Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Guaranteed superheat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

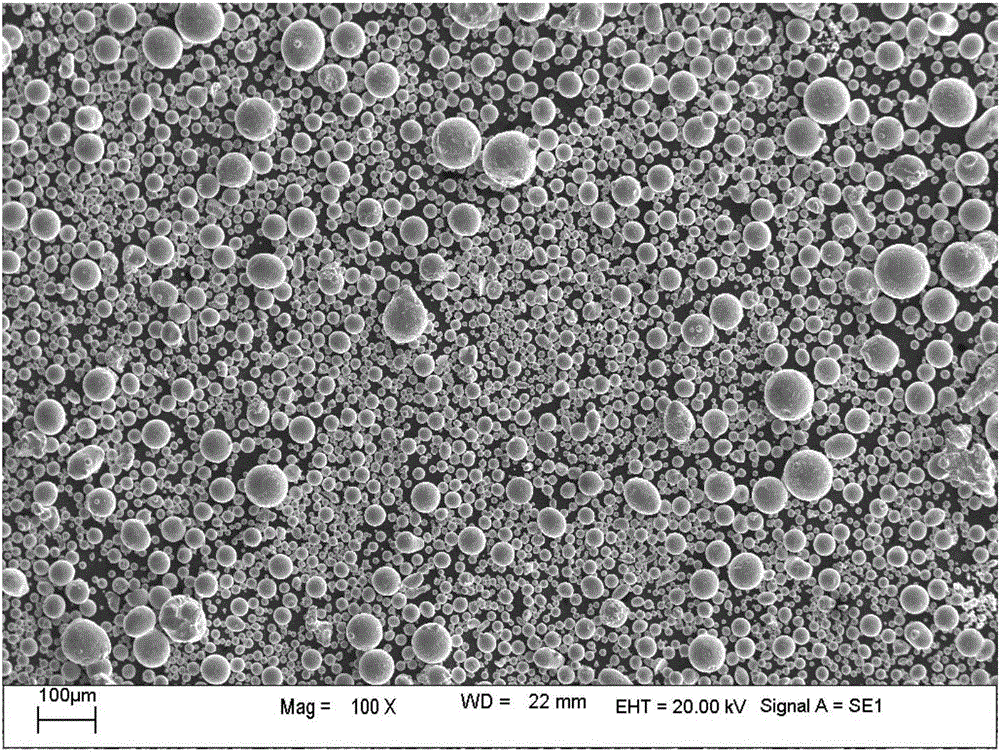

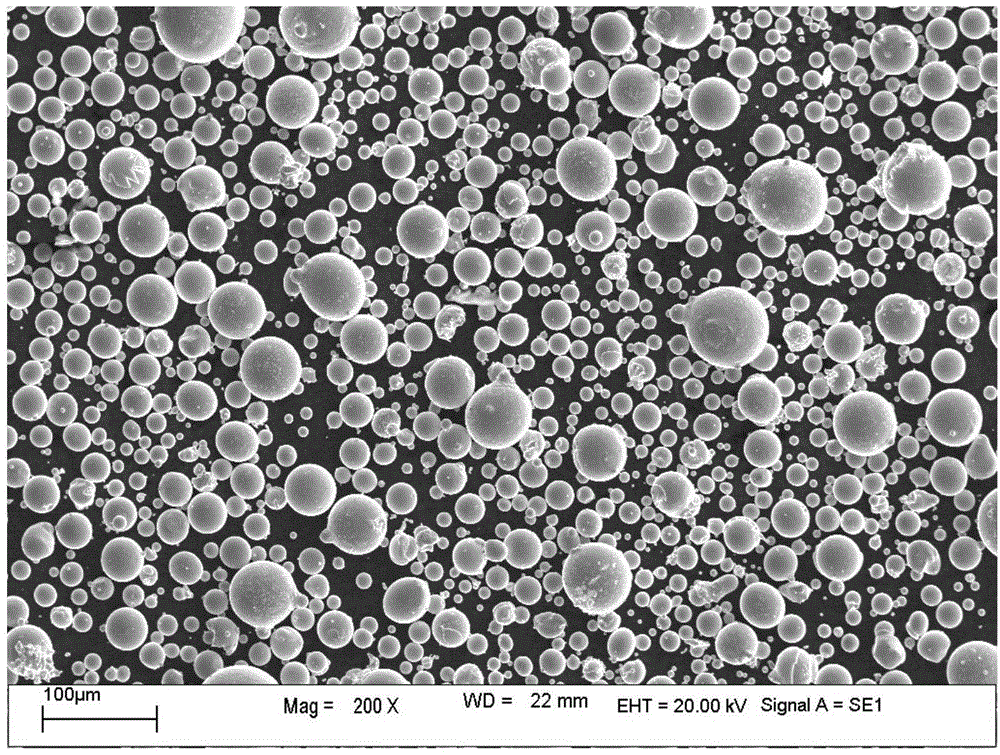

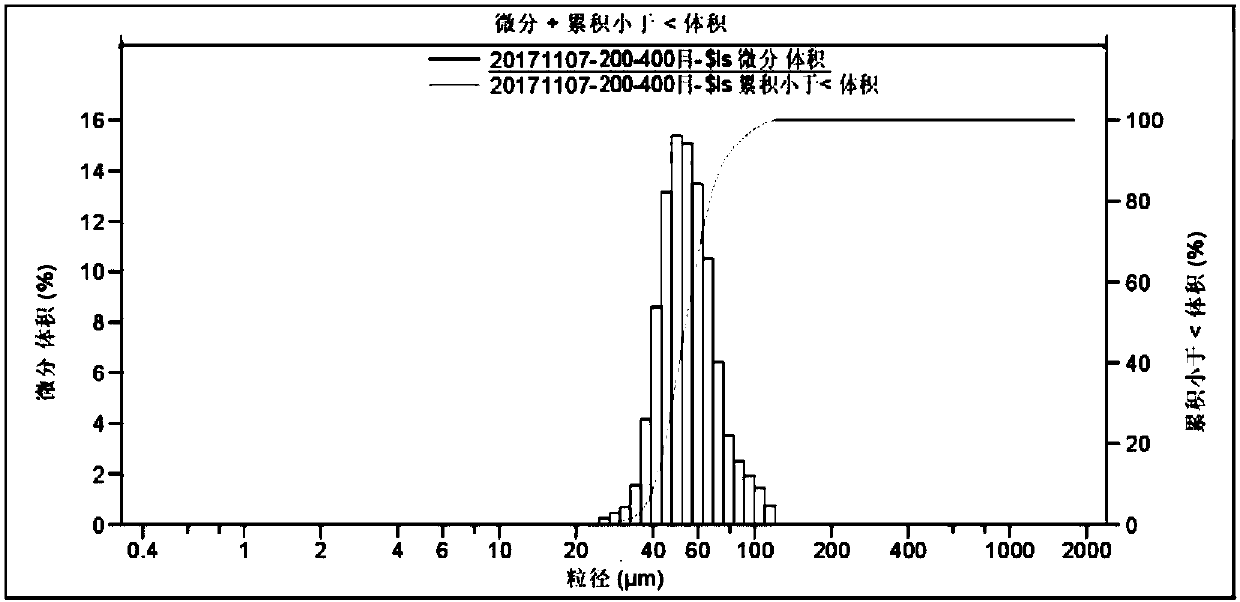

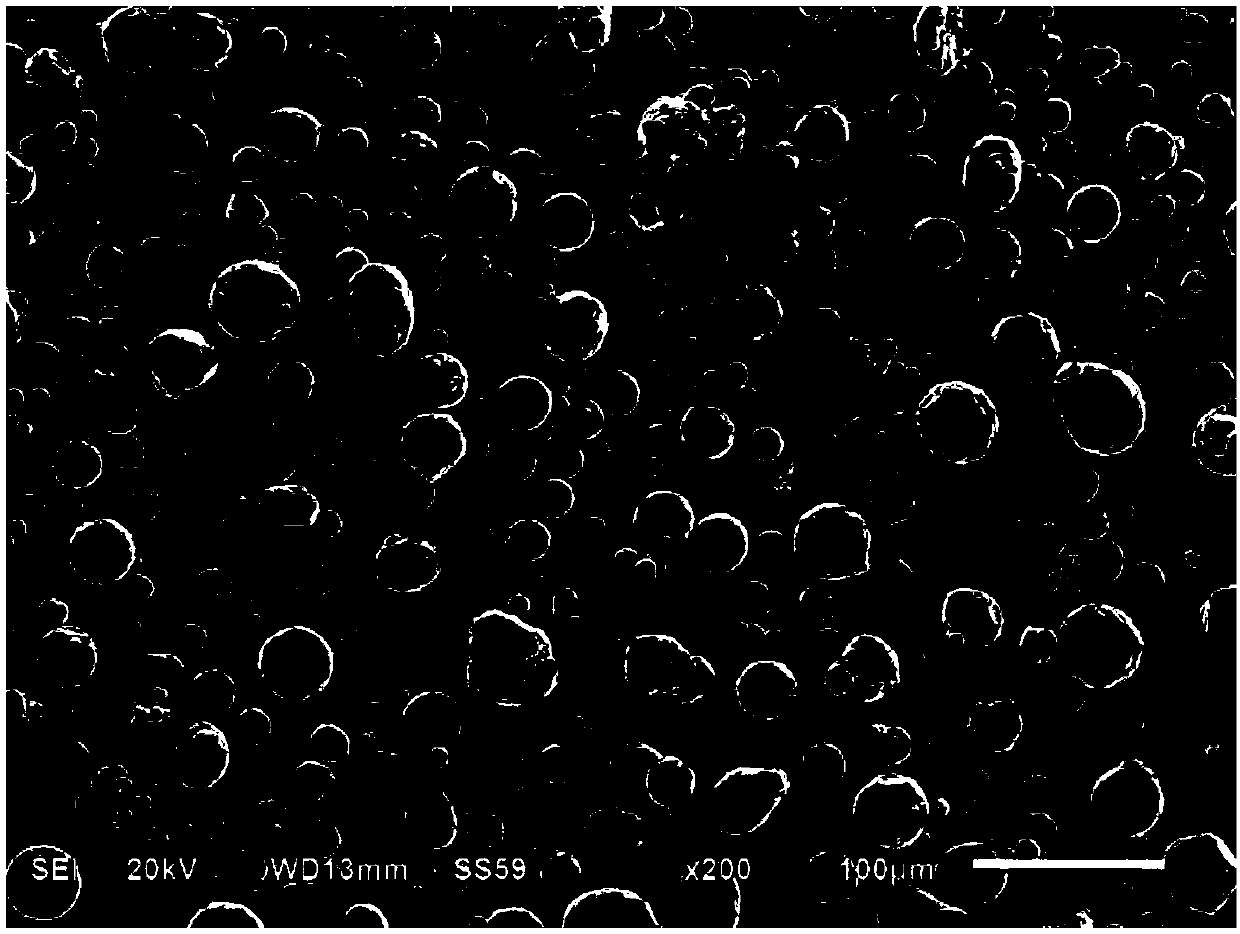

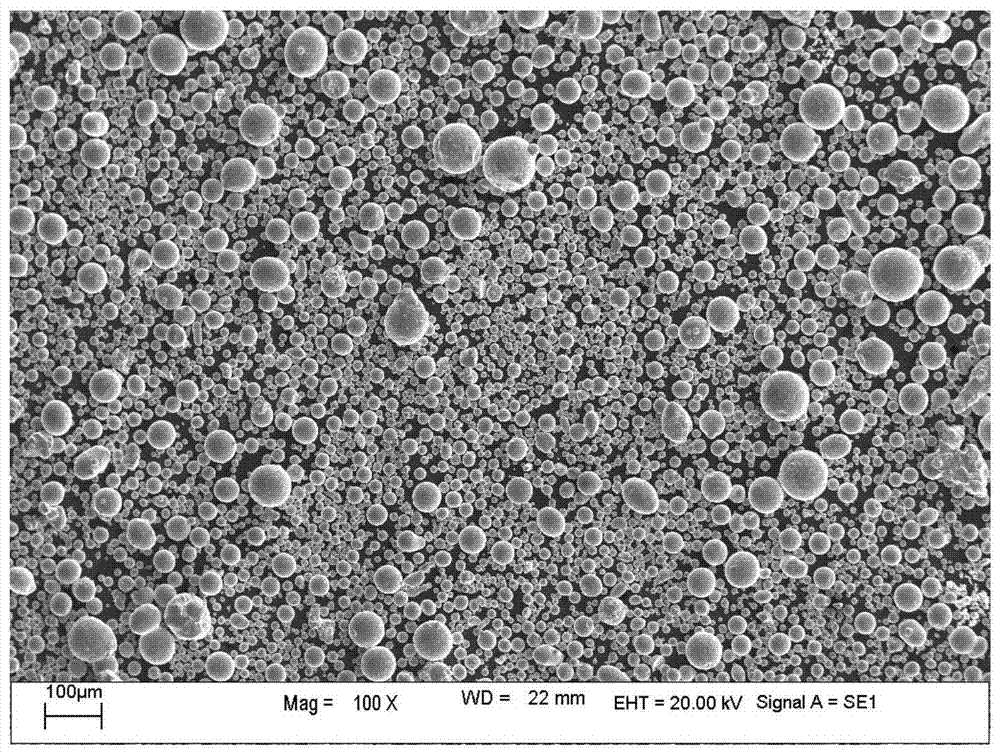

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

In situ self-spread welding repair method of aluminum mother plate

InactiveCN101474719AQuick Weld RepairUnique process methodAlumino-thermic welding apparatusFusible plugGraphite

The invention relates to a welding repairing method for aluminum parent metal, in particular to an in-situ self-propagting welding repairing method for aluminum parent metal. The method is characterized in that: self-propagting medical preparation is firstly prepared, and cleaning, oil removal, oxide film removal are carried out on parts to be welded of aluminum parent metal, then welding fluid is coated on a groove face; according to the shape and size of the groove, a mould with lower holes is made by graphite and is fixed on the upper part of the groove, and a graphite plate is clamped at the two sides of the groove by a clamping device and forms a melting chamber together with the mould, an automatic fusible plug is laid at the bottom part of the mould, then the self-propagting medical preparation is poured into the mould, pyrophoric powder is coated above the self-propagting medical preparation, after the parent metal is preheated to a certain temperature, the pyrophoric powders is lighted, thus realizing in-situ self-propagting welding repairing of the aluminum parent metal. By the method provided by the invention, intense magnetic field interference can be avoided, welding quality can be improved, labor intensity can be relieved, and the operation is easy and rapid.

Owner:QINGTONGXIA ALUMINUM IND GROUP +1

Hot-rolled steel wire rod for large bridge cable rope zinc-plated steel wire over 2000 MPa level and production method

ActiveCN109468530APlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWater bathsIngot

The invention relates to a hot-rolled steel wire rod for a large bridge cable rope zinc-plated steel wire over the 2000 MPa level. Chemical components of the steel wire rod comprise, by weight percentage, 0.90-1.10% of C, 0.20-0.60% of Si, 0.30-0.90% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.10-0.40% of Cr, 0.010-0.070% of Al, 0.02-0.15% of V, smaller than or equal to 0.05% of Cu, 20-40 ppm of Ca, 20-90 ppm of N and the balance Fe and inevitable residual elements. The content of sorbite texture of the steel wire rod is larger than or equal to 95%. Thethrough ring range of the tensile strength is smaller than or equal to 70 MPa (uniformity). After the steel wire rod is subjected to drawing and zinc plating, the tensile strength of the zinc-platedsteel wire is larger than or equal to 2000 MPa, and the number of torsions is larger than or equal to 12. According to the technical flow of the steel wire rod, pretreatment of molten iron is carriedout, steel is smelted through a converter or an electric furnace, LF refining is carried out, RH degassing treatment is carried out, continuous casting of 390*510 cogged ingot is carried out, a blankis reheated, the blank is rolled, the surface of an intermediate billet is subjected to finishing, the intermediate billet is reheated, the intermediate billet is rolled, the steel wire rod is subjected to EDC water bath toughening treatment, and the steel wire rod is collected and packed.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

