Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Improve thermal responsiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

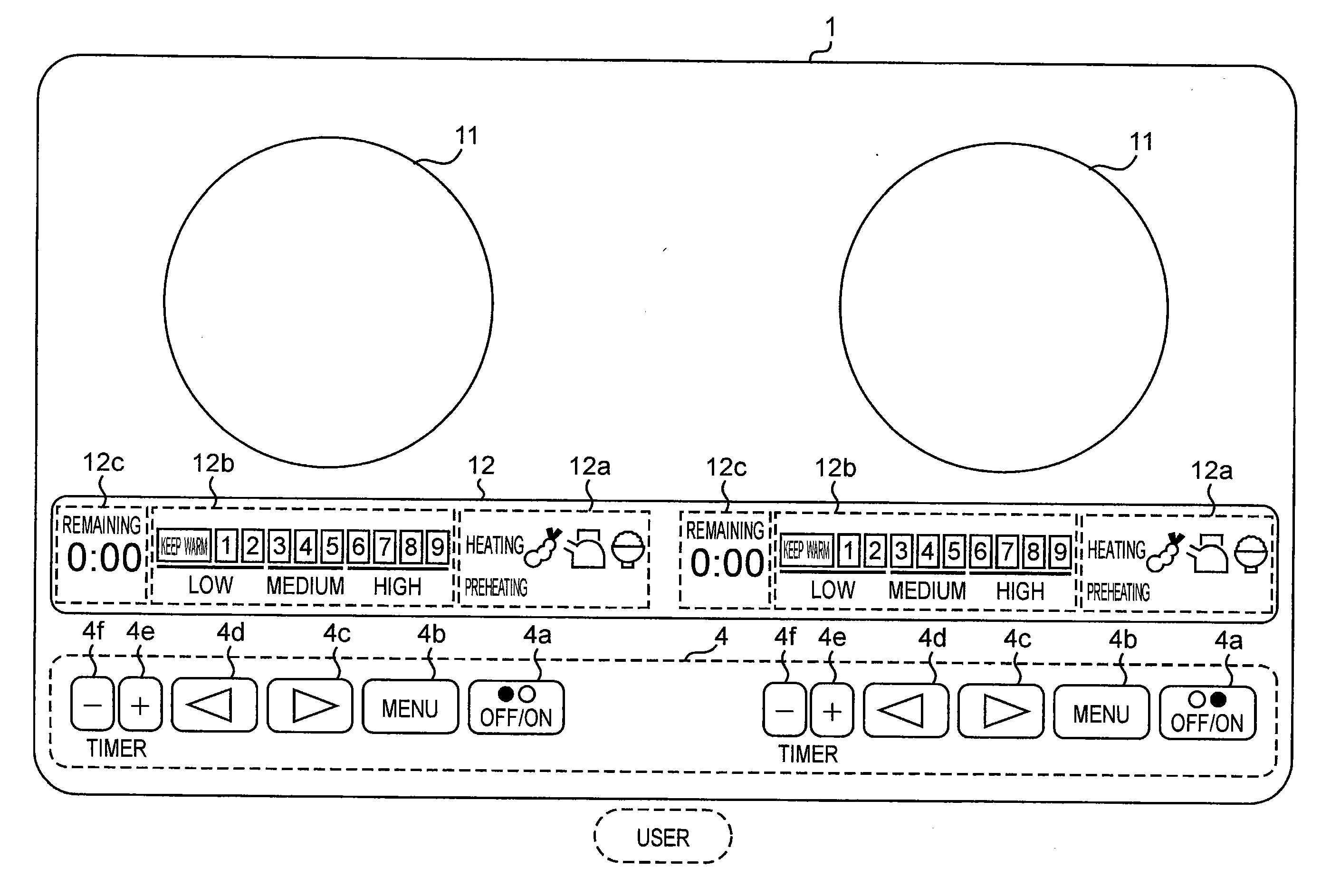

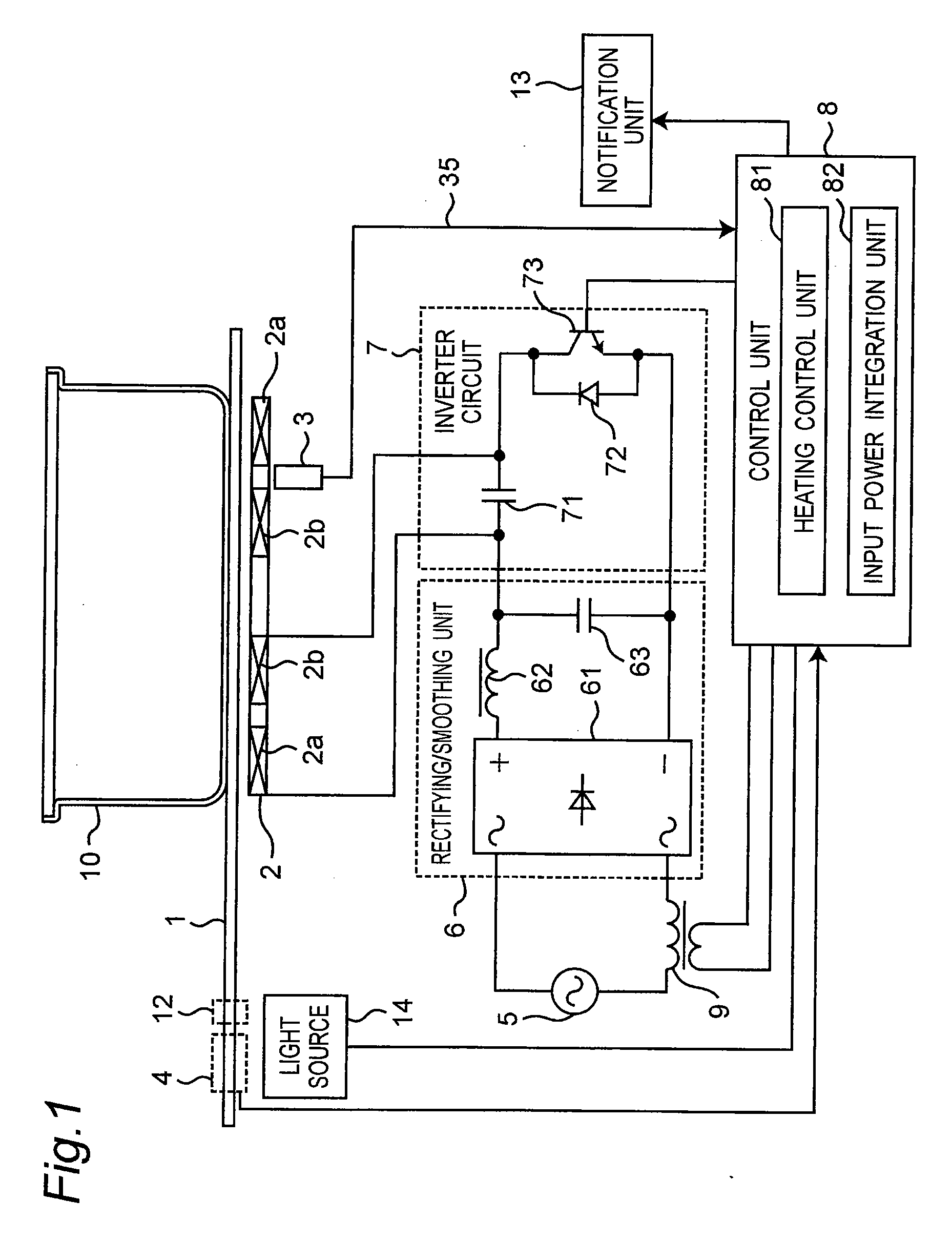

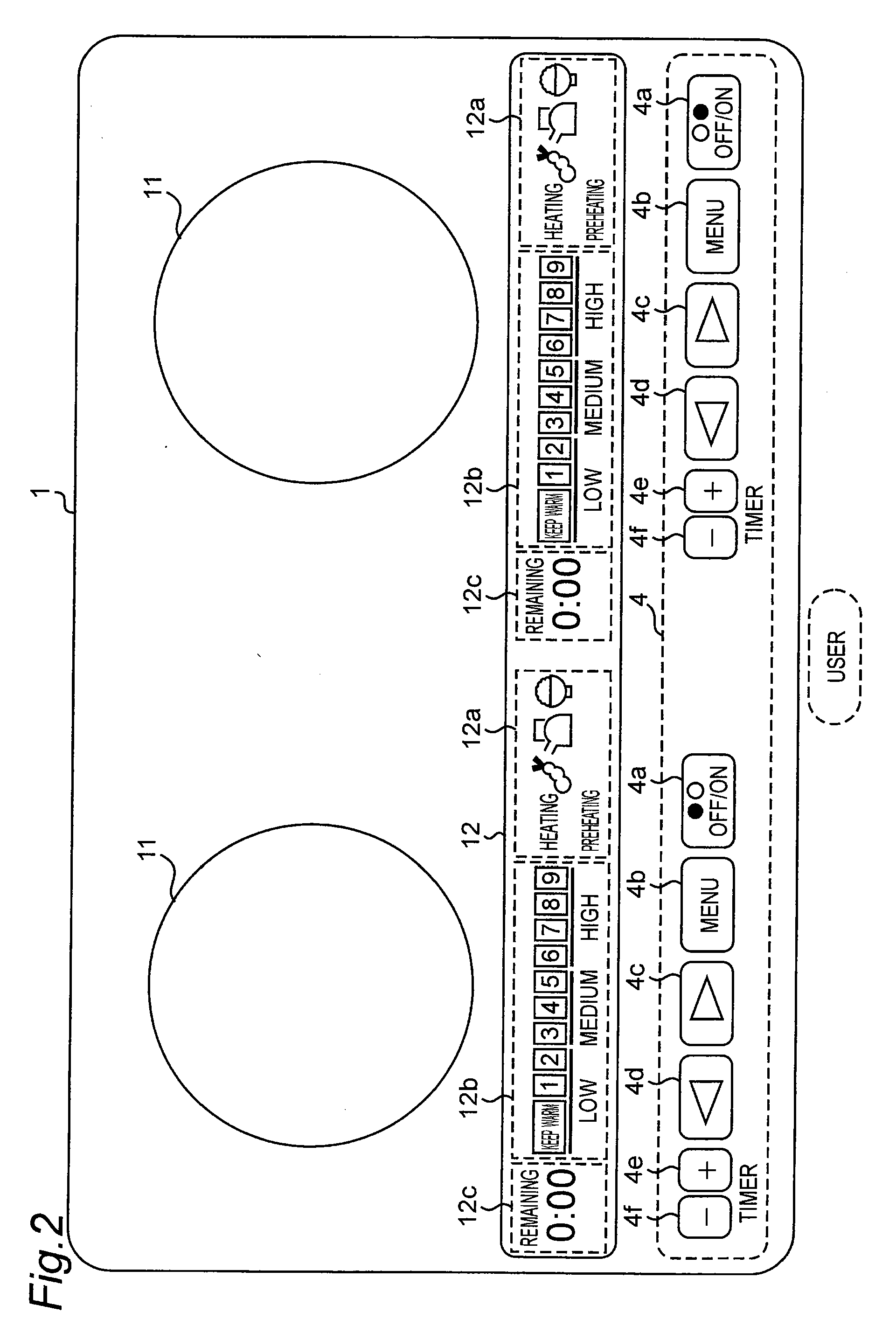

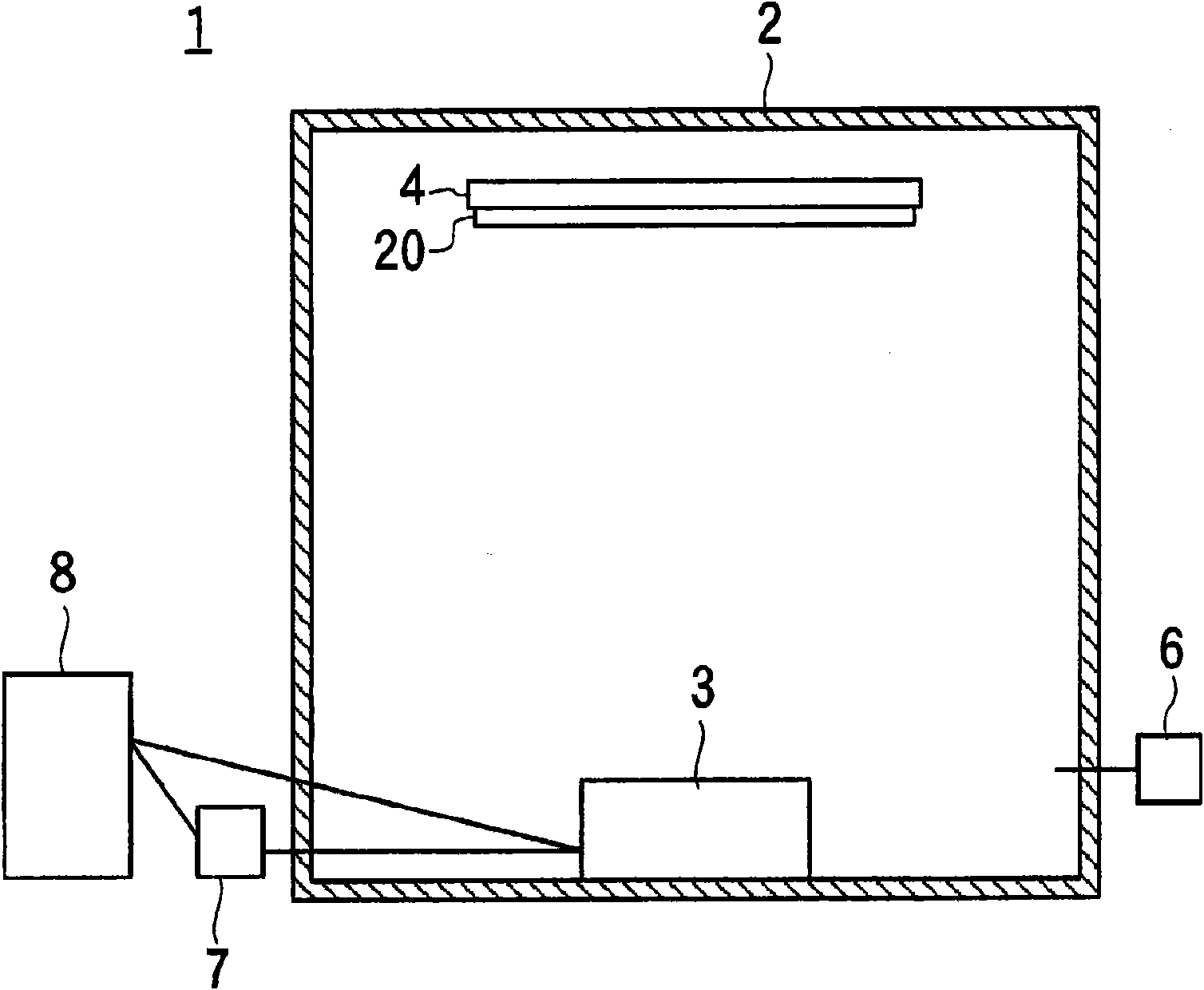

Induction heat cooking device

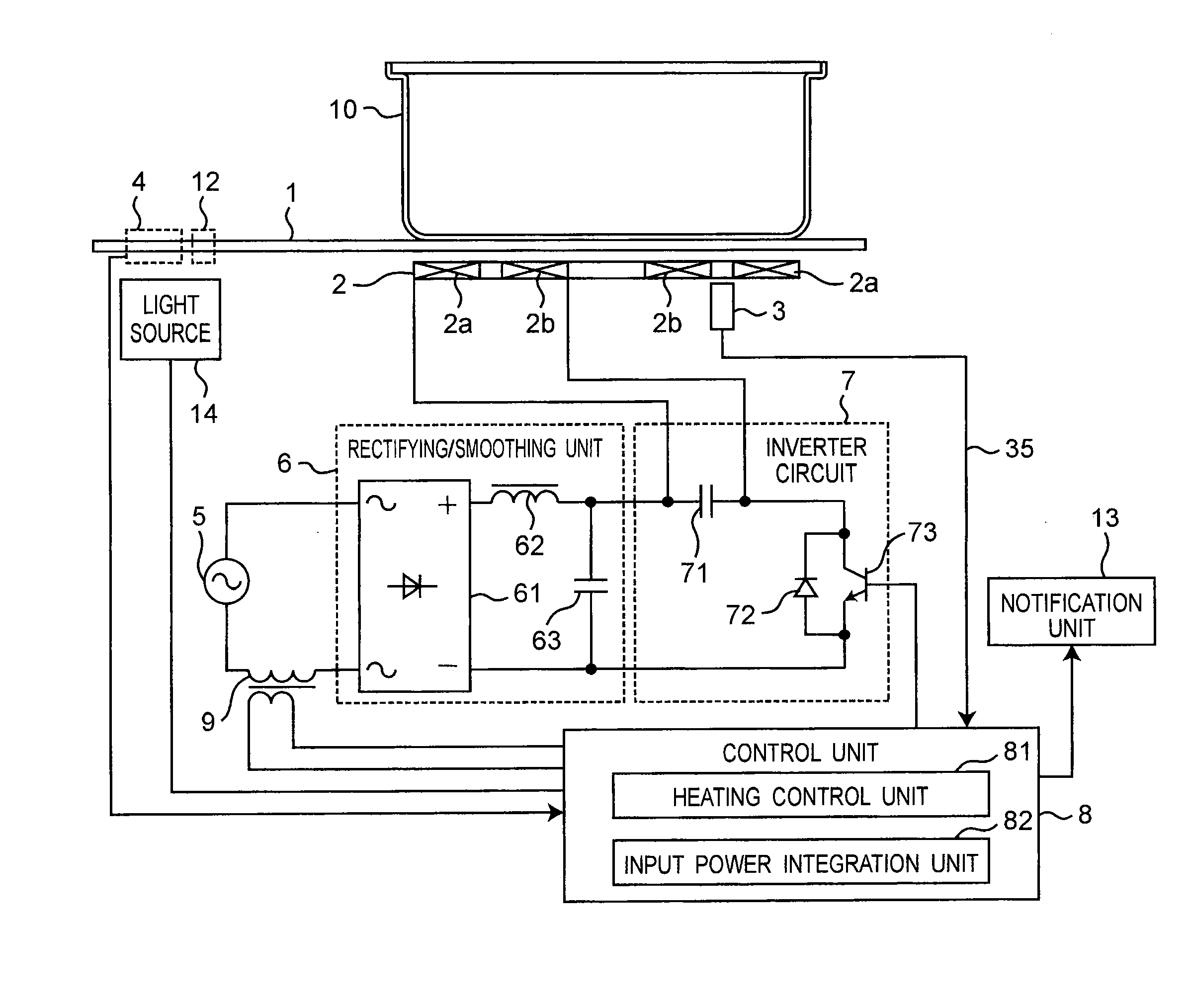

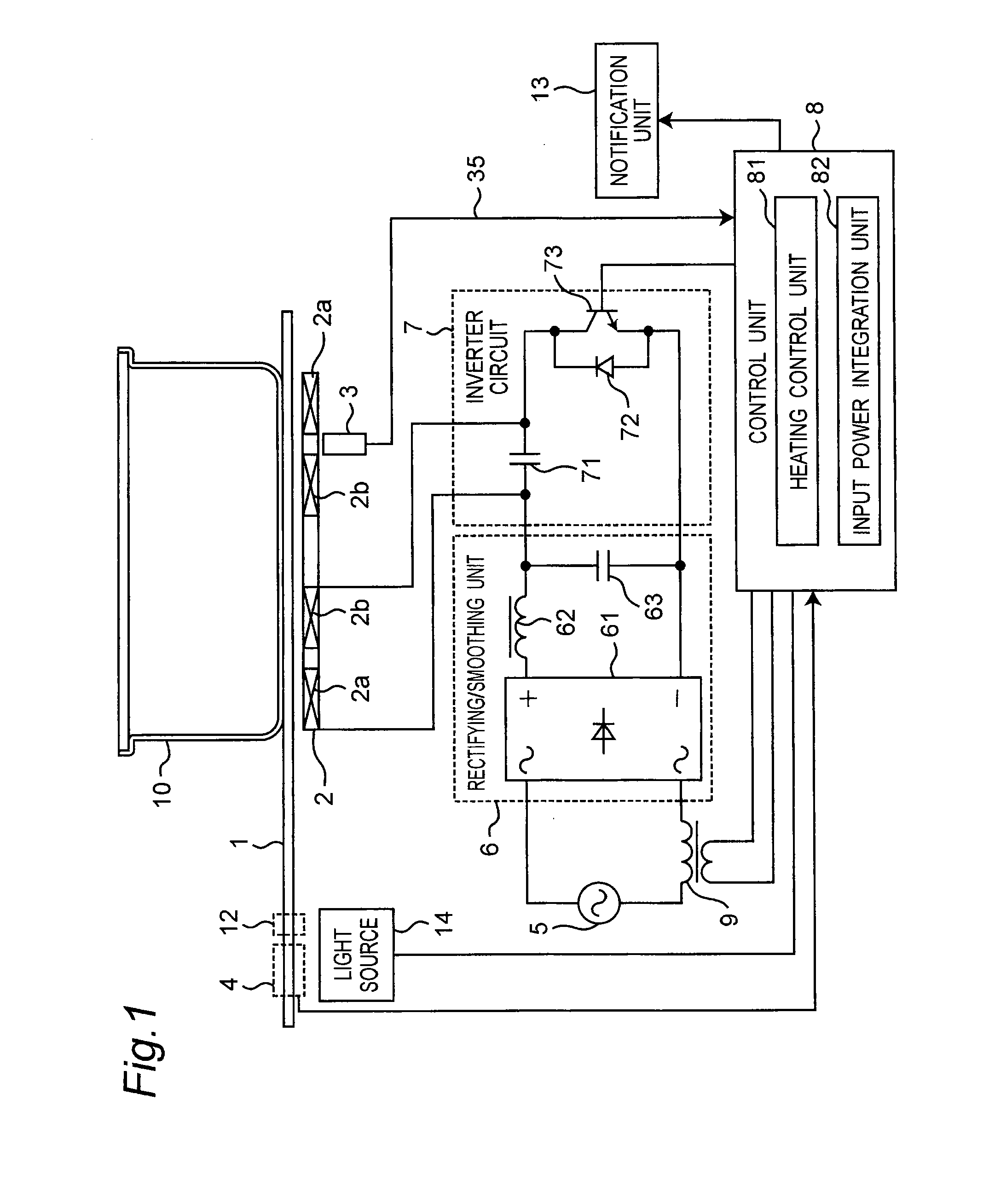

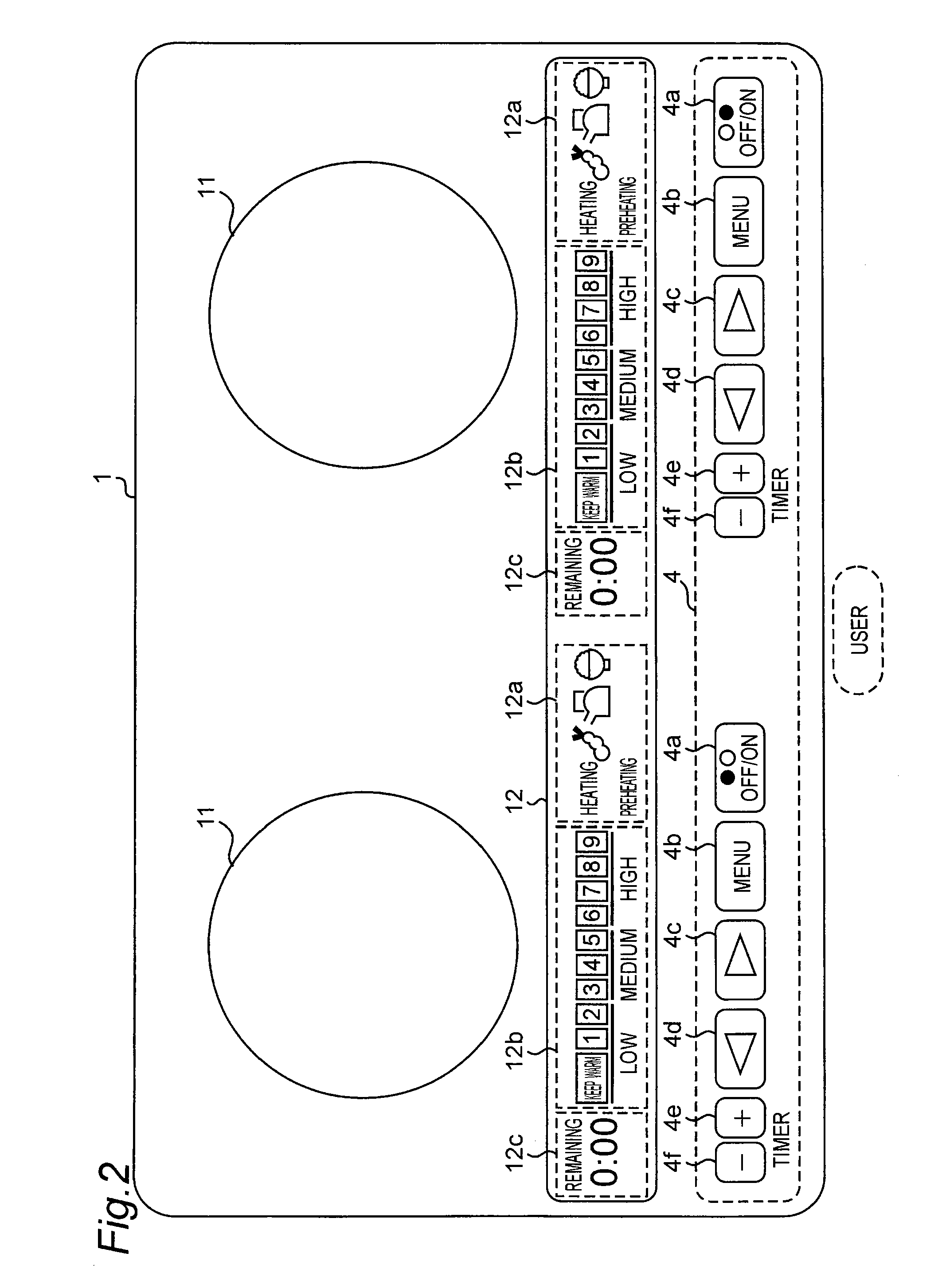

ActiveUS20110000904A1Accurate detectionImprove usabilityInduction heating apparatusEngineeringOperation mode

An induction heat cooking device is provided that finishes preheating in a short time and maintains the temperature obtained at the finish of the preheating. When a preheating heating mode is selected as an operation mode, a control unit (8) arranged in the induction heat cooking device starts operation in a preheating mode in which a cooking container is heated with a first heating output. When an increment of an output value of an infrared sensor exceeds a first predetermined increment since the heating starts with the first heating output, the control unit causes a notification unit to notify a user that the preheating is finished, and the operation mode is changed to a waiting mode for performing heating with a second heating output that is lower than the first heating output. Further, when the user sets a heating power by means of a heating power setting unit in the preheating mode, the control unit prohibits changing to the heating power set by the user. When the user sets a heating power by means of a heating power setting unit in the waiting mode, the control unit permits changing to the heating power set by the user, and the operation mode is changed to a heating mode for performing heating with a third heating output corresponding to the heating power set by the user.

