Heating assembly for electronic cigarette

A technology for heating components and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of poor liquid guiding performance, low reliability, and low atomization efficiency of fiber ropes, so as to improve atomization efficiency, improve atomization efficiency, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

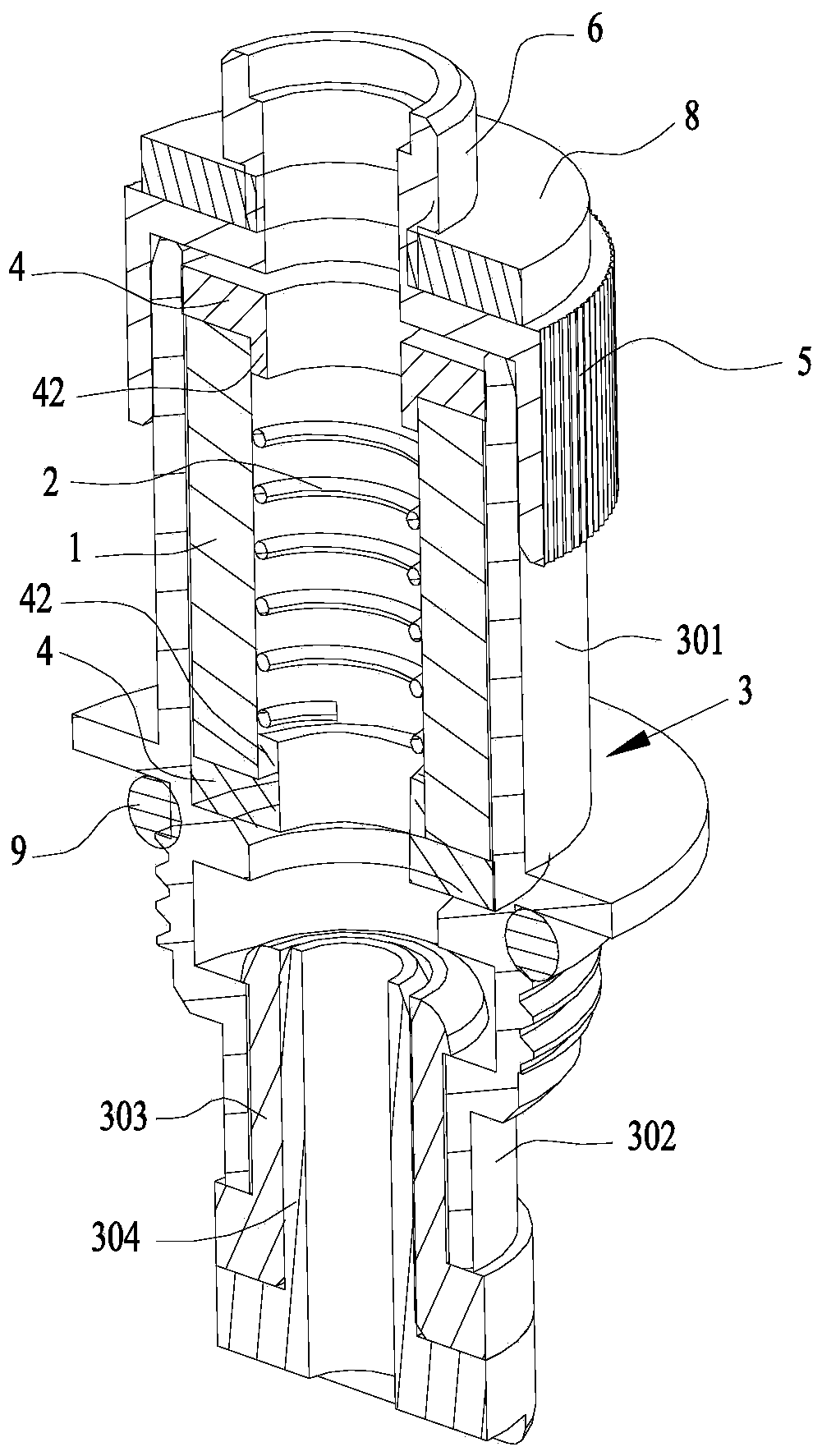

[0024] like Figure 1~3 The heating component of an electronic cigarette shown includes a liquid-conducting ceramic body 1, a heating wire 2 and a fixing seat 3. The fixing seat 3 is provided with an accommodating cavity 300, and the liquid-conducting ceramic body 1 is fixed in the accommodating cavity 300. Both ends of the seat 3 are provided with an inlet 31 and an outlet 32 communicating with the accommodating cavity 300 , the side wall of the fixed seat 3 is provided with an e-liquid inlet 33 communicating with the accommodating cavity 300 , and a fixing hole runs through the liquid-conducting ceramic body 1 11. The opening at one end of the fixing hole 11 is opposite to the inlet 31, and the opening at the other end of the fixing hole 11 is opposite to the outlet 32; the heating wire 2 is fixed in the fixing hole 11 and contacts the wall of the fixing hole 11, And it is electrically connected with the fixing base 3 .

[0025] Among them, the liquid-conducting ceramic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com