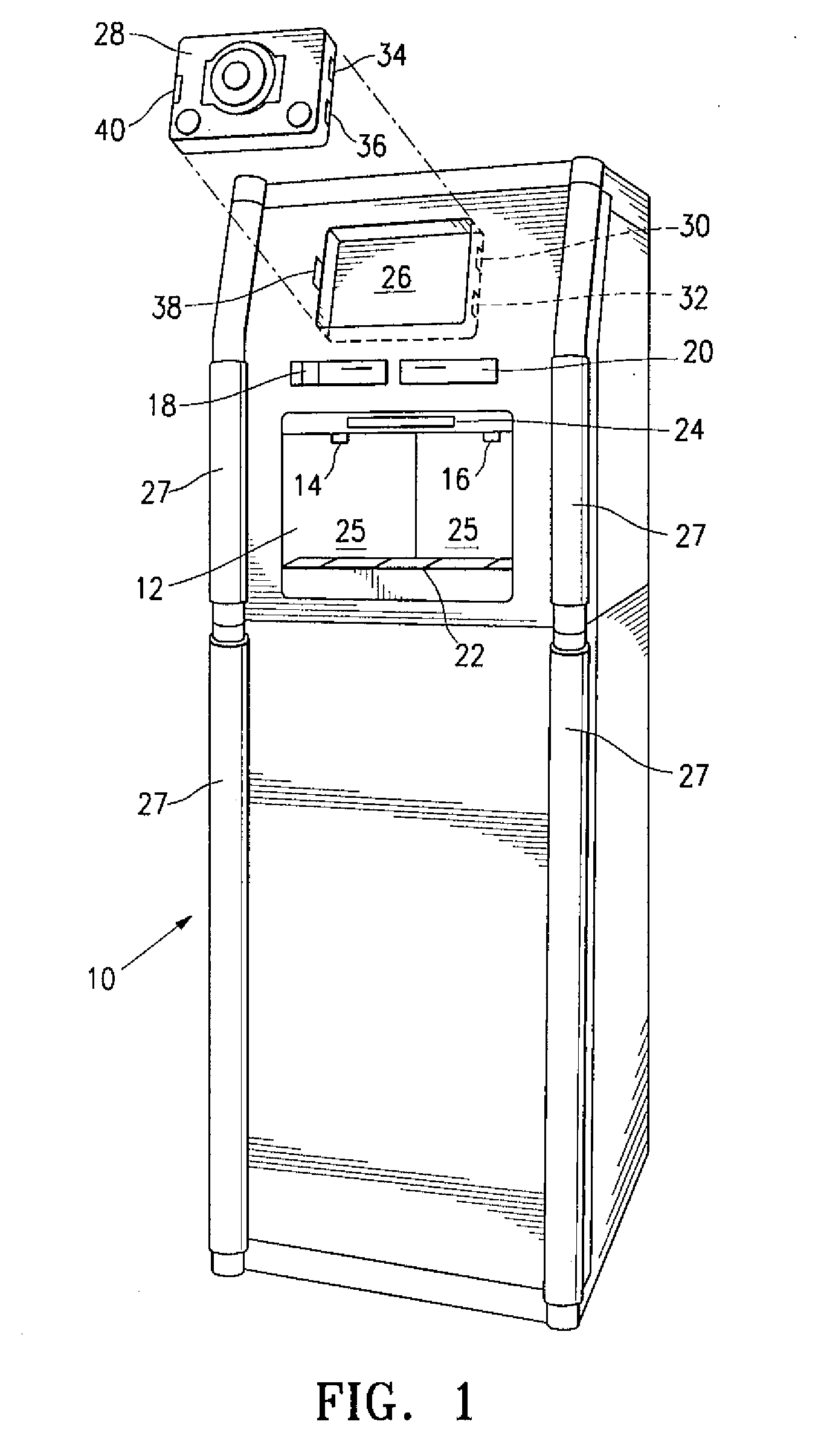

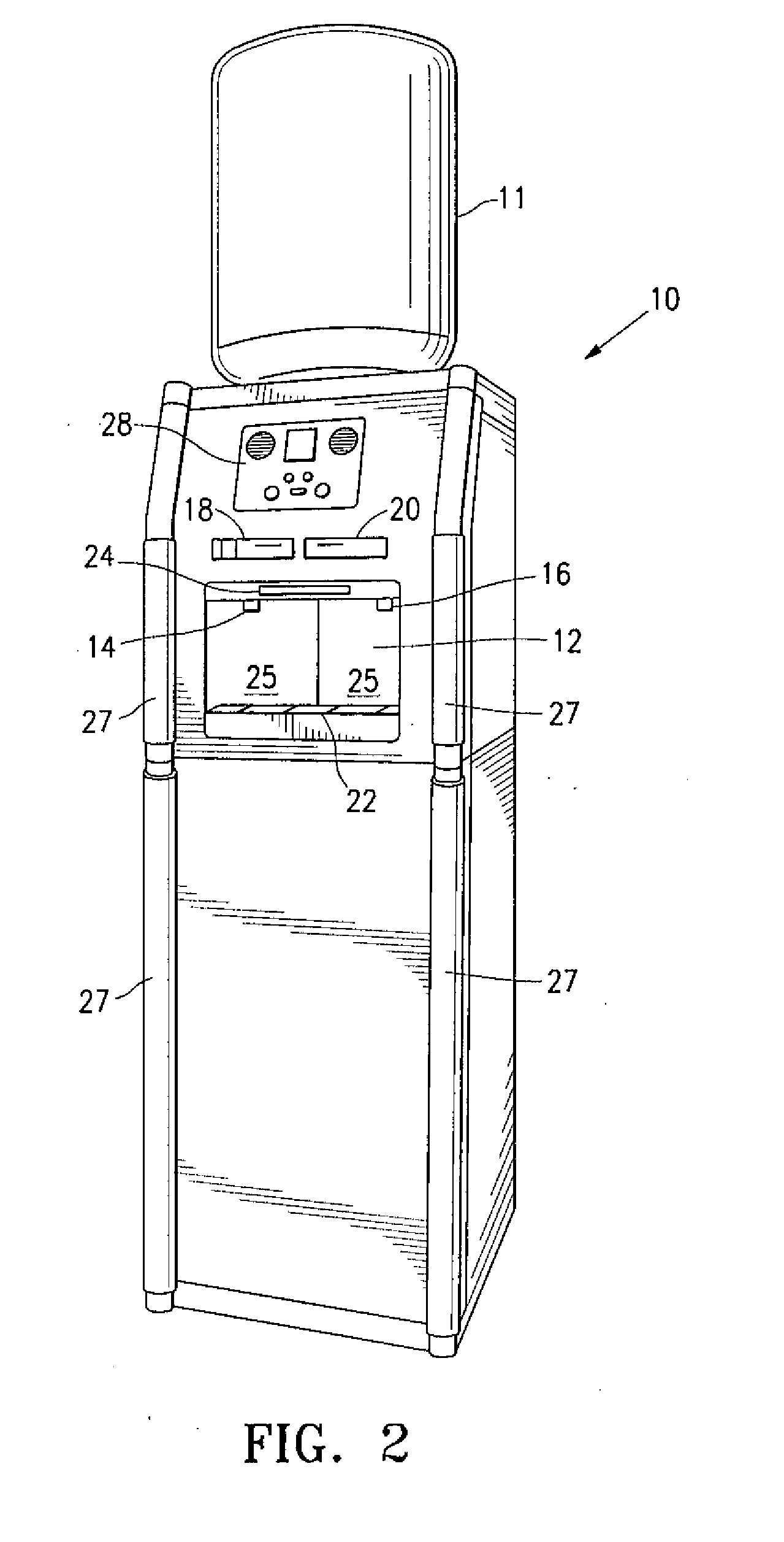

Beverage dispenser

InactiveUS20070137726A1Easy entryEasy exitLiquid fillingLiquid flow controllersUltraviolet lightsEngineering

A beverage dispenser includes an outlet for dispensing beverages and a tray for supporting a container underneath the outlet. An ultraviolet light source is directed at the outlet for disinfecting the outlet. A light source illuminates a path of a beverage between the outlet and the tray. Exterior lights are mounted on an exterior of the dispenser. A cradle secures an appliance module to the dispenser and includes an interface for communication of data or power between the appliance module and the dispenser. A bottle storage cabinet may be formed underneath the dispensing bay for storing a bottle. The storage cabinet includes a door for opening and closing the cabinet, a movable trolley for supporting and moving the bottles and a hinged ramp to facilitate entry and exit of the trolley into and out of the cabinet. Alternatively, for counter top applications, a built-in mover is formed underneath the dispenser to facilitate easy movement of the dispenser.