Owner:PANASONIC CORP

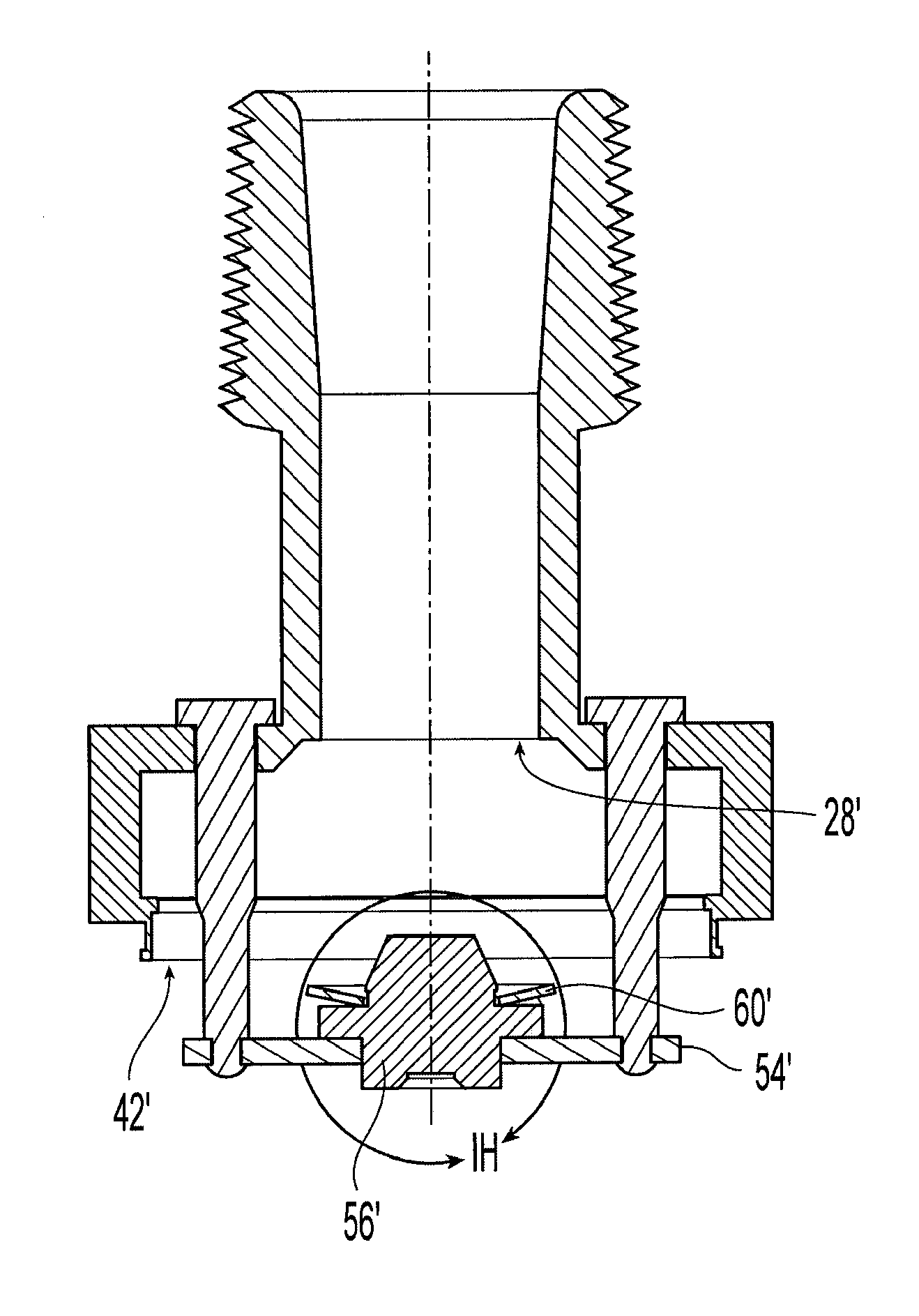

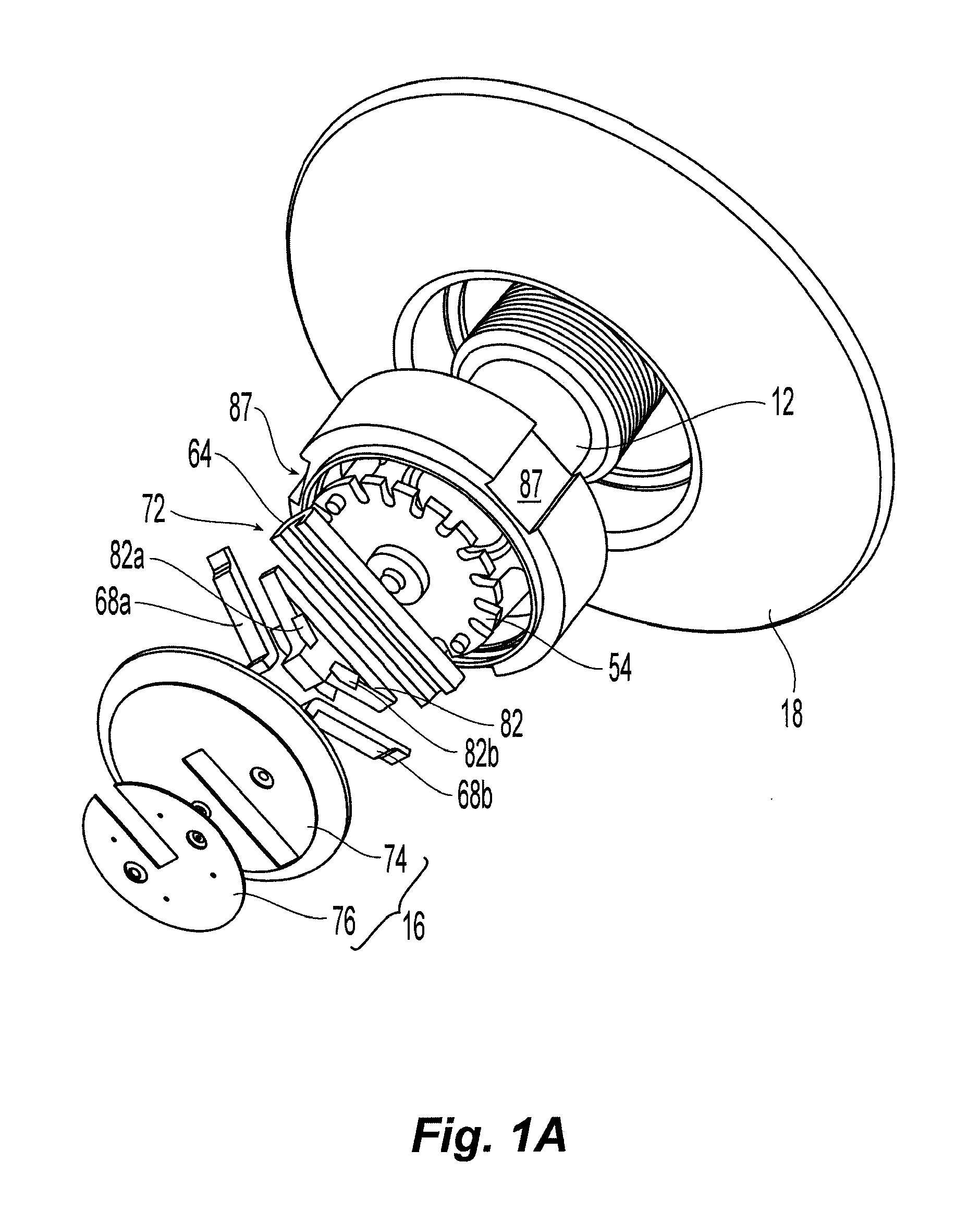

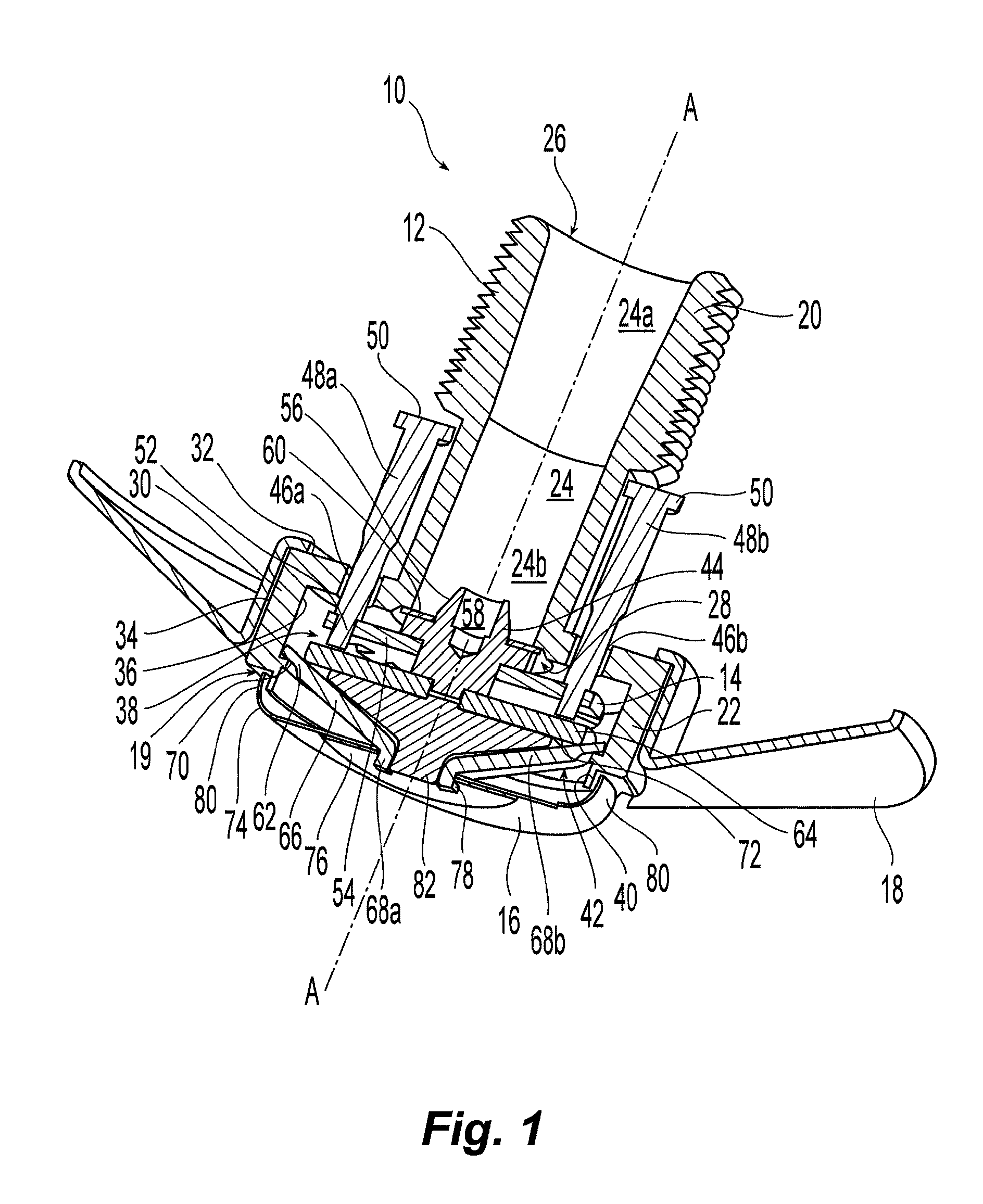

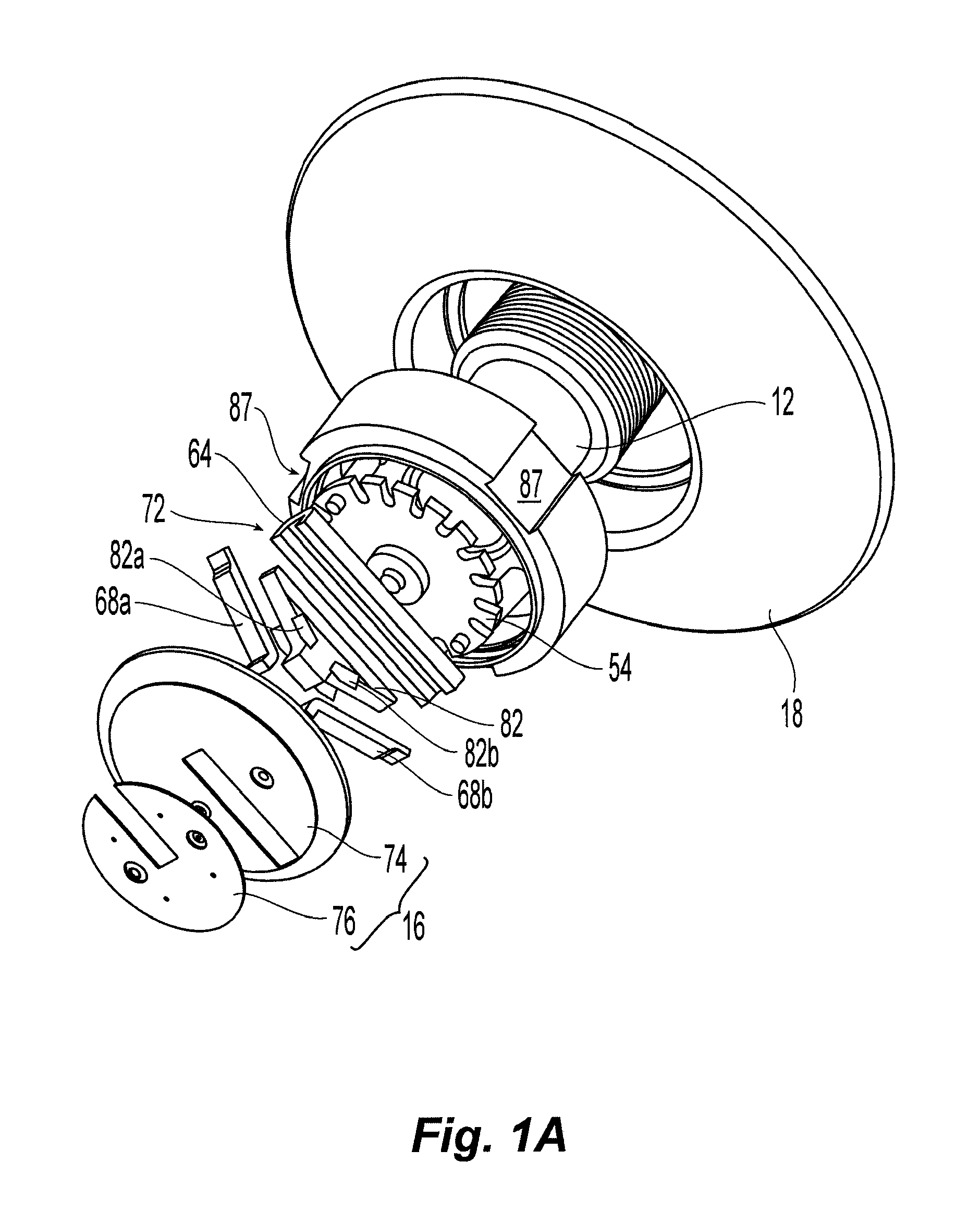

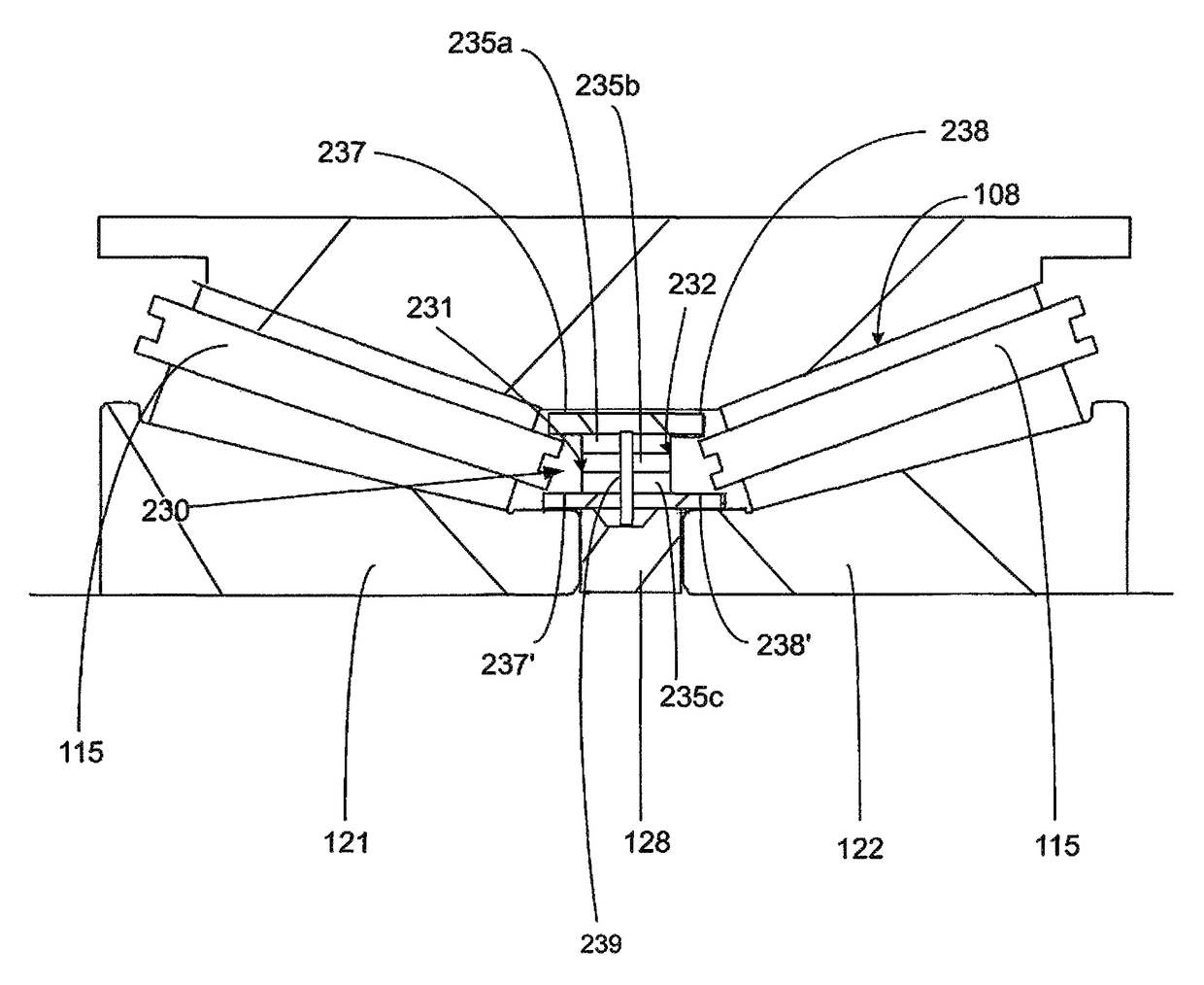

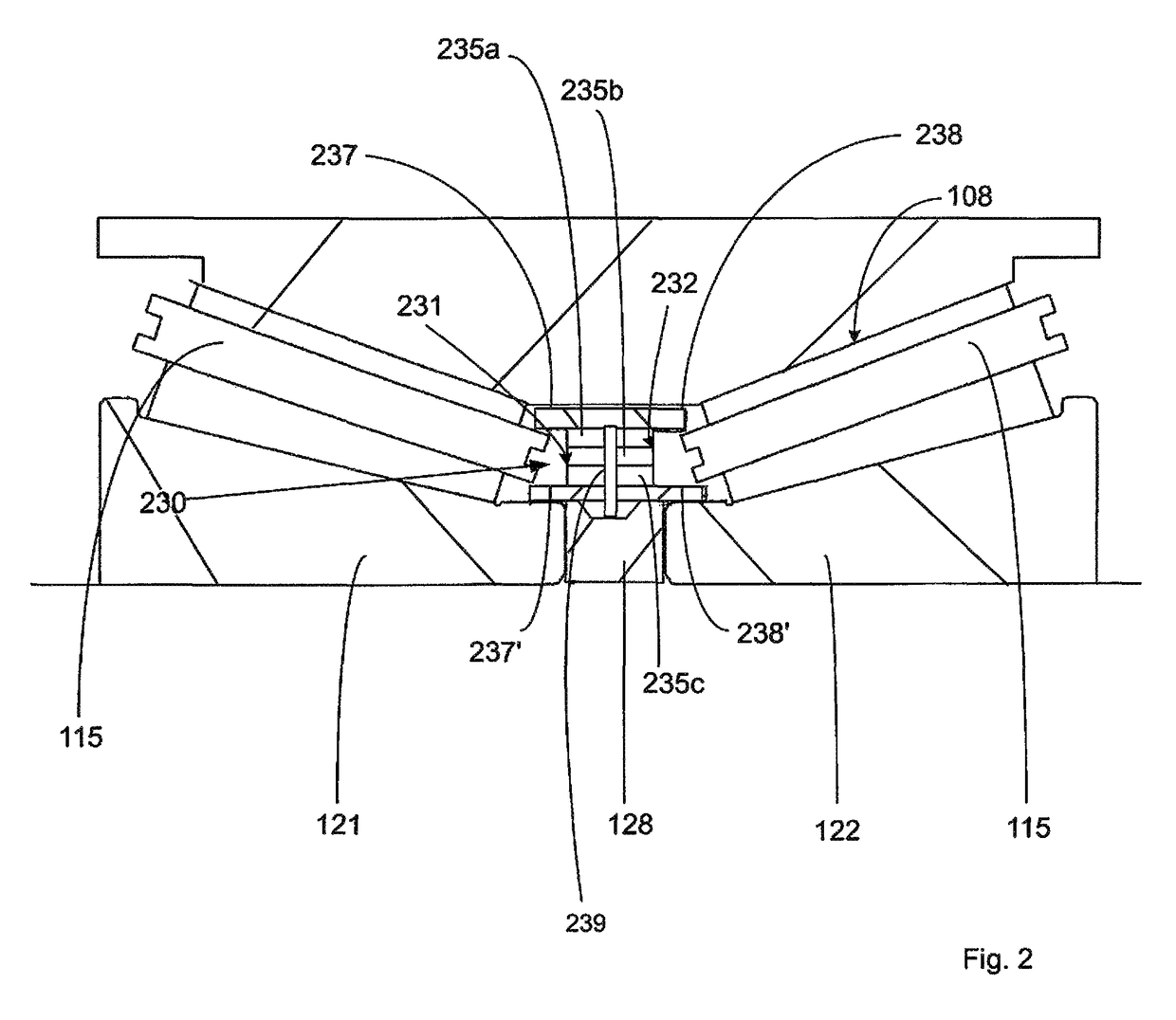

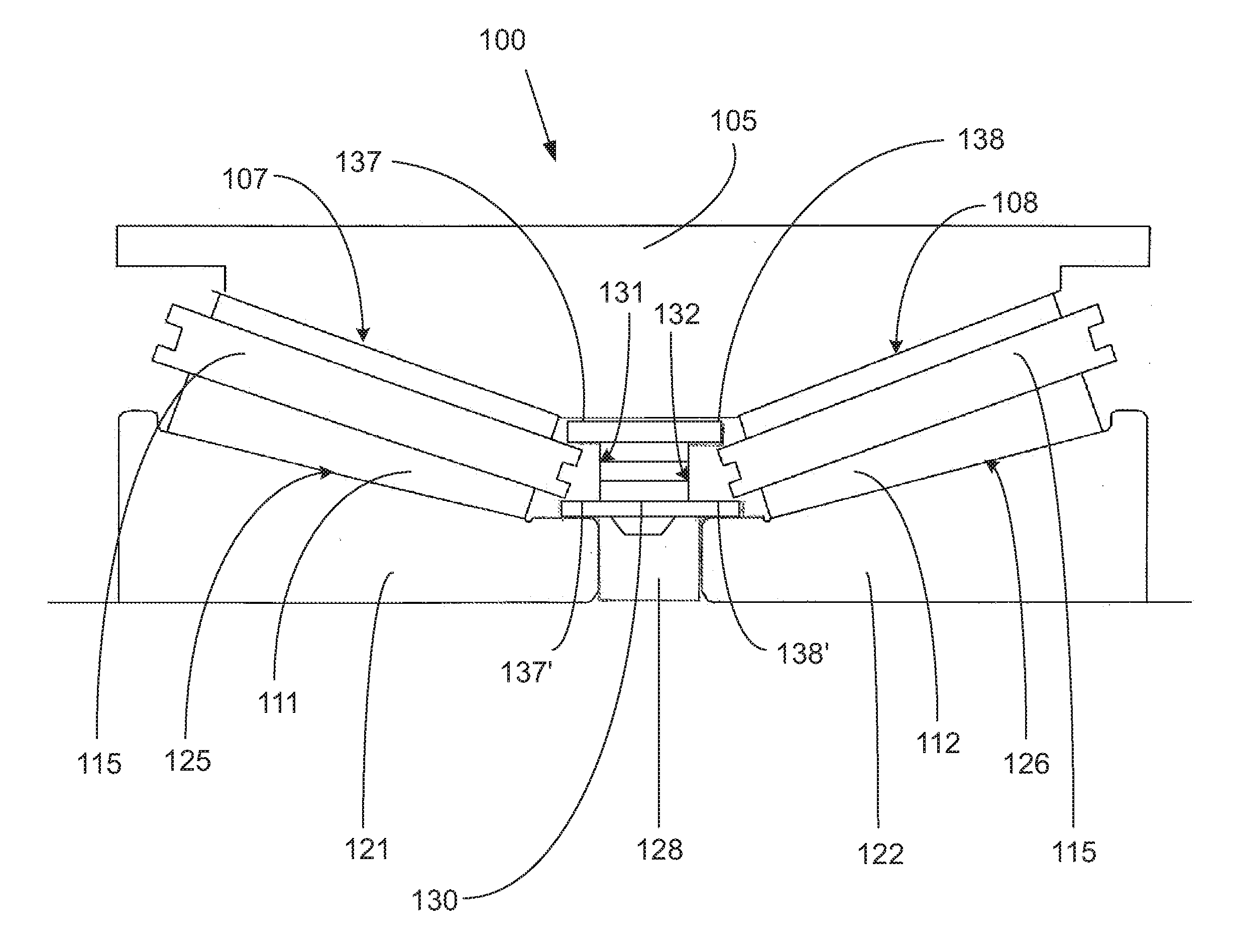

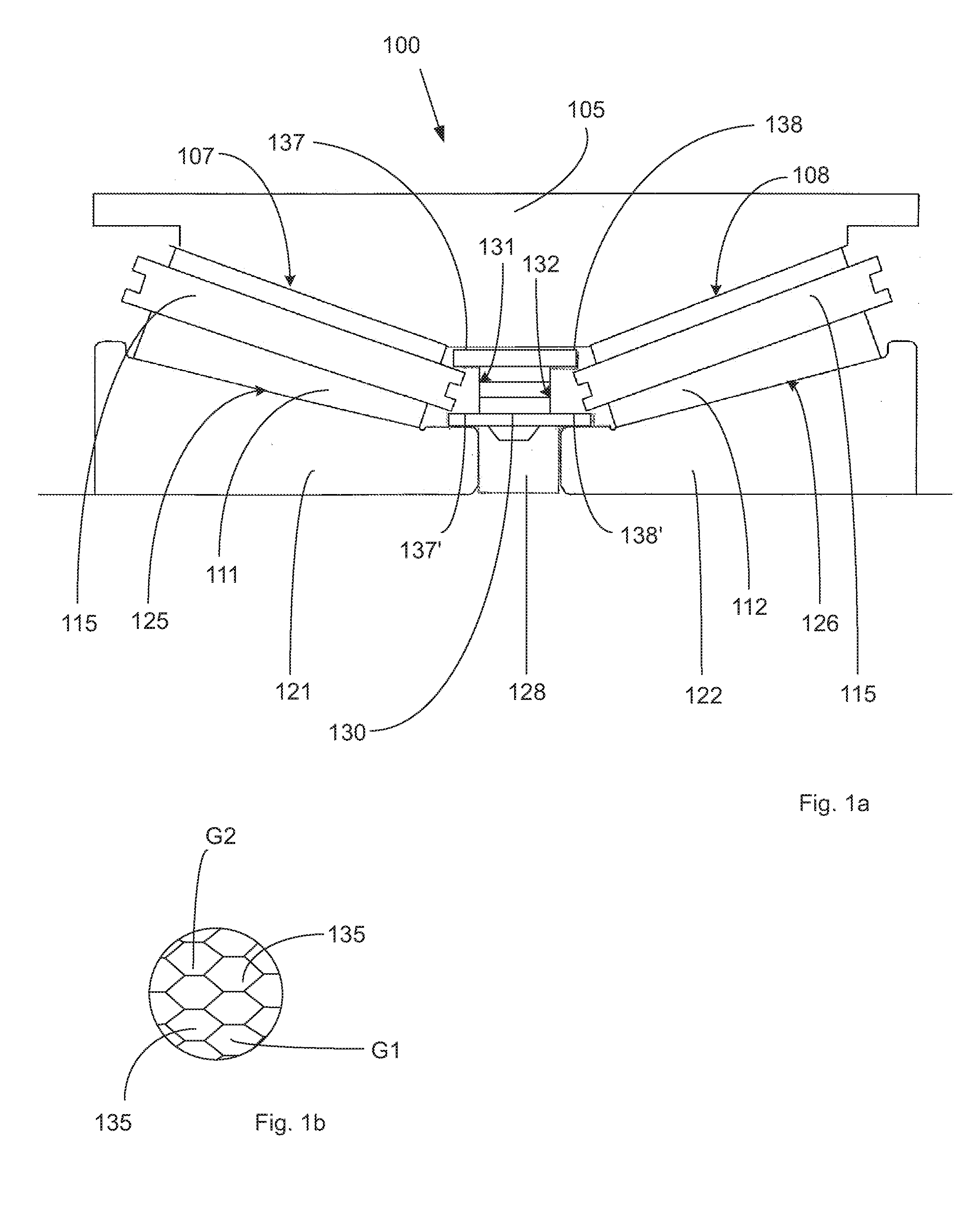

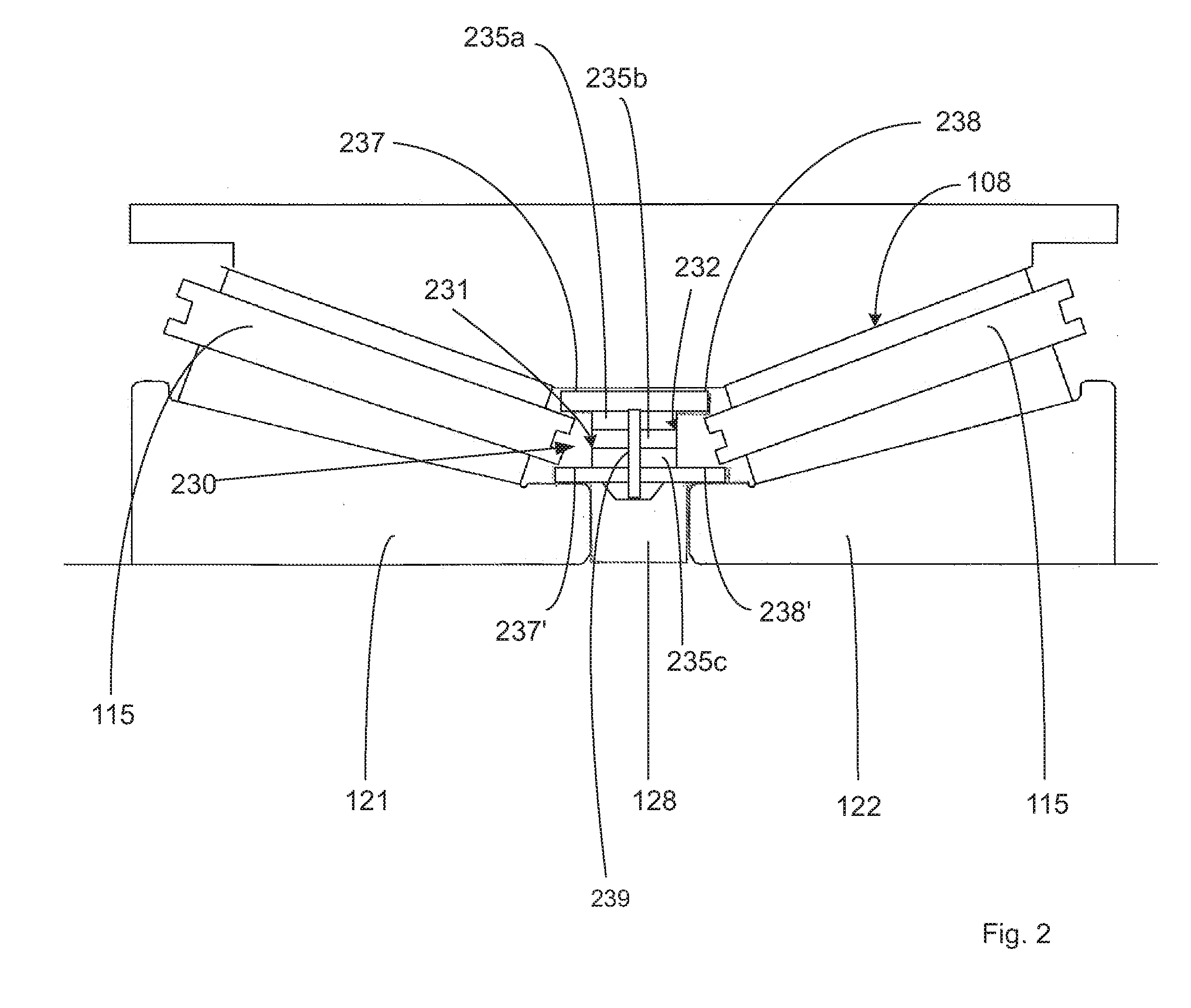

Concealed sprinkler

ActiveUS20100263883A1Minimize pathwayMinimize access pointMovable spraying apparatusSpray nozzlesDistal portionEngineering

A concealed sprinkler including a body having a proximal portion and a distal portion. The distal portion includes an annular wall defining a chamber and an opening in communication with the chamber. A deflector assembly is disposed within the chamber. A trigger assembly having a lever assembly engaged with an inner surface of the annular wall supports the deflector assembly in the first position, the trigger assembly including and a thermally rated plate assembly having a lip portion to substantially circumscribe and substantially cover opening and chamber.

