Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Increase water evaporation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

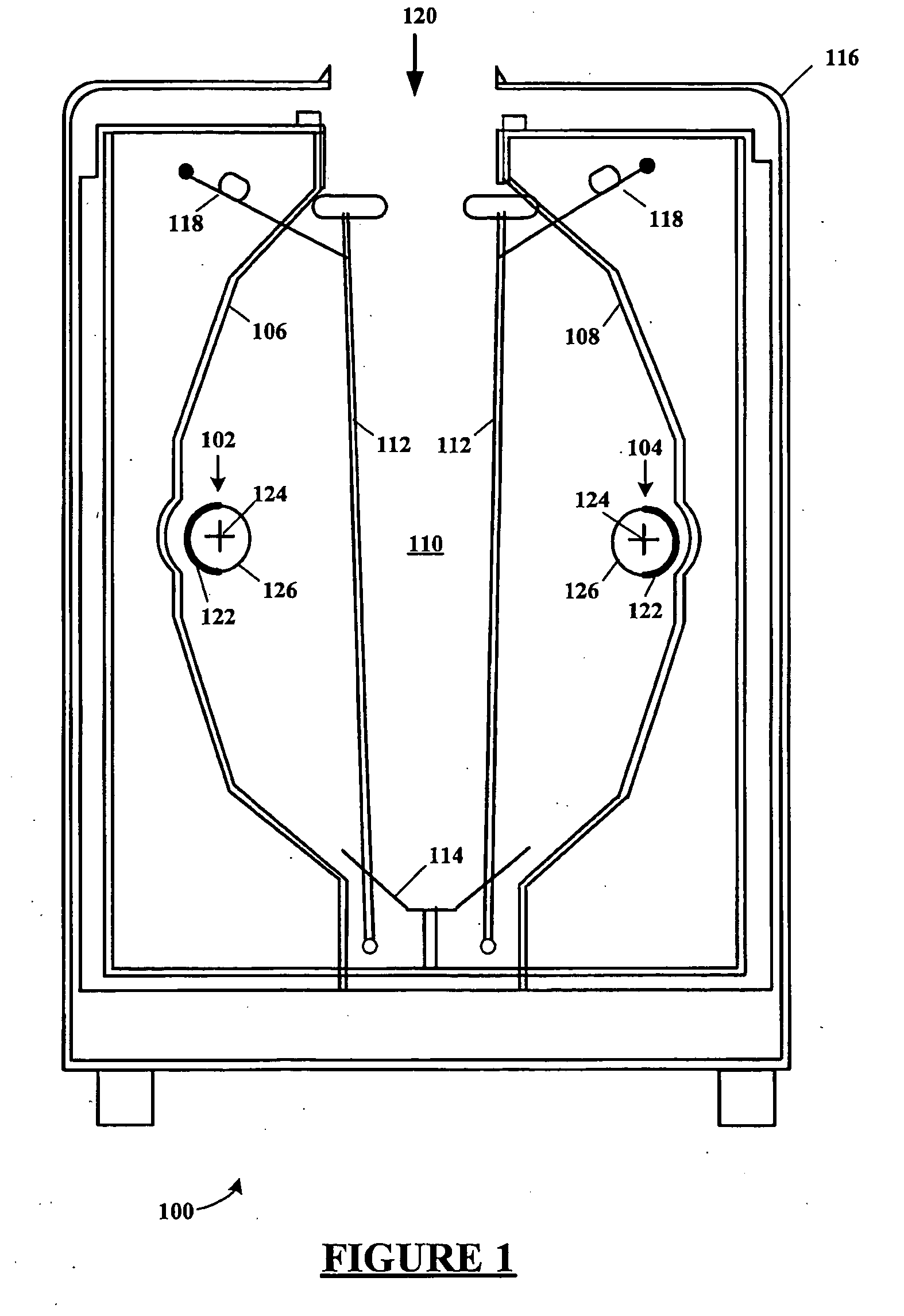

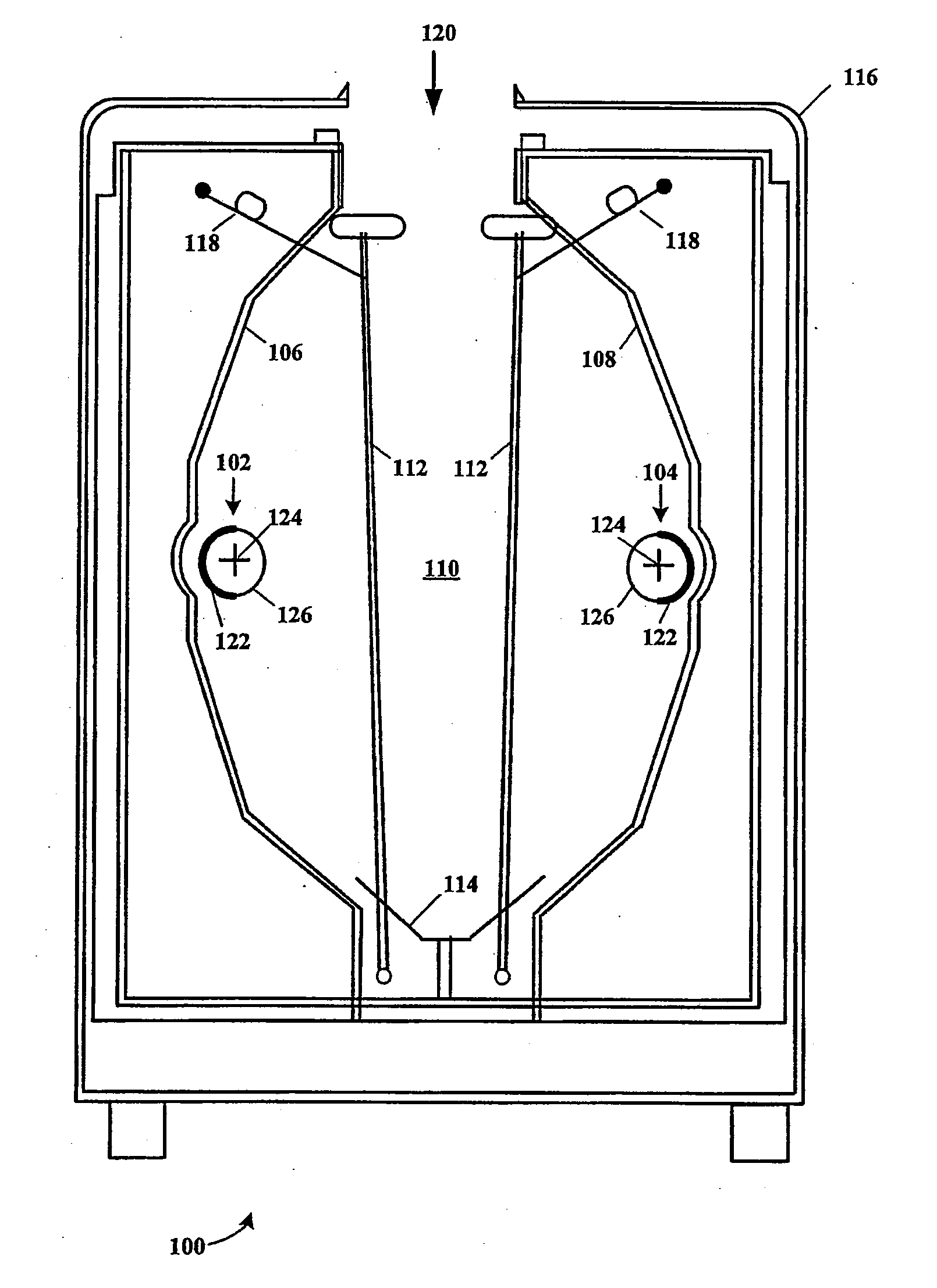

