Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

397results about How to "Improve atomization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

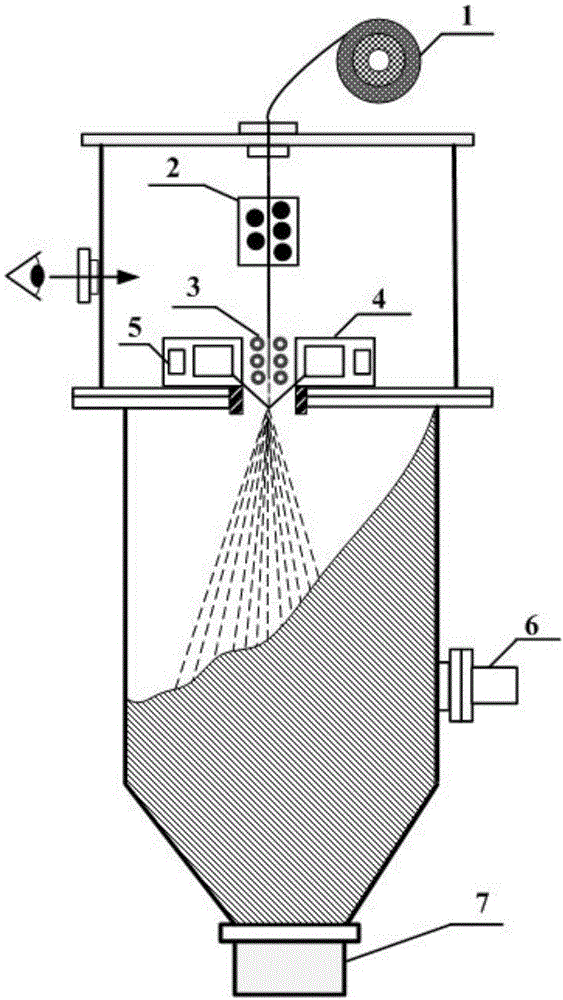

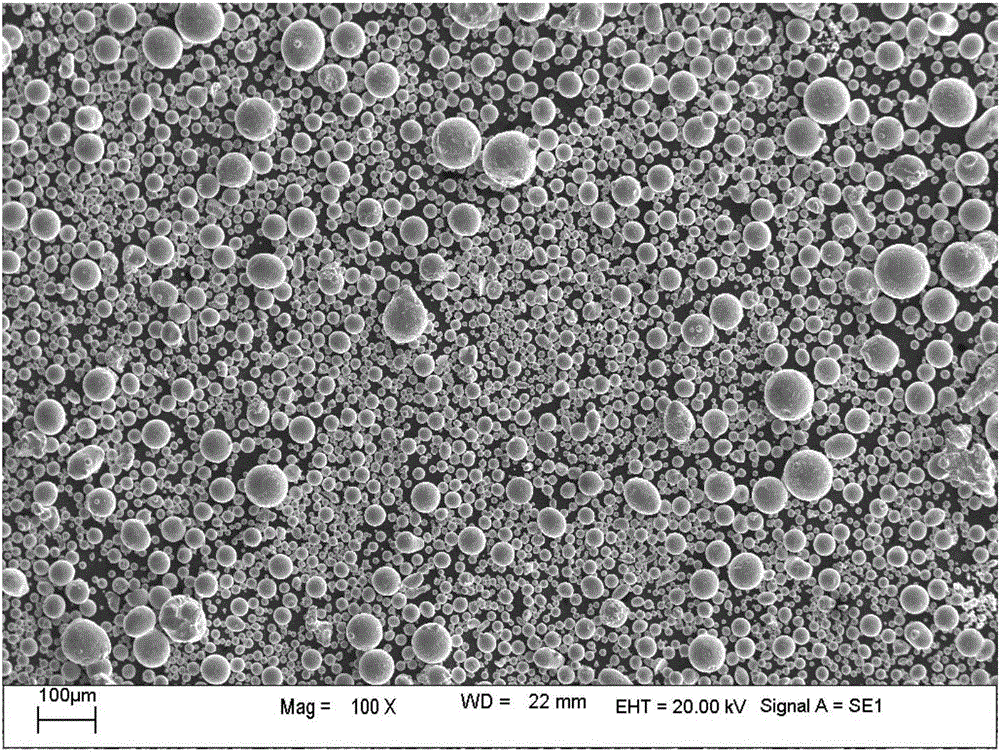

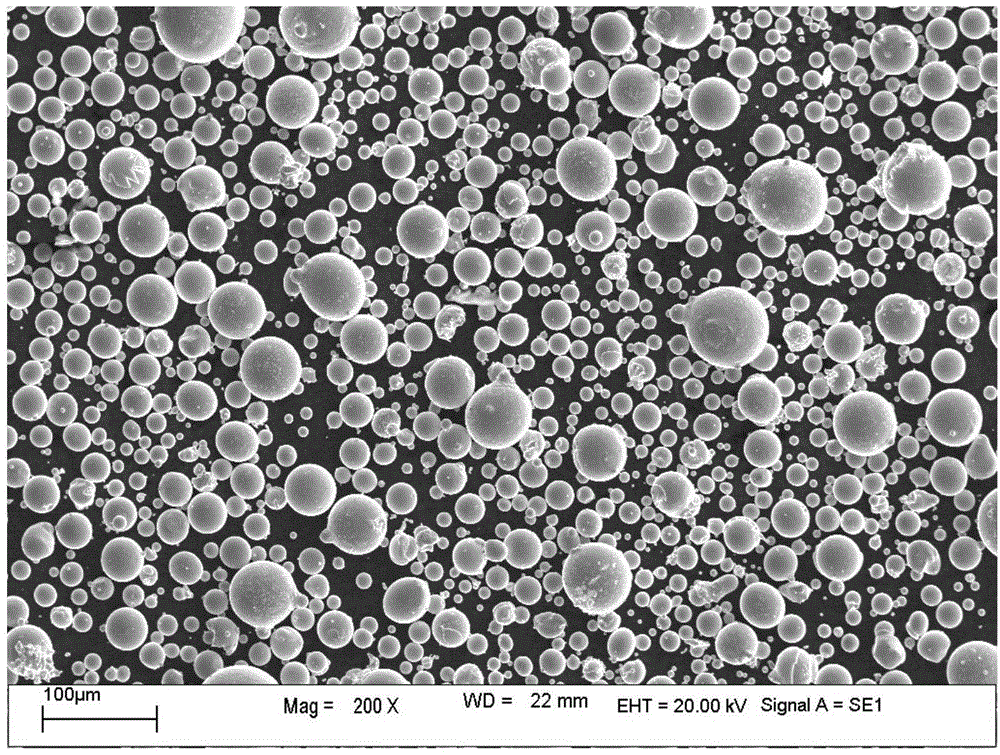

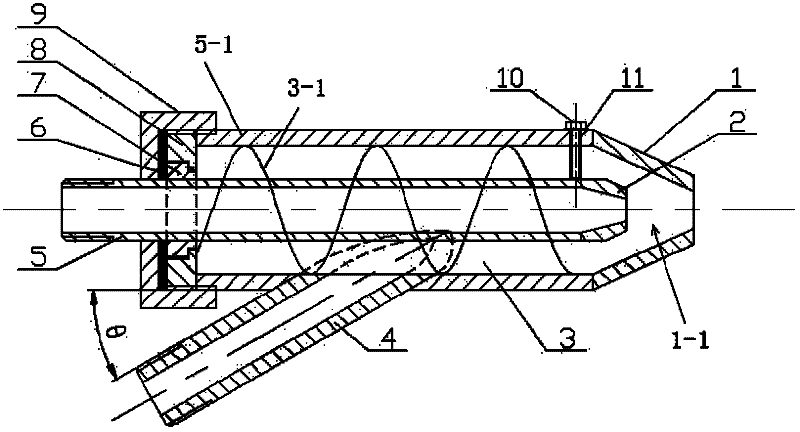

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

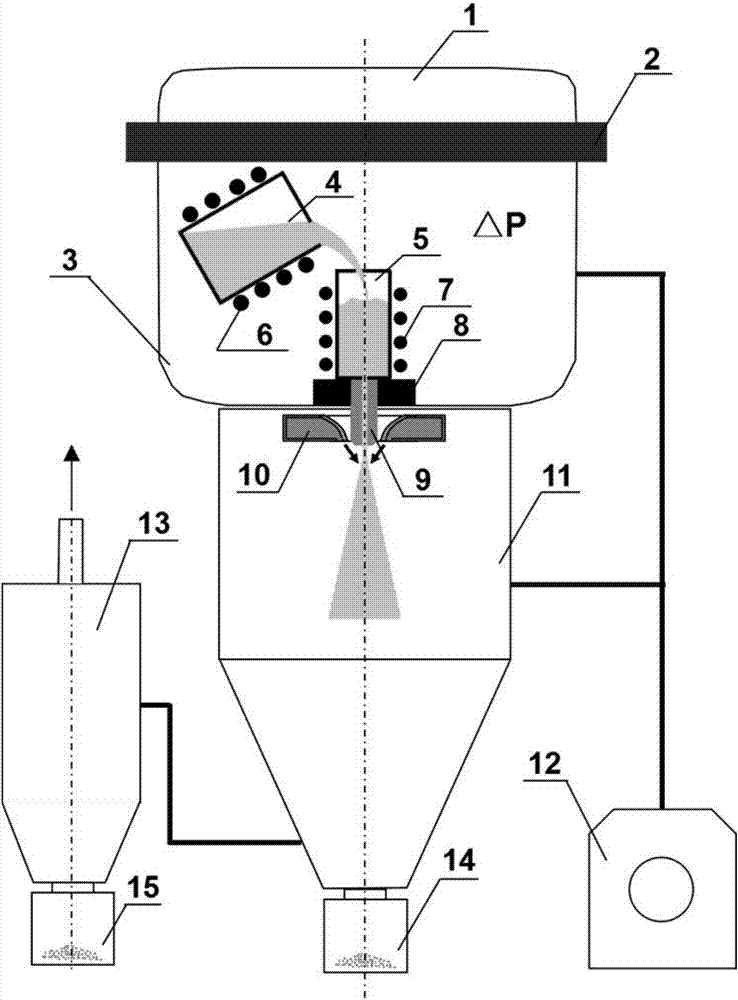

Gas atomization preparing method for micro spherical metal powder and equipment thereof

ActiveCN107262730AIncrease characteristic surface energyHigh yield of fine powderTransportation and packagingMetal-working apparatusPositive pressureProduct gas

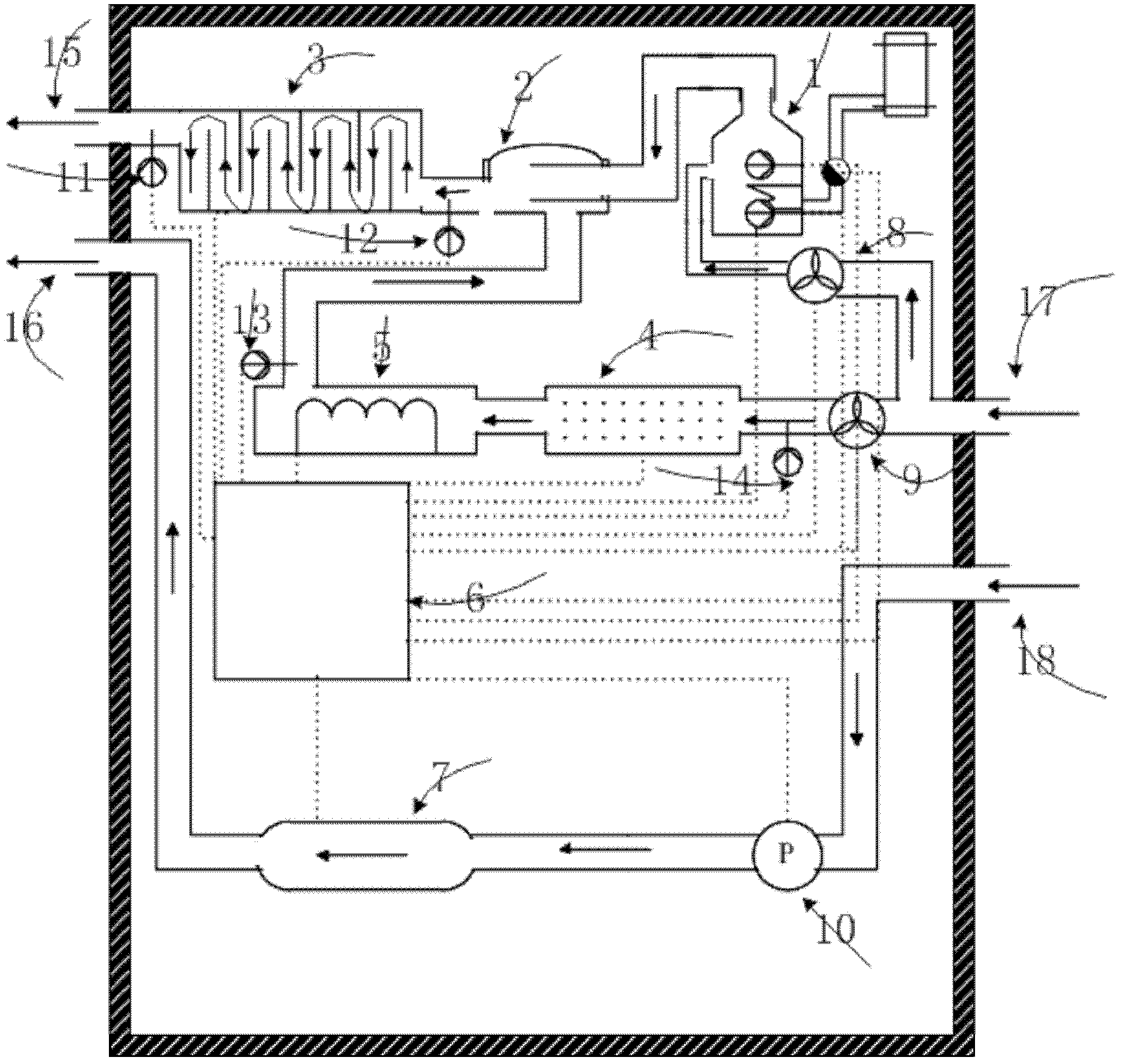

The invention belongs to the technical field of preparing a metal powder material and provides a gas atomization preparing method for micro spherical metal powder and equipment thereof. The preparing method comprises the technological process of smelting a material, driving molten metal jet flow through positive pressure, atomizing gas, carrying out cooling, collecting powder, detecting performance, and carrying out screening, packaging and the like, by reducing the outlet hole diameter of a flow guide nozzle, inert gas is reversely filled into a smelting chamber to certain positive pressure, the smelting chamber in the gas atomizing equipment is designed into a pressure container, a locking sealing device is adopted in the connecting portion of a furnace cover and a furnace body, the smelting chamber and an atomizing tank are designed into cavities which are isolated mutually and communicate only through the flow guide nozzle, and the fine powder yield of the metal powder is effectively increased. Compared with the existing gas atomizing metal powder preparing technology, the fine powder yield of the metal powder prepared by the utilization of the method is high, size distribution is narrow, the sphericity degree is good, the oxygen content is small, atomized gas consumption is low, and the technology equipment is simple, high in continuity and suitable for industrialized production and can be widely applied.