Owner:TYCO FIRE PRODS LP

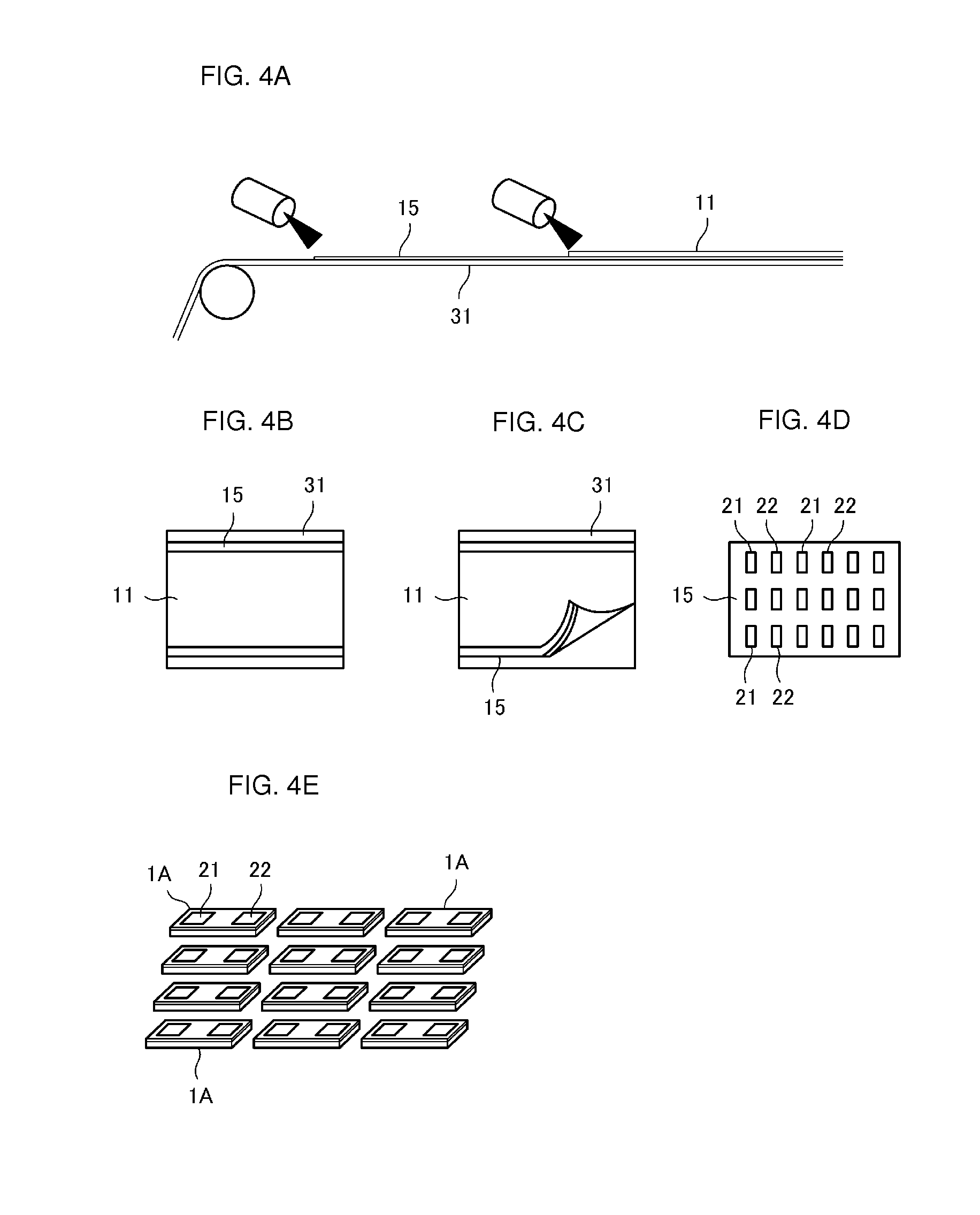

Temperature sensor and temperature sensor attaching structure

ActiveUS20130288091A1Does not affect flexibilityDetectable heatingThermometer detailsThermometers using electric/magnetic elementsElectrical conductorEngineering

A flexible board includes a base layer, a wiring conductor layer that is located on the base layer, and a cover layer that is stacked over the base layer and covers the wiring conductor layer. A portion of the wiring conductor layer defines connecting portions that connect each of split electrodes of a flexible thermistor. The cover layer includes an opening that exposes the connecting portions, and receives the flexible thermistor. The split electrodes of the flexible thermistor are mounted on the connecting portions of the wiring layer. The height of the exposed surface of the flexible thermistor from the opening is substantially equal to the height of the surface of the cover layer.

Owner:MURATA MFG CO LTD

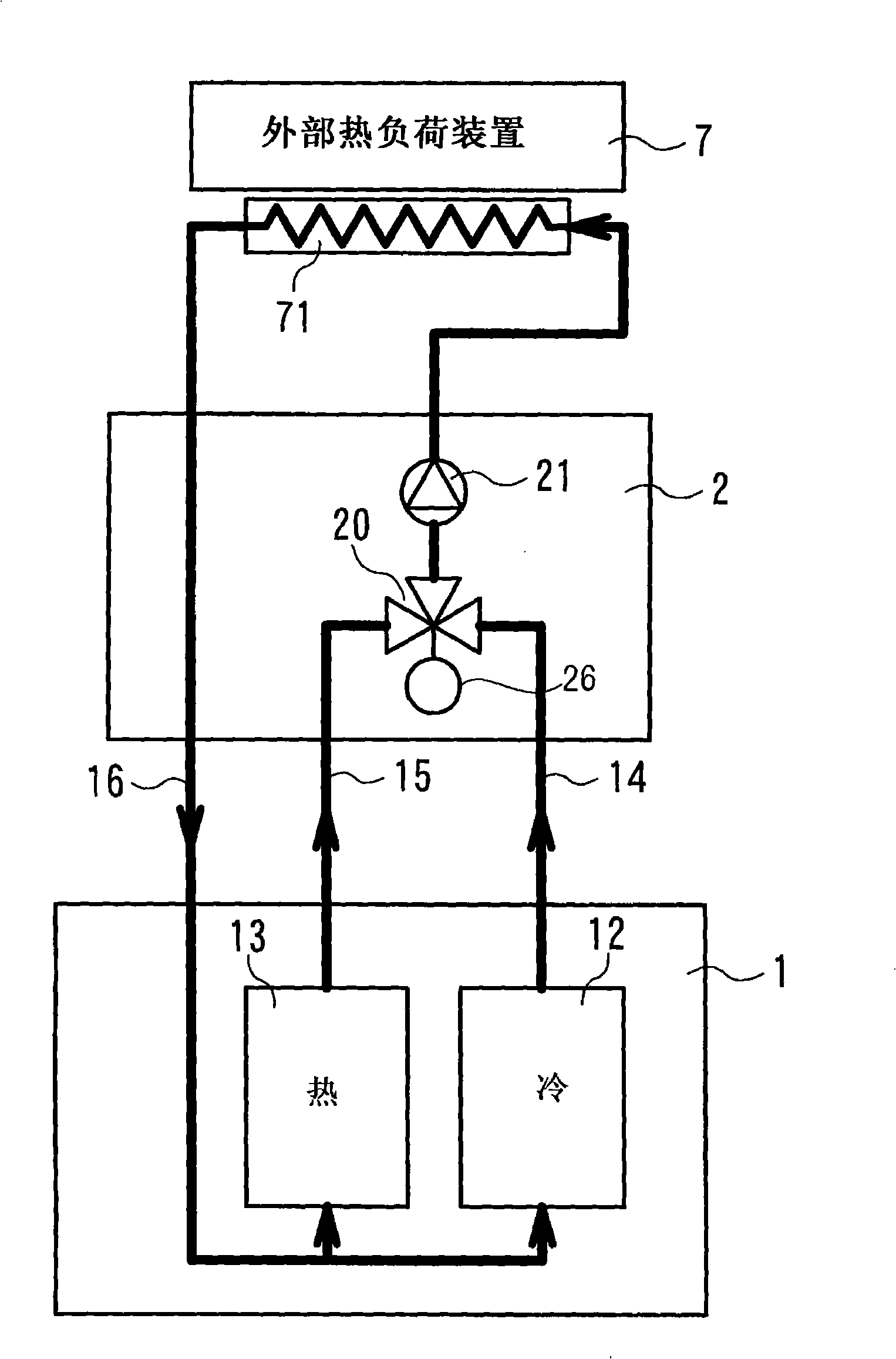

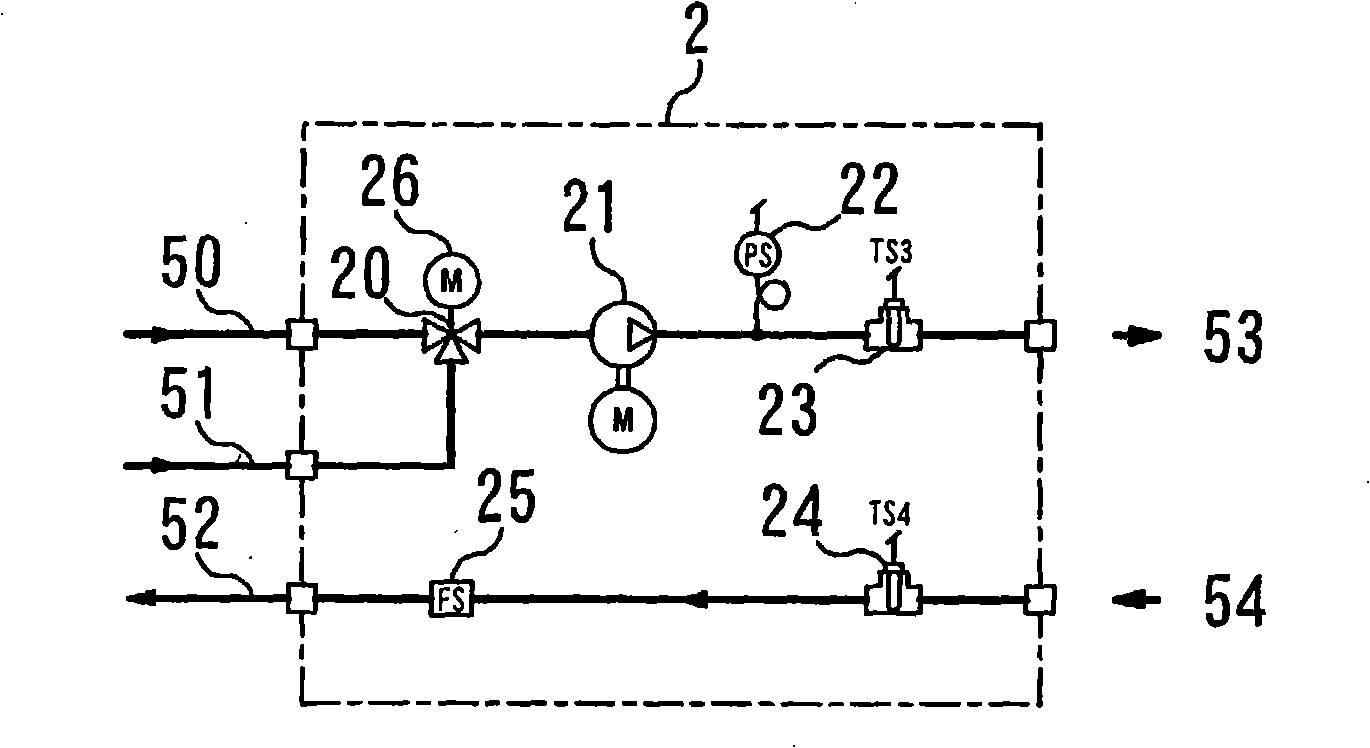

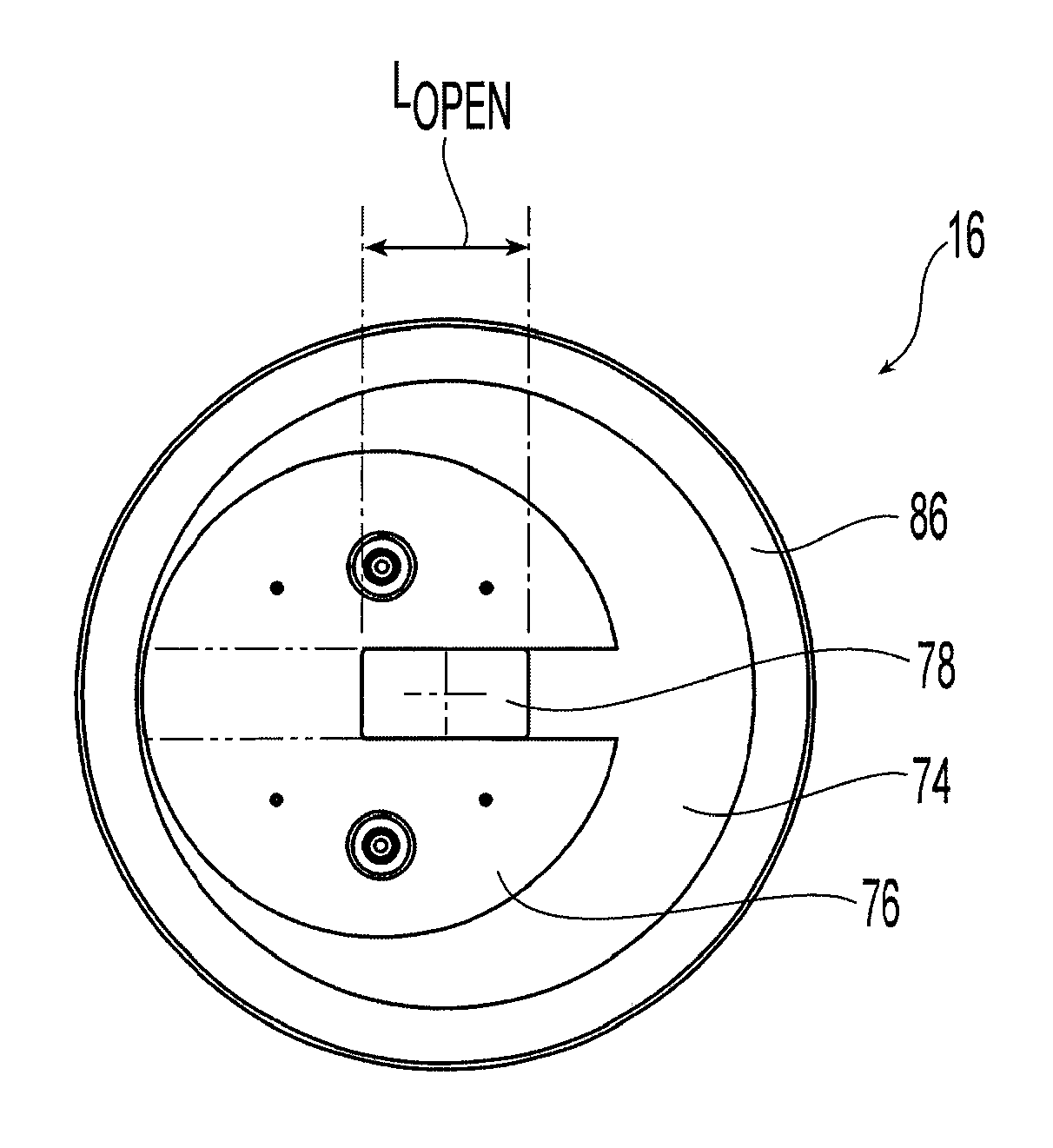

Constant temperature keeping device

InactiveCN101311867AImprove thermal responsivenessHigh precisionTemperature control without auxillary powerCompression machines with non-reversible cycleTemperature controlEngineering

This invention provides a constant temperature controller capable of processing the sharp temperature change of an external heat load, high heat responsiveness and controlling temperature with high precision. A cool fluid of a predetermined temperature is supplied to a three-way valve (20) of a sub unit (2) from a cooling side tank (43) of a main unit (1) of a controller, through a supply pipe (14). Hot fluid of a predetermined temperature is supplied to the three-way valve (20) from a heating side tank (44) through another supply pipe (15). The cool and hot fluids are mixed in a predetermined ratio by the three-way valve (20) according to a temperature of the external heat load (7), and supplied to a heat exchange chamber of the external heat load (7), to maintain the temperature thereof at a target temperature. The temperature of the external heat load (7) is measured by one of a sensor (72) in a processing chamber, a sensor (23) in a constant temperature fluid supply pipe, and a sensor (24) in a constant temperature fluid return pipe, for feedback control of aperture of the three-way valve (20).

Owner:ATS JAPAN CORP

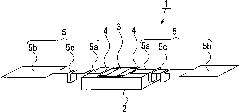

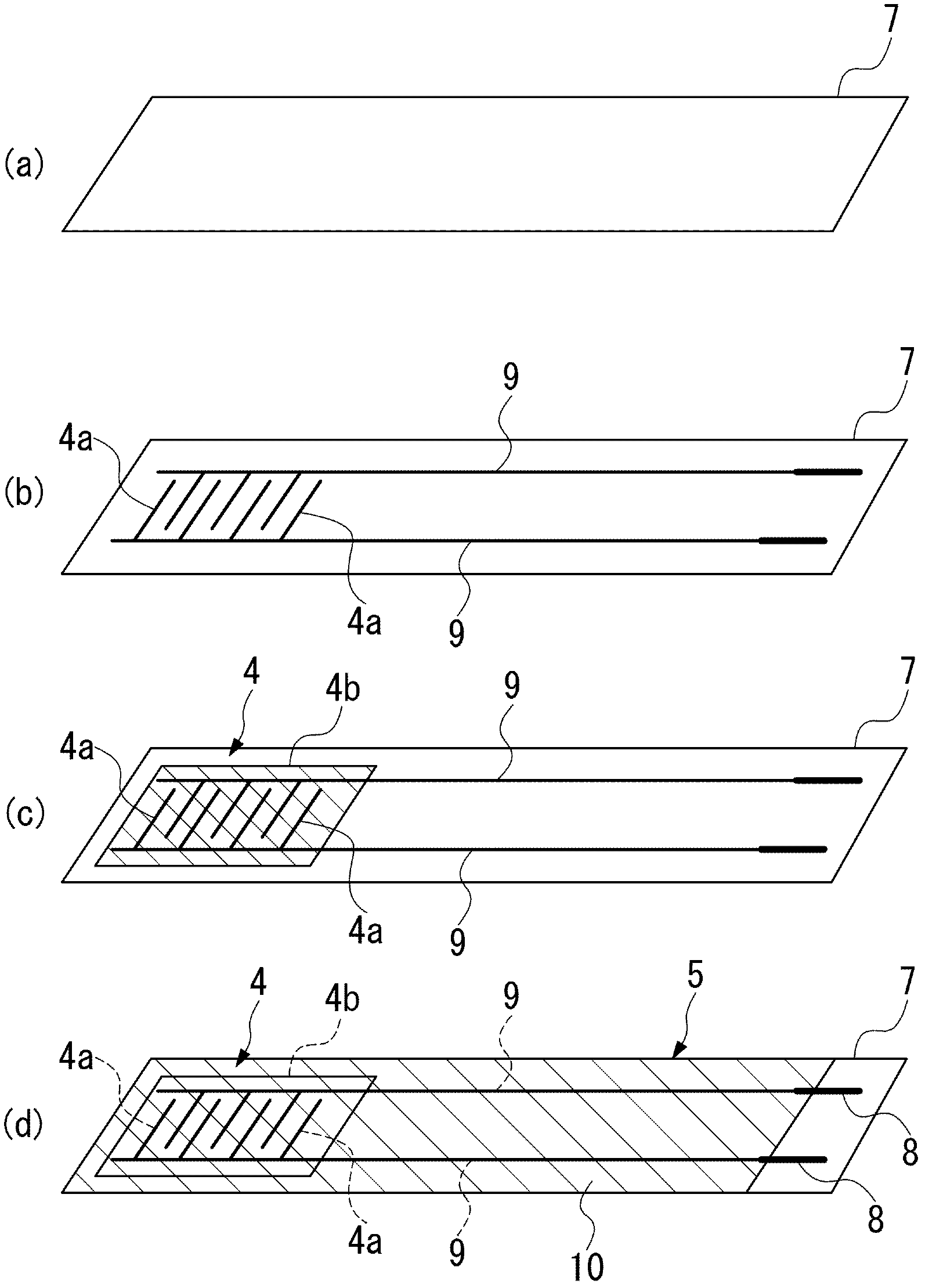

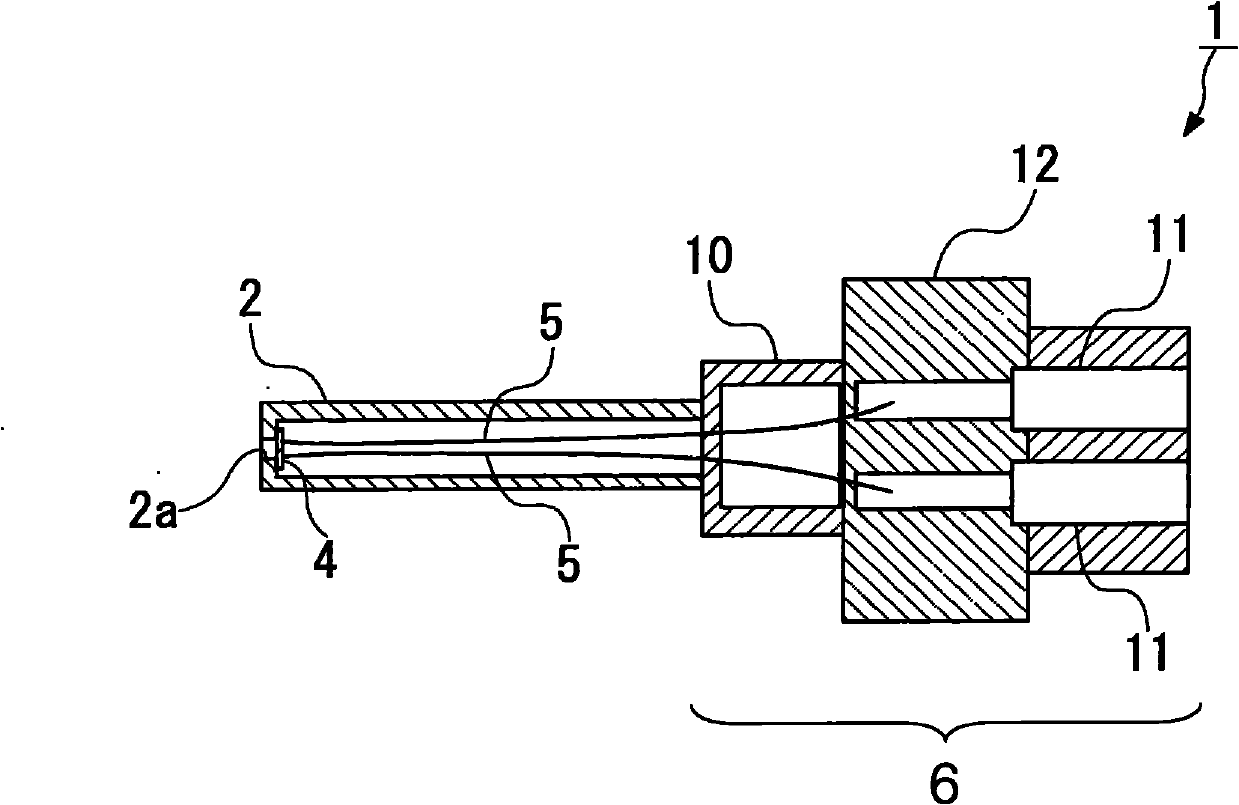

Film thermistor sensor

InactiveCN102192792AImprove reliabilityImprove thermal responsivenessThermometer detailsThermistorLead frame

The invention discloses a film thermistor sensor, which has high tensile strength and can increase the reliability. The film thermistor sensor comprises an insulating substrate (2), a thermistor film (3) which forms patterns on the upper surface of the insulating substrate (2), one pair of electrodes (4) which form patterns from the upper surface of the insulating substrate (2) via the upper surface of the thermistor film (3), and one pair of wire leading frames (5) connected to one pair of electrodes (4), wherein each wire leading frame (5) consists of following parts: a front end jointing part (5a) jointed with the electrodes (4), a wire leading end part (5b) connected with the outer part, and a bent part (5c) formed between the front end jointing part (5a) and the wire leading end part (5b) and forming a bent shape.

Owner:MITSUBISHI MATERIALS CORP

Induction heat cooking device

ActiveUS20110000903A1Improve usabilityAccurate detectionInduction heating apparatusEngineeringOperation mode

An induction heat cooking device is provided that finishes preheating in a short time and maintains the temperature obtained at the finish of the preheating. The induction heat cooking device includes a heating coil (2) for heating a cooking container by induction, an inverter circuit (7) for providing a high frequency current to the heating coil, an operation unit (4) including an operation mode setting unit (4b) for setting an operation mode of the inverter circuit, an infrared sensor (3) for detecting an infrared light that is emitted from a bottom surface of the cooking container, a control unit (8) for controlling an output of the inverter circuit based on an output of the infrared sensor and a setting inputted to the operation unit, and a notification unit (13). When the operation mode is set to a preheating heating mode, the control unit starts operation in a preheating mode for heating the cooking container with a first heating output, and wherein when an increment of an output value of the infrared sensor is more than a first predetermined increment since the heating starts with the first heating output, the control unit causes the notification unit to notify a user that the preheating is finished, and the operation mode is changed to a waiting mode for performing heating with a second heating output that is lower than the first heating output.

Owner:PANASONIC CORP

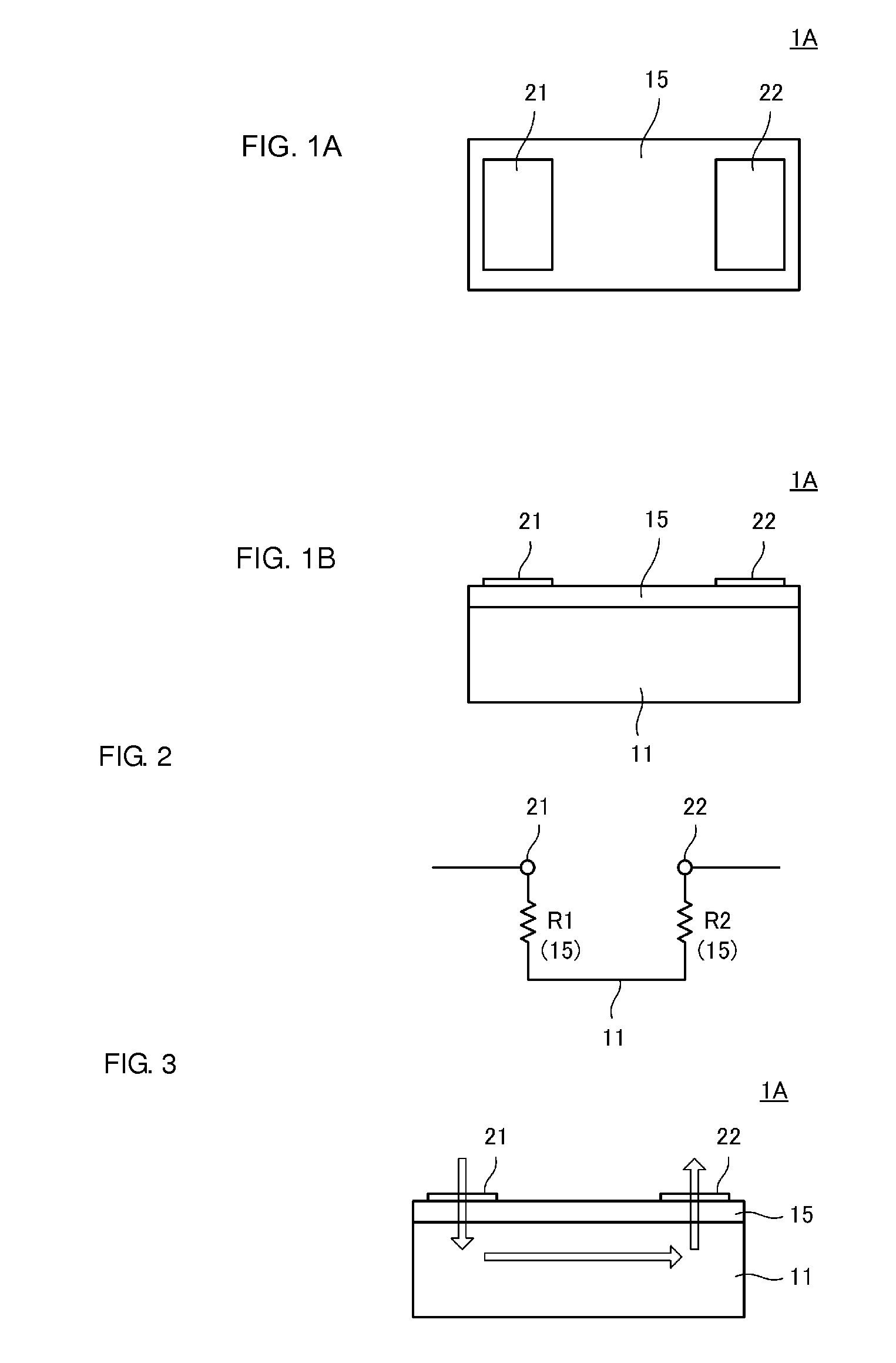

Temperature sensor and temperature sensor attaching structure

ActiveUS9316546B2Does not affect flexibilityDetectable heatingThermometer detailsThermometers using electric/magnetic elementsElectrical conductorThermistor

A flexible board includes a base layer, a wiring conductor layer that is located on the base layer, and a cover layer that is stacked over the base layer and covers the wiring conductor layer. A portion of the wiring conductor layer defines connecting portions that connect each of split electrodes of a flexible thermistor. The cover layer includes an opening that exposes the connecting portions, and receives the flexible thermistor. The split electrodes of the flexible thermistor are mounted on the connecting portions of the wiring layer. The height of the exposed surface of the flexible thermistor from the opening is substantially equal to the height of the surface of the cover layer.

