Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

716results about How to "Not easy to hydrolyze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

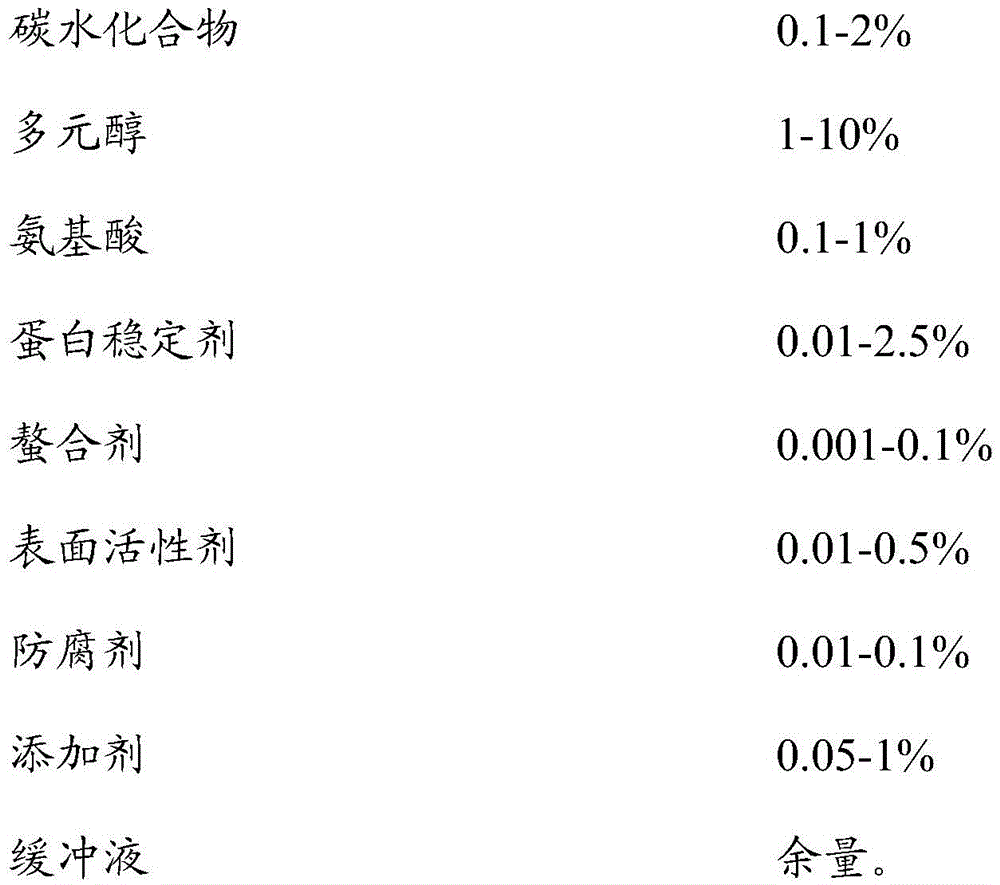

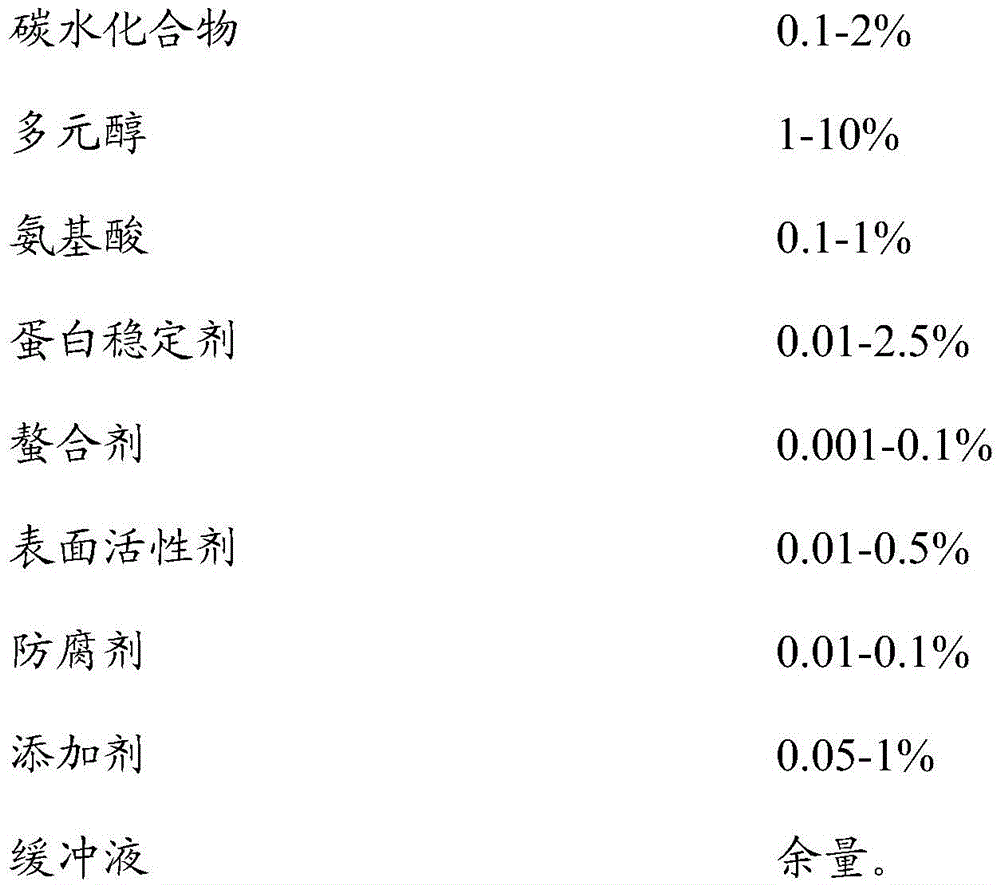

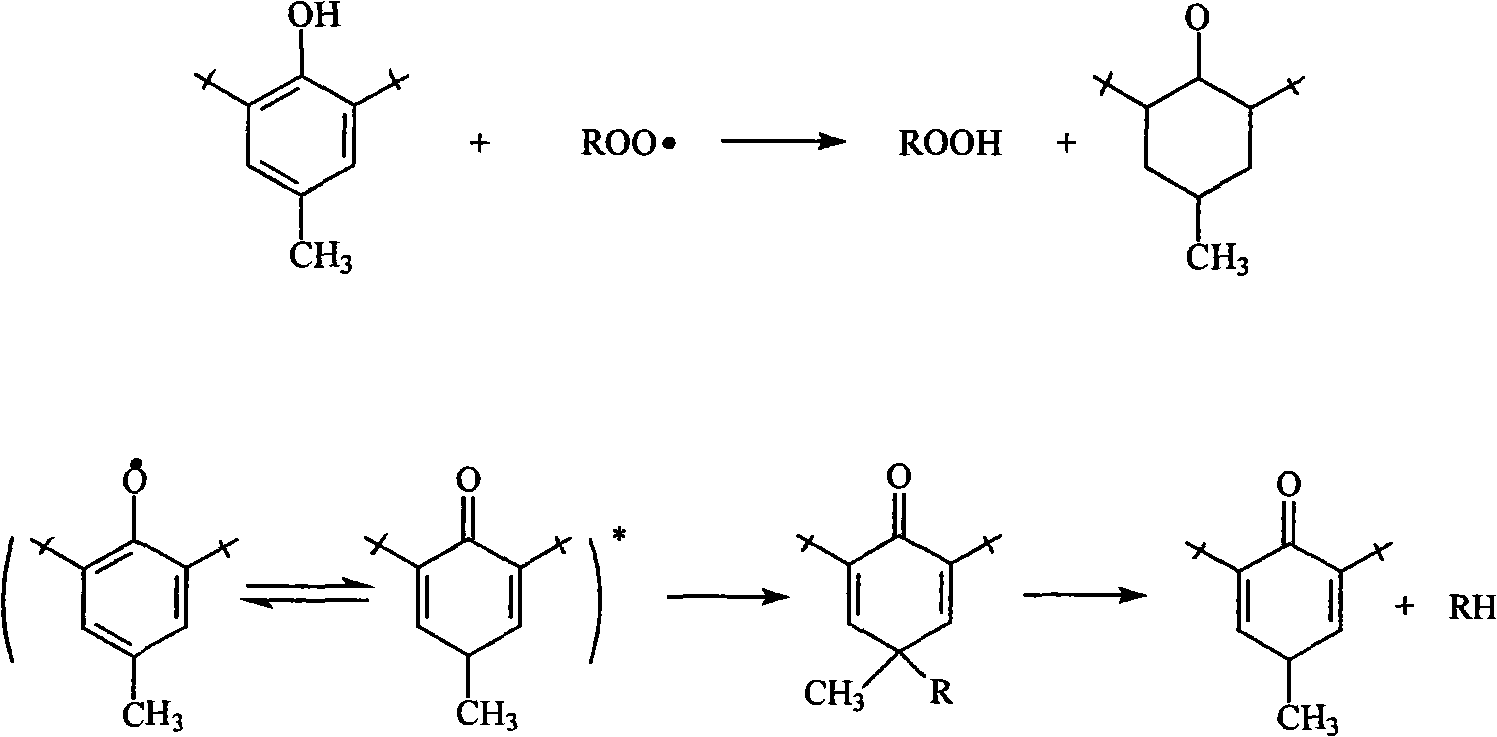

Diluent enabling stability for acridinium ester antigen-antibody conjugate and preparation method of diluent

ActiveCN105628914ANot easy to hydrolyzeExtended shelf lifeBiological testingPreservativeAntibody conjugate

The invention discloses a diluent enabling stability for acridinium ester antigen-antibody conjugate. The diluent is prepared by adding a carbohydrate, polyalcohol, amino acids, a protein stabilizer, a chelating agent, a surfactant, a preservative and an additive into a buffer solution; the diluent prepared by the invention overcomes the defect that acridinium ester is unstable and easily hydrolyzes in the buffer solution, can protect the acridinium ester antigen-antibody conjugate to improve its stability and prolong its service life, and also can be fully used in in-vivo diagnostic kits.