Owner:有研金属复材技术有限公司

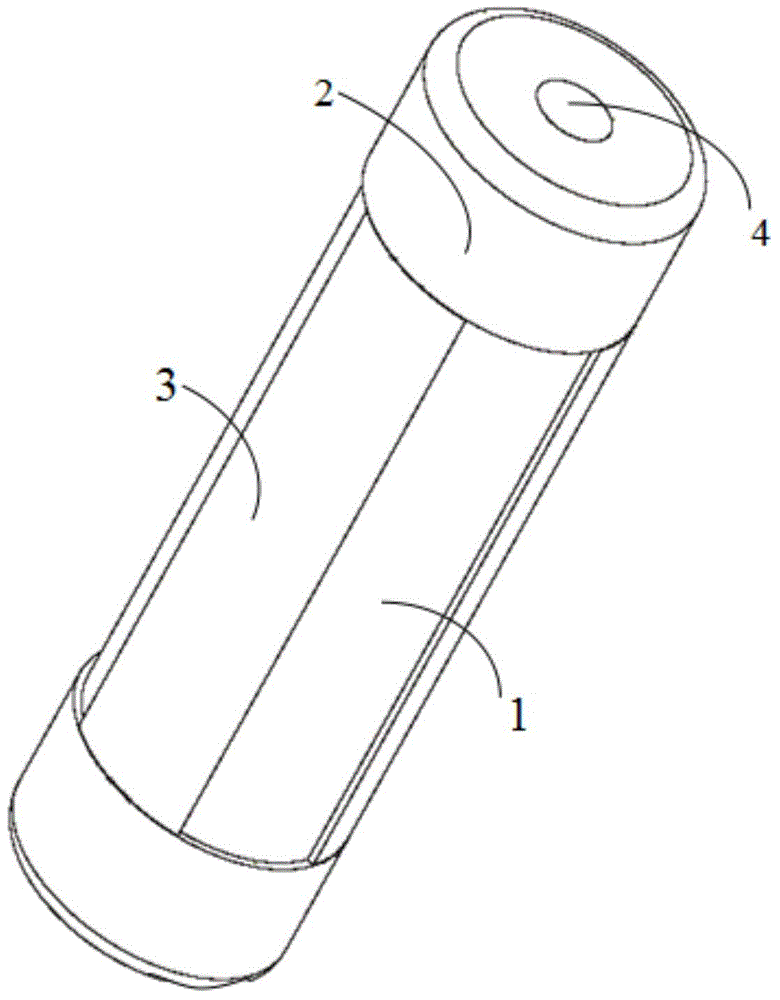

Ceramic slurry, ceramic porous oil guiding body and heating assembly for electronic cigarette

InactiveCN105218137AImprove atomization efficiencyReduce manufacturing costTobacco devicesCeramicwareElectrical resistance and conductanceSlurry

The invention provides ceramic slurry and further provides a ceramic porous oil guiding body prepared from the ceramic slurry and a heating assembly for an electronic cigarette. The heating assembly is prepared from the ceramic porous oil guiding body, metal layer slurry and resistance layer slurry. The heating assembly comprises the oil guiding body made of a ceramic material, a metal layer and a resistance layer, wherein the metal layer and the resistance layer are arranged on the surface of the oil guiding body. The oil guiding body, the metal layer and the resistance layer are combined, the production cost of the heating assembly is reduced, the resistance layer and the oil guiding body are in tight contact, the contact area is large, and the atomization efficiency of the electronic cigarette is greatly improved.

Owner:CHAOZHOU THREE CIRCLE GRP

Method and system for preparing particle-reinforced metal-based composite material through injection molding

The invention relates to a method and system for preparing a particle-reinforced metal-based composite material through injection molding. Ceramic reinforced particles and high-pressure inert gas are uniformly mixed in an acceleration nozzle to be used as an atomizing medium, thereby improving the density, momentum and impact force of the atomizing medium, obviously enhancing the atomization effect and reducing the inert gas consumption as compared with the atomization based on the single use of inert gas. After atomization is completed, the ceramic particles are uniformly dispersed in atomized molten drops, and the molten metal drops doped with the reinforced particles are gradually solidified in the flying process and are ultimately deposited, solidified and molded on a receiver, thus obtaining the high-performance metal-based composite material of which the ceramic reinforced particles are uniformly distributed. In addition, the ceramic reinforcements used in the invention are prepared by a reaction and ball milling method, thereby ensuring that the reinforced particles better in strength, interface stability, high-temperature performance and other aspects can be prepared at a low cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

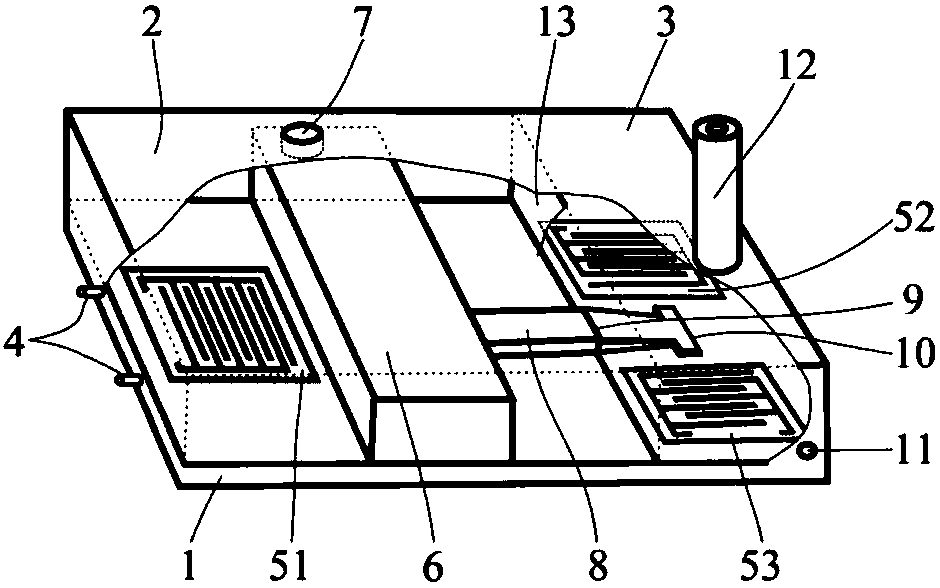

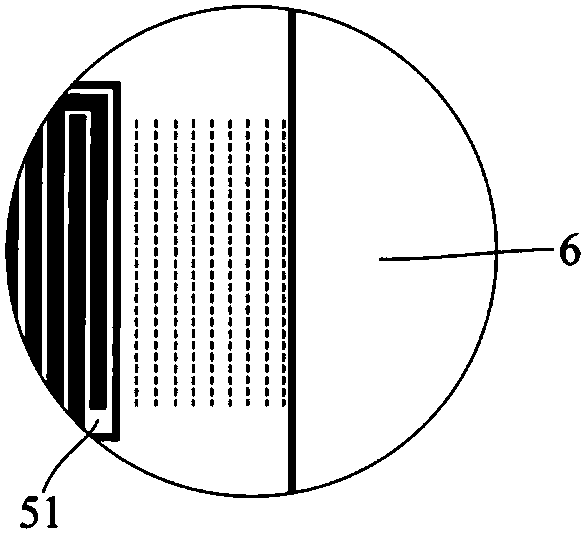

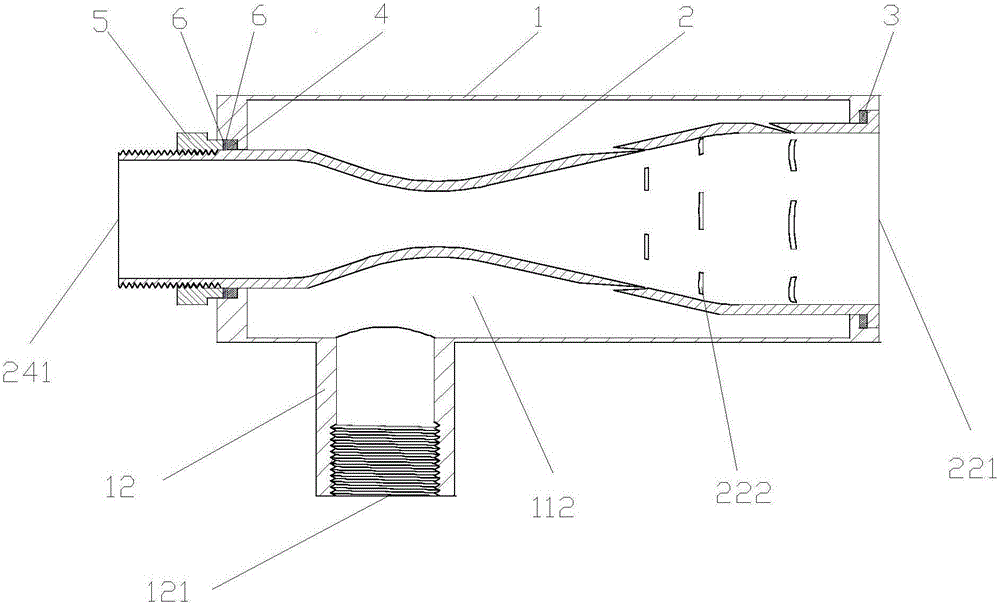

Acoustic surface wave electronic cigarette system

ActiveCN108030153AContinuous and stable pumpingFully atomizedMaterial analysis using sonic/ultrasonic/infrasonic wavesTobacco treatmentElectricityElectronic cigarette

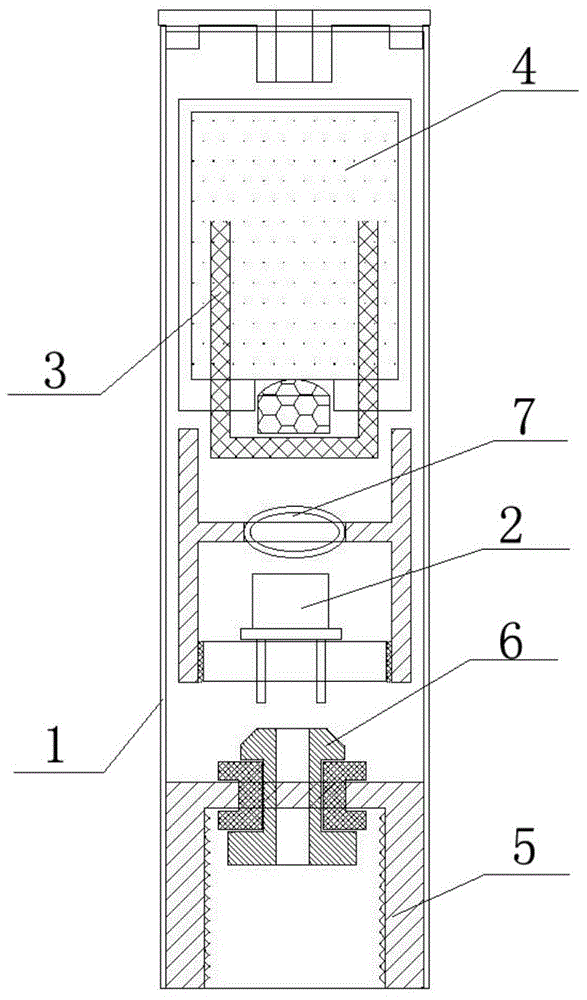

The invention discloses an acoustic surface wave electronic cigarette system which comprises a piezoelectric substrate (1), a liquid guide cavity (2), an atomization cavity (3) and feed ports (4). Thefeed ports (4) are used for loading high-frequency signals. The liquid guide cavity (2) and the atomization cavity (3) are arranged on the upper side of the piezoelectric substrate (1); an isolationplate (13) is arranged between the liquid guide cavity (2) and the atomization cavity (3); the feed ports (4) are arranged on the outer side of the piezoelectric substrate (1). The acoustic surface wave electronic cigarette system has the advantages that aerosol generated by the acoustic surface wave electronic cigarette system by means of atomization has small particle sizes, accordingly, the acoustic surface wave electronic cigarette system is high in smoking comfort, and aroma is mellow and exquisite.

Owner:CHINA TOBACCO YUNNAN IND

Laser atomization device

The invention provides a laser atomization device; the laser atomization device comprises a housing; a laser generator and fluid guidance fibers opposite to the laser generator are arranged inside the housing; the laser generator is further connected with a power supply for driving the laser generator; the fluid guidance fibers contact with an atomization fluid in atomization fluid carriers. By comparing the provided laser atomization device with a conventional atomization device, not only the structure of the atomization device is simplified, and the problem of uneven heat of heating wires is solved, but also the electricity consumption of the atomization device is effectively reduced by using the laser generator for achieving the atomization of fluid; therefore, the atomization efficiency is increased.

Owner:王彦宸 +1

Mobile type indoor disinfectant vapor disinfection system

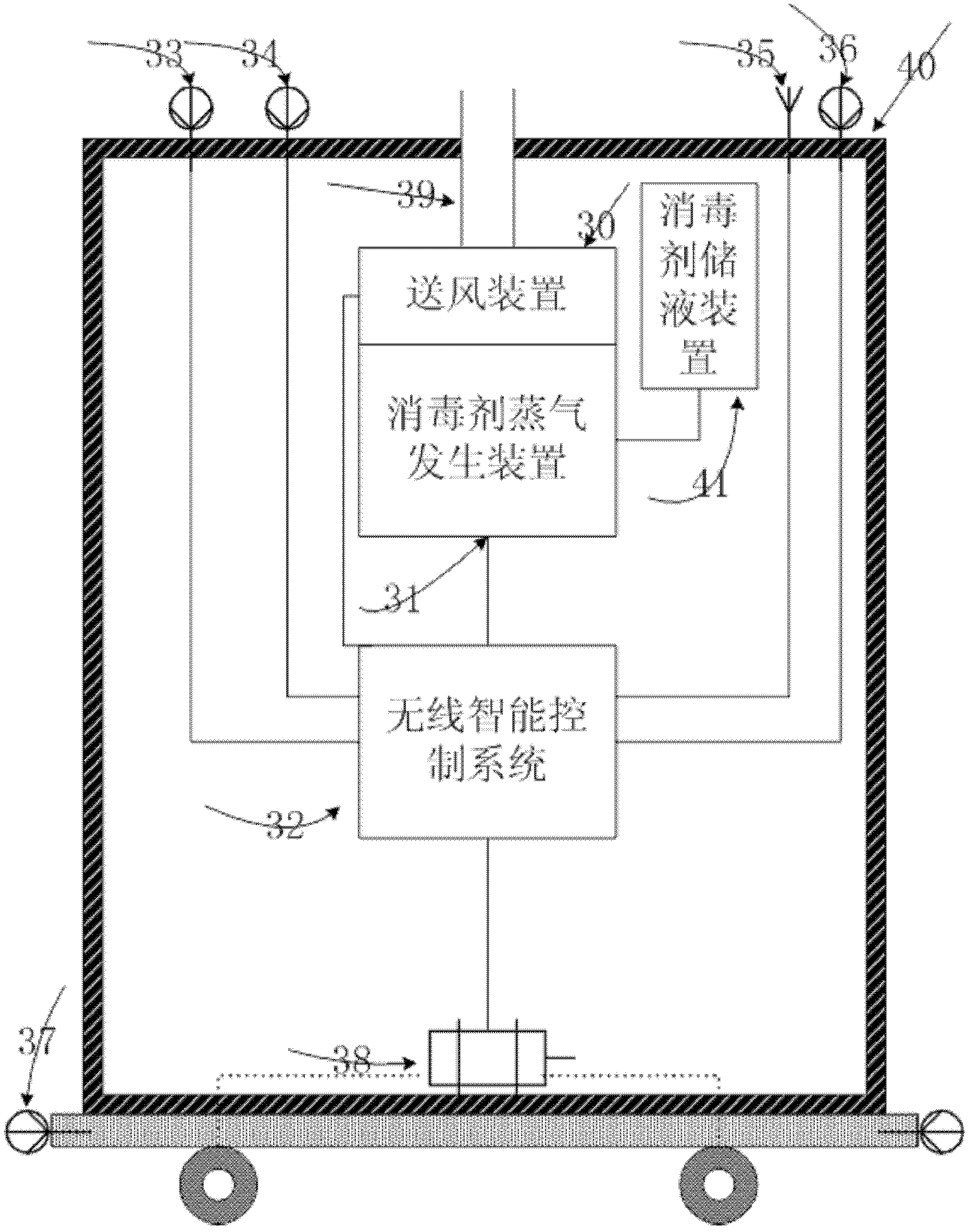

InactiveCN102423496AImprove disinfection efficiencyEasy to controlLavatory sanitoryDeodrantsThree levelEngineering

The invention relates to a mobile type indoor disinfectant vapor disinfection system, which comprises a disinfectant vapor generation device, a wireless intelligent control system, a power-driven device, an environmental monitoring device, an air supply device, a mobile device and a disinfectant storage device. The disinfectant vapor generation device comprises a disinfectant vapor three-level refinement system, a filtering and catalyzing integrated system and a vapor generation control device; the air supply device supplies secondary power for scattering vapor in a space; and the wireless intelligent control system is communicated with the environmental monitoring device, the air supply device and the power-driven device so as to finish the operations of controlling the disinfectant vapor generation device, acquiring environmental parameters, and switching on / off the air supply device and the power-driven device in a disinfection target. The mobile type indoor disinfectant vapor disinfection system can intelligently, comprehensively and efficiently finish the disinfection operation of a closed space of large-sized equipment and is particularly suitable for the disinfection operation of a closed space with long and narrow passages, so that the mobile type indoor disinfectant vapor disinfection system has the advantages of strong maneuverability, high disinfection efficiency, no secondary pollution, and the like.