Owner:MURATA MFG CO LTD

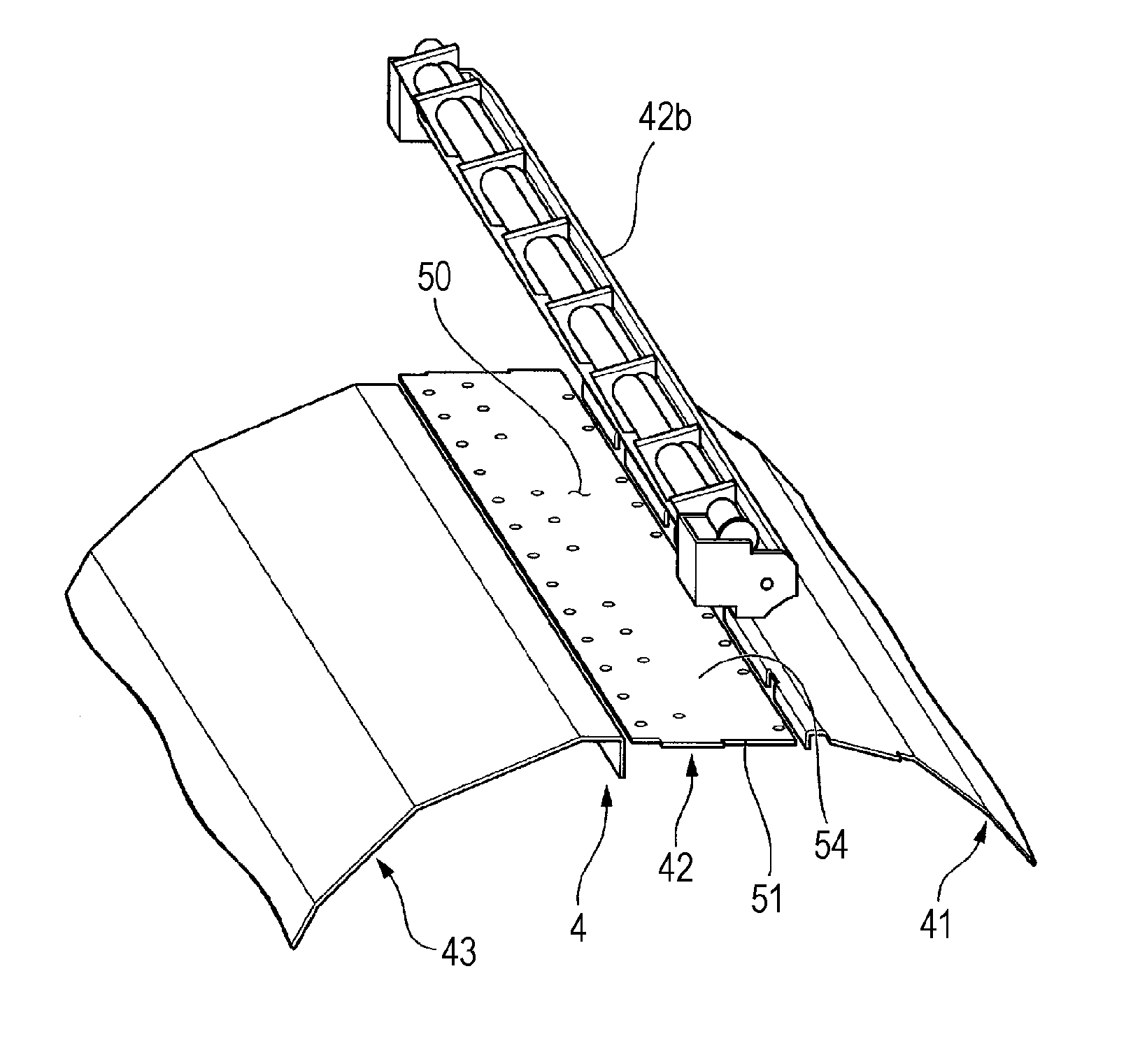

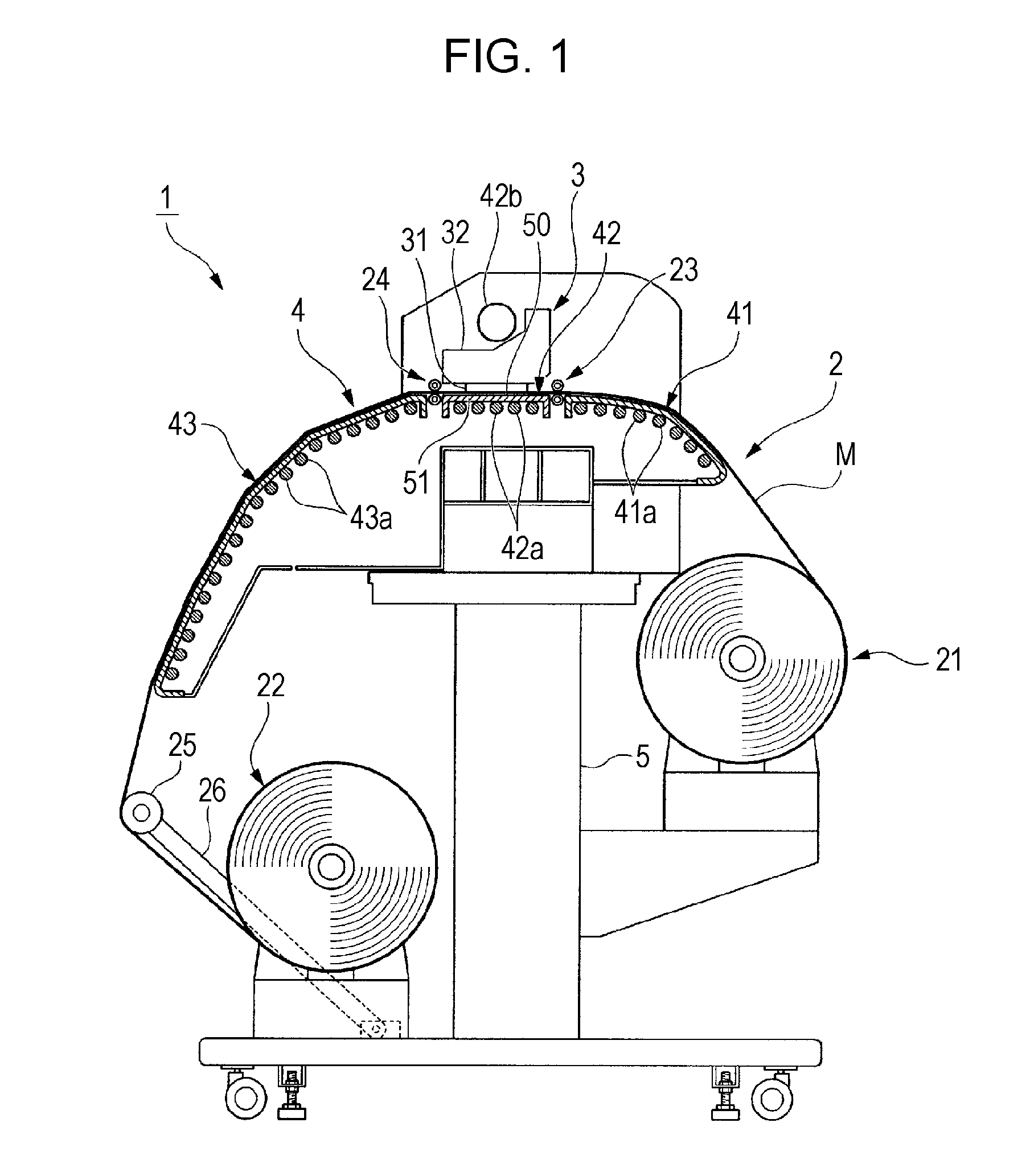

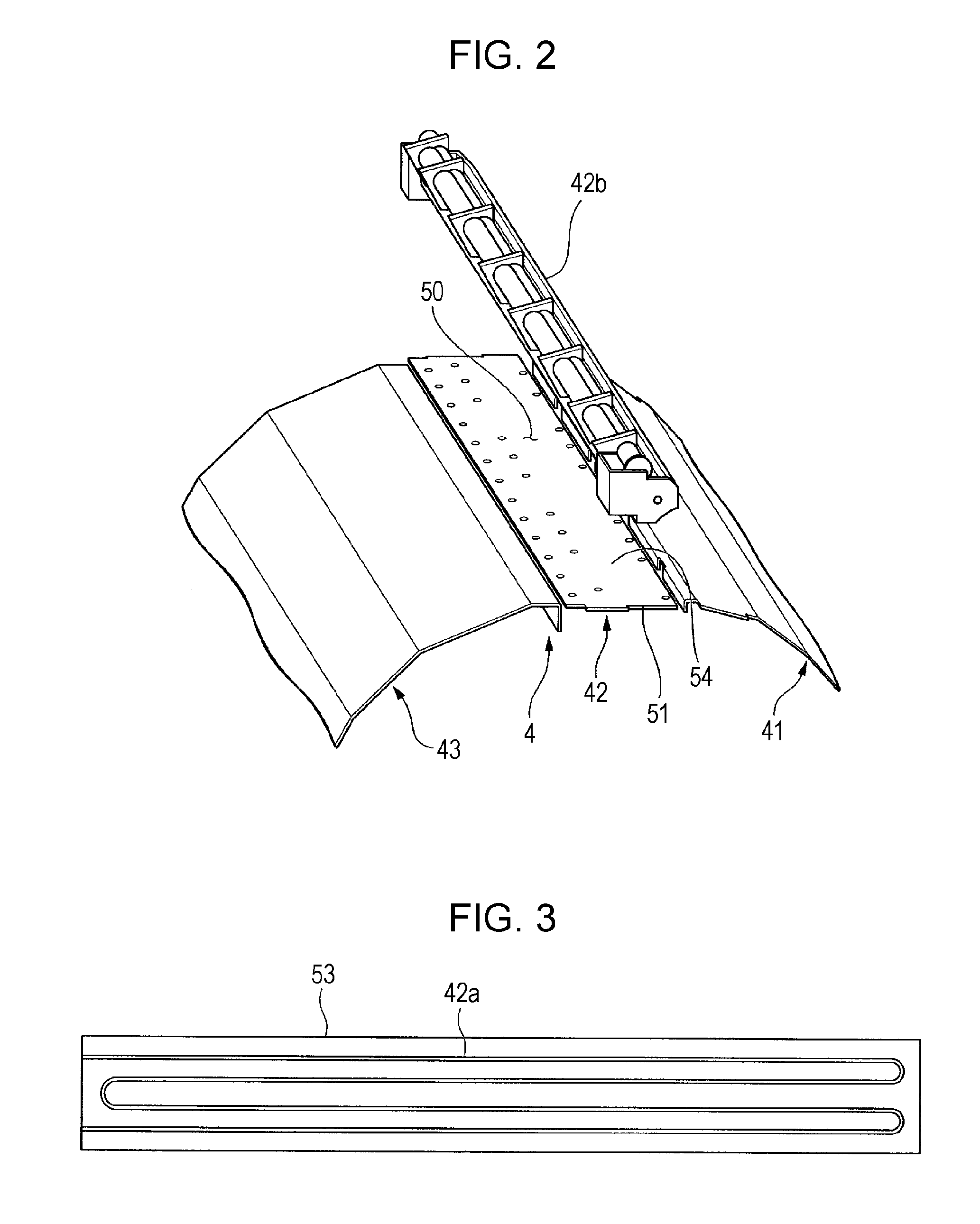

Recording apparatus

ActiveUS20120162335A1Prevent heatGood thermal responseOther printing apparatusRecording headRadiation

A recording apparatus includes: a recording head that ejects fluid onto a recording medium; a supporting member that supports the recording medium; and a heating device that heats the supporting member, in which a supporting surface that supports the recording medium in the supporting member has a surface treatment layer having a radiation factor of 0.85 or more.

Owner:SEIKO EPSON CORP

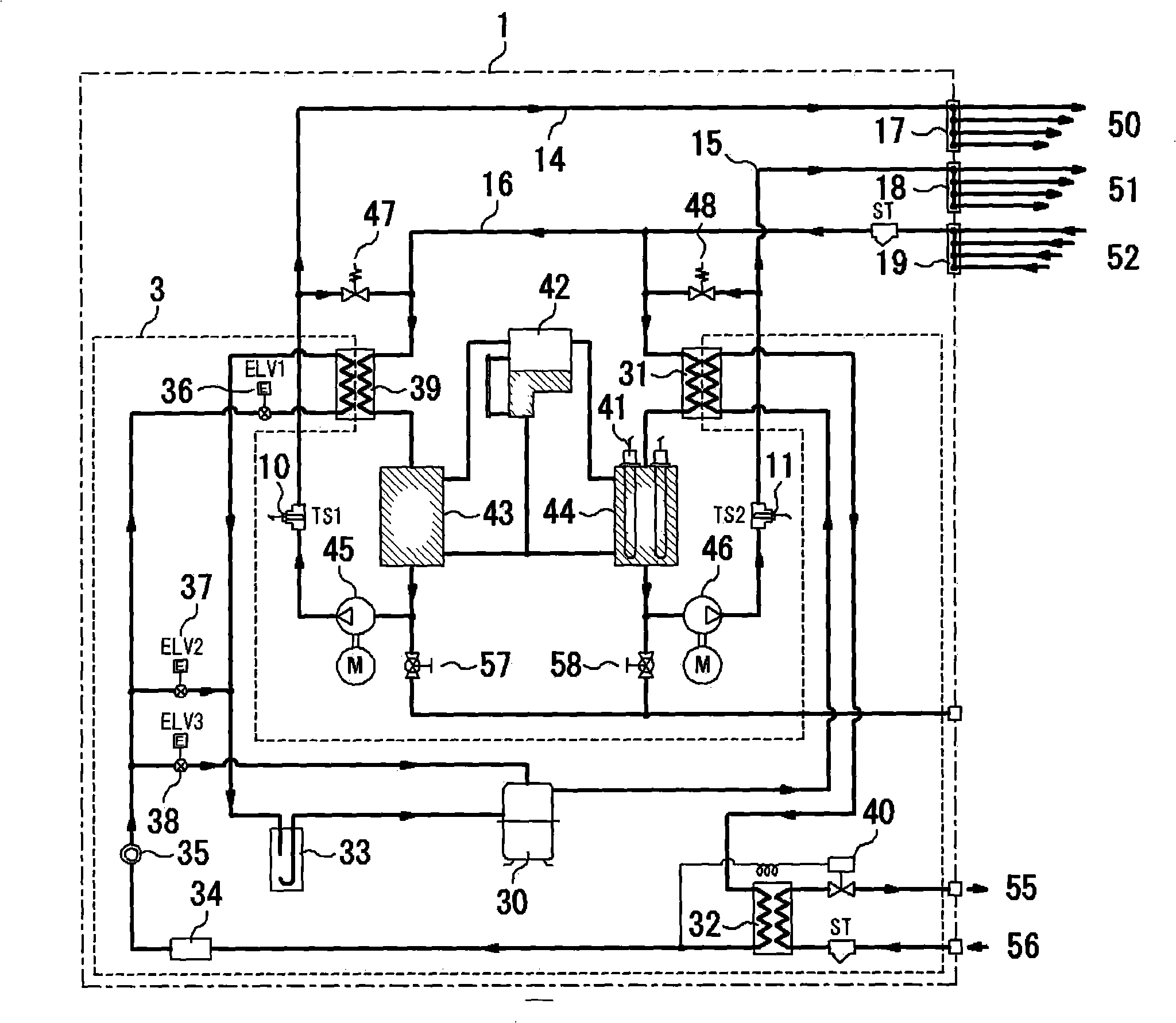

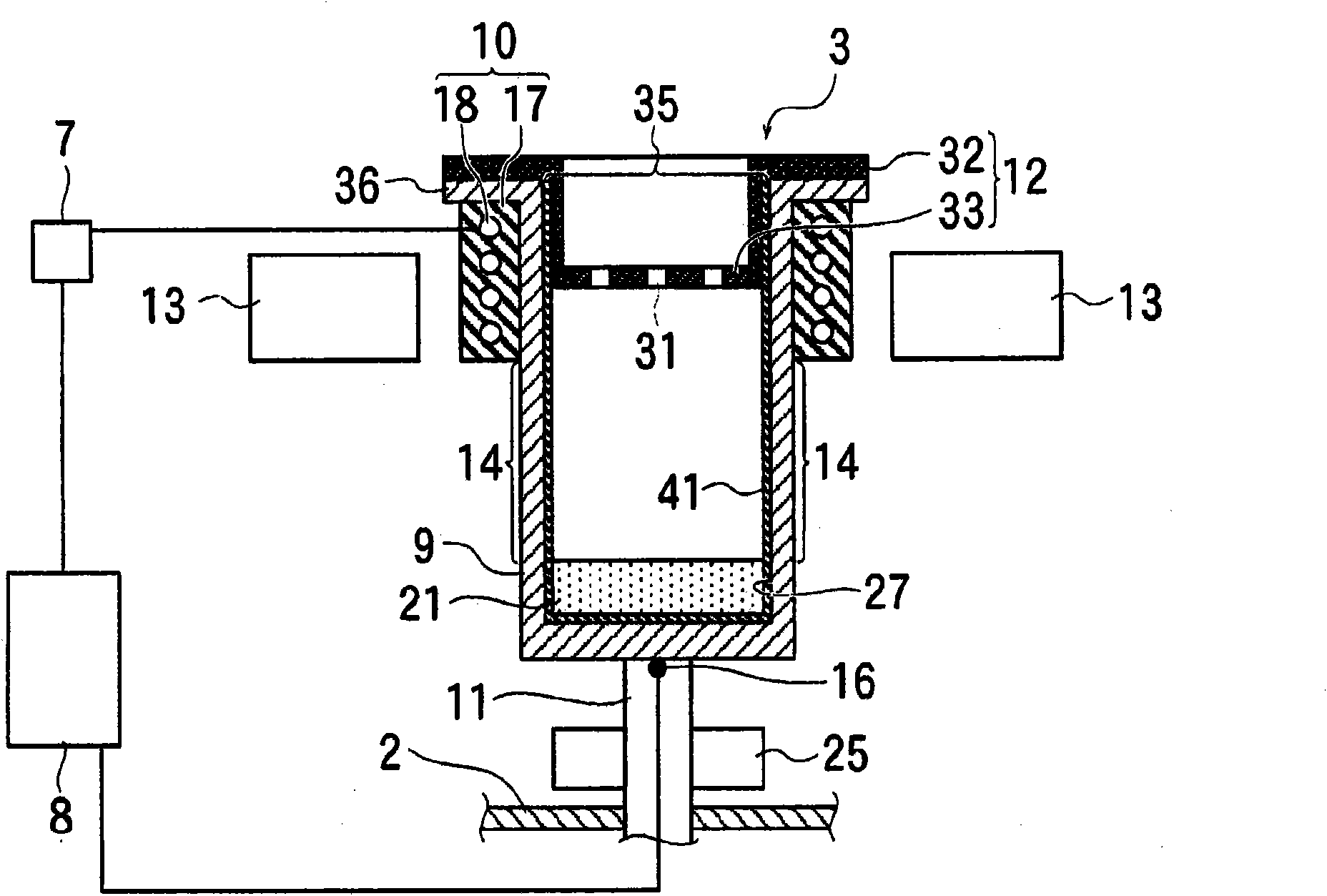

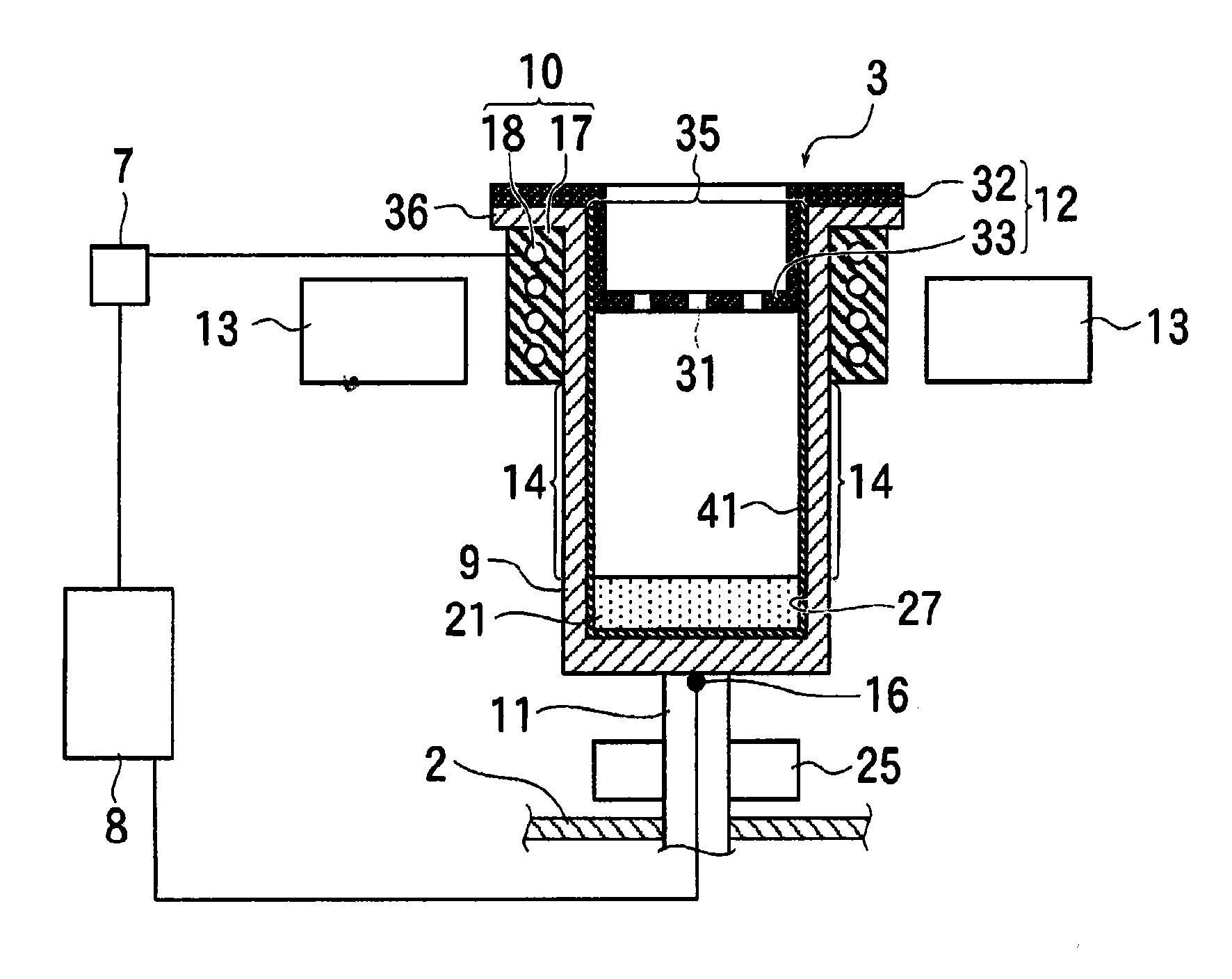

Vacuum-evaporation source, and organic EL element manufacturing apparatus

ActiveCN101849032AImprove thermal responsivenessStable release rateVacuum evaporation coatingSemiconductor/solid-state device manufacturingManufactured apparatusEngineering

This aims to improve the heat controllability of an evaporation container (9) of a vacuum-evaporation source. This vacuum-evaporation source (3) comprises the evaporation container (9) having an organic material (21) arranged therein, and a heater wire (18) wound on the outer circumference of the evaporation source (3). The organic material (21) is arranged such that its portion to contact the sidewall of the evaporation container (9) is below the lower end of the heater wire (18), and a substrate (20) is attached to a substrate holder (4). When a power source (7) is started so that the heater wire (18) generates heat to heat the evaporation container (9), the vapor of the organic material (21) is released from an upward through hole (31) to the inside of a vacuum bath (2), so that it sticks to the substrate (20) thereby to form a thin film. The heater wire (18) is arranged up to the upper end of the evaporation container (9), so that it can heat the opening to an evaporation temperature or higher. The evaporation container (9) is made of a metal material selected from at least one kind of copper, an alloy of copper and beryllium, Ti and Ta, and is formed to have a side wall and abottom wall of a thickness of 0.3 mm to 0.7 mm. Thus, the vacuum-evaporation source (3) has a small heat capacity and excellent controllability.

Owner:ULVAC INC

Concealed sprinkler

ActiveUS8646539B2Minimize pathway and access pointPrevent and substantially minimize unauthorized tamperingMovable spraying apparatusSpray nozzlesDistal portionEngineering

A concealed sprinkler including a body having a proximal portion and a distal portion. The distal portion includes an annular wall defining a chamber and an opening in communication with the chamber. A deflector assembly is disposed within the chamber. A trigger assembly having a lever assembly engaged with an inner surface of the annular wall supports the deflector assembly in the first position, the trigger assembly including and a thermally rated plate assembly having a lip portion to substantially circumscribe and substantially cover opening and chamber.