Owner:GUANGZHOU KEFEN BIOTECH CO LTD

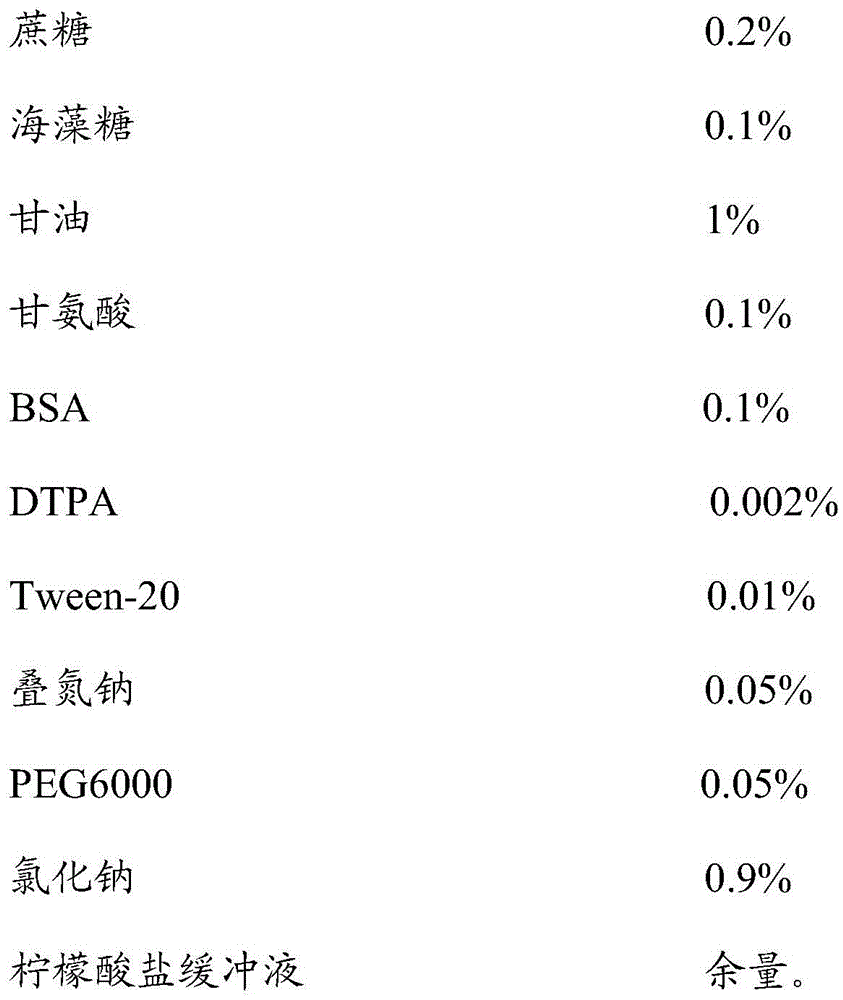

Solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging

InactiveCN101626039AIncrease crosslink densityModerate reaction temperatureElectrical equipmentGlass/slag layered productsAntioxidantPhosphate

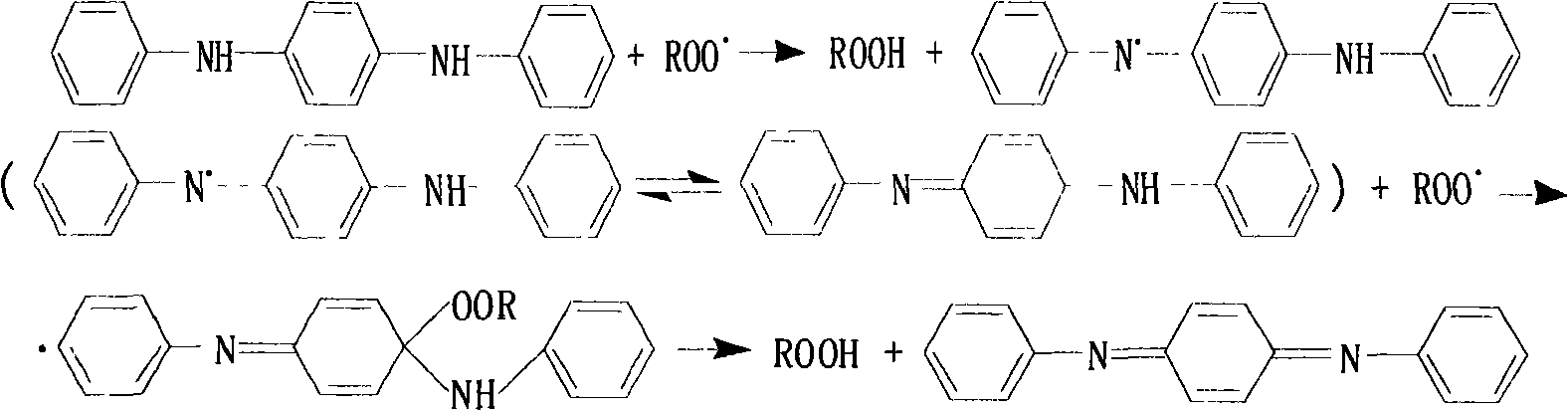

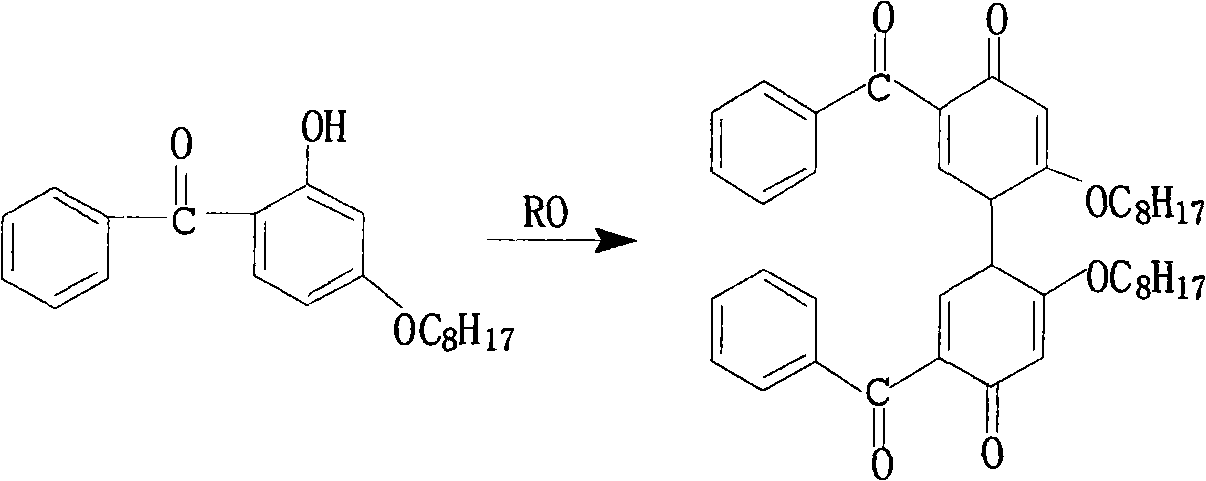

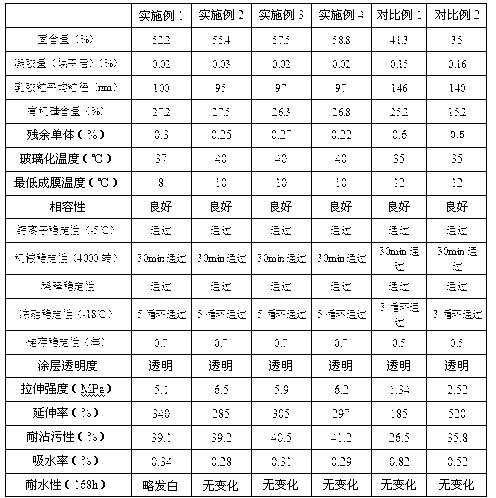

The invention relates to a solar cell packaging EVA adhesive film capable of resisting heat, humidity, ultraviolet light and aging, which comprises the following materials by weight portions: 100 portions of copolymer of ethylene vinyl acetate, 0.8-1.4 portions of crosslink curing agent, 0.05-0.15 portion of crosslink curing accelerator, 0.2-0.6 portion of tackifier, 0.1-0.5 portion of antioxidant, 0.05-0.25 portion of ultraviolet light stabilizer and 0.1-0.3 portion of ultraviolet light absorbent, wherein the crosslink curing agent is tert butyl peroxy 2-ethyl hexyl carbonate; the crosslink curing accelerator is triallyl isocyanurate; the tackifier is r-glycidyl ether oxy-propylltrimethoxysilane; the antioxidant is one or two selected from the group consisting of bis(2,4-dicumylphenyl)pentaerythritol diphosphite, distearyl pentaerythritol diphosphite, tris(nonyl phenyl)phosphate and tris(2,4-butylphenyl)phosphate; and ultraviolet light absorbent is gas phase silicon dioxide. The solar cell packaging EVA adhesive film can resist high temperature of 85 DEG C, humidity of 85 percent, ultraviolet light and thermal oxidative aging.

Owner:苏州爱康商务咨询服务有限公司

Pullulan polysaccharide hollow hard capasule and its preparing method

InactiveCN101069677ASmall range of molecular weight variationProduct quality is easy to controlPharmaceutical non-active ingredientsCapsule deliveryPullulanHard Capsule

The present invention discloses a hollow hard capsule and its preparation method. It is made up by adopting prolanpolysaccharide as main body material and adding gelling agent, coagulant aids, surfactant and humectant through a certain preparation process. Said invention also provides the concrete steps of its preparation method.

Owner:广东强基药业有限公司

Feed for crabs

InactiveCN103284016AMeet the needs of growthIncrease appetiteAnimal feeding stuffBiotechnologyAnimal science

The invention belongs to the technical field of feeds and particularly relates to a feed for crabs. The feed for crabs is characterized by comprising the following materials in parts by weight: 30-60 parts of pork skin, 20-50 parts of fat pork, 5-15 parts of lean pork, 6-9 parts of corn meal, 3-5 parts of soybean meal, 1-5 parts of edible oil, 0.1-1 part of garlic cloves, 1-2 parts of fish scale powder and 0.5-1.5 parts of rape seed cakes. The main problems that since the feed for crabs is difficult to absorb, the crabs grow slowly and the water quality is contaminated in the prior art are solved; the feed disclosed by the invention has the beneficial effects of being rich in nutrition and aromatic in smell, containing antiviral components, and enabling the crabs to grow fast after the feed is eaten; the feed is simple to prepare and all the materials of the feed are rich in supply.

Owner:陈瑜 +7

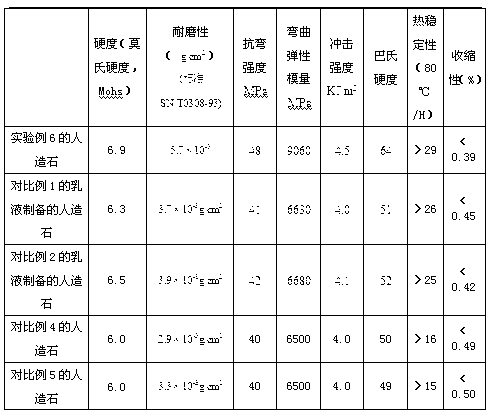

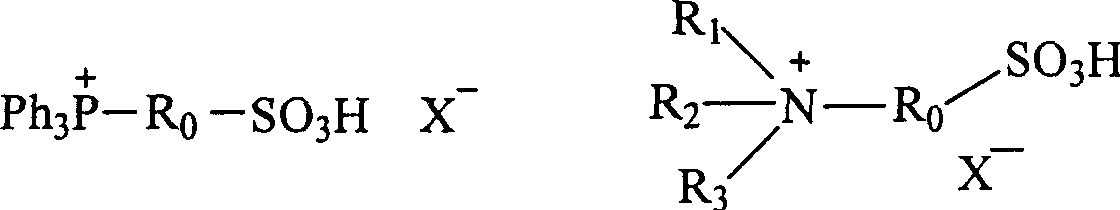

Organosilicone modified acrylate emulsion, preparation method thereof and water-based artificial stone prepared from organosilicone modified acrylate emulsion

The invention provides an organosilicon modified acrylate emulsion with a weight-average molecular weight of 201205 and also provides a preparation method of the organosilicon modified acrylate emulsion and an artificial stone prepared from the organosilicon modified acrylate emulsion. According to the specific technical scheme, the preparation method comprises the following steps of: (1) preparing a siloxane intermediate emulsion; (2) preparing a silicon-acrylic copolymer core emulsion; and (3) preparing a silicon-acrylic copolymer shell emulsion. The molecular structure of the organosilicon modified acrylate emulsion has a special core-shell structure design, wherein an innermost core of a particle is made of an organosilicon component, an intermediate layer of the particle is made of a polyacrylate component and the shell of the particle is made of a multi-crosslinked organosilicon and polyacrylate component. The organosilicon modified acrylate emulsion not only has high organosilicon content, but also has high hardness and adhesive force. Compared with a common product, the organosilicon modified acrylate emulsion has higher emulsion hardness and resistance to soiling and water. The artificial stone prepared from the organosilicon modified acrylate emulsion has the advantages of good compatibility, high abrasion resistance, low water absorption, good heat resistance, high fire resistance and low shrinkage rate in an artificial stone formula.