Owner:中国人民解放军防化学院 +1

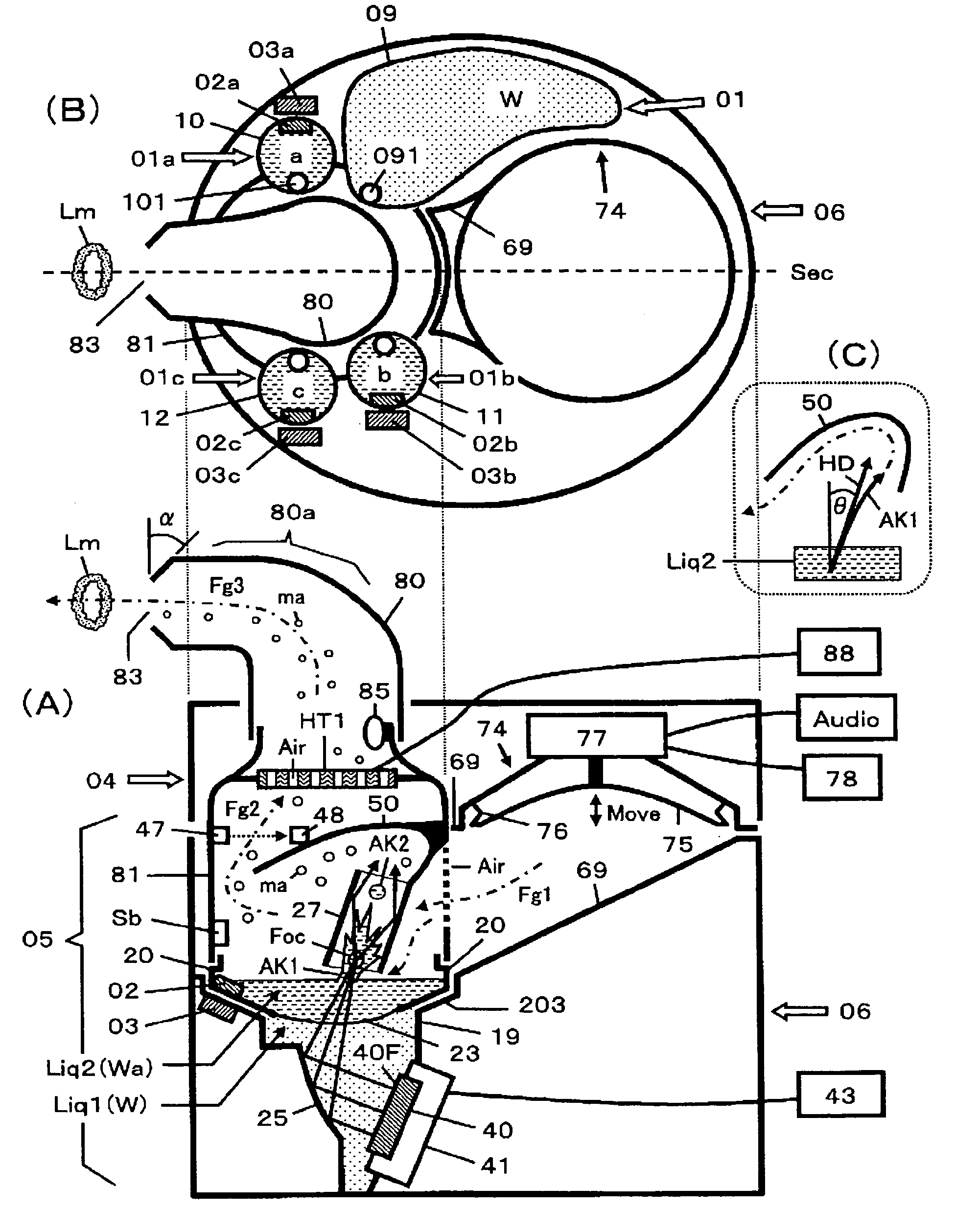

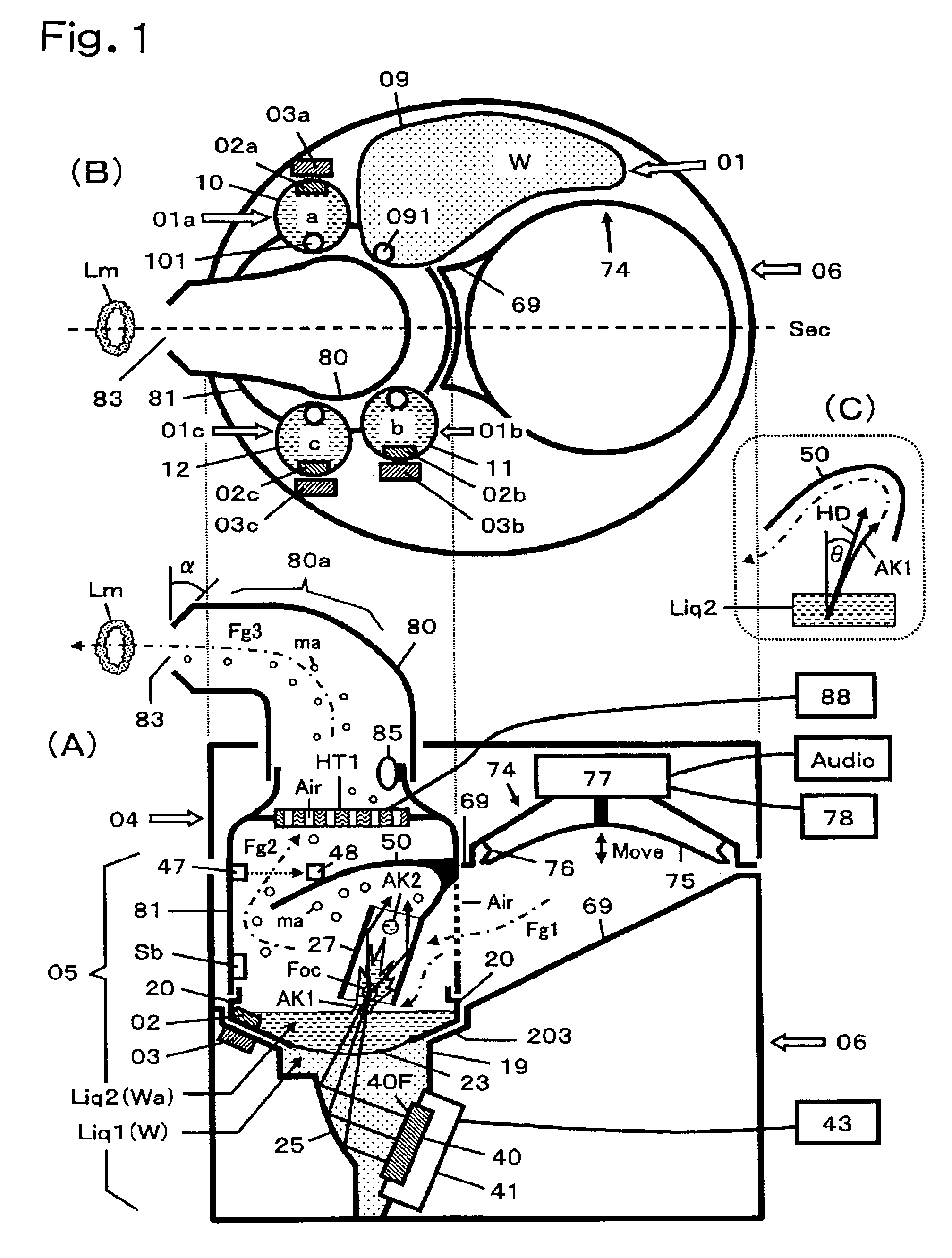

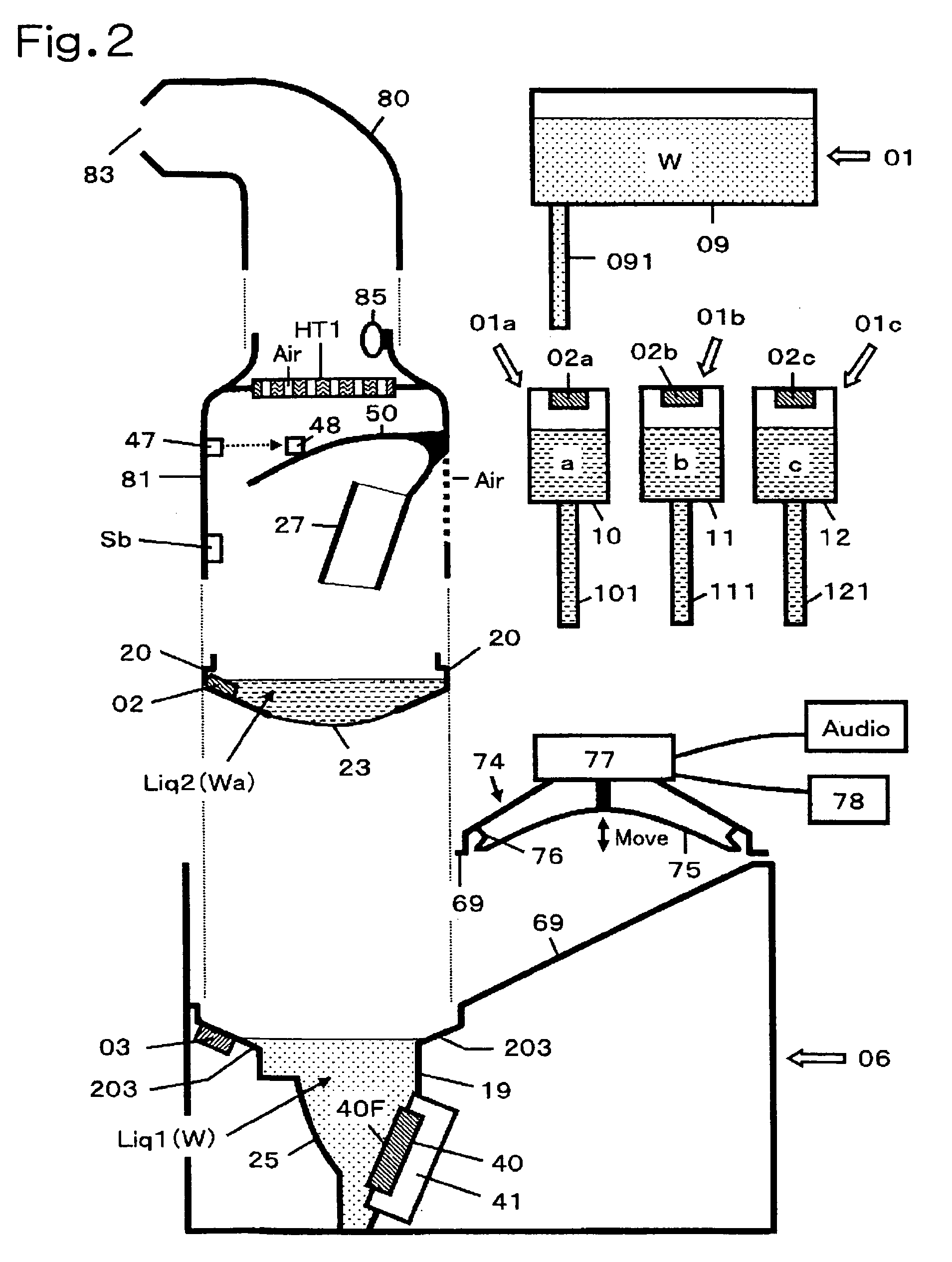

Mist generator and mist emission rendering apparatus

InactiveUS7934703B2Improve atomization efficiencyImprove overall utilizationSpace heating and ventilationMixing methodsTransducerEngineering

An apparatus includes an ultrasonic transducer; an ultrasonic propagation medium disposed so as to fill a plane of vibration of the transducer; liquid retaining means disposed so as to be in contact with an end face of the medium; and an ultrasonic focusing reflecting mechanism disposed in an ultrasonic propagation path, thereby the apparatus attains discharging into air and atomization of the liquid by use of ultrasonic waves. Atomization efficiency is enhanced by the use of an ultrasonic reflection tube, and mist emission is carried out. Use is made of a compact liquid container equipped at its bottom with an ultrasonic transmission membrane. Various types of liquids can be atomized by changing the direction of ultrasonic course.