Owner:C ART

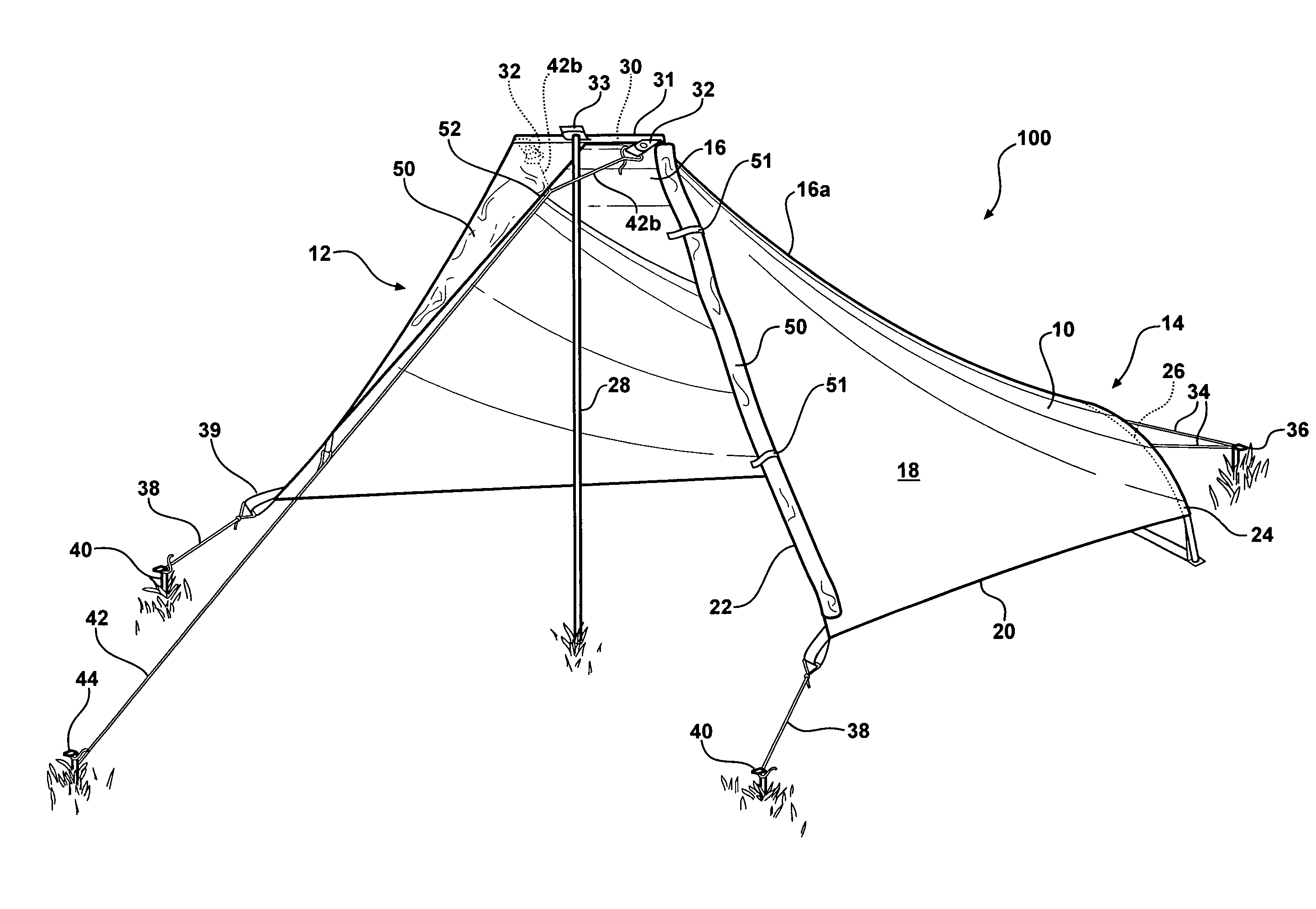

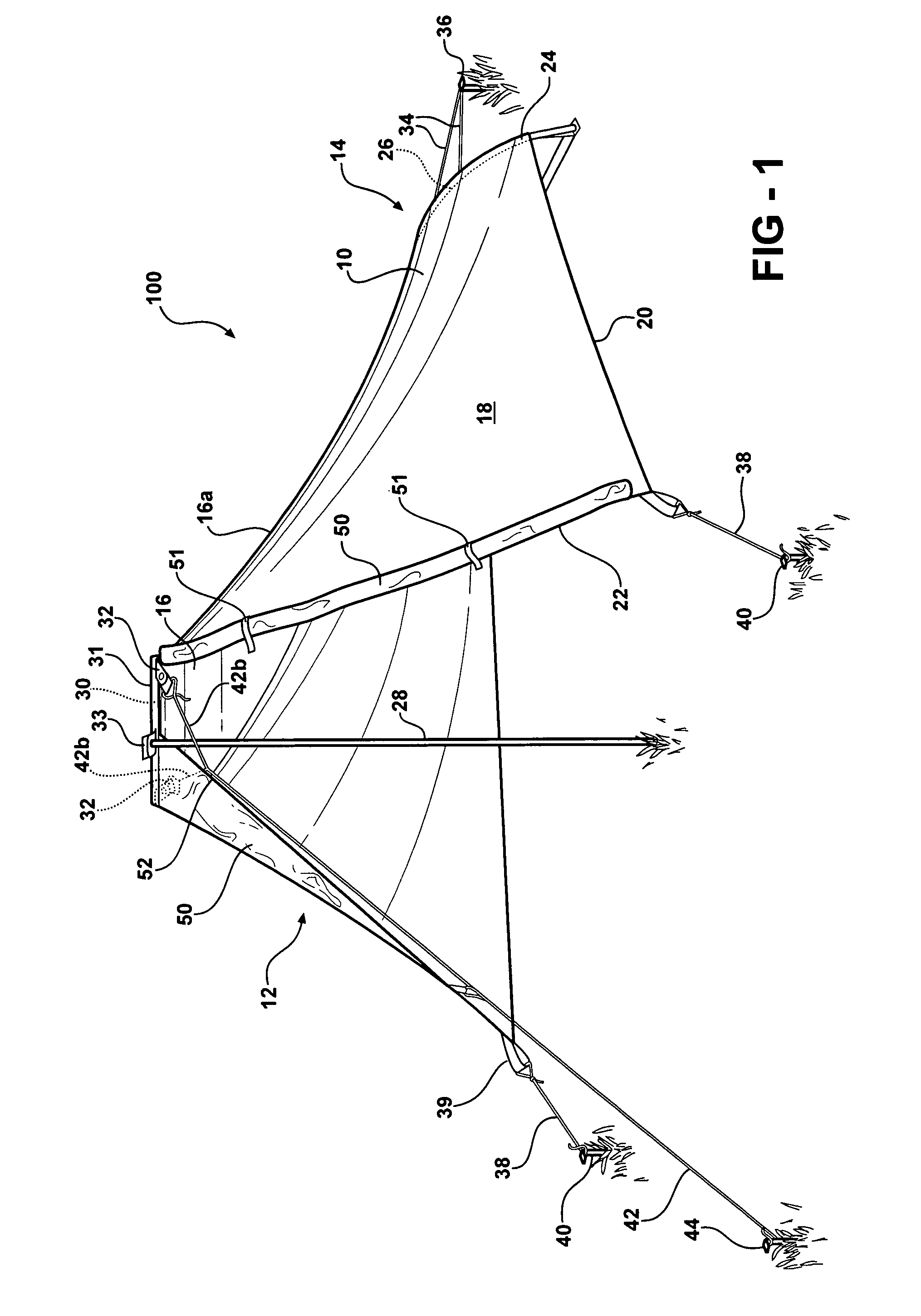

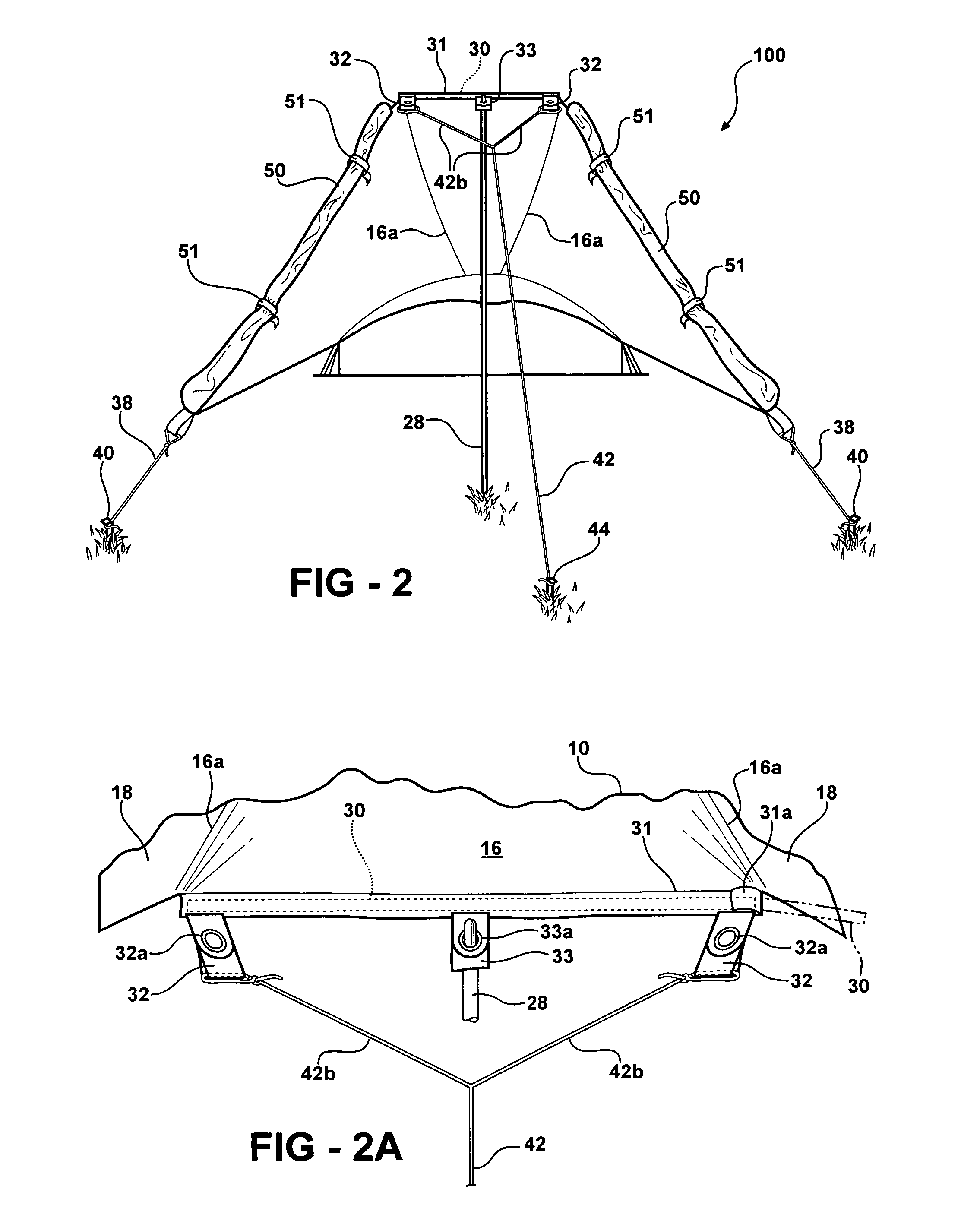

Lightweight shelter

The present invention is an improved tensioned canopy shelter of the type used by backpackers. The canopy of the new shelter has a lower rear support and a higher front pole support with a horizontal ridge strut. The ridge strut spreads the forward end of the canopy's ridgeline into a catenary-tensioned panel, with dual catenary curves running from the ends of the ridge strut to the rear end of the canopy. The horizontal ridge strut can be supported by a single central upright pole, or it can alternately be supported at its ends by spaced upright poles for even greater stability and easier entry and exit through the front of the shelter, for example using two trekking-type poles. In the preferred form the ridge strut is provided with pole connections to allow either the single- or double-pole options. In a further preferred form, the ridge strut is removably held in a sleeve in such a manner that it may either be left in place or removed when the shelter is rolled up for storage. In yet a further form, the ridge strut provides structural support for an adjustable ventilation flap.

Owner:SHIRES HENRY C

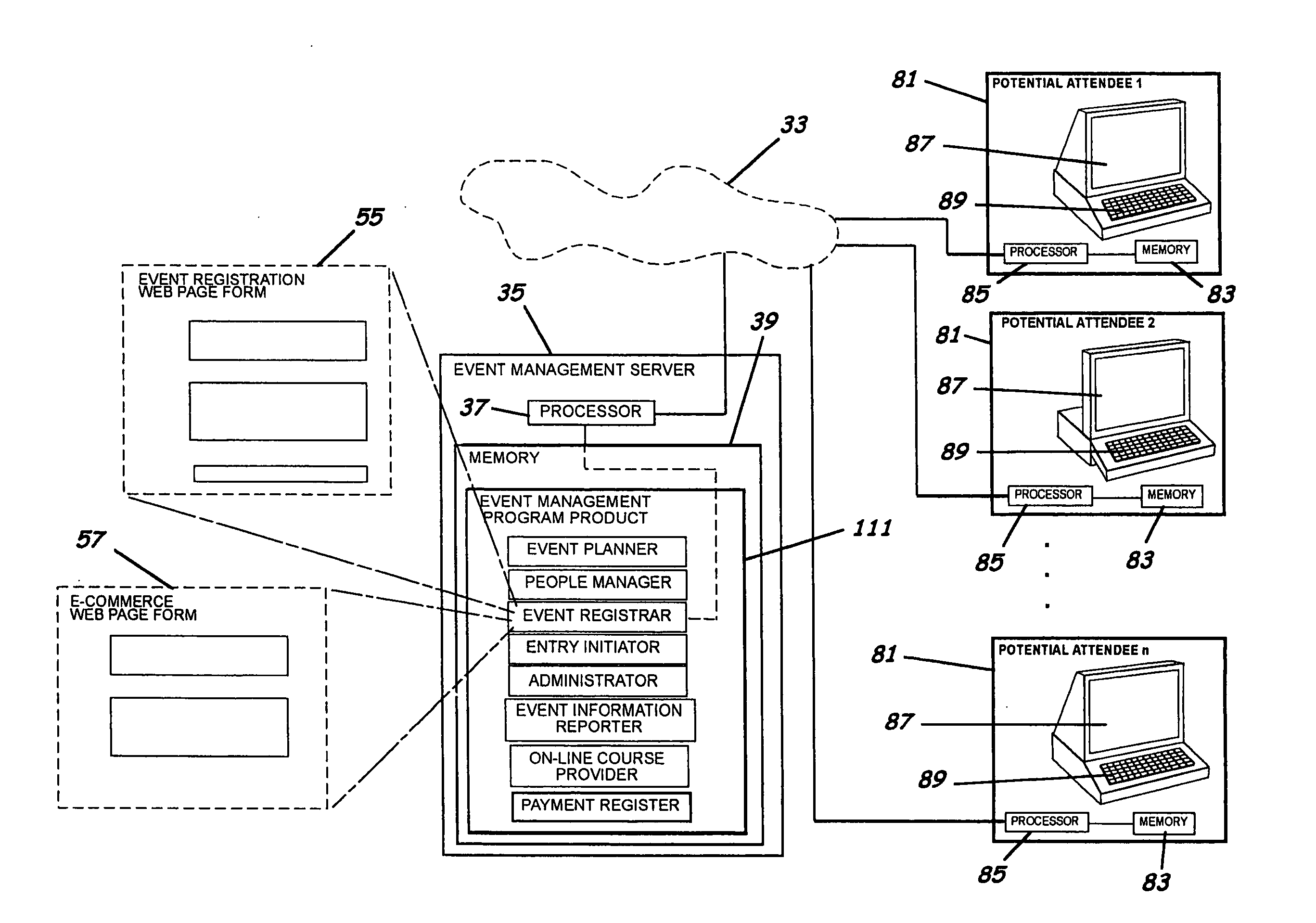

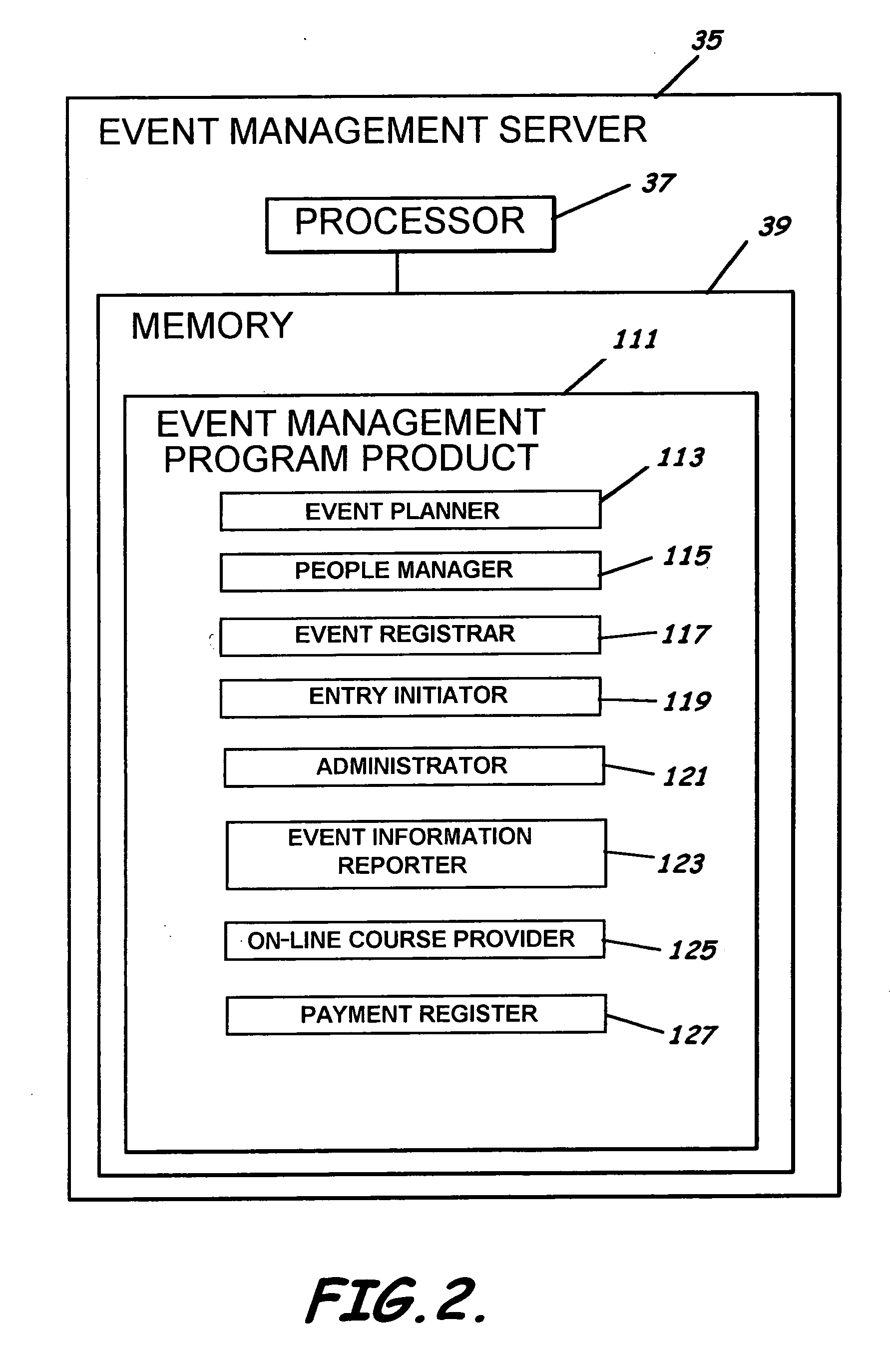

System, program product, and methods for managing events

InactiveUS20060265418A1Most efficientEnhancing event planningDigital data processing detailsOffice automationWeb siteProgram planning

A system to facilitate event registration, planning, promotion, and management of events through an on-line event management website over a computer network, program product, and associated methods are provided. The system includes an event management server, a database accessible to the event management server and including user data records and event data records, a plurality of event management member user's computers to provide event management member users with on-line web-based access over the computer network to the data records, and a plurality of potential event attendee user's computers to provide potential event attendee users with on-line web-based access to the data records. The system also includes an event management program product stored in the memory of the event management server to provide each of the event management member users concurrent access to data records over the computer network to manage event planning and delivery, and to provide the potential event attendee users concurrent access to the data records over the computer network to self-register for the events and to manage continuing education requirements.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