Owner:广东海顺新材料科技有限公司

Process of preparing biological diesel

InactiveCN1861750AImprove stabilityNot easy to hydrolyzeBiofuelsLiquid hydrocarbon mixture productionIonChemistry

This invention relates to the preparation method of the biological diesel fuel. It belongs to the composition of biological fuel and green regenerated energy resource technology area. It adopts the Bronsted acid ion as the catalyst, and the biological diesel fuel can be produced under the temperature is from 20DEG C to 300DEG C, the pressure is from 0.1Mpa to 10Mpa, the mole ratio of biological fat (or fat acid) to short chain alcohol is from 1:30 to 1:1300, the mole ratio of biological fat (or fat acid) to ion catalyst solution is from 300:1 to 1:1. Adopting the Bronsted acid iron catalyst to prepare the biological diesel fuel, the activity of the catalyst is high, the stability of it is good and it can reuse. There is no corrosion to the equipment and the process environment is friendly, and the product can be separated easily. The investment of equipment and cost of operation is low.

Owner:TSINGHUA UNIV

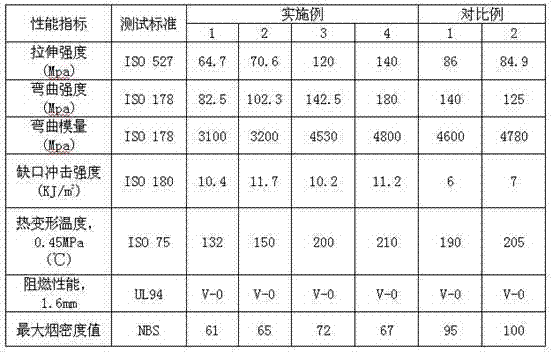

Flame-retardant polyamide composite material and preparation method thereof

The invention discloses a flame-retardant polyamide composite material and a method for preparing the flame-retardant polyamide composite material. The flame-retardant polyamide composite material is characterized by comprising 40-80wt% (weight percent) of polyamide resin, 0-30wt% of reinforcing material, 10-25wt% of flame retardant, 2-4wt% of synergistic flame retardant, 2-5wt% of compatibilizer, 0.5-1wt% of heat stabilizer and 0.5-1wt% of processing aid. The method for preparing the flame-retardant polyamide composite material comprises the following steps: adding the polyamide resin, the reinforcing material, the flame retardant, the synergistic flame retardant, the compatibilizer, the heat stabilizer and the processing aid into a twin-screw extruder, melting, mixing, extruding and granulating. The flame-retardant polyamide composite material disclosed by the invention has stable thermal stability and flame-retardant effect, good comprehensive mechanical performance and processing and forming performance and wider application range and field and can be applied to the fields of automotive industry, electronic industry and furniture industry.

Owner:SHANGHAI KINGFA SCI & TECH +1

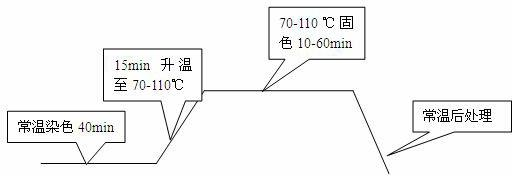

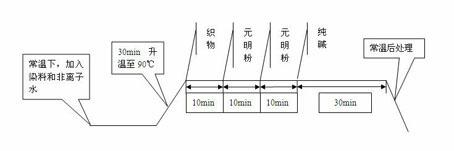

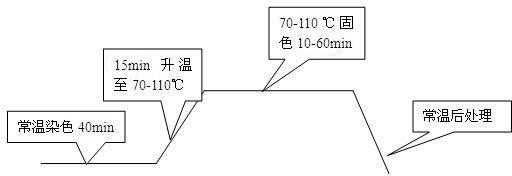

Dyeing process of pure cotton fabric

The invention discloses a dyeing process of a pure cotton fabric, which comprises the following steps: a. taking one mass part of pure cotton fabric to be dyed; b. grinding a powdery reactive dye occupying 2-8% of the total mass of the fabric in a ball grinding mill for 2h, adding ethanol and grinding for 1h, wherein the mass of ethanol is nine times of that of the powdery reactive dye; c. adding decamethylcyclopentasiloxane, high-speed cutting for 5min at a rotating speed of 600r / min, and preparing a powdery reactive dye / decamethylcyclopentasiloxane suspension system, wherein the mass of the decamethylcyclopentasiloxane is 50 times of the total mass of the fabric; d. pretreating the pure cotton fabric to be dyed in an alkali solution of 1-130g / L so as to enable the pure cotton fabric tofully swell, and controlling the fabric liquid carrying rate to be 100-220% through a rolling machine; and e. immersing the treated fabric into the powdery reactive dye / decamethylcyclopentasiloxane suspension system, dyeing for 40min at normal temperature, slowly rising the temperature to 70-110 DEG C within 15min, fixing color for 10-60 min at the temperature of 70-110 DEG C, and finally reducing the temperature to the normal temperature to finish dyeing. The dyeing process disclosed by the invention has the advantages of high dyeing fixation rate, environmental-protection and no pollution.

