High-impact-resistance nylon 66 insulating material, and preparation method and application thereof

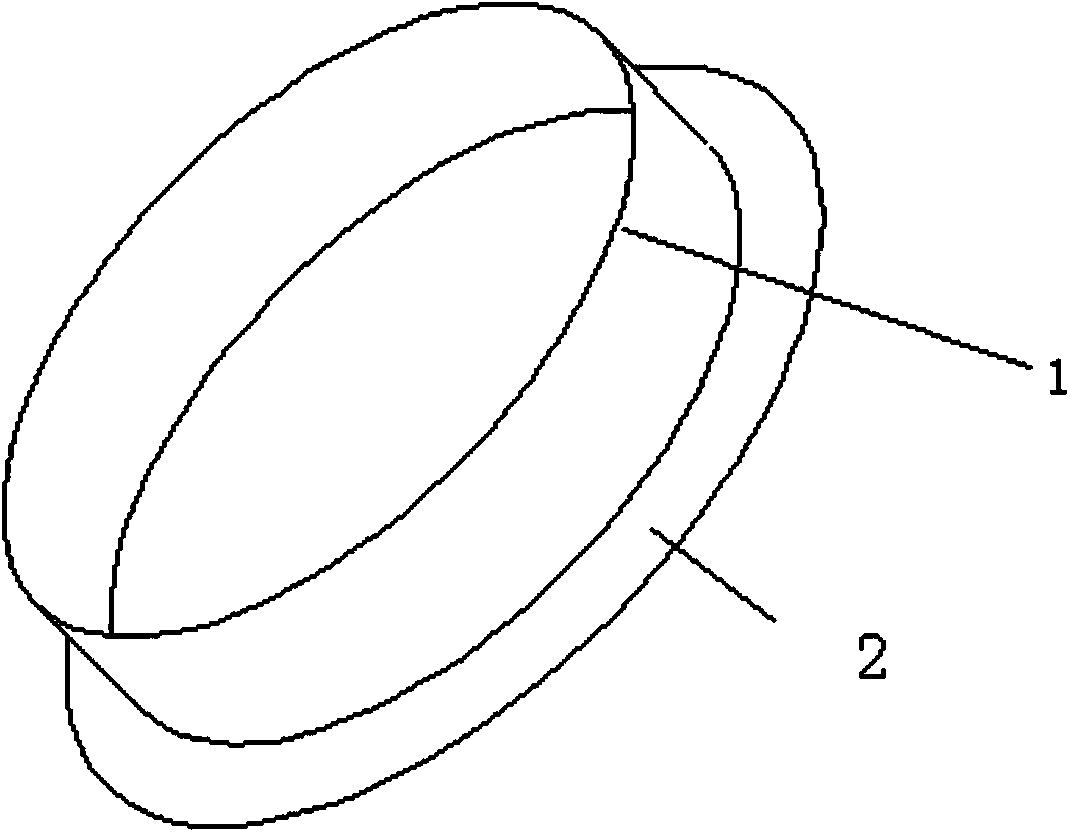

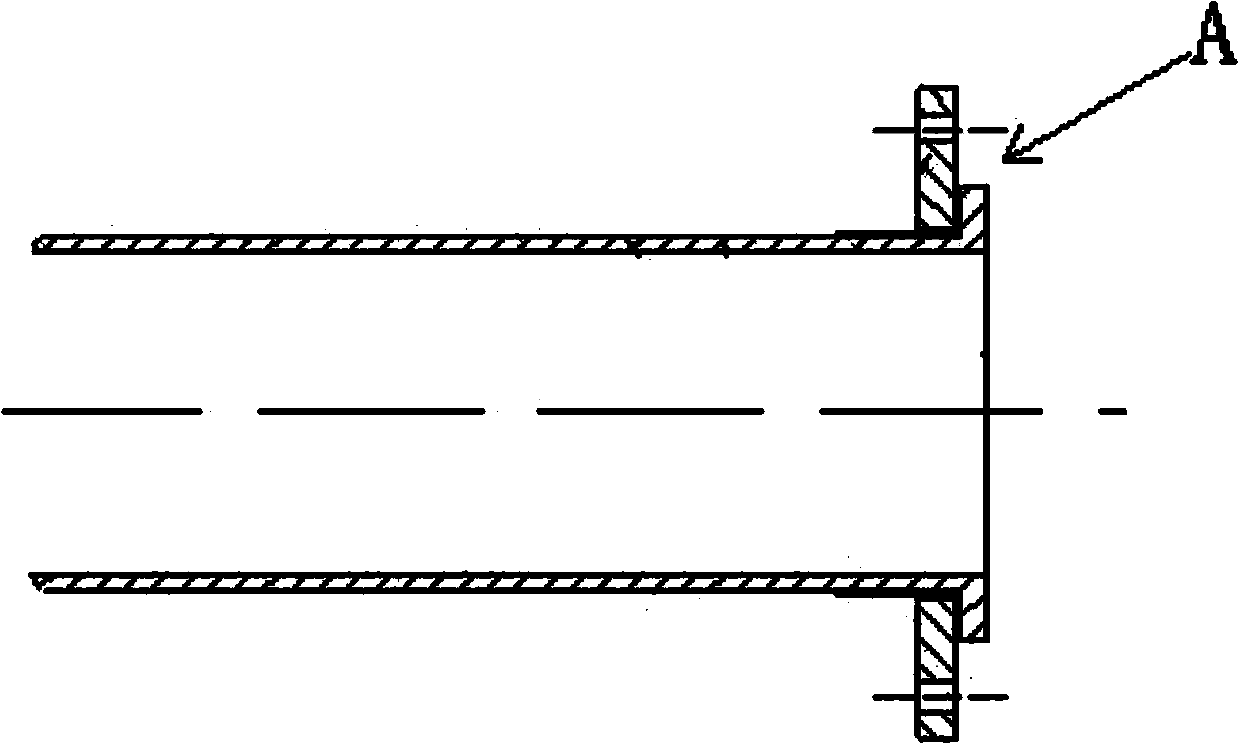

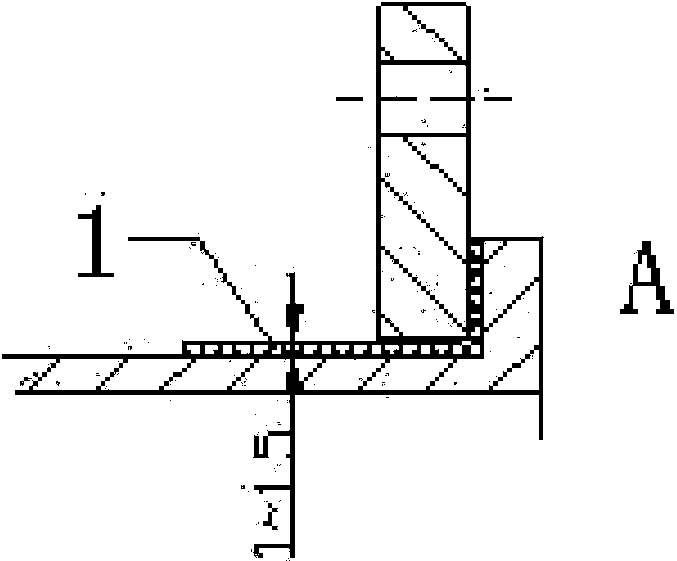

It is an insulating material and high impact resistance technology, which is applied in mechanical equipment, damage protection, pipeline anti-corrosion/rust protection, etc. It can solve the problems of loss of sealing performance of flanges, galvanic corrosion of loose flanges, and high labor costs. It is convenient for injection molding processing and use, shortens the construction period, and facilitates the construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An insulating protective cover, which is made of high-impact nylon 66 insulating material, and the high-impact nylon 66 insulating material comprises the following components in parts by weight: nylon 66 (i.e. polyhexamethylene adipamide ) 600 parts, HLDPE (ie linear low density polyethylene) 300 parts, antioxidant 168 (ie (2,4-di-tert-butylphenyl) phosphite triester) 1 part, antioxidant 1010 (ie four [ β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester) 0.5 parts, lubricant EBS (that is, ethylene bis stearamide) 2 parts, anti-ultraviolet agent 6 parts, arsenic-free 32 parts of glass fiber.

[0035] The preparation method of insulating protective cover of the present invention comprises the following steps:

[0036] S1 mixes the raw materials weighed in parts by weight, heats and melts, and makes colloidal particles;

[0037] S2 drying the colloidal particles;

[0038] S3 heats and melts the dried colloidal particles, and extrudes them according ...

Embodiment 2