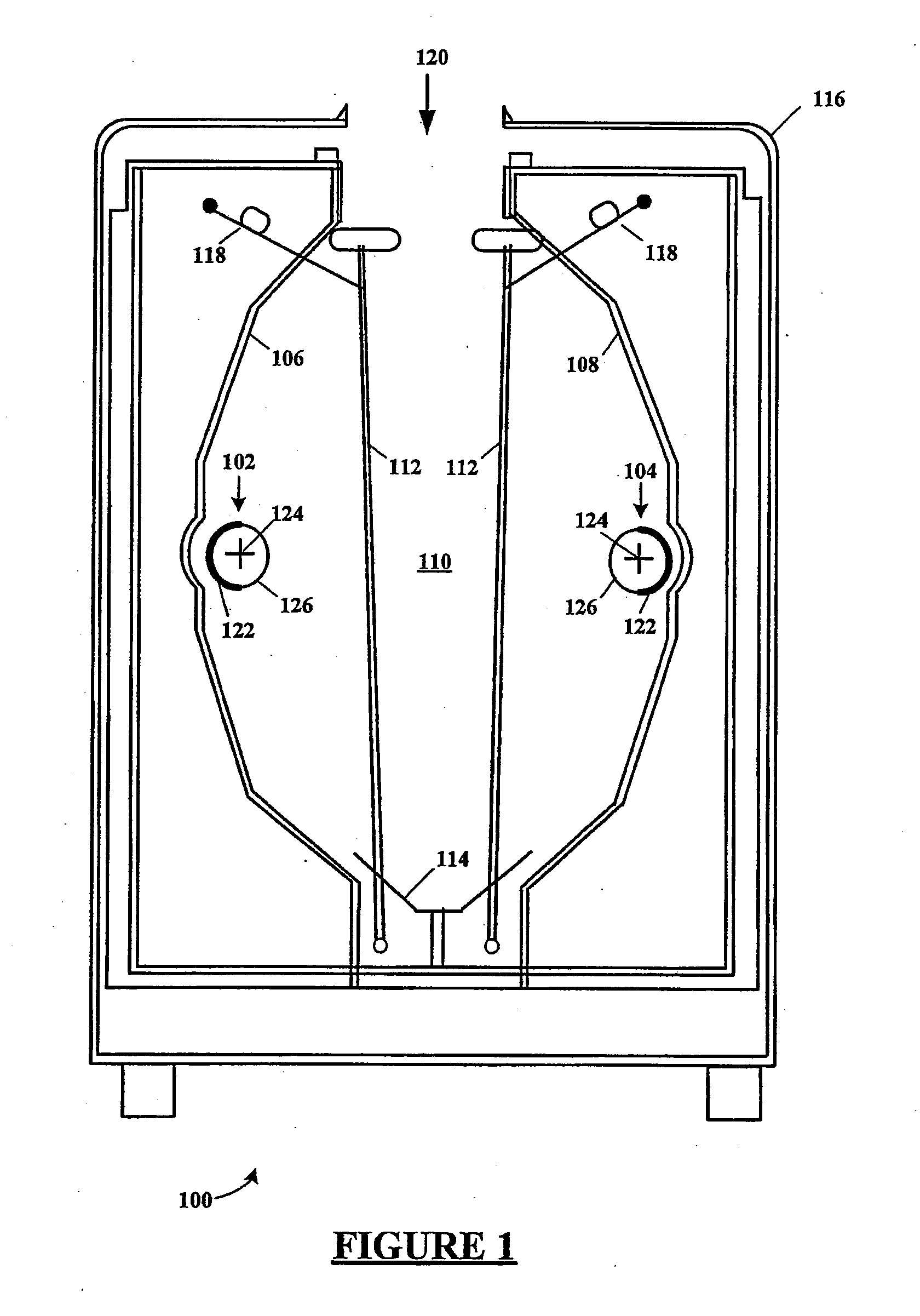

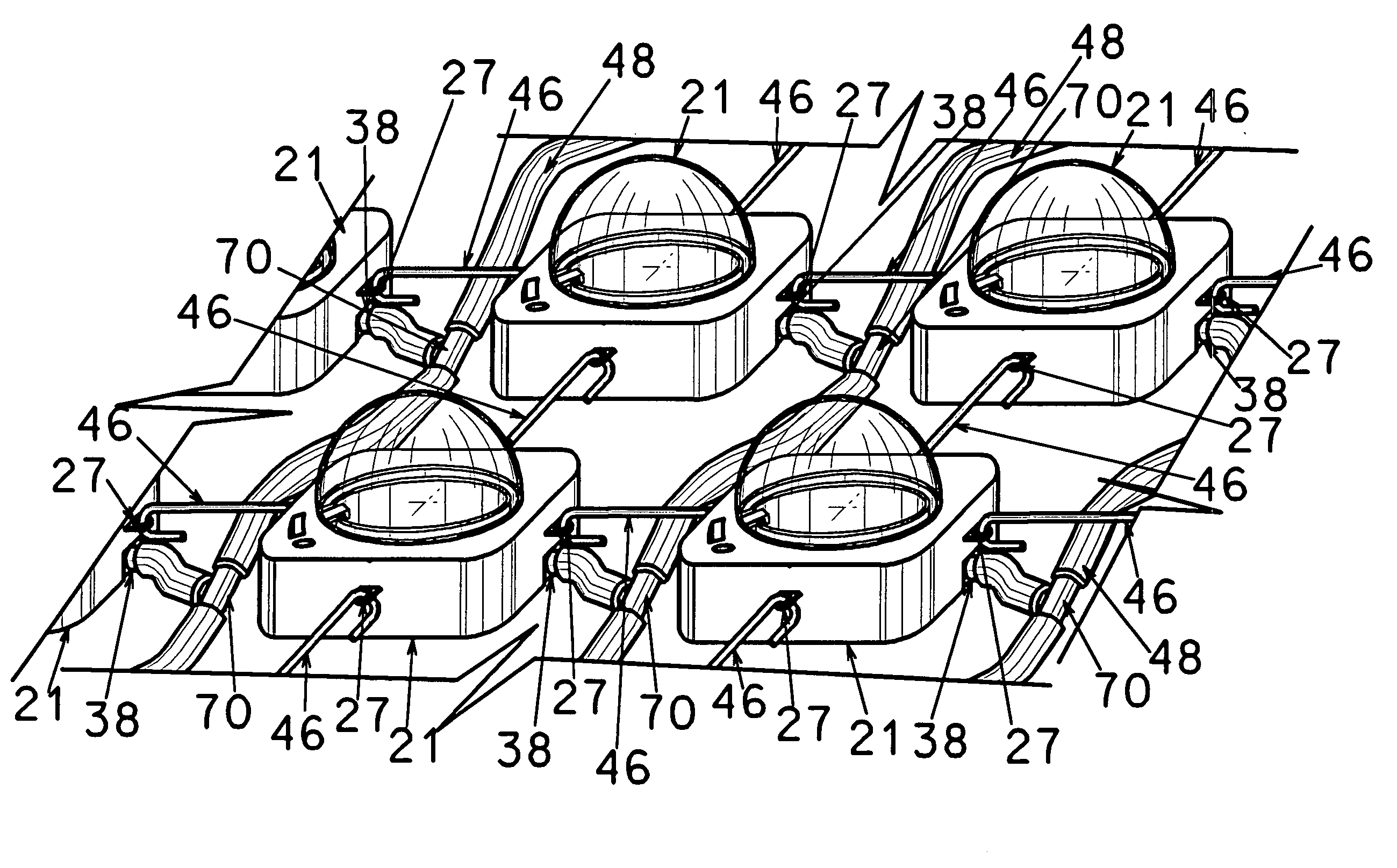