Owner:HAINING GREEN UNIVERSE TEXTILE TECH CO LTD

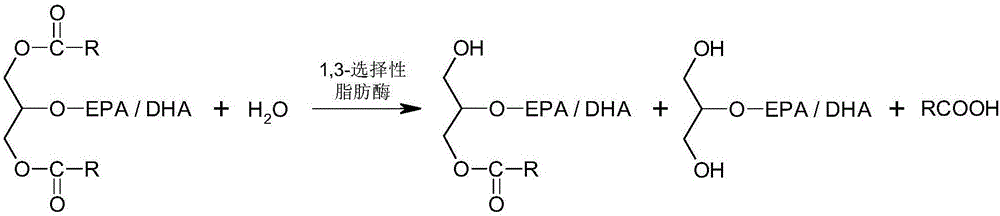

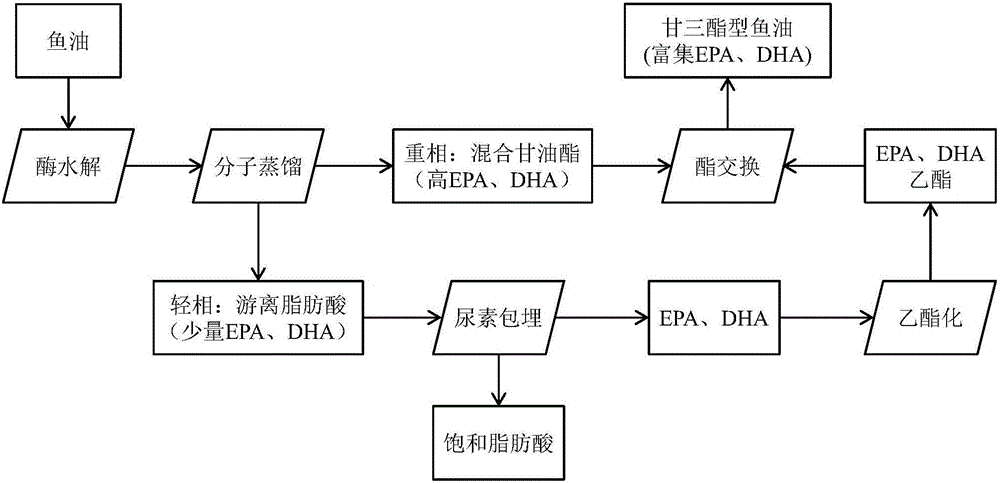

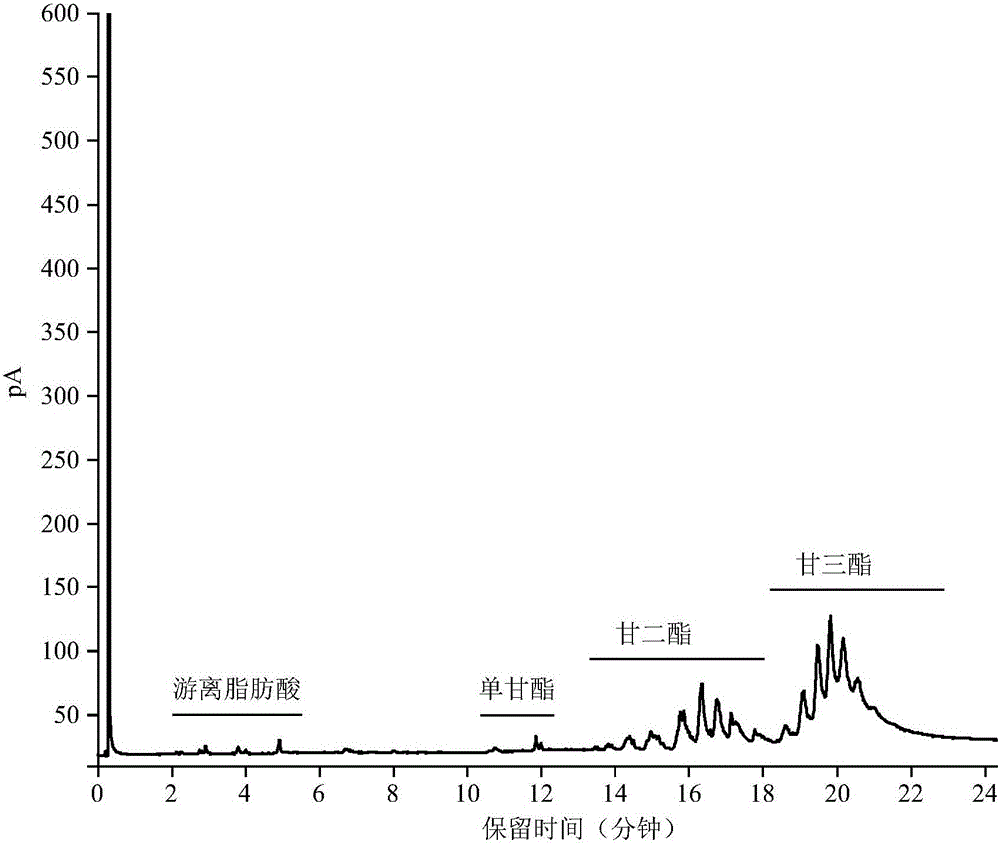

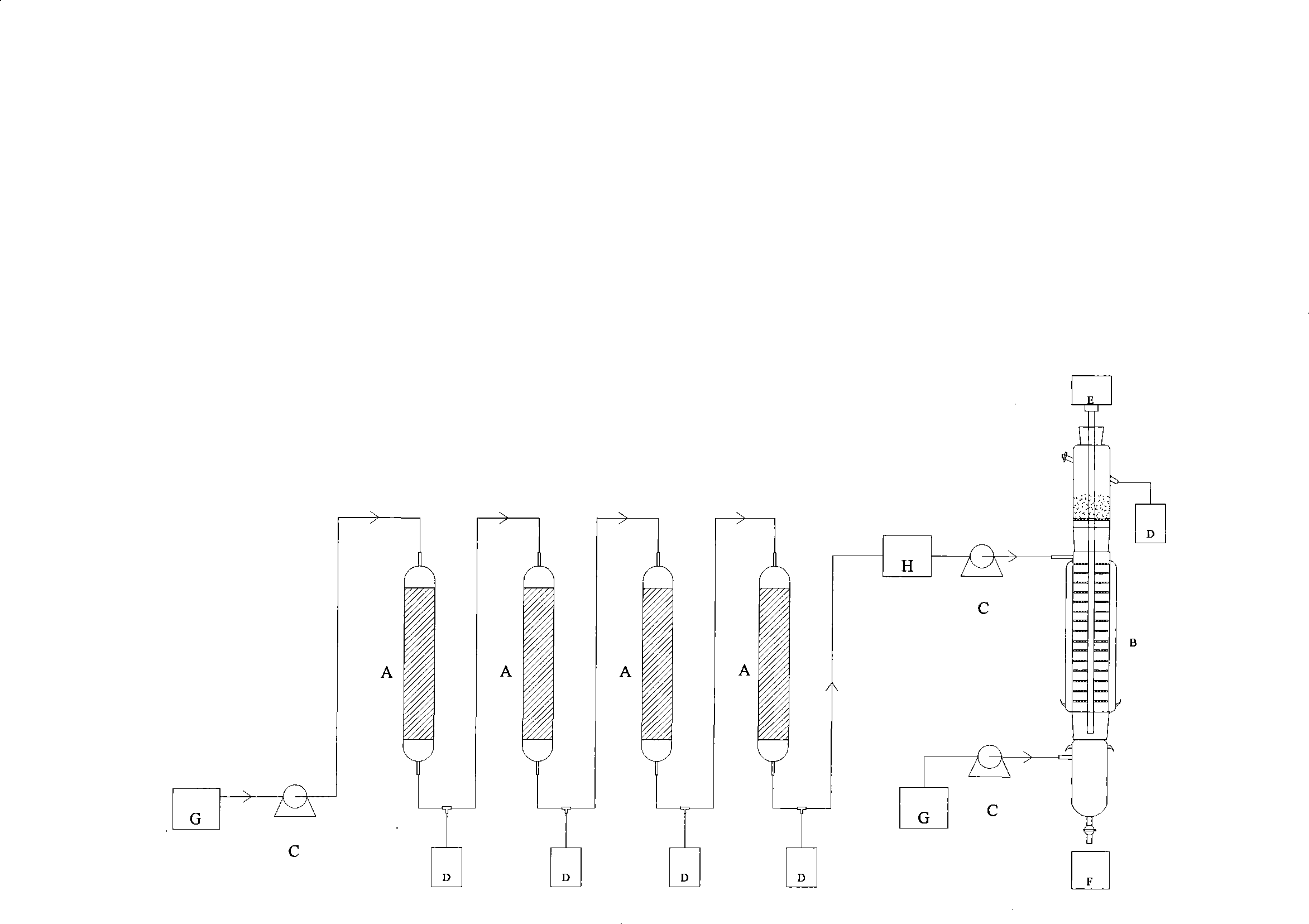

Method for preparing glyceride rich in EPA and DHA through enzyme catalysis

ActiveCN105821088AGood for retaining activityGood for retention and recyclingFermentationDistillationTransesterification

The invention belongs to the technical field of deep processing and modification of oil, and particularly discloses a method for preparing glyceride rich in EPA and DHA through enzyme catalysis .Fish oil rich in EPA and DHA is used as the raw material, efficient selective catalysis of fish oil hydrolysis is conducted with lipase, and glyceride rich in EPA and DHA is obtained through molecular distillation separation purification by strictly controlling hydrolysis conditions including enzyme adding amount, pH, water-oil ratio, temperature and time .To increase the utilization rate of raw materials, EPA and DHA in a free fatty acid product obtained through molecular distillation are recovered with the urea coating method, so that transesterification can be conducted between EPA and DHA subjected to ethyl esterification and glyceride obtained through molecular distillation and rich in EPA and DHA, and the content of triacylglycerol, the content of EPA and the content of DHA in glyceride are further increased .The content of EPA and the content of DHA in triacylglycerol type fish oil obtained with the method can be increased by 25% and 15% or more respectively.

Owner:广东至润油脂食品工业有限公司

Novel method for preparing high-purity chlorogenic acid

InactiveCN101503356AReduce decompositionHigh purityOrganic compound preparationMetabolism disorderChlorogenic acidOrganic solvent

The invention provides a new method for preparing high purity chlorogenic acid, comprising the steps: after the stock solution of the chlorogenic acid is processed by washing impurity and eluting through at least four levels of macroporous resin series connection adsorption column, and then the eluate is regenerated for continuous countercurrent extraction, so that the high purity chlorogenic acid is obtained. The method is applicable to light concentration stock solution of the chlorogenic acid, and can complete the process of absorbing, washing impurity, eluting, regenerating, countercurrent extracting and recycling the solvent in a semicontinuous way; the handling capacity of samples is large, the operation is simple, the production cost can be lowered, the residual organic solvent is reduced, and the environmental pollution is relieved.

Owner:NANJING UNIV OF TECH

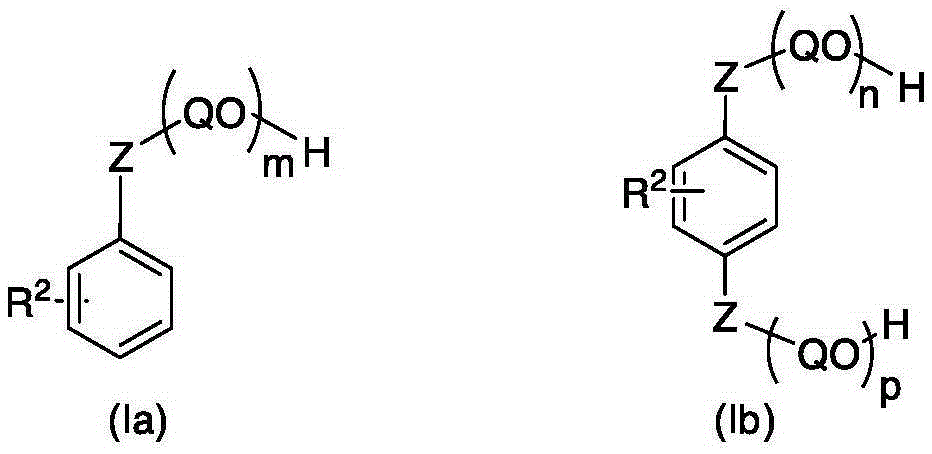

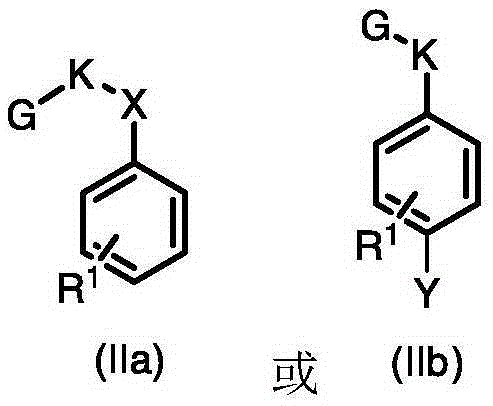

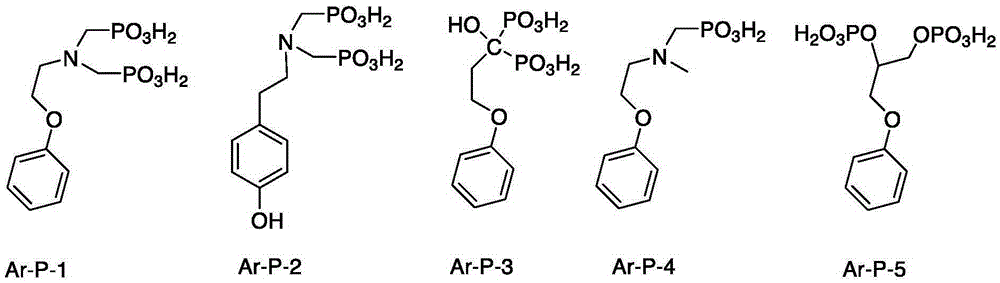

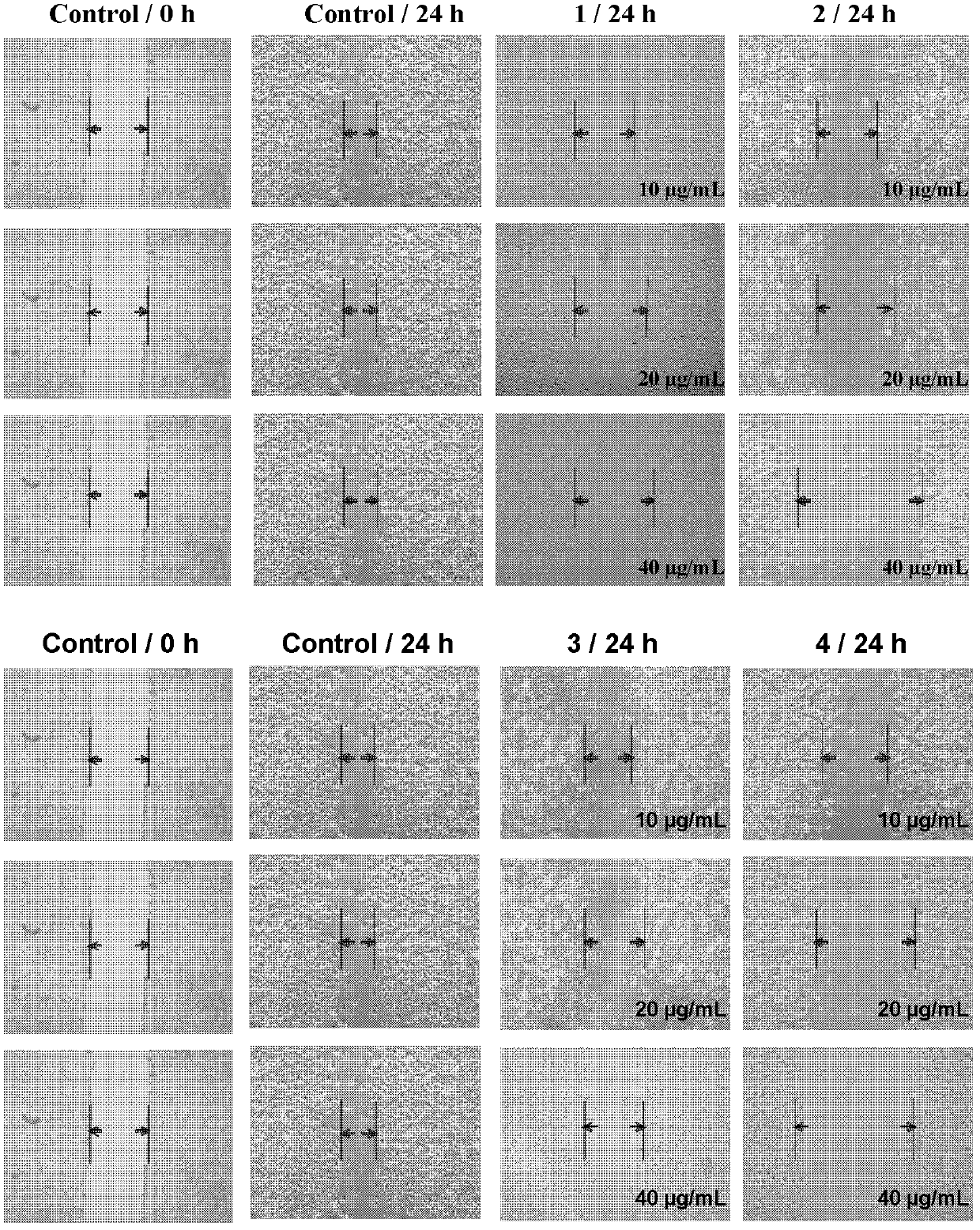

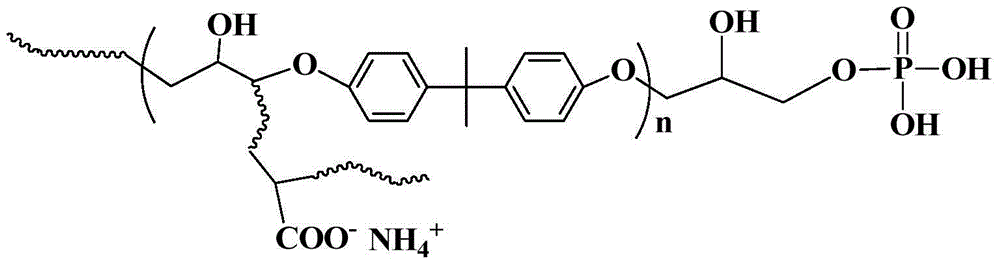

Preparation method and application of anti-soil polymer

The invention provides a preparation method and application of an anti-soil polymer. The prepared polymer is used as a dispersant for a hydraulic cementing agent and / or an aqueous dispersion for potential hydraulic cementing agent and has good anti-soil performance. The preparation method the anti-soil polymer comprises a step of subjecting polyether macromonomer A with a special structure, monomer B containing a phosphoric acid or phosphorous acid group, optional monomer D and aldehyde C to condensation polymerization so as to prepare the anti-soil polymer, wherein the monomer D is selected from the group consisting of phenol, aniline, p- / o-aminobezene solfonic acid, p- / o-hydroxybenzoic acid, p- / o-aminobenzoic acid, p- / o-hydroxyezene solfonic acid, p- / o-toluidine and p- / o-methylphenol, a mol ratio of the polyether macromonomer A to the monomer B to the monomer D is 1: (0.5-12): (0-8.0), and a mol ratio of the polyether macromonomer A to the monomer B and the monomer D is 1: (0.5-12.0).