Owner:TYCO FIRE PRODS LP

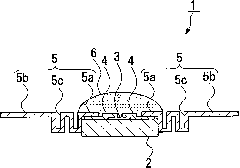

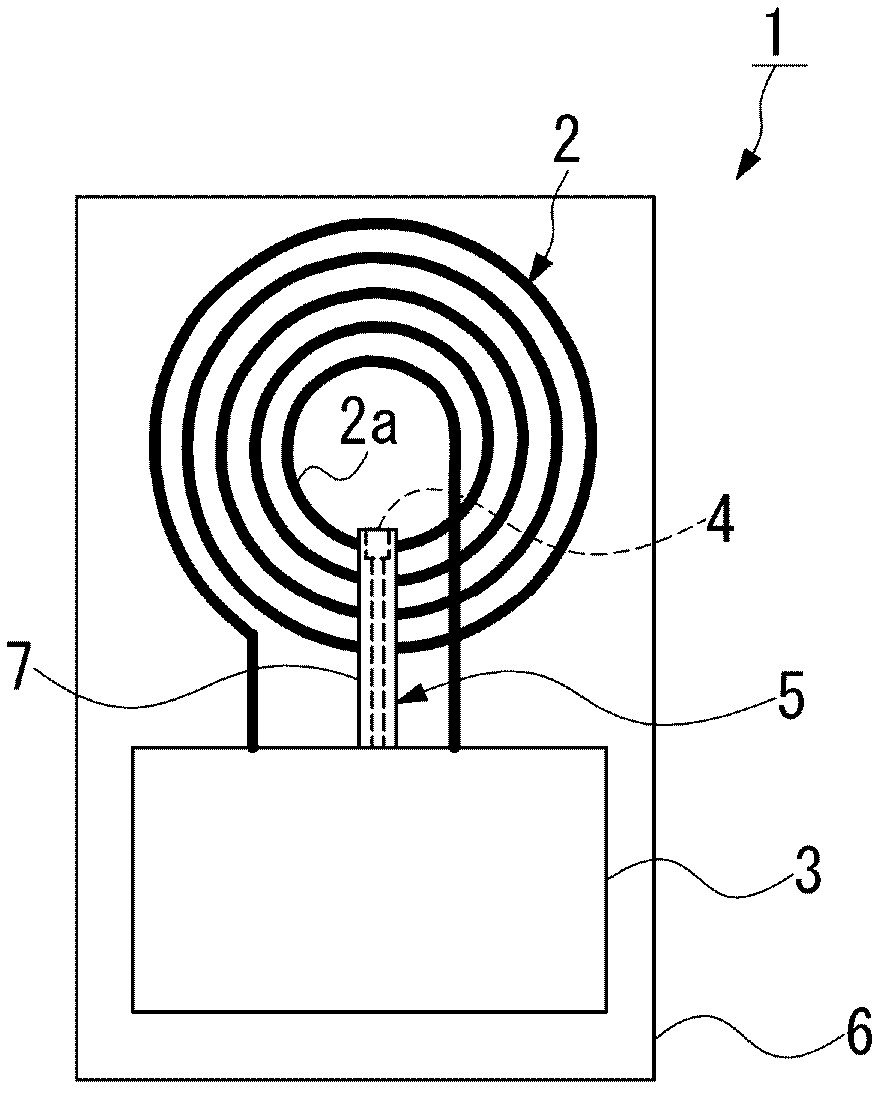

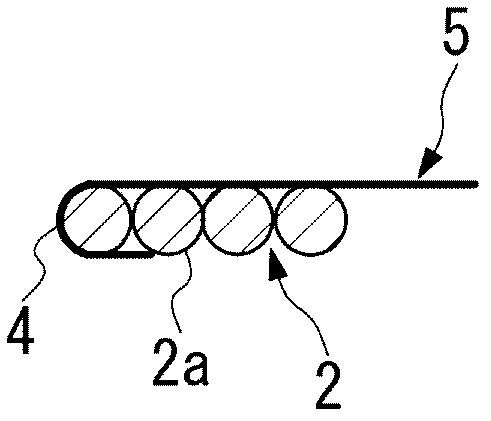

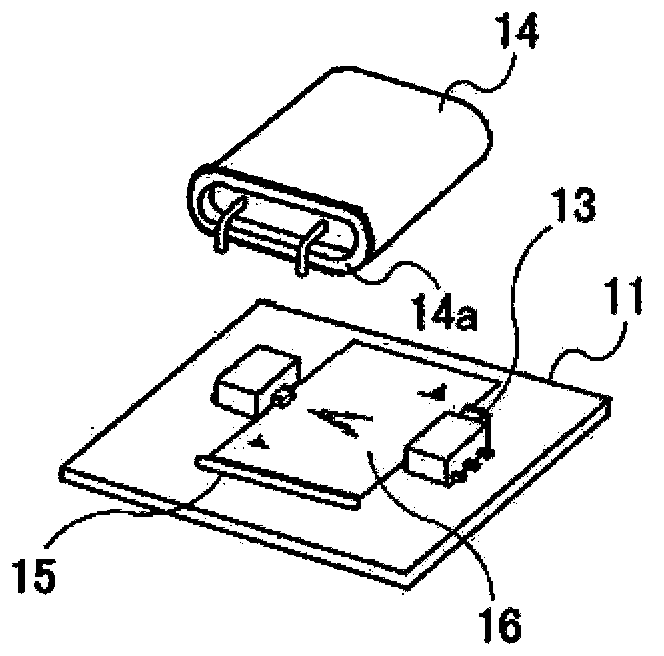

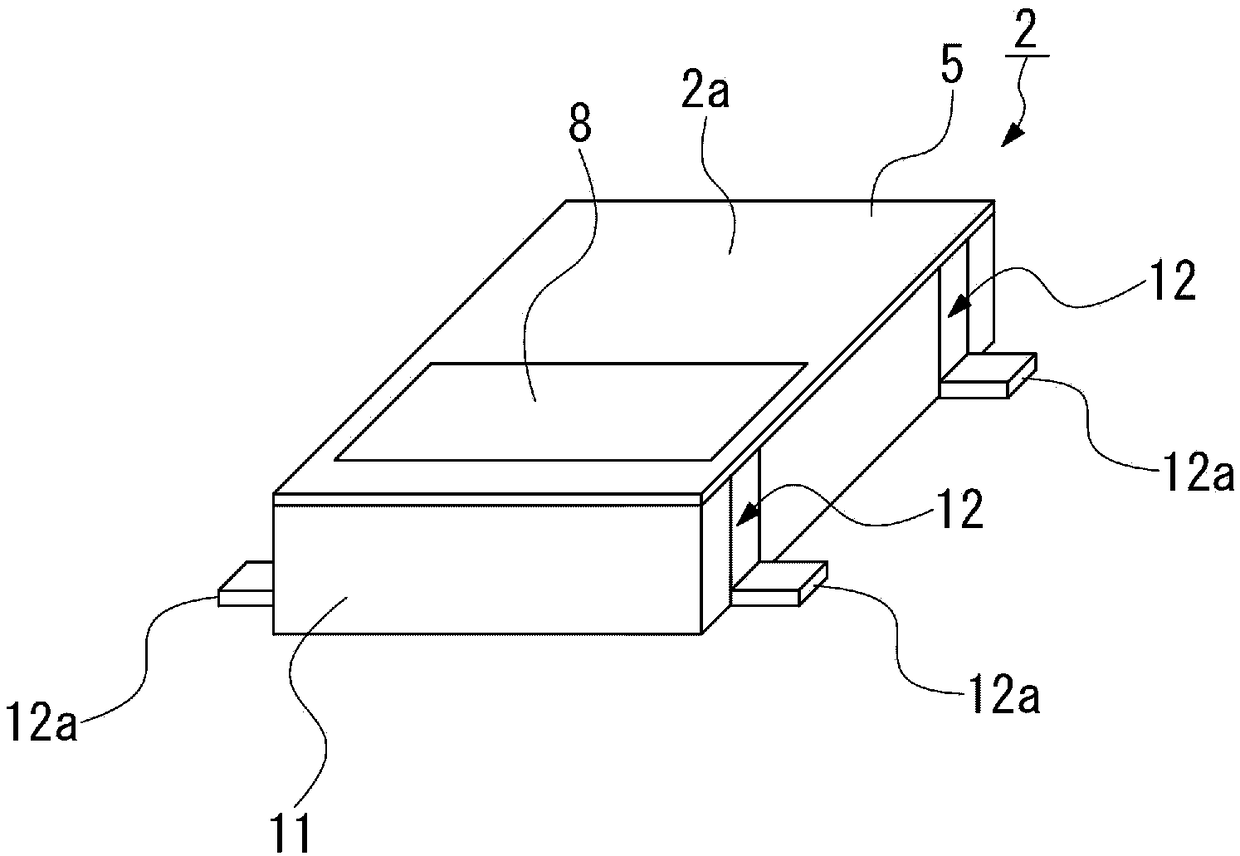

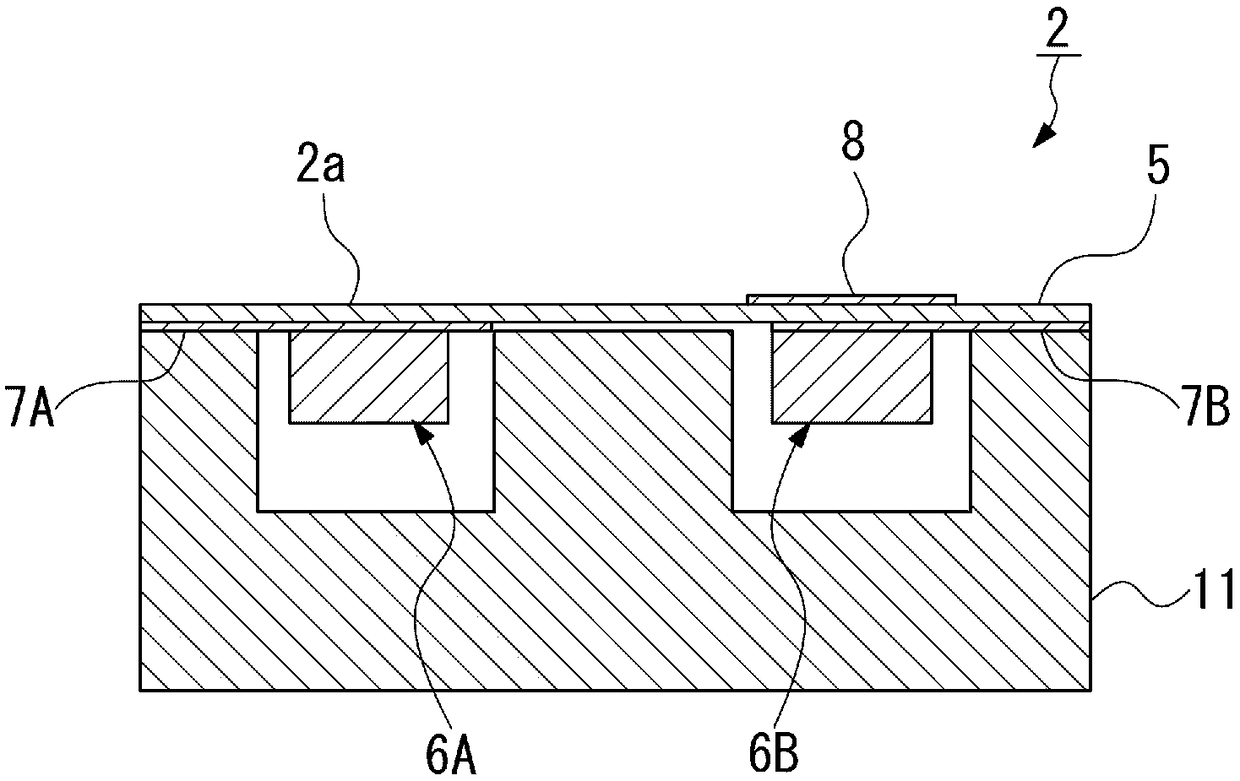

Non-contact power supply device provided with temperature sensor

InactiveCN102651575AEasy to secure the setting positionAccurate measurementElectromagnetic wave systemTransformersElectrical resistance and conductanceElectric power

The invention provides a non-contact power supply device provided with a temperature sensor, which can be used to measure the temperature of the plane coil accurately, to prevent the concave-convex parts of the appearance as much as possible, to set the temperature sensor or the accommodation of the coils easily, and has a good responsive performance. The non-contact power supply device provided with the temperature sensor is provided with a transmission coil (2) formed by the swirling-shaped coils, and a circuit part (3) used for controlling the AC voltage applied on the transmission coil (2). The AC voltage can be applied on the transmission coil (2) by supplying power to the device, to which the power is supplied, or the device to be charged by the electromagnetic induction. A film-shaped temperature sensor (5) of a thermosensitive part (4), the resistance of which can be changed according to the temperature, is disposed on the transmission coil (2), and the thermosensitive part (4) is winded on one part of the coils (2a).

Owner:MITSUBISHI MATERIALS CORP

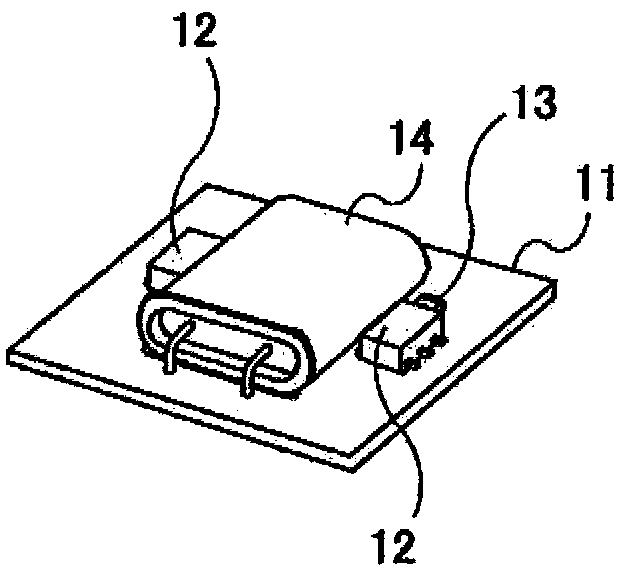

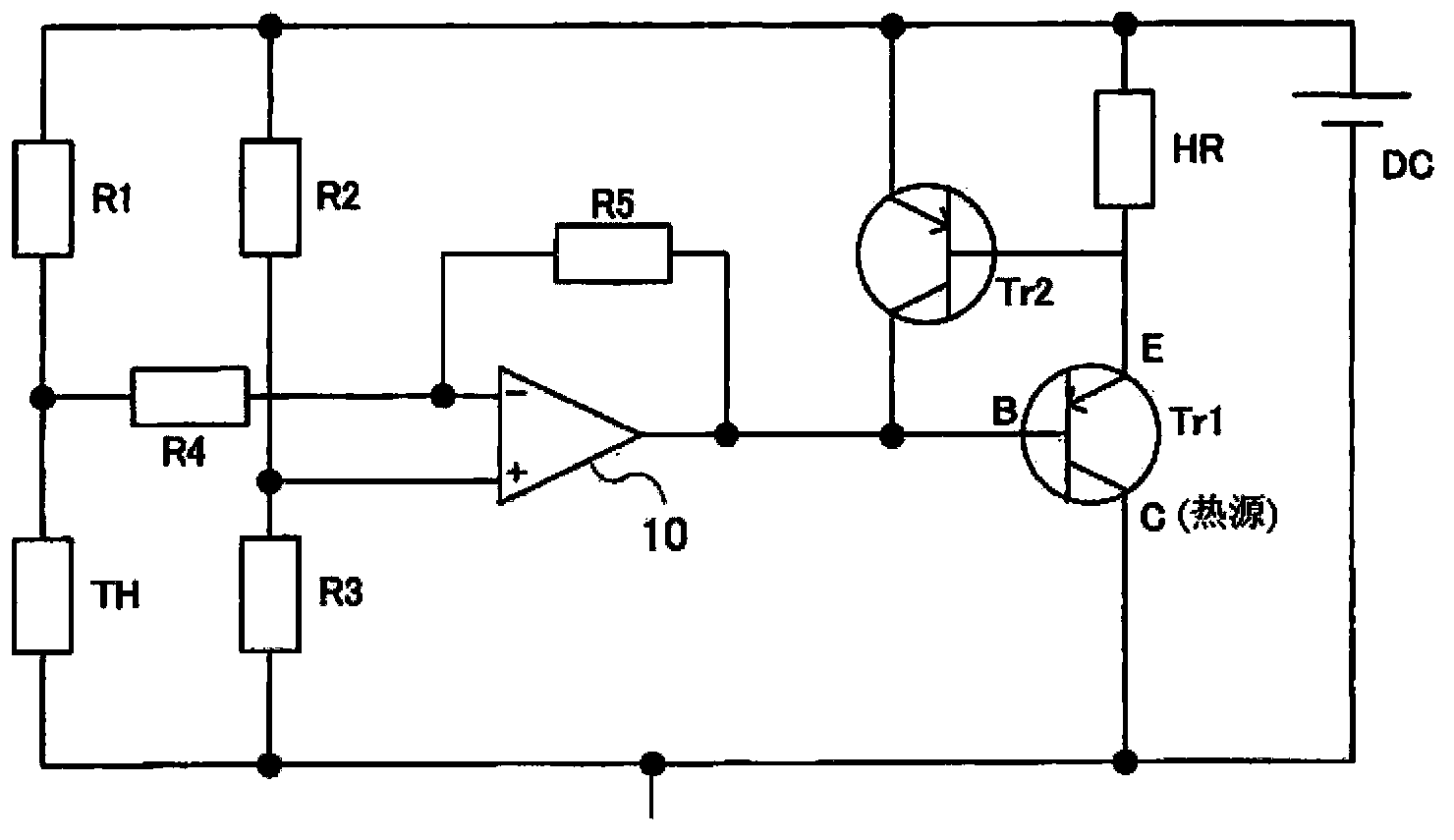

Oven controlled crystal oscillator

ActiveCN103546148AGood temperature characteristicsImprove thermal responsivenessGenerator stabilizationTemperature controlThermistor

An oven controlled crystal oscillator includes a crystal unit, a temperature control circuit, and a circuit board. The temperature control circuit is configured to control a temperature of the crystal unit. The crystal unit includes a flange that projects outward to an entire outer periphery in one end. The circuit board includes a depressed portion in which the flange is partially inserted. The temperature control circuit includes a power transistor, a thermistor as a temperature sensor, and a metal pattern. The power transistor becomes a heat source. The metal pattern commonly connects a ground terminal of the crystal unit, a collector of the power transistor, and a ground terminal of the thermistor. The crystal unit is positioned in a state where the flange is partially inserted in the depressed portion. The crystal unit is connected to the metal pattern.

Owner:NIHON DEMPA KOGYO CO LTD

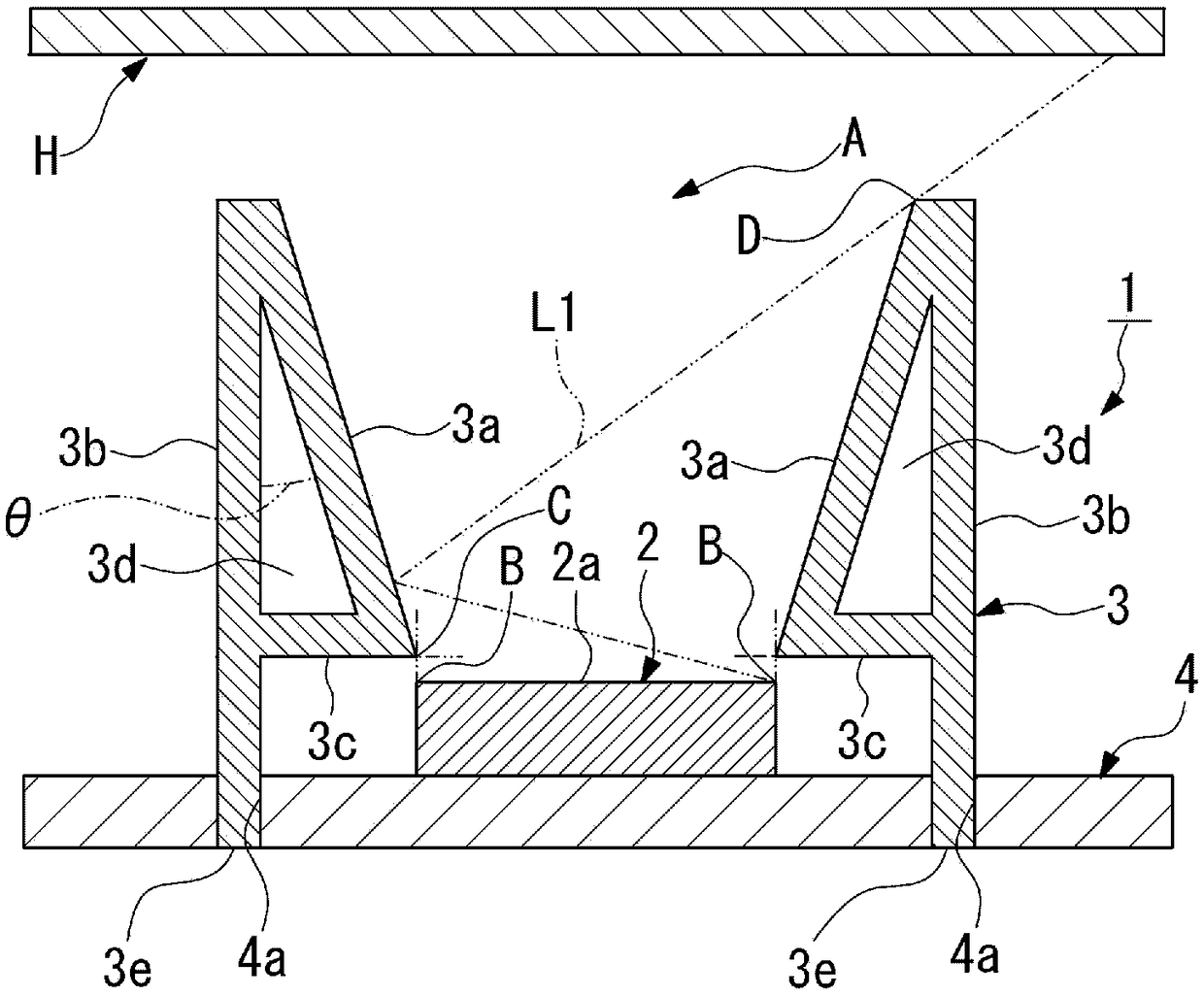

Infrared sensor device

InactiveCN108369136AInhibition reflexSuppress incidentRadiation pyrometryPhotometryLine sensorInfrared

Provided is a small-sized infrared sensor device which is capable of measuring temperatures with high accuracy, and wherein a light guide path member has a low heat capacity. An infrared sensor deviceaccording to the present invention is provided with: an infrared sensor main body; and a light guide path member that is arranged so as to surround at least a light receiving surface of the infraredsensor main body and has an opening positioned immediately above the light receiving surface. The light guide path member is formed of a plate material, and at least one surface among the surfaces that surround the light receiving surface is formed as an infrared light reflecting surface that is configured from an inclined plate part wherein the light receiving surface-side surface is inclined toward the opening.

Owner:MITSUBISHI MATERIALS CORP

Bearing assembly with lubrication cartridge

ActiveUS9850952B2Increase surface areaImprove heat transfer performanceRoller bearingsBearing componentsRolling-element bearingHoneycomb structure

A bearing assembly comprising a rolling element bearing having a first row of rolling elements arranged in a first bearing cavity between a first inner raceway and a first outer raceway of the bearing, and having a second row of rolling elements arranged in a second bearing cavity between a second inner raceway and a second outer raceway of the bearing. The assembly further comprises an annular grease cartridge arranged between the first and second rows of rolling elements. The annular grease cartridge is at least partly formed from a honeycomb structure having axially extending passageways filled with a grease lubricant, wherein at least some of passageways are open towards the first and second bearing cavities.

Owner:AB SKF

Bearing assembly with lubrication cartridge

ActiveUS20160138653A1Facilitated releaseIncrease surface areaRoller bearingsBall bearingsRolling-element bearingEngineering

A bearing assembly comprising a rolling element bearing having a first row of rolling elements arranged in a first bearing cavity between a first inner raceway and a first outer raceway of the bearing, and having a second row of rolling elements arranged in a second bearing cavity between a second inner raceway and a second outer raceway of the bearing. The assembly further comprises an annular grease cartridge arranged between the first and second rows of rolling elements. The annular grease cartridge is at least partly formed from a honeycomb structure having axially extending passageways filled with a grease lubricant, wherein at least some of passageways are open towards the first and second bearing cavities.

Owner:AB SKF

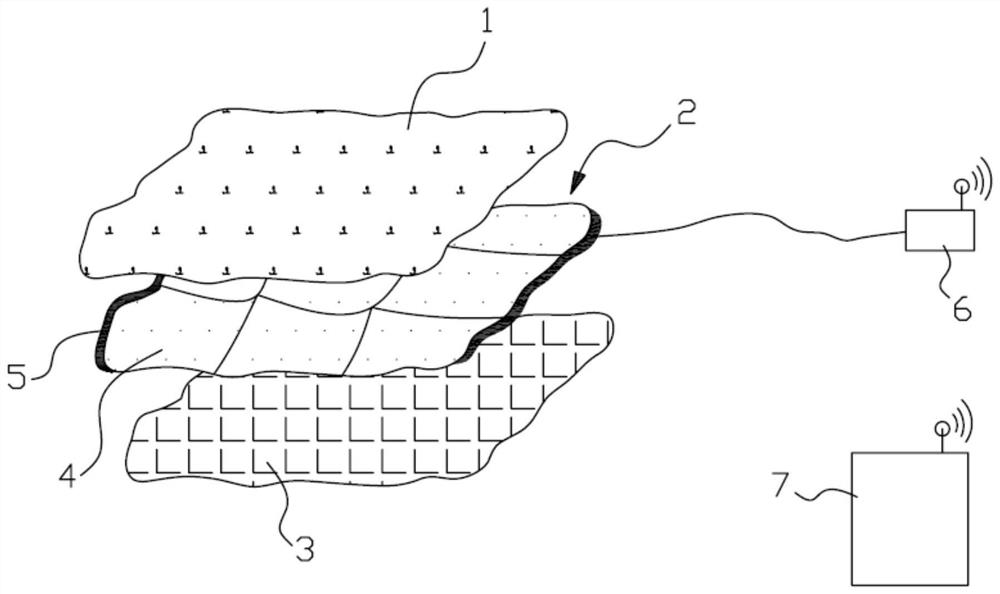

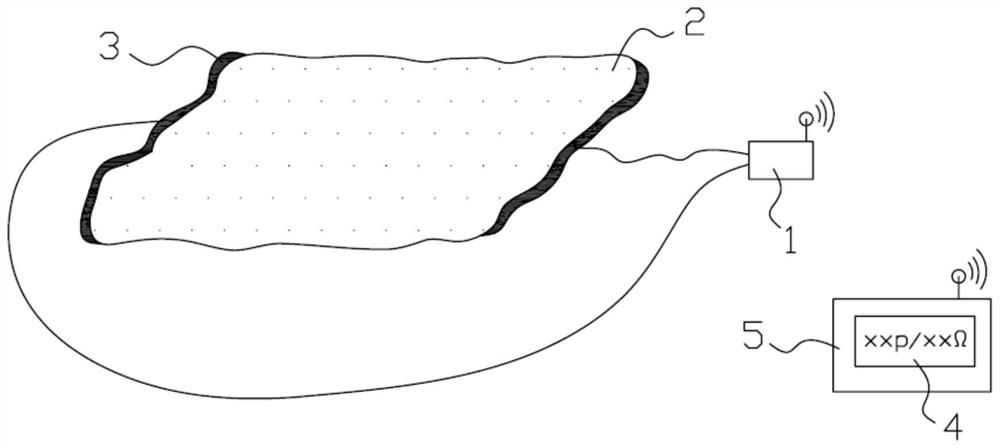

Mattress based on flexible sensors

ActiveCN113068961AHigh sensitivityImprove stabilityStuffed mattressesSpring mattressesGraphiteGraphene

The invention particularly relates to a mattress based on flexible sensors. The mattress comprises a skin-friendly layer, a sensing layer and a waterproof layer, wherein the sensing layer is formed by arranging a plurality of flexible sensors in an array mode, each flexible sensor comprises a conductive fabric, the conductive fabric comprises a flexible base material and a graphene film layer, and graphene conductive slurry on the graphene film layer is a solution with the effective content ratio of graphene to polyurethane being 1%-6%. The mattress further comprises a signal collecting device connected with the side surface of the sensing layer, wherein the signal collecting device is electrically connected with an intelligent display terminal, the signal collecting device comprises a signal collecting control module, the signal collecting control module sends a pressure signal or a humidity signal, which is obtained by the sensing layer, of a user on the mattress to the intelligent display terminal, and the intelligent display terminal analyzes according to the pressure signal or the humidity signal to obtain physiological parameter information of the user. The mattress is high in reliability, good in real-time responsiveness, high in monitoring precision, high in comfort and worthy of being widely popularized and applied.

Owner:QINGDAO UNIV

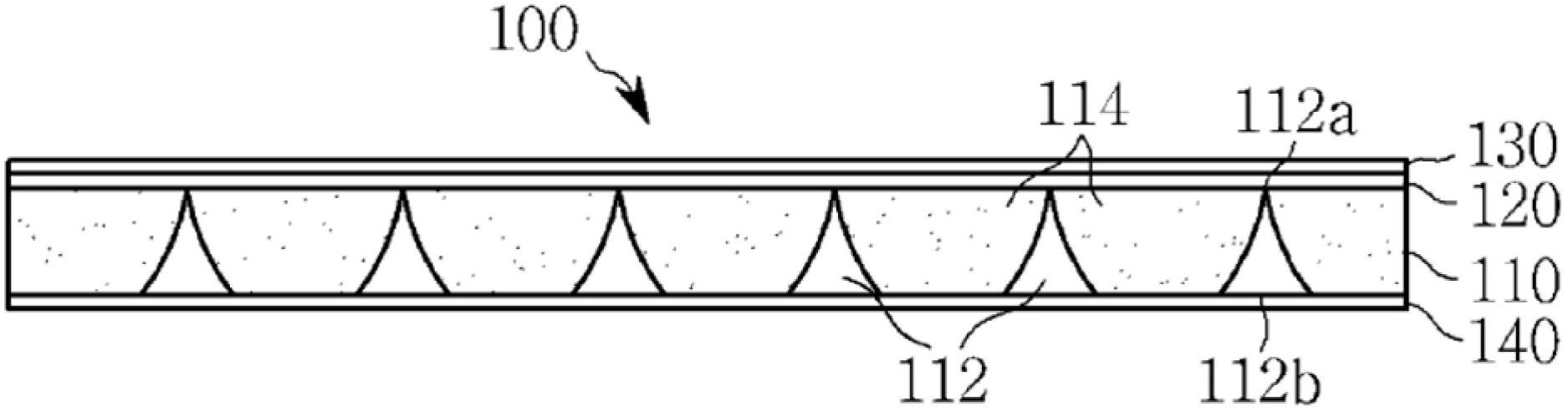

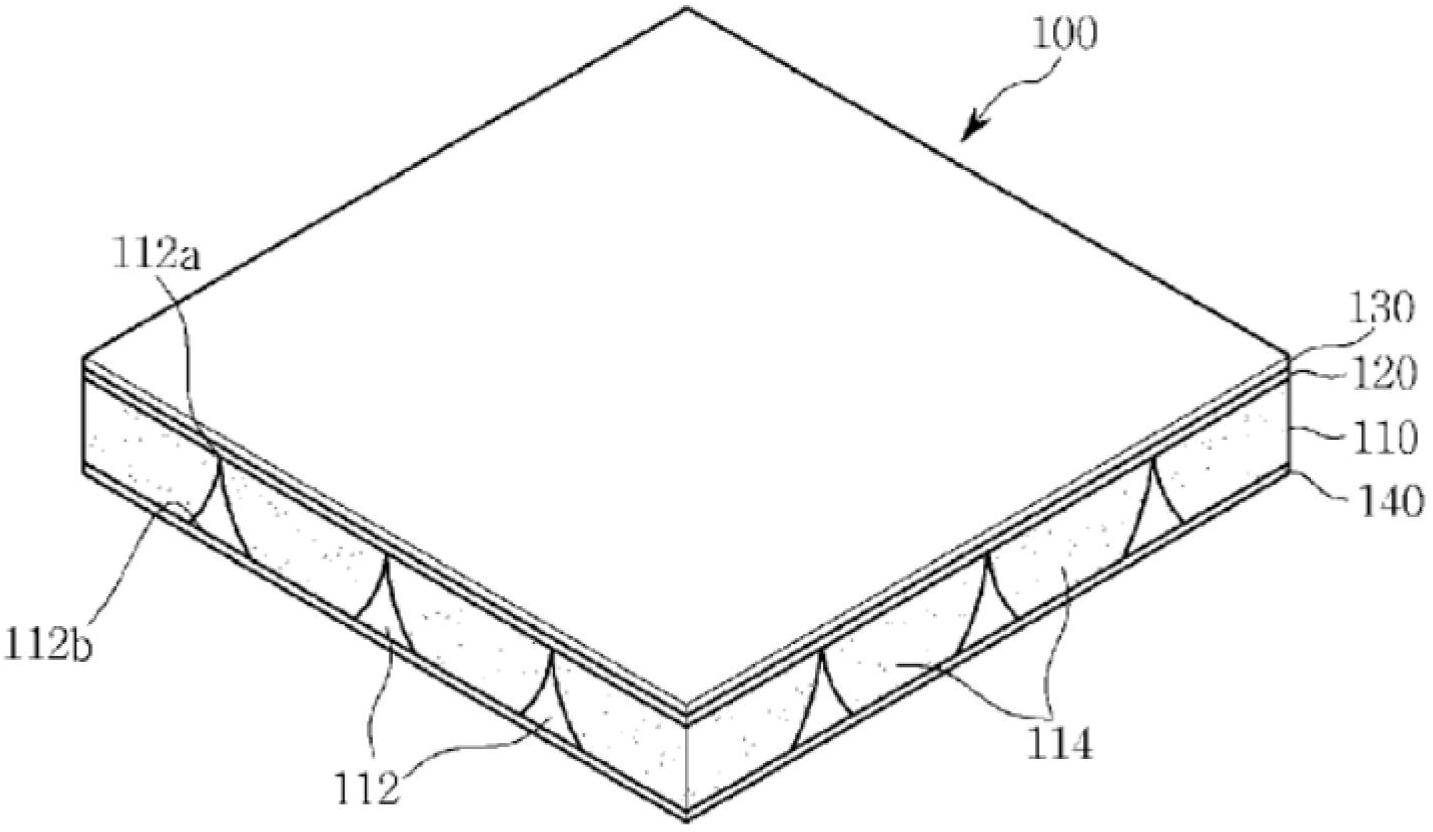

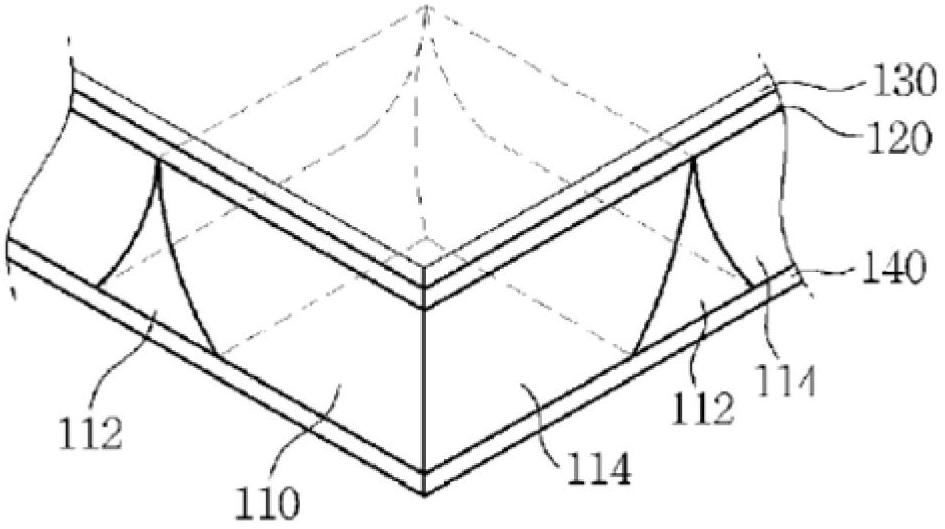

Hard panel for construction

InactiveCN102656326AEasy construction and durabilityExcellent insulationConstruction materialFlooring insulationsEngineeringSurface plate

The present invention relates to a hard panel for construction, comprising a hard panel body, an upper bonded fabric, and a lower bonded fabric. The hard panel body has one or more triangular cross-sectional elongate grooves. The apex of each of the elongate grooves contacts the upper surface of the hard panel body or is slightly spaced apart from the upper surface of the hard panel body, and each of the elongate grooves has a bottom side which penetrates through the lower surface of the hard panel body. The hard panel body is divided into two or more sections visible to the naked eye or physically divided by the triangular cross-sectional elongate grooves. The upper bonded fabric is bonded to the upper surface of the hard panel body so as to exhibit limited elasticity. The lower bonded fabric is bonded to the lower surface of the hard panel body so as to exhibit limited elasticity. According to the present invention, triangular cross-sectional elongate grooves are formed at a predetermined interval in the hard panel body, and the upper bonded fabric is bonded to the upper surface of the hard panel body and the lower bonded fabric is bonded to the lower surface of the hard panel body, thus providing the hard panel with limited fine flexibility. Therefore, the hard panel of the present invention can be precisely and smoothly attached even to a non-uniform surface, thereby enabling easy construction and providing durability.

