Micro alloyed oxide dispersion-strengthening ferrite steel and preparation method

A ferritic steel and micro-alloying technology, which is applied in the field of metal material preparation, oxide dispersion strengthened ferritic steel and preparation, can solve the problems of poor process controllability, low production efficiency, easy introduction of pollution, etc. Preparation cost, convenient operation, and the effect of improving high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Preparation of Ball Milling Powder

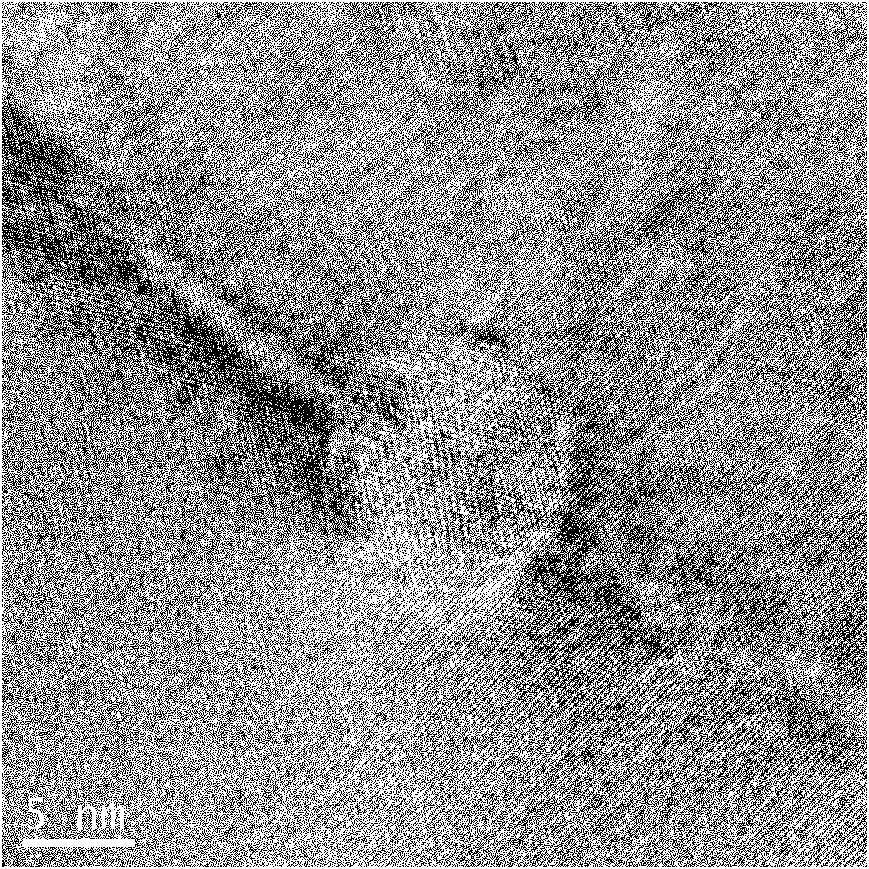

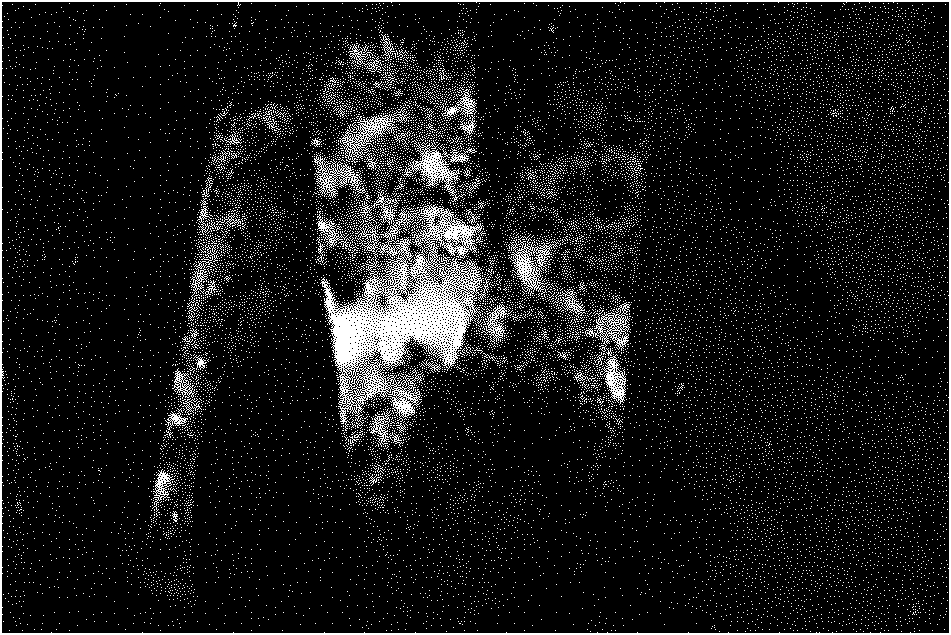

[0038] According to the designed component distribution ratio, the average particle size is -325 mesh YH 2 Powder, average particle size -325 mesh TiH 2 Powder, Fe with an average particle size of 50nm 2 o 3The powder is mixed with the Fe-14Cr-3W alloy powder with a particle size of -200 mesh prepared by the argon gas atomization method. Under the protective atmosphere of argon gas with a purity of 99.99%, a planetary ball mill is used, and the ball milling speed is 350r / min; the time is 24h; the ratio of ball to material is 8:1 mechanical ball milling to obtain ball milling powder; wherein the weight percentage of each component is: YH 2 0.4wt.%, TiH 2 0.4wt.%, Fe 2 o 3 0.3wt.%, Cu 1%, the balance is Fe-14Cr-3W;

[0039] Step 2: Thermal Consolidation Forming

[0040] Put the ball mill powder in the first step into the ladle, degas, seal and weld, and carry out hot extrusion molding at 1150°C, the extrusion ratio i...

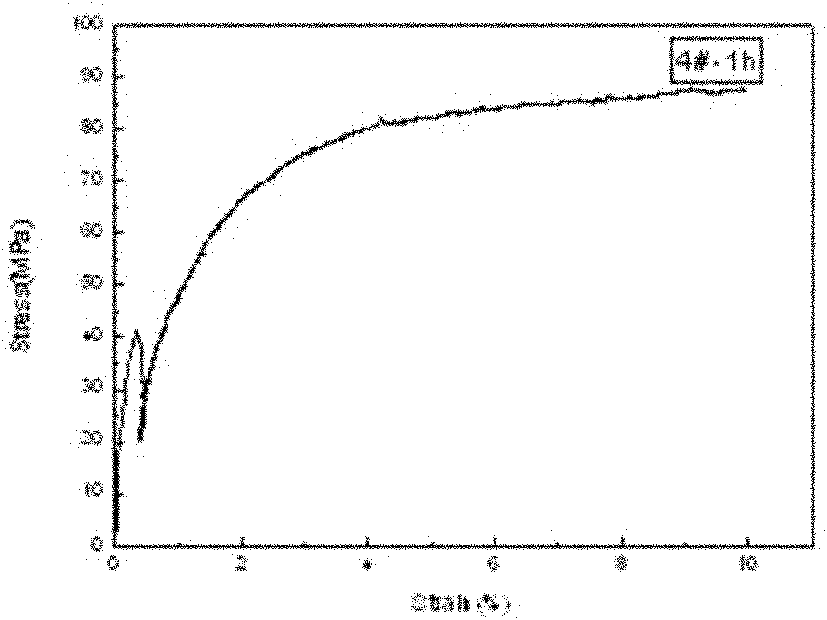

Embodiment 2

[0045] Step 1: Preparation of Ball Milling Powder