Owner:JIANGSU SOBUTE NEW MATERIALS +1

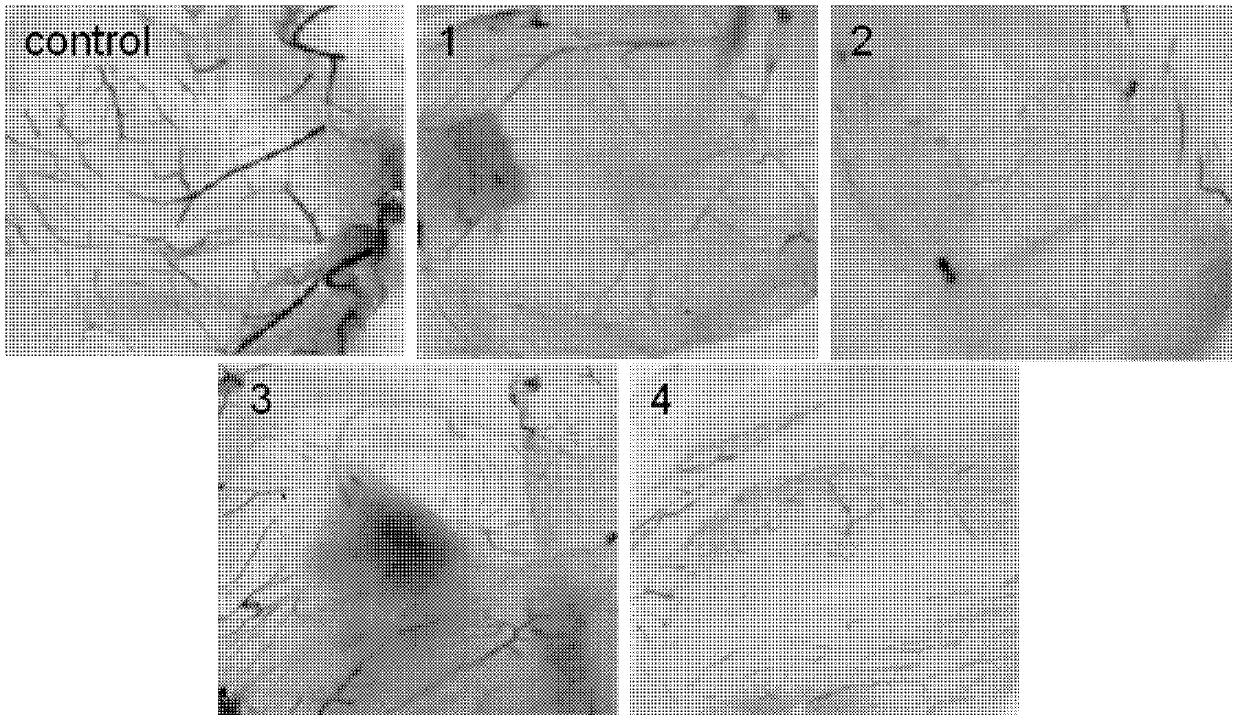

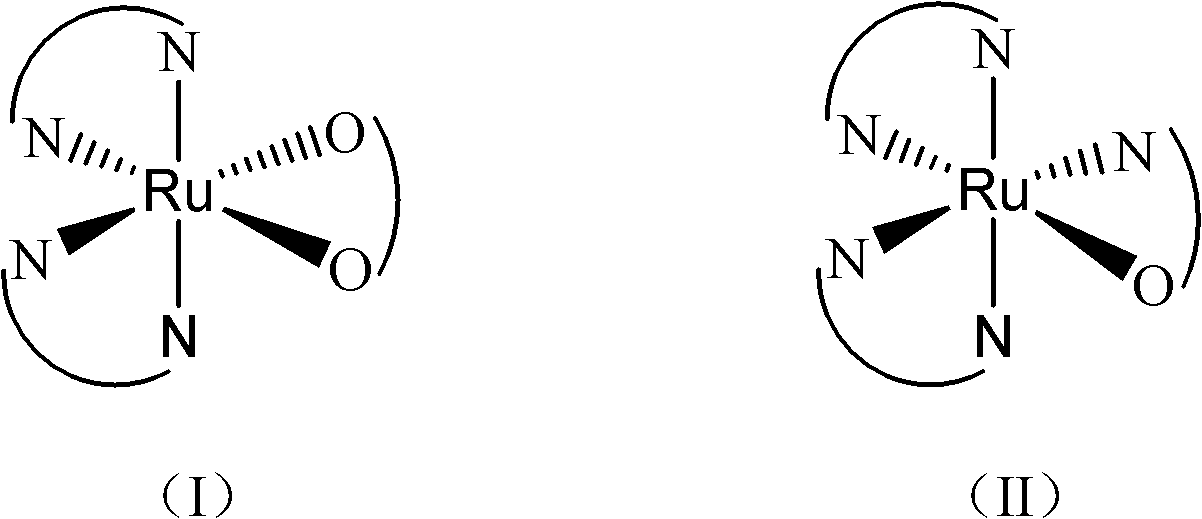

Ruthenium complex capable of inhibiting tumor angiogenesis and preparation method and application thereof

InactiveCN102516309AImprove stabilityImprove solubilityOrganic active ingredientsGroup 8/9/10/18 element organic compoundsSolubilityLithium chloride

The invention belongs to the field of chemical drugs, and discloses a ruthenium complex capable of inhibiting tumor angiogenesis and a preparation method and application thereof. The ruthenium complex provided by the invention has a structure shown in a formula I or II. The preparation method comprises the following steps of: dropwise adding a silver nitrate solution to a sodium salt solution, stirring and reacting, then filtering, washing and vacuum drying a precipitate, and thereby obtaining a ligand O-O; taking ruthenium chloride, L, and lithium chloride to be dissolved in N-, N-dimethyl formamide, heating and refluxing under the protection of argon atmosphere to obtain an intermeidate Ru (L2) Cl22 +; allowing the ligand O-O and the Ru (L2) Cl22 + to be dissolved in an ethanol / water mixed solvent, heating and refluxing to obtain the ruthenium complex shown in the formula I; and allowing the Ru (L2) Cl22 +, 8- hydroxyquinoline, and ammonium acetate to be dissolved in ethanol, and heating and refluxing under the protection of argon atmosphere to obtain the ruthenium complex shown in the formula II. The ruthenium complex has the advantages of good stability, uneasiness in hydrolysis, good solubility, low toxicity, and the ability to inhibit tumor angiogenesis, and is easily absorbed by the human body.

Owner:JINAN UNIVERSITY

Polytef double-film composite filtering materials

InactiveCN1895759ANot easy to hydrolyzeExtended service lifeSemi-permeable membranesPolytetrafluoroethyleneYarn

A dual teflon films combined filtering material is prepared from glass fibers through twisting to become glass fiber yarns, coating teflon film by immersing in teflon solution and baking, weaving to obtain raw fabric, and covering a teflon film on its surface.

Owner:江苏正大森源集团有限公司

Poly(ethylene carbonate) type polyurethane water-based adhesive

ActiveCN102093836AGood bond strengthImprove storage stabilityPolyureas/polyurethane adhesivesChemistryCarbon dioxide

The invention discloses a poly(ethylene carbonate) type polyurethane water-based adhesive which is prepared through the following method: taking 100 parts of poly(ethylene carbonate) diol according to parts by weight, adding 2-10 parts of dimethylol propionic acid, stirring and slowly raising temperature to 100-120 DEG C under nitrogen protection, reducing the temperature to 50-70 DEG C after dissolution, dropping 20-60 parts of diisocyanate, raising the temperature to 70-80 DEG C, reacting for 2-3 hours, stopping heating when glue solution has viscosity and is transparent, naturally cooling to 40-50 DEG C, stopping introducing nitrogen, adding 100-700 parts of 5-30% of catalyst water solution while stirring intensely, neutralizing, emulsifying and preparing the adhesive. As a large number of carbonate bonds are contained in molecules of poly(ethylene carbonate) polyol, the bonding strength of a product is high; simultaneously, the carbonate bonds are less prone to hydrolysis, the storage stability of the product is high. In addition, the poly(ethylene carbonate) polyol is prepared by copolymerizing carbon dioxide and epoxy ethane, the cost is low, and the poly(ethylene carbonate)type polyurethane water-based adhesive has broad market application space.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

Pulullan polysaccharide empty hard capsule and preparation method thereof

InactiveCN101579326AReduce moisture contentSmall range of molecular weight variationPharmaceutical non-active ingredientsCapsule deliveryPlasticizerHard Capsule

The invention discloses a polullan polysaccharide empty hard capsule and a preparation method thereof. The preparation method comprises the following steps: mainly adopting polullan polysaccharide, gel agent, plasticizer, emulsifying agent, latent solvent, water, and the like as raw materials; stirring and dissolving the raw materials in a heating-stirring tank which is vacuumized, heating to form glue, filtering, conveying glue solution into a capsule making machine for making a capsule and finally obtaining the polullan polysaccharide empty hard capsule. The empty hard capsule has the advantages of good quality stability, uneasy friability, stable breakdown index, difficult hydrolysis, no misty and yellowing appearance on the surface while in long-term deposition and can hold solids, oily liquid, semisolids and pasty materials; especially, as the water content of the capsule is lower than that of a gelatine capsule, the capsule is more suitable for being filled with moisture-absorption medicines and aldehydes-containing medicines and has wide market prospect and practical value.

