Method and device for improving surface quality of cast blank of continuous casting machine by adding covering slag

A technology of surface quality and mold slag, which is applied in the technical field of improving the surface quality of the casting billet, can solve the problems of low molten steel superheat, breakout accidents, deterioration of the surface quality of the casting billet, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

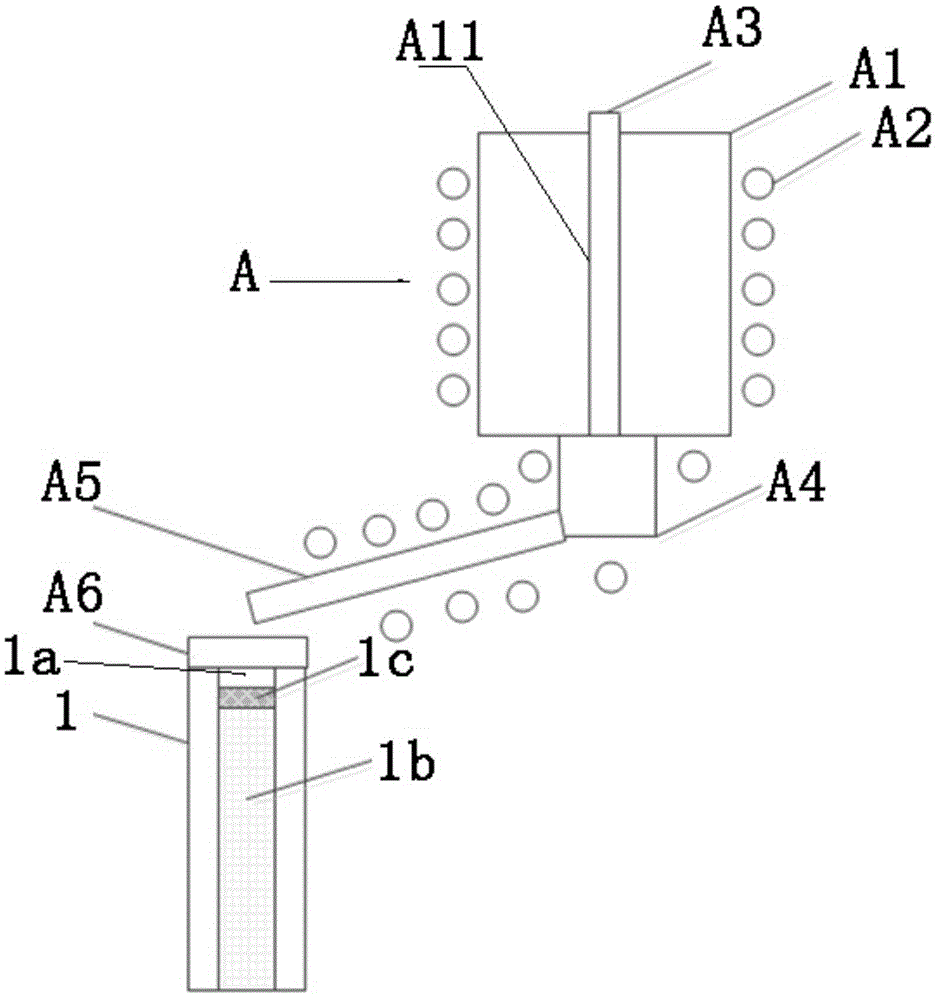

[0030] like figure 1 As shown, the method and device for improving the surface quality of continuous caster slab by adding mold slag, including the crystallizer 1, the overall process is as follows:

[0031] 1) Before the casting of the continuous casting machine starts, add the solid mold slag to the crystallizer and the liquid mold slag to the crucible A1 of system A. After starting the induction heater A2, the crucible and the solid mold slag are heated successively, and the crucible is heated to a certain temperature. , adjust the heating power to ensure that the temperature of the crucible is not too high. After the solid mold flux is melted, continue heating to 1345°C ~ 1355°C, so that the change in viscosity of the liquid mold flux is as small as possible when the temperature of the liquid mold flux is relatively small;

[0032] 2) In step 1), in order to reduce the heat loss of the liquid mold slag during the transportation process, before the liquid mold slag flows o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com