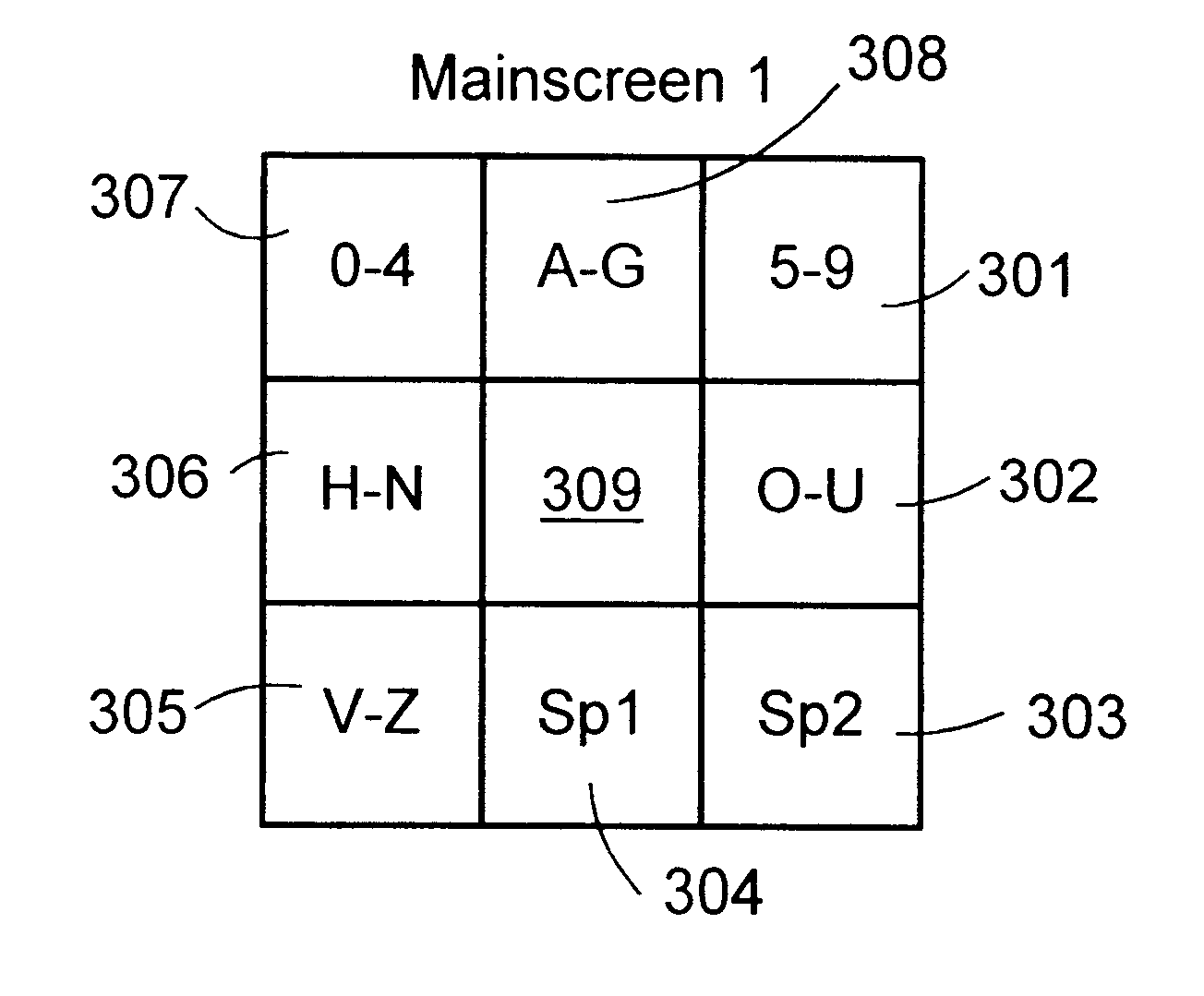

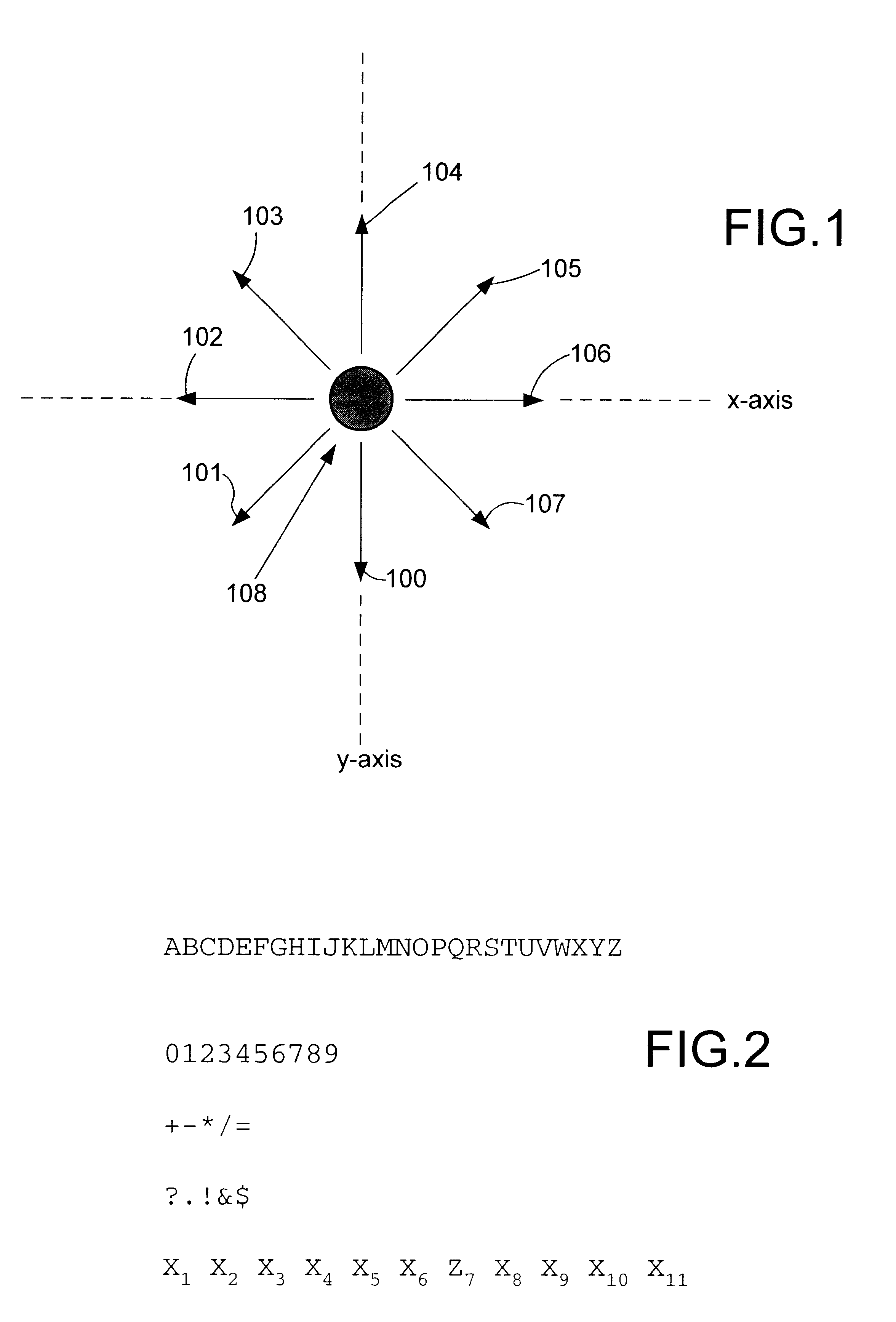

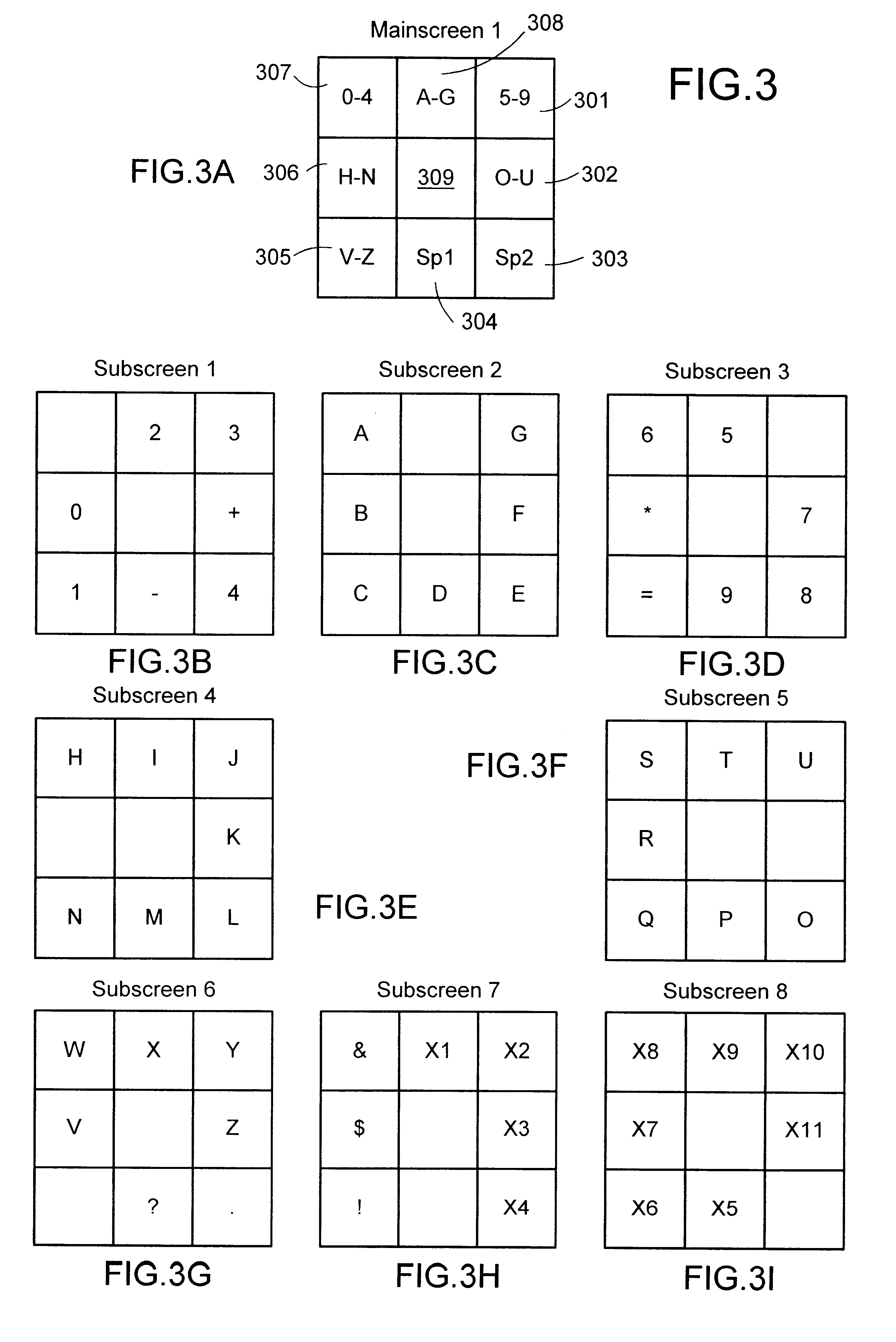

Data input

InactiveUS6812940B2Easy entryQuick and accurate and efficientCordless telephonesCathode-ray tube indicatorsHuman–computer interactionData input