Owner:TOMONO AKIRA

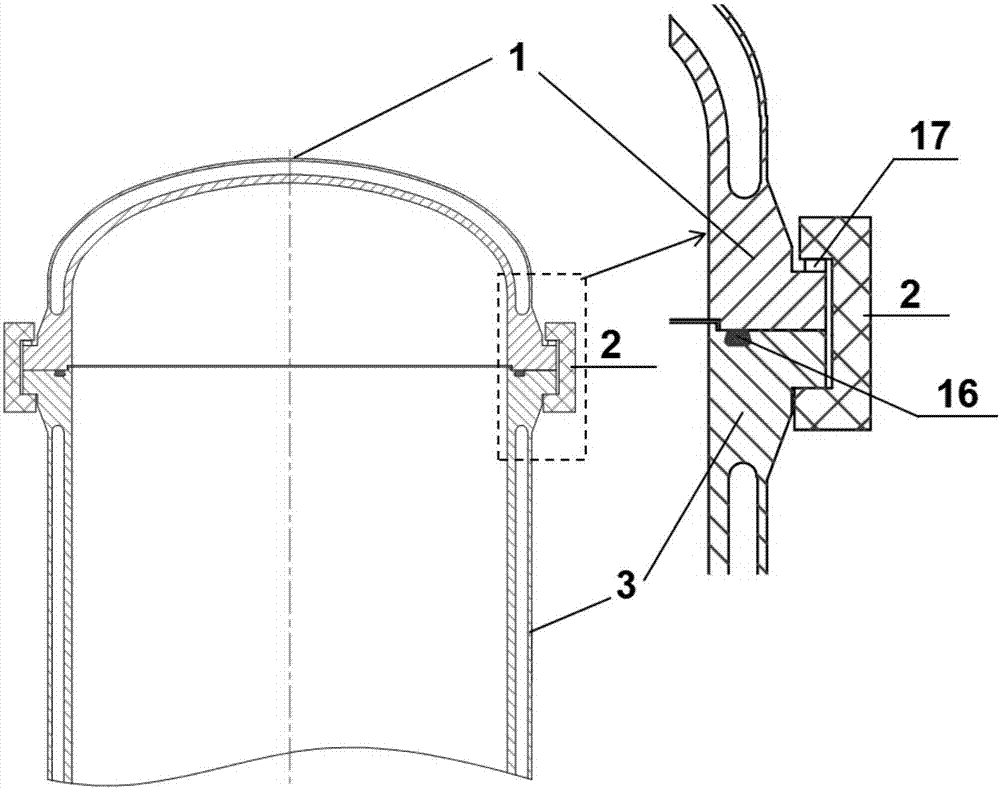

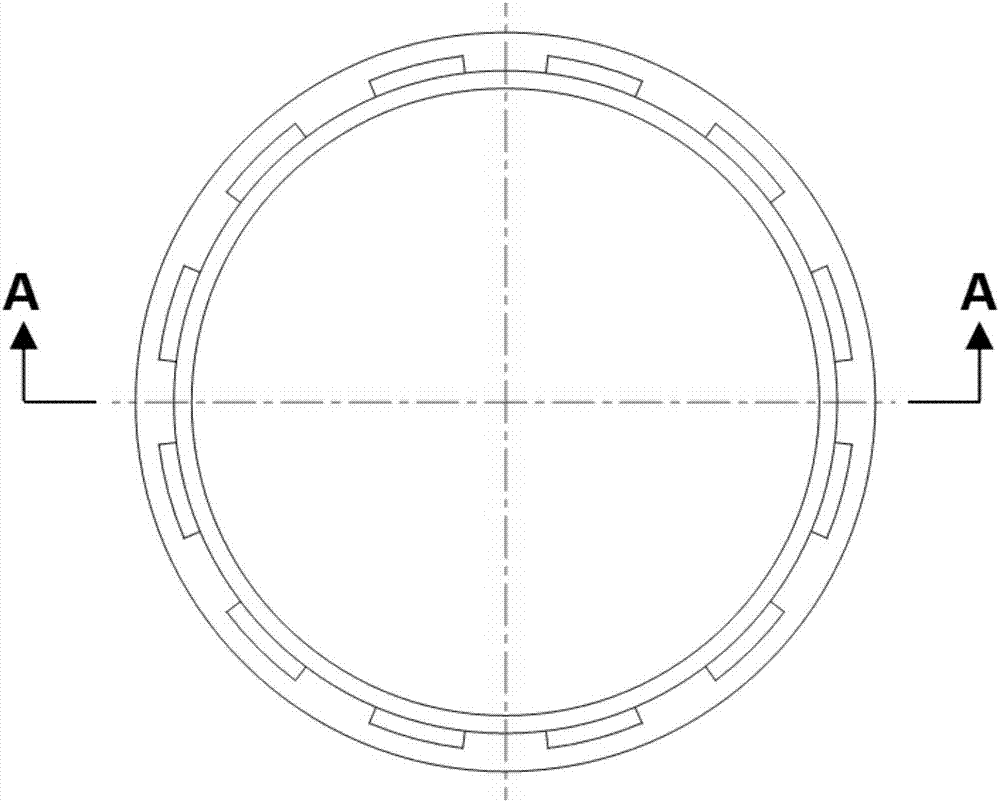

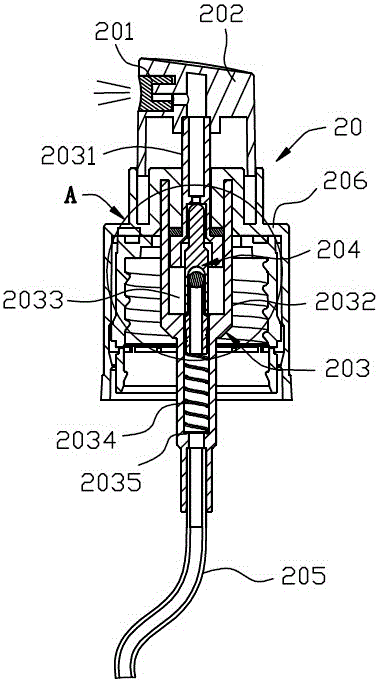

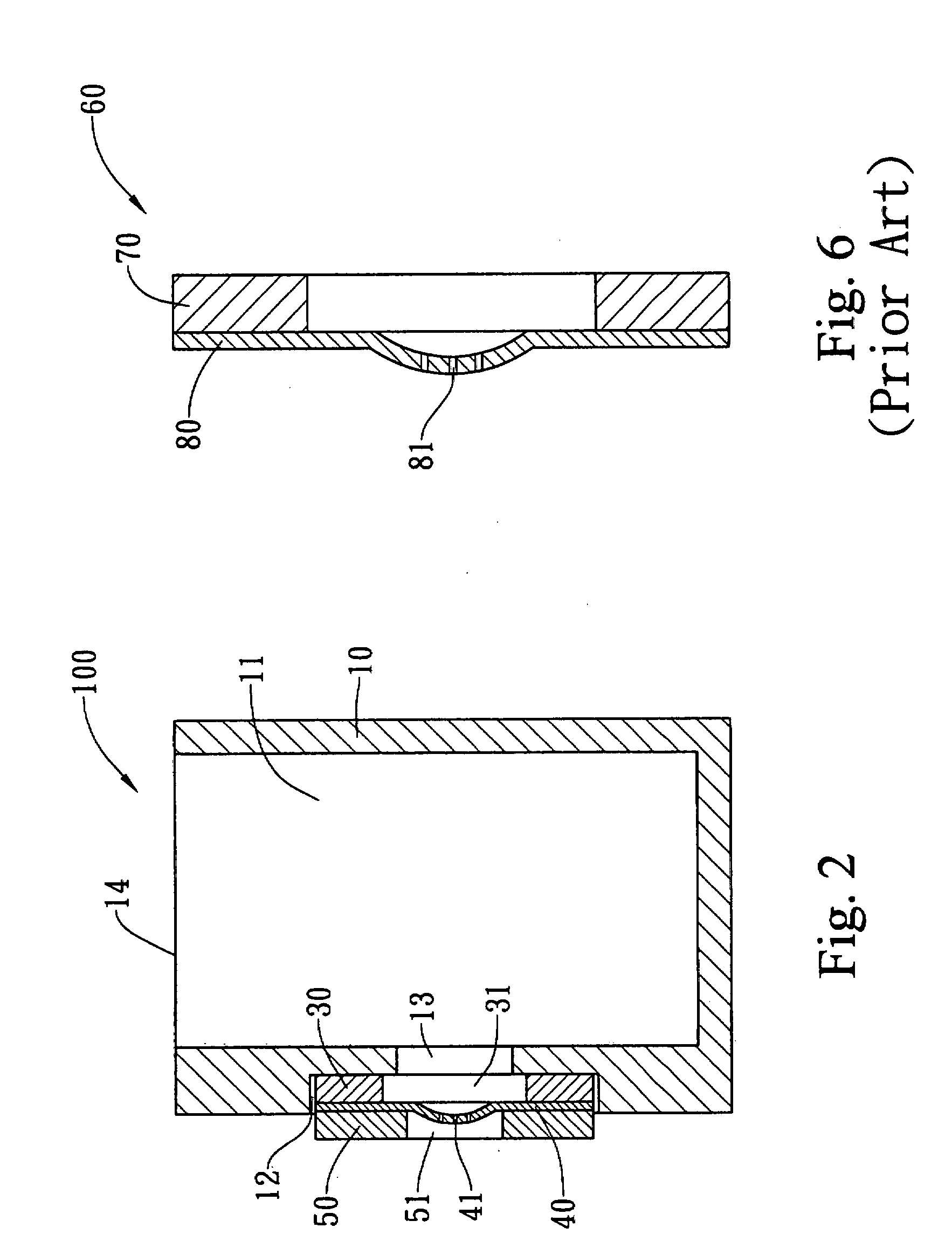

Heating assembly for electronic cigarette

ActiveCN104068476ALong-term efficient heating workImprove reliabilityTobacco devicesEngineeringElectronic cigarette

The invention discloses a heating assembly for an electronic cigarette. The heating assembly comprises a liquid guide ceramic body, a heating wire and a fixed seat, wherein an accommodating cavity is formed in the fixed seat, the liquid guide ceramic body is fixed in the accommodating cavity, an inlet and an outlet which are communicated with the accommodating cavity are formed in the both ends of the fixed seat, a cigarette liquid inlet communicated with the accommodating cavity is opened in the sidewall of the fixed seat, a fixing hole penetrates in the liquid guide ceramic body, an orifice at one end of the fixing hole is opposite to the inlet, and an orifice at the other end of the fixing hole is opposite to the outlet; and the heating wire is fixed in the fixing hole, in contact with the wall of the fixing hole, and electrically connected with the fixed seat. The heating assembly disclosed by the invention is high in atomization efficiency and reliability, and moreover, the generated cigarette smoke is good in taste.

Owner:SHENZHEN KANGER TECH CO LTD

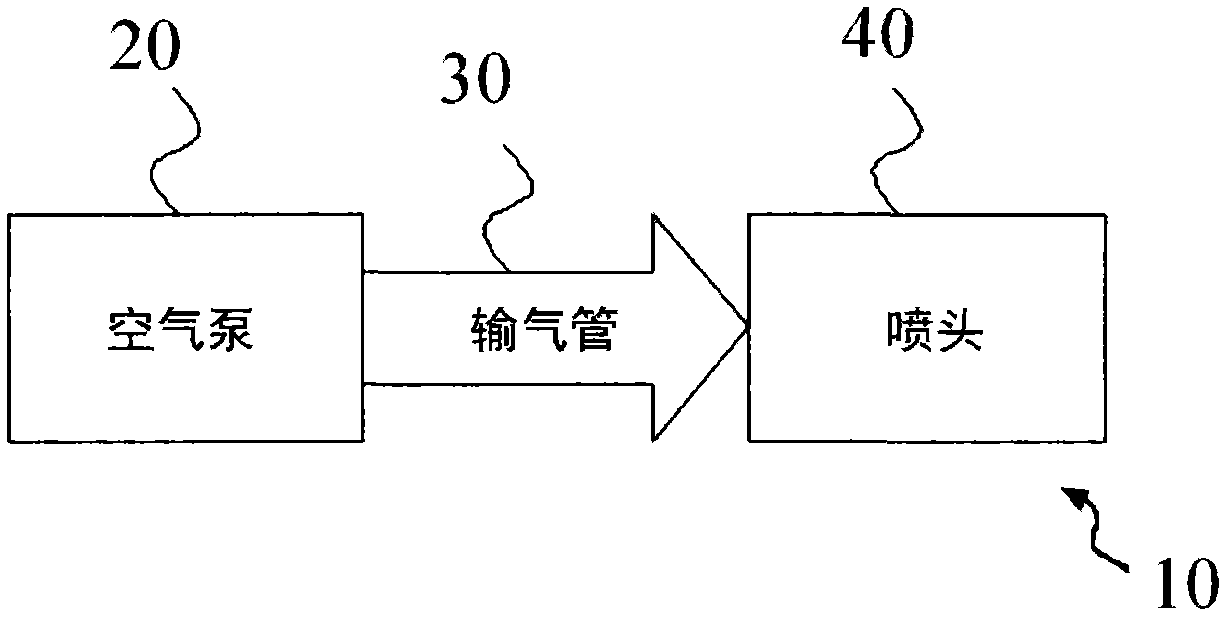

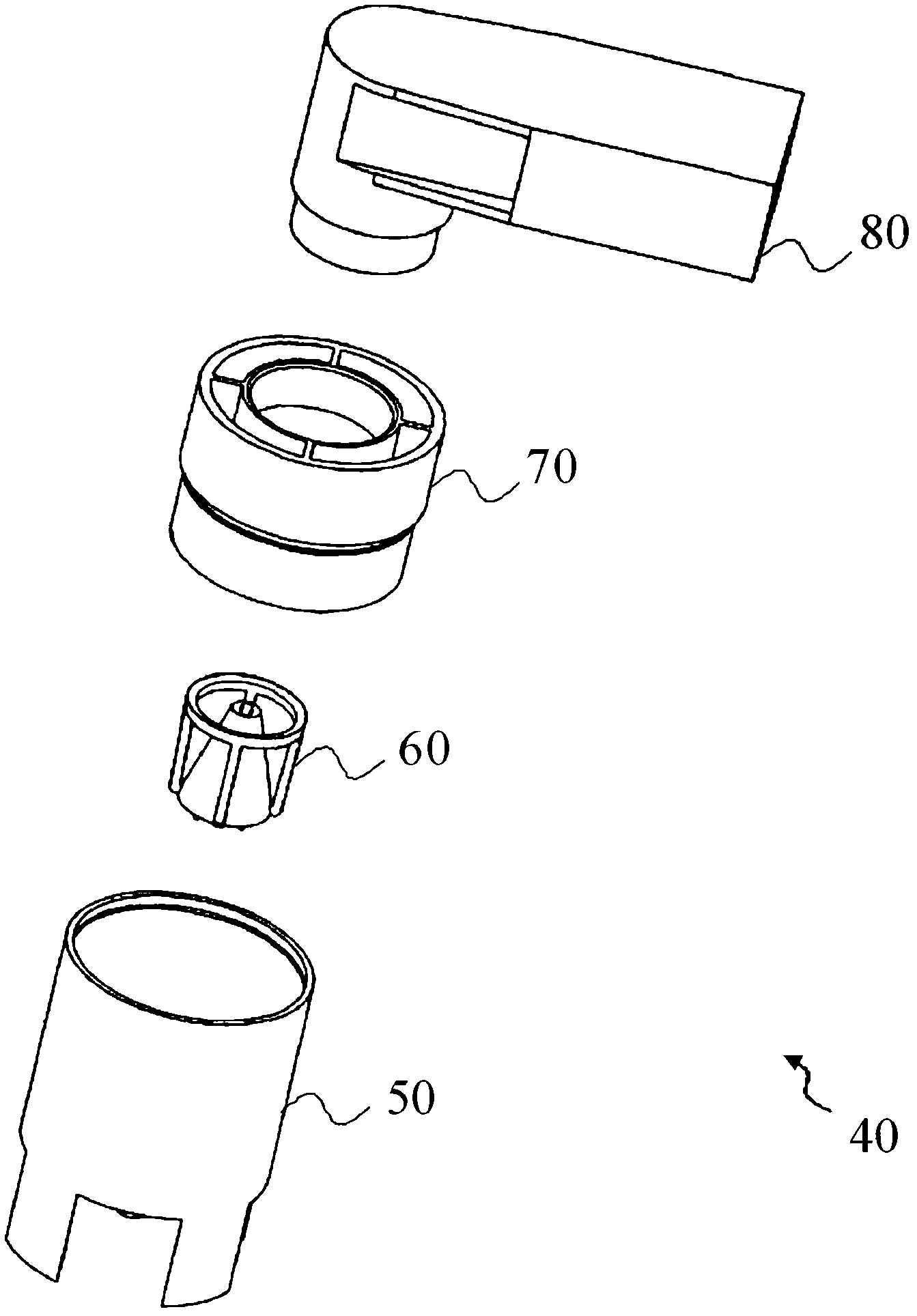

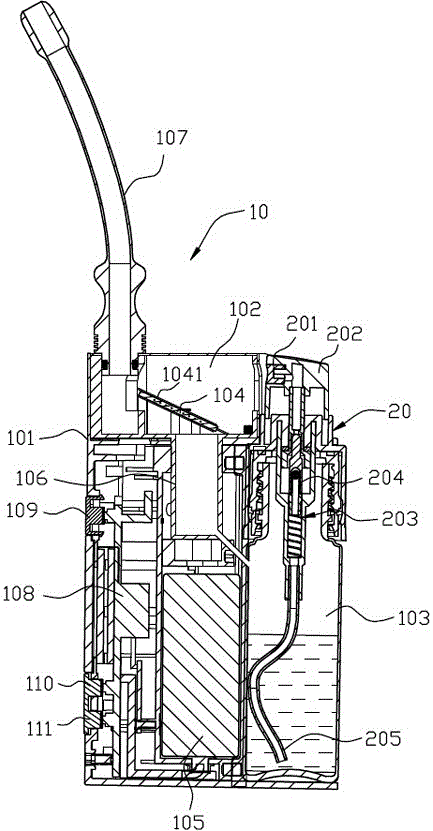

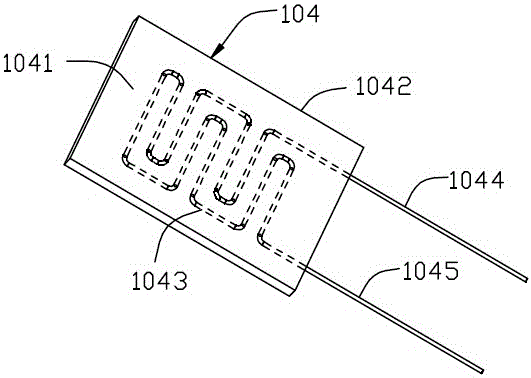

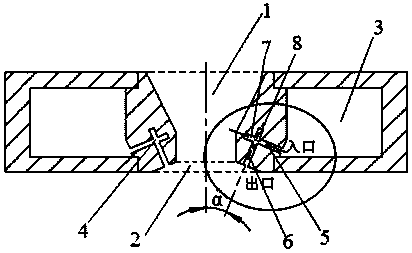

Atomization device and nozzle thereof

InactiveCN103041480AImprove atomization efficiencyLiquid spraying apparatusMedical atomisersEngineeringAirflow

The invention provides an atomization device and a nozzle thereof. The nozzle comprises a groove seat and an air flow guiding structure. The groove seat is provided with an air inlet, an air conveying pipe, a liquid storing tank and a liquid conveying structure. The air conveying pipe is provided with an air inlet end and an air outlet end. The liquid conveying structure extends from a liquid storing tank to the air outlet end. The air flow guiding structure includes an air flow guiding channel and a stopper. A first opening of the air flow guiding channel communicates with an air inlet. The stopper is arranged in front of the air outlet end. The stopper is provided with a protruding curved surface which faces the air outlet end. An air flow sprayed from the air outlet end strikes to the protruding curved surface and flows to a second opening of the air flow guiding channel. Air in the air inlet is guided to the first opening. The air inlet is arranged at the groove seat and the stopper with the protruding curved surface is arranged in front of the air outlet end to increase the atomization efficiency.