Owner:李昌镐

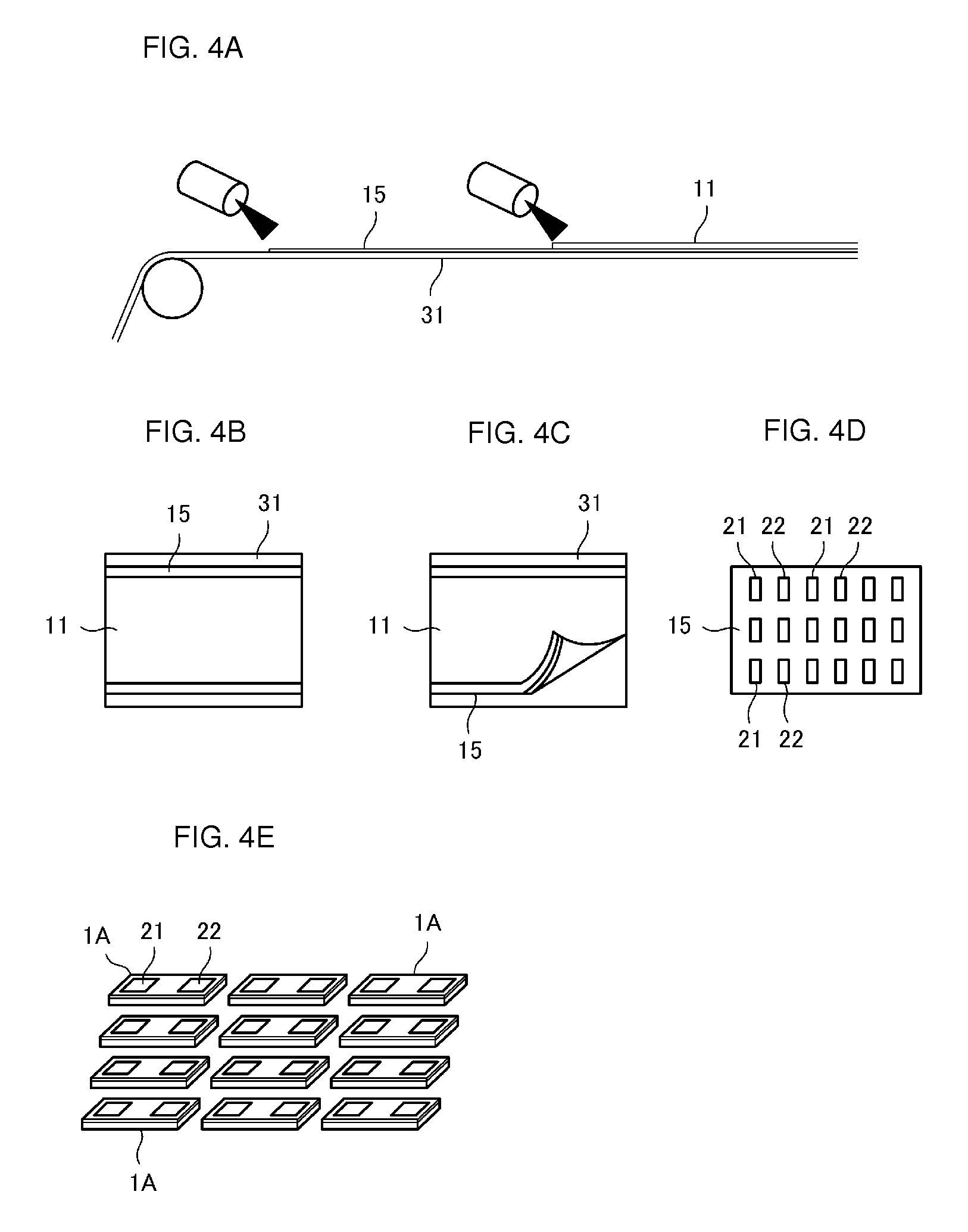

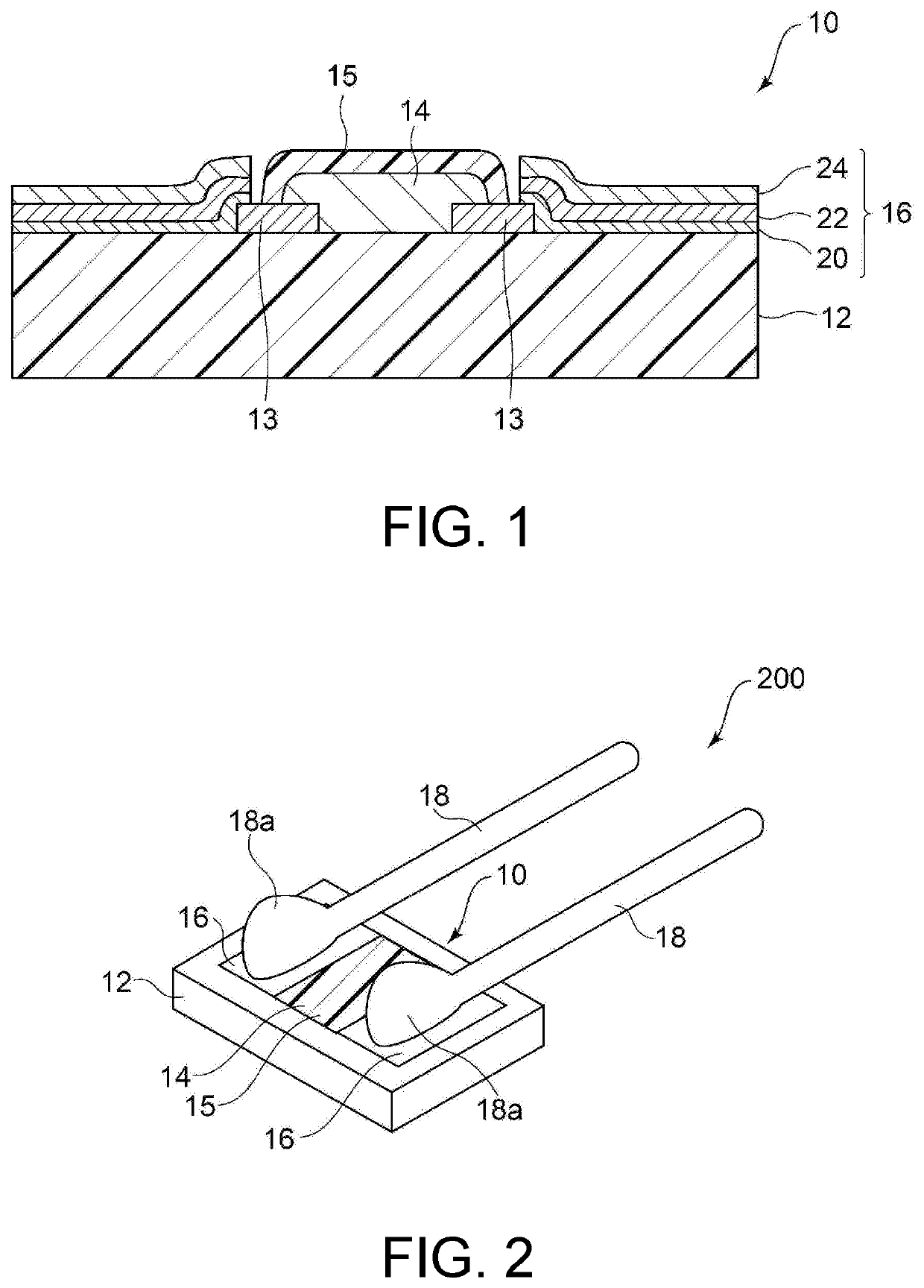

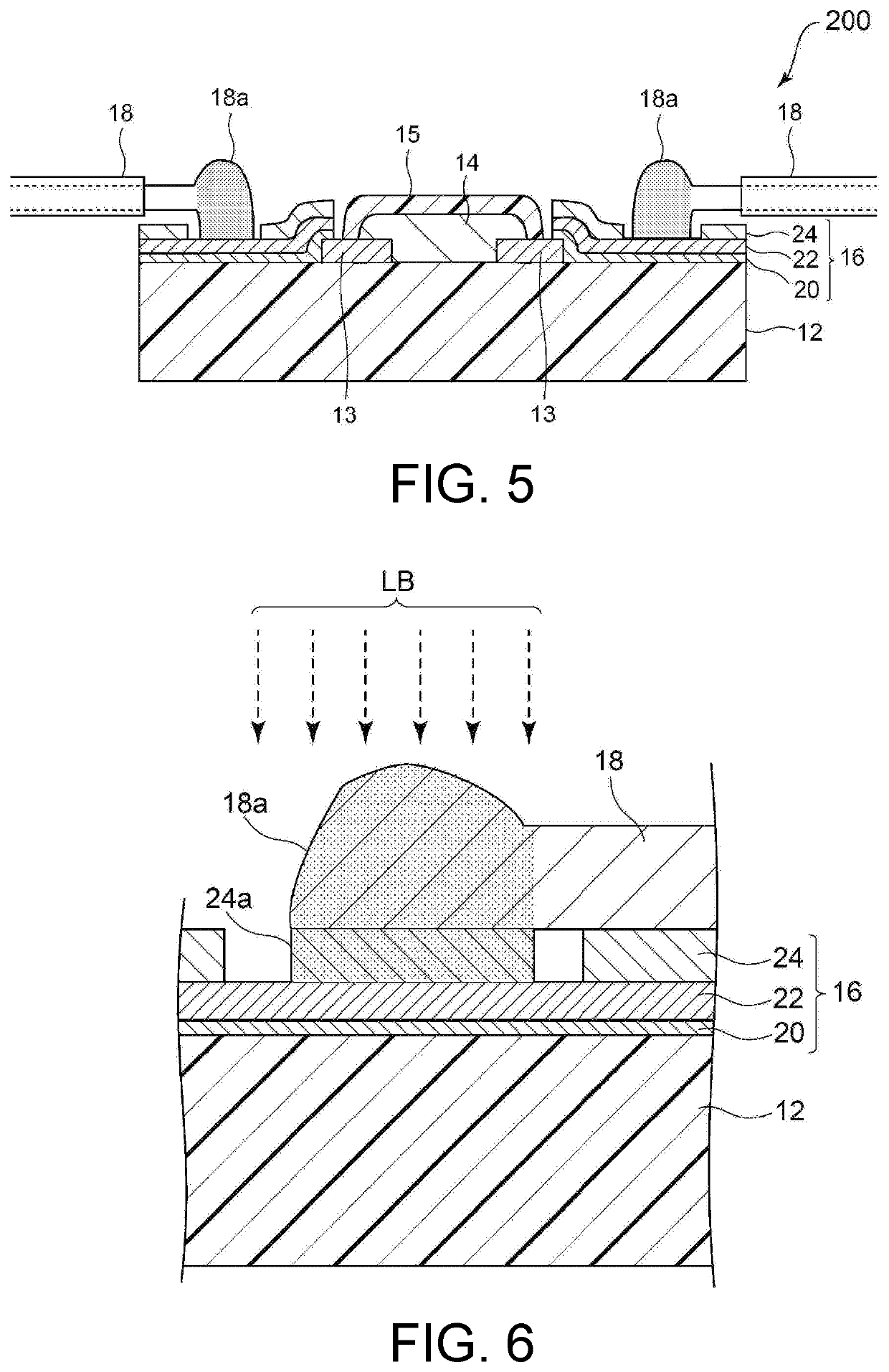

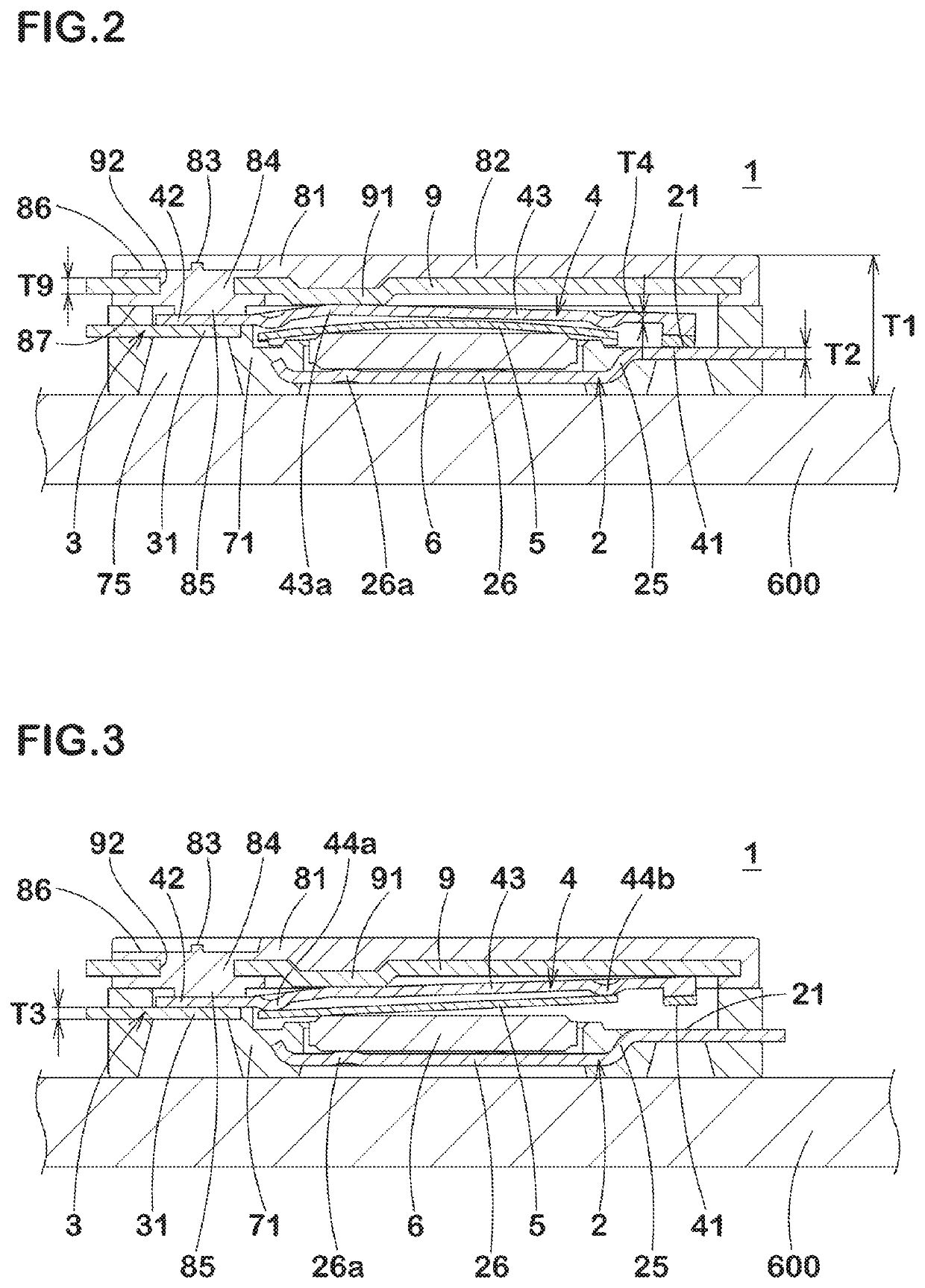

Electronic component for welding, mounted board and temperature sensor

ActiveUS11215514B2Reduce thicknessImprove thermal responsivenessThin/thick film capacitorResistor terminals/electrodesCapacitanceElectrical connection

The present invention enables the achievement of: high density mounting by means of an electronic component for welding; and improvement of thermal responsivity and tensile strength at high temperatures by means of reduction in size and thickness of a temperature sensor. An electronic component for welding, which has a function of a resistor, a capacitor, an inductor or the like, comprises: an insulating substrate; a function part and a bonding electrode part, which are provided on the insulating substrate; and a lead which is electrically connected to the bonding electrode part. The bonding electrode part is configured of: an adhesive active metal layer which is formed from a high-melting-point metal on the insulating substrate; a barrier layer which is formed from a high-melting-point metal on the active metal layer; and a bonding metal layer which is mainly composed of a low-melting-point metal and is formed on the barrier layer.