Owner:INVENTION INVESTMENT IRELAND LLC

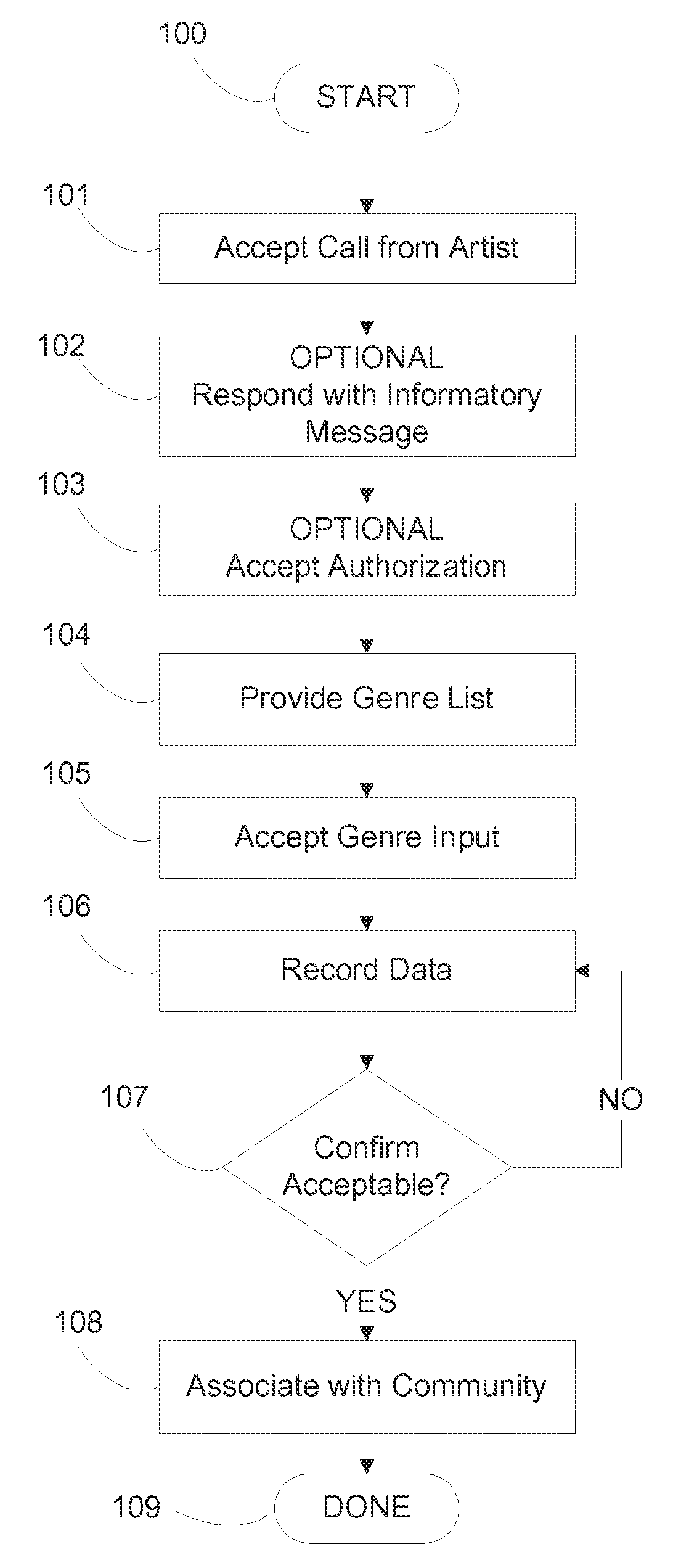

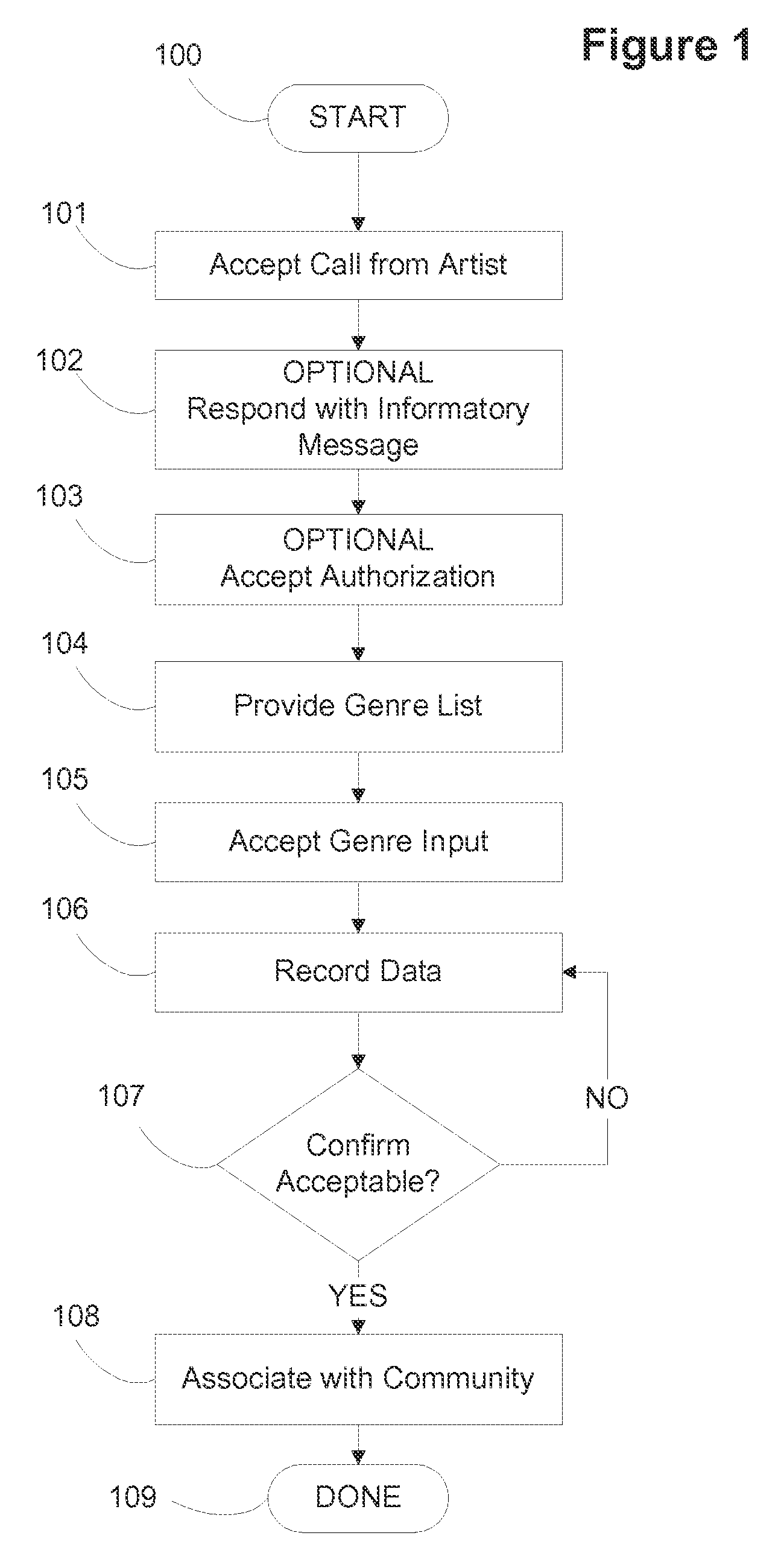

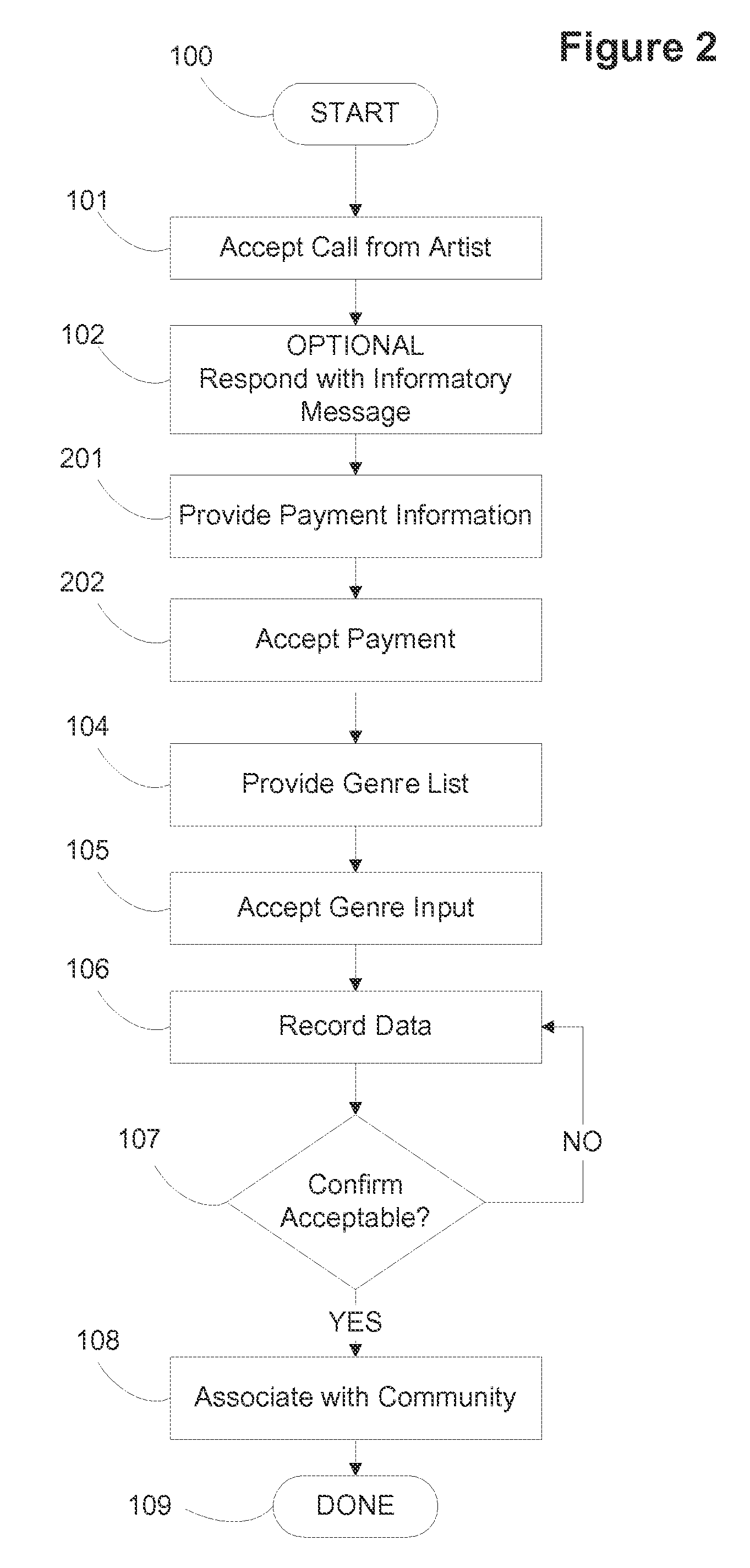

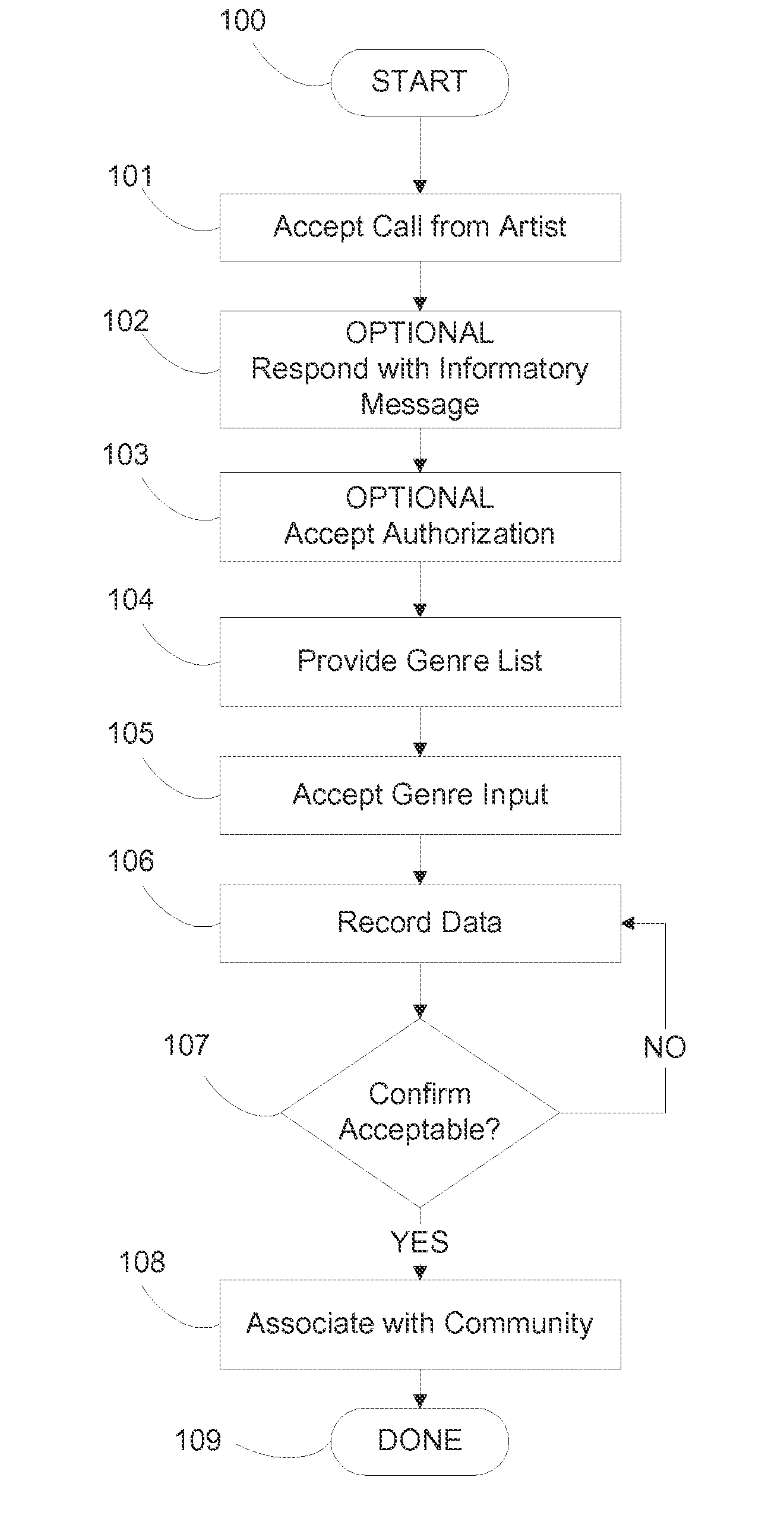

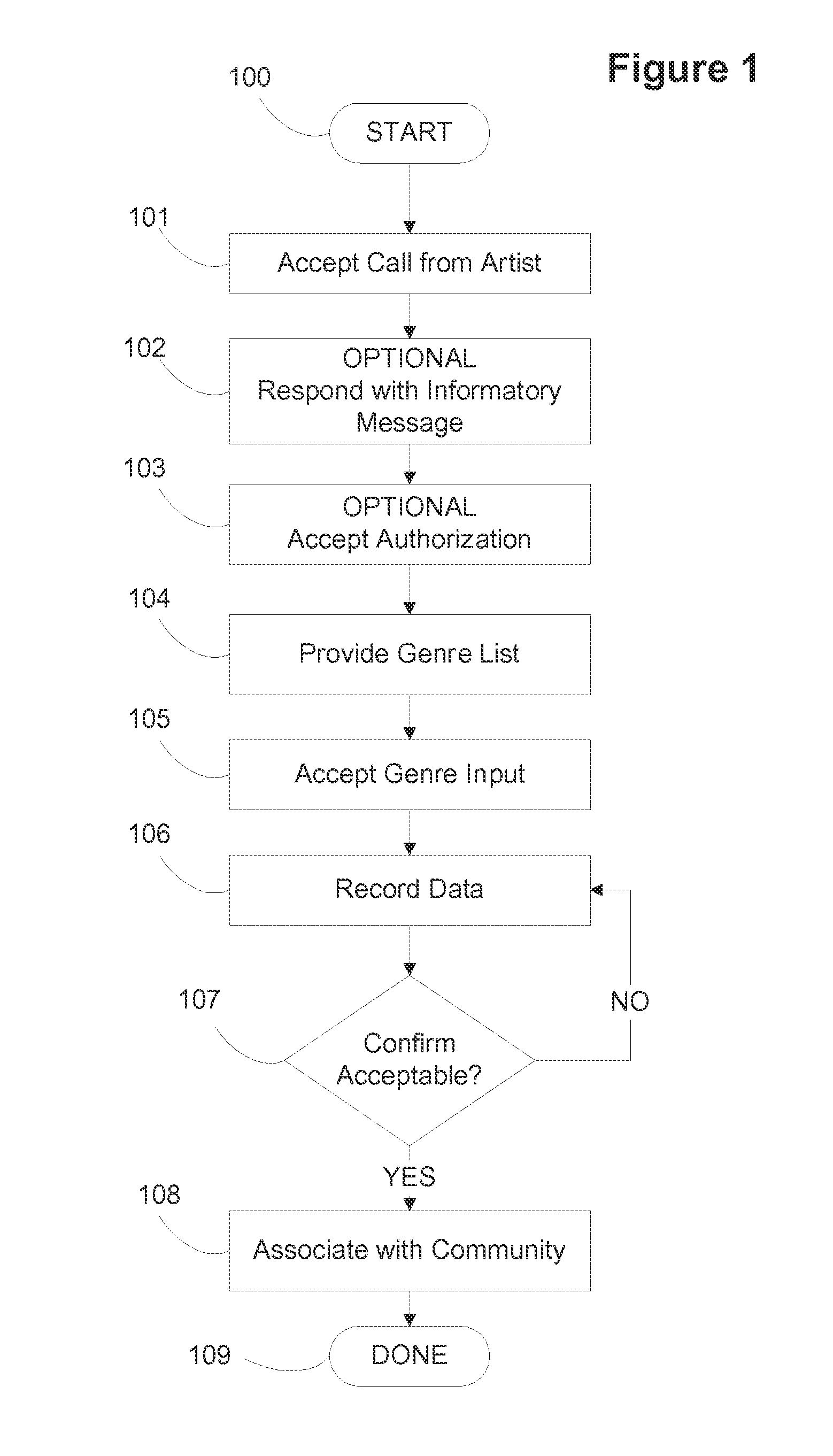

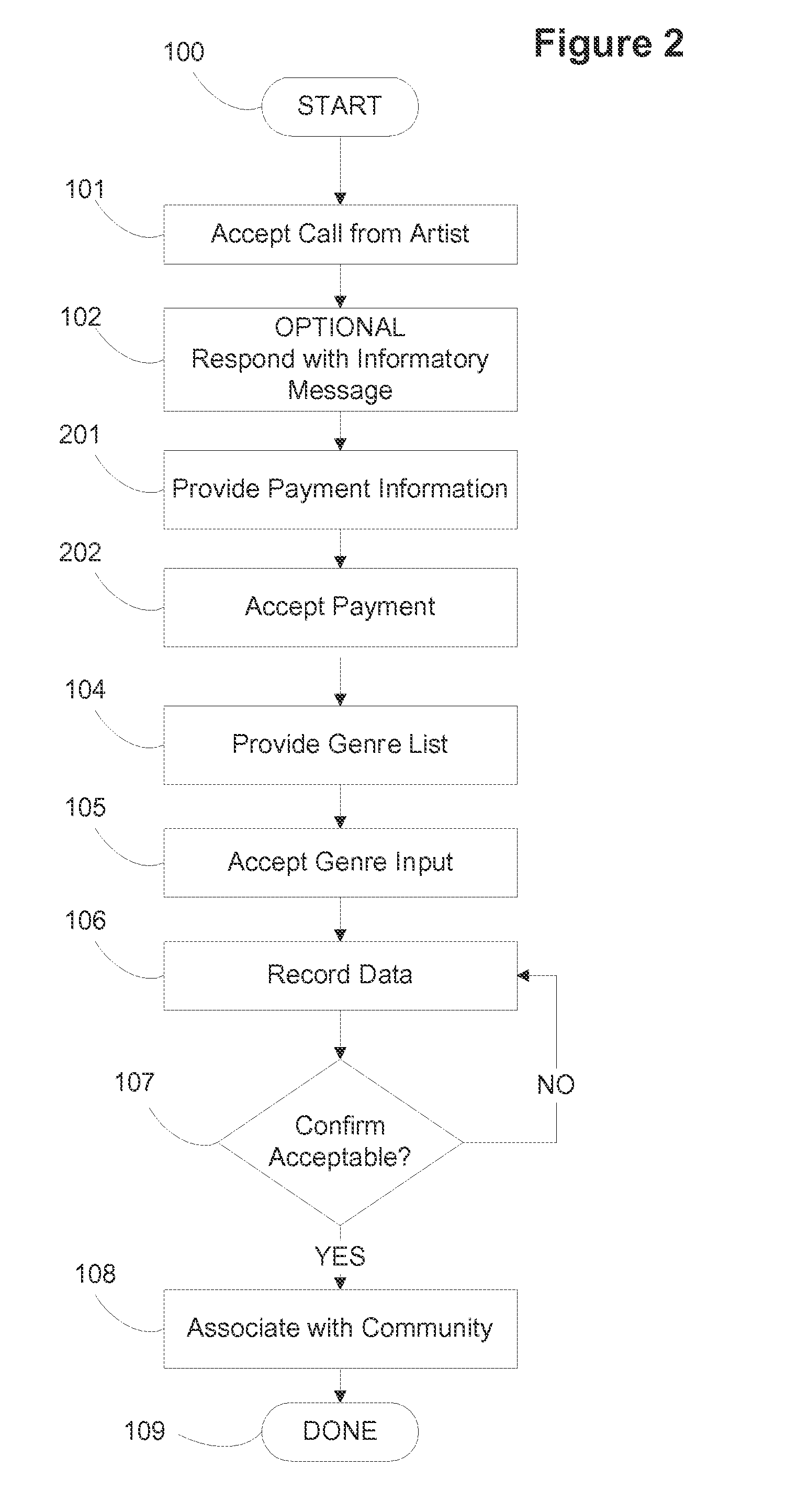

System for submitting performance data to a feedback community determinative of an outcome

InactiveUS20080050714A1Inexpensive competition entryImprove controlElectrical appliancesMechanical appliancesRecording durationPayment

Uses a telecommunications device / computer as an open microphone for collecting media, for example audio, video or text performances that are then integrated into an online community for feedback / judging. The media may include singing, instrumental music, rhythmic music, videos, writings. The performances may also be made available as ring tones. Allows for a server to accept a call / IP connection from an artist, accept payment for a number of recording minutes, provide a genre list (e.g., singing, band, DJ, beat makers), accept selection of a genre and record a performance. Furthermore, the server may also be configured to play, transfer or email a performance, for example as directed from a website or telecommunications device. The media may be judged and / or ranked by members of the community. Recording time may be monitored and a charge levied for submission of the performance. Server may play, download or email the performance.

Owner:ELASTIC MINDS LLC

Mechanical broadhead with expandable blades

ActiveUS20070161438A1Relieve pressureImproved cutting designThrow gamesArrowsEngineeringMechanical engineering

A mechanical broadhead for attachment to an arrow having a broadhead body including a plurality of blade windows formed therein, a geometrically angled retractable blade attached within each of the blade windows, retaining springs for retaining the blades in a retracted position during flight, a front body slidably mounted onto the broadhead body, and a front tip secured to the front body. Upon contact with a target, the front tip and front body slide rearwardly into an end of the geometrically angled blades, thus pushing each of the blades through the blade windows into a deployed position. The blades of the broadhead are reset by inserting a sharp point underneath an end portion of the retaining springs and applying a slight twisting motion allowing the blades to retract back into the broadhead body into a loaded position.

