Method for preparing cesium tungstate of tungsten bronze structure

A technology of cesium tungstate and tungsten bronze, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of risk index and cost increase, and achieve the effect of environmental protection, simplified preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

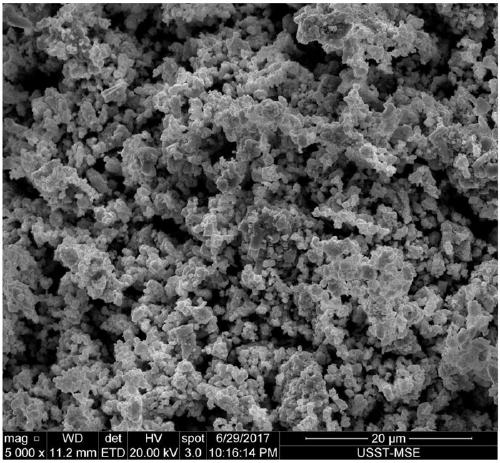

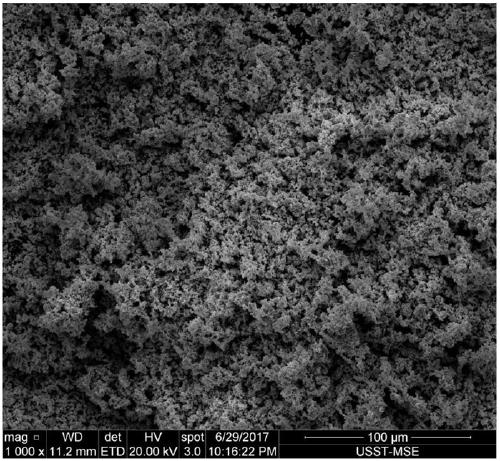

Image

Examples

Embodiment 1

[0026] A preparation method of cesium tungstate of tungsten bronze structure, comprising the following steps;

[0027] (1) Mix cesium carbonate, tungsten oxide and deionized water to obtain mixture A, add a small amount of sintering aid, and perform wet ball milling at normal temperature to obtain a mixed slurry;

[0028] Wherein, the mol ratio of cesium carbonate and tungsten oxide is 1:1;

[0029] Burning aid is LiNbO 3 and boric acid, sintering aid weight accounted for 0.4% of mixture A, LiNbO 3 The mass ratio with boric acid is 1:1;

[0030] (2) Take out the mixed slurry, dry it, then dry the material in H 2 and N 2 Heat treatment at 450°C for 2 hours in a mixed atmosphere;

[0031] Among them, H 2 3%, N 2 97%.

[0032] (3) sintering the material obtained in (2) for the second time to obtain a blue material;

[0033] Among them, the sintering conditions are: the sintering temperature is 800°C, the holding time is 4 hours, and the air atmosphere;

[0034] (4) Ball...

Embodiment 2

[0036] A preparation method of cesium tungstate of tungsten bronze structure, comprising the following steps;

[0037] (1) Mix cesium carbonate, tungsten oxide and deionized water to obtain mixture A, add a small amount of sintering aid, and perform wet ball milling at normal temperature to obtain a mixed slurry;

[0038] Wherein, the mol ratio of cesium carbonate to tungsten oxide is 0.99:1;

[0039] The sintering aid is boric acid, and the weight of the sintering aid accounts for 0.2% of the mixture A;

[0040] (2) Take out the mixed slurry, dry it, then dry the material in H 2 and N 2 Heat treatment at 460°C for 3 hours in a mixed atmosphere;

[0041] Among them, H 2 3%, N 2 97%.

[0042] (3) sintering the material obtained in (2) for the second time to obtain a blue material;

[0043] Among them, the sintering conditions are: the sintering temperature is 850°C, the holding time is 1 hour, and the air atmosphere;

[0044] (4) Ball milling the blue material obtained ...

Embodiment 3

[0046] A preparation method of cesium tungstate of tungsten bronze structure, comprising the following steps;

[0047] (1) Mix cesium carbonate, tungsten oxide and deionized water to obtain mixture A, add a small amount of sintering aid, and perform wet ball milling at normal temperature to obtain a mixed slurry;

[0048] Wherein, the mol ratio of cesium carbonate to tungsten oxide is 1.03:1;

[0049] Burning aid is LiNbO 3 , the weight of the sintering aid accounts for 1% of the mixture A;

[0050] (2) Take out the mixed slurry, dry it, then dry the material in H 2 and N 2 Heat treatment at 470°C for 4 hours in a mixed atmosphere;

[0051] Among them, H 2 3%, N 2 97%.

[0052] (3) sintering the material obtained in (2) for the second time to obtain a blue material;

[0053]Among them, the sintering conditions are: the sintering temperature is 900°C, the holding time is 3 hours, and the air atmosphere;

[0054] (4) Ball milling the blue material obtained in (3) to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com