[0046] According to the designed component distribution ratio, the average particle size is -200 mesh YH 2 Powder, average particle size -200 mesh TiH 2 Powder, Fe with an average particle size of 70nm 2 o 3 The powder is mixed with the Fe-15Cr-2W alloy powder with a particle size of -300 mesh prepared by the argon gas atomization method. Under the protective atmosphere of argon gas with a purity of 99.99%, a planetary ball mill is used, and the ball milling speed is 250r / min; the time is 48h; the ratio of ball to material is 7:1 mechanical ball milling to obtain ball milling powder; wherein the weight percentage of each component is: YH 2 0.3wt.%, TiH 2 0.3wt.%, Fe 2 o 3 0.2wt.%, Cu 2%, the balance is Fe-15Cr-2W;

[0047] Step 2: Thermal Consolidation Forming

[0048] Put the ball mill powder in the first step into the ladle, degas, seal and weld, and carry out hot extrusion molding at 1100°C, the extrusion ratio ...

Embodiment 3

[0053] Step 1: Preparation of Ball Milling Powder

[0054] According to the designed component distribution ratio, the average particle size is -250 mesh YH 2 Powder, average particle size -250 mesh TiH 2 Powder, Fe with an average particle size of 100nm 2 o 3 The powder is mixed with the Fe-16Cr-1W alloy powder with a particle size of -250 mesh prepared by the argon gas atomization method. Under the protective atmosphere of argon gas with a purity of 99.99%, a planetary ball mill is used, and the ball milling speed is 300r / min; the time is 36h; the ball-to-material ratio is 6:1 mechanical ball milling to obtain ball milling powder; wherein the weight percentage of each component is: YH 2 0.6wt.%, TiH 2 1.0wt.%, Fe 2 o 3 0.5wt.%, Cu 3wt.%, the balance is Fe-16Cr-1W;

[0055] Step 2: Thermal Consolidation Forming

[0056] Put the ball mill powder in the first step into the ladle, degas, seal and weld, and carry out hot extrusion molding at 1050°C, the extrusion ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com