Owner:RAMCAT LLC

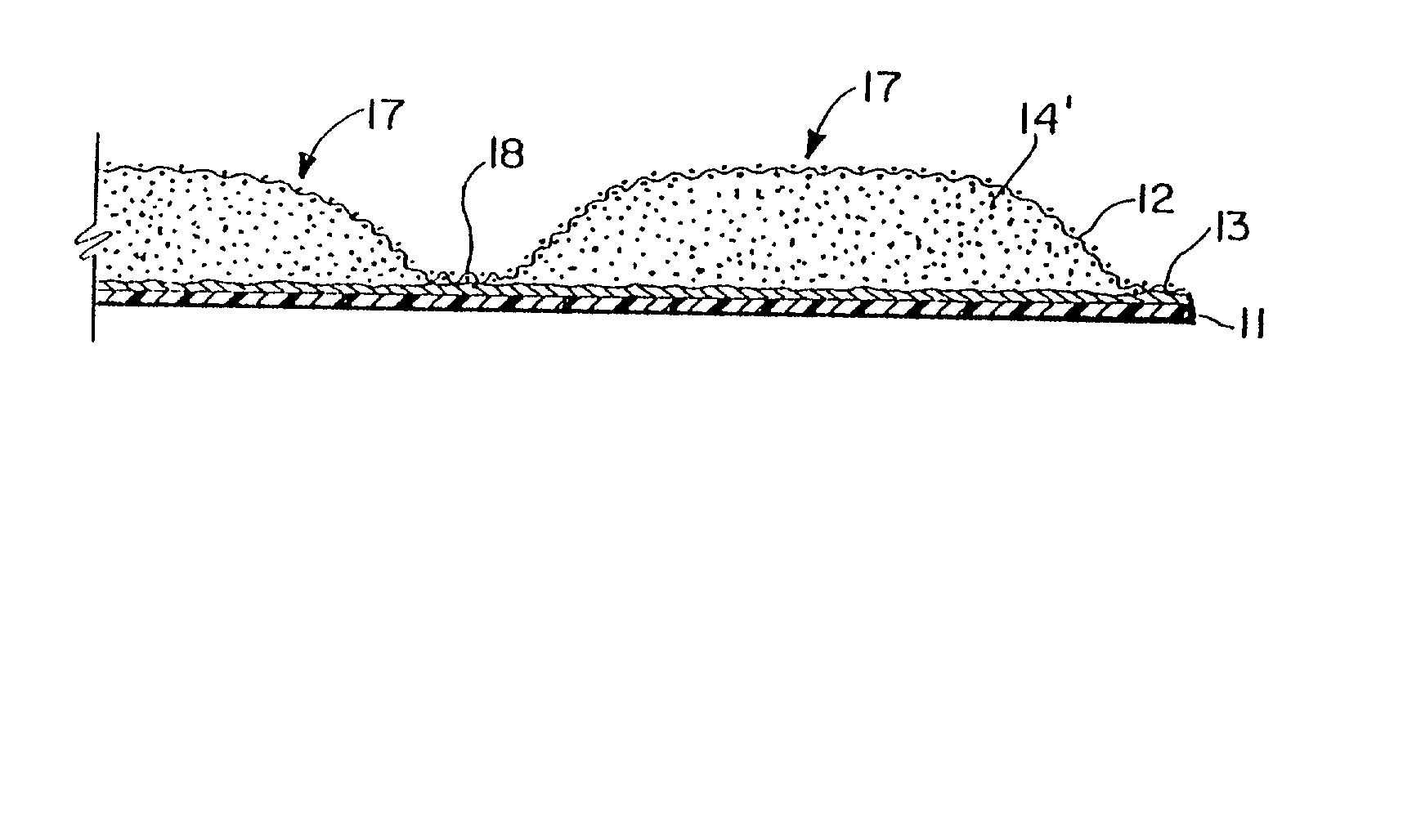

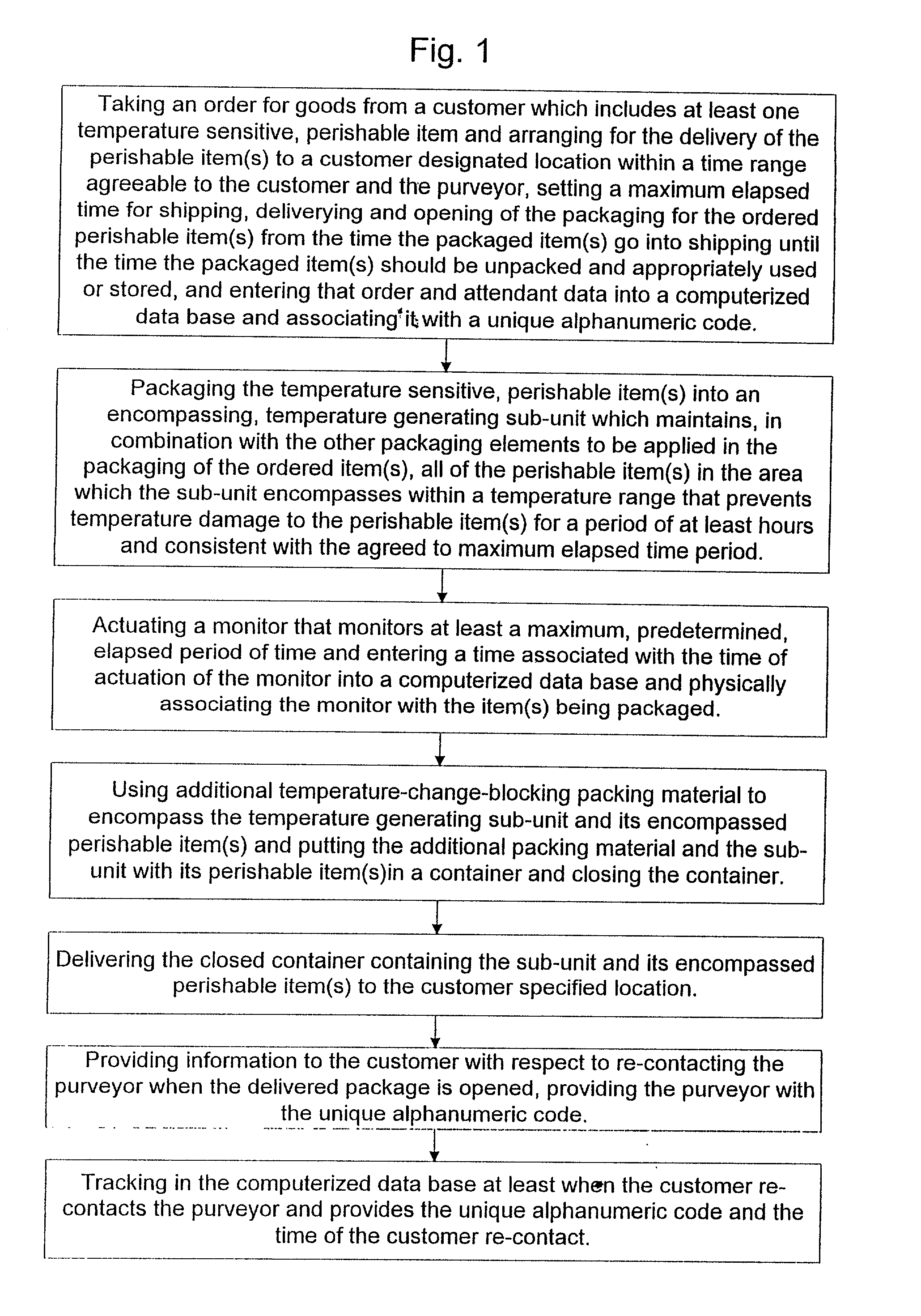

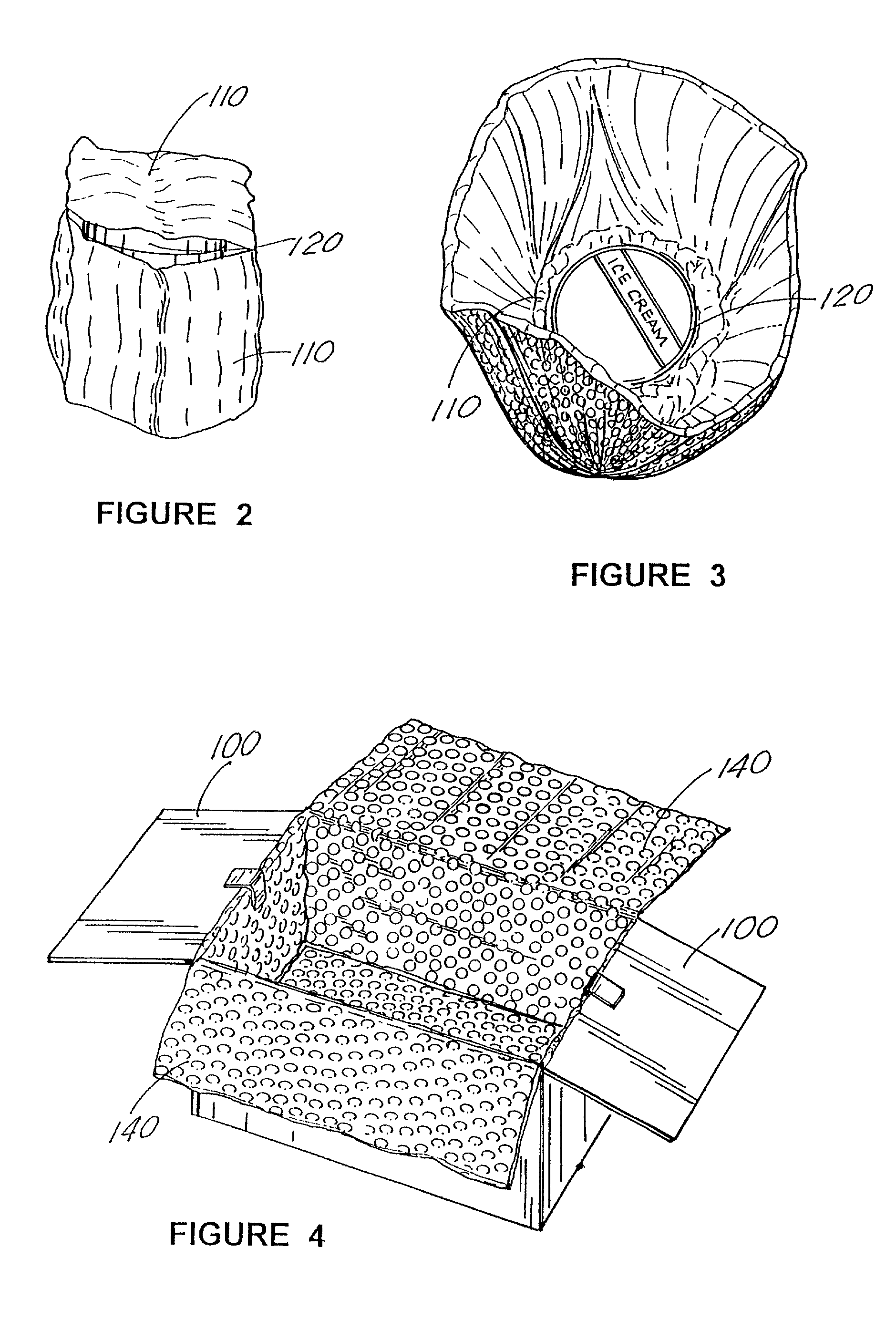

Insulating packaging material and related packaging system

InactiveUS20030087051A1Easy entryTransfer delaySynthetic resin layered productsPackaging foodstuffsCardboardNatural state

Insulating packaging material is wrapped or otherwise positioned around the typically temperature sensitive product, with the packing material including, alternatively, 1 ply (FIG. 22; metallized plastic film), 2 ply (FIGS. 23 & 24) and 3 ply (FIG. 25) material, in which some of the 2 ply & 3 ply embodiments include a layer of bubble wrap material having its bubble side placed or laminated against the flat side of the adjacent ply, which adjacent ply can be, for example, a mettalized plastic film or a foam layer or both layers can be included. With such a bubble side arrangement, multitudinous air pockets are formed between the bubbles of the bubble wrap and the other ply's typically flat interfacing surface. A separate layer of bubble wrap also preferably is placed about the interior of the box with its bubble side placed against the interior flat surfaces of the box, with the bubbles forming air pockets with the flat sides, further enhancing the insulating properties of the packaging for the goods. An exemplary system for delivering perishable groceries (120 / 120'), including a corrugated cardboard or other type box (100); a source of cold (or heat as needed) maintaining the temperature inside the box within a desired temperature range for hours or days, using an all encompassing pouch of packet material (110 / 10), used individually (FIGS. 2 & 3) or collectively (FIGS. 5 & 6), with each packet (17) containing a super-absorbent polymer (14, FIG. 12) which is hydrated (14', FIG. 12A) and then either frozen (e.g., in a freezer) or heated (e.g., in a microwave), without producing moisture as the polymer returns to its natural state; a protective cover (130) protecting the box and its contents from heat radiation (e.g., sunlight).

Owner:THERMAFREEZE PRODS CORP

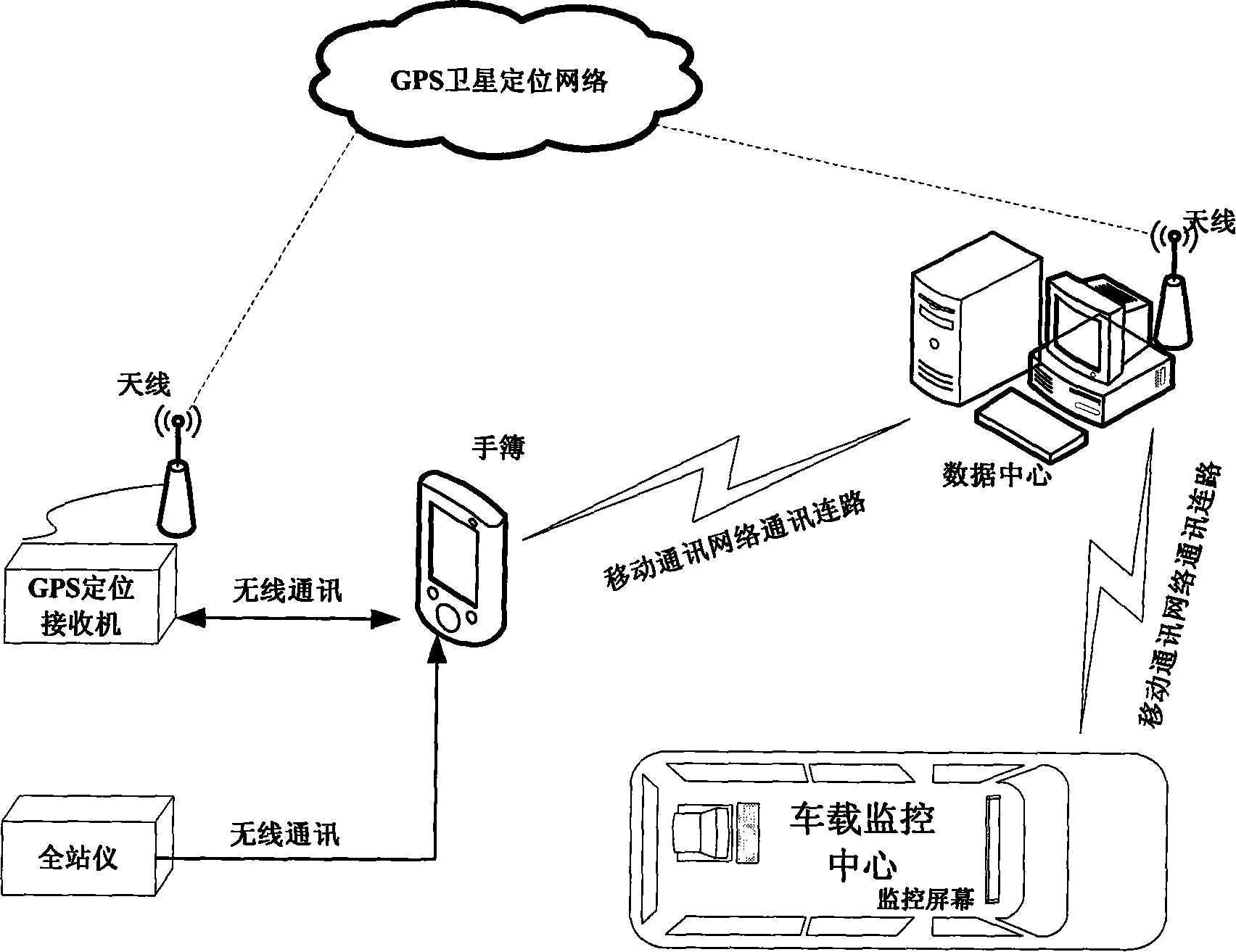

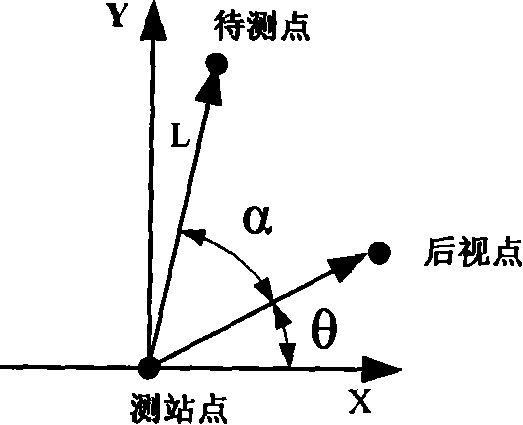

Information acquisition and processing method for field operation equipment executing land patrolling and real time monitoring

InactiveCN101159068AEasy entryImprove efficiencyRegistering/indicating time of eventsNetwork connectionTotal station

The invention combines a field working portable device such as a portable computer as a hardware platform for mobile GIS with satellite positioning technique and total station positioning technique to realize the whole process on illegally applied ground including transgress information collection, site image forming, displaying, editing, storing and refreshing. The portable computer is communicated with the total station via the connection with a wire cable serial-port line or wireless Bluetooth to receive and extract positioning information; meanwhile, the portable computer builds network connection with a monitoring central server via a mobile communication network to realize real-time satellite differential positioning, map data download, and site information upload. With the invention, the visual geometric mapping results is the final results and information inputting is easily achieved, so that the whole data process procedure is paper-free, electronized, real-time, fool-type, and intelligent, thereby greatly increasing field working efficiency, reducing labor intensity and reducing professional requirement for the measurement personnel.