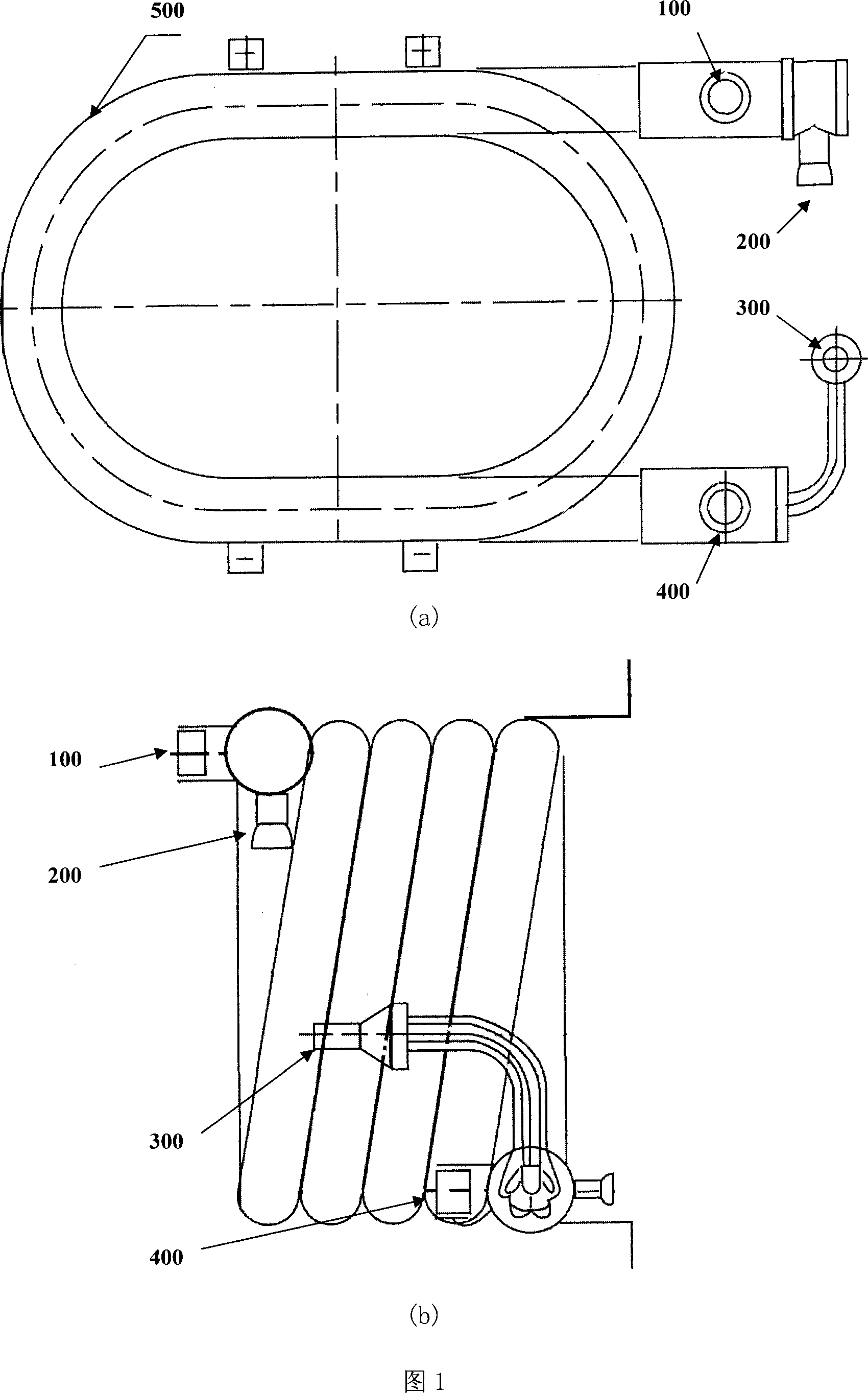

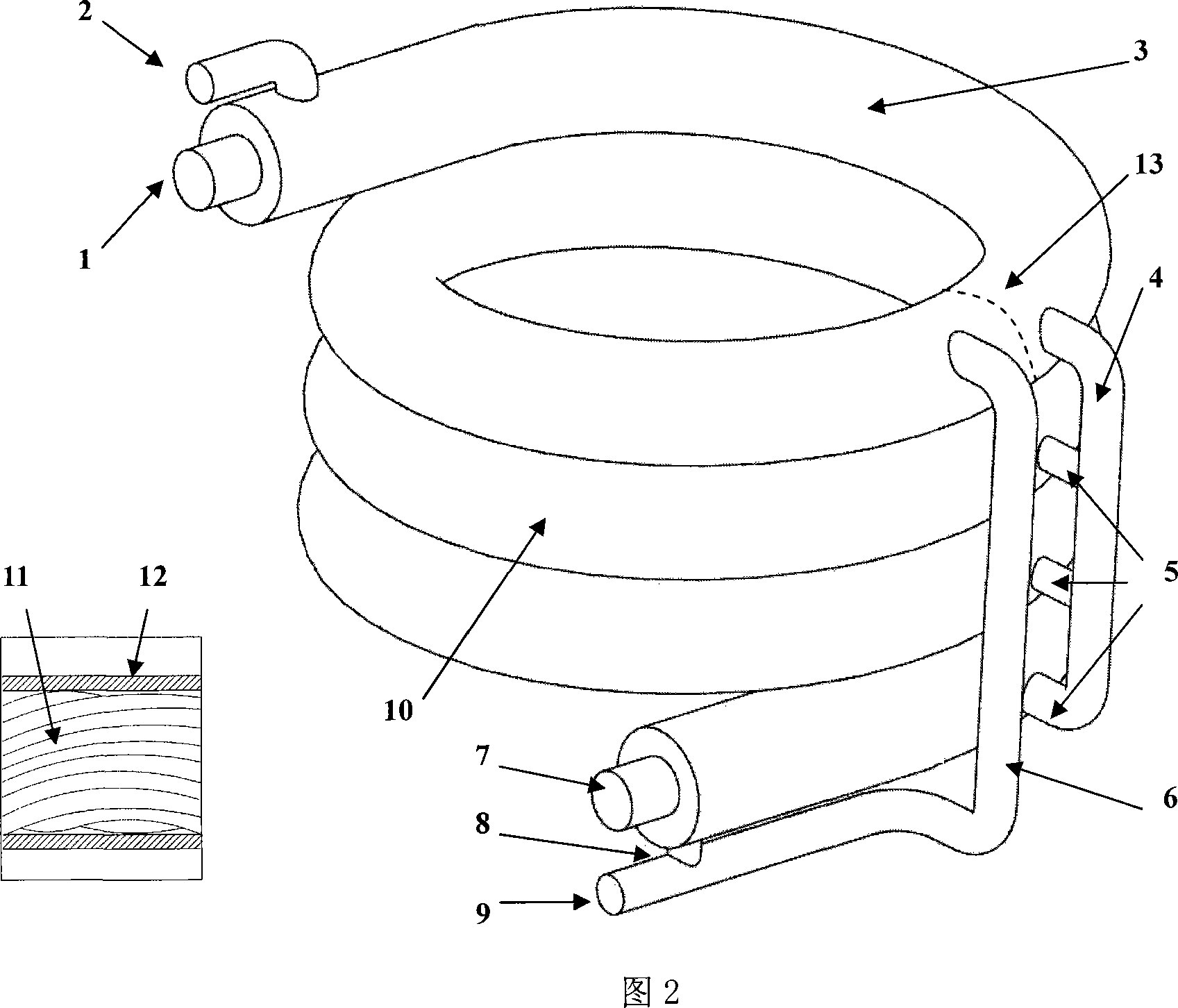

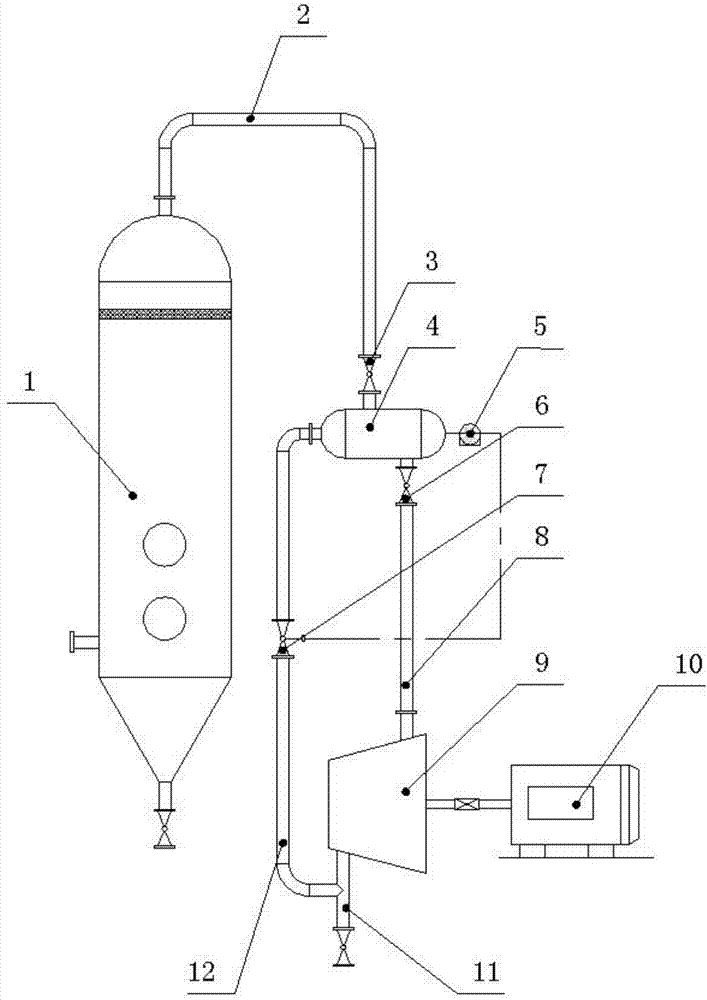

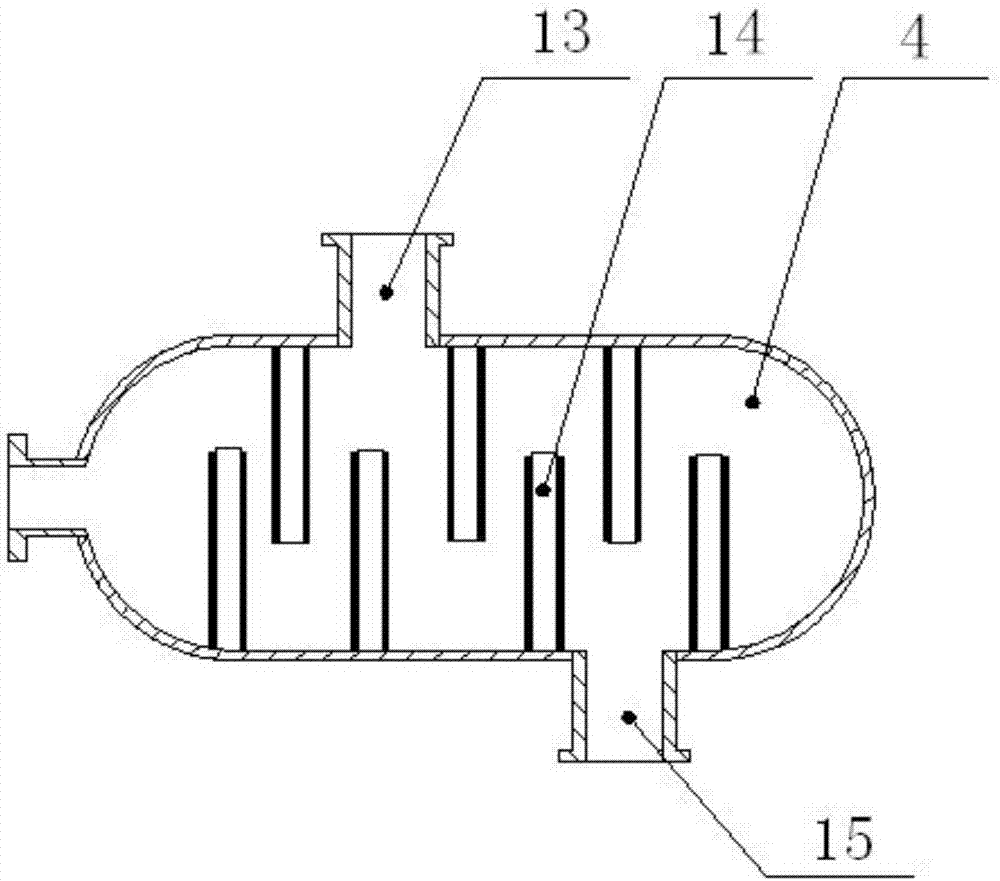

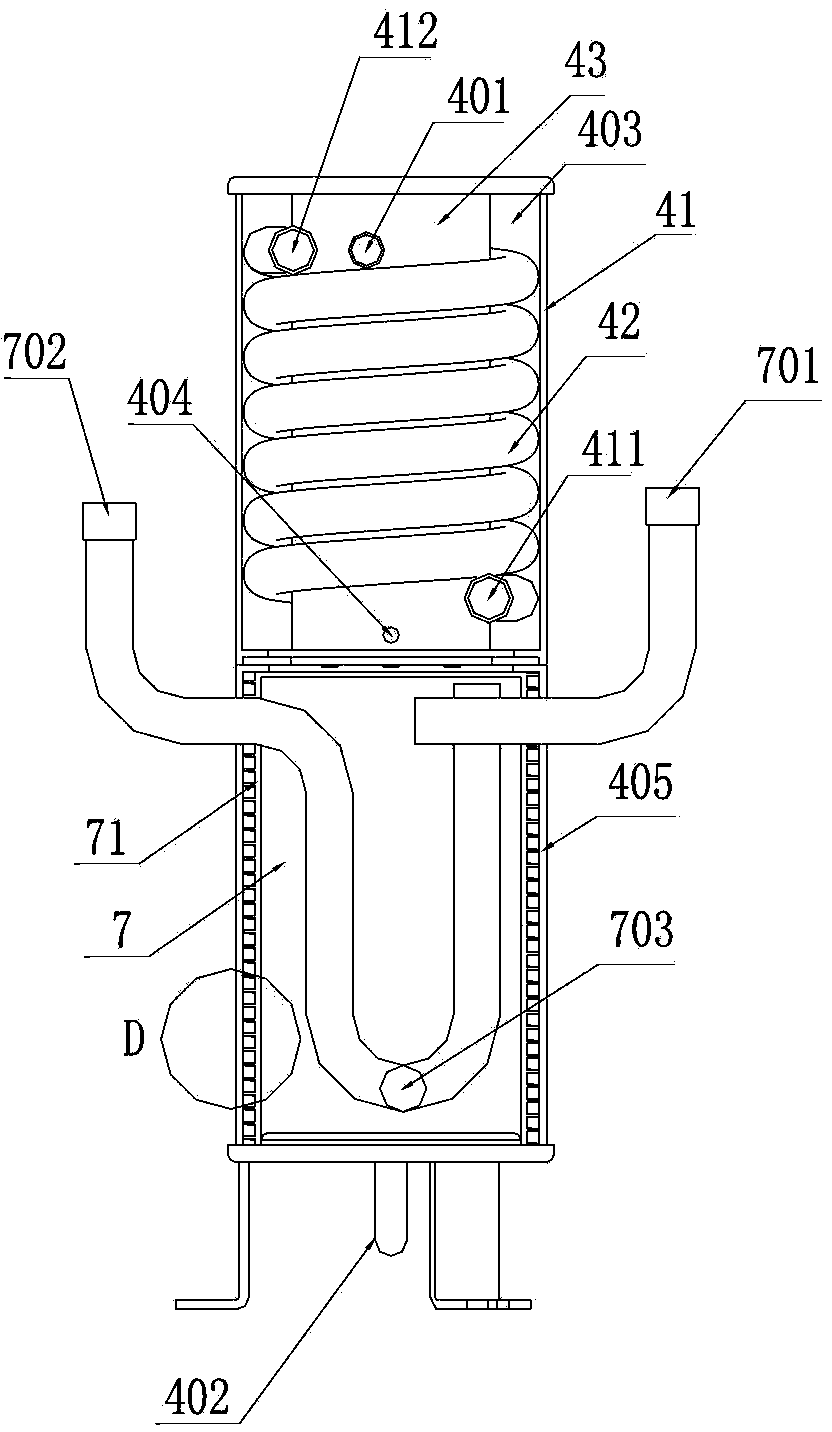

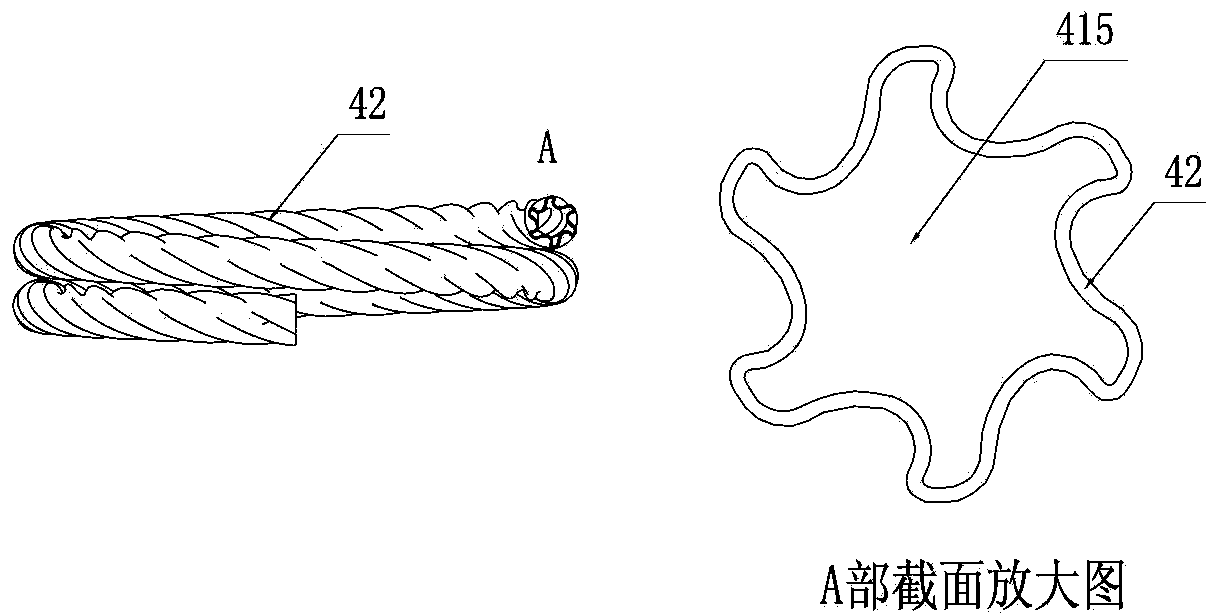

Gas-liquid separation type sleeve evaporator

The utility model relates to a gas-liquid separating bushing evaporator, belonging to the technical field of thermal equipment, which comprises an outer sleeve tube (12) and a plurality of torsion inner tube bundles (11) helically distributed in the outer sleeve tube as the basic heat exchanging part. One end of the inner pipe is an inlet (1) for heating liquid , while the other end is an outlet for heating liquid; the inlet (9) for evaporated liquid is arranged at the bottom of the spiral outer sleeve tube (12), and connected with a liquid phase return pipe (8) for residual evaporated liquid; a gas-collecting exhaust port (5) is communicated with a gas-collecting exhaust pipe (4) at the same location of each layer of spiral jacket; the exhaust port (5) is arranged at the upper reach of the interface of the evaporated liquid inlet (6) and the outer sleeve tube (12) to divide the whole heat exchanging part into a spiral heat exchanging section (10) and a spiral overheating section (3). The utility model also comprises a vertical type S-shaped gas-liquid separating casing evaporator. The utility model has the advantages of simple processing, better overall performance of bushing evaporative heat exchanger, less costs of the manufacture and operation of the evaporator.

