Detecting method for thermoelectric conversion efficiency of thermoelectric element device

A technology of thermoelectric conversion and testing method, which is applied in the direction of instruments, thermometers, measuring devices, etc., which can solve the problems that the measurement accuracy of thermoelectric conversion efficiency is difficult to guarantee and difficult to measure, so as to improve the measurement accuracy and avoid the effect of side convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

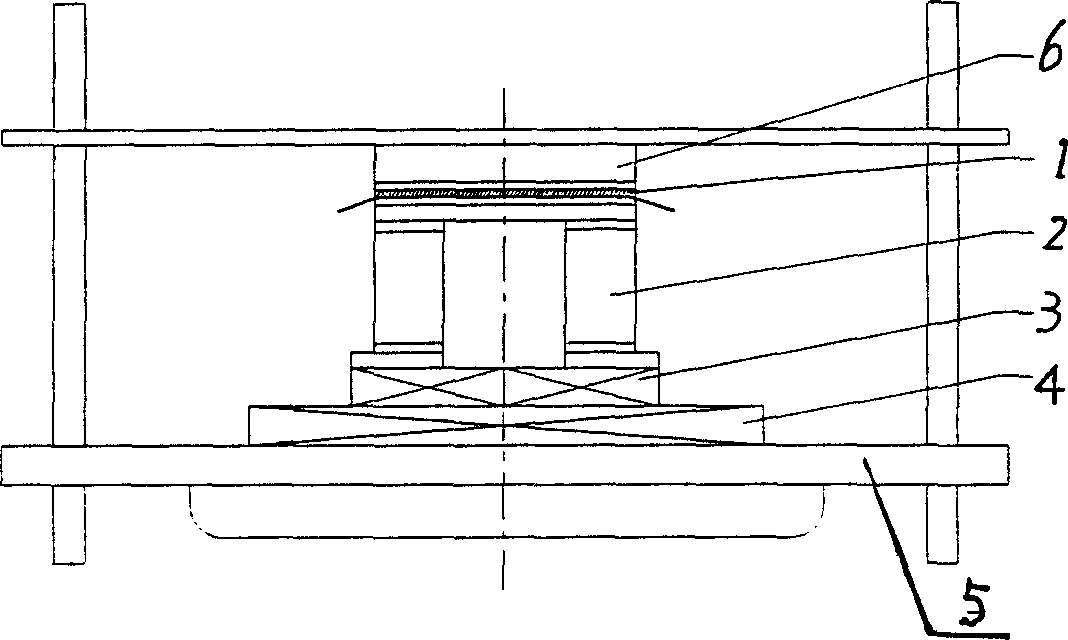

[0023] Clamp the electric heater 1, the thermocouple 2, the thermoelectric power meter 3, and the heat tank 4 sequentially from top to bottom on the test bench 6, and place a layer of heat preservation material 6 on the electric heater 1. Install temperature measuring thermocouples on the hot and cold surfaces of the thermoelectric single couple, respectively install temperature measuring thermocouples on the upper and lower sides of the thermoelectric power meter, install electrical output leads on the thermoelectric single couple, and install electrical output leads on the thermoelectric power meter. The thermocouple and the electrical output leads are respectively connected with the temperature measuring instrument and the voltage measuring instrument.

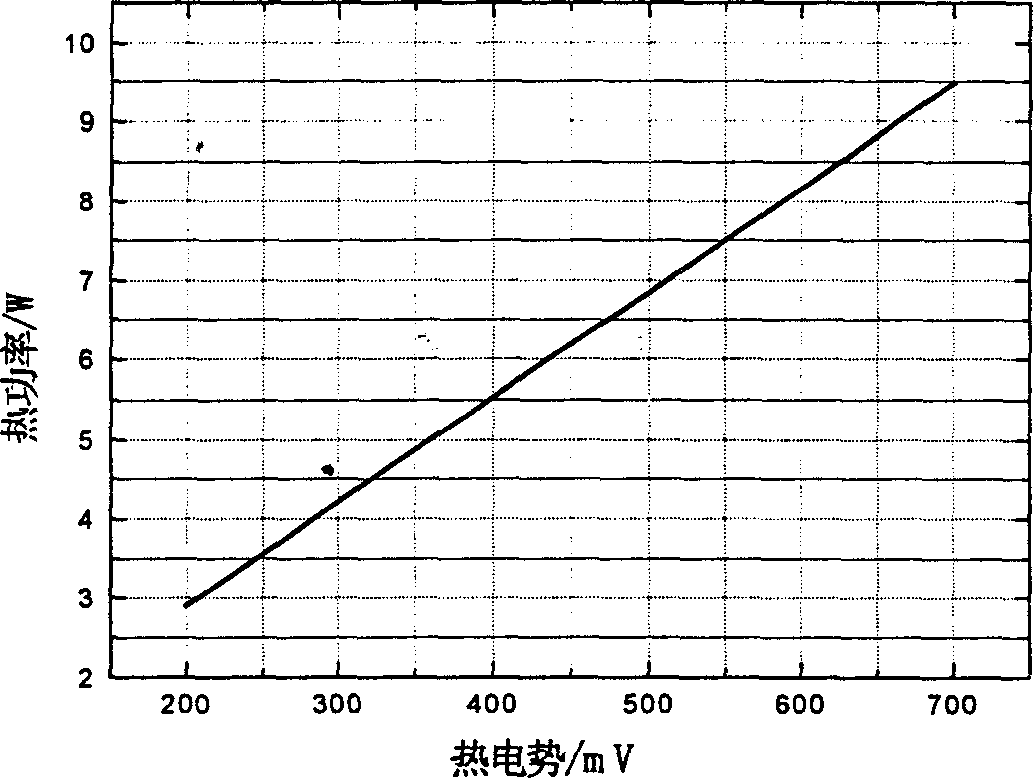

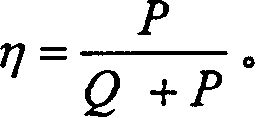

[0024] The thermoelectric coupler is connected to a resistive load. Heat up the electric heater, and adjust the temperature of the hot tank at the same time, so that the temperature of the hot surface and cold surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com