Owner:SOUTHEAST UNIV

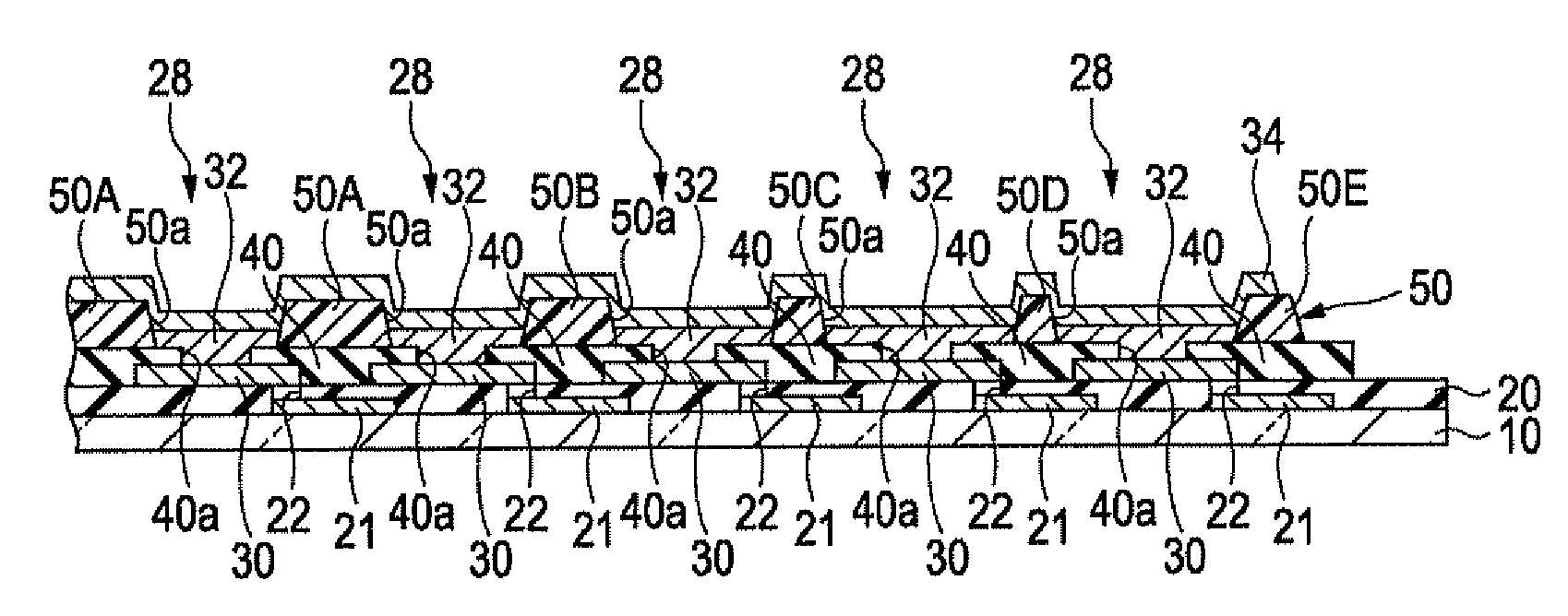

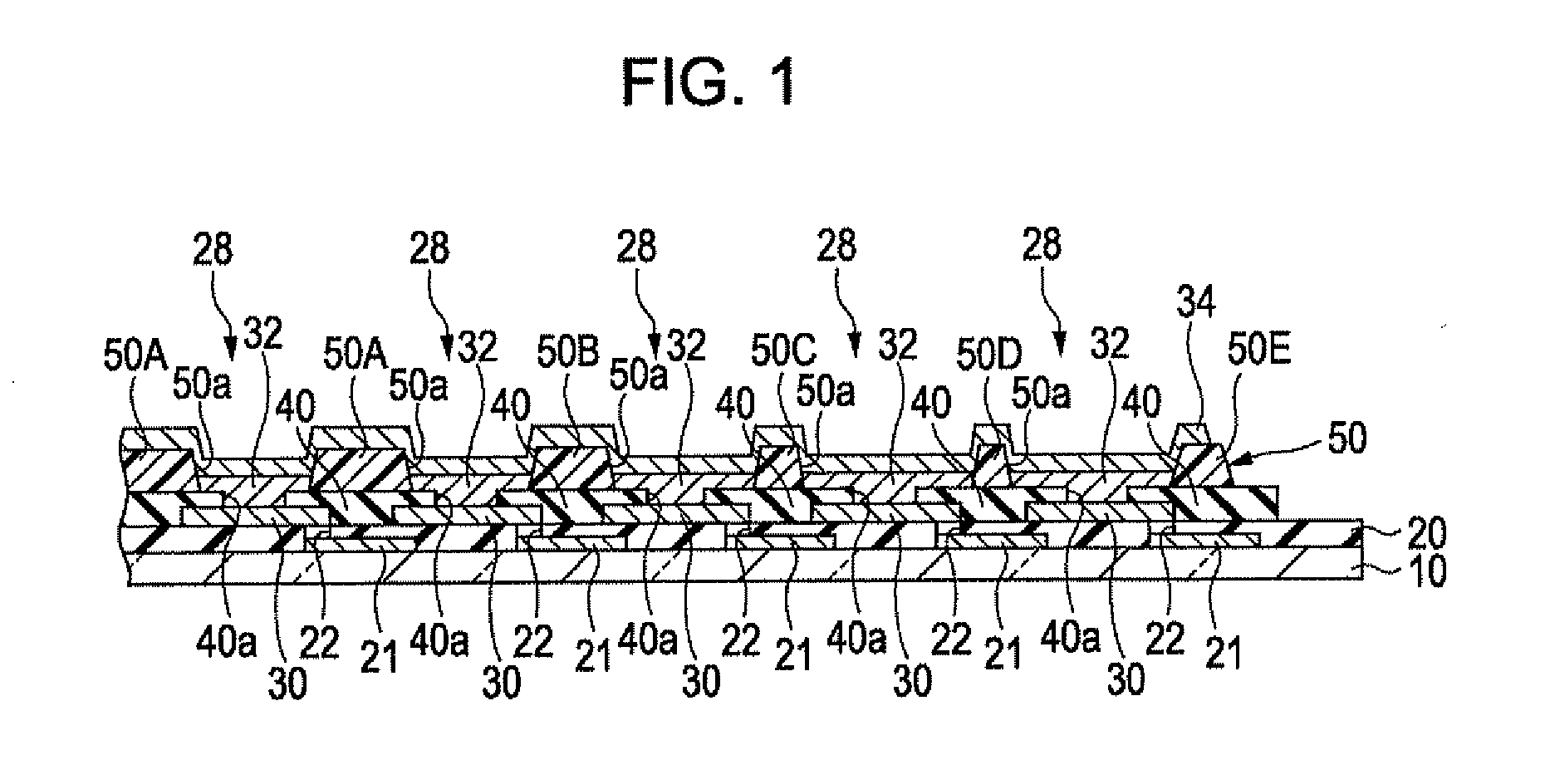

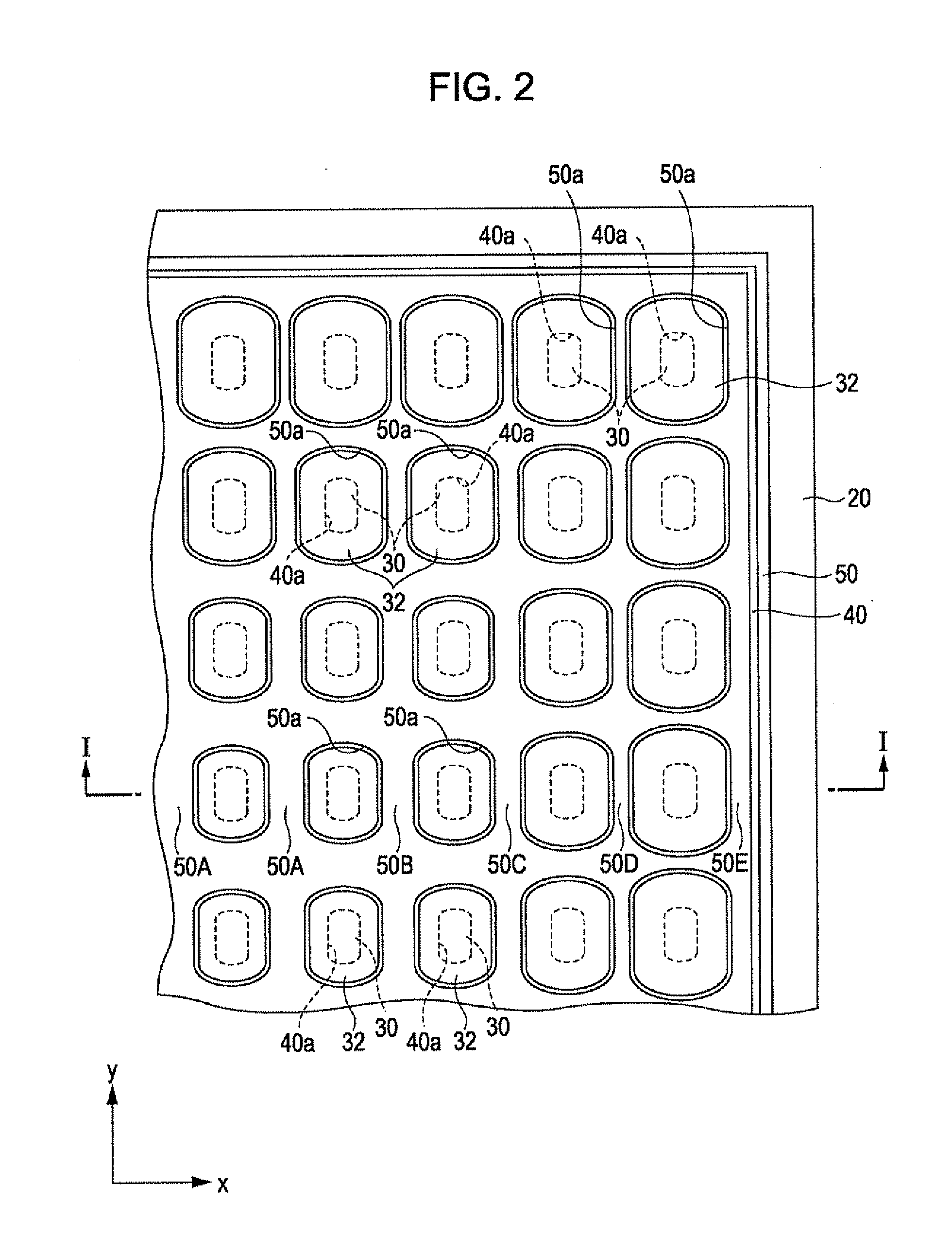

Organic electroluminescent apparatus and elctronic appratus

InactiveUS20090072724A1Ensure efficient flowExtended service lifeDischarge tube luminescnet screensLamp detailsOrganic layerEngineering

An organic electroluminescent apparatus includes a plurality of light-emitting elements each having an organic layer held between a pixel electrode and a counter electrode, and a partition pattern with which the organic layers of the individual light-emitting elements are defined. The partition pattern has a plurality of openings in which the organic layers are respectively provided, the plurality of openings including first openings provided in a peripheral region of a element area, in which the light-emitting elements are arranged, and second openings provided in a region closer to the center of the element area than the region where the first openings are provided. The first openings have larger planar dimensions than those of the second openings.