Owner:SEMITEC

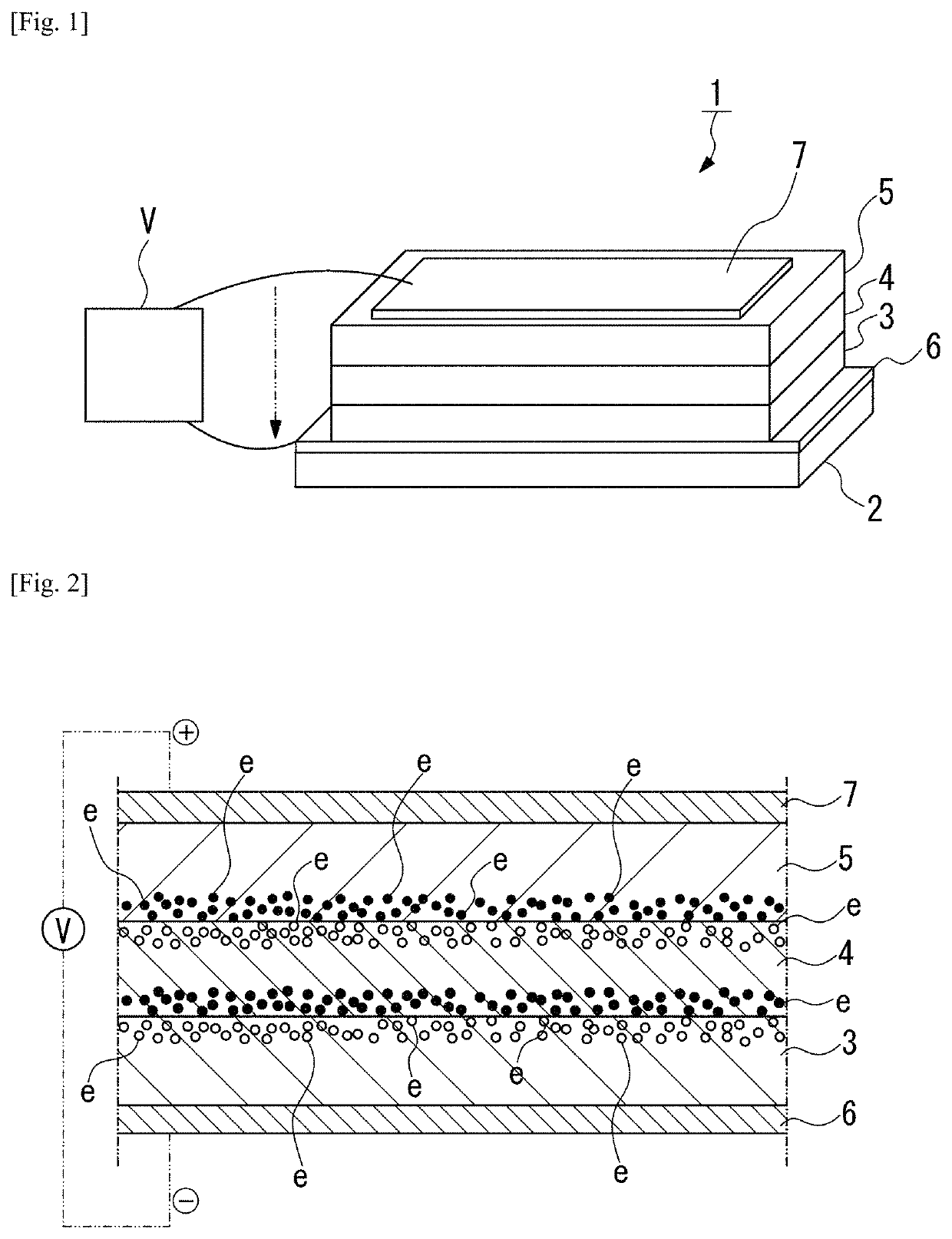

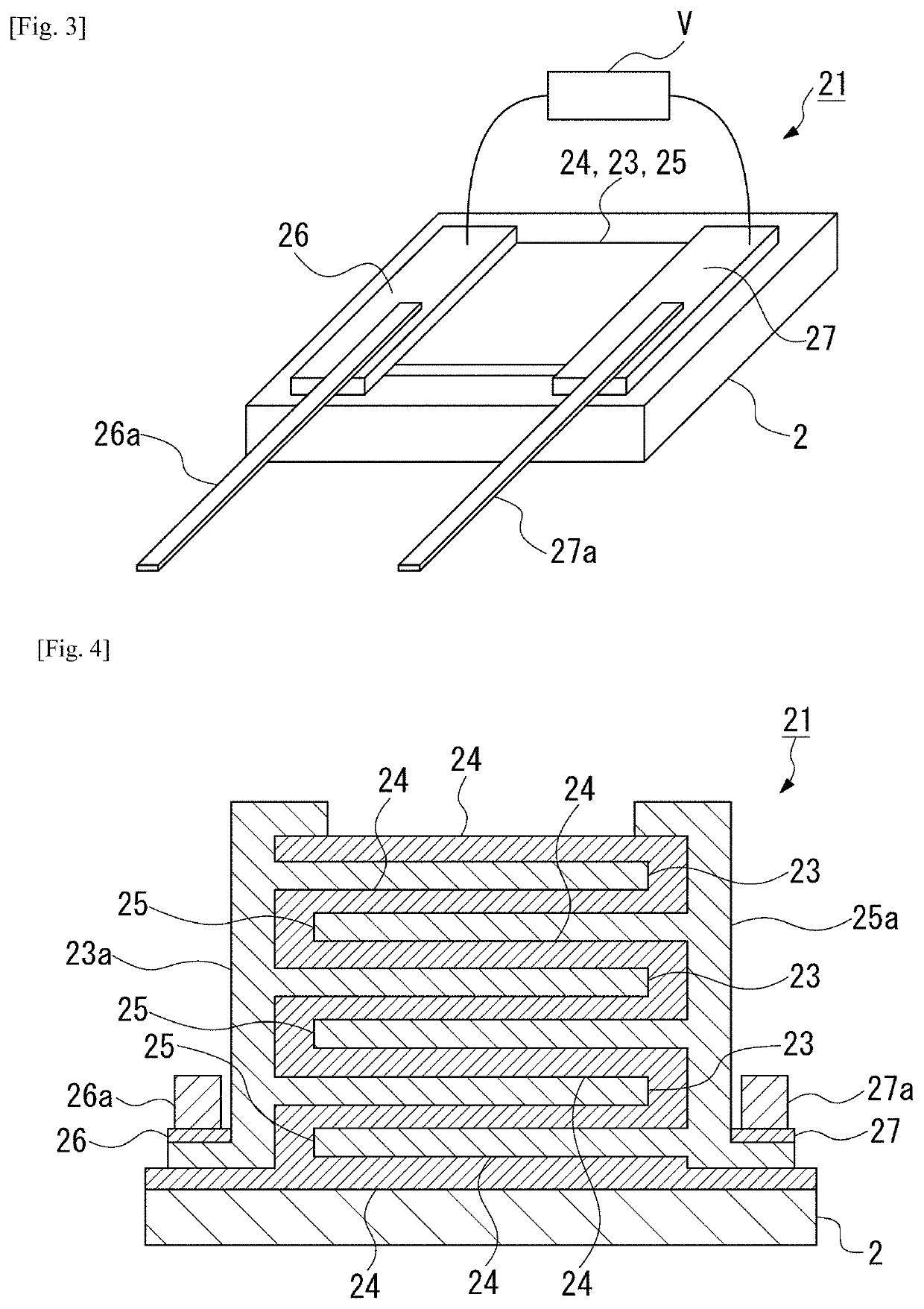

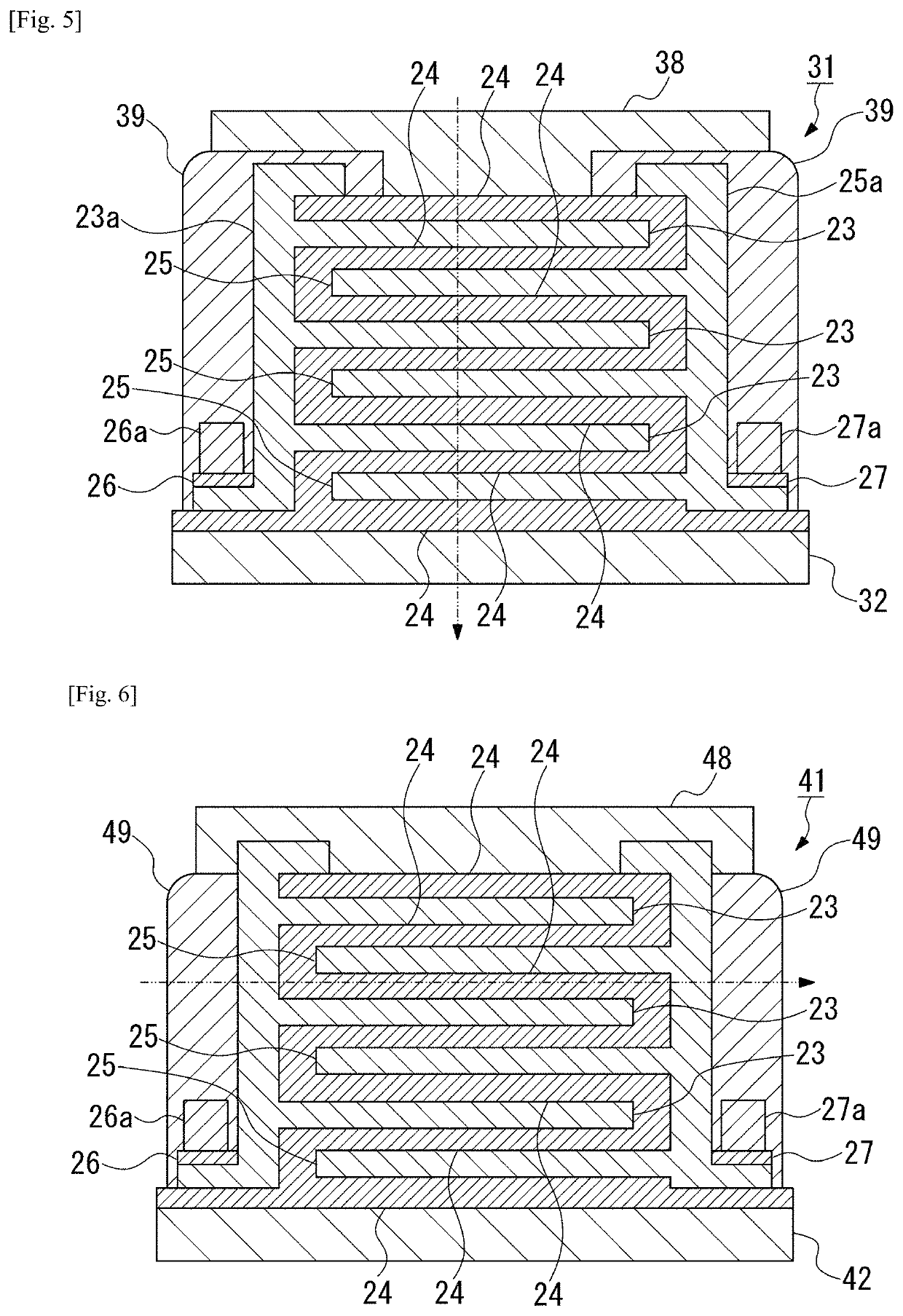

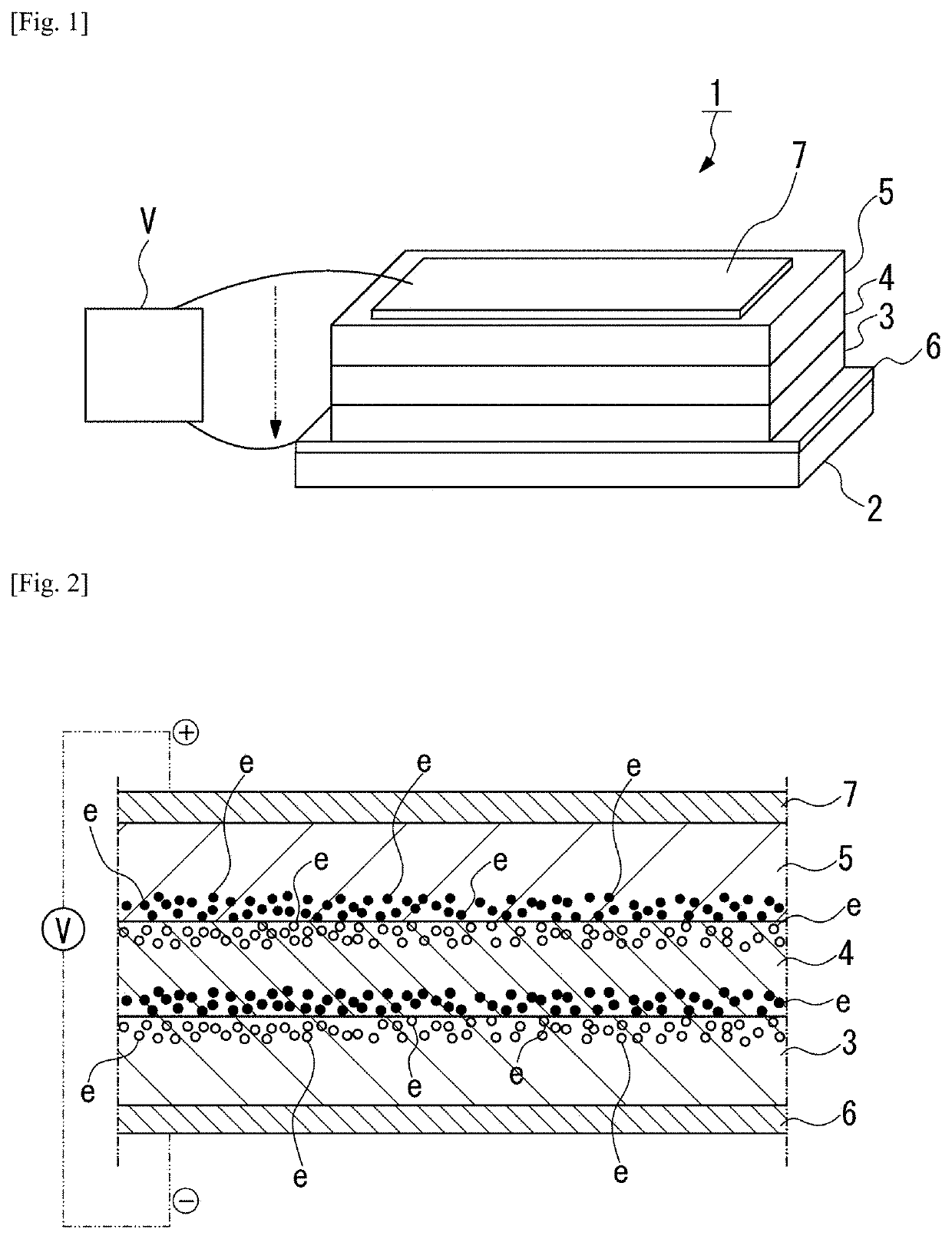

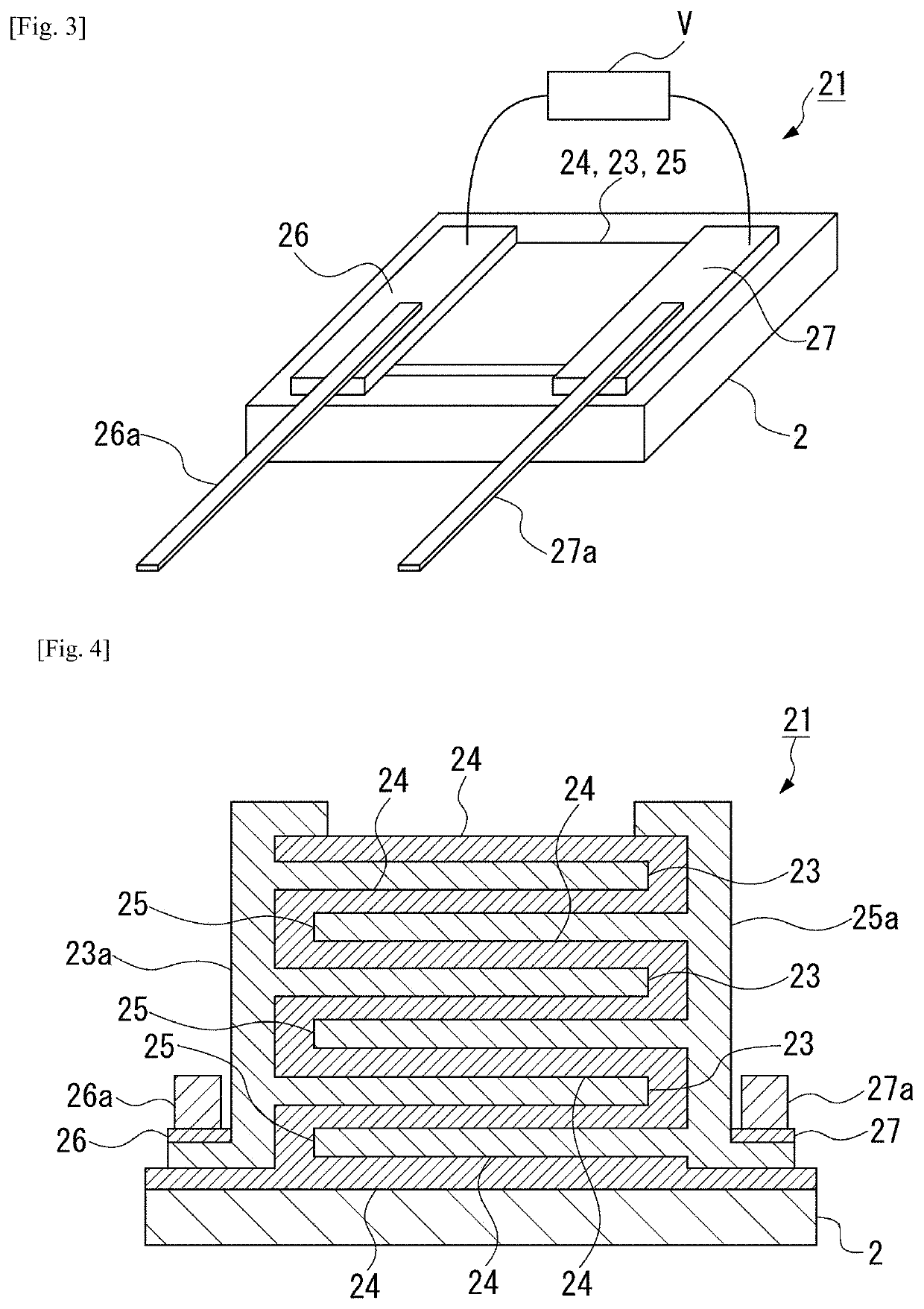

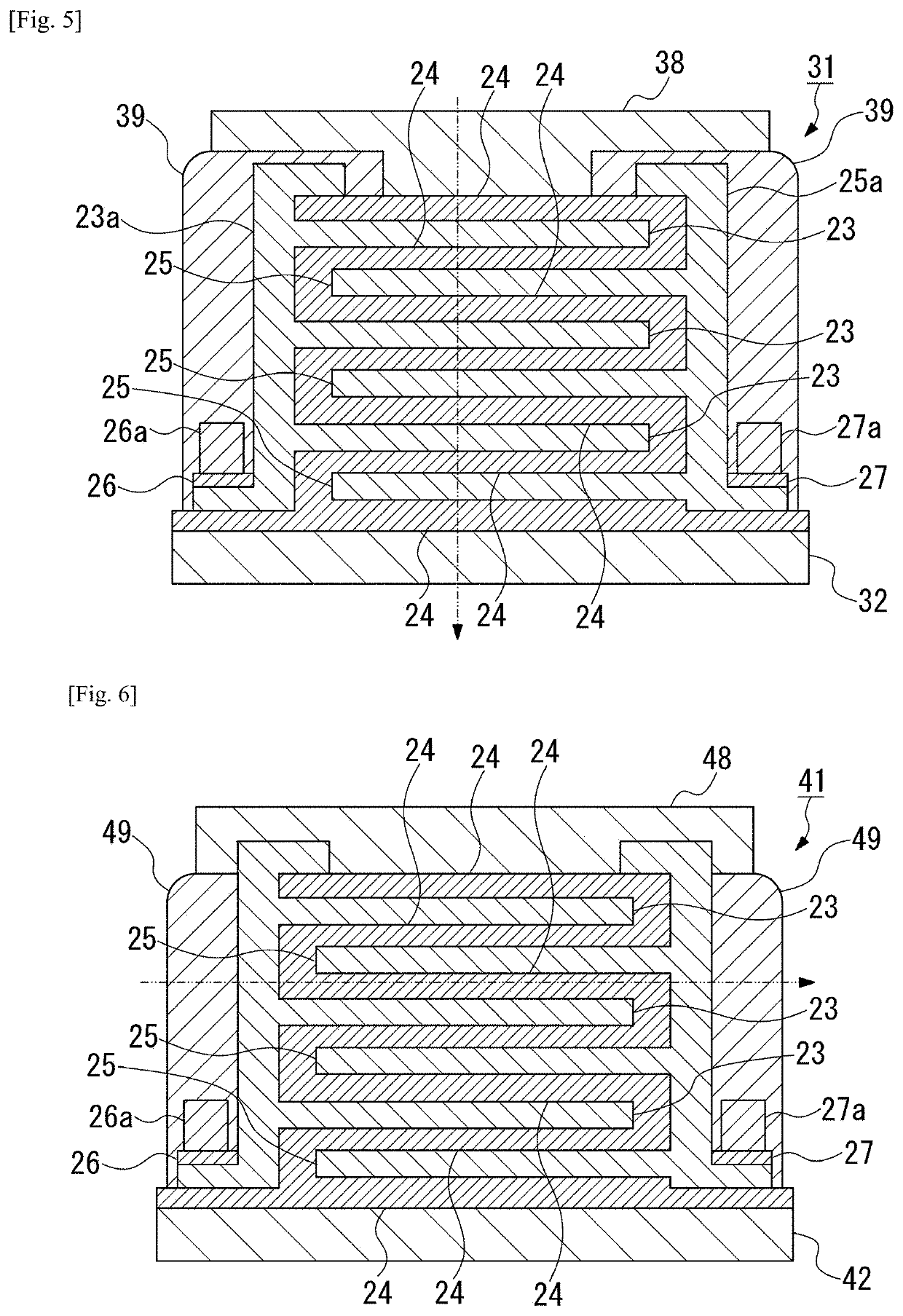

Heat flow switching element

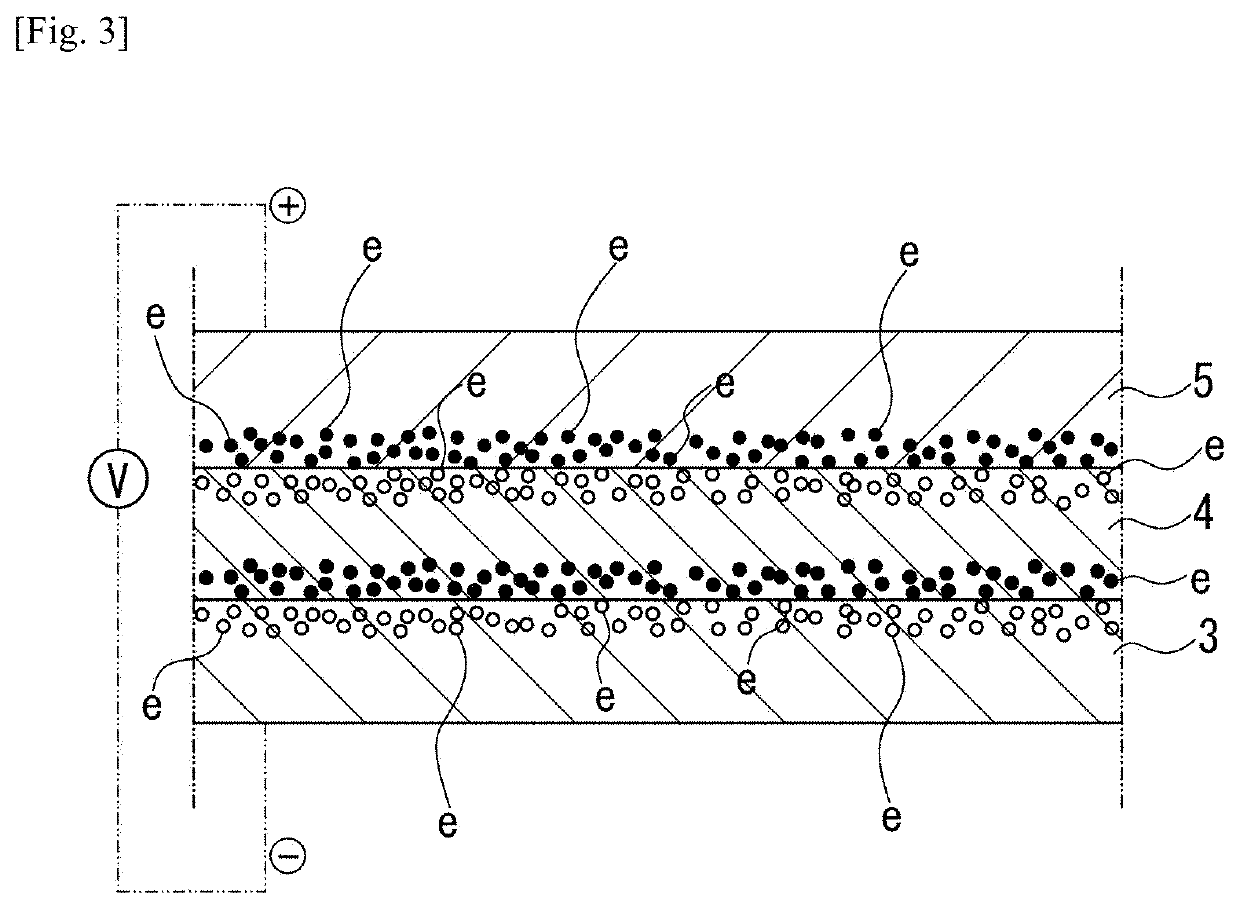

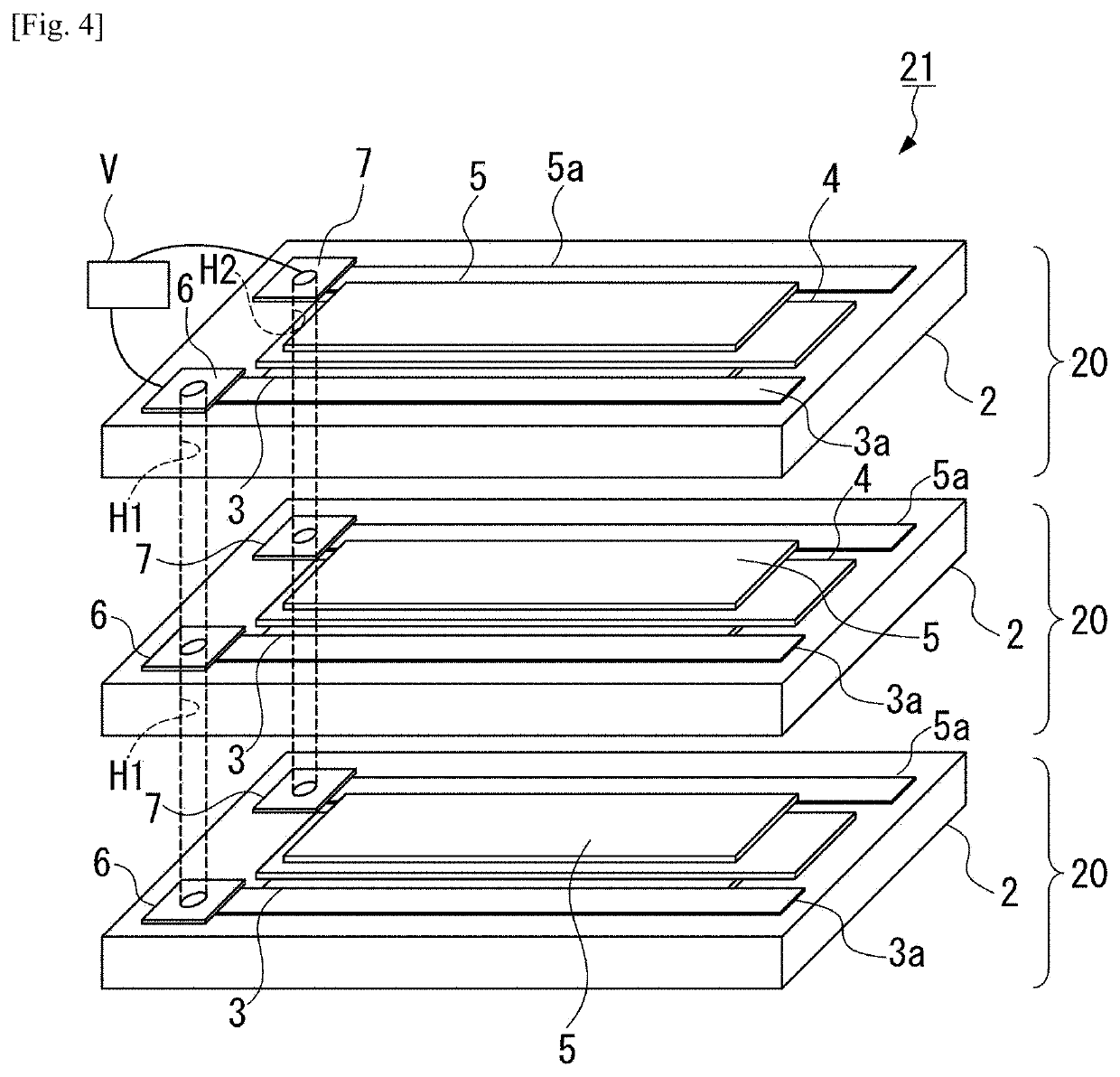

PendingUS20210249577A1Large variation in thermal conductivityImprove thermal responsivenessThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHeat flowEngineering physics

A substrate of which at least an upper surface is formed of an insulating material, an N-type semiconductor layer, a P-type semiconductor layer, and an insulator layer are provided, one semiconductor layer of the N-type semiconductor layer and the P-type semiconductor layer is formed on the substrate, the insulator layer is formed on the one semiconductor layer, and the other semiconductor layer of the N-type semiconductor layer and the P-type semiconductor layer is formed on the insulator layer. In this way, since electric charges induced by an external voltage are generated both at and near an interface between the N-type semiconductor layer and the insulator layer and at and near an interface between the P-type semiconductor layer and the insulator layer, an amount of the generated charge increases, and thus a larger variation in thermal conductivity and high thermal responsiveness can be obtained.

Owner:MITSUBISHI MATERIALS CORP +1

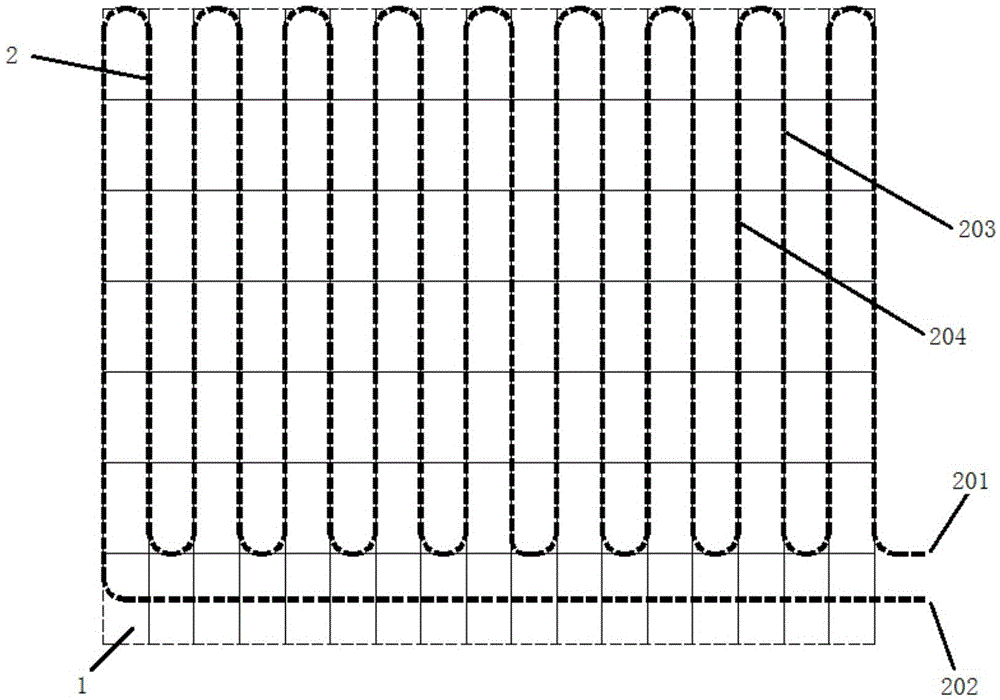

Ceiling radiant tube structure embedded under reinforcing steel bars and construction method of ceiling radiant tube structure

PendingCN106759970AReduce the amount requiredReduce total calorific valueLighting and heating apparatusFloorsRebarThermal efficiency

The embodiment of the invention discloses a ceiling radiant tube structure embedded under reinforcing steel bars and a construction method of the ceiling radiant tube structure. The ceiling radiant tube structure embedded under the reinforcing steel bars comprises a reinforcing mesh, S-type ceiling radiant tubes, a floor and a concrete layer, wherein the reinforcing mesh comprises at least one grid; the ceiling radiant tubes are connected with the reinforcing mesh through the grids of the reinforcing mesh; the reinforcing mesh and the ceiling radiant tubes which are connected are arranged on the bottom face of the floor; the distance between the reinforcing mesh and the ceiling radiant tubes which are connected and the bottom face of the floor is 5 mm; and the gaps among the reinforcing mesh, the ceiling radiant tubes and the bottom face of the floor are filled with the concrete layer. Thus, the problems that a current heat insulation constant-temperature scheme is low in heat utilization efficiency, high in cost and difficult to maintain are solved.

Owner:MOMA CHINA CO LTD

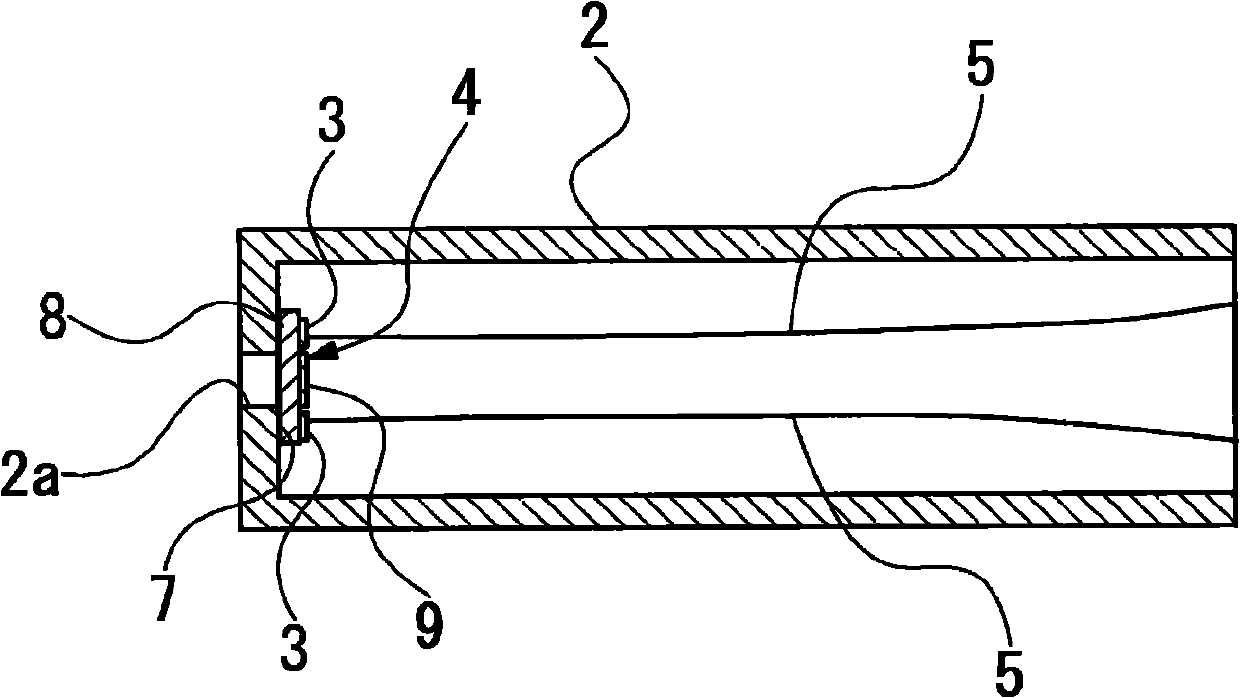

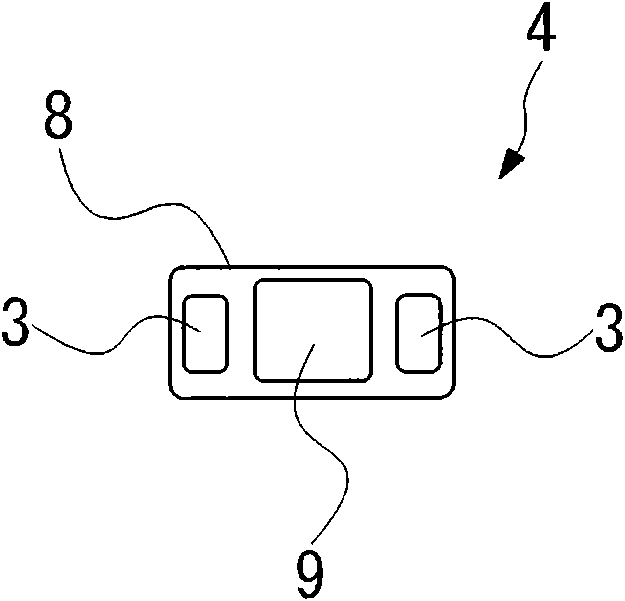

Temperature sensor

InactiveCN101995305AImprove thermal responsivenessThermometer detailsThermometers using electric/magnetic elementsEngineeringHeat sensitive

The present invention provides a temperature sensor, used for measuring temperature of EGR gas and the like, and capable of further improving thermal response. The temperature sensor comprises a bottom cylindrical metal pipe (2), a heat-sensitive element (4) arranged on an inner bottom face of the metal pipe (2) and provided with a pair of terminal electrodes, and a pair of conductors (5) connected to the terminal electrodes, the bottom of the metal pipe (2) is provided with a through hole (2a), and the heat-sensitive element (4) is configured to block the through hole (2a). Thereby, at least a part of the heat-sensitive element (4) is bared outwards from one end part of the metal pipe (2), and thermal response is improved by directly contacting with an external discharge gas and the like.

