Organosilicone modified acrylate emulsion, preparation method thereof and water-based artificial stone prepared from organosilicone modified acrylate emulsion

A technology of acrylate and methyl acrylate, applied in the field of water-based artificial stone, can solve the problems of low silicon content, poor hardness, adhesion, weather resistance, etc., and achieve the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

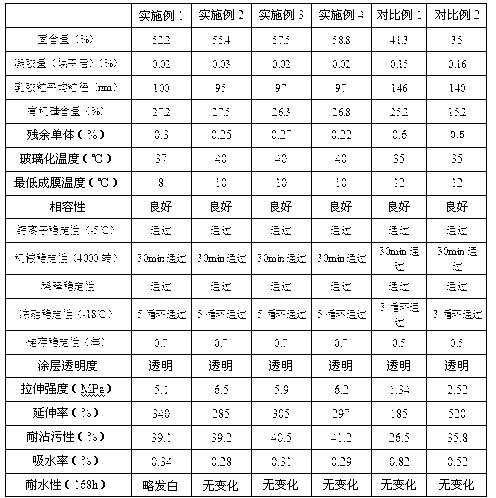

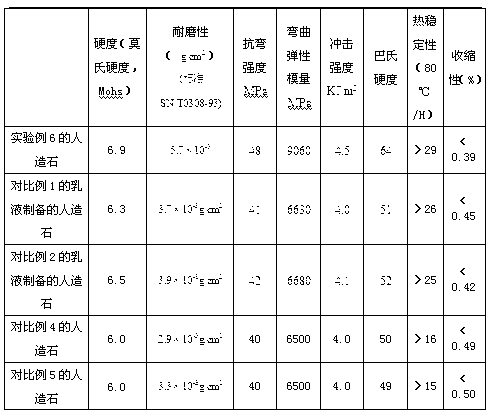

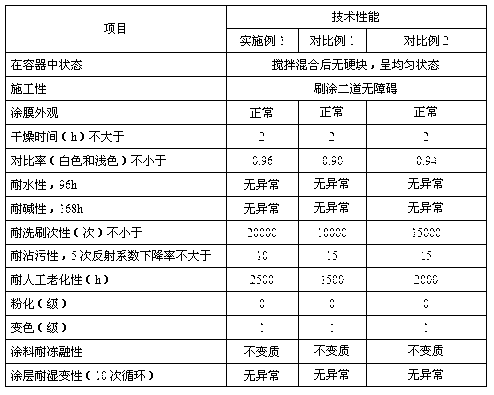

Examples

Embodiment 1

[0067] Example 1 Preparation of silicone-acrylic emulsion

[0068] 1) Preparation of silicone intermediate emulsion:

[0069] 4.0 parts by weight of dodecylbenzenesulfonic acid and 150 parts by weight of water were added to the reaction kettle and stirred, the water bath was heated to 80 ° C, 37.0 parts by weight of octamethylcyclotetrasiloxane D4 was added, and 6.0 parts by weight of Y-methyl were added. Acryloyloxypropyltrimethoxysilane KH570, 0.4 parts by weight of hexamethyldisiloxane MM, incubated for 7 hours, cooled to room temperature, and neutralized to pH=7.

[0070] 2) Preparation of silicone-acrylic copolymer core emulsion:

[0071] 80% siloxane intermediate emulsion, 30 parts by weight of water, 0.2 part by weight of sodium lauryl sulfate, 0.3 part by weight of nonylphenol polyoxyethylene ether, first-step mixed monomer (30 parts by weight of styrene, 180 parts by weight of methyl methacrylate, 85 parts by weight of methyl acrylate, 5 parts by weight of acrylic ...

Embodiment 2

[0075] Example 2 Preparation of silicone-acrylic emulsion

[0076] 1) Preparation of silicone intermediate emulsion:

[0077] 3 parts by weight of dodecylbenzene sulfonic acid and 120 parts by weight of water were added to the reaction kettle and stirred, the water bath was heated to 80° C., 30 parts by weight of octamethylcyclotetrasiloxane D was added, and 4 parts by weight of Y-methyl were added. Acryloyloxypropyltrimethoxysilane KH570, 0.1 part by weight of hexamethyldisiloxane MM, incubated for 7 hours, cooled to room temperature, and neutralized to pH=7.

[0078] 2) Preparation of silicone-acrylic copolymer core emulsion:

[0079] Mix 80% siloxane intermediate emulsion, 10 parts by weight of water, first-step mixed monomer (30 parts by weight of styrene, 170 parts by weight of methyl methacrylate, 75 parts by weight of methyl acrylate, 5 parts by weight of acrylic acid) Homogeneous, as a pre-emulsion

[0080] 20% siloxane intermediate emulsion, 0.2 parts by weight o...

Embodiment 3

[0083] Example 3 Preparation of silicone-acrylic emulsion

[0084] 1) Preparation of silicone intermediate emulsion:

[0085] 4.5 parts by weight of dodecylbenzene sulfonic acid and 180 parts by weight of water were added in the reaction kettle and stirred, the water bath was heated to 80° C., 40 parts by weight of octamethylcyclotetrasiloxane D4 were added, and 10 parts by weight of Y-methyl were added. Acryloyloxypropyltrimethoxysilane KH570, 1.0 parts by weight of hexamethyldisiloxane MM, incubated for 8 hours, cooled to room temperature, and neutralized to pH=7.

[0086]2) Preparation of silicone-acrylic copolymer core emulsion:

[0087] 80% siloxane intermediate emulsion, 50 parts by weight of water, 1 part by weight of sodium lauryl sulfate, 1 part by weight of nonylphenol polyoxyethylene ether, first-step mixed monomer (60 parts by weight of styrene, 230 parts by weight of methyl methacrylate, 130 parts by weight of methyl acrylate, 8 parts by weight of acrylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com