Owner:TSINGHUA UNIV

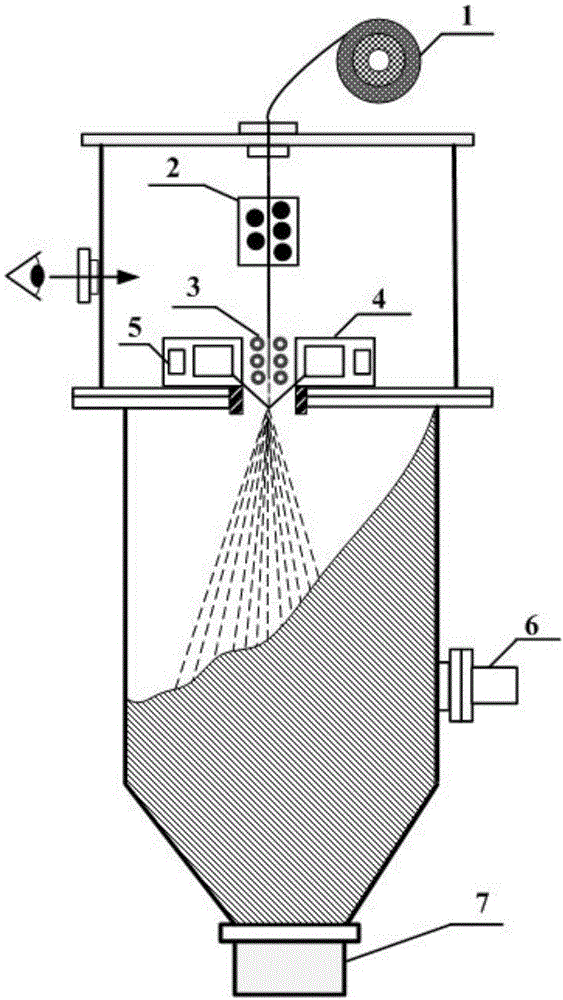

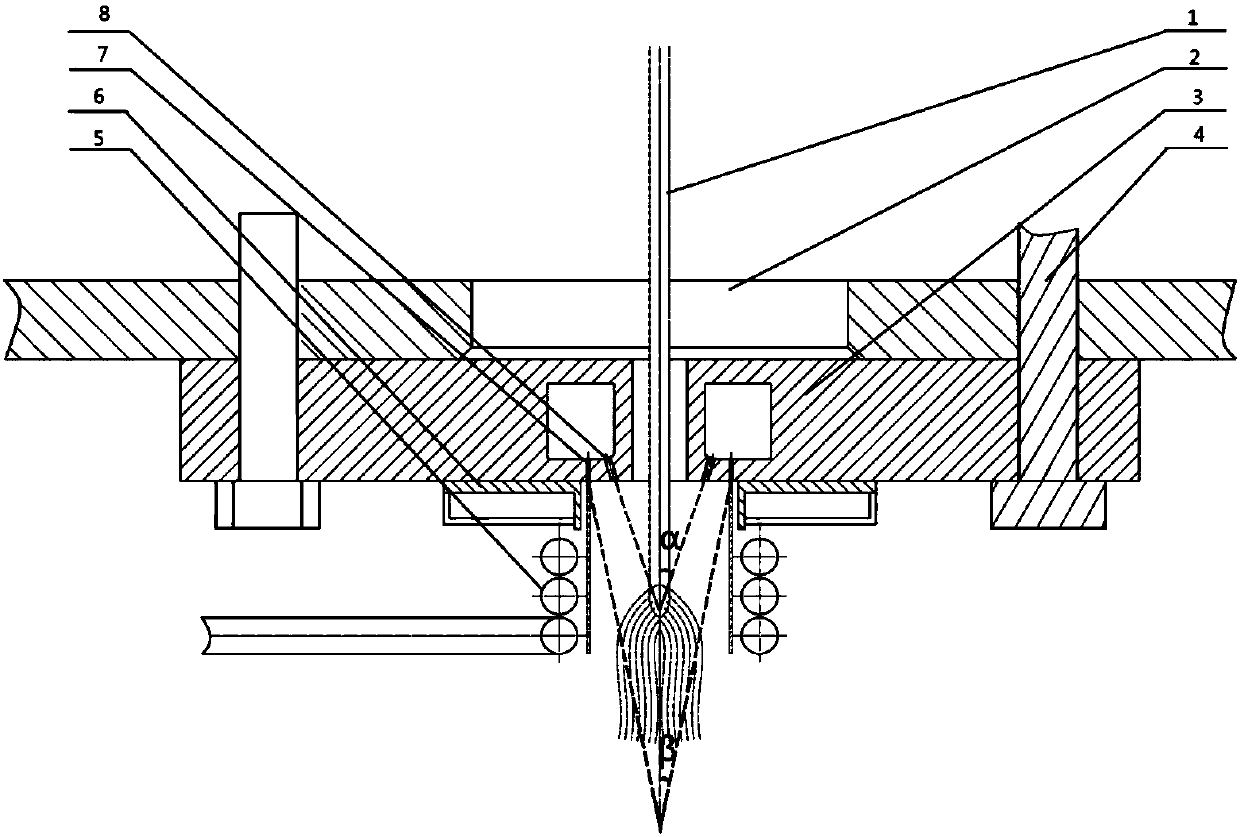

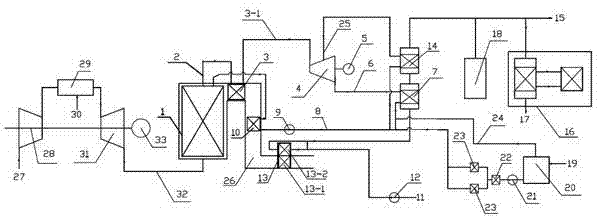

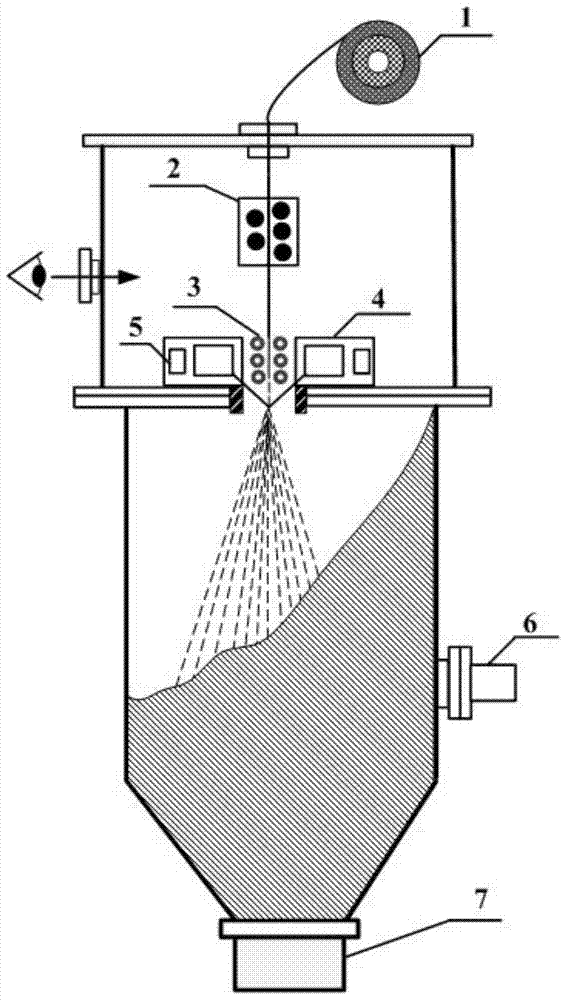

Device and method for continuously preparing titanium or titanium alloy powder for 3D printing through gas atomization

ActiveCN107900366AIncrease productivityReduce lossesAdditive manufacturing apparatusHeat lossesTitanium

The invention relates to a device and a method for continuously preparing a titanium or titanium alloy powder for 3D printing through gas atomization. The device comprises an atomization spray disc fixing top plate, an atomization spray disc, an electromagnetic shielding ring and a high-frequency induction coil from top to bottom, wherein the atomization spray disc and the fixing top plate are fixed through a fixing bolt; continuous conveying feeding holes for a titanium or titanium alloy wire material are formed in the central positions of the atomization spray disc fixing top plate and the atomization spray disc; the atomization spray disc and the electromagnetic shielding ring are coaxially installed about the axes of the conveying feeding holes; the atomization spray disc comprises a main atomization gas flow nozzle and auxiliary protection gas flow nozzles; and atomization gas flow sprayed out via the main atomization gas flow nozzle is collected on the wire material to form an atomization centre, and the atomization centre is superposed with a melting centre formed due to the heating of the high-frequency induction coil for the end part of the wire material. Therefore, melting flow is immediately limited and atomized by the main atomization gas flow after being generated, so that a superheating degree is furthest ensured, heat loss is reduced, and a high fine powder yieldof titanium or titanium alloy atomization is realized.

Owner:BEIJING COMPO ADVANCED TECH

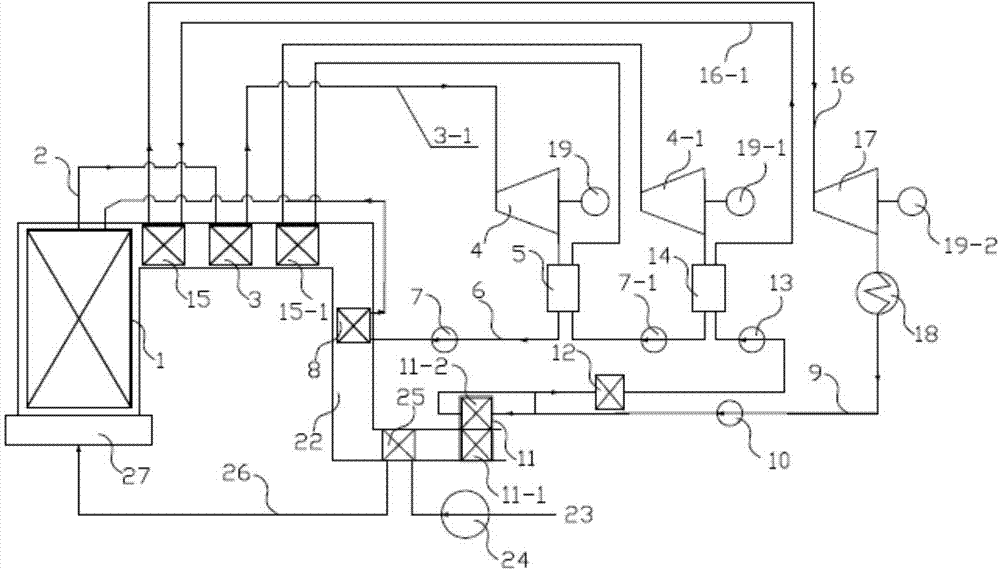

Combined cooling, heating and power device of distributed type industrial boiler

ActiveCN103089349ALow costImprove energy savingSteam engine plantsSteam boilersRefrigerationEnergy source

The invention relates to a combined cooling, heating and power device of a distributed type industrial boiler. A steam Rankine cycle system positive pressure and closed type method is adopted, a condenser of an outlet steam exhaust of a steam turbine serves as heat sources for a heating plant and an absorption refrigeration device, and therefore gradient utilization of energy sources is achieved. High quality energy of fuel is recovered for generating electricity, more than 260 KWh electric quantity can be recovered from per ton evaporation capacity (or 0.7MW heating load), at the same time, cooling and heating combination is achieved, and exhaust gas waste heat can be effectively recovered. According to a steam Rankine cycle system, waste acid and waste alkali are not produced, and the problems of oxygen corrosion and scale formation of the boiler are effectively avoided. Therefore the distributed type industrial boiler is energy-saving, environment-friendly and very remarkable in social benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

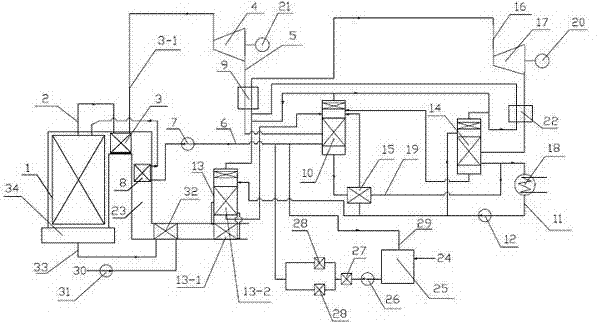

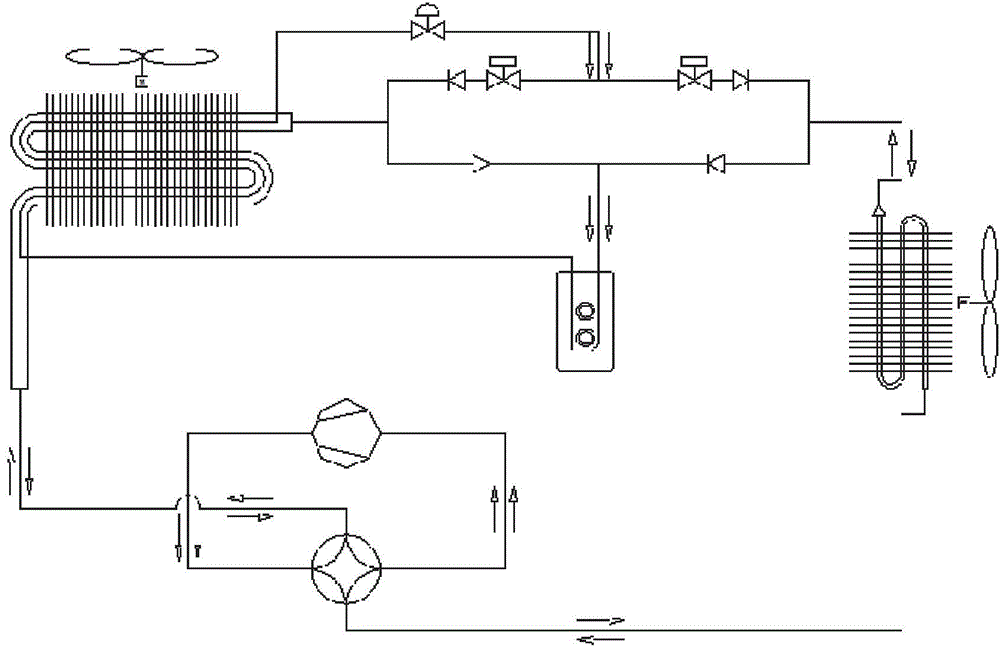

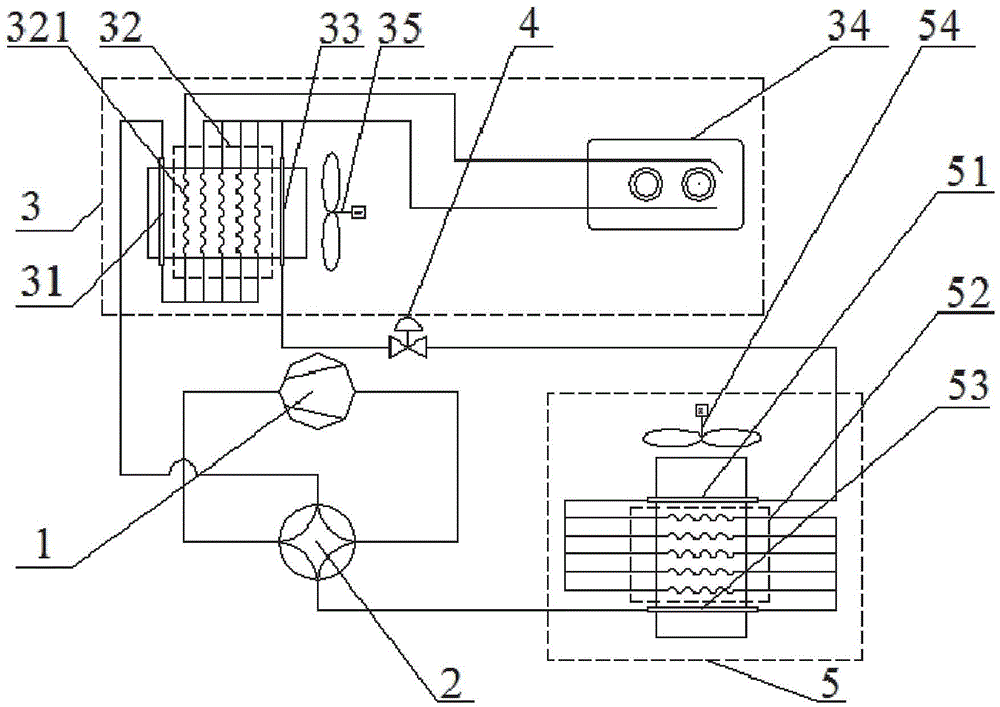

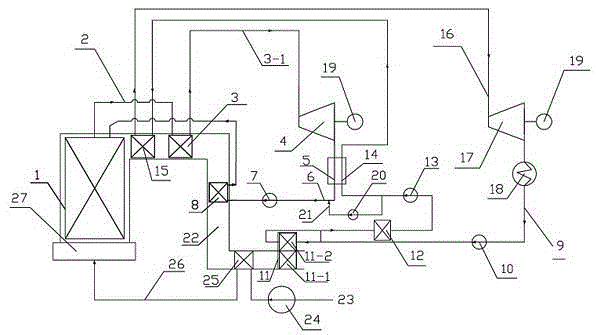

Distributed pneumatic-Rankine combined cycle combined cooling heating and power device

ActiveCN103089441ALow costImprove energy savingSteam useGas turbine plantsWater treatment systemRefrigeration

The invention relates to a distributed pneumatic-Rankine combined cycle combined cooling heating and power device. The distributed pneumatic-Rankine combined cycle combined cooling heating and power device is characterized in that the exhaust of a pneumatic machine is adopted as a heat source of a Rankine cycle waste heat boiler, a steam Rankine cycle system adopts a positive pressure and close type operating mode, a condenser of outlet dead steam of a steam turbine is utilized as a heat source of a heating system and an absorption refrigeration machine, and the cascading use of an energy source is realized; and high grade energy of a recycled fuel is used for generating electricity, evaporative capacity (or the heating load of 0.7 MW) of per ton can recover electric quantity which is more than 340 degrees, meanwhile, the cooling heating combination is realized, and the waste heat of fume is recovered in a high efficiency manner. A water treatment system of the steam Rankine cycle system causes no or only a little of waste acid and waste caustic to generate, and an oxygen corrosion and scaling problem of the boiler is effectively avoided. Therefore, energy conservation, environmental friendliness and social benefits are very notable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