Owner:MITSUBISHI MATERIALS CORP

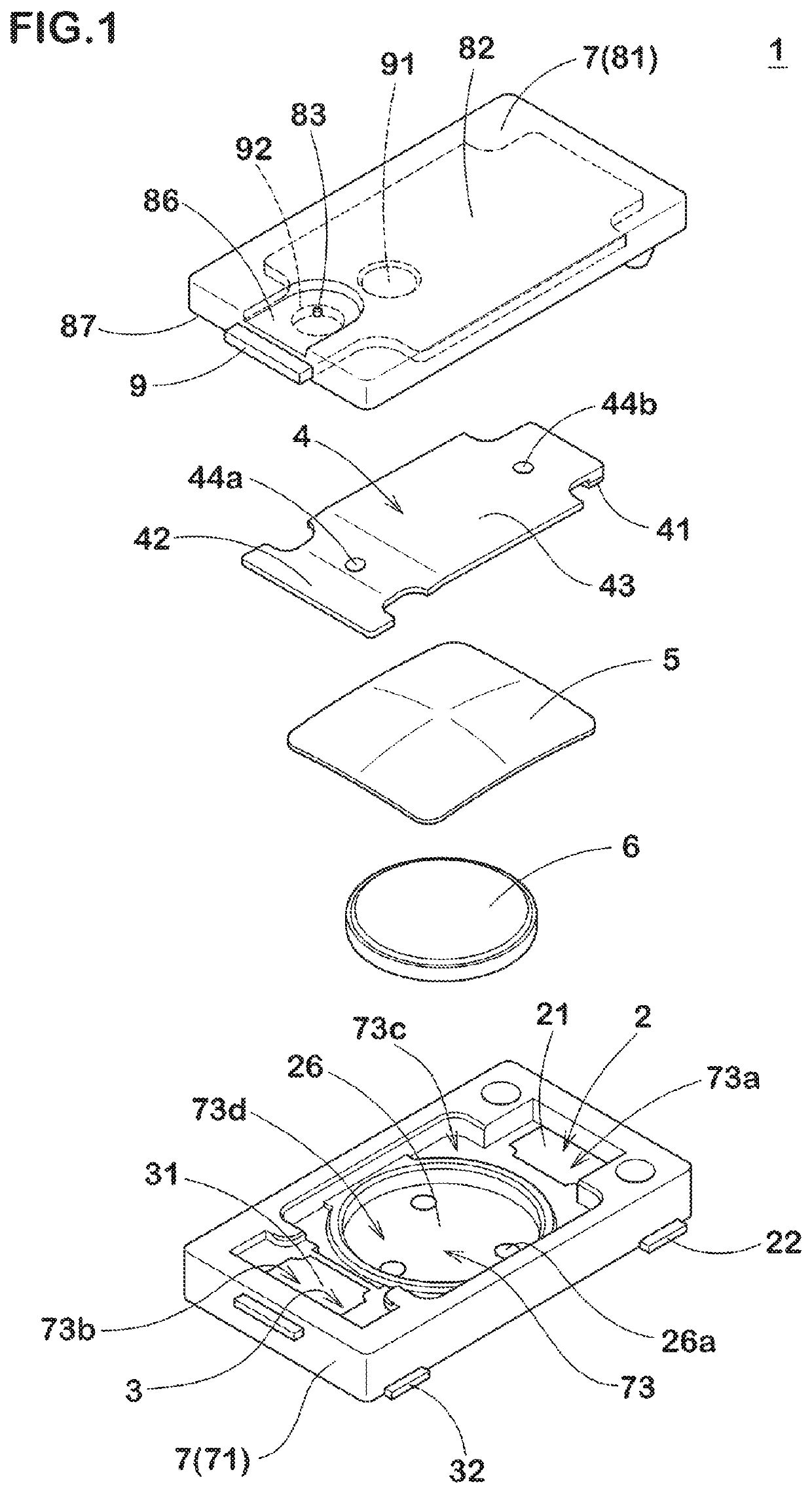

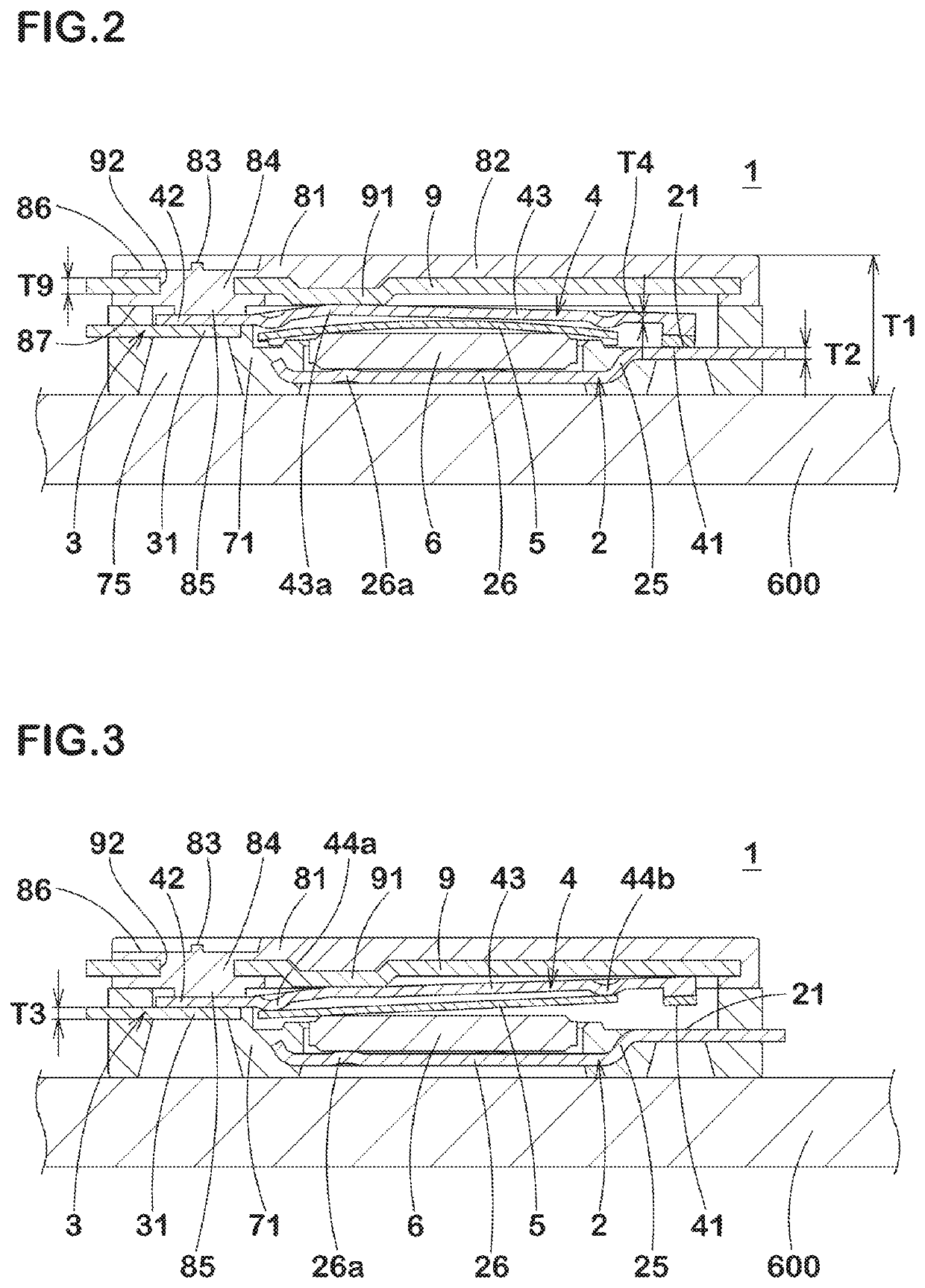

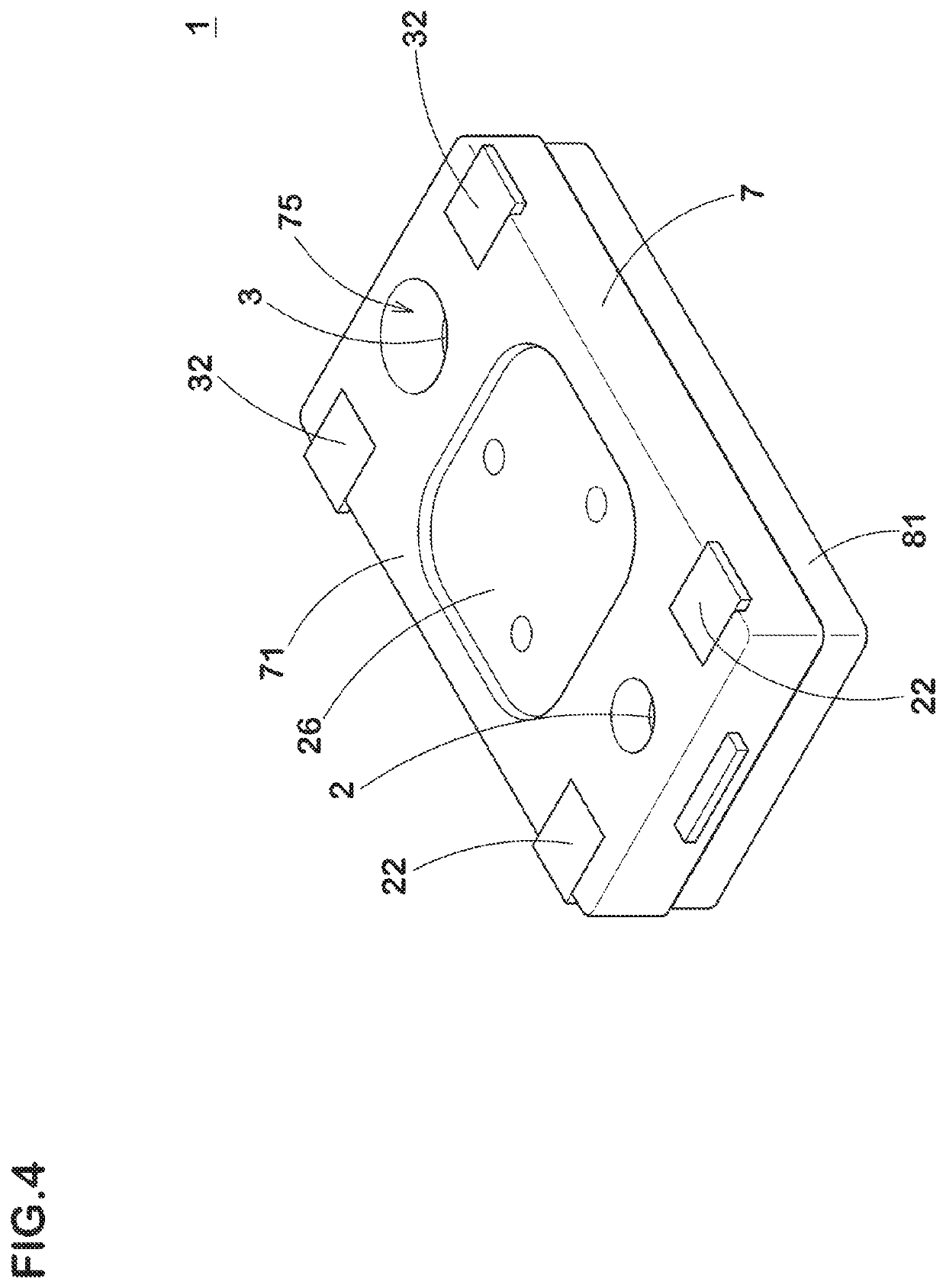

Breaker and safety circuit provided with same

ActiveUS20200144009A1Increase delayImprove thermal responsivenessCell component detailsThermal switch detailsHemt circuitsEngineering

A breaker 1 includes a fixed piece 2 having a fixed contact 21, a movable piece 4 including a movable contact 41 and having the movable contact 41 so as to be pressed against and in contact with the fixed contact 21, a thermally actuated element 5 shifting the movable piece 4 from a conductive state to a cut-off state in accordance with a temperature change, and a case 7 accommodating the fixed piece 2, the movable piece 4, and the thermally actuated element 5. The case 7 includes a case main body 71 accommodating the movable piece 4 and the thermally actuated element 5, a lid member 81 covering a housing concave portion 73 of the case main body 71, and a metal plate 9 embedded in the lid member 81. Heat capacity of the metal plate 9 is larger than heat capacity of the fixed piece 2.

Owner:BOURNS KK

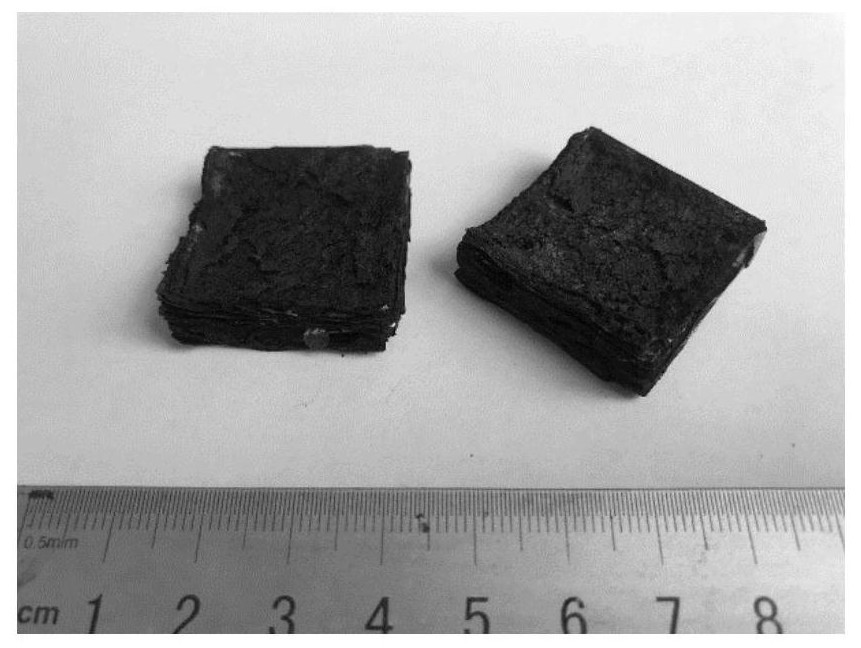

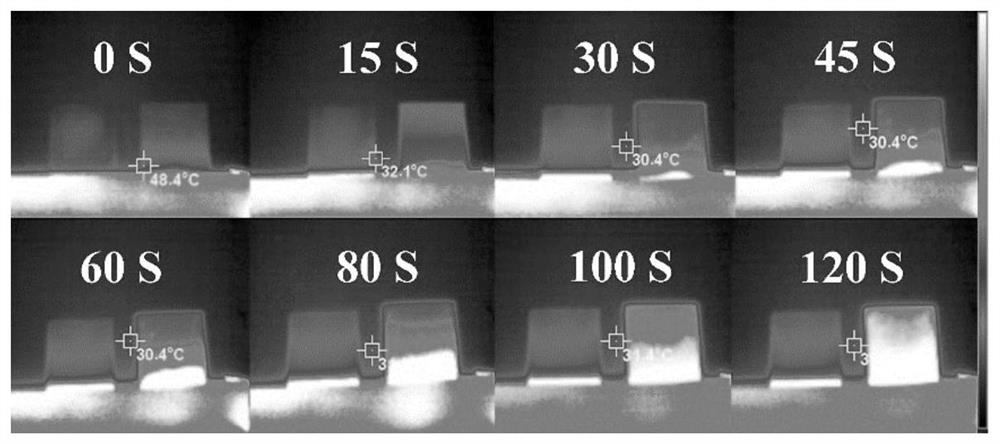

A graphene-based composite phase change material with hierarchical thermal conductivity structure and preparation method thereof

ActiveCN113265230BImprove thermal responsivenessIncrease loading capacityChemical industryHeat-exchange elementsThin membraneGraphite

The invention is a graphene-based composite phase change material with a hierarchical heat conduction structure. The composite material is obtained by impregnating an organic phase change material with a hierarchical heat conduction structure composed of a two-dimensional graphene film with high thermal conductivity and a three-dimensional graphene heat conduction network as a skeleton. Compared with the existing phase change materials, the composite phase change material solves the contradiction between high thermal conductivity and high enthalpy, the thermal response performance is greatly improved, the thermal conductivity is increased by 160 times and the phase change material can maintain more than 70% The enthalpy value can greatly promote the application of phase change materials in temperature management, energy dispatching and other fields.

Owner:山东国烯新材料创新中心有限公司

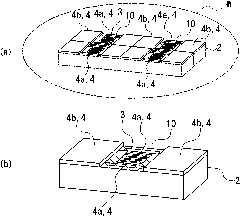

Heat flow switching element

ActiveUS11362255B2Significant changeGood thermal responseThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsDielectricHeat flow

Provided is a heat flow switching element which has a larger change in a thermal conductivity and has excellent thermal responsiveness. The heat flow switching element includes an N-type semiconductor layer, an insulator layer laminated on the N-type semiconductor layer, a P-type semiconductor layer laminated on the insulator layer, an N-side electrode connected to the N-type semiconductor layer, and a P-side electrode connected to the P-type semiconductor layer. In particular, the insulator layer is formed of a dielectric. Also, a plurality of N-type semiconductor layers and P-type semiconductor layers are laminated alternately with the insulator layer interposed therebetween.

Owner:MITSUBISHI MATERIALS CORP +1

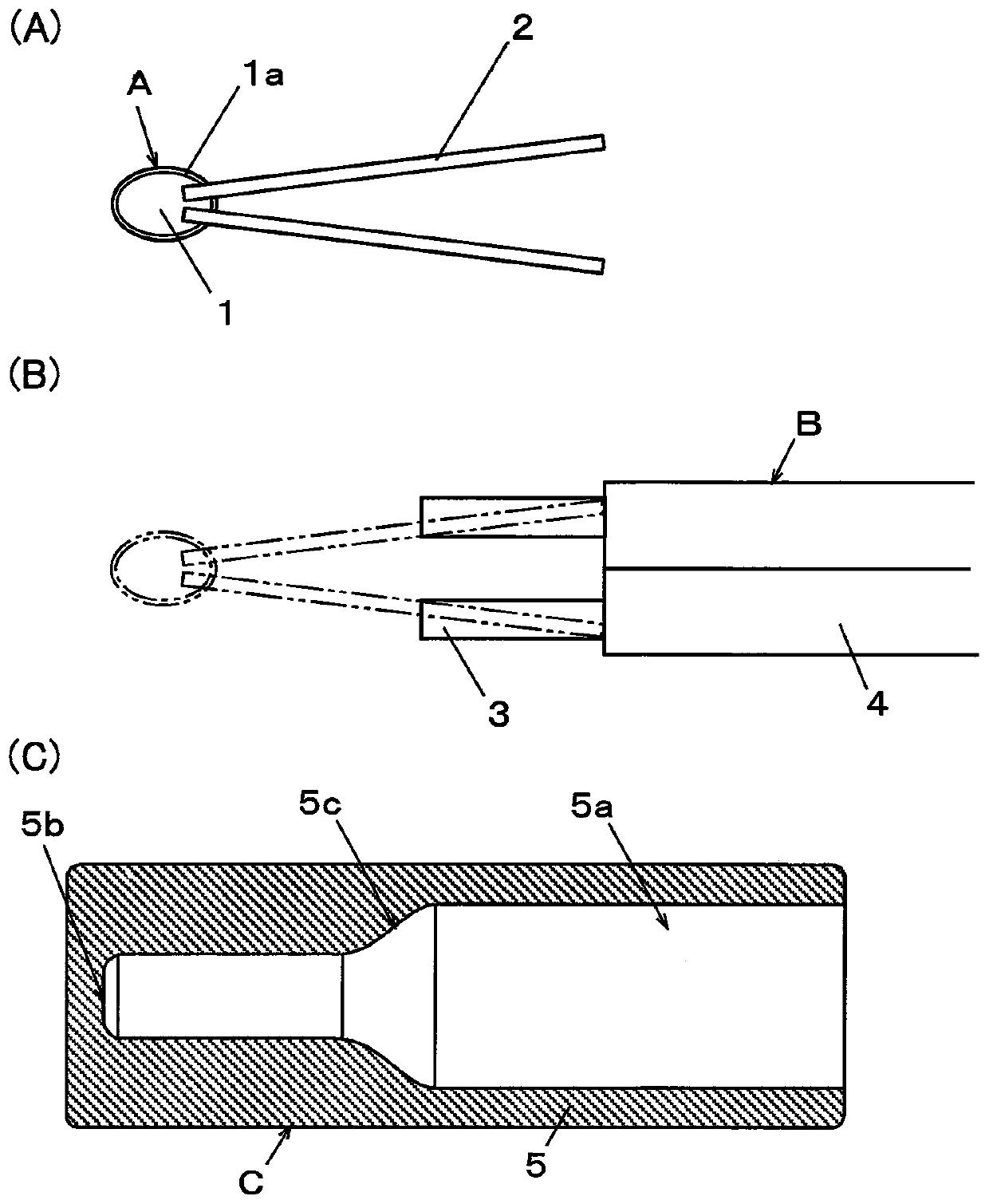

Temperature sensor and manufacturing method for same

InactiveCN111247407ALocation determinationStress reliefThermometer detailsThermometers using electric/magnetic elementsEngineeringResin coating

The present invention relates to: a temperature sensor in which a thermistor element is resin molded; and a manufacturing method for the temperature sensor. Provided is a temperature sensor and a manufacturing method therefor, in which airtightness of a thermistor element is enhanced and performance stability and yield during manufacturing are increased. The temperature sensor comprises: a sensorpart (A) composed of a thermistor element (1) and a connection terminal (2); a cable part (B) connected to the connection terminal (2); and a coating part (C) that covers the entirety of the sensor part (A) and the tip of the cable part (B). The coating part (C) comprises: a sensor case (5) having an internal space (5a) that tapers towards the center of the tip where the thermistor element (1) isstored; an elastic resin coating layer (6) covering the entire surface of the thermistor element (1); and a filling resin layer (7) that fills the space between the inner surface of the sensor case (5) and the elastic resin coating layer (6).

Owner:TATEYAMA KAGAKU SENSOR TECH

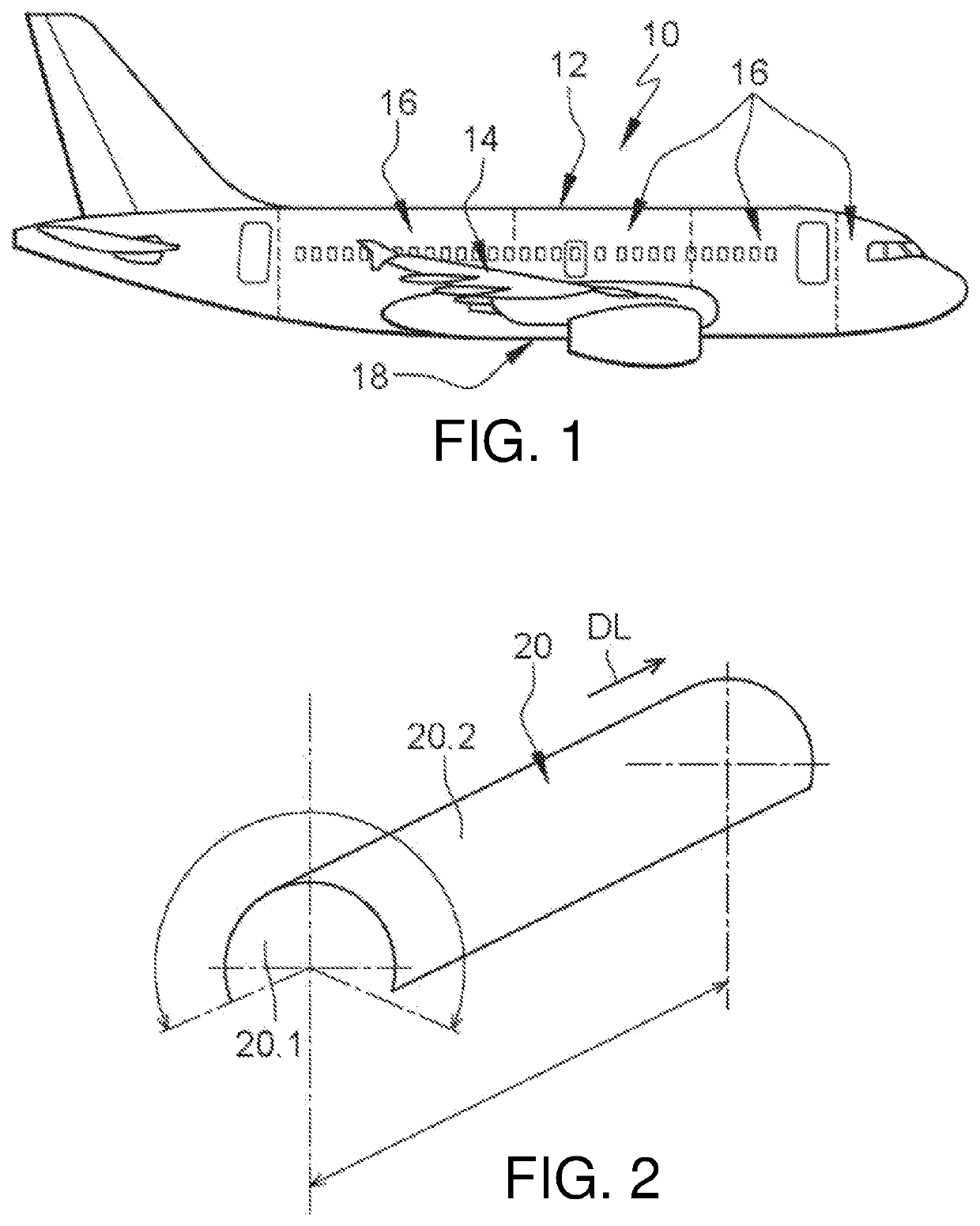

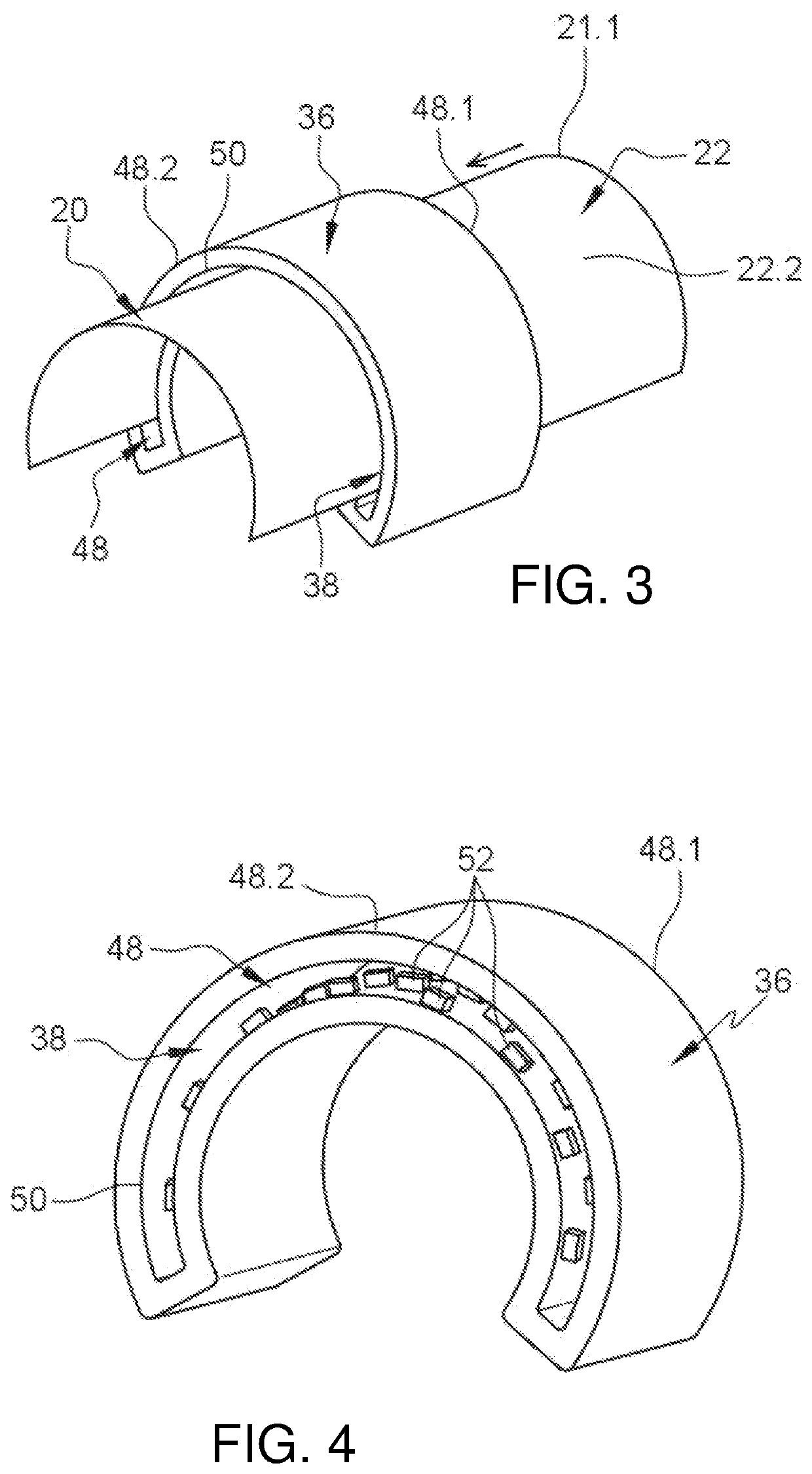

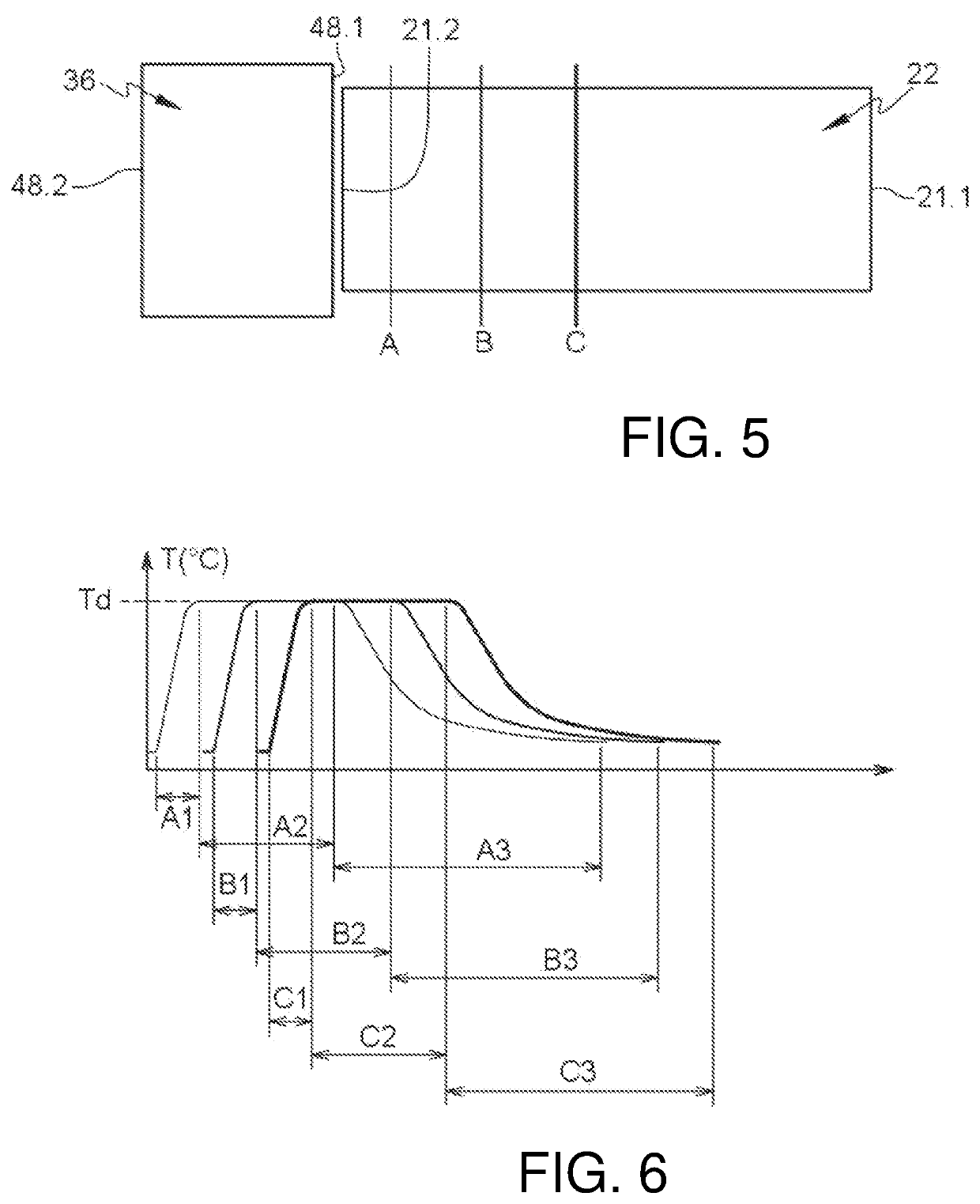

Device for consolidating a part made of composite material by induction heating

PendingUS20220266480A1Improve thermal responsivenessImprove energy efficiencyDomestic articlesFiberSusceptor

A device for consolidating a fiber preform to obtain a panel made of composite material of large dimension, comprising an induction heating system configured to generate at least one electromagnetic field in a heating zone, at least one susceptor incorporated in a first die tool supporting the fiber preform and / or a cladding covering the fiber preform, each susceptor producing a uniform heating of the fiber preform when it is positioned in the electromagnetic field of the induction heating system, and a mechanism configured to induce a relative movement between the induction heating system and the first die tool so that all the fiber preform crosses the heating zone.

Owner:AIRBUS OPERATIONS (SAS)

A fabric-based flexible control system and method

ActiveCN113093588BImprove reliabilityGood real-time responsivenessProgramme controlComputer controlConductive pasteControl system

The invention particularly relates to a fabric-based flexible control system. It includes a flexible sensor, and a controller. The controller is connected to a display device with a display. The fabric includes a flexible substrate, a graphene film layer, and the graphene conductive paste is composed of a graphene solution and a water-soluble polyurethane solution in a certain proportion. Prepared after mixing, the graphene conductive paste is a solution with a graphene / polyurethane effective content ratio of 1%-6%; after the flexible sensor detects the detection signal of the pressure or tensile force acting on the fabric, the detection signal is sent to the controller, the controller performs calculation after receiving the detection signal, and sends the calculated required data to the display device. A fabric-based flexible control method is also included. The control system of the present invention can be applied to the field of monitoring human physiological activities, especially to monitor the daily physiological activities of patients, children and the elderly; and has high reliability, good real-time responsiveness, and high monitoring accuracy.

Owner:QINGDAO UNIV

Heat flow switching element

ActiveUS20210249581A1Significant changeGood thermal responseThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsDielectricHeat flow

Provided is a heat flow switching element which has a larger change in a thermal conductivity and has excellent thermal responsiveness. The heat flow switching element includes an N-type semiconductor layer, an insulator layer laminated on the N-type semiconductor layer, a P-type semiconductor layer laminated on the insulator layer, an N-side electrode connected to the N-type semiconductor layer, and a P-side electrode connected to the P-type semiconductor layer. In particular, the insulator layer is formed of a dielectric. Also, a plurality of N-type semiconductor layers and P-type semiconductor layers are laminated alternately with the insulator layer interposed therebetween.

Owner:MITSUBISHI MATERIALS CORP +1

Breaker and safety circuit provided with same

ActiveUS11004634B2Increase delayImprove thermal responsivenessCell component detailsThermal switch detailsHemt circuitsEngineering

A breaker 1 includes a fixed piece 2 having a fixed contact 21, a movable piece 4 including a movable contact 41 and having the movable contact 41 so as to be pressed against and in contact with the fixed contact 21, a thermally actuated element 5 shifting the movable piece 4 from a conductive state to a cut-off state in accordance with a temperature change, and a case 7 accommodating the fixed piece 2, the movable piece 4, and the thermally actuated element 5. The case 7 includes a case main body 71 accommodating the movable piece 4 and the thermally actuated element 5, a lid member 81 covering a housing concave portion 73 of the case main body 71, and a metal plate 9 embedded in the lid member 81. Heat capacity of the metal plate 9 is larger than heat capacity of the fixed piece 2.

Owner:BOURNS KK

Graphene conductive paste for textile-based sensor and preparation method of graphene conductive paste

ActiveCN112908515AImprove electrical conductivityImprove thermal response performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureWoven fabricPolymer chemistry

The invention relates to the technical field of graphene conductive materials, and in particular relates to graphene conductive paste for a textile-based sensor. The graphene conductive paste is prepared by blending a graphene solution and a water-soluble polyurethane solution according to a certain proportion, the graphene conductive paste is a solution in which the effective content ratio of graphene to polyurethane is 1% to 6%, the graphene solution is prepared by adding a dispersing agent in the process of adding a reducing agent into a graphene oxide solution for reduction, and the concentration mass percent of the graphene solution is 0.1 to 5%. The invention further discloses a preparation method of the graphene conductive paste for the textile-based sensor. The graphene conductive paste prepared by the invention can be coated on textiles, such as yarns and fabrics, so that the textiles have a sensing function, have excellent conductivity, washing resistance and good thermal responsiveness, and the graphene conductive paste is worthy of wide popularization and application.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com