Volumetric air heat absorber of multi-cavity surface for solar thermal power generation

A technology of solar thermal power generation and heat absorber, which is applied in the direction of solar thermal power generation, solar heat collectors, and solar heat collector safety, and can solve the effects of internal air working fluid heat transfer efficiency, thermal ablation of porous media materials, absorption Problems such as uneven temperature distribution of the heater can be achieved to improve the thermal response effect, reduce radiation heat loss, and improve the subsequent working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

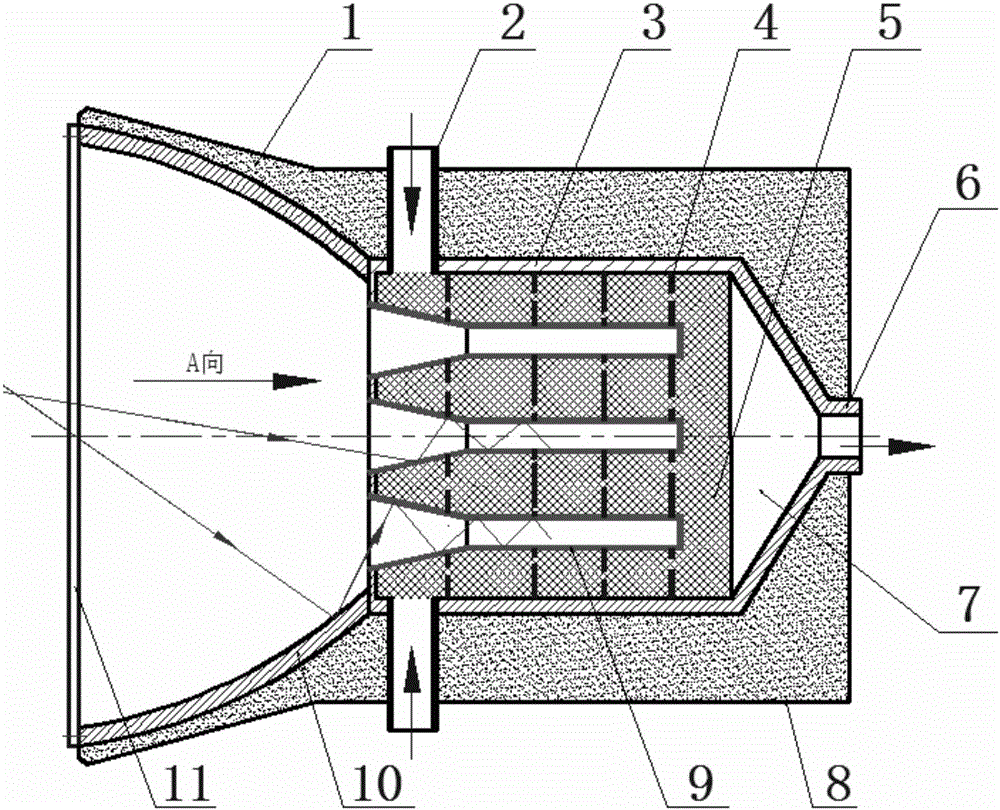

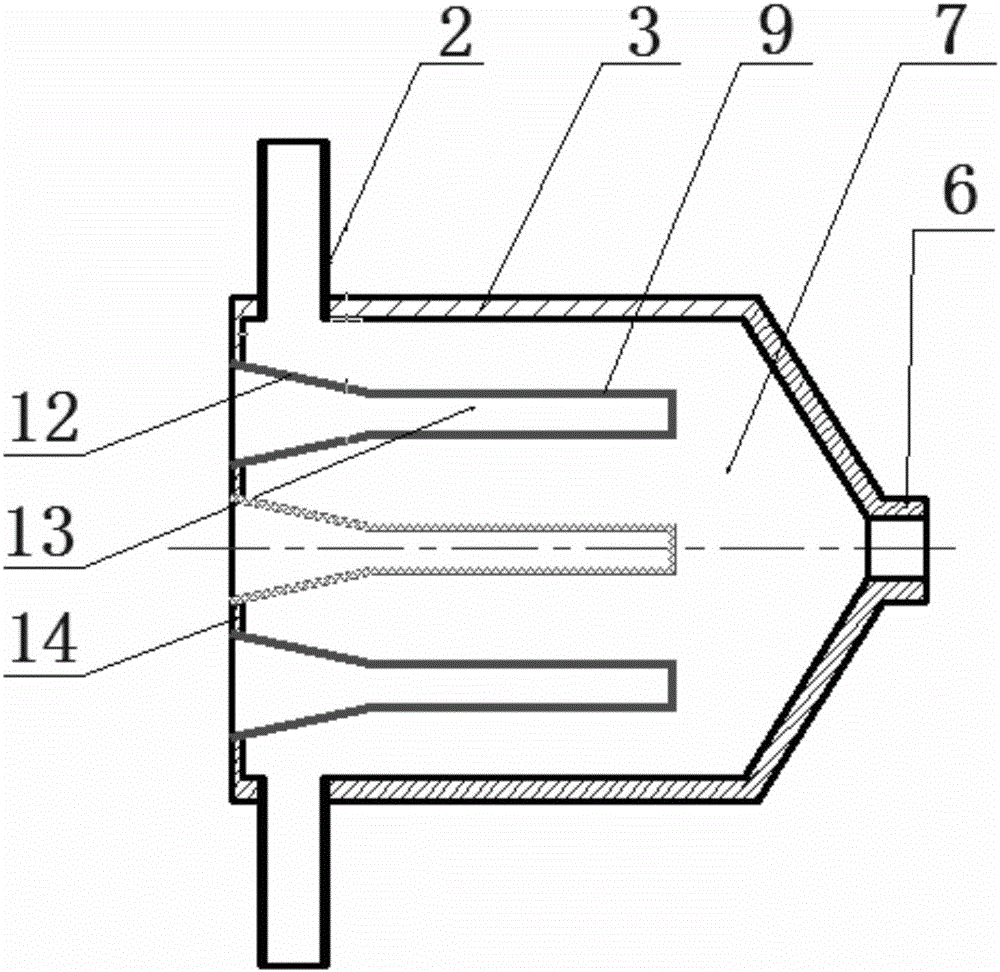

[0030] Such as figure 1 As shown, the present invention includes a secondary concentrator 10 for concentrating solar energy, a heat absorbing carrier 5 , a thermal insulation body 1 and a metal container 3 forming a closed heat absorber cavity 7 . The front end of the metal container 3 is open, and the front end is connected to the rear end of the secondary concentrator 10 . The outer side of the metal container 3 and the secondary concentrator 10 is provided with a thermal insulation body 1 . The metal container 3 is provided with an air intake pipe 2, an air outlet pipe 6, a light-absorbing cavity 9 and a front end sealing plate 14, and the air intake pipe 2 communicates with the inner cavity of the metal container; the light-absorbing cavity 9 is arranged in the inner cavity of the metal container 3, and The secondary concentrator 10 is connected, the light-absorbing cavity 9 is facing the opening direction of sunlight energy projection, and the front end of the light-abso...