Owner:TAIDOC TECH CORP

Jet-type atomization device

PendingCN105901775AImprove atomization efficiencyRealize secondary atomizationMedical devicesTobacco devicesLiquid storage tankEngineering

The invention discloses a jet-type atomization device. The jet-type atomization device comprises a shell, a liquid storage tank, a jet device, a heating element and a power supply. An atomization chamber is arranged in the shell; the liquid storage tank is used for storing cigarette liquid to be atomized; the jet device is used for jetting the cigarette liquid into the atomization chamber to form cigarette liquid particles of a certain particle size; the heating element is located in the atomization chamber and provided with a heating surface, the heating surface is used for bearing the cigarette liquid particles and heating and evaporating the cigarette liquid particles to form smoke; the power supply is arranged in the shell and used for supplying power to the heating element. Compared with the prior art, the jet-type atomization device improves the atomization efficiency, improves the smoking taste for users and improves the use experience as a jetting mode and a heating mode are adopted for dual atomization.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Side exhaust Venturi paint spraying chamber

ActiveCN102658251AImprove protectionImprove atomization efficiencyLiquid surface applicatorsSpraying apparatusSewageDynamic pressure

The invention discloses a side exhaust Venturi paint spraying chamber. The chamber comprises a dynamic pressure chamber, a workshop, an air supply device, an air flow guide device, a waste paint adsorption device, a waste paint catching device and an exhaust device, wherein a grid plate is arranged at the bottom of the workshop; the waste paint adsorption device comprises a waste mist generation device; the water mist discharge end of the waste mist generation device is connected with a water mist conveying channel; a spraying device is arranged in the water mist conveying channel; a sewage collection device is arranged on the lower part of the spraying device; and the exhaust device is arranged at the outlet of the water mist conveying channel. The waste mist generation device can atomize a large amount of water, so that the capacity of adsorbing paint mist is enhanced; and the spraying device intercepts most of waste paint-containing waste mist in the sewage collection device when water mist on which waste paint is adsorbed is discharged through the water mist conveying channel, and the residual paint mist-doped air passes through the waste paint catching device and is intercepted for the second time when continuously discharged, so that the rate of adsorbing the paint mist is further improved, and the environment is protected.

Owner:MH ROBOT & AUTOMATION

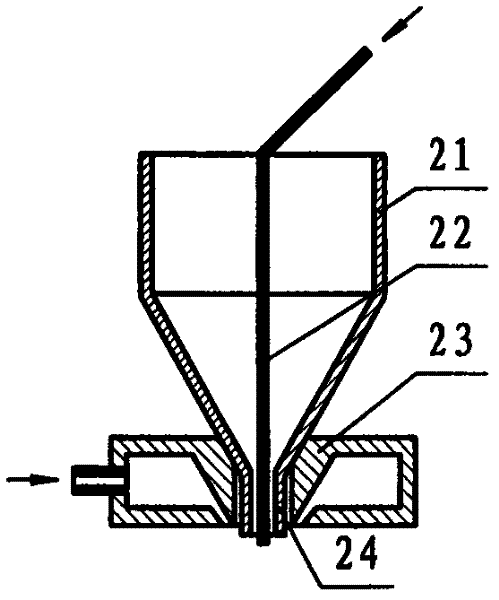

Supersonic atomizing nozzle with two-stage laval and hartmann combined structure

The invention relates to a supersonic atomizing nozzle with a two-stage laval and hartmann combined structure. The supersonic atomizing nozzle comprises a liquid guide cavity, wherein a nozzle orifice is formed in the lower part of the liquid guide cavity; an annular high-pressure air inlet cavity surrounds the liquid guide cavity; an air inlet passage is formed in the inner side wall of the annular high-pressure air inflow cavity; the annular high-pressure air inflow cavity is communicated with the nozzle orifice through the air inlet passage; the air inlet passage is of a cross hartmann two-stage resonance tube structure which is formed by communicating an inlet guide pipe, an outlet guide pipe, a first-stage resonance tube and a second-stage resonance tube; the inlet guide pipe and the first-stage resonance tube are arranged on the same straight line; the outlet guide pipe and the second-stage resonance tube are arranged on the same straight line; the tail ends of the first-stage resonance tube and the second-stage resonance tube are sealed; the inlet guide pipe and the outlet guide pipe are reducer pipes with characteristics of a laval pipe. Compared with the prior art, the supersonic atomizing nozzle disclosed by the invention has the advantages that the characteristics of the laval pipe and the cross hartmann resonance tubes are combined to form the air inlet passage with the annular ring structure, so as to obviously improve the nozzle atomizing efficiency, lower the diameter of the atomized particles and narrow the particle size distribution.

Owner:TONGJI UNIV

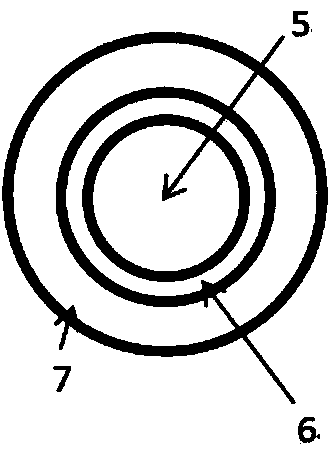

Natural focusing type ultrasonic atomization nozzle

ActiveCN104324839AReduce volumeEvenly distributedLiquid spraying apparatusPrintingTransformerEngineering

Owner:千藤(南京)环保科技有限公司

Laval and hartmann structure integrated type supersonic-speed atomizing nozzle

ActiveCN104368820AImprove atomization efficiencyNarrow particle size distributionEngineeringHigh pressure

The invention relates to a laval and hartmann structure integrated type supersonic-speed atomizing nozzle. The nozzle comprises a drainage cavity, wherein a nozzle hole is formed in the lower side of the drainage cavity, an annular high-pressure air inlet cavity surrounds the drainage cavity, an air inlet channel is formed in the inner wall of the high-pressure air inlet cavity which is communicated with the nozzle hole through the air inlet channel, the air inlet channel is of a cross-shaped hartmann two-stage resonating tube structure which is formed after an inlet conduit, an outlet conduit, a primary resonating tube and a secondary resonating tube are communicated, the inlet conduit and the primary resonating tube are located on the same straight line, the outlet conduit and the secondary resonating tube are located on the same straight line, the tail end of the primary resonating tube and the tail end of the secondary resonating tube are closed, the inlet conduit is a reducing channel which has the features of a laval tube, and the outlet conduit is a reducing channel which has the features of a compression tube. Compared with the prior art, the nozzle has the advantages that due to the fact that a laval tube and a cross-shaped hartmann resonating tube are integrated to form the air inlet channel which is of an annular ring structure, nozzle atomization efficiency can be improved remarkably, the diameter of an atomization particle can be reduced, and particle size distribution can be narrowed.

Owner:TONGJI UNIV

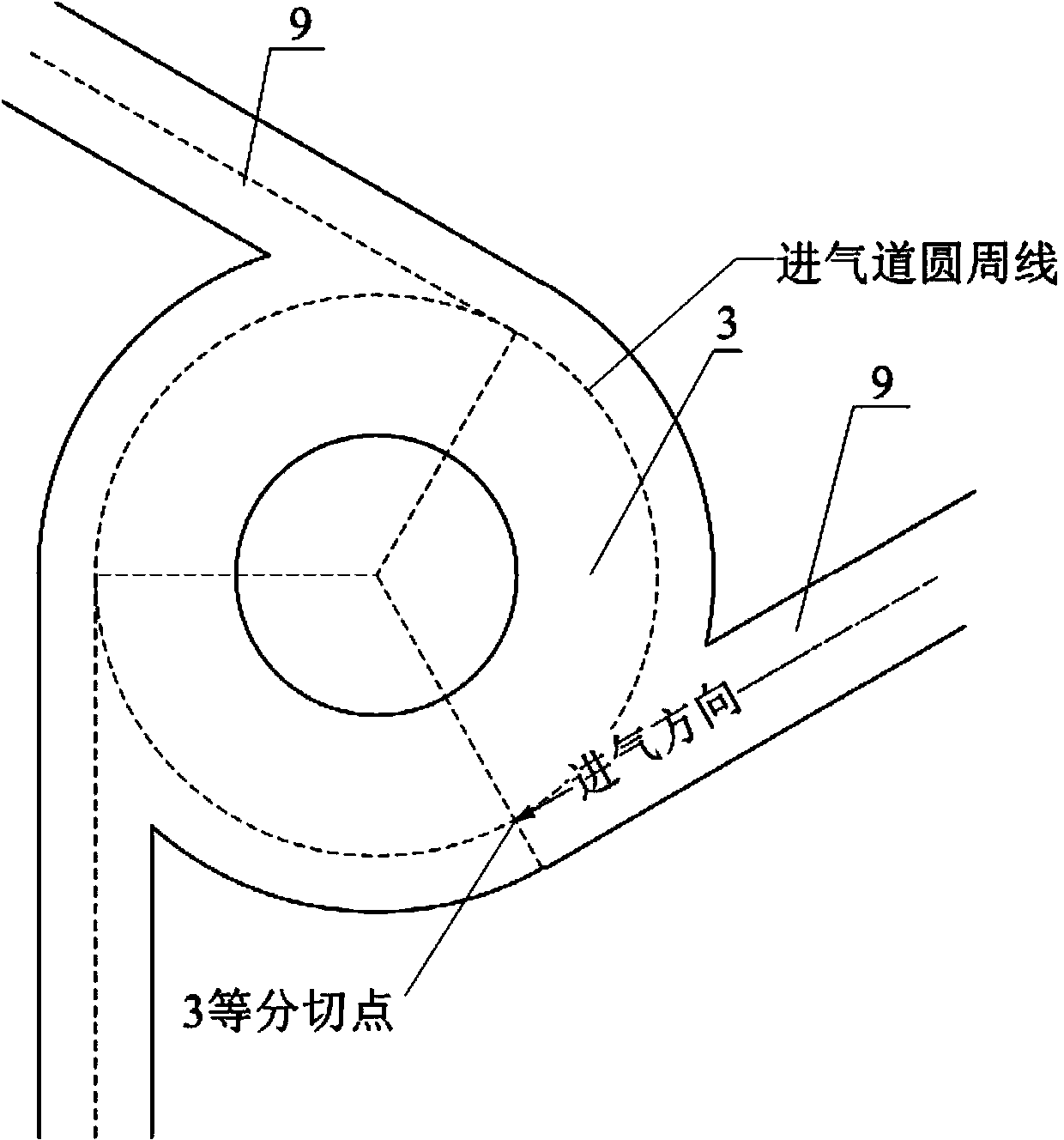

Bubble atomizing nozzle and adjusting method of bubble atomizing nozzle

The invention relates to a bubble atomizing nozzle and an adjusting method of the bubble atomizing nozzle. The bubble atomizing nozzle comprises a multi-channel air intake structure consisting of two or more layers of sealing rings, or an external part of an air intake structure of a swirl groove, and an external part having a diffusion conical spray hole, a jackscrew hole and an air-liquid inlet quick mounting joint, wherein the internal part is directly inserted in the external part to assemble the nozzle; the internal part and the external part are sealed by an O-shaped rubber ring and fixed by a jackscrew; and a space between the internal part and the external part is a mixing chamber. The flowing resistance of the internal part is lower, so that the pressure of the mixing chamber can be kept in a higher range, and the atomizing efficiency of the nozzle is higher; a bubble flow formed in the air-liquid two-phase mixing process in the mixing chamber is uniform and stable, so that the stable atomizing effect is realized under the low-air-liquid mass flow ratio (between 0.07-0.1); and the working pressure is low, and the liquid flow is low, so that the stable atomization can be kept under the liquid flow of 3.5-6.0 kg / h and the absolute air-liquid inlet pressure of 0.36-0.40 MPa. The bubble atomizing nozzle is applied to such fields as chemical engineering, motive power and heating and ventilation.

Owner:HEBEI UNIV OF TECH +1

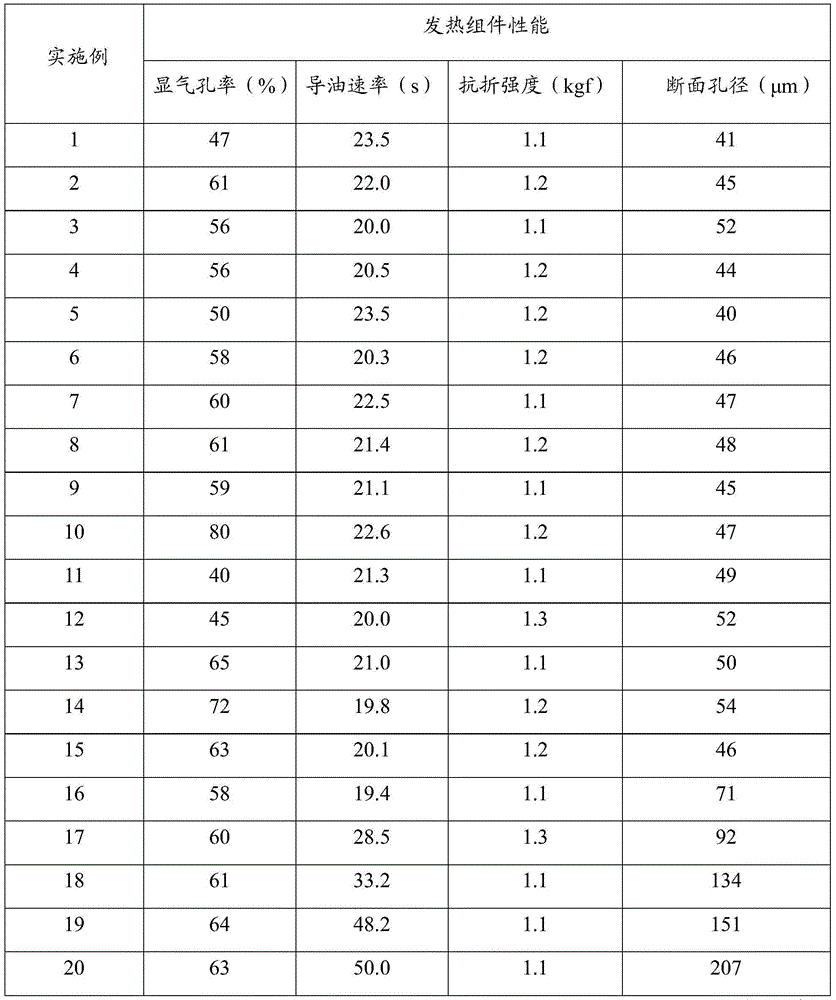

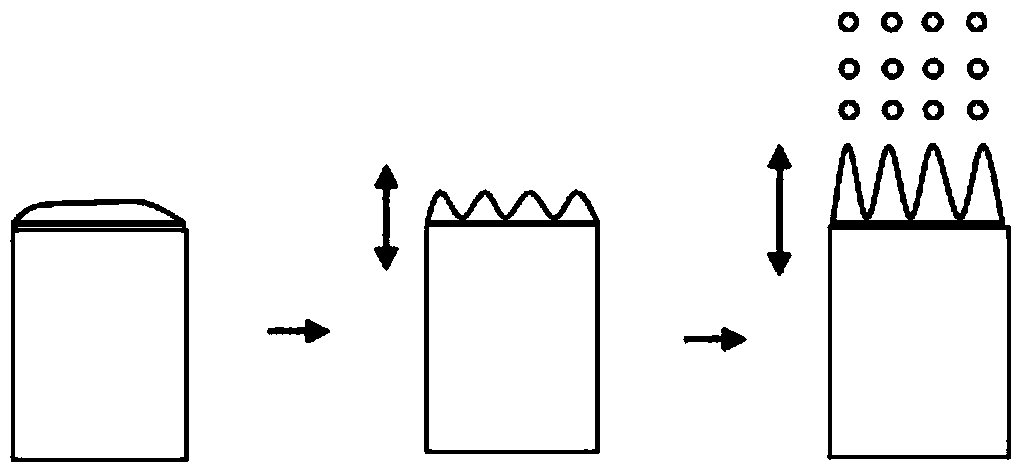

Self-adjusting type intelligent atomizing core and manufacturing method thereof

The invention provides a self-adjusting type intelligent atomizing core which comprises a body and a printing resistor arranged on the upper surface of the body. The aperture of crystalline grains inthe body is increased from top to bottom. Due to the big-end-down aperture of the crystalline grains, cigarette liquid can conveniently permeate through the crystalline grains from bottom to top and can be prevented from flowing downward, the upward moving cigarette liquid in a liquid inlet groove can press against the downward movement of the atomized cigarette liquid and the cigarette liquid pressed by the atomized cigarette liquid to move downward, the volatilizing efficiency of the atomized cigarette liquid is improved, and the atomizing efficiency of the cigarette liquid is improved. Dueto the design, the invention further provides a manufacturing method of the self-adjusting type intelligent atomizing core. The manufacturing method includes the steps of sequential overlapping of a plurality of ceramic layers, calcinating, silk-screening and sintering. The method is simple in process and reliable.