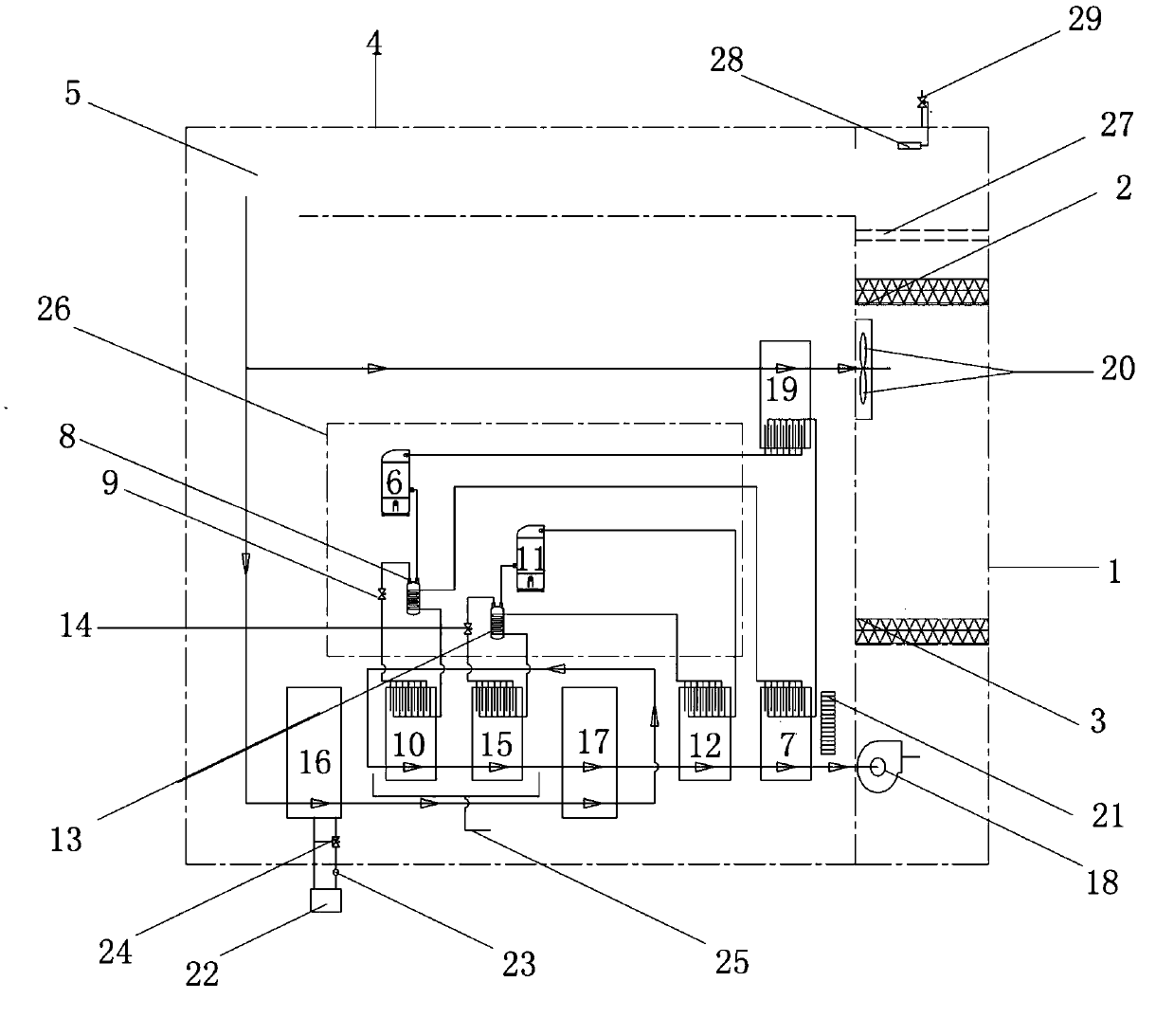

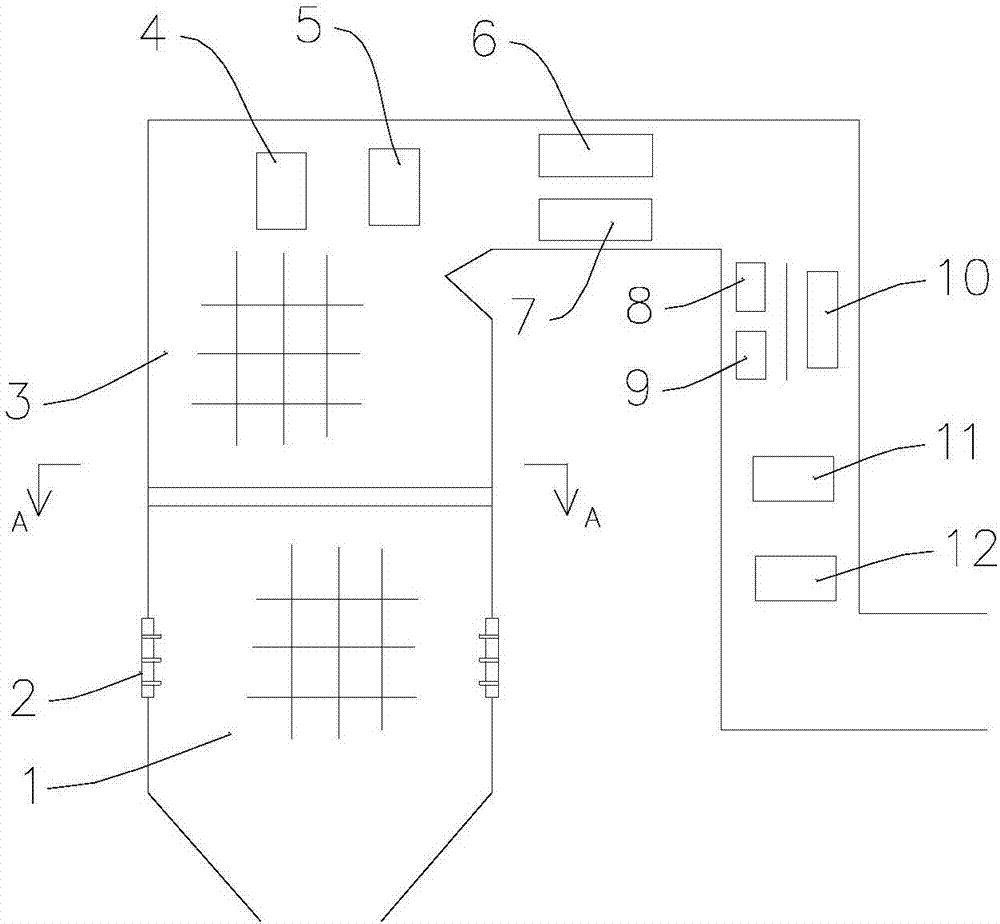

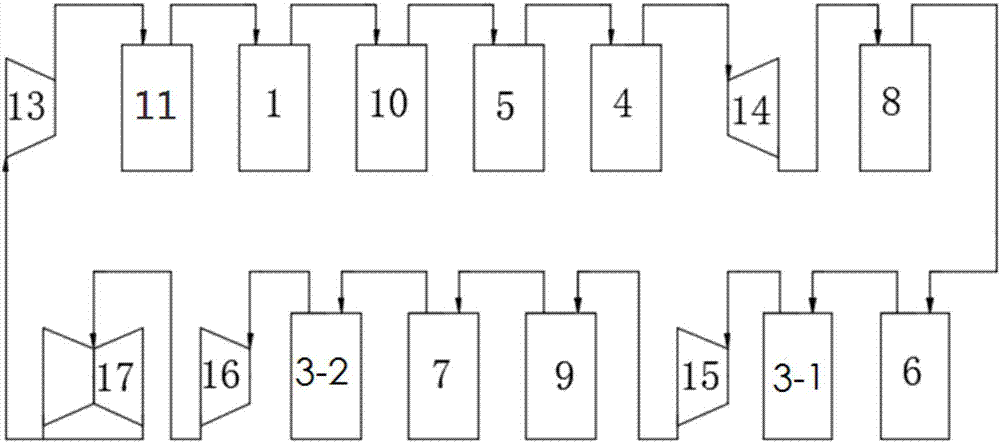

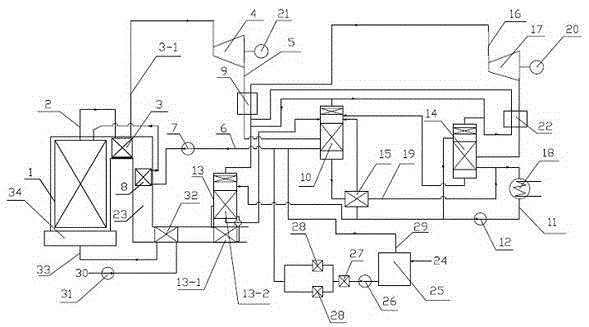

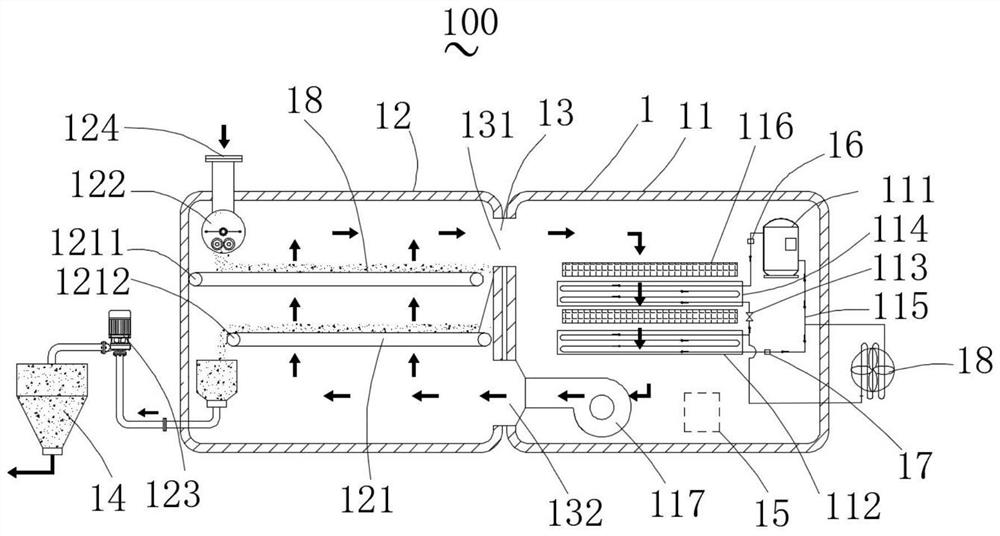

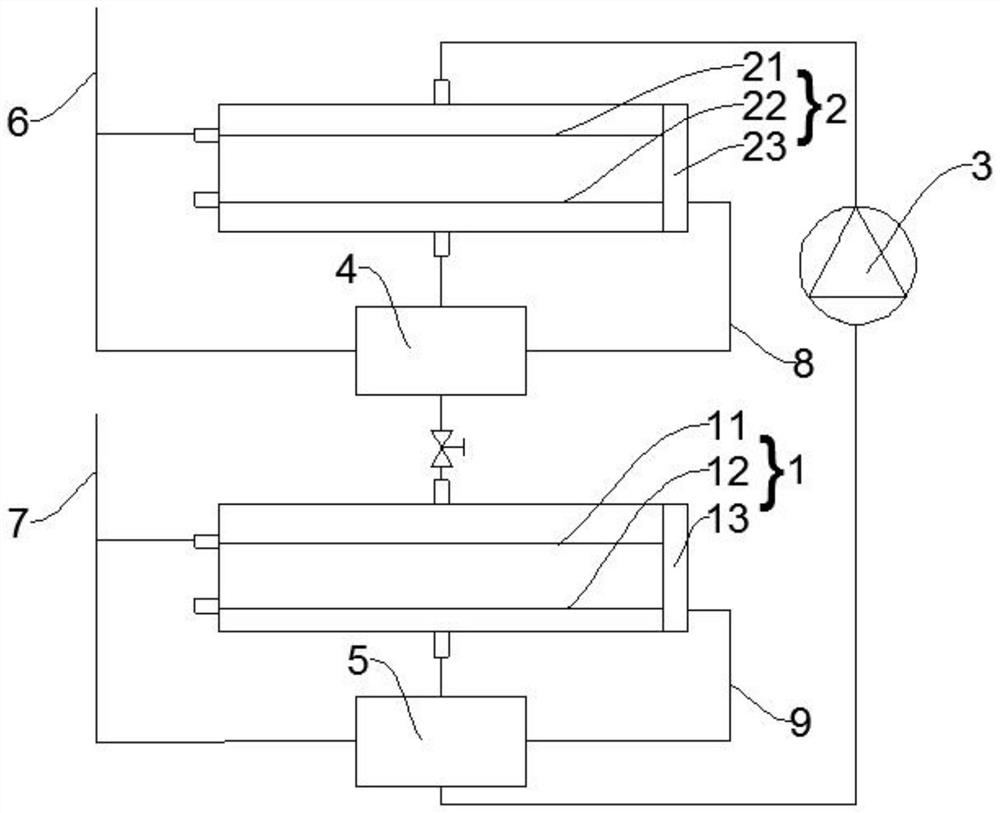

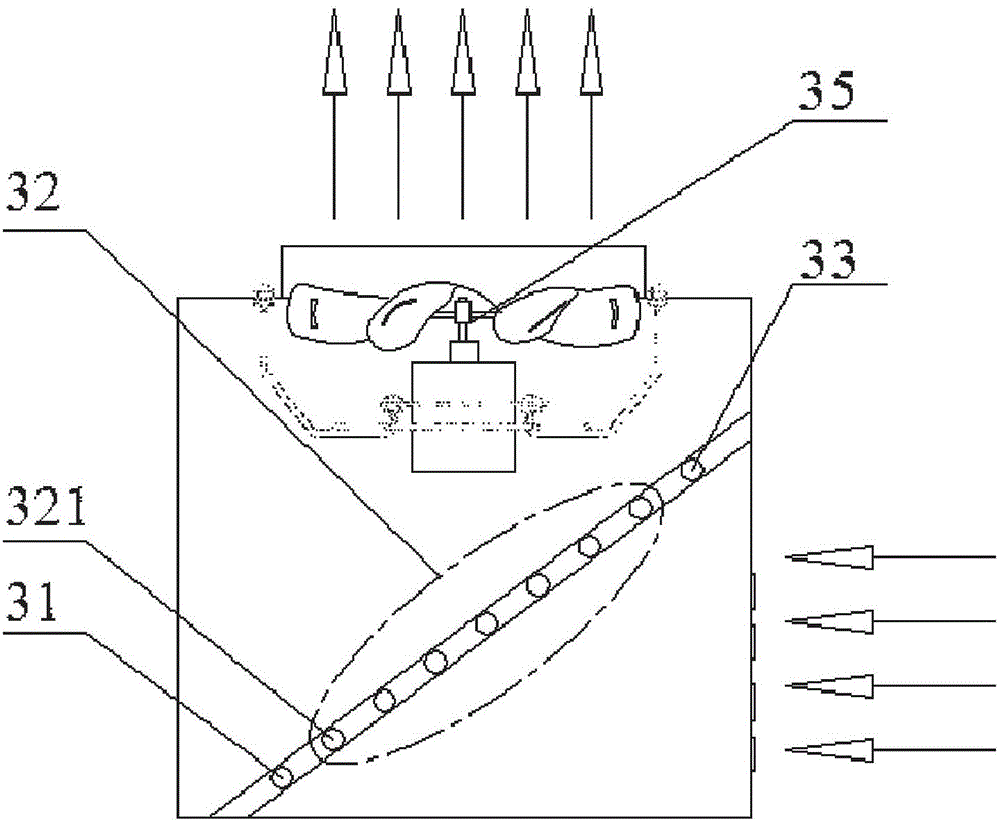

Heat pump type closed sludge drying system and control method of same

ActiveCN109553270AAvoid corrosionIncrease water evaporation rateSludge treatment by de-watering/drying/thickeningHeat pumpsEnvironmental resistanceSludge

A heat pump type closed sludge drying system comprises: a drying room (1), an upper conveyor belt (2) which is arranged on the upper part of the drying room and used for conveying sludge, and a lowerconveyor belt (3) which is arranged on the lower part of the drying room and used for conveying sludge. The heat pump type closed sludge drying system also comprises a system housing (4) at one side of the drying room (1), where the top of the drying room and the top of the system housing are connected to form an air return channel (5). A main air supply port, connected with the system housing, isformed in the side wall where the lower part of the lower conveyor belt is connected with the system housing. The system also includes a first heating circulation system, a second heating circulationsystem and an air flue circulation system that are arranged inside the system housing. The sludge drying system and the control method of same are energy-saving, environment-friendly and high-effective.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Supercritical carbon dioxide secondary reheat coal-fired power generation boiler system

PendingCN106979512ANovel structural designHigh heat transfer efficiencyCombustion processIndirect carbon-dioxide mitigationFlueSuperheater

The invention relates to a supercritical carbon dioxide secondary reheat coal-fired power generation boiler system comprises a furnace and a flue, wherein the furnace is vertically arranged; the side wall of the furnace is formed by a cooling wall and a reheat wall; the cooling wall is positioned below the reheat wall; a burner is arranged in each of the middle part area and the lower part area of the cooling wall; the reheat wall comprises a primary reheat wall and a secondary reheat wall; the ground clearances of the primary reheat wall and the secondary reheat wall are equal or approximate; an overheater module and a reheater module are arranged in the flue in the flue gas flowing direction in a staged manner. The supercritical carbon dioxide secondary reheat coal-fired power generation boiler system has the benefits as follows: the reheat wall is novel in structural design, three-stage heat absorption and energy conversion are realized on the premise that the height of the furnace is not increased, and the furnace does not need to be designed as horizontal, and the energy utilization ratio is high; besides, by opening and closing appropriate valves, the specific combination manner of the primary reheat wall and the secondary reheat wall can be selected, that is, the heating surface area of the primary reheat wall and the secondary reheat wall can be adjusted, the temperature of the reheat working medium can be flexibly adjusted, and that the superheat degree of the reheat working medium reaches the standard can be ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