Owner:金斐嘉

Acrylic acid modified epoxy phosphate resin and aqueous dispersion thereof

InactiveCN104497225AImprove rust resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of painting, and particularly relates to acrylic acid modified epoxy phosphate resin and an aqueous dispersion thereof. In the formula, the acrylic acid modified epoxy phosphate resin is prepared from 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid, 8-12 parts of acrylic acid (ester) monomer of which acrylic acid accounts for 1.4-2 parts, 0.5-0.8 part of an initiator, 3.2-5.2 parts of neutralizer and 80-100 parts of water. The resin is prepared by the following steps: modifying epoxy resin with phosphoric acid, and reacting with acrylic acid and ester monomers thereof; adding the neutralizer and deionized water, stirring and emulsifying to obtain the acrylic acid modified epoxy phosphate aqueous dispersion, wherein the acid value of the emulsion is 10-12mgKOH / g, and the solid content is 28-38 percent. The prepared main resin dispersion body is epoxy resin, has a phosphate structure, and has a good adhesive force for metal base materials, thus having good corrosion resistance; acrylic resin is modified, introduced with carboxyl and neutralized by the neutralizer to give aqueous dispersion to resin, so that the resin can be produced into water-borne painting, and the content of VOC is greatly reduced; and multiple hydroxyl radicals are arranged on the main chain of the epoxy resin, and can be crosslinked with amino resin, urea resin and phenolic resin to produce stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Process of producing xylose with stalks

The process of producing xylose with stalks includes the following steps: crushing stalks into 10-20 mesh stalk powder, heating water to 70-80 deg.c and adding sulfuric acid to compound dilute sulfuric acid solution of 2-3 % concentration, mixing the stalk powder and the dilute sulfuric acid solution in the weight ratio of 1 to 4-4.5 to compound hydrolyzed liquid, heating the hydrolyzed liquid at 100-105 deg.c for 50-60 min while evaporating water to reach material / liquid weight ratio of 1 to 2-3, separating the liquid from slag through squeezing, neutralizing the separated liquid with CaCO3 to pH 3-4, and filtering to obtain xylose hydrolysate. The present invention has low cost, simple pre-treatment, low power consumption and high xylose content in the product.

Owner:张海龙

Crystallization method for trichlorosucrose

ActiveCN101210034AShort crystallization timeEasy to operateSugar derivativesSugar crystallisationSolubilitySucrose

The invention discloses a crystallization method of trichloro sucrose. The method dissolves a concentrate or a solid that contains the trichloro sucrose in a mixed impregnant. The mixed impregnant contains two impregnant with large difference in boiling points; wherein, the impregnant with a low boiling point has higher solubility to the trichloro sucrose while the impregnant with a high boiling point has lower solubility to the trichloro sucrose. In the condition of proper temperature and vacuum degree, the impregnant is concentrated and crystals of the trichloro sucrose are separated when the impregnant with low boiling point volatilizes and finished product of trichloro sucrose crystals is obtained through filtering and desiccation after being settled. The method has the advantages of low production cost, high production yield, mild condition, stable quality and simple equipment, etc.