Owner:INNOKIN TECH

Liquid atomizer

ActiveUS20080073447A1Reduce noiseExtended service lifeMovable spraying apparatusSpray nozzlesStructuring elementMechanical engineering

Owner:MICRO BASE TECH CORP

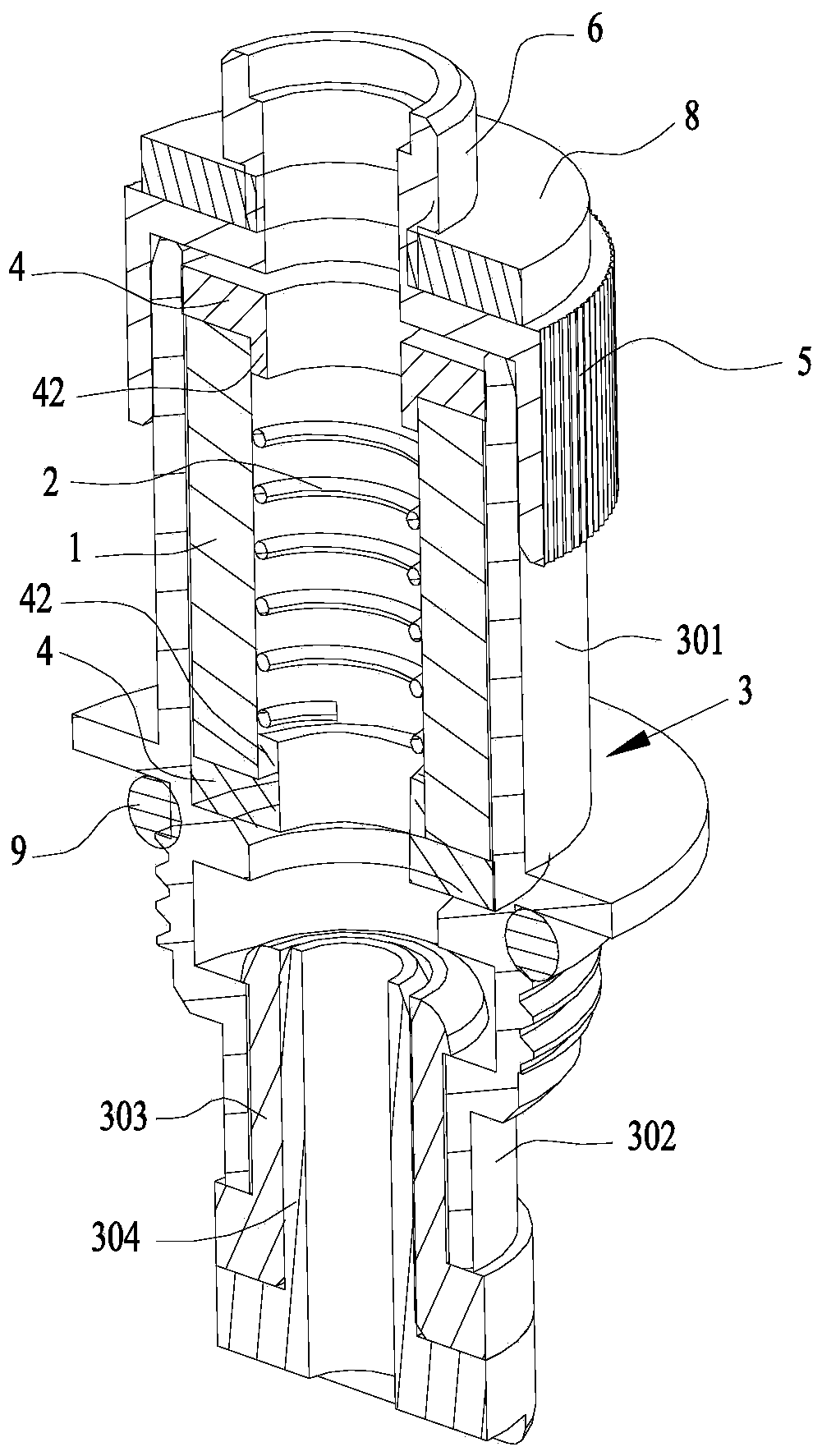

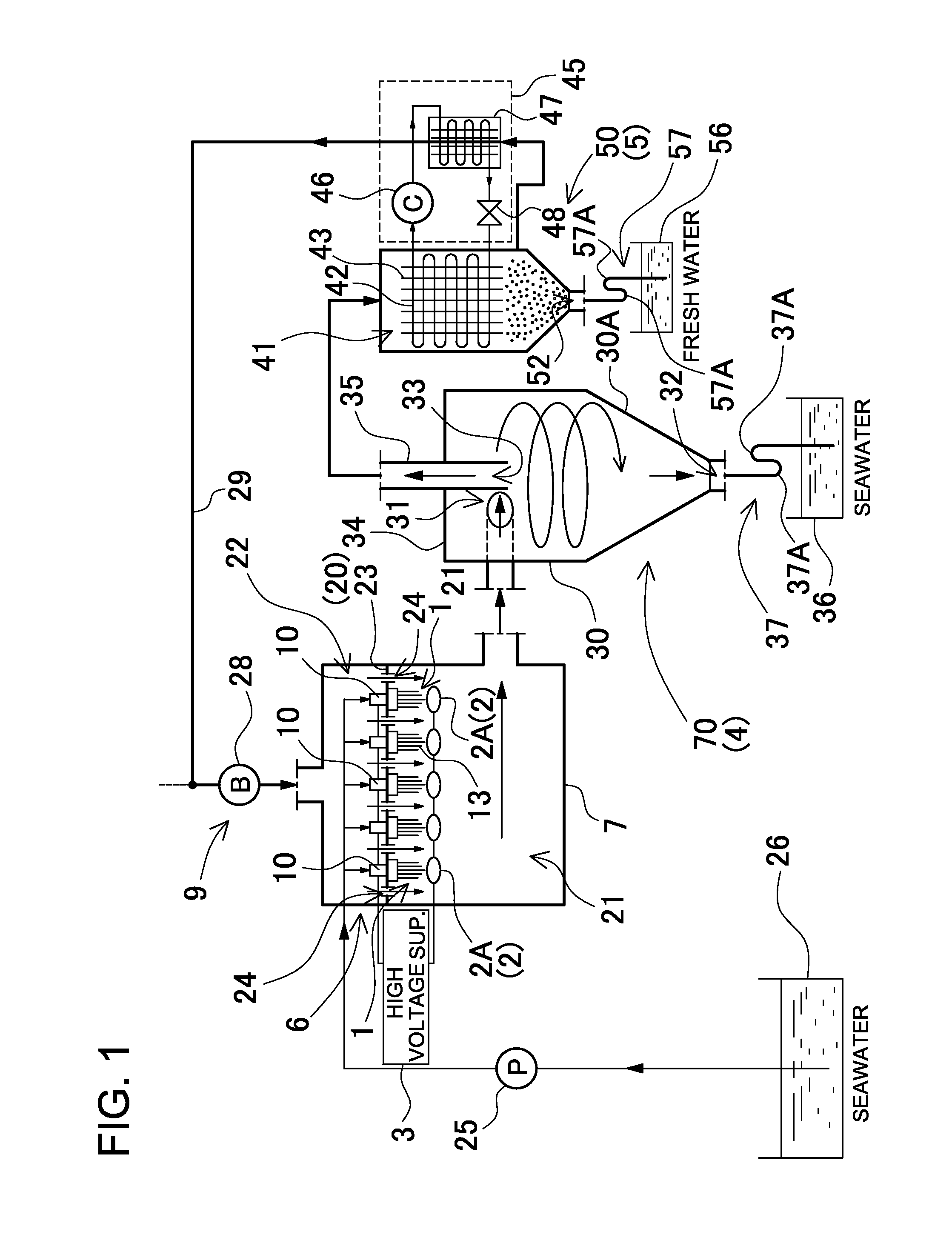

Seawater desalination apparatus

InactiveUS20140048467A1Reduce power consumptionEfficiently atomizedGeneral water supply conservationSeawater treatmentFresh waterSeawater

A seawater desalination apparatus includes a spray (1), a gas supplier (9), an atomizing electrode (2), a high voltage power supply (3), a mist classifier (4), and a mist collector (5). The spray includes apertures for producing a seawater mist. The supplier supplies gas for carrying the mist from the spray. The electrode electrostatically produces fine droplets from the mist from the spray. The power supply is connected to the electrode and the spray, and applies high voltage between the electrode and the spray for the production of fine droplets from the mist from the atomizer. The classifier separates the fine droplets in the mist from the electrode. The collector collects the mist discharged from the classifier thereby producing fresh water.

Owner:NANO MIST TECH

Spiral aluminum oxide ceramic nozzle for flue gas desulfurization slurry atomization and manufacturing method thereof

InactiveCN101874974ASmall sizeHigh strengthDispersed particle separationSpray nozzlesBoron carbideSlurry

The invention discloses a spiral aluminum oxide ceramic nozzle for flue gas desulfurization slurry atomization and a manufacturing method thereof. The spiral aluminum oxide ceramic nozzle is made of aluminum oxide ceramic powder by a gel injection molding process, wherein the aluminum oxide ceramic powder comprises the following components in parts by weight: 90-98 parts of superfine high-purity aluminum oxide powder, 1-1.5 parts of calcium carbonate, 2-7 parts of kaolin, 0.5-2 parts of burned talcum and 0.5-1 part of boron carbide. The nozzle has the characteristics of high wear resistance, high shock resistance, high corrosion resistance, low cost and long service life. In the invention, a spiral aluminum oxide ceramic nozzle blank with accurate size is prepared by the gel injection molding process and a blank cold machining process, thus overcoming the defects of the blank shaped by the traditional grouting molding method such as nonuniform density, cracking, low strength of the blank, difficult machining and the like, and improving the consistency and the size accuracy of the blank and a sintering body.

Owner:山东省环保陶瓷工程技术研究中心

Liquid-coated gas desulfurizing/atomizing nozzle

InactiveCN102389703AImprove efficient atomizationGood desulfurization effectDispersed particle separationLiquid spraying apparatusEngineeringSlurry

The invention discloses a liquid-coated gas desulfurizing / atomizing nozzle which comprises an internal tapered slurry nozzle and an internal tapered gas nozzle, wherein the gas nozzle is arranged in the slurry nozzle, a gap is formed between the outer wall of the gas nozzle and the inner wall of the slurry nozzle, the outer wall of the slurry nozzle is provided with a slurry inlet pipe, and the internal circumferential surface of the slurry nozzle is a thread surface. Pressure gas subjected to pressurization is fed into the gas nozzle with an internal tapered end, further compressed, jetted out from the gas nozzle, and then converged with slurry in a tapered jet chamber of the slurry nozzle so as to form 'liquid-coated gas'; and under the action of high speed and pressure difference, the 'liquid-coated gas' is broken, and liquid drops are separated and broken and finally jetted out by the slurry nozzle, so that the slurry is efficiently atomized, thereby achieving an optimal flue gas desulfurization effect. The slurry inlet pipe is communicated with the gas nozzle in an obliquely-tangential direction, and the installation angle is consistent with the spiral angle of a thread structure, thereby further facilitating the formation of a natural spiral rotational flow when the slurry is fed into a slurry cavity, and facilitating the formation of the 'liquid-coated gas'.

Owner:SOUTH CHINA UNIV OF TECH

Quadric injection metal atomization device of rotary-forming film

The invention relates to a metal atomization device for the secondary injection of a rotary film, which comprises an input liquid metal jet supplying part; a ring-shaped atomization combined nozzle is formed concentrically with an input liquid metal jet center; a rotating impact platform is arranged at the lower part of the ring-shaped atomization combined nozzle which is provided with an upper nozzle and a lower nozzle; the airstream jetting direction of the upper nozzle is in a downward centrifugal direction to impact the rotary film formed when the impact platform is impacted by the input metal jet, thereby breaking a formed film; the airstream jetting direction of the lower nozzle is in a downward central direction and forms an effective cross angle with the airstream jetting direction of the upper nozzle, thereby impacting the broken liquid metal particles of the formed film and realizing secondary breaking. By adopting the device, better atomization effect and finer metal droplets and powders can be obtained.

Owner:江苏今越控股集团有限公司

Supersonic atomizing nozzle with single-stage laval and hartmann combined structure

The invention relates to a supersonic atomizing nozzle with a single-stage laval and hartmann combined structure. The supersonic atomizing nozzle comprises a liquid guide cavity, wherein a nozzle orifice is formed in the lower part of the liquid guide cavity; an annular high-pressure air inflow cavity is encircled around the liquid guide cavity; an air inlet channel is formed in the inner side wall of the high-pressure air inflow cavity; the high-pressure air inflow cavity is communicated with the nozzle orifice through the air inlet channel; the air inlet channel adopts a cross hartmann two-stage resonance tube structure which is formed from an inlet guide pipe, an outlet guide pipe, a first-stage resonance tube and a second-stage resonance tube which are communicated; the inlet guide pipe and the first-stage resonance tube are arranged on the same straight line; the outlet guide pipe and the second-stage resonance tube are arranged on the same straight line; the tail ends of the first-stage resonance tube and the second-stage resonance tube are sealed; the inlet guide pipe is a reducer pipe with characteristics of a laval pipe. Compared with the prior art the supersonic atomizing nozzle with the single-stage laval and hartmann combined structure disclosed by the invention has the advantages that the characteristics of the laval pipe and the cross hartmann resonance pipe are combined to form the air inlet channel with the annular ring structure, so as to obviously increase the nozzle atomizing efficiency, lower the diameter of the atomized particles and narrow the size distribution.

Owner:TONGJI UNIV

Fine metal powder atomizing spray nozzle with molten metal easily flowing out

The invention discloses a fine metal powder atomizing spray nozzle with molten metal easily flowing out. The fine metal powder atomizing spray nozzle is formed by a first assembly and a second assembly, wherein the first assembly is formed by connecting a cone frustum with the lower part of a cylindrical table; a liquid guide pipe is arranged at the center of the first assembly; the second assembly is formed by connecting a conical inner cavity with the lower part of a cylindrical inner cavity; an annular groove is formed in the wall of the cylindrical inner cavity of the second assembly; a horizontal ring surface and an inner arc rotating body which are sequentially connected are arranged at the connected part of the cylindrical table and the cone frustum; a horizontal ring surface and an outer arc rotating body which are sequentially connected are arranged at the connected part of the cylindrical inner cavity and the conical inner cavity; the annular groove forms an air inlet cavity; a three-section type Laval gas channel is formed between the first assembly and the second assembly; the first section is a horizontal air inlet retraction section formed by the horizontal ring surfaces of the first assembly and the second assembly; the second section is an arc expansion section formed by the inner arc rotating body of the first assembly and the outer arc rotating body of the second assembly; and the third section is a linear expansion section formed by the cone frustum of the first assembly and the cylindrical inner cavity of the second assembly.