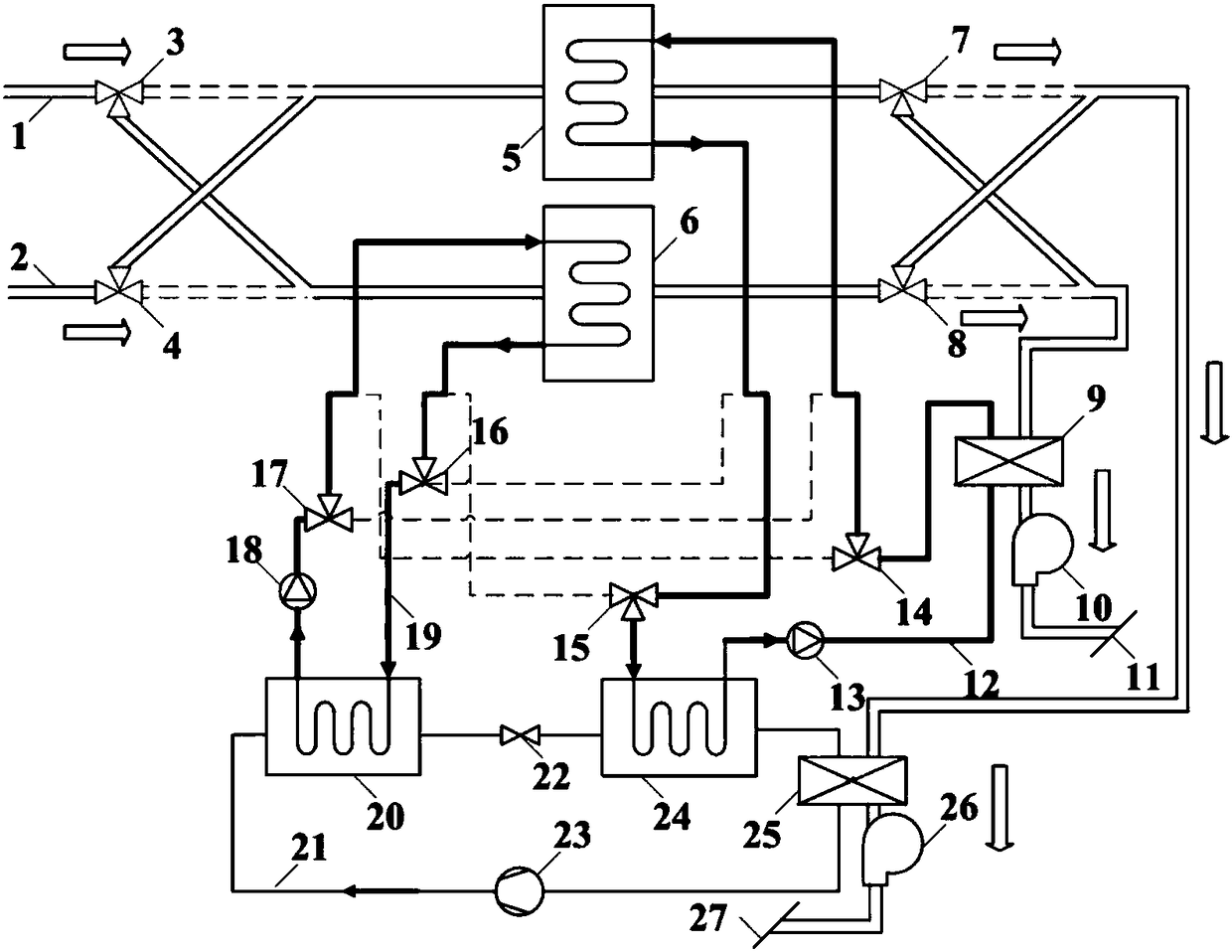

Regenerative and recuperative dehumidifying heat pump system and running method thereof

ActiveCN105805868AContinuous dehumidification and cooling effectPrecise regulation of temperature and humidityAir treatment detailsHeat recovery systemsChillerEvaporator

Owner:SHANGHAI JIAO TONG UNIV

Multistage cascaded steam Rankine combined cycle power generation device

PendingCN104727870APromote circulationAbsolute Efficiency Value ImprovementIncreasing energy efficiencySteam engine plantsSteam condensationLoad following power plant

The invention relates to a multifunctional cascaded steam Rankine combined cycle power generation device. A multistage cascaded mode including a high-voltage end Rankine cycle, a middle-voltage end Rankine cycle and a low-voltage end Rankine cycle is adopted, discharged latent heat of vaporization during the vapor condensation of the high-voltage end Rankine cycle and the middle-voltage end Rankine cycle is recycled efficiently and is used for electricity generating of a Rankine cycle system, load of a condenser of a traditional steam Rankine cycle system is efficiently reduced over an absolute value of 20 percent, the system optimization technology is adopted, and the cycled absolute heating efficiency of the whole system can be improved by over 5 percent. The multifunctional cascaded steam Rankine combined cycle power generation device can be used for energy conservation transformation of an existing reheat cycle steam Rankine cycle unit and can also be used for the design and construction of a new-built unit, and the economic benefit, social benefit and environmental protection benefit are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

Clothes treatment apparatus

ActiveCN107675453AIncrease the heat exchange areaImprove utilizationTextiles and paperLaundry driersEngineeringRefrigerant

The invention discloses a clothes treatment apparatus, including a drum rotatably provided within a cabinet to accommodate washing and drying objects; and a heat pump module including an evaporator, acompressor, a condenser, and an expansion valve, through which a refrigerant is circulated, to provide heat to air discharged from the drum and circulated to the drum, wherein the heat pump module further includes an internal heat exchanger configured to exchange heat between the refrigerant discharged from the condenser and the refrigerant passing through the evaporator.

Owner:LG ELECTRONICS INC

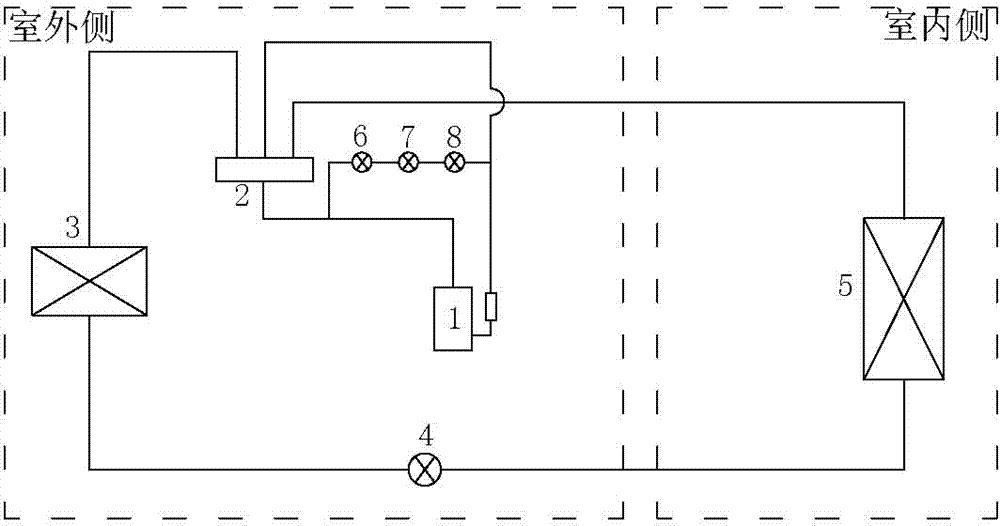

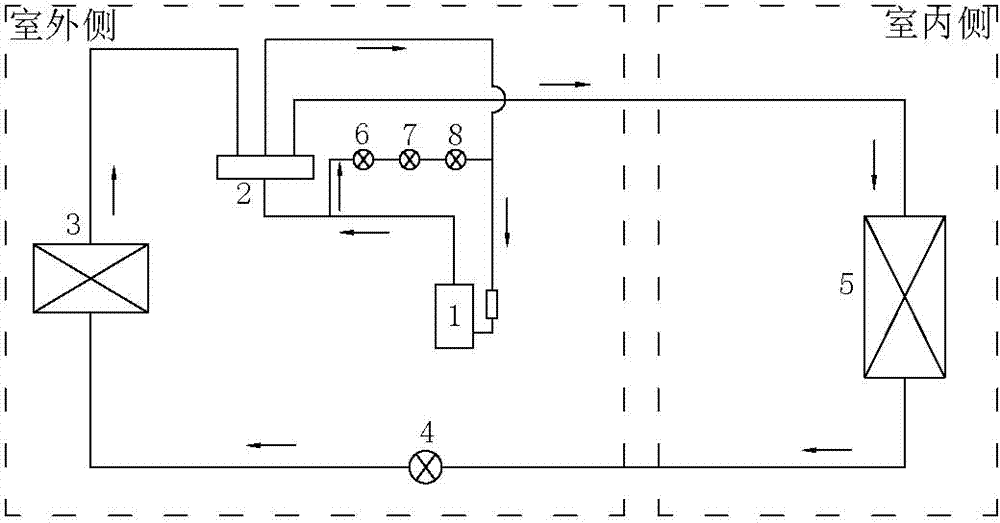

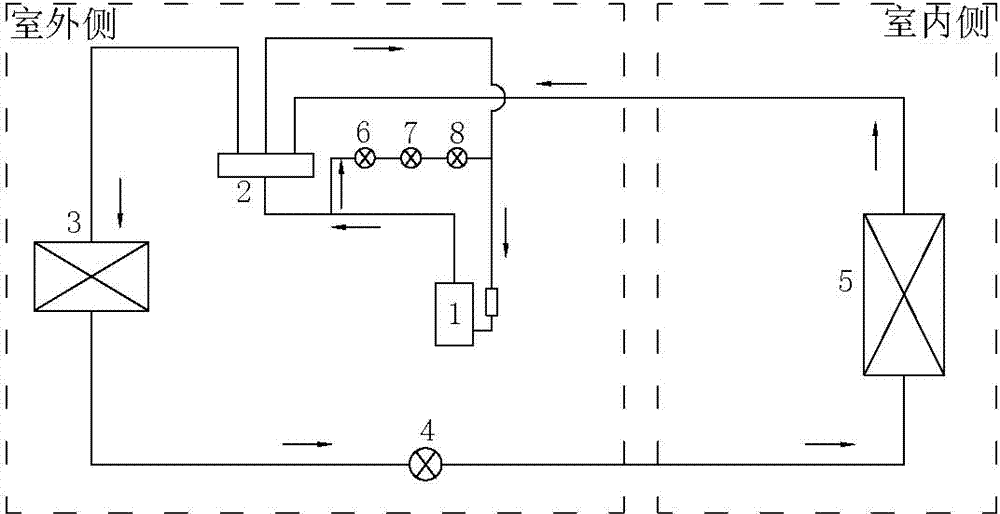

Novel defrosting system and control method thereof

ActiveCN103712388AReduce waiting timeGuaranteed superheatMechanical apparatusCorrosion preventionFrostEngineering

The invention discloses a novel defrosting system and a control method thereof. The novel defrosting system comprises a compressor, a four-way reversing valve, an outdoor heat exchanger, an electronic expansion valve and an indoor heat exchanger, an air outlet and an air inlet of the compressor are connected through a second air return pipeline, and an electromagnetic valve device is arranged on the second air return pipeline. A novel defrosting method of an air conditioner includes the steps of (1) thin frost and thick frost detection and judgment, and (2) defrosting: when judgment is thin frost, adopting a thin frost removal mode, and when judgment is thick frost, adopting a thick frost removal mode. By the novel defrosting system and the control method thereof, the thin frost and the thick frost can be distinguished automatically, different defrosting modes are adopted for the thin and thick frost to allow indoor temperature to be more stable, defrosting effect is better, and waiting time of customers is shortened.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

Steam Rankine-low boiling point working medium Rankine combined cycle power generation device

ActiveCN103089355AEfficient use ofImprove energy savingFeed water supplyEnergy industryExhaust fumesWastewater

The invention relates to a steam Rankine-low boiling point working medium Rankine combined cycle power generation device. Steam in a steam Rankine cycle is cooled through low boiling point working mediums such as a low boiling point working medium in an ammonia vapor Rankine cycle, latent heat of vaporization of the steam in the steam Rankine cycle is recovered for power generation of a low temperature working medium cycle, and therefore the steam Rankine and the low boiling point working medium Rankine cycle are compounded together. At the same time, safety problem of recovering of waste heat of the low boiling point working medium Rankine cycle is solved, exhaust gas temperature is effectively reduced, low-temperature corrosion of the exhaust gas is avoided, and the exhaust gas, waste water and the waste heat of exhaust steam of a steam Rankine cycle system are effectively recovered and utilized. The steam Rankine-low boiling point working medium Rankine combined cycle power generation device not only can be used for energy conservation improvement on an existing machine unit, but also can be used for designing and building a newly built machine unit. The steam Rankine-low boiling point working medium Rankine combined cycle power generation device is especially suitable for new construction, extending construction and reconstruction of a power unit in water-deficient areas, power shortage areas and other areas, and therefore the steam Rankine-low boiling point working medium Rankine combined cycle power generation device has remarkable economic, social and environmental protection benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

Steam Rankine-organic Rankine combined cycle power generation device

ActiveCN103147806AImprove energy savingImprove efficiencyEnergy industryIndirect heat exchangersOrganic Rankine cycleFlue gas

The invention relates to a steam Rankine-organic Rankine combined cycle power generation device, wherein steam in a steam Rankine cycle is cooled by an organic working medium in an organic Rankine cycle, and latent heat of vaporization of the steam in the steam Rankine cycle is recycled to be used for organic Rankine cycle power generation, so that the steam Rankine cycle and the organic Rankine cycle are combined together and an implementable combined recycling device is formed; and meanwhile, the safety difficult problem that waste heat of flue gas is recycled by the organic Rankine cycle is solved, exhaust gas temperature is effectively reduced, and low-temperature corrosion of the flue gas is avoided, and waste gas, waste water and waste heat of waste steam in a steam Rankine cycle system can be effectively recycled. The steam Rankine-organic Rankine combined cycle power generation device can be used for energy-saving reconstruction of existing units, also can be used for designing and constructing new generator units as well, and is especially suitable for new construction, extension and reconstruction of generator units in severe cold areas, water-deficient areas, power shortage areas and the like, so that economic, social and environmental-friendly benefits are remarkable.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

