Module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

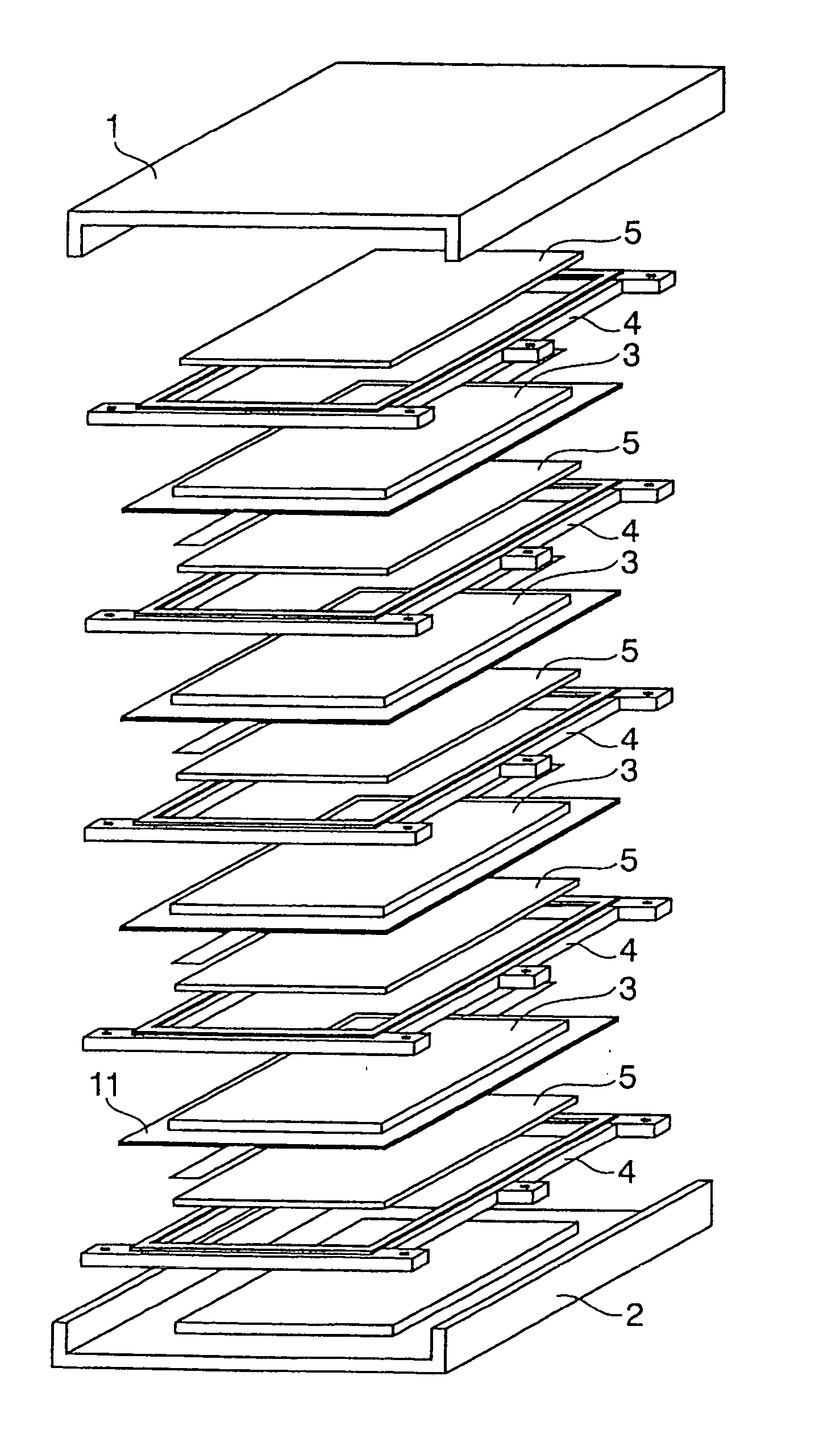

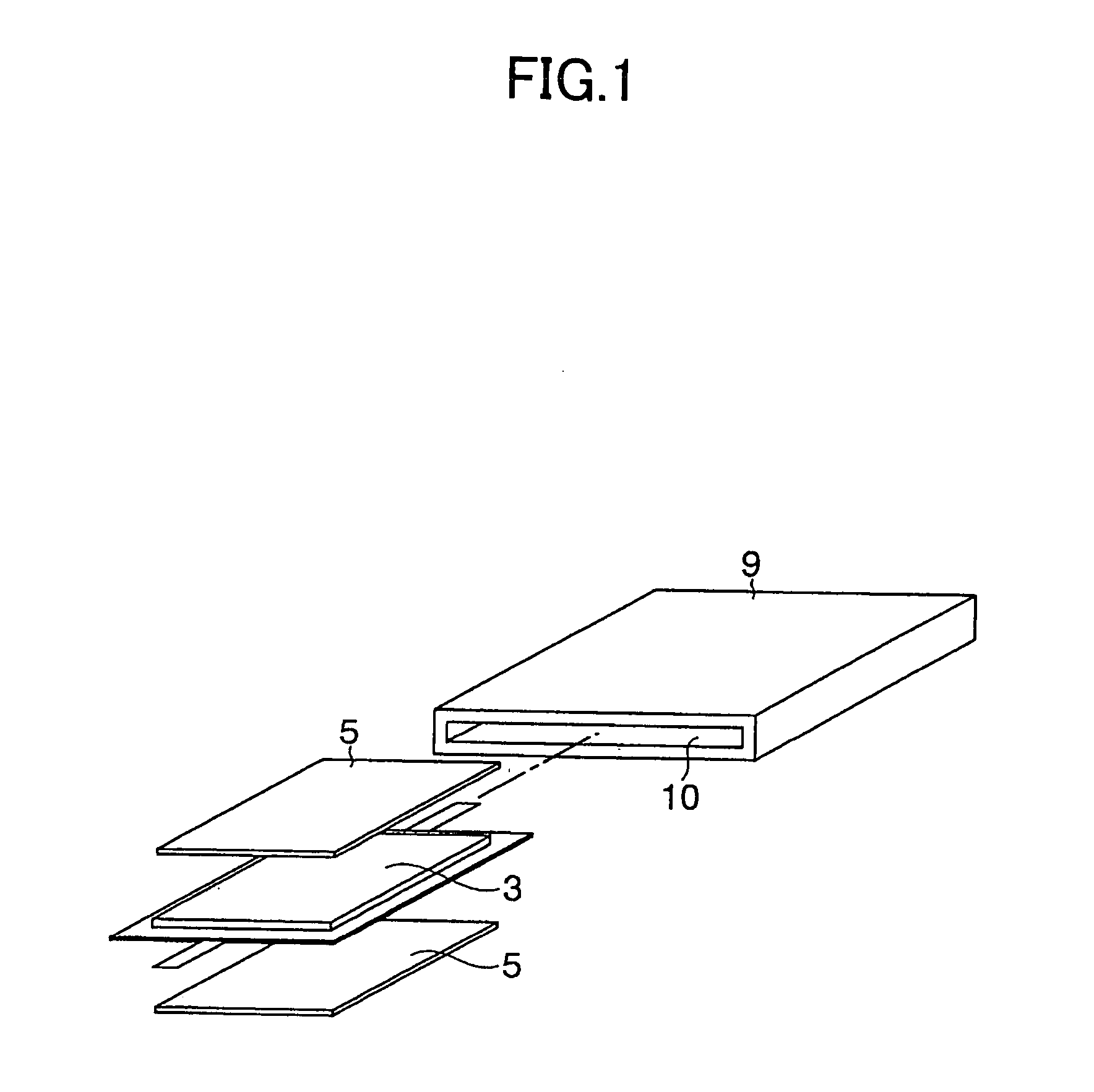

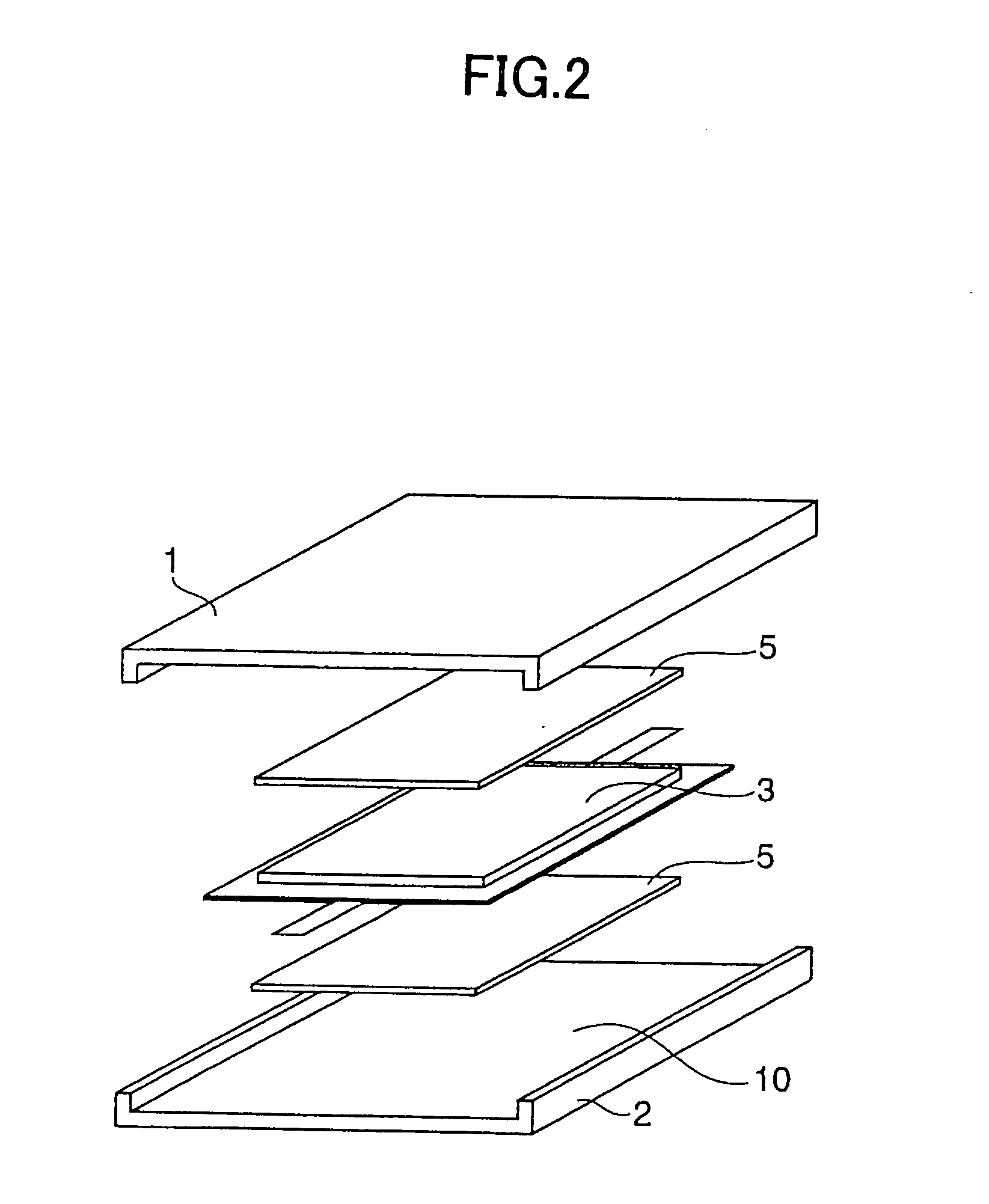

[0028] An embodiment of the present invention will be described below with reference to attached drawings. As illustrated in FIG. 3, the embodiment of the present invention is characterized by a structure to sandwich the flat laminate film secondary battery 3 between the module top and bottom covers 1 and 2, respectively via the sealing accessory plates 4. The sealing accessory plates 4 are disposed so as to sandwich, from upside to downside, the sealing area 11 of the laminate film as the armored body of the flat laminate film secondary battery 3.

[0029] Since the sealing accessory plate 4 is required to have rigidity or stiffness for mechanically cramping the sealing area of the laminate film, it is appropriate that a high rigid metal material or a high rigid plastic material is used for the sealing accessory plate 4. Meanwhile, since electrodes are extracted from the laminate film sealing area, the cross section of the electrode-extracting side of the sealing section has a concav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com