Owner:HUNAN HENGJI POWDER TECH

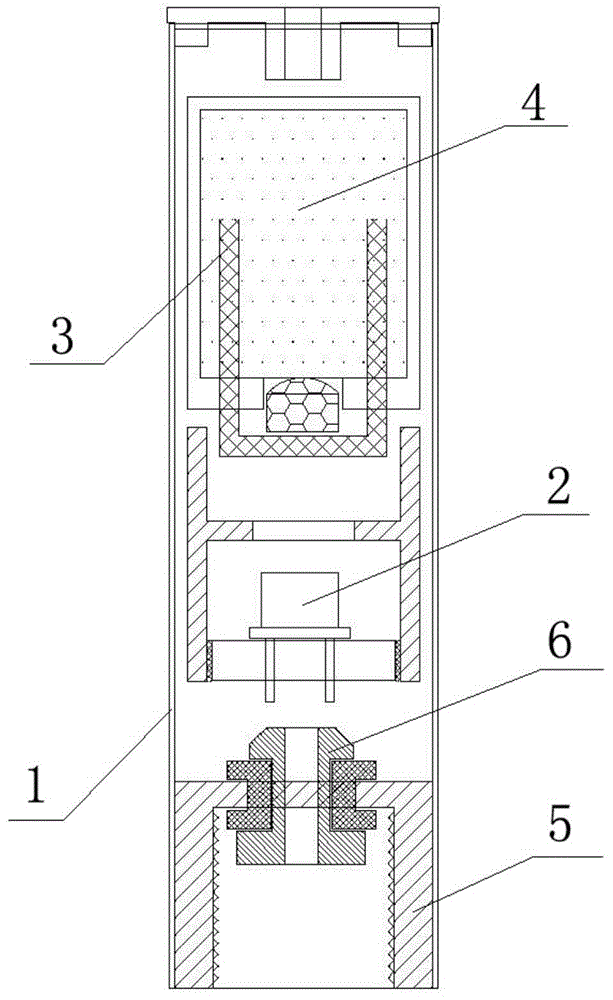

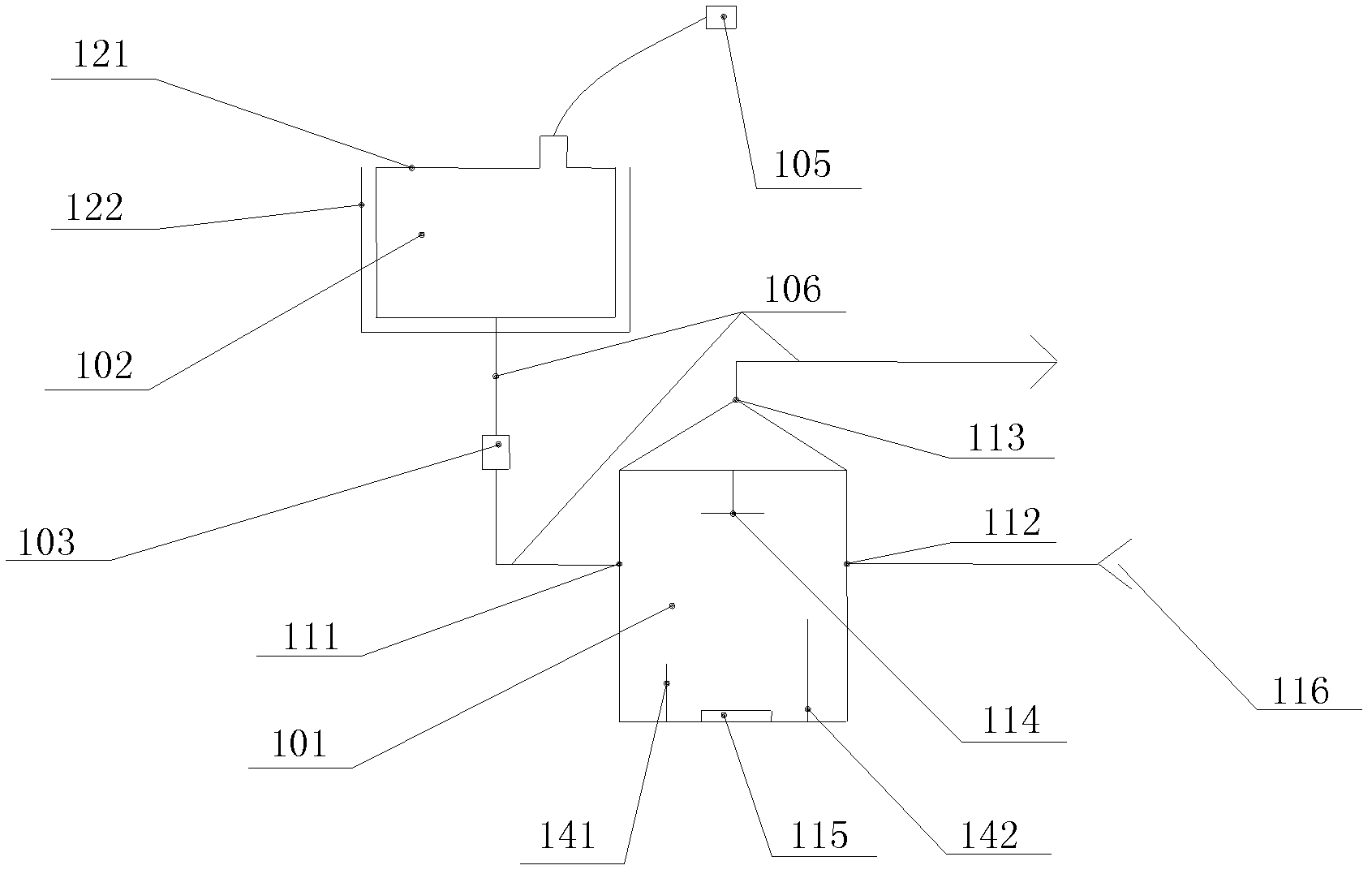

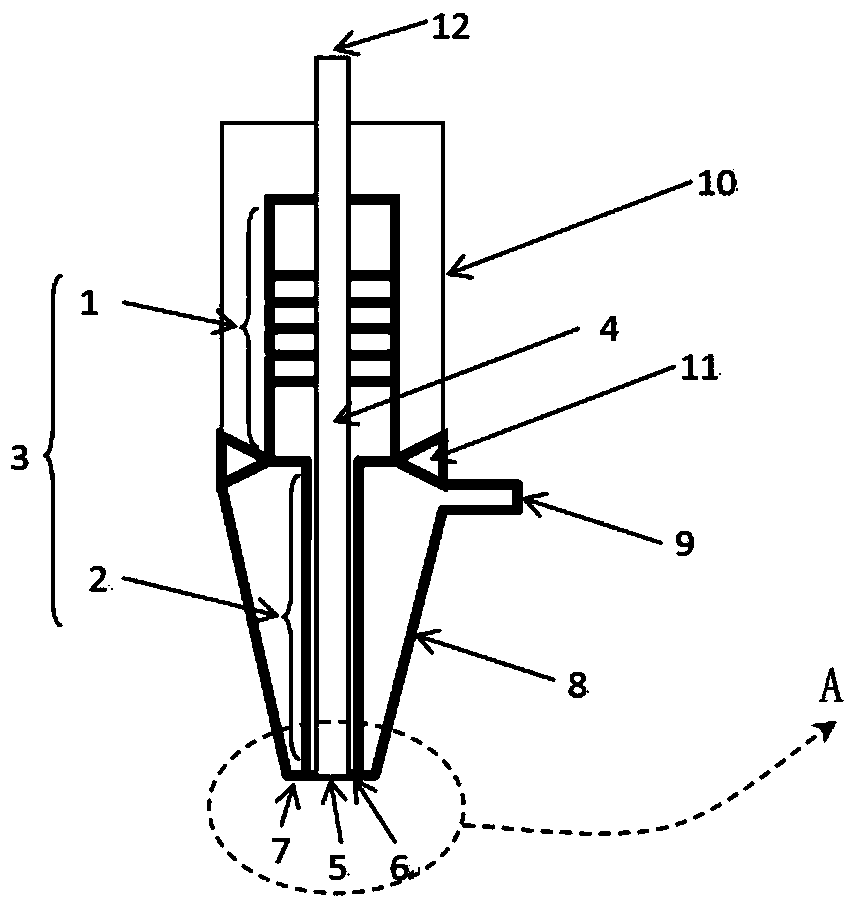

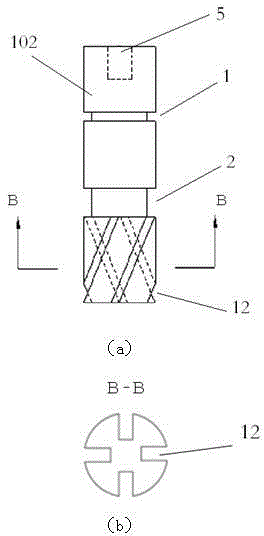

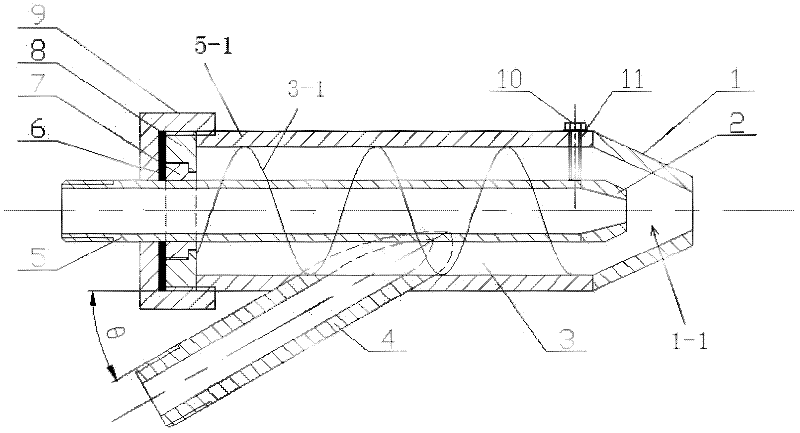

Rotating electrode preparing micro spherical metal powder and method of rotating electrode

The invention discloses a rotating electrode preparing micro spherical metal powder and a method of the rotating electrode. A plasma gun is composed of a Laval spraying pipe and a plasma gun head capable of conducting axial feeding, and a plasma gun inner gas way is formed between the plasma gun head and the Laval spraying pipe. The plasma gun head is connected with a gun head push rod, and a rotating electrode bar is connected with an electrode bar push rod. The axial relative position of the rotating electrode bar and the axial relative position of the plasma gun head are controlled and adjusted through the electrode bar push rod and the gun head push rod. A cylinder electrode bar is used as the raw material, and a plasma rotation electrode process is used for conducting the first time of atomization; supersonic speed high-temperature inert gas exerted to an electrode bar melting pool and injected by the adjustable plasma gun head is used for conducting the second time of atomization; centrifugal force of a centrifugal atomization mechanism overcomes tension on the surface of alloy liquid to serve as the upper limit of the atomization collected powder granularity; the efficiency of converting atomization energy into atomization drop surface energy is greatly improved; and the yield of micro powder smaller than 50 microns is greatly increased compared with traditional centrifugal atomization.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