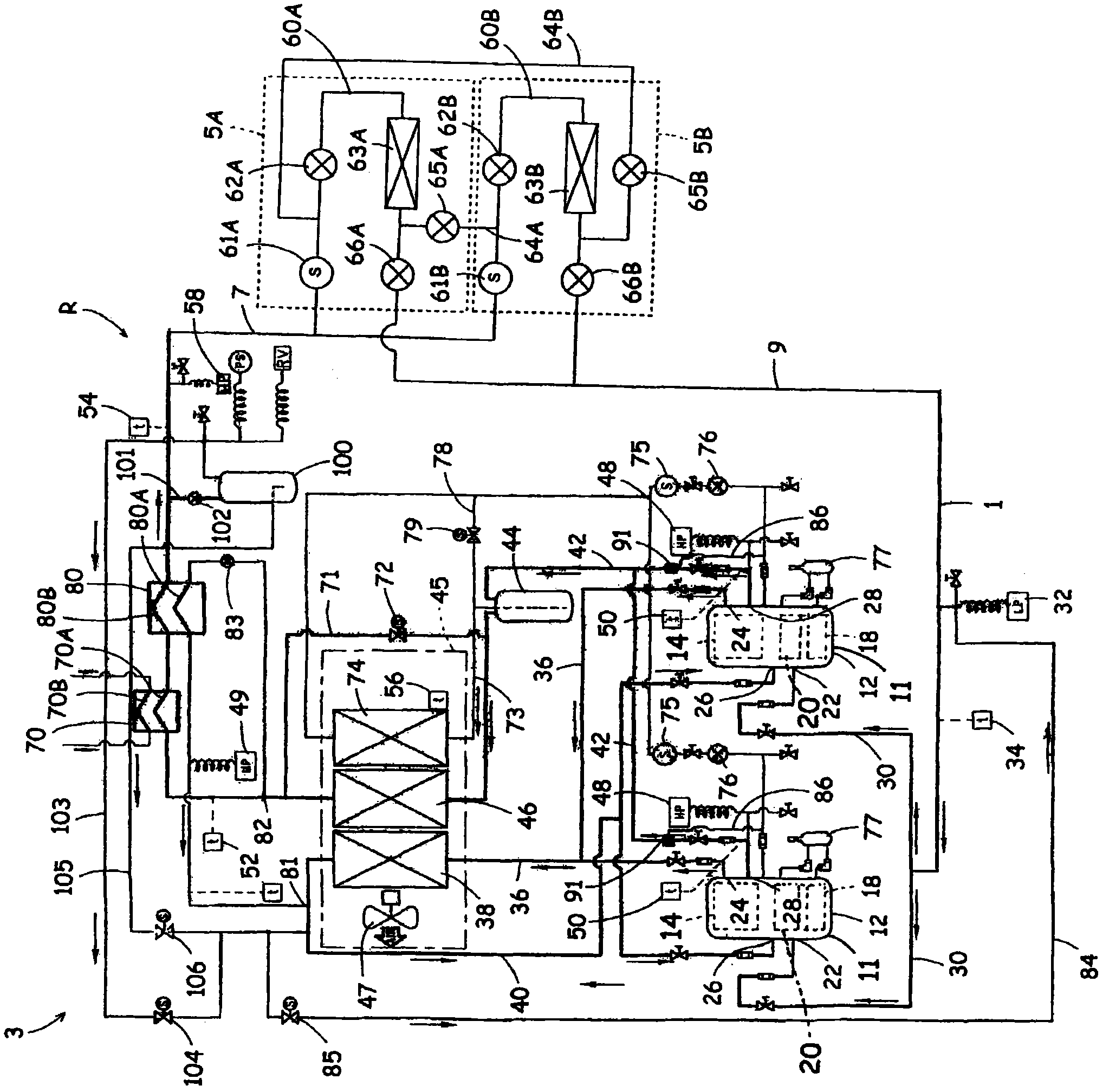

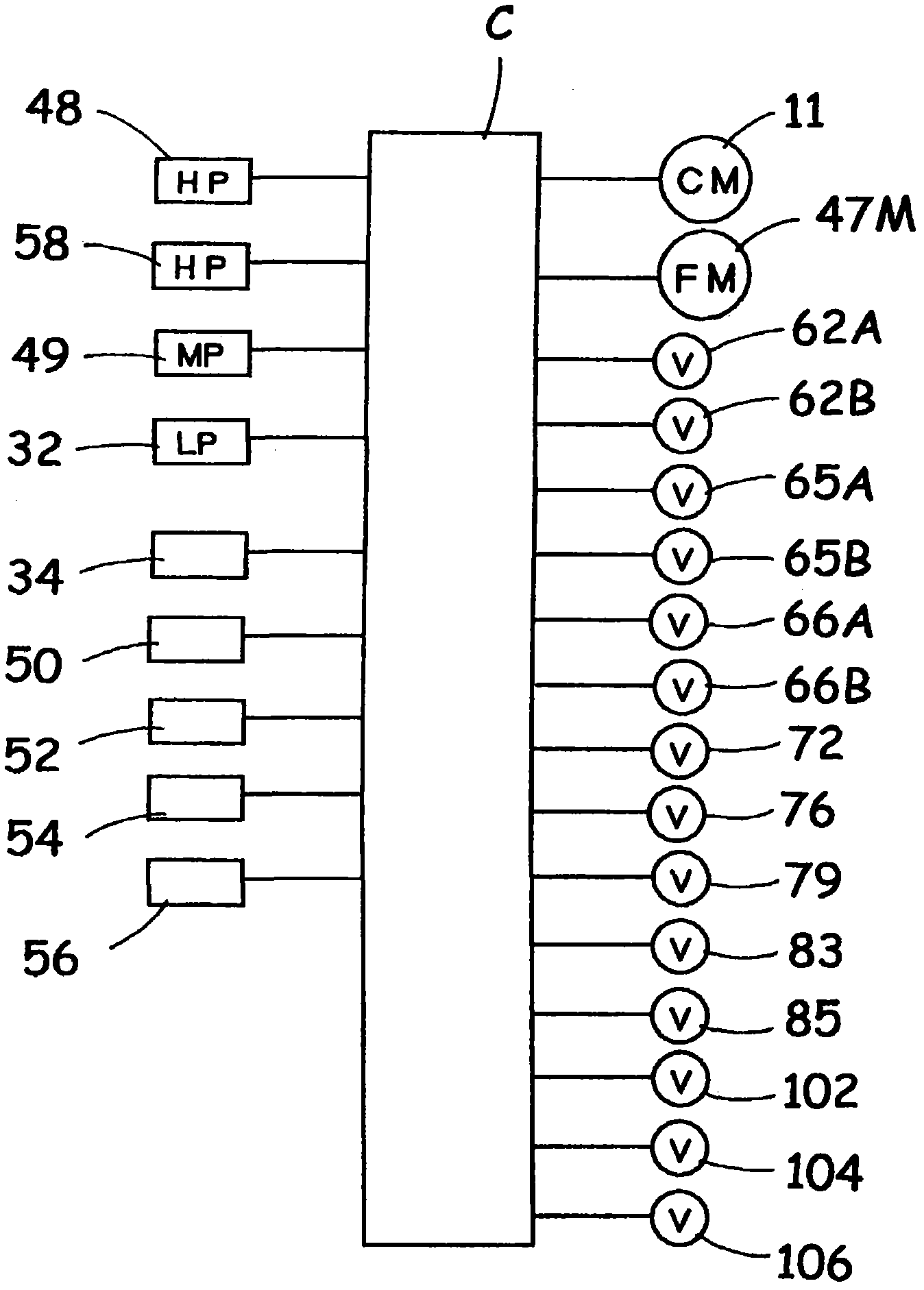

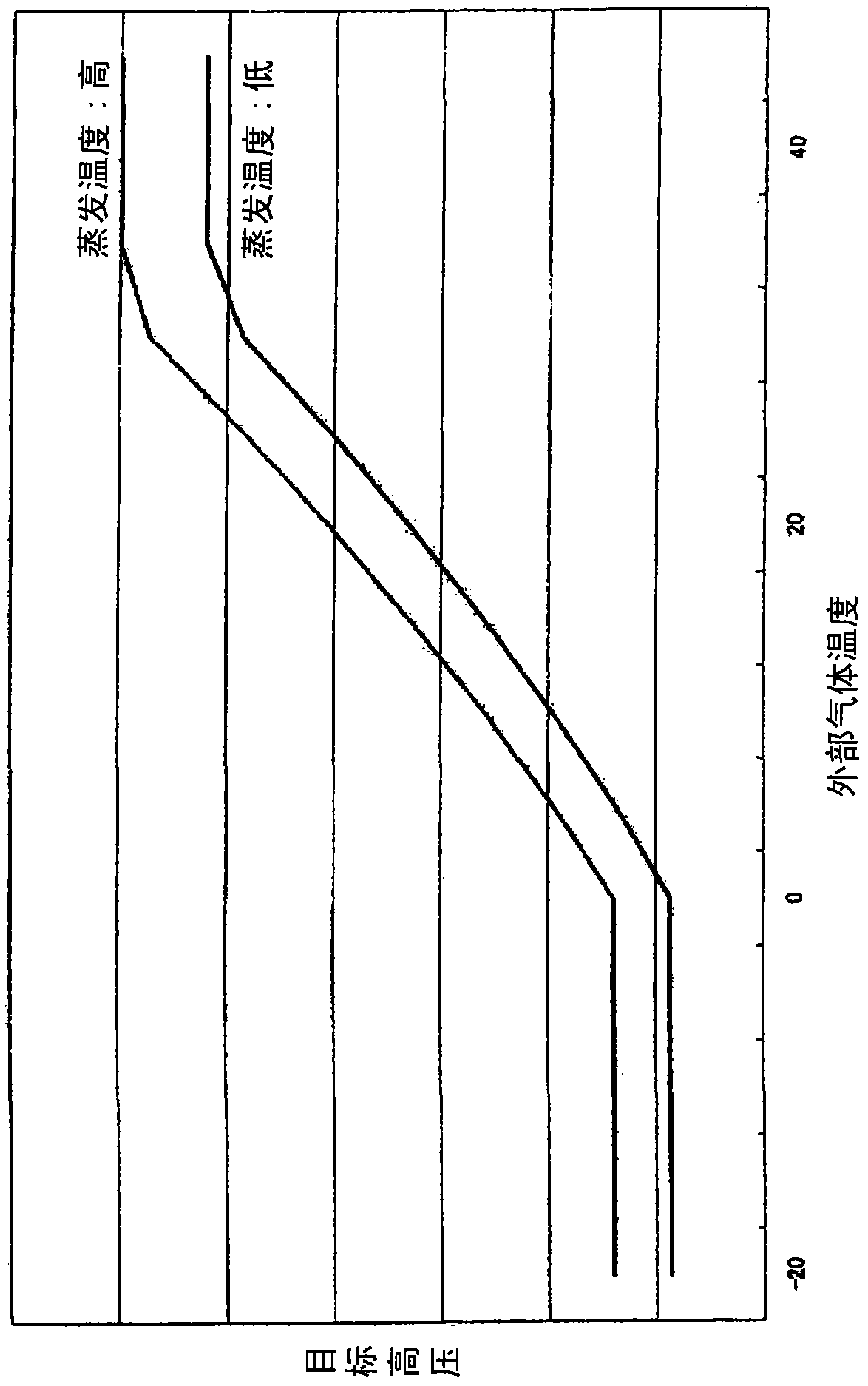

Refrigerating apparatus

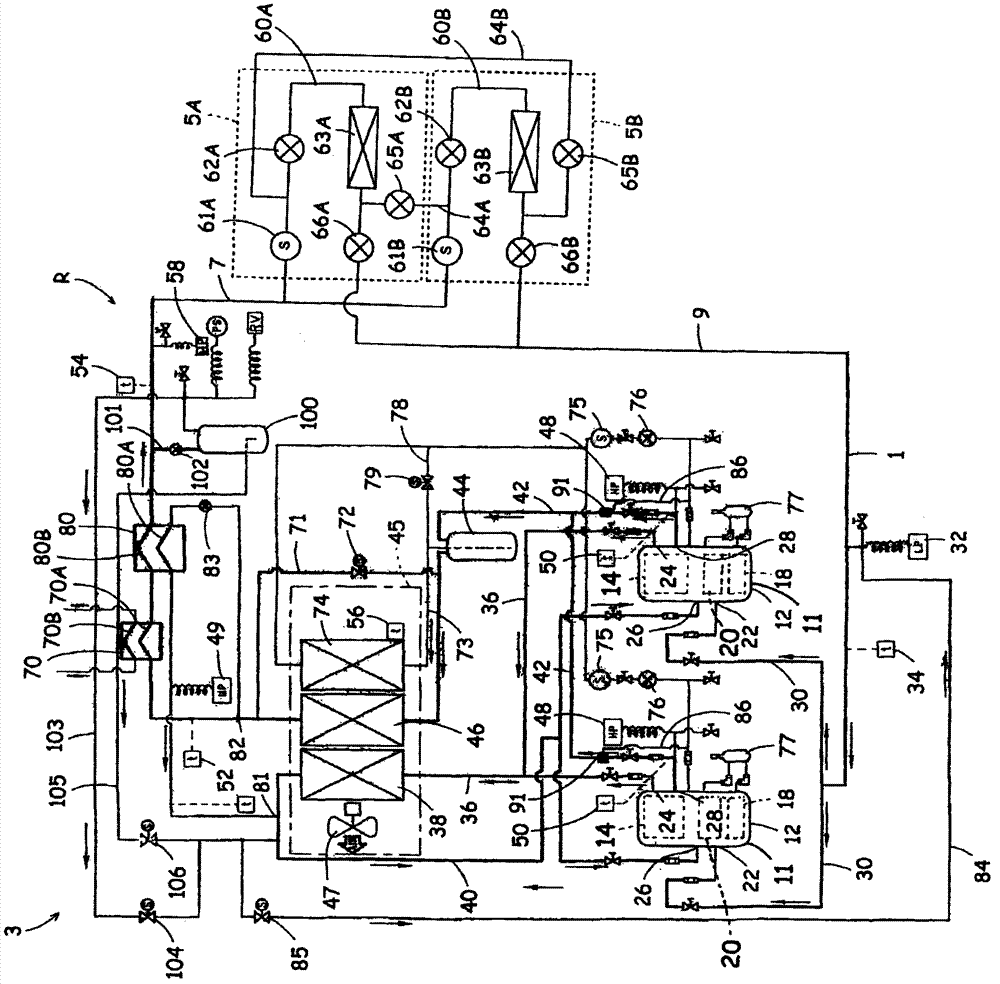

ActiveCN102109260AReduced specific enthalpyReduce the amount of compression workMechanical apparatusRefrigeration safety arrangementIntermediate heat exchangerGas cooler

The present invention provides a refrigerating apparatus to obtain an adequate medium pressure of the refrigerant circuit of the refrigerating apparatus and precisely obtain the effect of a split cycle, thereby enhancing the performance of the refrigerating apparatus. The refrigerating apparatus (R) in the present invention has a split cycle device, in the refrigerating apparatus (R), an operation amount of the valve open degree of a auxiliary reducing means (83) is determined by calculating and merging from a first control amount to a third control amount, wherein the first control amount isobtained based on a discharged refrigerant temperature (DT) of the compressor (11), the second control amount is obtained based on an over-compression judgment value (MPO) and a high pressure side pressure (HP), wherein the over-compression judgment value (MPO) is obtained based on an adequate medium pressure (MP) and a low pressure side pressure (LP) of the refrigerant circuit, and the third control amount is obtained by a difference between a temperature (GCT) of the refrigerant passed through the gas cooler and a temperature (LT) of the second refrigerant flow passed through the intermediate heat exchanger.

Owner:SANYO ELECTRIC CO LTD

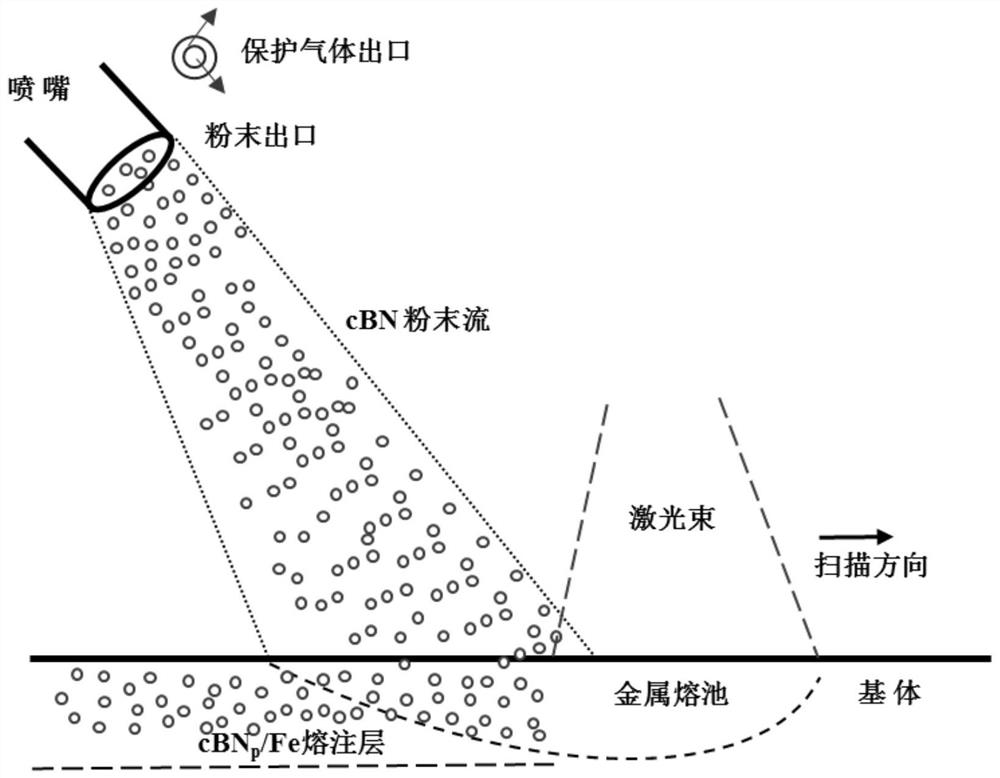

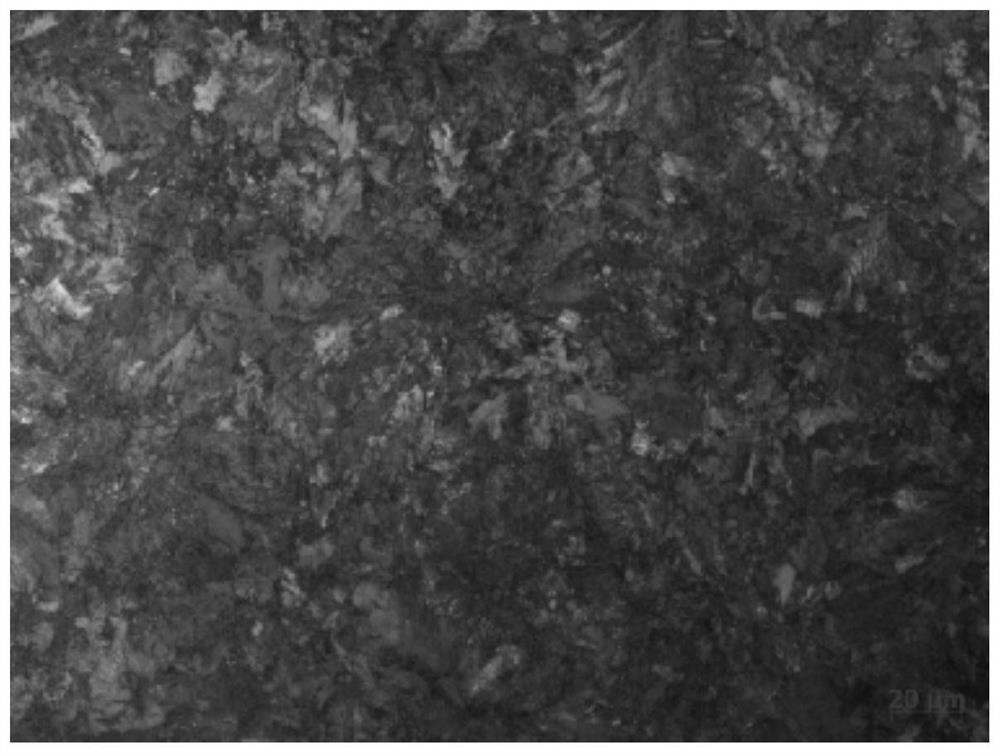

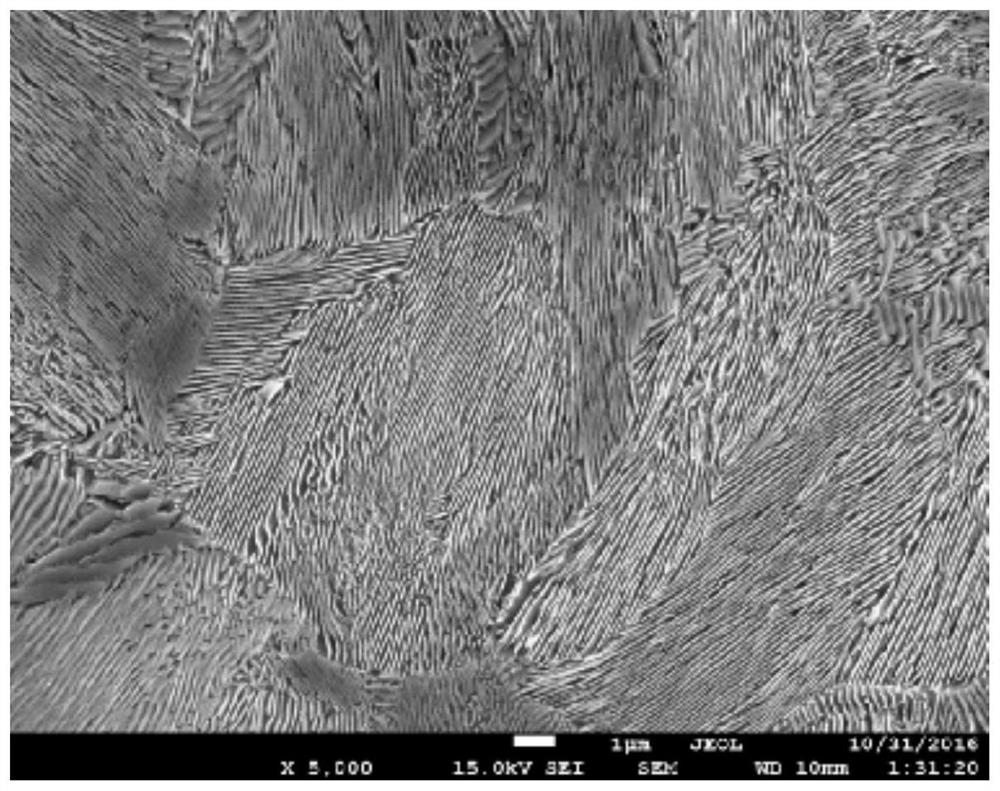

Method for strengthening ferroalloy surface through laser melt injection

ActiveCN112553621AGood wear resistanceHigh hardnessMetallic material coating processesCeramic particleMolten pool

The invention belongs to the related technical field of metal surface treatment, and particularly discloses a method for strengthening a ferroalloy surface through laser melt injection. The method specifically includes the steps that lasers are used for conducting melt injection on the to-be-reinforced ferroalloy surface, and meanwhile, a paraxial powder feeding mode is adopted for injecting cBN ceramic particles into molten pool trailing, so that the cBN ceramic particles enter a molten pool through the molten pool trailing to form a cBNp / Fe melt injection layer after cooling, and the ferroalloy surface is strengthened through laser melt injection. According to the method, the paraxial powder feeding mode is adopted for injecting the cBN ceramic particles into the molten pool trailing toprevent the cBN ceramic particles from being directly oxidized and decomposed or directly sublimated under the action of the lasers, and meanwhile, the power density of the lasers, the paraxial inclination angle and the injection range of cBN ceramic are optimized to guarantee that the cBN ceramic is successfully and effectively injected into the ferroalloy surface to form the cBNp / Fe melt injection layer, so that the ferroalloy surface is strengthened.

