High strength heat resistant alloy

A technology of heat-resistant alloys and aluminum alloys, which is applied in the field of cast aluminum-silicon alloys, high-strength and hot aluminum alloys, can solve problems such as undiscovered alloy materials reported in literature, and achieve performance stability problems, small structures, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

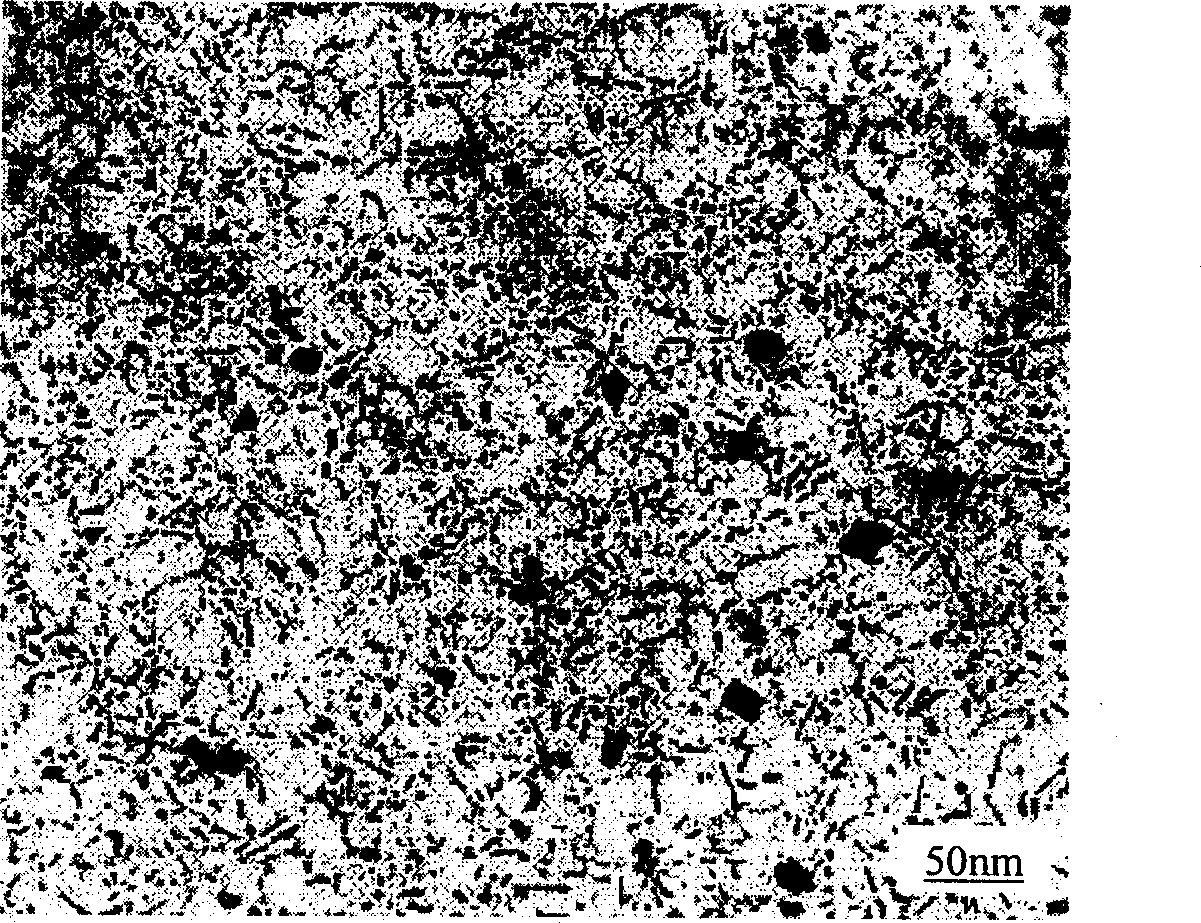

[0044] see figure 1 , the alloy of the present invention is welded by alloy smelting method, and its chemical composition (wt%) is as follows: Si: 14.5, Cu: 2.7, Ni: 1.5, Mn: 0.7, Mg: 0.6, Ti: 0.1, Fe: 0.3, B: 0.08 , Zr: 0.04, Cd: 0.2, P: 0.03, and the rest are aluminum. Put industrial pure aluminum, pure magnesium, crystalline Si, electrolytic nickel Ni, electrolytic copper Cu, titanium Ti, manganese Mn or Al-Si, Al-Cu, Al-Ti, Al-Mn, Al-Ni master alloy in the crucible furnace Melting, pouring parts after refining, metamorphism, and static. The room temperature tensile strength of the obtained material is 320-380MPa, and the high-temperature (350°C) tensile strength is 120-160MPa, which is 3-4 times of the high-temperature strength of common aluminum-silicon alloys. The hardness is 50% higher than that of the aluminum-silicon matrix alloy, and the elastic modulus is 40% higher than that of the aluminum-silicon matrix alloy. figure 1 is the heat treatment metallographic stru...