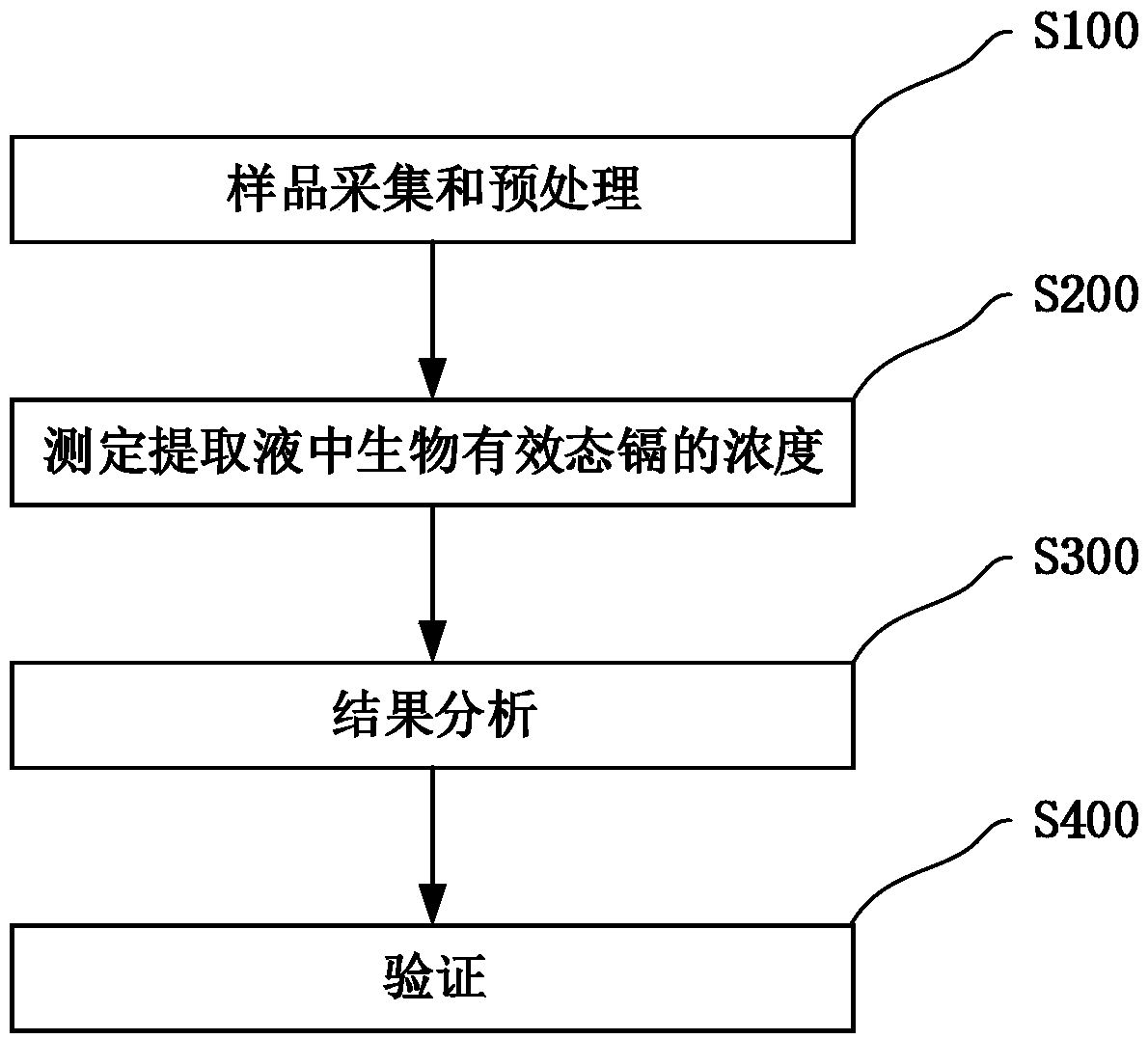

Method for detecting bio-available cadmium in soil

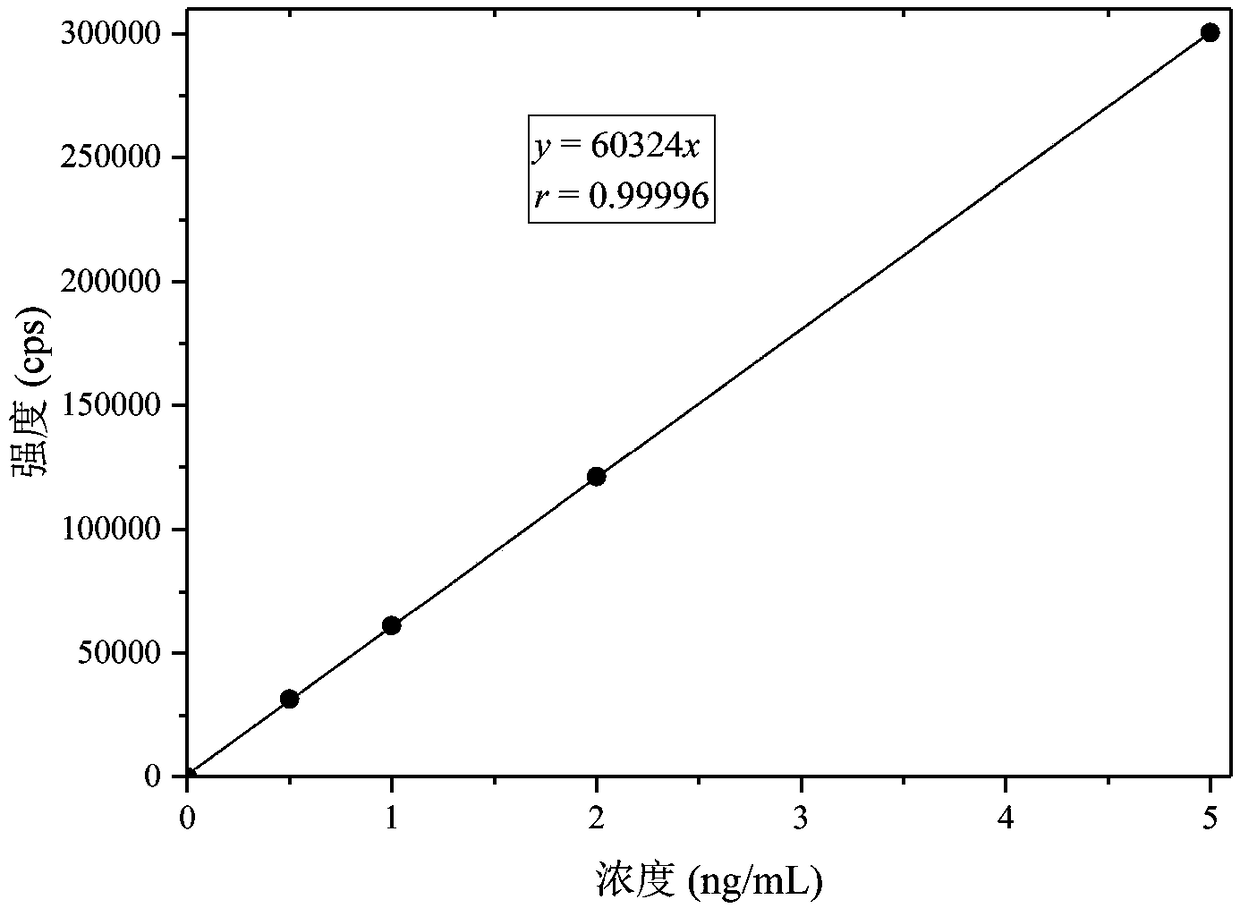

ActiveCN109142004AAcid-base damage is smallPrevent curingComponent separationPreparing sample for investigationInductively coupled plasmaCadmium Cation

A method for detecting bio-available cadmium in soil includes steps: S100, sample collection and pretreatment, to be more specific, sampling soil, subjecting sampled soil to air drying at the room temperature, grinding, and filtering through a 200-mesh screen to obtain a soil sample; weighing 1-5g of the soil sample, adding into a 250mL polytetrafluoroethylene centrifugal cup, adding 25mL of 1mol / L ammonium chloride solution and 25mL of 80% ethanol solution, cleaning through an ultrasonic cleaner, centrifuging through a centrifuge, filtering supernatant through a filter membrane to obtain extract liquid, and adopting HNO3 solution in concentration of 1% to obtain a constant volume; S200, determination of the concentration of bio-available cadmium in the extract liquid, to be more specific,adopting an inductively coupled plasma source mass spectrometer for creating a standard curve for determining different concentrations of bio-available cadmium according to an inductively coupled plasma mass spectrometry method; adopting the inductively coupled plasma source mass spectrometer for measuring concentration of bio-available cadmium in the extract liquid according to the standard curve; S300, result analysis, to be more specific, calculating the content of bio-available cadmium in the soil sample according to measured soil sample mass and measured extract liquid concentration.

Owner:JILIN UNIV

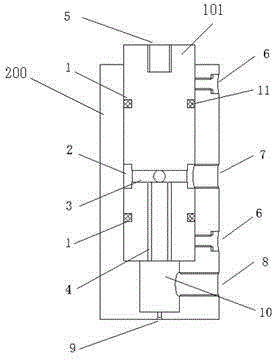

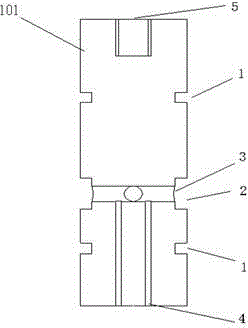

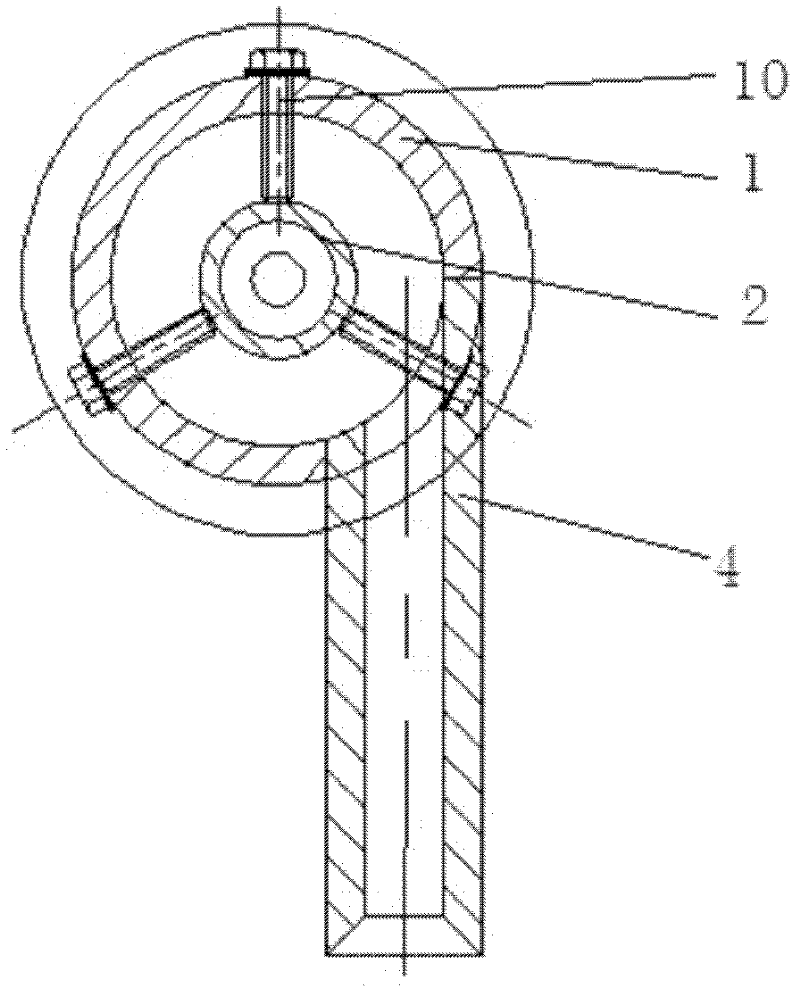

Gas atomization nozzle for preparing superfine metal powder

The invention discloses a gas atomization nozzle for preparing superfine metal powder. The nozzle is characterized in that the working portion of an upper nozzle (1) is a cone frustum and a metal outflow channel (3) is axially arranged in the center of the upper nozzle; a lower nozzle (2) is formed by connecting an inner cone frustum below a cylindrical inner cavity; an arc-shaped transition section (7) of the lower nozzle is arranged at the joint; an air inlet cavity (4) is formed between the upper nozzle (1) and the cylindrical inner cavity of the lower nozzle (2); and throats (5) and airflow expansion sections (6) are formed by combination of the cone frustum of the upper nozzle (1) and the inner cone frustum of the lower nozzle (2), thus forming a channel with Laval nozzle structure characteristics. The nozzle is suitable for atomization of all the metals and alloy melts with melting points below 1500 DEG C and especially provides a new solution to preparation of the superfine powder of such metals with low melting points as aluminium, zinc, magnesium, tin and the like and alloys.

Owner:CENT SOUTH UNIV

Supersonic speed gas atomization sprayer

InactiveCN106111362AImprove atomization efficiencyEnhanced secondary atomizationDust removalFire preventionShock waveSprayer

The invention discloses a supersonic speed gas atomization sprayer which comprises an outer shell and an inner spraying pipe assembled inside the outer shell. The outer shell is provided with a spraying outlet sealing stepped cylindrical hole, an air intake hole pressing stepped cylindrical hole and a water inlet. An inner cavity with holes in the side face is defined by the outer wall face of the inner spraying pipe and the inner wall face of the outer shell. The water inlet communicates with the inner cavity. The inner spraying pipe is provided with an air intake hole and a spraying outlet. A mixing chamber is defined by the area between the spraying outlet and the laryngoneck portion of a Laval convergent-divergent pipe; a liquid membrane circular seam is formed in the side wall of the mixing chamber, and the inner cavity communicates with the mixing chamber through the liquid membrane circular seam. Through high-speed airflow and shock wave atomization, the supersonic speed gas atomization sprayer is capable of saving energy and water, low in requirement for water pressure and pipelines, capable of forming fine mist more easily, and excellent in diffusion effect, atomization effect and dust removal effect, and the situation of the sludgy downhole environment caused by wet dust removal is avoided.

Owner:ANHUI UNIV OF SCI & TECH

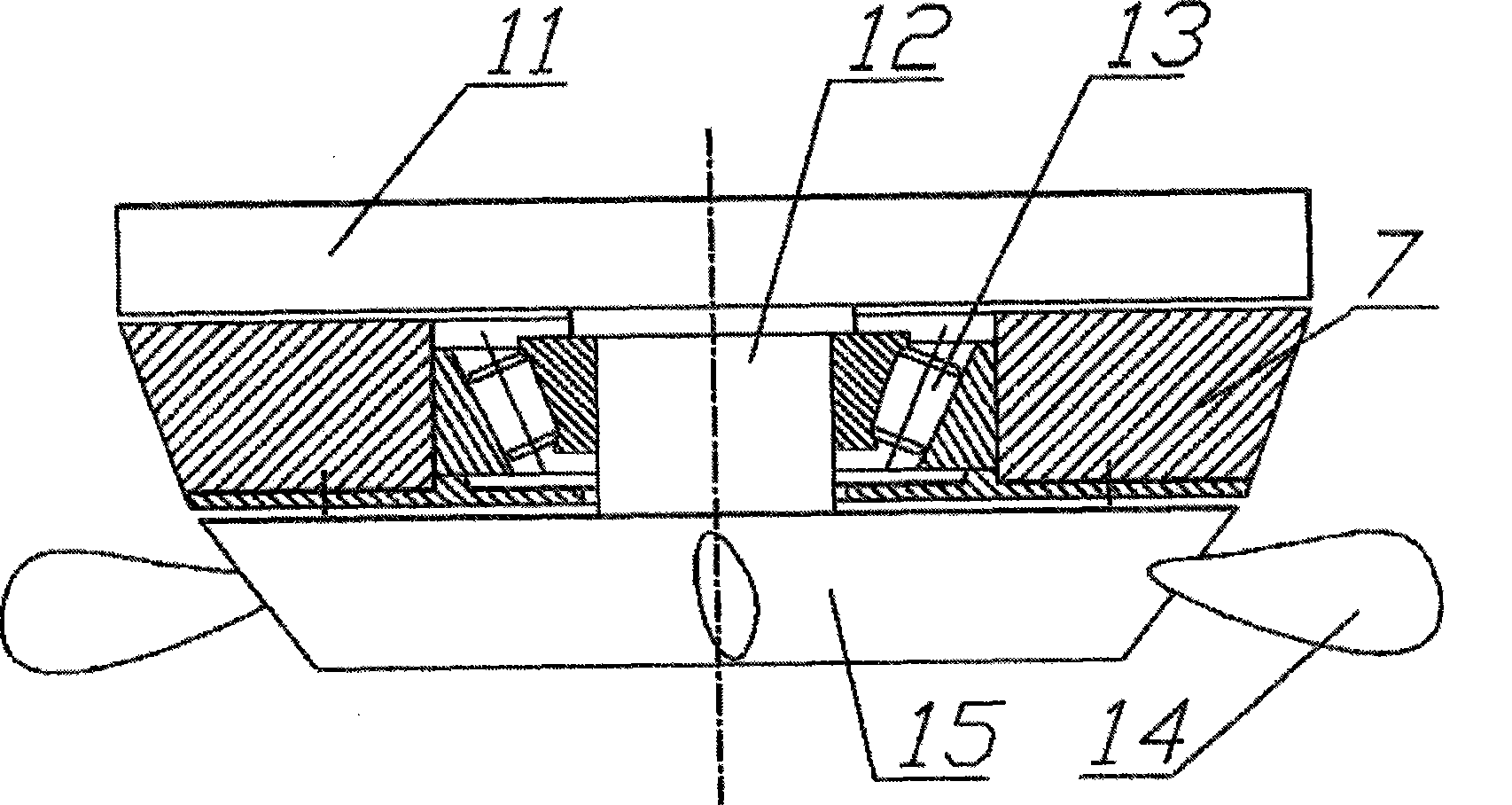

Ultrasonic atomization piece, electronic cigarette atomization core and electronic cigarette atomizer

ActiveUS20190142063A1Simple structureWork at highMedical devicesTobacco devicesElectricityElectrical connection

Disclosed are an ultrasonic atomization piece, an electronic cigarette atomization core and an electronic cigarette atomizer. The ultrasonic atomization piece includes a piezoelectric ceramic main body; one surface of the piezoelectric ceramic main body is in contact with a positive electrode conducting layer, and the other surface of the piezoelectric ceramic main body is in contact with a negative electrode conducting layer, the negative electrode conducting layer extends to the surface of the piezoelectric ceramic main body on which the positive electrode conducting layer is located along a side edge of the piezoelectric ceramic main body, and a plurality of convex point areas, which cover the edge of the positive electrode conducting layer are provided on an edge of the negative conductive layer. The ultrasonic atomization piece, the electronic cigarette atomization core and the electronic cigarette atomizer have the advantages of simple structure, reliable electrical connection, reliable work, high atomization speed, good smoke taste and long service life.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Electronic cigarette atomizer with divergent smoke outlet pipe

The invention discloses an electronic cigarette atomizer with a divergent smoke outlet pipe. The electronic cigarette atomizer comprises an atomizer pipe, an atomization device and a connecting part; one end of the atomizer pipe is provided with a suction nozzle segment, the other end of the atomizer pipe is provided with an atomization connecting segment, the middle of the atomizer pipe is provided with a liquid storage segment, a suction nozzle containing cavity which has the large section and can contain additives is formed in the suction nozzle segment, the smoke outlet pipe which is integrally formed with the atomizer pipe is arranged at the central axis inside the liquid storage segment, the two ends of the smoke outlet pipe are communicated with an atomization cavity and the suction nozzle containing cavity respectively, and the inner diameter of the smoke outlet pipe is gradually increased from one end of the atomization cavity to one end of the suction nozzle containing cavity; a liquid storage cavity used for storing cigarette liquid is formed between the smoke outlet pipe and the atomizer pipe; the atomization device is connected with the liquid storage cavity and the smoke outlet pipe, so that the cigarette liquid in the liquid storage cavity is atomized and then exhausted through the smoke outlet pipe. The electronic cigarette atomizer has the advantages that the volume of smoke sucked from a suction nozzle is increased, the smoke flow rate of the end, located in the atomization cavity, of the smoke outlet pipe is increased, therefore, it is guaranteed that air in the atomization cavity fully flows and quickly brings the smoke out, and the atomization efficiency is improved.

Owner:林光榕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com