Owner:HUAZHONG UNIV OF SCI & TECH

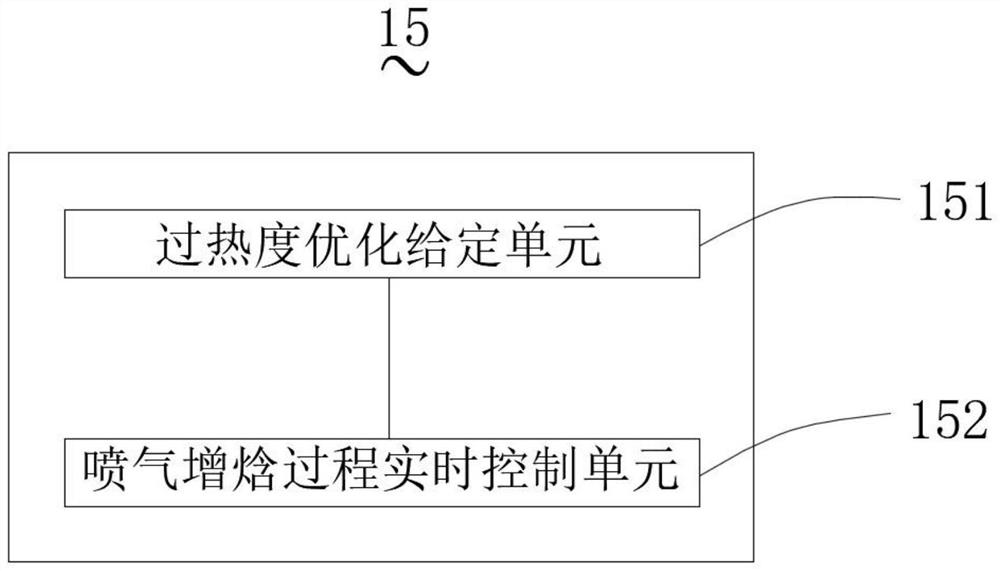

Efficient low-temperature enthalpy increasing control device and method thereof

PendingCN113248106AReduce multiple startsReduce moisture contentSludge treatment by de-watering/drying/thickeningGas treatmentAir cycleThermodynamics

The invention relates to an efficient low-temperature enthalpy increasing control device, which comprises a shell, the shell is divided into a heat pump system and a drying chamber, the heat pump system is communicated with the drying chamber, and gas exchange is carried out between the heat pump system and the drying chamber. The heat pump system is used for drying wet air, and the drying chamber is used for drying wet sludge. The heat pump system and the drying chamber form an air circulation, wet sludge entering the drying chamber is dried through the circulation, the moisture content of the sludge is reduced, subsequent use and recovery of the sludge are facilitated, the efficient low-temperature enthalpy increasing control device is a closed device, internal energy is isolated from the outside, heat energy is basically used for drying the sludge, the constant temperature in the device can be guaranteed, multiple times of starting of the heat pump system are reduced, energy consumption of the heat pump system is reduced, the working efficiency of the device is improved, energy leakage is reduced, the energy-saving effect is achieved, further, the structure of the efficient low-temperature enthalpy-increasing control device is simple, the device purchase cost of a user is reduced, and the use experience of the user is improved.

Owner:深圳德尔科机电环保科技有限公司

Steam Rankine-ammonia vapor Rankine combined cycle power generation device

ActiveCN103089354AEfficient use ofImprove energy savingFeed water supplySteam useExhaust fumesWastewater

The invention relates to a steam Rankine-ammonia vapor Rankine combined cycle power generation device. Ammonia vapor in an ammonia vapor Rankine cycle is used for cooling steam in a steam Rankine cycle. Latent heat of vaporization of the steam in the steam Rankine cycle is recovered for power generation of the ammonia vapor Rankine cycle, and therefore the steam Rankine and the ammonia vapor Rankine cycle are compounded together to form an enforceable combined cycle device. At the same time, safety problem of recovering of waste heat of exhaust gas of the ammonia vapor Rankine cycle is solved, exhaust gas temperature is effectively reduced, low-temperature corrosion of the exhaust gas is avoided, and the exhaust gas, waste water and the waste heat of exhaust steam of a steam Rankine cycle system can be effectively recovered and utilized. The steam Rankine-ammonia vapor Rankine combined cycle power generation device not only can be used for energy conservation improvement on an existing machine unit, but also can be used for designing and building a newly built machine unit, is especially suitable for new construction, extending construction and reconstruction of a power unit in water-deficient areas, power shortage areas and other areas, and therefore the Britten-steam Rankine-ammonia vapor Rankine combined cycle power generation device has remarkable economic, social and environmental protection benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

Refrigerating apparatus

ActiveCN102109260BReduced specific enthalpyReduce the amount of compression workMechanical apparatusRefrigeration safety arrangementIntermediate heat exchangerGas cooler

The present invention provides a refrigerating apparatus to obtain an adequate medium pressure of the refrigerant circuit of the refrigerating apparatus and precisely obtain the effect of a split cycle, thereby enhancing the performance of the refrigerating apparatus. The refrigerating apparatus (R) in the present invention has a split cycle device, in the refrigerating apparatus (R), an operation amount of the valve open degree of a auxiliary reducing means (83) is determined by calculating and merging from a first control amount to a third control amount, wherein the first control amount is obtained based on a discharged refrigerant temperature (DT) of the compressor (11), the second control amount is obtained based on an over-compression judgment value (MPO) and a high pressure side pressure (HP), wherein the over-compression judgment value (MPO) is obtained based on an adequate medium pressure (MP) and a low pressure side pressure (LP) of the refrigerant circuit, and the third control amount is obtained by a difference between a temperature (GCT) of the refrigerant passed through the gas cooler and a temperature (LT) of the second refrigerant flow passed through the intermediate heat exchanger.

Owner:SANYO ELECTRIC CO LTD

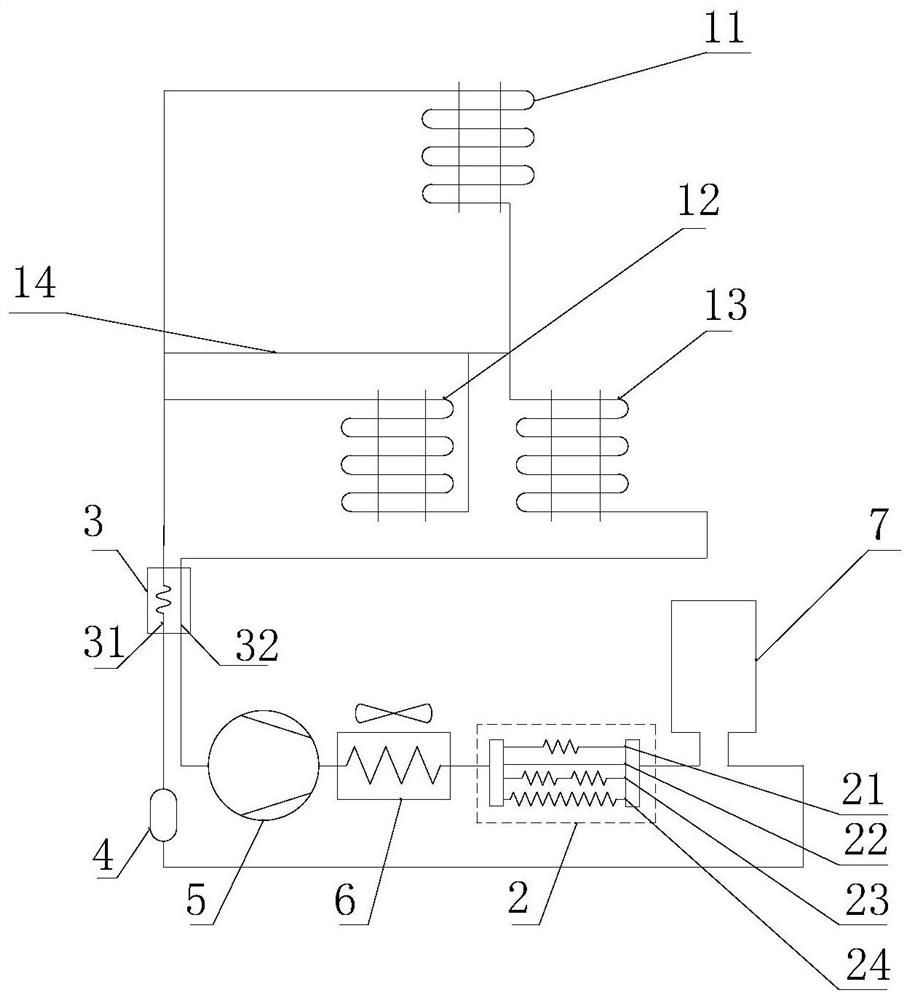

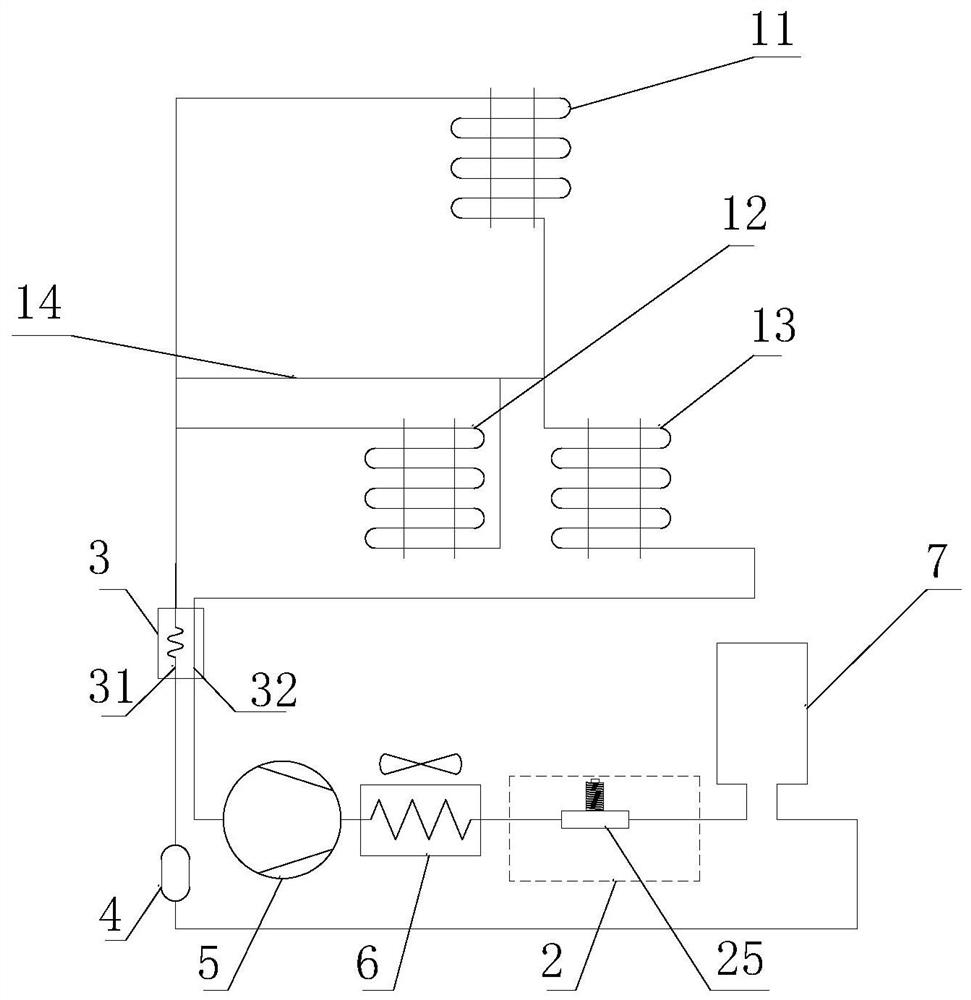

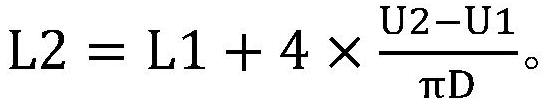

Refrigerant flow adjusting device, refrigerant circulating system and refrigerator

PendingCN112797674AOptimal perfusion volumeGuaranteed superheatDomestic refrigeratorsFluid circulation arrangementIceboxRefrigerant

The invention provides a refrigerant flow adjusting device, a refrigerant circulating system and a refrigerator. The refrigerant flow adjusting device is arranged in the refrigerant circulating system in series and comprises an adjusting cavity, the volume of the adjusting cavity is adjustable, and the refrigerant flow adjusting device is configured to adjust the refrigerant flow in other components of the refrigerant circulating system by changing the volume of the adjusting cavity connected in the refrigerant circulating system in series. According to the refrigerant flow adjusting device, the volume of the adjusting cavity participating in refrigerant circulation is changed, the amount of refrigerant kept in the adjusting cavity in the normal circulating process of the refrigerant is changed, the flow of the refrigerant circulating in an evaporation component is correspondingly changed, the refrigerant in the evaporation component can be kept at the most proper refrigerant flow all the time, the local part in the refrigerant circulating system can reach the optimal refrigerant filling amount, the refrigerant at an outlet of an evaporator has a certain superheat degree all the time, and the power of a compressor and the utilization rate of the heat exchanger area of the evaporator are increased.

Owner:GREE ELECTRIC APPLIANCES INC

Overheating device for inlet steam of mechanical compression type compressor

InactiveCN107514627AGuaranteed service lifeIncrease temperatureSuperheating controlRefluxEngineering

The invention relates to an overheating device for inlet steam of a mechanical compression type compressor. The device comprises a motor, the compressor, a separator and steam pipes, wherein the motor drives the compressor; an outlet of the separator is connected to an inlet of the compressor through one steam pipe; and one steam pipe is connected to an outlet of the compressor. The device is characterized in that an overheating steam mixer is further connected between the outlet of the separator and the inlet of the compressor; an inlet of the overheating steam mixer is connected to an upper section of the corresponding steam pipe; an outlet of the overheating steam mixer is connected to a lower section of the corresponding steam pipe; a steam reflux pipe is connected between the overheating steam mixer and the outlet of the compressor; an inlet of the steam reflux pipe is connected with the outlet steam pipe of the compressor; and an outlet of the steam reflux pipe is connected with the overheating steam mixer. According to the overheating device for the inlet steam of the mechanical compression type compressor, the structural design is scientific and reasonable, the overheating degree of the steam entering the compressor is effectively improved, damage to blades of the compressor caused by liquid entrainment is avoided, temperature real-time control is carried out through a temperature sensor, and thus efficient utilization of energy is guaranteed.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hot-rolled wire rod for galvanized steel wire of bridge cables above 2000mpa and its production method

ActiveCN109468530BPlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWire rodSteelmaking

The invention relates to a hot-rolled wire rod for galvanized steel wires of bridge cables above 2000 MPa. The chemical composition of the product is calculated by weight percentage: C: 0.90-1.10%, Si: 0.20-0.60%, Mn: 0.30-0.90% , P≤0.010%, S≤0.005%, Cr: 0.10‑0.40%, Al: 0.010‑0.070%, V: 0.02‑0.15%, Cu: ≤0.05%, Ca: 20‑40ppm, N: 20‑90ppm, Others are Fe and unavoidable residual elements; the sorbite structure content of the wire rod is ≥95%, and the tensile strength of the through circle is poor ≤70MPa (uniformity). After the wire rod is drawn and galvanized, the galvanized steel wire is tensile Strength ≥ 2000MPa, torsion times ≥ 12 times. The process flow of the wire rod, molten iron pretreatment, converter or electric furnace steelmaking, LF refining, RH degassing treatment—390*510 bloom continuous casting—billet reheating—billet rolling—intermediate billet surface finishing—intermediate billet reprocessing Heating—rolling of intermediate slab—on-line EDC water bath toughening treatment of wire rod—collection and packaging of wire rod.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

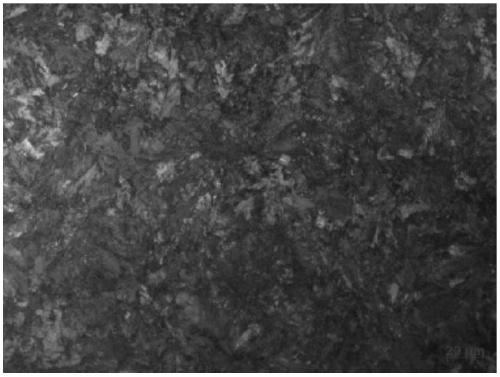

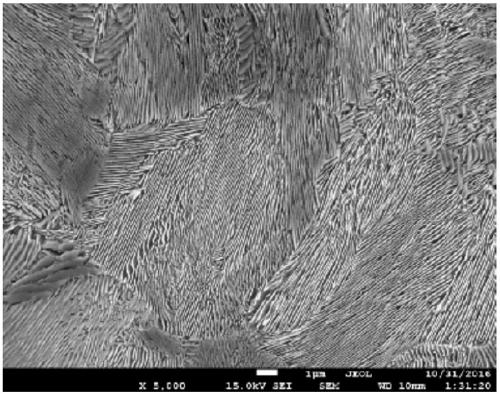

Fe-Al-Cr blocky nanocrystalline material and preparation method thereof

The invention relates to an Fe-Al-Cr blocky nanocrystalline material and a preparation method thereof. The Fe-Al-Cr blocky nanocrystalline material comprises the following components in percentage by weight: 9.8 to 14 percent of Al, 60 to 85 percent of Fe and 0 to 30 percent of Cr. The preparation method comprises the following steps of: weighing corresponding components in percentage by weight, mixing the weighed powder for 16h, then putting the well-mixed reactant in a copper die, compacting under the pressure of 60MPa, putting an ignition agent on the surface of the reactant, then reacting in a reaction vessel, introducing argon at room temperature, isothermally heating to 180 DEG C and exhausting again, then introducing argon under the pressure of 8MPa and continuously heating the vessel; beginning to react the ignition agent and releasing a great deal of heat when the temperature in the vessel reaches about 260 DEG C, thereby initiating the reaction among materials; and cooling the generated product to the room temperature along with a furnace so as to prepare the alloy.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Water chilling unit

InactiveCN113028665AReduce chargePrevent liquid shockCompression machines with non-reversible cycleEvaporators/condensersEngineeringSuperheater

The invention belongs to the technical field of water chilling units, and aims to solve the problem that a falling film evaporator adopted by an existing water chilling unit cannot remarkably reduce the refrigerant filling amount. For this aim, the provided water chilling unit comprises an evaporator, a condenser, a compressor, a subcooler and a superheater, and the condenser, the subcooler, the evaporator, the superheater and the compressor form a closed refrigerant circulation loop, the water chilling unit further comprises a first cooling water inlet pipe, a second cooling water inlet pipe, a first cooling water connecting pipe and a second cooling water connecting pipe, the first cooling water inlet pipe is connected with the condenser and the subcooler, the first cooling water connecting pipe is connected between the subcooler and the condenser, the second cooling water inlet pipe is connected with the evaporator and the superheater, and the second cooling water connecting pipe is connected between the superheater and the evaporator. According to the water chilling unit, the refrigerant filling amount of the water chilling unit can be greatly reduced, and greenhouse gas emission is remarkably reduced.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

A fresh air air handling unit with synchronous subcooling and superheating

ActiveCN102927628BImprove heat transfer effectGuaranteed subcoolingFluid circulation arrangementHeating and refrigeration combinationsFresh airAir treatment

The invention discloses a full-fresh-air air handling unit capable of overcooling and overheating synchronously. The full-fresh-air air handling unit comprises a compressor, a four-way reversing valve, an outdoor handling unit heat exchanger, a bi-directional expansion valve and an indoor air supply unit heat exchanger. An air inlet end and an air outlet end of the compressor are connected with two opposite connectors on the four-way reversing valve respectively, a refrigeration inlet of the outdoor handling unit heat exchanger and a refrigeration outlet of the indoor air supply unit heat exchanger are connected with the other two opposite connectors on the four-way reversing valve respectively, and a refrigeration outlet of the outdoor handling unit heat exchanger is connected with a refrigeration inlet of the indoor air supply unit heat exchanger through the bi-bidirectional expansion valve. The full-fresh-air air handling unit effectively solves the problem of loss of obtained overcooling degree, improves the stability and reliability of working of the expansion valve, avoids wet compression of the compressor, can improve safety and reliability of the unit, and increases working energy efficiency ratio.