Embodiment 2

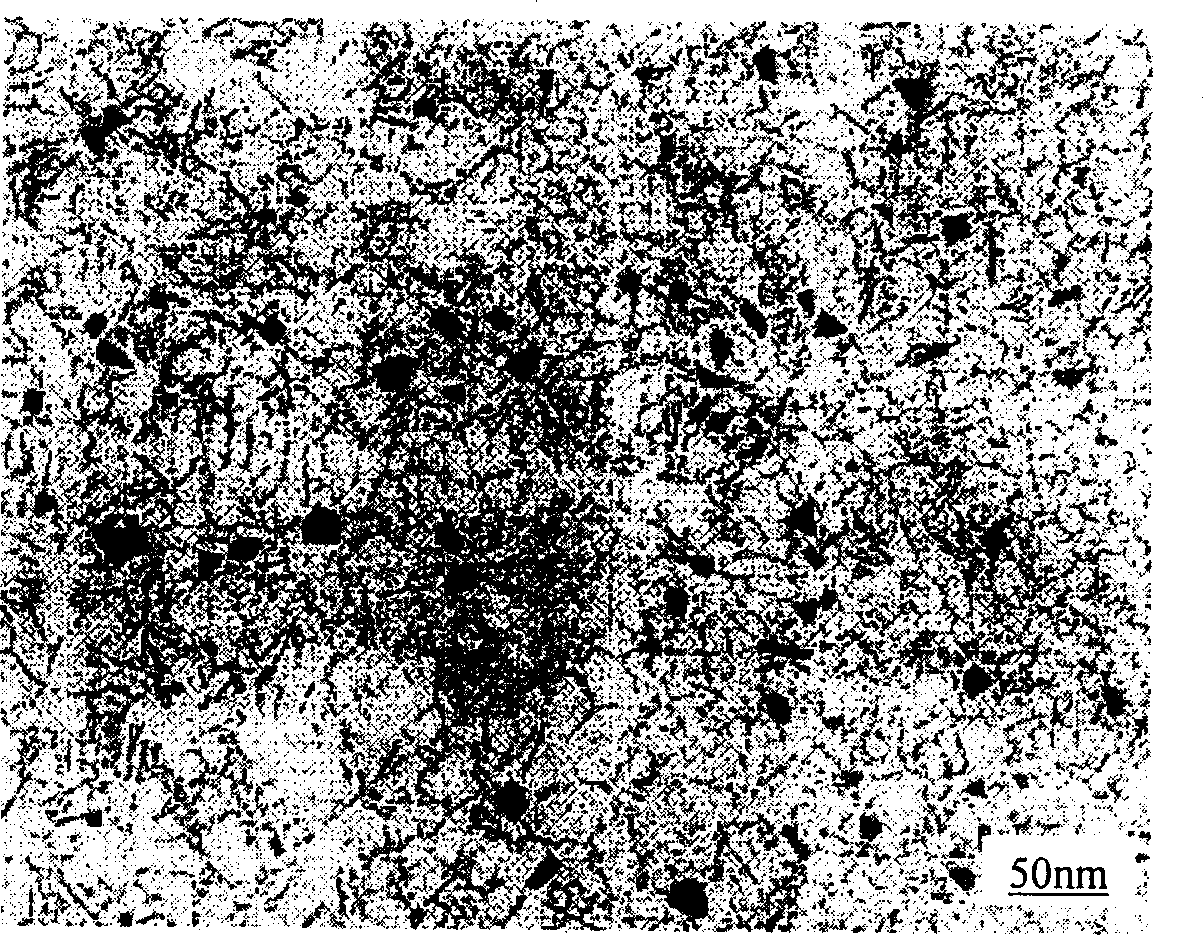

[0047] The preparation method is the same as in Example 1, and the alloy of the present invention is prepared by using the alloy smelting technology. Its chemical composition (wt%) is as follows: Si: 7.0, Cu: 2..0, Ni: 1.5, Mn: 0.7, Mg: 0.6, Ti: 0.15, Fe: 0.3, B: 0.08, Zr: 0.04, Cd: 0.2, P: 0.005, the rest is aluminum, the room temperature tensile strength of the obtained material is 320-400MPa, the high temperature (350°C) tensile strength is 120-140MPa, and the hardness is 32% higher than that of the aluminum-silicon matrix alloy. image 3 It is the as-cast metallographic structure photo of the alloy