Embodiment 2

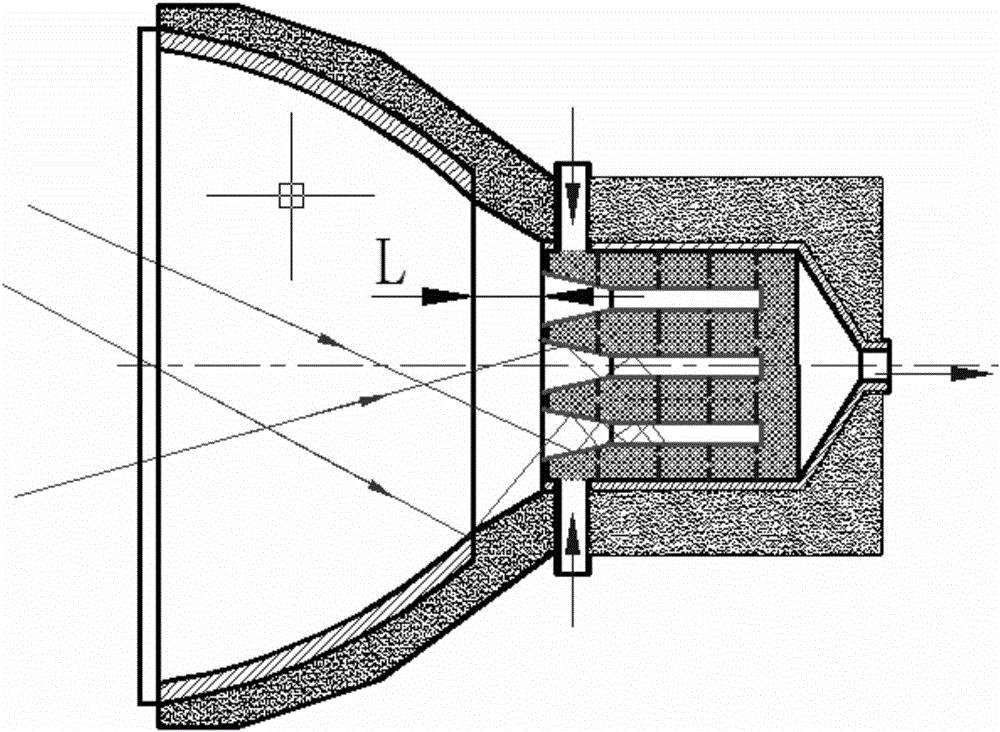

[0036] Such as figure 2 As shown, its structure is similar to that of Embodiment 1, the only difference is that a gap L can be left between the front end of the metal container 3 and the tail of the secondary concentrator 10, which ensures that the energy flow distribution on the front surface of the metal container 3 is even .

Embodiment 3

[0038] Such as Figure 4As shown, its structure is similar to that of Embodiment 1, except that the secondary concentrator 10 for gathering solar energy is replaced by a composite cavity 15 arranged in the metal container 3, and on the basis of the curved surface geometry of the composite cavity 15 Several light-absorbing cavities 9 are arranged uniformly or according to the distribution of sunlight.

[0039] Such as Figure 5-7 As shown, the geometric shape of the light-absorbing cavity 9 can be a cylindrical cavity, an inverted cone cavity and a combined cavity, and the combined cavity is formed by combining an inverted cone structure and a cylindrical cavity.

[0040] The present invention adopts a high-temperature-resistant metal container 3 to form a closed volume, so that the internal air working medium can work under relatively high pressure and high temperature conditions, effectively improving the subsequent working ability of the working medium; A number of light-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com