Owner:SEIKO EPSON CORP

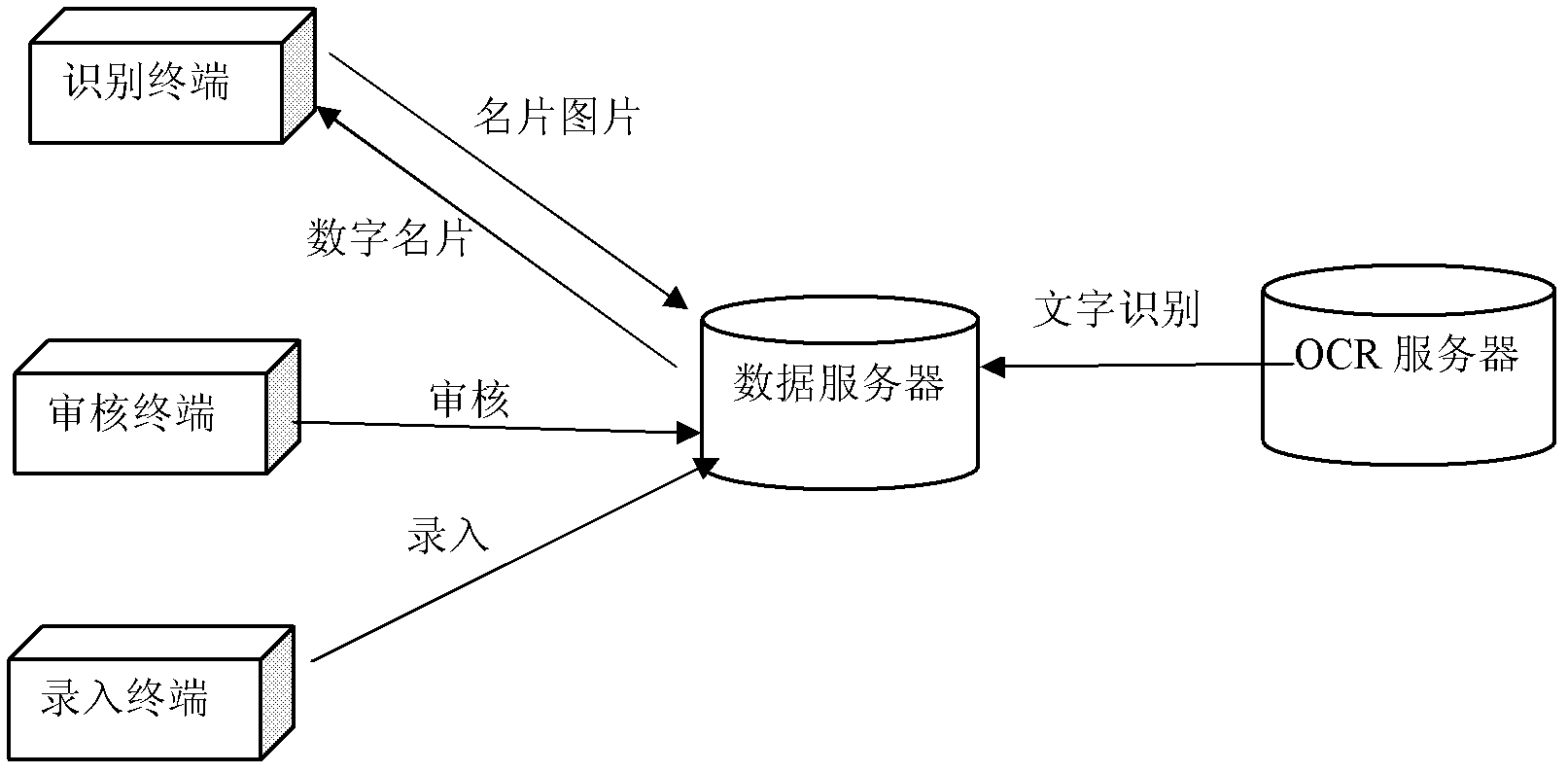

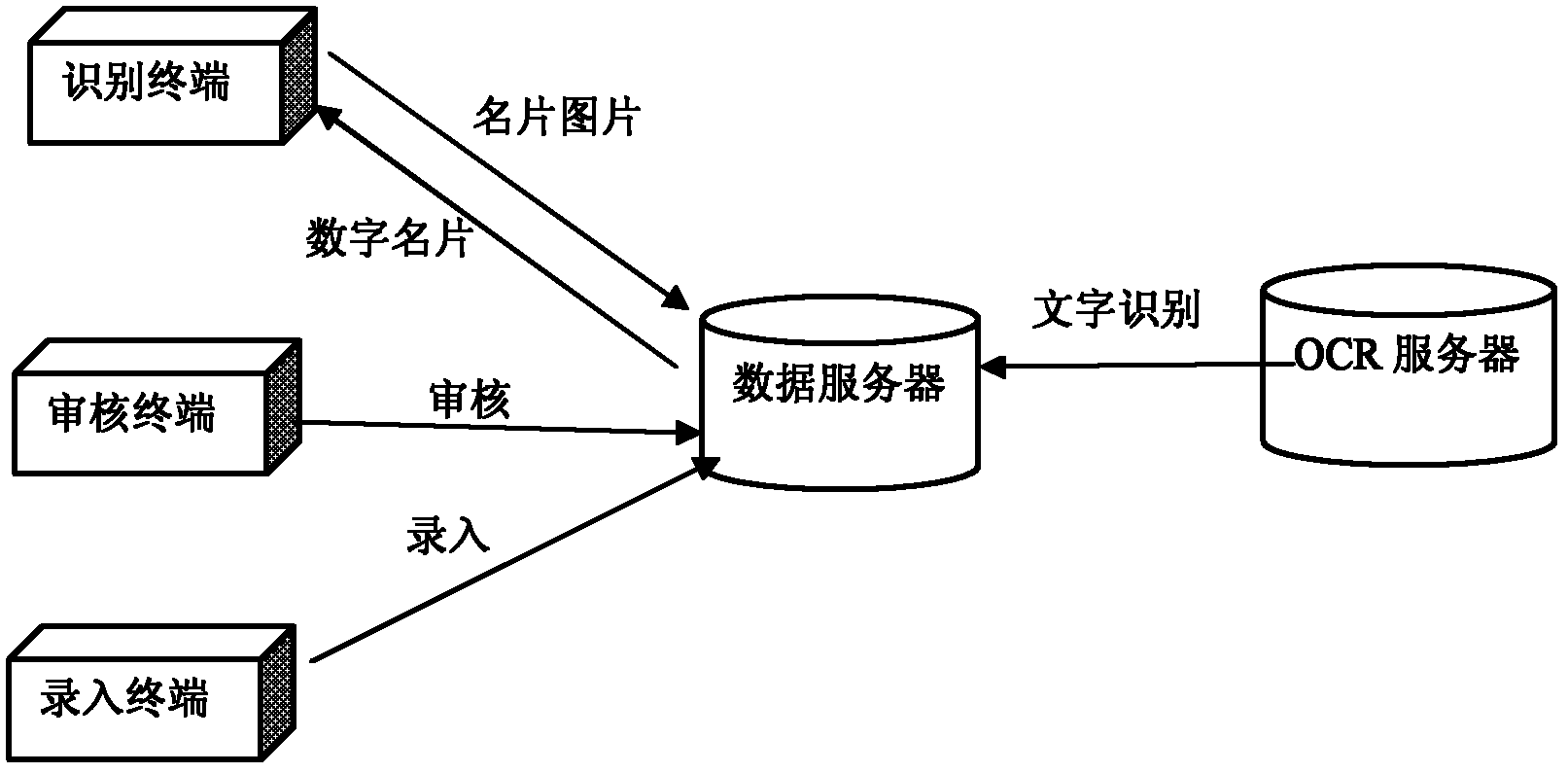

Name card recognition method based on cloud technology

InactiveCN102622592AAchieve accuracyImprove entry efficiencyCharacter and pattern recognitionTransmissionComputer terminalOptical character recognition

The invention discloses a name card recognition method based on a cloud technology, and belongs to the technical field of information. The name card recognition method comprises the steps as follows: 1) collecting a picture of a name card and uploading to a cloud terminal data server by a name card recognition terminal; 2) transferring the picture of the name card to an OCR (Optical Character Recognition) server by a data server, and recreating a digital name card; 3) sending the recognized data to the data server by the recognition server, looking up the matched name card in the passed digital name cards by the data server, and marking the properties different from those of the matched name card in the digital name cards; 4) auditing the digital name card by an audit terminal, and judging if the content of the digital name card is the same as that of the picture of the corresponding name card; if so, marking that the digital name card is passed; if not, sending success information to an input terminal; and if the digital name card cannot be recognized, sending failure information to the recognition terminal; and 5) modifying the recognition information of the digital name card and sending to the data server by the input terminal. According to the name card recognition method, the name card recognition accuracy and efficiency are greatly improved.

Owner:BEIJING YOULU ONLINE TECH DEV

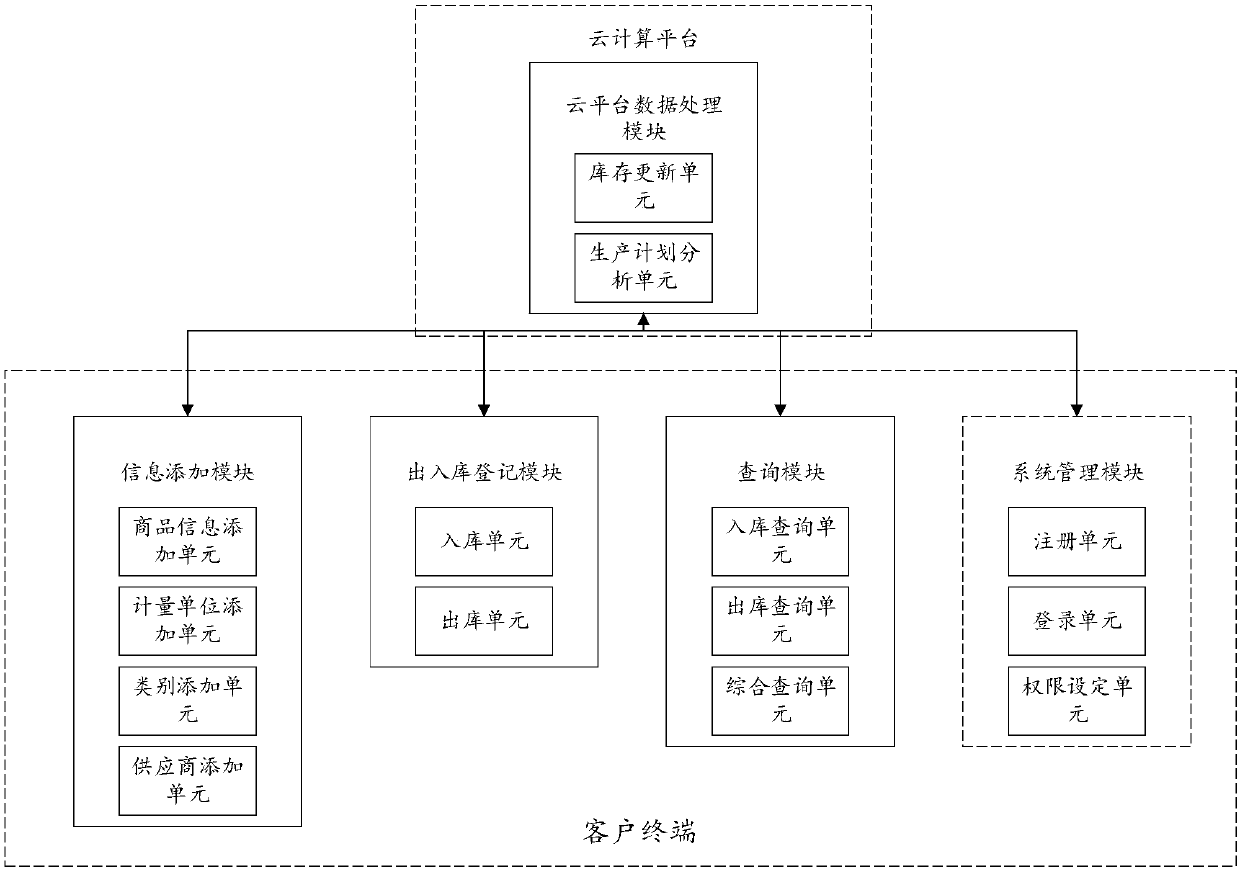

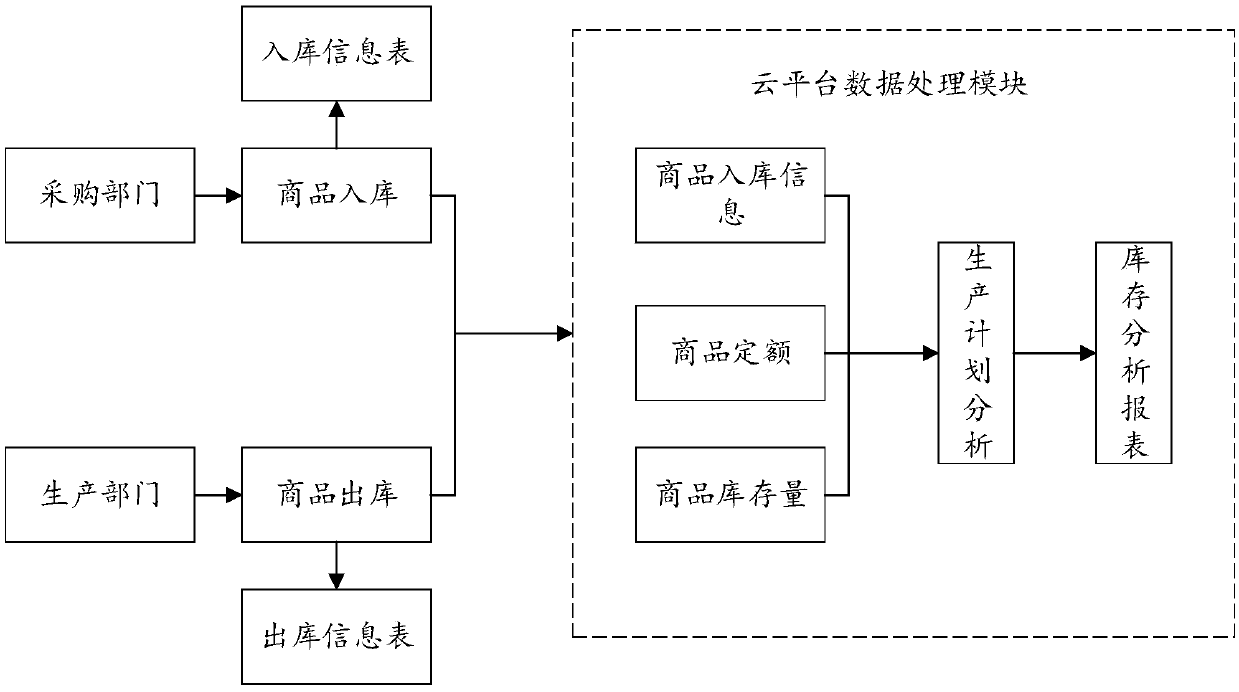

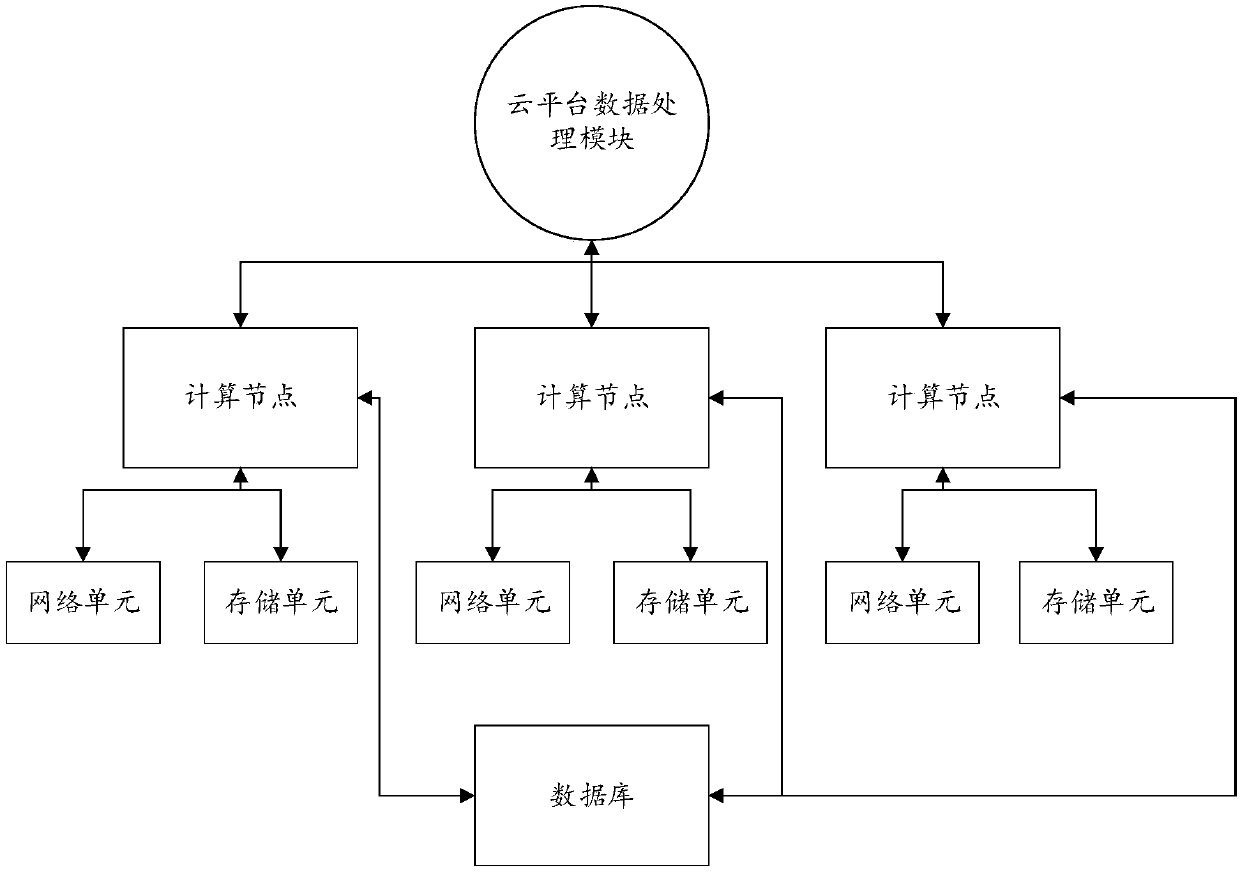

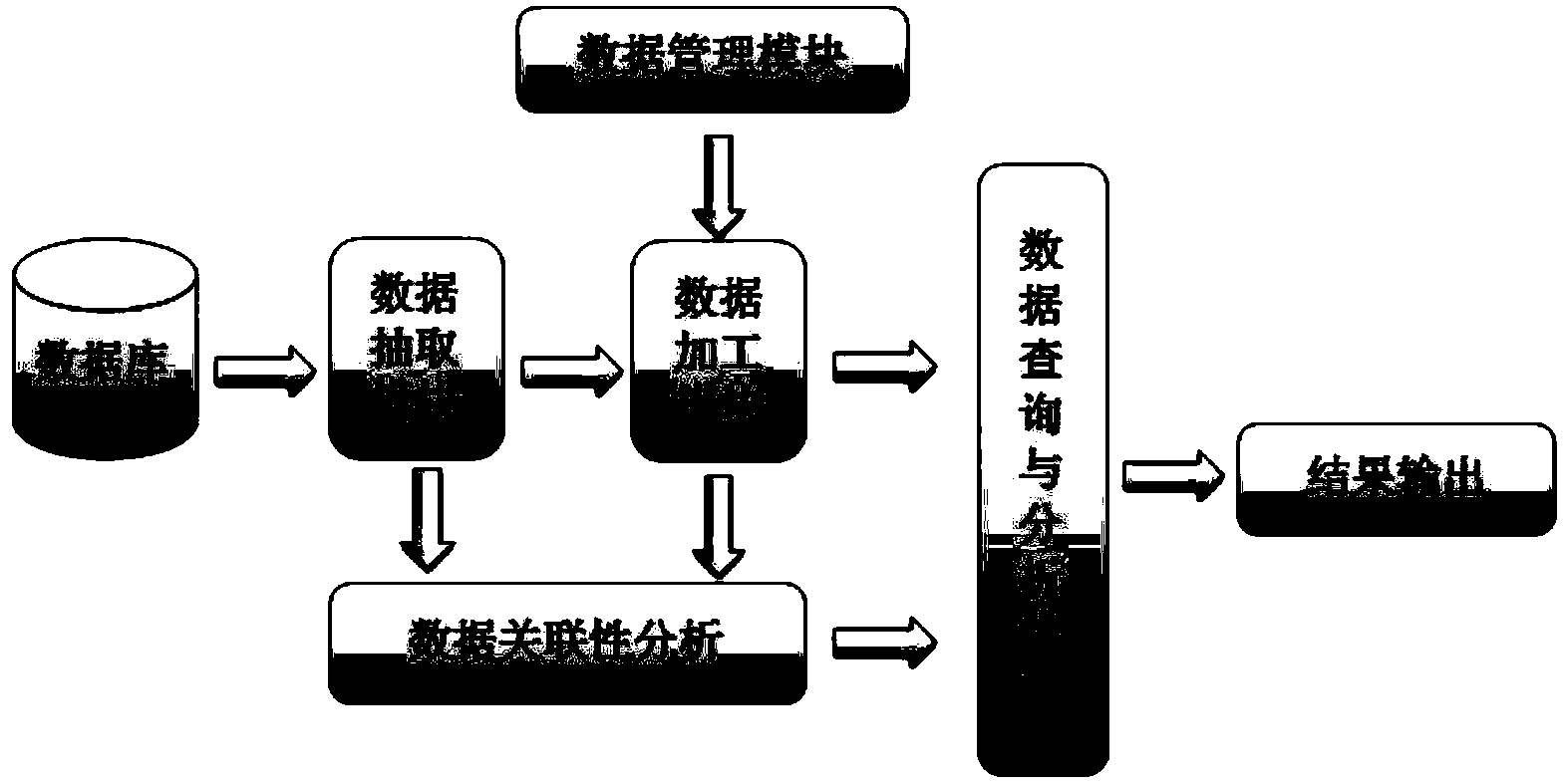

System and method for warehouse management based on cloud computing

The present invention provides a system and a method for warehouse management based on cloud computing. The system comprises a client terminal and a cloud computing platform. The client terminal comprises an information adding module, an in-and-out warehouse registration module and a query module. The cloud computing platform comprises a cloud platform data processing module; the information adding module is configured to add related field information of commodities; the in-and-out warehouse registration module is configured to register the in-and-out warehouse information of the commodities and generate an in-warehouse information table and an out-warehouse information table; the query module is configured to inquire about inventory commodity information; and the cloud platform data processing module is configured to update the inventory commodities in real time and analyze a production plan. The cloud computing platform is employed to perform data sharing for warehouse management toensure real-time sharing of data information between departments, avoid problems that an inventory is redundant or is low caused by delayed data update, ensure normal operation of enterprises and reduce cost of inventory management.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Standards-based personalized learning assessments for school and home