Owner:JK SUCRALOSE

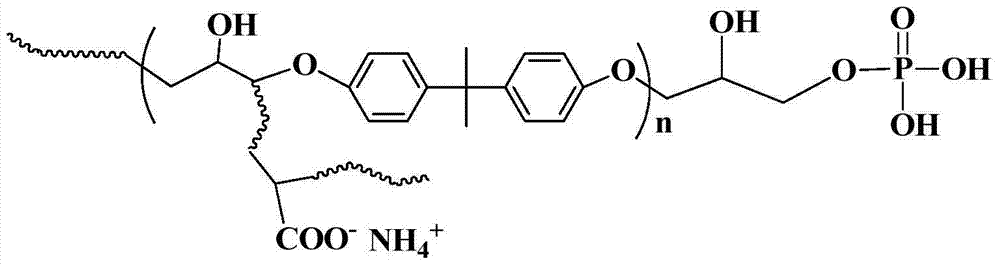

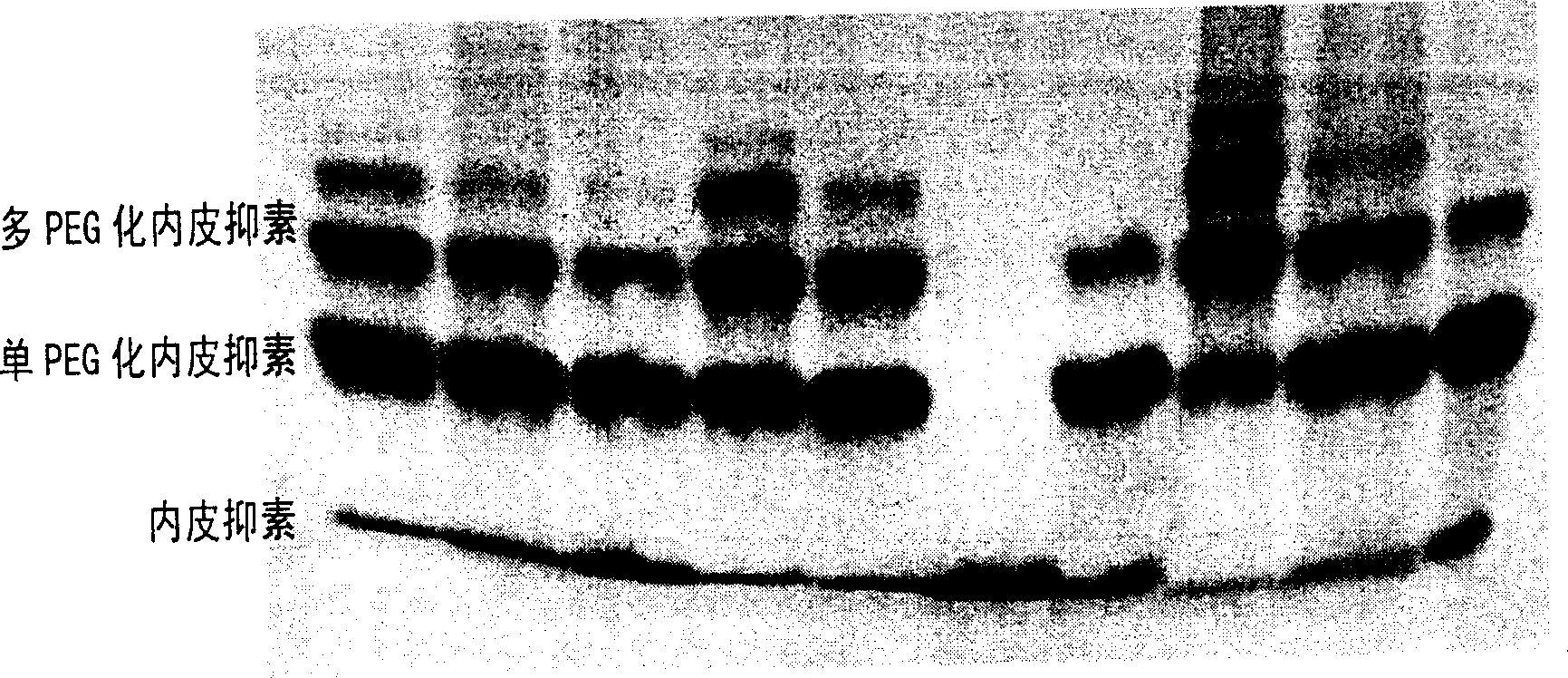

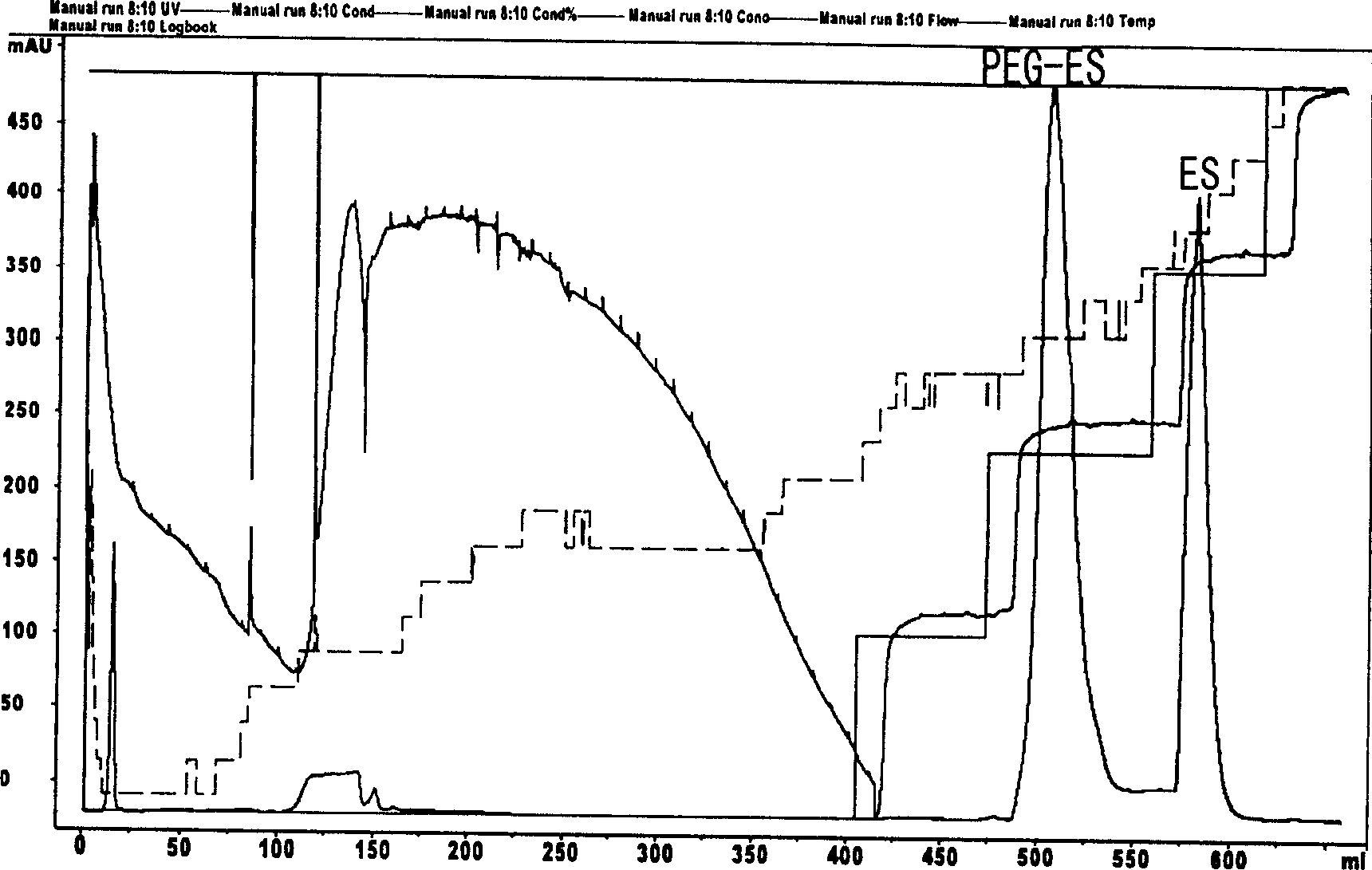

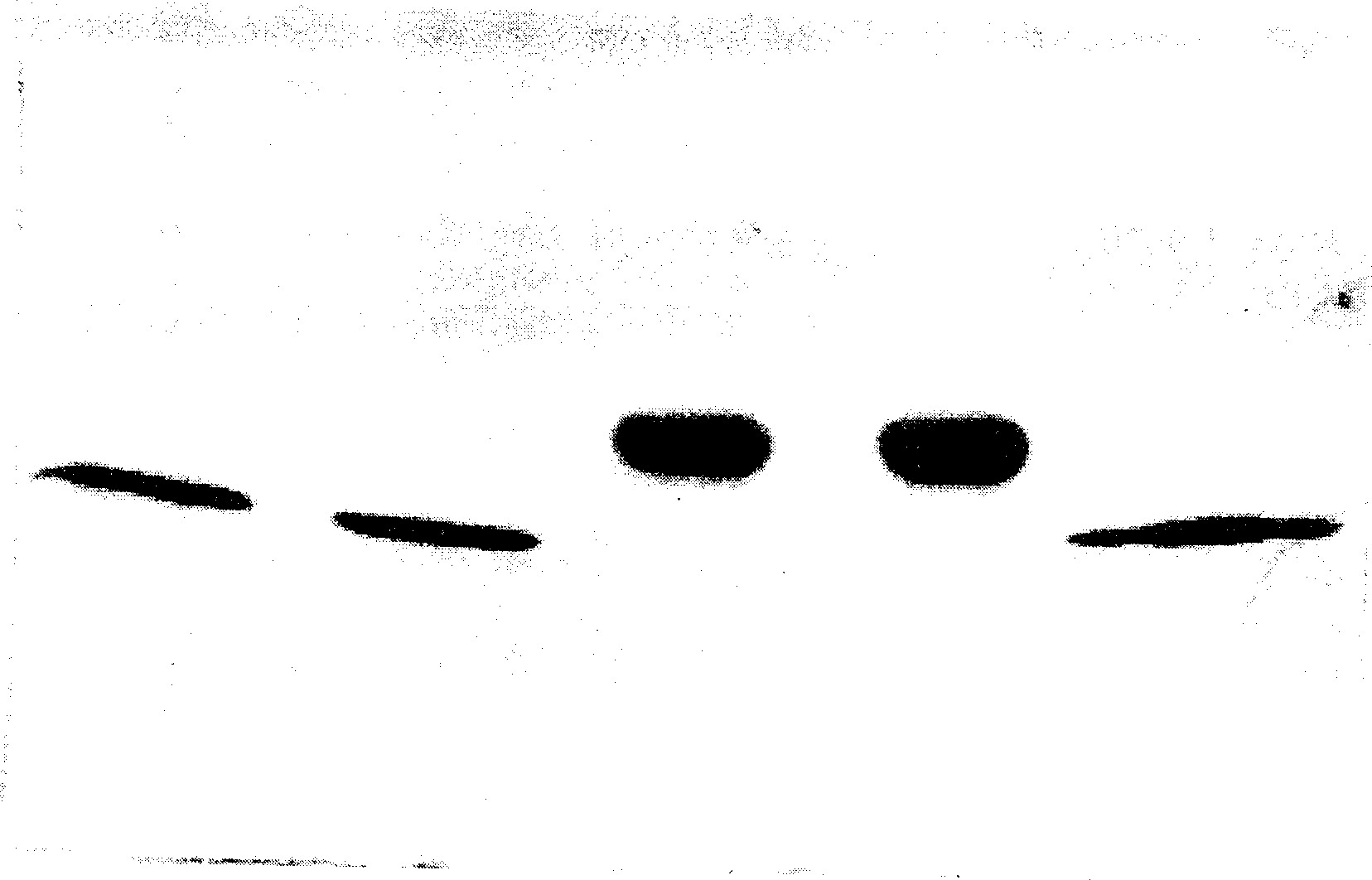

Chemical modification method of endostatin and its use

InactiveCN1891717ANot easy to hydrolyzeStable pHPeptide/protein ingredientsPeptide preparation methodsMonomethoxypolyethylene glycolChymotrypsin

The invention belongs to the field of bio-pharmaceutical products, which provides a chemical modification method for recombinate human rh-Endostatin ('rh-ES' is called for short) through the way of using mPEG-propionaldehyde to be combined on the fixed point of free amino of N-terminal amino acid of rh-ES. Mono-PEG-rhES is the output material, its purity meet the requirements of biological products. It plays a key role in the hydrolysis resistance of trypsin and chymotrypsin, it can be used as long-acting formulations for its stability for pH and temperature and there is a great perspective in the clinical treatment of cancer.

Owner:NANJING UNIV +1

Dry preparation method for large-size boehmite

InactiveCN102249270AImprove heat resistanceHigh whitenessAluminium oxides/hydroxidesAluminium hydroxideGranularity

The invention discloses a dry preparation method for large-size boehmite. The method comprises the following steps of: at a temperature of 120-350DEG C and under a pressure intensity of more than or equal to 10kPa, converting the gibbsite crystal structure of aluminium hydroxide into boehmite; then grinding the boehmite till the granularity is of 1-4 micrometers, and scattering the boehmite particles into water uniformly by a wet high-speed stirring method, and conducting a nano-SiO2 coating treatment on the surface; and finally performing impurity removing, purification and drying, thus obtaining the product of large-size boehmite. The large-size boehmite prepared by a dry method of the invention has low impurity content, high boehmite conversion rate and controllable crystallization granularity. In addition, employing an inorganic modifier, the method provided in the invention can substantially reduce material oil absorption rate and improve liquidity, thus broadening the application of the method in the field of electronic materials.

Owner:ANHUI ESTONE MATERIAL TECH CO LTD

Safe lithium ion battery

InactiveCN102208678AImprove securityImprove cycle performanceElectrode carriers/collectorsSecondary cellsElectrical batteryThermistor

The invention discloses a safe lithium ion battery, which comprises an anode system, a cathode system, a membrane spaced between an anode and a cathode, and an electrolyte system, wherein the anode system comprises an anode current collector and a membrane attached to the anode current collector and containing an anode active substance; the cathode system comprises a cathode current collector and a membrane attached to the cathode current collector and containing a cathode active substance; an organic conductive film is used as the current collector in one or both of the anode system and the cathode system; and a polymer matrix with positive temperature coefficient (PTC) thermistor property is adopted in the organic conductive film. The organic conductive film has the PTC thermistor property. The lithium ion battery can avoid the safety problems of battery combustion and even explosion and the like caused by over charge and battery temperature rise due to external short circuit.

Owner:CENT SOUTH UNIV +1

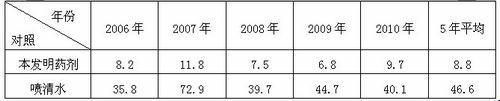

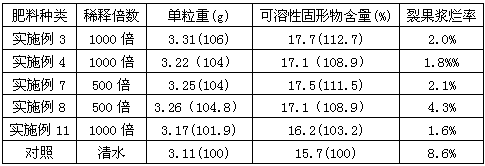

Fruit anti-cracking nutritional agent and preparation method thereof

ActiveCN102040429AEnhance cell viabilityPromote cell divisionFertilizer mixturesChemistryAqueous solution

The invention discloses a fruit anti-cracking nutritional agent and a preparation method thereof. The fruit anti-cracking nutritional agent comprises the following raw materials in part by weight: 5 to 15 parts of sodium carboxymethylcellulose, 3 to 7 parts of calcium, 1 to 5 parts of ethylene glycol, 0.01 to 0.9 part of plant growth regulator and 10 to 20 parts of water. The preparation method comprises the following steps of: (1) dissolving the sodium carboxymethylcellulose with the water so as to obtain sodium carboxymethylcellulose aqueous solution; (2) adding the calcium into the sodium carboxymethylcellulose aqueous solution and heating to the temperature of between 40 and 50 DEG C; and (3) adding the ethylene glycol into the solution obtained in the step (2), stirring at the temperature of between 40 and 50 DEG C for 30 to 40 minutes, lowering the temperature to the normal temperature, adding the plant growth regulator and stirring uniformly so as to obtain the fruit anti-cracking nutritional agent. The medicinal agent forms a film after being applied by spraying, is difficultly dissolved in the water for the second time after being dried, has a controllable thickness and can effectively lower fruit cracking rate by about 10 percent.

Owner:李开森

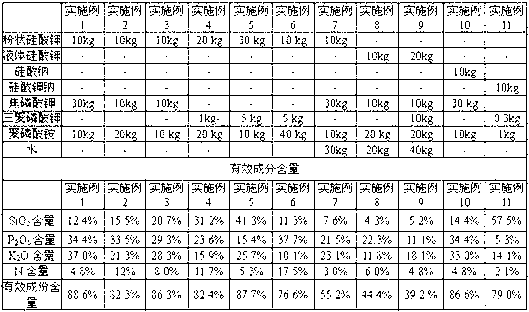

Silicon-containing water-soluble fertilizer

The invention relates to a silicon-containing water-soluble fertilizer. The silicon-containing water-soluble fertilizer is characterized by comprising four main nutrient elements N, P, K and Si, wherein the four main nutrient elements N, P, K and Si are supplied by three substances including water-soluble silicate, poly-condensed potassium phosphate and ammonium polyphosphate. The silicon-containing water-soluble fertilizer can be produced into a solid fertilizer or a liquid fertilizer. The fertilizer with high content of effective elements has a function of obviously increasing the yield, the quality and the stress resistance of plants, and is applicable to food crops, vegetables, fruit trees and the like.

Owner:HEBEI ACAD OF FORESTRY SCI

Acrylic acid modified epoxy phosphate ester resin and preparation method of aqueous dispersion thereof

The invention belongs to the field of coating and provides acrylic acid modified epoxy phosphate ester resin and a preparation method of aqueous dispersion thereof. The formula comprises 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid and 8-12 parts of acrylic acid (acrylate) monomer, wherein the acrylic acid monomer accounts for 1.4-2 parts, an initiator accounts for 0.5-0.8 part, a neutralizer accounts for 3.2-5.2 parts and water accounts for 80-100 parts. The preparation method comprises the following steps: modifying the epoxy resin by using the phosphoric acid, reacting the epoxy resin with the acrylic acid and the ester monomer thereof, adding the neutralizer and deionized water, stirring and emulsifying to obtain the aqueous dispersion of the acrylic acid modified epoxy phosphate ester resin, wherein the acid value of the emulsion is 10-12 mg KOH / g, and the solid content is 28-38%. The main body of the obtained resin dispersion is epoxy resin, has a phosphate structure and has a good adhesive force on a metal base material, so that the corrosion resistance is excellent, carboxyls are introduced by the modification of the acrylic resin and provides water dispersibility after being neutralized by the neutralizer, the resin can be made into a water-based paint, the VOC content is greatly reduced, and a plurality of carboxyls are carried on the epoxy main chain to be crosslinked with such resin as amino, urea formaldehyde and phenolic aldehyde to be made into stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

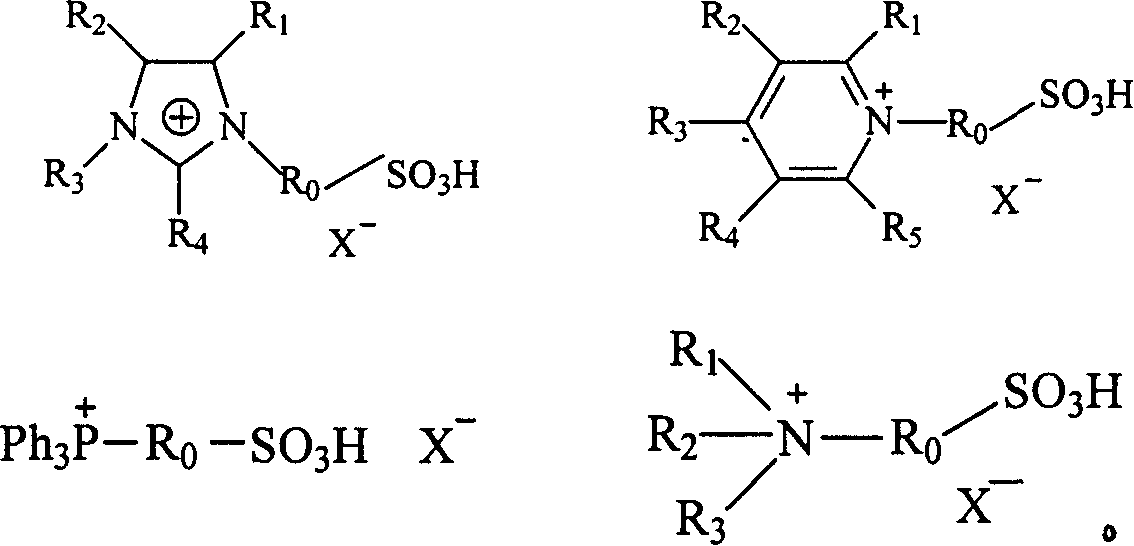

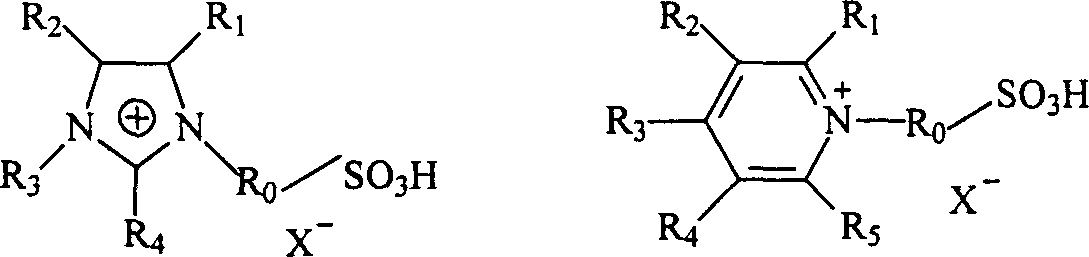

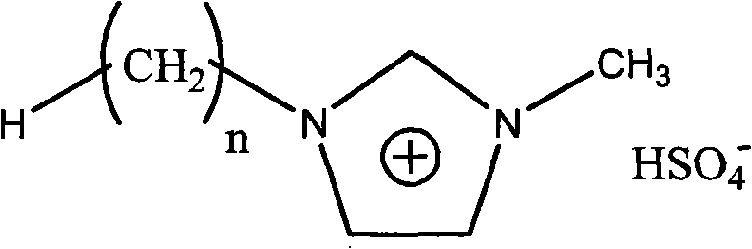

Method for producing lactic acid ester with ion liquid catalysis

InactiveCN101402572AThe synthesis process is simpleLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidAlcohol

