Multi-effect burnt-out woven fabric processing method

A processing method and technology of woven fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., to achieve a unique and novel appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

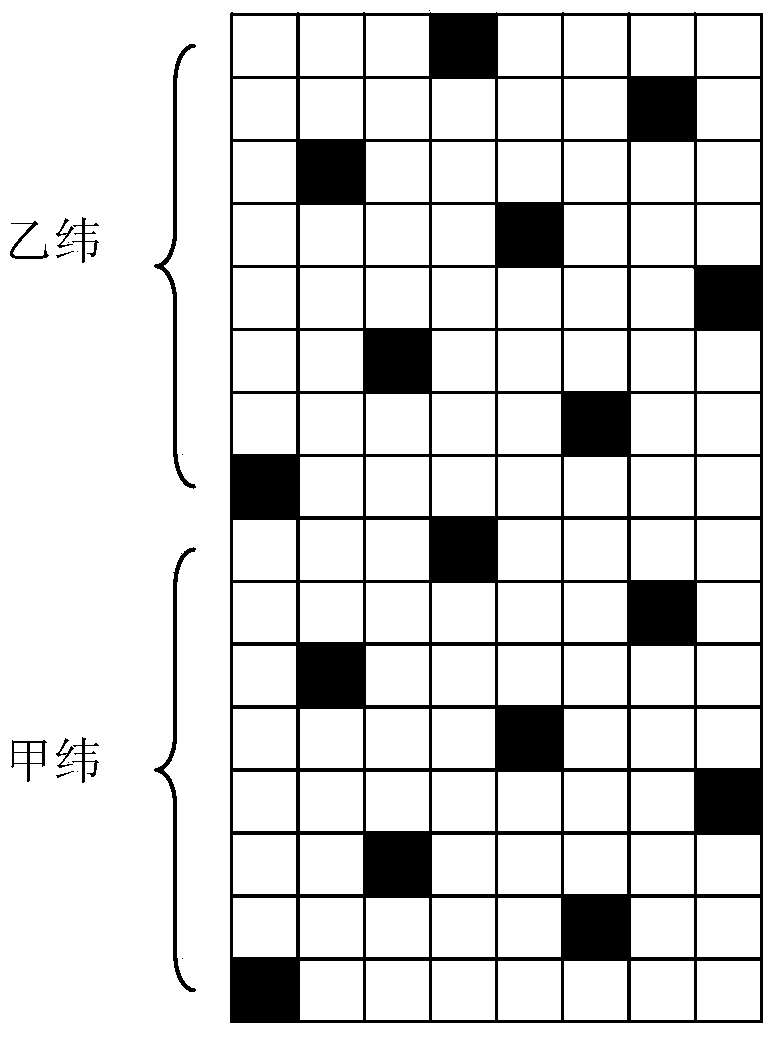

[0055] Example 1: Combining figure 1 , figure 2 , image 3 with Figure 4 As shown, the processing method of this multi-effect burnt-out fabric provided by the present invention specifically refers to a processing method of a double-effect burnt-out fabric with a weft weft structure using polyester yarn as warp and silk / adhesive strands as weft.

[0056] Concrete preparation method flow process is as follows:

[0057] 1. Fabric preparation

[0058] Warp combination: 1 / 55.5dtex polyester (mechanical pulp)

[0059] Weft thread combination: Jiawei [1 / 83.3dtex spun yarn + 1 / 83.3dtex viscose yarn (color)] 2.5T / S (Note: T refers to twist, unit twist number / cm, S refers to twist direction, the same below); B weft [1 / 83.3dtex spun yarn + 1 / 83.3dtex viscose yarn (color)] 2.5T / S; the color of the viscose yarn in A and B wefts is different, A weft: B weft = 8:8.

[0060] Warp thread density: 480 threads / 10cm; Weft thread density: 370 threads / 10cm.

[0061] Basic organization: 8 p...

