Method for producing lactic acid ester with ion liquid catalysis

An ionic liquid, catalytic preparation technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve problems such as environmental pollution, achieve low price, good selectivity, easy control and industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

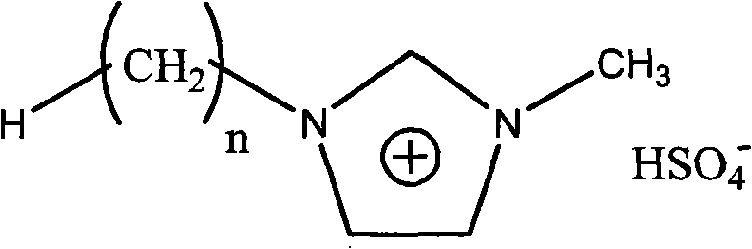

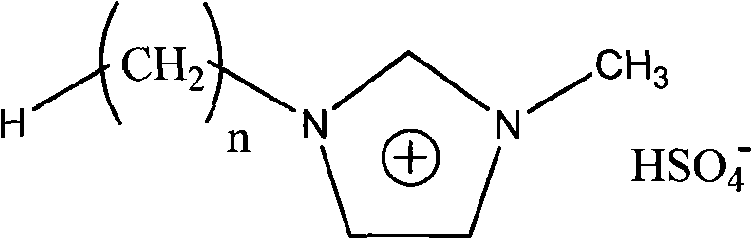

Image

Examples

Embodiment 1

[0025] Put 0.05mol ionic liquid 1-methylimidazolium bisulfate, 0.2mol methanol, 0.1mol racemic lactic acid, 0.1mol ethyl acetate into a round-bottomed flask equipped with a reflux condenser, stir magnetically, and heat at 63°C Heating and reacting for 2 hours; then atmospheric pressure distillation to remove alcohol and ethyl acetate, and then vacuum distillation to collect the product racemic methyl lactate with a yield of 90% and a selectivity of 100%; the ionic liquid was subjected to vacuum dehydration treatment and reused.

Embodiment 2

[0027] Put 0.04mol ionic liquid 1-methylimidazolium bisulfate, 0.15mol ethanol, 0.1mol racemic lactic acid, 0.1mol ethyl acetate into a round-bottomed flask equipped with a reflux condenser, stir magnetically, and heat at 70°C Heating and reacting for 3 hours; then removing alcohol and ethyl acetate by distillation under normal pressure, and then collecting the product racemic ethyl lactate by distillation under reduced pressure, with a yield of 88% and a selectivity of 100%; the ionic liquid is reused after vacuum dehydration.

Embodiment 3

[0029] With 0.06mol ionic liquid 1-methylimidazolium bisulfate, 0.18mol n-propanol, 0.1mol racemic lactic acid, 0.1mol ethyl acetate; add in the round bottom flask equipped with reflux condenser, magnetically stir, and in Heating and reacting at 82°C for 6 hours; then distilling off alcohol and ethyl acetate under normal pressure, and then distilling under reduced pressure to collect the product racemic n-propyl lactate, with a yield of 77% and a selectivity of 97%; the ionic liquid is reused after vacuum dehydration .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com