InactiveUS20140024008A1Improve abilitiesEasy entryElectrical appliancesMechanical appliancesPersonalizationPersonalized learning

Assessment devices, and teaching methods involving the use of the assessment devices, are disclosed. The assessment devices include iterative homework, quizzes, and / or tests, each of which allows for individual students to answer an initial question, and, based on the answer to that question, the next question will be harder or easier. The assessment devices can be administered to the students in print form, or electronically, such as on a computer or a personal digital assistant. Once the data is collated, students can be screened based on their ability to grasp all or a portion of the questions in a given test, and separated into groups based on their understanding of the subject matter. Teachers can then individually teach the different groups of students, ideally using lesson plans designed to work in tandem with the assessment devices, based on the students' grasp of the material.

Owner:SATHY KUMAR R

System for submitting performance data to a feedback community determinative of an outcome

InactiveUS20080050713A1Inexpensive competition entryImprove controlElectrical appliancesMechanical appliancesRecording durationPayment

Uses a telecommunications device / computer as an open microphone for collecting media, for example audio, video or text performances that are then integrated into an online community for feedback / judging. The media may include singing, instrumental music, rhythmic music, videos, writings. The performances may also be made available as ring tones. Allows for a server to accept a call / IP connection from an artist, accept payment for a number of recording minutes, provide a genre list (e.g., singing, band, DJ, beat makers), accept selection of a genre and record a performance. Furthermore, the server may also be configured to play, transfer or email a performance, for example as directed from a website or telecommunications device. The media may be judged and / or ranked by members of the community. Recording time may be monitored and a charge levied for submission of the performance. Server may play, download or email the performance.

Owner:SCORPCAST

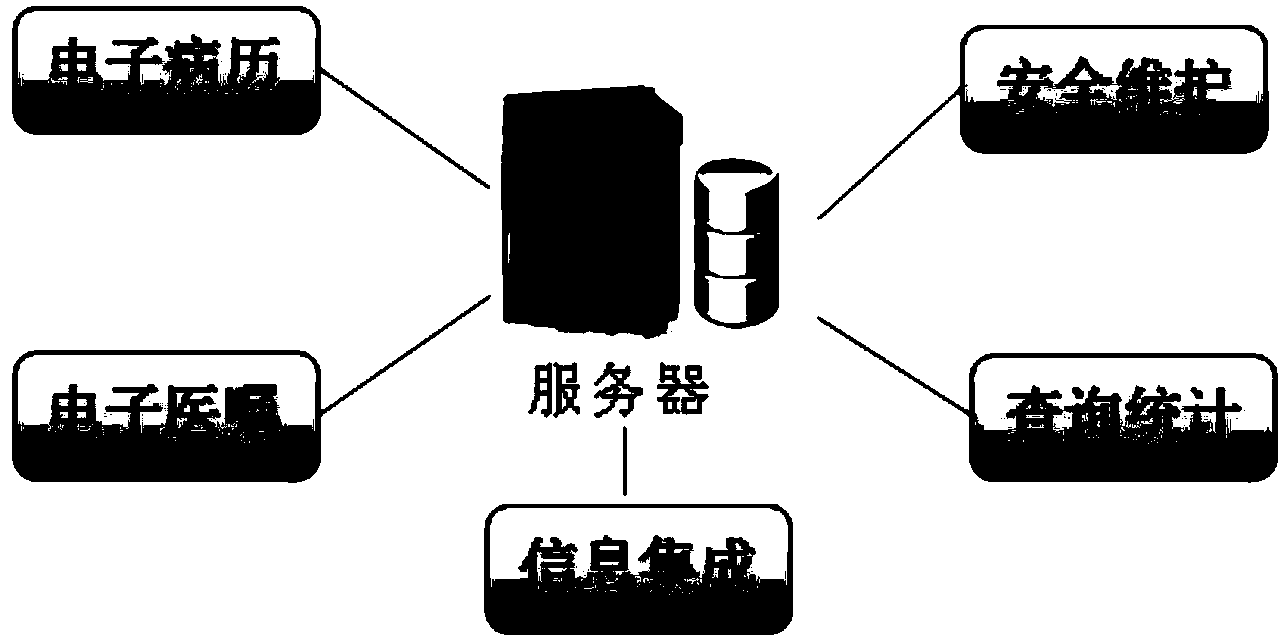

Emergency treatment electronic medical record system and information processing method thereof

InactiveCN103617343AQuick buildQuick releaseSpecial data processing applicationsInformation processingMedical record

The invention discloses an emergency treatment electronic medical record system and an information processing method thereof. The emergency treatment electronic medical record system comprises a server, an electronic medical record module, an electronic medical advice module, a safety maintenance module, an information integrating module and an inquiry counting module. By building, saving and calling templates, an electronic medical record can be built fast, electronic medical advices can be given fast, an inspection sheet, an check list and a prescription list can be prescribed, the characteristics of emergency treatment is adapted to, precious time can be saved for emergency rescuing, medical record input speed can be increased evidently, and prescriptions can be generated automatically according to the medical advices.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

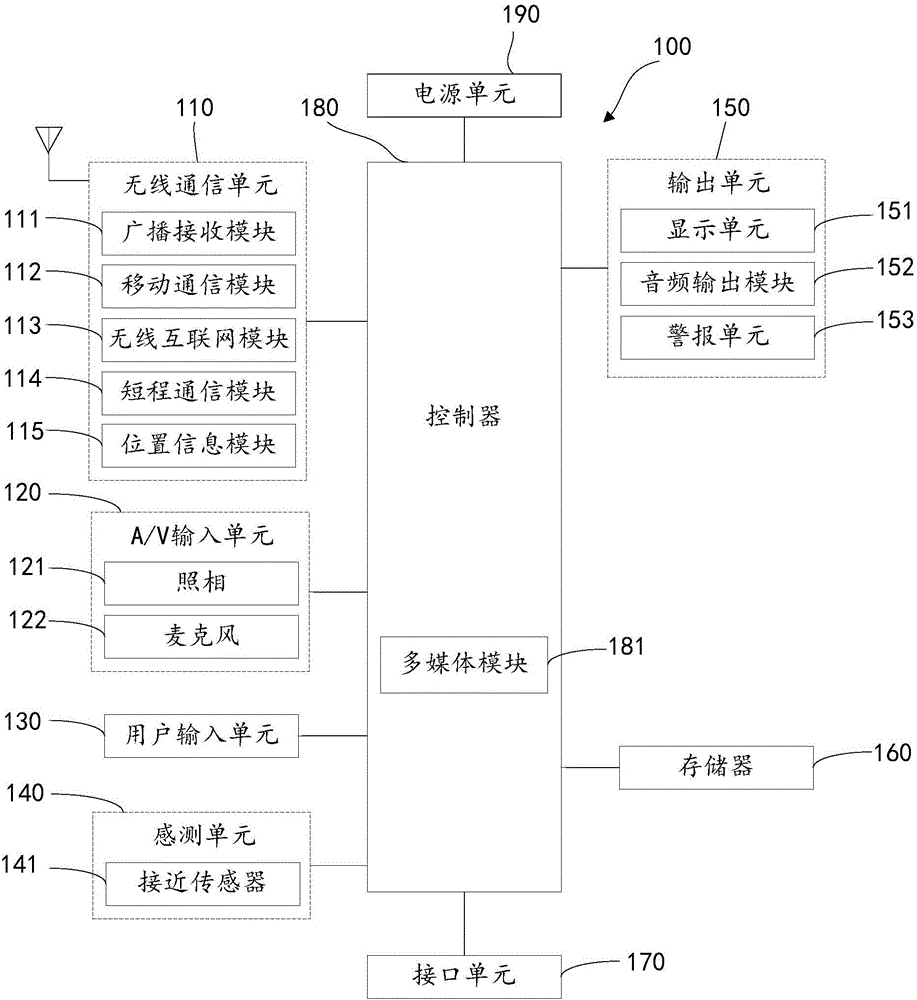

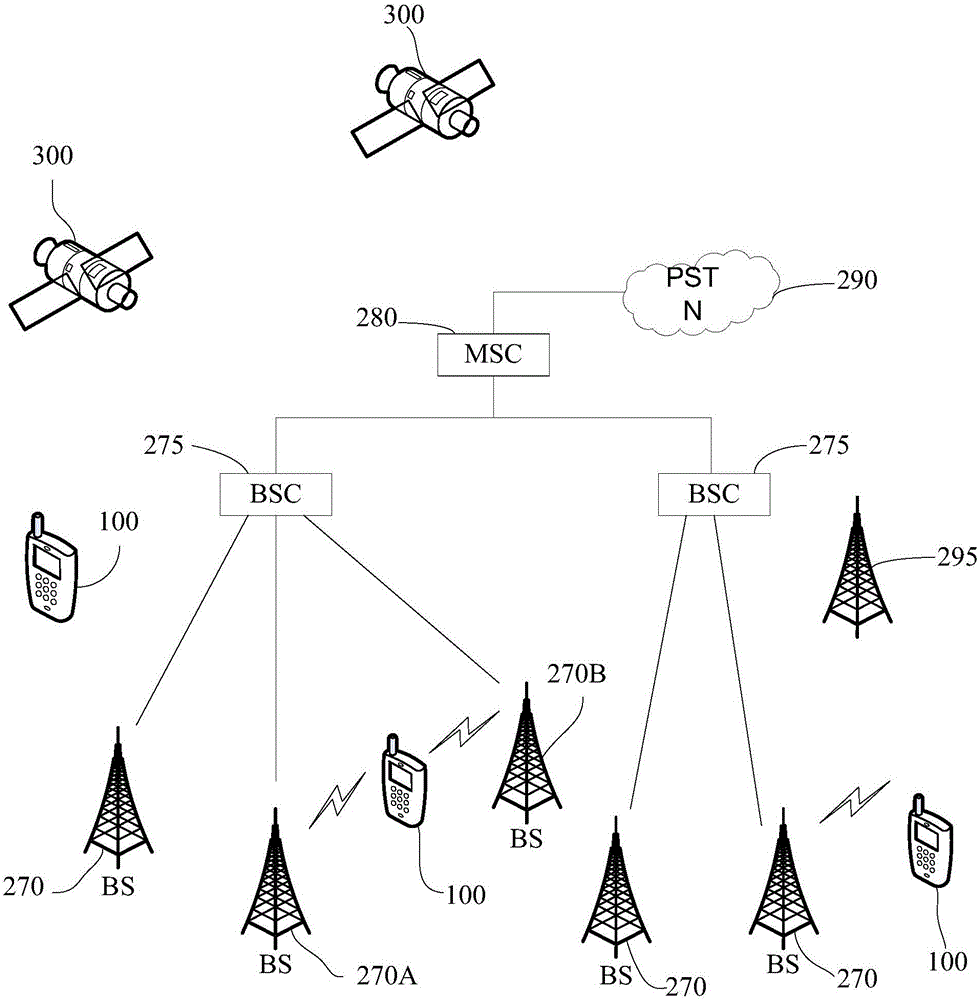

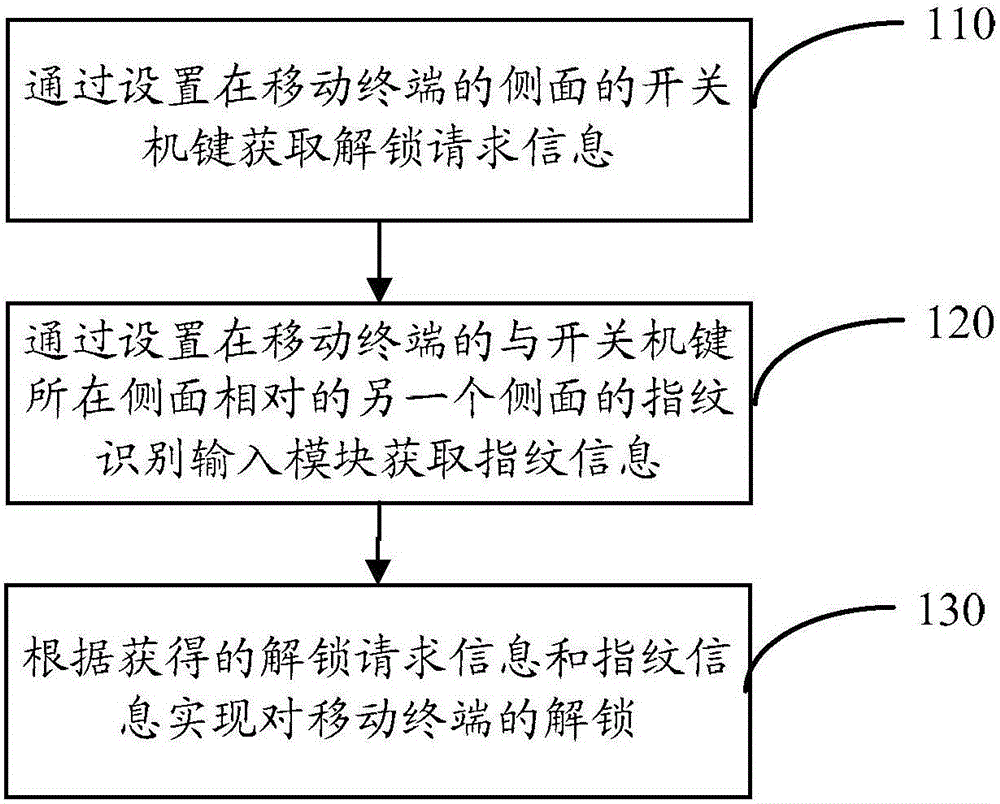

Mobile terminal unlocking method and device, and mobile terminal

ActiveCN104994222AReduce difficultyReduce manufacturing costSubstation equipmentUser needsComputer module

The invention provides a mobile terminal unlocking method and device, and a mobile terminal. The mobile terminal is characterized in that the mobile terminal comprises an on-off key, a fingerprint identification input module and a controller, wherein the on-off key is arranged at the side surface of the mobile terminal; the fingerprint identification input module is arranged on the side surface, opposite to the side surface of the on-off key, of the mobile terminal and is used for obtaining fingerprint information; and the controller realizes the operation and control functions of the mobile terminal according to the fingerprint information. According to the invention, when a user needs to unlock a mobile phone, the trigger unlocking operation or the logging of the fingerprint information can be finished at the same time, a rapid and one-hand unlocking operation mode is provided, and the user experience is improved; in addition, by adopting the above scheme, the difficulties of ID design and hardware realization are lowered, a specially customized LCD screen is not needed, and a mobile phone can be produced by using an existing LCD screen, so that the production cost is lowered.

Owner:NUBIA TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com