Embodiment 3

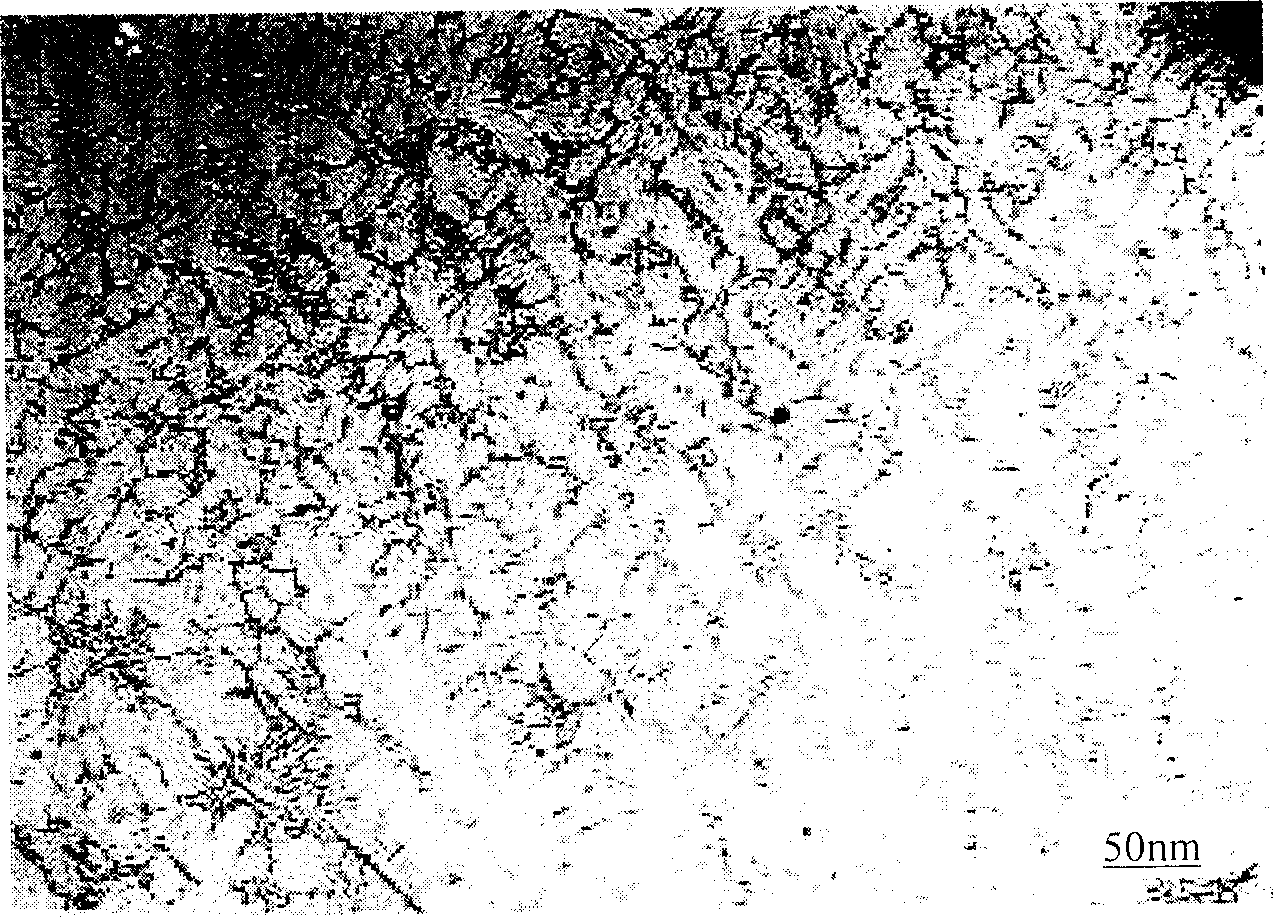

[0049] The preparation method is the same as in Example 1, and the alloy of the present invention is prepared by using the alloy smelting technology. Its chemical composition (wt%) is as follows: Si 7, Cu 2, Ni 0.5, Mn 0.2, Mg 0.6, Ti 0.08, Fe 0.3, B 0.02, Zr0.04, Cd 0.15, P 0.01, the rest is aluminum, because the alloy including evenly distributed L1 2 Crystal structure of Al 3 X particles (X is Ti, Zr, Ni) and TiB with hcc crystal structure 2 , their lattice parameters are coherent with the aluminum matrix, have good high temperature stability, and play the role of grain refinement and high temperature strengthening in the alloy. The room temperature tensile strength of the obtained material is 340-410MPa, the high-temperature (350°C) tensile strength is 80-120MPa, and the hardness is 30% higher than that of the aluminum-silicon matrix (aluminum-silicon binary alloy with the same silicon content) alloy. Figure 4 is the alloy coherent nanophase Al 3 TEM topography of Ti;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com