The invention discloses a method for making lactate by ionic liquid catalyst. The method comprises the following steps: mixing alcohol and acid the molar ratio of which is 1.5 to 2 with a Brphinsted acid imidazole ionic liquid as a catalyst and a solvent for reaction together, adding ethyl acetate as a dehydrating agent, stirring and reacting for 2 to 6 hours under normal pressure at a temperature of between 60 and 90 DEG C, then distilling under the normal pressure to remove alcohol and ethyl acetate, and finally reducing pressure and stilling to collect products, wherein the feeding amount of the ionic liquid is 10 to 50 percent of the total mol number of the alcohol and acid. Because the ionic liquid catalyst used in the method has high catalytic activity, good selectivity, low cost and stable quality, is not easy to hydrate, and can be used repeatedly through simple vacuum dehydration, the method has high percent conversion and can reduce the cost for manufacturing the lactate greatly.

Owner:SICHUAN UNIV

Aluminum-zirconium-phosphorus master alloy and preparation method thereof

The invention belongs to the field of metal materials, relating to an aluminum-zirconium-phosphorus master alloy used for refining eutectic and primary silicon in hypereutectic Al-siliceous ferroalloy and a preparation method thereof. In a master alloy system, P exists in a mode of a ZrP compound which contains the following components by weight percent 78.0 percent to 94.0 percent of aluminum, 3.0 percent to 20.0 percent of zirconium and 1.0 percent to 6.0 percent of phosphorus. The preparation method comprises the following steps: preparing industrial pure aluminum, aluminum-phosphorus master alloy, sponge zirconium or potassium fluorozirconate according to the ratio; melting the industrial pure aluminum to 900 DEG C to 1300 DEG C in a melting furnace; firstly adding the aluminum-phosphorus master alloy to mix for 10 to 20 min; and then adding the sponge zirconium or the potassium fluorozirconate to fully react and uniformly mix, and directly casting the mixture to form a ingot or prepare a wire. The aluminum-zirconium-phosphorus master alloy has favorable refining effect, and can remarkably improve the high temperature mechanical properties of the alloy.

Owner:SHANDONG UNIV

'Xingnaojing' dripping pills for treating cephalitis and hepatic coma and preparation process thereof

InactiveCN1634145AQuality improvementDefinite curative effectMammal material medical ingredientsDrug compositionsJapanese encephalitisDisease

The invention discloses a pharmaceutical composition for treating diseases including epidemic type B encephalitis and hepatic coma, which has the advantages of wherein the bolus has the advantages of high biological availability, quick-speed medicine release, quick-speed effect, less toxic and side effects, higher medicinal content, smaller amount of administration, accurate administration dosage, easy administration, low price, and facilitated carrying. The preparation is prepared through the conventional injection extracting processes.

Owner:SHANDONG WOHUA PHARMACEUTICALS CO LTD

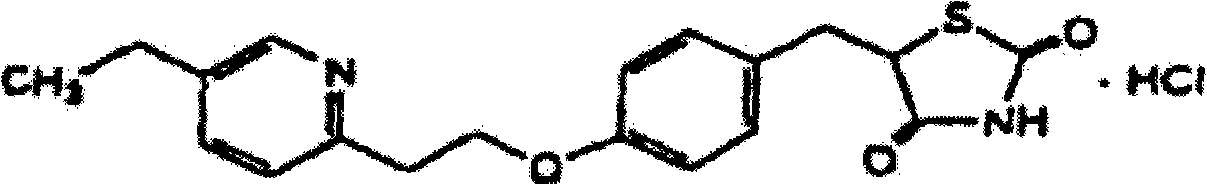

Pioglitazone hydrochloride sustained-release dropping pill and preparation method thereof

InactiveCN101269040AIncrease surface areaHas a wetting effectOrganic active ingredientsMetabolism disorderPharmaceutical formulationBlood drug concentration

The invention discloses to a drug compound for treating diabetes and particularly relates to a drug compound oral pharmaceutical formulation adopting pioglitazone as the ingredient. The drug compound aims to supplement the deficiency of the prior oral pharmaceutical formulation used for treating Type-2 Diabetes and provide a drug compound oral pharmaceutical formulation, sustained-release pioglitazone dropping pill which has high bioavailability, controllable release time, long-acting effect, low frequency of drug taking, steady plasma concentration, low cost and absence of contamination during the production. The sustained-release pioglitazone dropping pill adopts pioglitazone as the chemical ingredient and is prepared jointly with the medicinal carriers of hydrophilic frame ingredients and hydrophobic frame ingredients used as the stroma.

Owner:北京博智绿洲医药科技有限公司

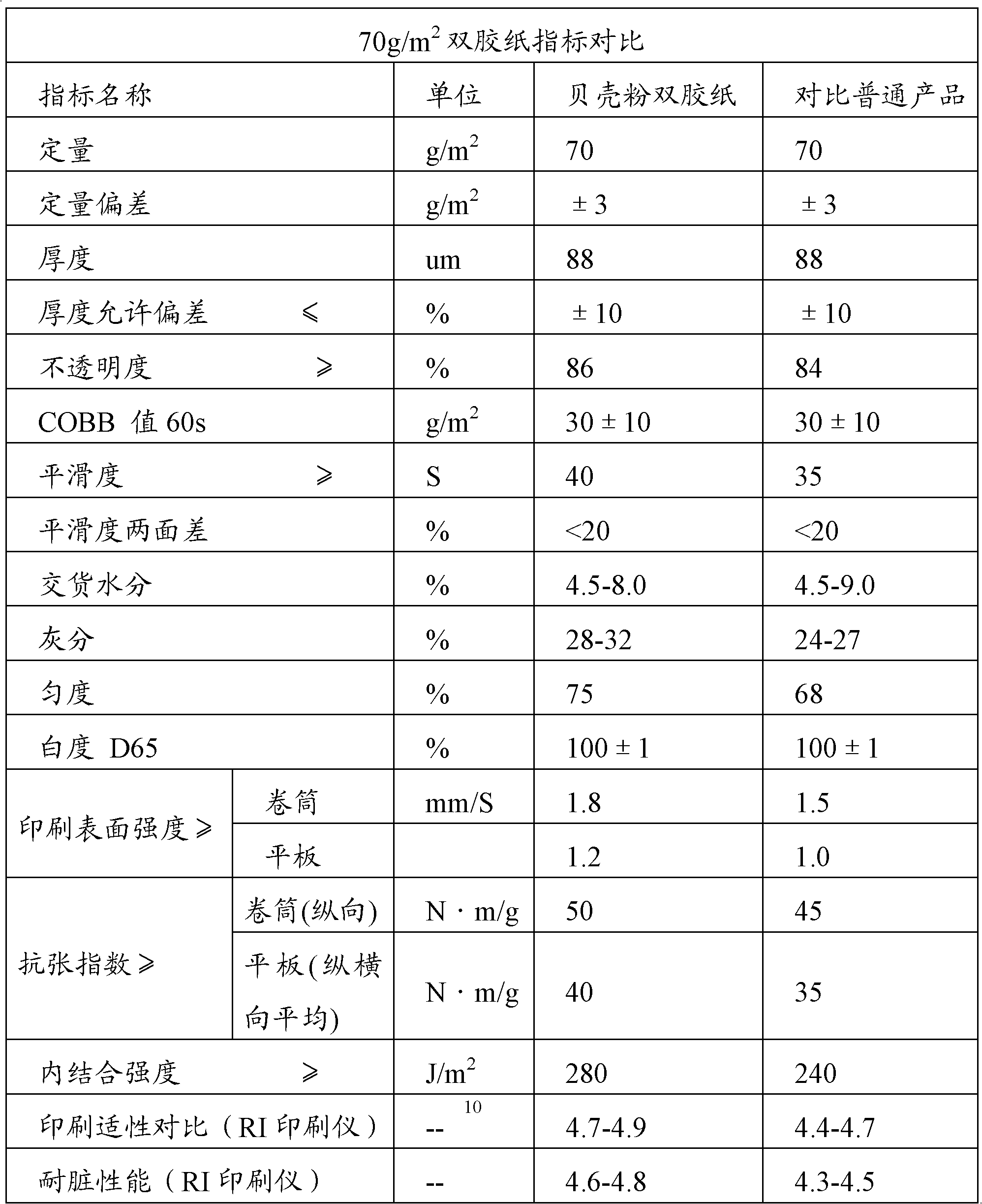

Side offset paper and preparation method thereof

ActiveCN102154927AReduce dosageHigh bonding strengthWater-repelling agents additionPaper coatingPapermakingUltimate tensile strength

The invention relates to the technical field of papermaking, in particular to a side offset paper produced by shell powder and a preparation method thereof. In the side offset paper, high-whiteness hard wood pulp and high-whiteness chemical-mechanical pulp serve as the main material, and meanwhile, shell powder is auxiliary filler for producing the side offset paper; oxidized Cual is added into surface amylopectin to improve the printing surface strength of the side offset paper and avoid the defects of printing hair slip and duslting because of high paper forming ash content; meanwhile, the paper forming printing adaptability and dirty resistance can be obviously improved; and the colorful printing quality of the product is substantially improved.

Owner:ASIA SYMBOL GUANGDONG PAPER

Vegetable disease prevention and control preparation containing plant inducer

InactiveCN103109811ANot easy to hydrolyzeStrong plant growthPlant growth regulatorsBiocidePolyglutamic acidBiology

The invention discloses a vegetable disease prevention and control preparation containing a plant inducer. The vegetable disease prevention and control preparation contains the components by weight percent of 30-70% of polyglutamic acid and 30-70% of chitooligo saccharide. The preparation method comprises the step of: evenly mixing the polyglutamic acid with the chitooligo saccharide according to a ratio. The polyglutamic acid and the chitooligo saccharide are mixed according to the ratio, namely 1.5-2g of the mixture of the polyglutamic acid and the chitooligo saccharide is mixed with water with the weight being 15000-20000 times that of the mixture of the polyglutamic acid and the chitooligo saccharide in each 667m<2>; and the vegetable disease prevention and control preparation is sprayed at the surfaces of plants for preventing and controlling fungal diseases such as cucumber downy mildews and botrytis cinereas before a disease appears.

Owner:SUZHOU ACADEMY OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com