Owner:NANJING NORMAL UNIVERSITY

A kind of preparation method of fine spherical titanium and titanium alloy powder

ActiveCN104475743BFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a method for preparing fine spherical titanium and titanium alloy powder, belonging to the technical field of metal and alloy powder preparation. The method uses national standard TA1 grade sponge titanium as raw material to make titanium and titanium alloy wire or rod; pre-vacuumize the powder making equipment, and then fill inert protective gas; through continuous feeding mechanism and straightener Feed the raw material wire or bar into the smelting chamber, use the high-frequency induction coil to heat and melt the raw material, so that the alloy raw material is melted to form a stable liquid flow or trickle flow; open the supersonic atomizing nozzle in the atomizer to melt The body fluid flow or drip flow is crushed, dispersed and forced to cool to make powder; the powder is obtained through the powder collector, and the powder is sieved by an ultrasonic vibrating sieve to obtain fine spherical powder of titanium and titanium alloy. The spherical titanium and titanium alloy powder prepared by the method has fine particle size, high sphericity, smooth surface, good fluidity and low impurity content.

Owner:有研增材技术有限公司

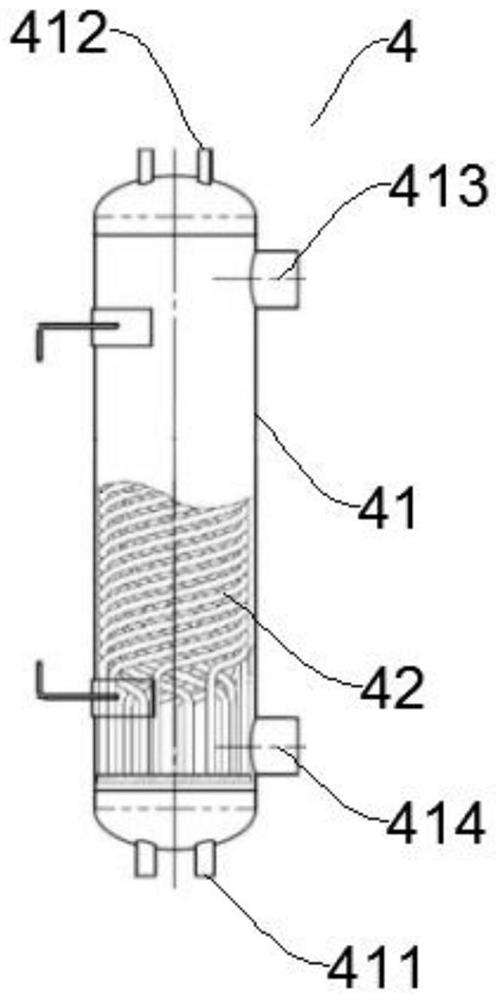

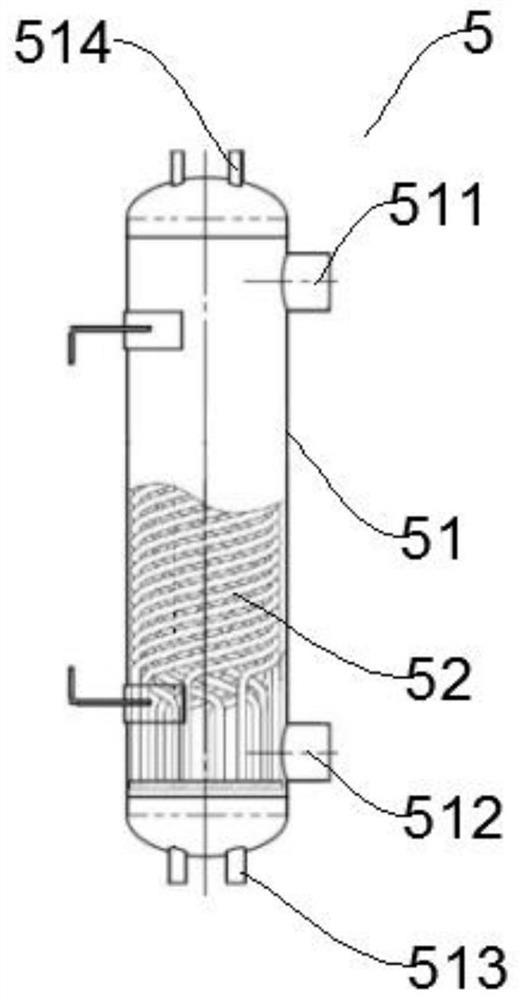

Heat utilization balance processor

ActiveCN102798254BImprove energy efficiencyGuaranteed uptimeEvaporators/condensersCondensation processVapor–liquid separator

A heat utilization balance processor relates to a heat exchanger unit for a heat pump hot water machine or a refrigerating cycle system, and in particular relates to a heat utilization balance processor which is suitable for R407C environment-friendly refrigerant. A heat exchange tube is coiled into a spiral shape and arranged in a main heat exchanging cavity; a vapor separation barrel of a vapor-liquid separator is arranged at the lower half part in a shell; an auxiliary heat exchanging cavity is formed between the lower half part of the shell and the outer periphery of the vapor separation barrel; the upper part of the main heat exchanging cavity is communicated to a working medium inlet outside the shell; the main heat exchanging cavity is communicated with the auxiliary heat exchanging cavity through a working medium passage hole; the bottom of the auxiliary heat exchanging cavity is communicated to a working medium outlet outside the shell; and a heat medium water passage is arranged inside the heat exchanging pipe. Through heat utilization balance exchange on the working medium in the process of condensation and evaporation in the auxiliary heat exchanging cavity, the problem of unbalanced phase change process caused by phase change non-isothermal characteristic of non-azeotropic mixing working medium R407C is solved, and the influence of the temperature slippage of the mixed refrigerant on the operation performance and safety of the equipment is eliminated.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Cascade type steam Rankine combined cycle generating device

ActiveCN103075213BReduce loadGuaranteed normal loadingSteam engine plantsCombined combustion mitigationSteam condensationEngineering

The invention relates to a cascade type steam Rankine combined cycle generating device which is characterized in that a steam condenser in a steam Rankine cycle of a high-pressure end is used as one of heat sources (i.e. a low-pressure evaporator) of the steam Rankine cycle of a low-pressure end, latent heat of vaporization of steam in the steam Rankine cycle of the high-pressure end is efficiently recovered to be used for steam Rankine cycle power generation of the low-pressure end, and the load of the condenser in a traditional steam Rankine cycle system can be effectively reduced by more than 20% of the absolute value. By adopting a system optimization technology, the cycle absolute heat efficiency of the whole system can be increased by more than 5%. The cascade type steam Rankine combined cycle generating device can be used for reforming the existing unit for saving energy, and for designing and constructing a novel unit, and the cascade type steam Rankine combined cycle generating device has obvious economic, social and environmental benefits.

Owner:NANJING RECLAIMER ENVIRONMENTAL TEKNIK

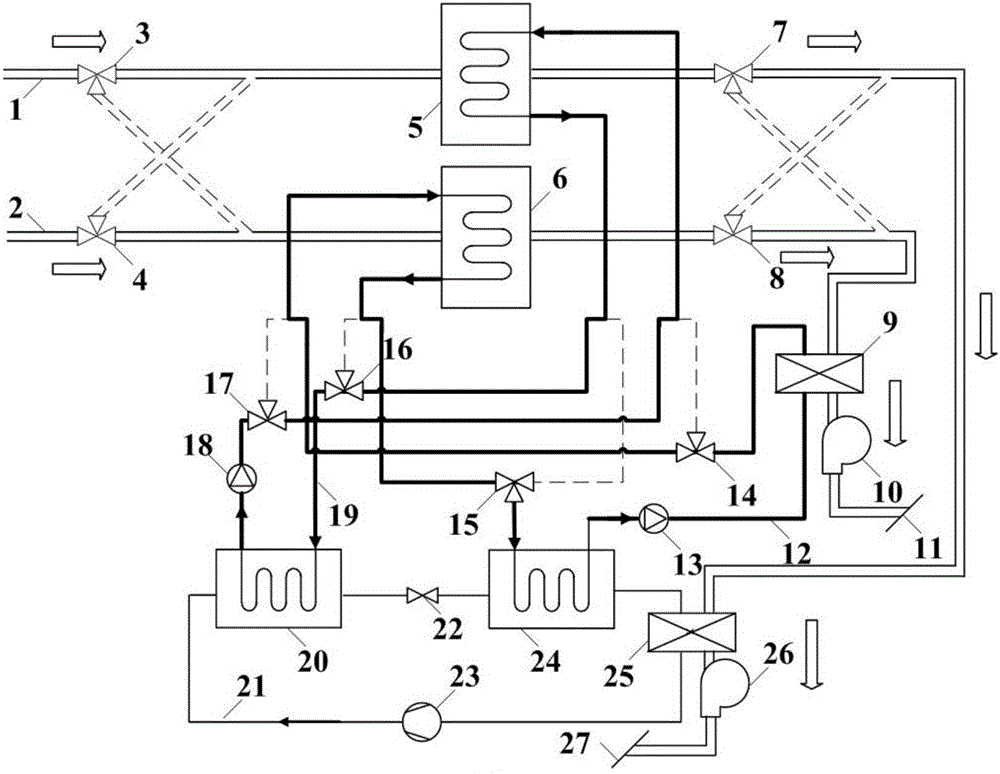

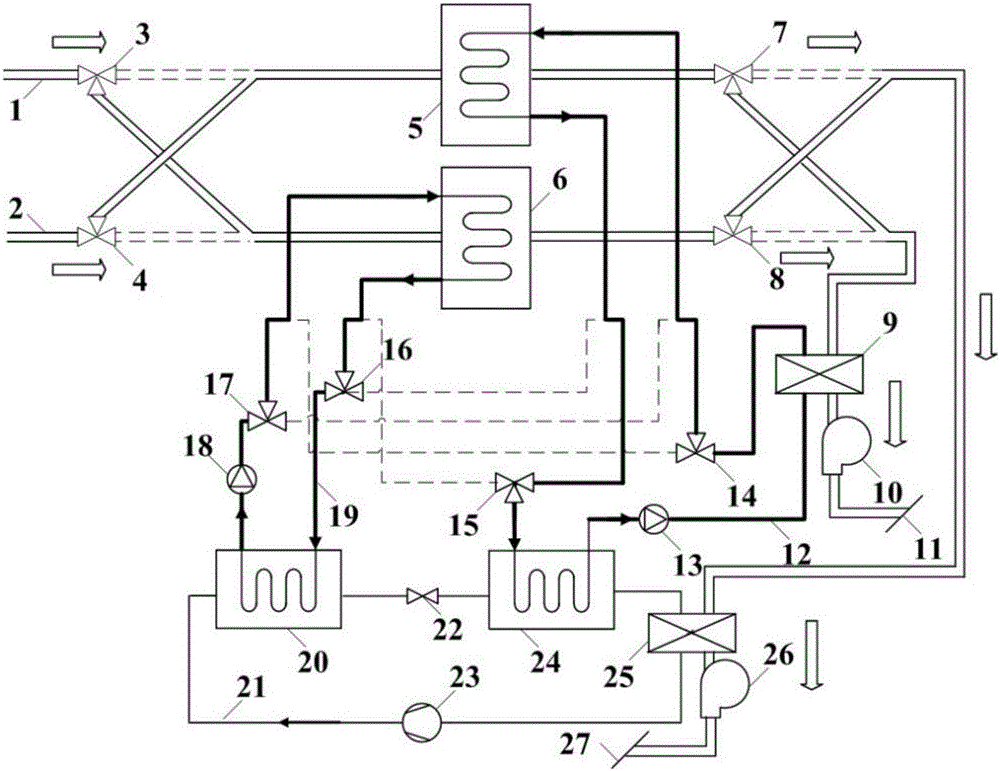

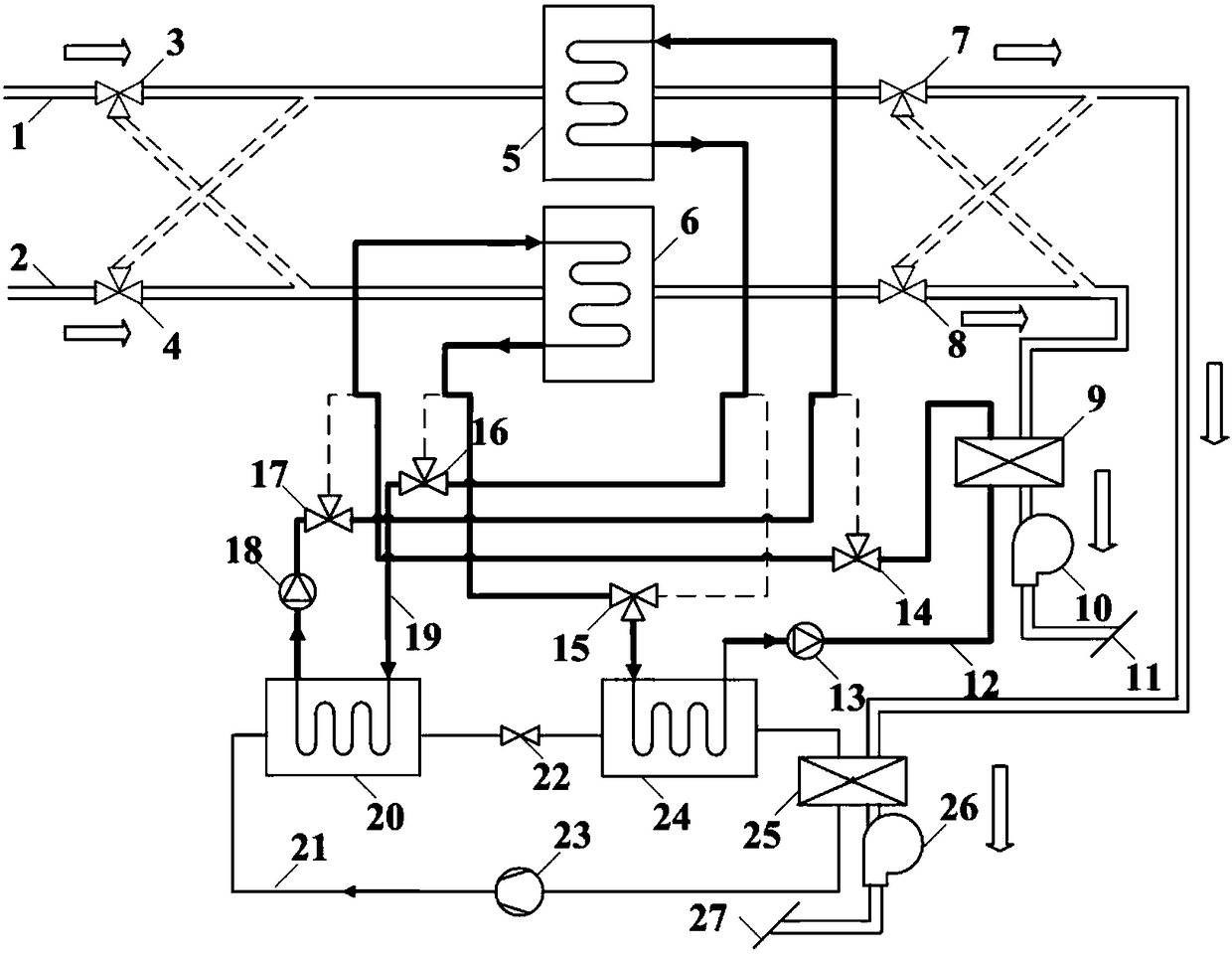

Regenerative heat recovery dehumidification heat pump system and its operation method

ActiveCN105805868BAchieve independent processingPrecise regulation of temperature and humidityHeat recovery systemsLighting and heating apparatusProcess engineeringChiller

The invention discloses a regenerative and recuperative dehumidifying heat pump system. The regenerative and recuperative dehumidifying heat pump system comprises a primary evaporator, a secondary evaporator, a condenser, a compressor, a throttling valve, a dehumidifying heat exchanger, a surface air cooler, a first water pump and a second water pump, wherein the dehumidifying heat exchanger comprises a dehumidifying cooler and a dehumidifying regenerator. By the dehumidifying property of the dehumidifying heat exchanger, the evaporator and the condenser of the heat pump system are respectively used as a cold source and a heat source in a dehumidifying and regenerating process of the dehumidifying heat exchanger, continuous running of the system is realized, and functions of cooling dehumidifying in summers and heating humidifying in winters can be fulfilled. In addition, the secondary evaporator is added in the heat pump system and is used for recycling heat in regenerated air, possibility of liquid impact of the compressor can be reduced, energy can be recycled, and the regenerative and recuperative dehumidifying heat pump system is energy-saving and environmentally friendly.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com