[0047] An insulating protective cover, which is made of high-impact nylon 66 insulating material, the high-impact nylon 66 insulating material includes the following components in parts by weight: 1000 parts of nylon 66, 300 parts of HLDPE, antioxidant 1683 parts, 10102 parts of antioxidant, 6 parts of lubricant EBS, 6 parts of anti-ultraviolet agent, 28 parts of arsenic-free glass fiber

[0048] Its preparation method and application are the same as in Example 1.

[0049] The performance of the insulating protective sheath prepared in this embodiment is similar to that of the insulating protective sheath in Example 1, but because the specific gravity of the arsenic-free glass fiber is slightly lower, its toughness is slightly weaker than that of the insulating protective sheath in Example 1.

Embodiment 3

[0051] An insulating protective cover, which is made of high-impact nylon 66 insulating material, and the high-impact nylon 66 insulating material includes the following components in parts by weight: 66800 parts of nylon, 200 parts of HLDPE, and 1682 parts of antioxidant 10101 parts of antioxidant, 4 parts of lubricant EBS, 4 parts of anti-ultraviolet agent, 30 parts of arsenic-free glass fiber.

[0052] Its preparation method and application are the same as in Example 1.

[0053] The performance of the insulating protective sheath prepared in this embodiment is similar to that of the insulating protective sheath in Example 1, but because the specific gravity of the arsenic-free glass fiber is slightly higher, its toughness is slightly stronger than that of the insulating protective sheath in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com