Embodiment 2

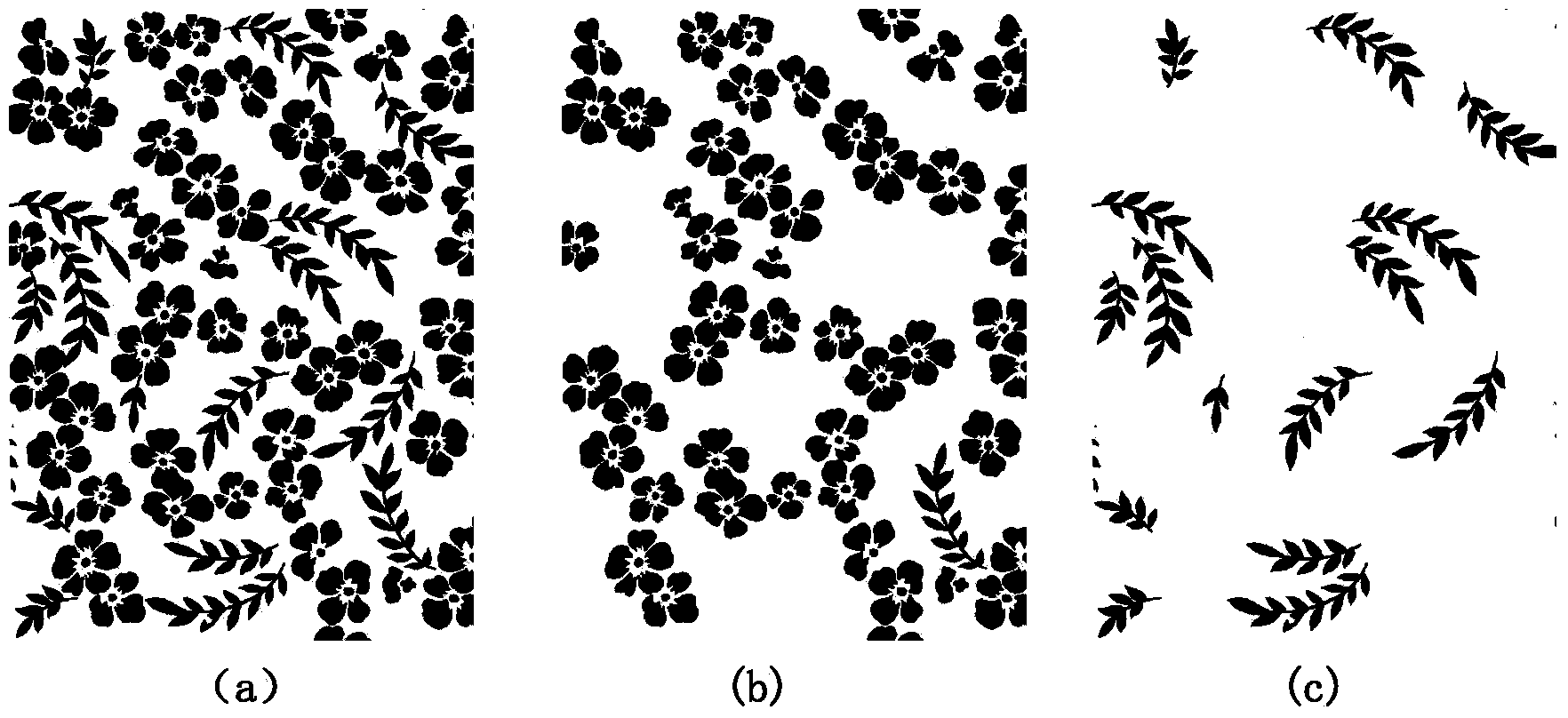

[0081] combine Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the processing method of this multi-effect burnt-out fabric provided by the present invention specifically refers to a processing method of a double-effect burnt-out fabric with the same plane weave using silk / cotton blended yarn as warp and weft.

[0082] Concrete preparation method flow process is as follows:

[0083] 1. Fabric preparation

[0084] Combination of warps: 1 / 125dtex silk / cotton blended yarn, in which the spun silk fiber is dyed dark, the cotton fiber is not dyed, and the blending ratio of spun silk fiber and cotton fiber is 50:50.

[0085] Weft combination: same warp

[0086] Warp thread density: 680 threads / 10cm; Weft thread density: 570 threads / 10cm

[0087] Basic organization: 2 ↖(organization chart as Figure 5 shown).

[0088] Prepared on ordinary rapier looms. The effect of the gray cloth made is as follows Image 6 shown.

[0089] 2. Fabric refining

[0090] Refining ...

Embodiment 3

[0107] combine Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, the processing method of this multi-effect burnt-out fabric provided by the present invention specifically refers to a kind of double-weft weaving three-effect fabric with polyester filament as warp, wool yarn and cotton yarn as surface weft, and polyester filament as inner weft. The processing method of burnt-out fabric.

[0108] Concrete preparation method flow process is as follows:

[0109] 1. Fabric preparation

[0110] Warp combination: (1 / 55.5dtex polyester filament 4T / Z×2) 2.5T / S (white).

[0111] Weft yarn combination: surface weft 1 / 166.7dtex wool yarn (dark gray), surface weft 2 1 / 161.9dtex cotton yarn (light gray), inner weft is the same as warp yarn. The weft yarns are arranged as table weft one: inner weft: table weft two = 1:1:1.

[0112] Warp thread density: 420 threads / 10cm; Weft thread density: 520 threads / 10cm

[0113] Basic weave: weft double weave, surface weave is 4 piece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com