High-temperature vacuum tube

A vacuum tube, high temperature technology, applied in the direction of heat preservation, pipeline protection, pipeline protection through heat insulation, etc., can solve the problems of poor quality insulation tube, high thermal conductivity, high heat loss, etc., to prolong the service life and suppress radiation heat transfer , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The high-temperature heat-insulating pipe of the present invention is a high-temperature vacuum pipe, also known as a vacuum interlayer pipe, and there are three basic modes of heat energy transfer: heat conduction, heat convection and heat radiation. When the temperature is as high as 800 to 1000°C, the heat transfer process is dominated by radiation heat transfer, and the radiation wavelength is in the range of 0.76 to 20 μm in the infrared (also known as heat ray) section. To reduce heat loss at high temperatures, radiative heat transfer must be suppressed. A metal surface with a high finish has a relatively high reflectivity to infrared radiation, which can be used to reduce radiation heat transfer. The vacuum interlayer tube uses this principle.

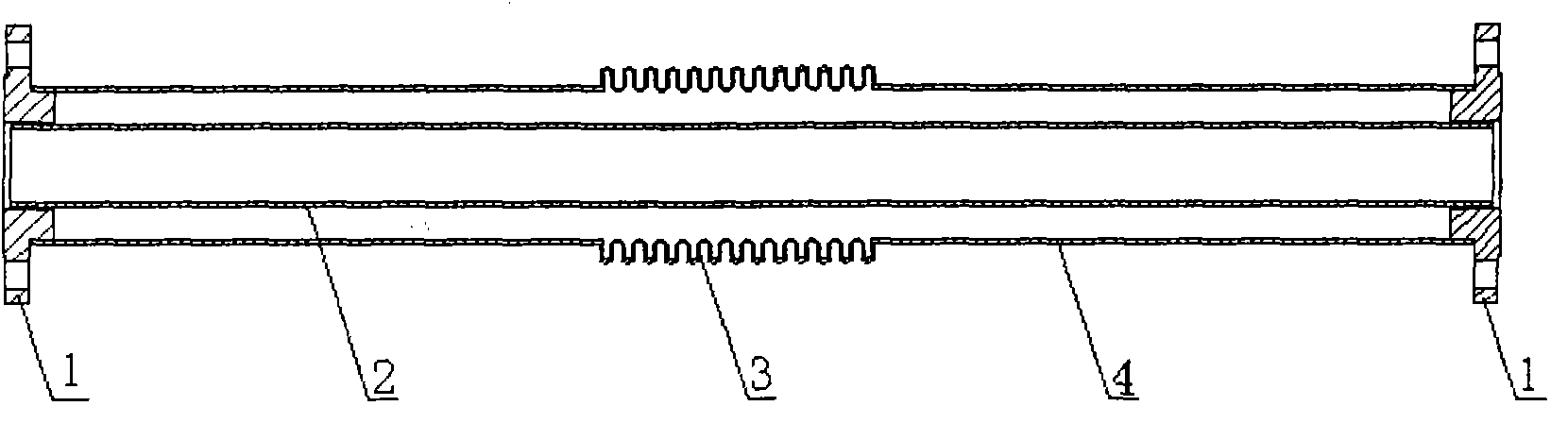

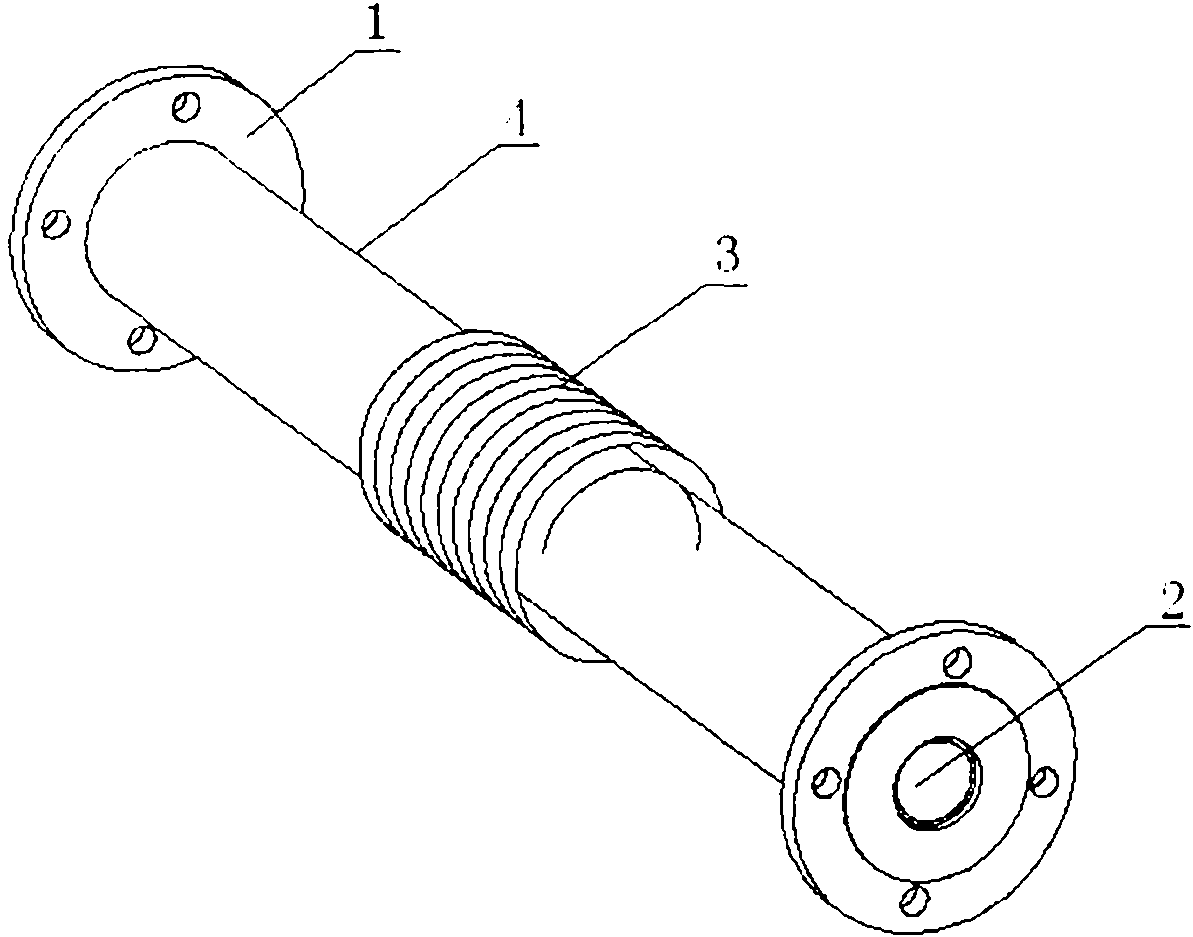

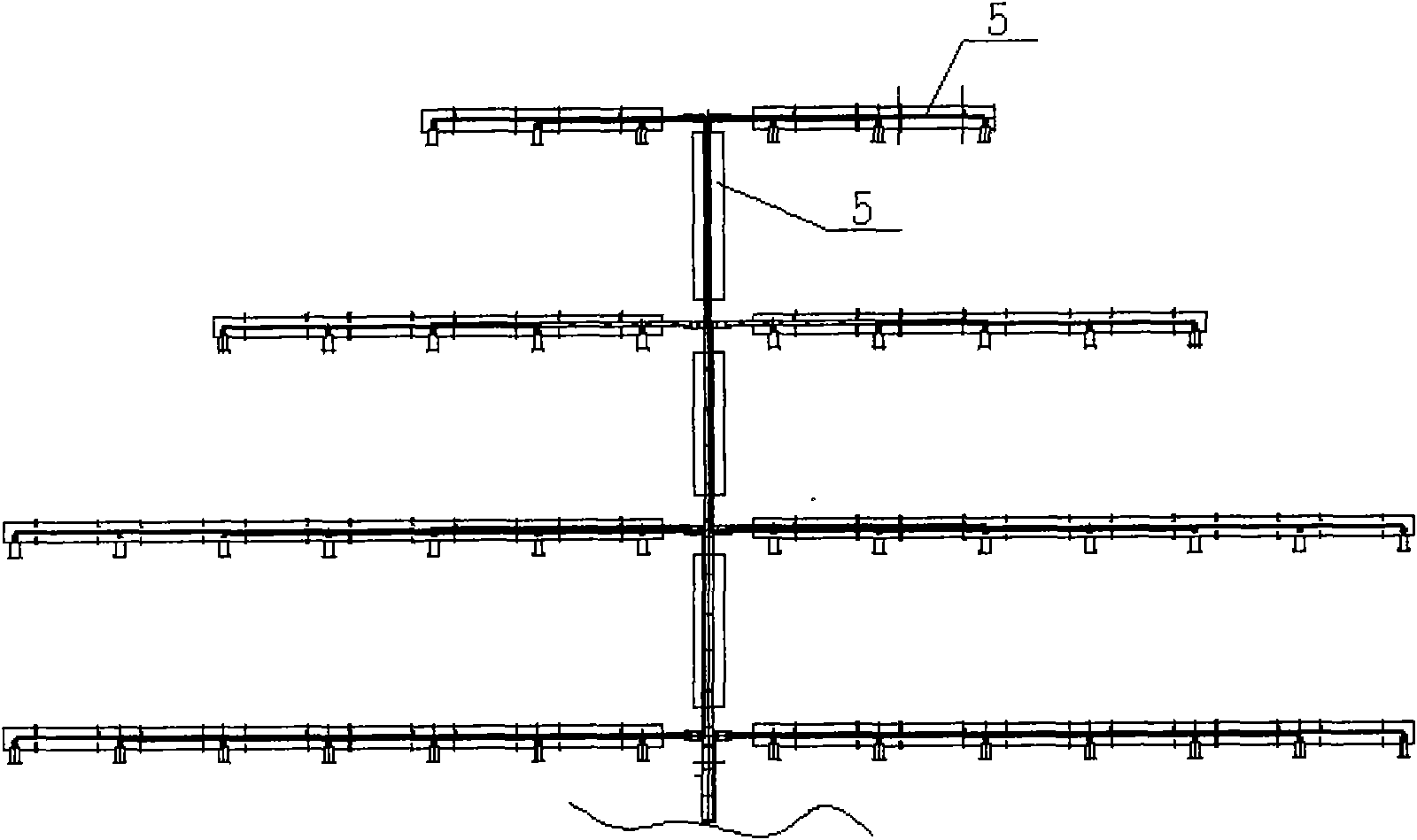

[0026] The high temperature vacuum tube of the present invention is mainly composed of the following parts:

[0027] Flange 1 is used for connection and sealing;

[0028] The inner tube 2 is made of stainless steel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com