Hard panel for construction

A building and panel technology, applied in the direction of buildings, building materials, building components, etc., can solve the problems of low thermal response of heating, long time, energy loss, etc., to achieve simple construction and durability, heating The effect of heat increase and excellent thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

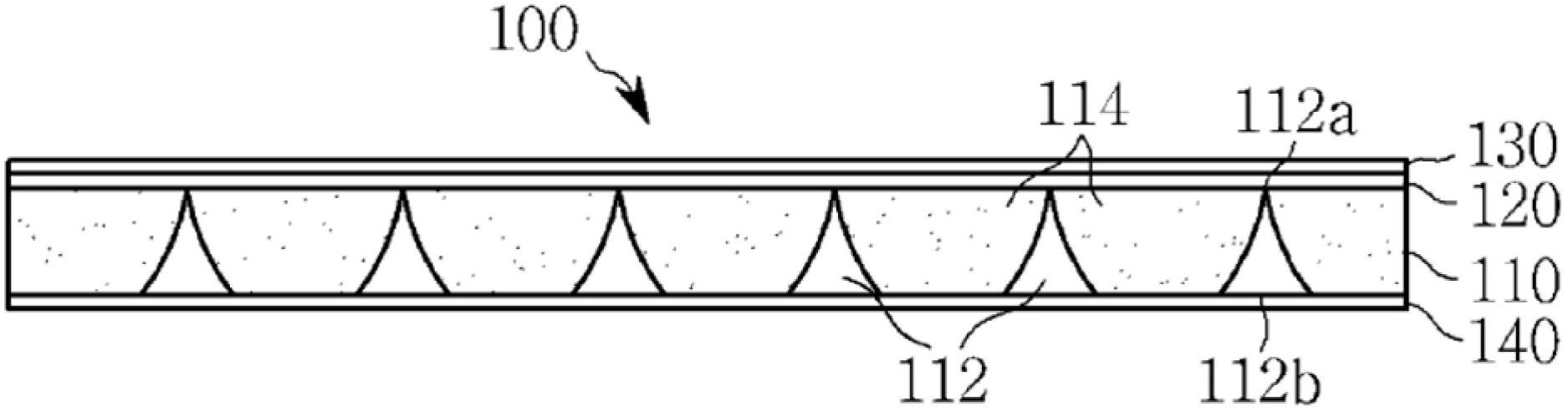

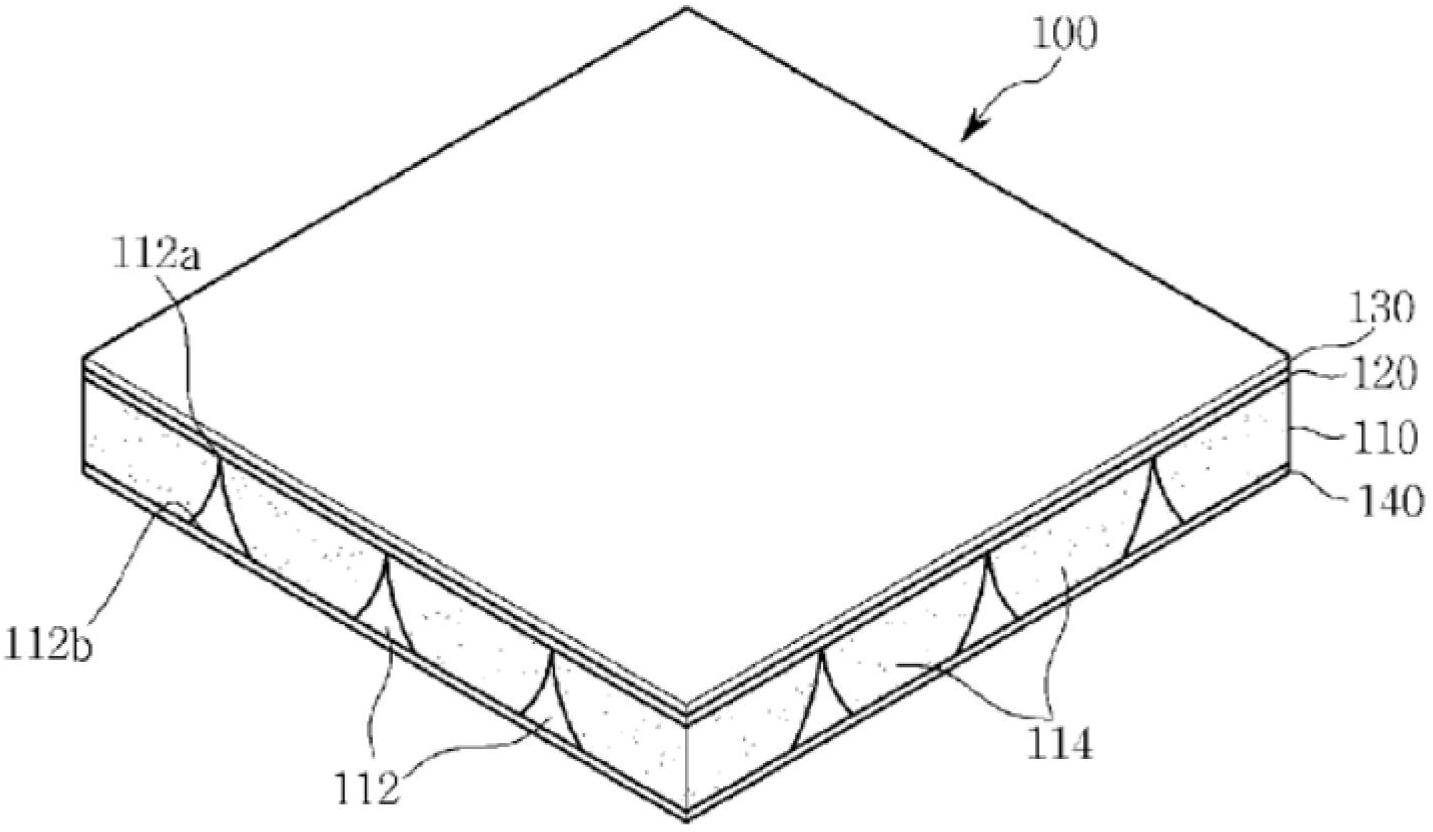

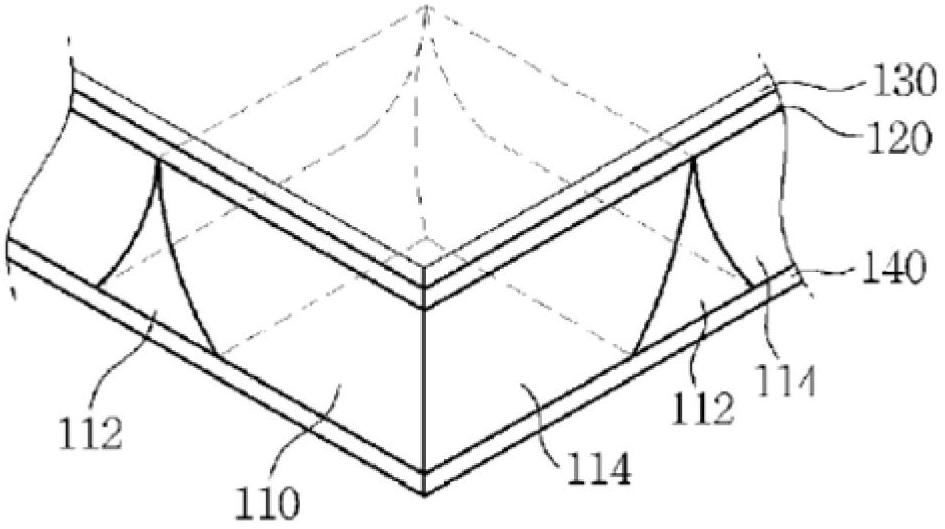

[0046] figure 1 is a cross-sectional view of a rigid panel body for construction according to a preferred embodiment of the present invention, figure 2 is a schematic stereogram thereof, image 3 is a perspective view of its main parts.

[0047] According to the rigid panel body 100 for construction of the present invention, the long grooves 112 with a triangular cross-sectional shape having a long length are formed at predetermined intervals in a rigid panel 110 such as a loess panel, whereby the rigid panel 110 is made of a plurality of The triangular cross-sectional long groove portion 112 is visually or physically divided into a plurality of distinguishing individuals 114 .

[0048] The upper end vertex 112a of the triangular-like cross-sectional shape long groove portion 112 is located at a position in contact with the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com