Cycloolefin polymer-polyphenyl ether resin composition as well as preparation method and application thereof

A technology of cyclic olefin polymer and polyphenylene ether resin, which is applied in the field of COP/PPO resin composition of photovoltaic junction boxes, can solve the problems of poor weather resistance, solvent resistance, environmental stress cracking, etc. Olefin polymer-polyphenylene ether COP/PPO alloy material is open, poor solvent resistance and other problems, to achieve the effect of strong mechanical properties, better mechanical properties, and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

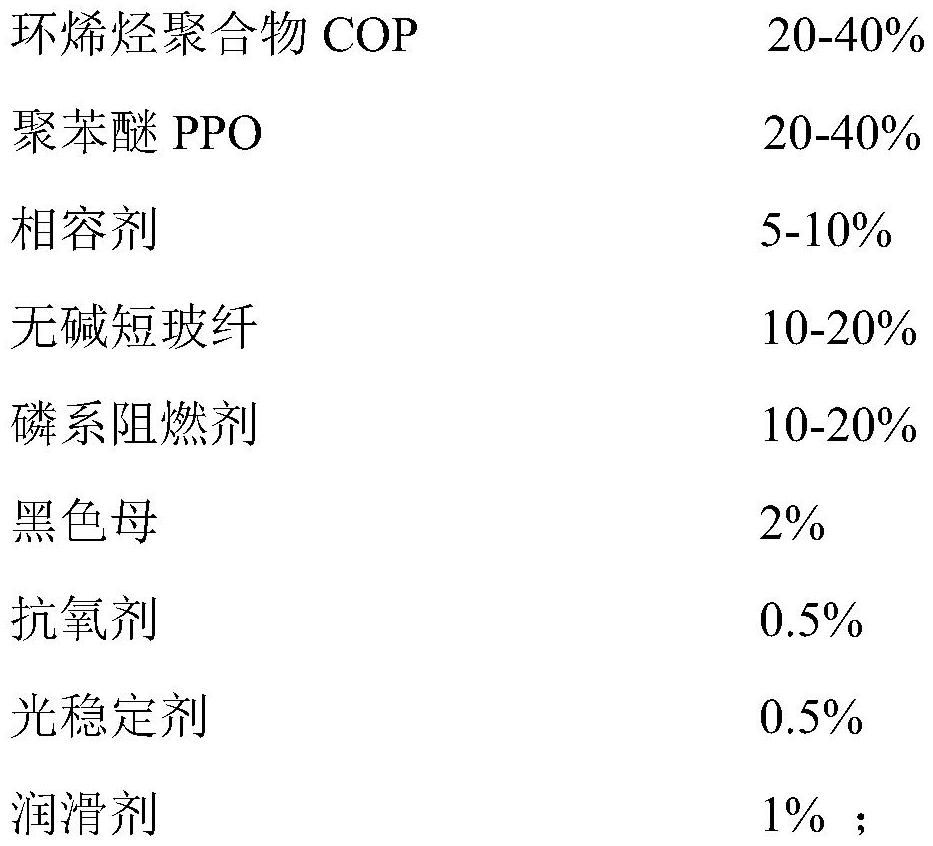

Method used

Image

Examples

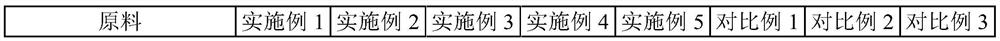

Embodiment 1

[0039] In the first step, 40% cycloolefin polymer (COP), 20% polyphenylene ether (PPO), 10% compatibilizer, 10% alkali-free short glass fiber, 16% phosphorus flame retardant, 2% black masterbatch , 0.5% antioxidant, 0.5% light stabilizer, and 1% lubricant are put into a high-speed mixer for pre-mixing for 6 minutes; the second step is to feed the pre-mixed raw materials into a twin-screw extruder with a length-to-diameter ratio of 56:1 , the temperature in the feeding section is 150-230°C, the temperature in the plasticizing section is 260-280°C, the temperature in the homogenizing section is 260-280°C, and the screw speed is 240rpm. After the materials are fully melted and mixed, carry out strand granulation; the third step , transport the finished plastic alloy granules to the boiling drying bin and dry at 100°C for 1 hour; step 4, carry out the second mixing and granulation of the dried plastic alloy granules according to steps 2 and 3.

Embodiment 2

[0041] In the first step, 20% cycloolefin polymer (COP), 40% polyphenylene ether (PPO), 6% compatibilizer, 20% alkali-free short glass fiber, 10% phosphorus flame retardant, 2% black masterbatch , 0.5% antioxidant, 0.5% light stabilizer, and 1% lubricant are put into a high-speed mixer for pre-mixing for 6 minutes; the second step is to feed the pre-mixed raw materials into a twin-screw extruder with a length-to-diameter ratio of 56:1 , the temperature in the feeding section is 150-230°C, the temperature in the plasticizing section is 260-280°C, the temperature in the homogenizing section is 260-280°C, and the screw speed is 240rpm. After the materials are fully melted and mixed, carry out strand granulation; the third step , transport the finished plastic alloy granules to the boiling drying bin and dry at 100°C for 1 hour; step 4, carry out the second mixing and granulation of the dried plastic alloy granules according to steps 2 and 3.

Embodiment 3

[0043] In the first step, 30% cycloolefin polymer (COP), 30% polyphenylene ether (PPO), 8% compatibilizer, 15% alkali-free short glass fiber, 13% phosphorus flame retardant, 2% black masterbatch , 0.5% antioxidant, 0.5% light stabilizer, and 1% lubricant are put into a high-speed mixer for pre-mixing for 6 minutes; the second step is to feed the pre-mixed raw materials into a twin-screw extruder with a length-to-diameter ratio of 56:1 , the temperature in the feeding section is 150-230°C, the temperature in the plasticizing section is 260-280°C, the temperature in the homogenizing section is 260-280°C, and the screw speed is 240rpm. After the materials are fully melted and mixed, carry out strand granulation; the third step , transport the finished plastic alloy granules to the boiling drying bin and dry at 100°C for 1 hour; step 4, carry out the second mixing and granulation of the dried plastic alloy granules according to steps 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com