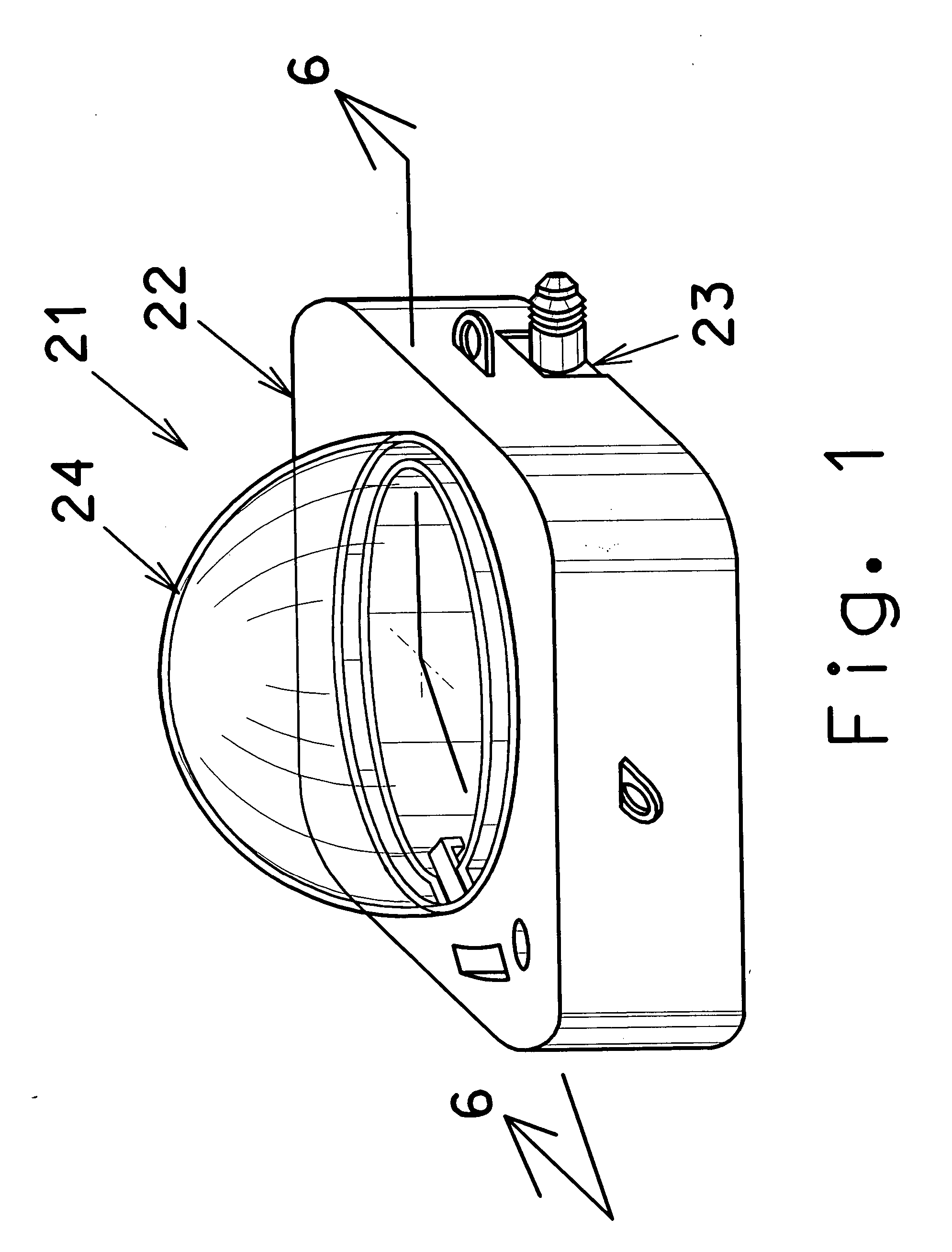

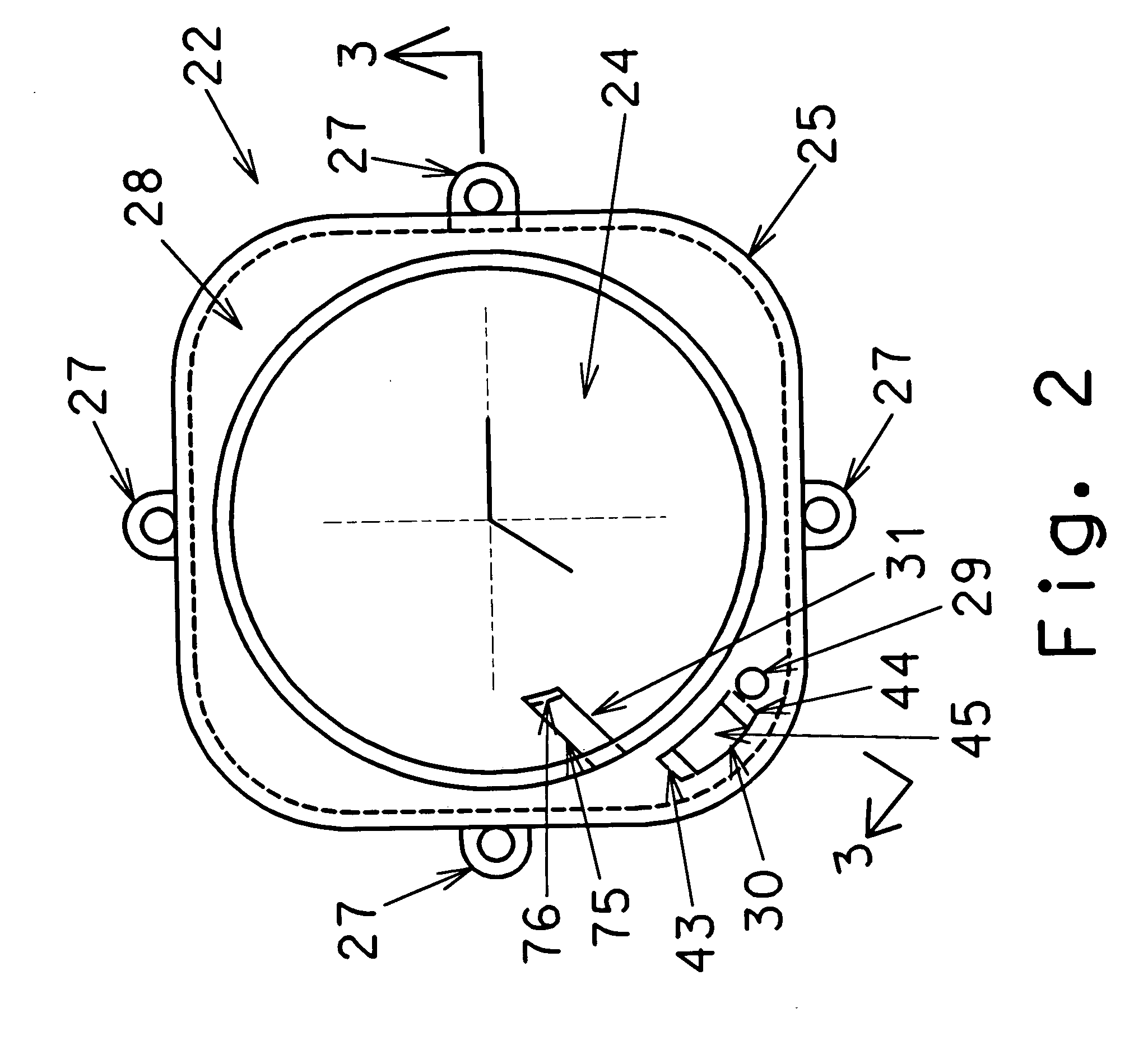

Stationary clothes drying apparatus with jet nozzles

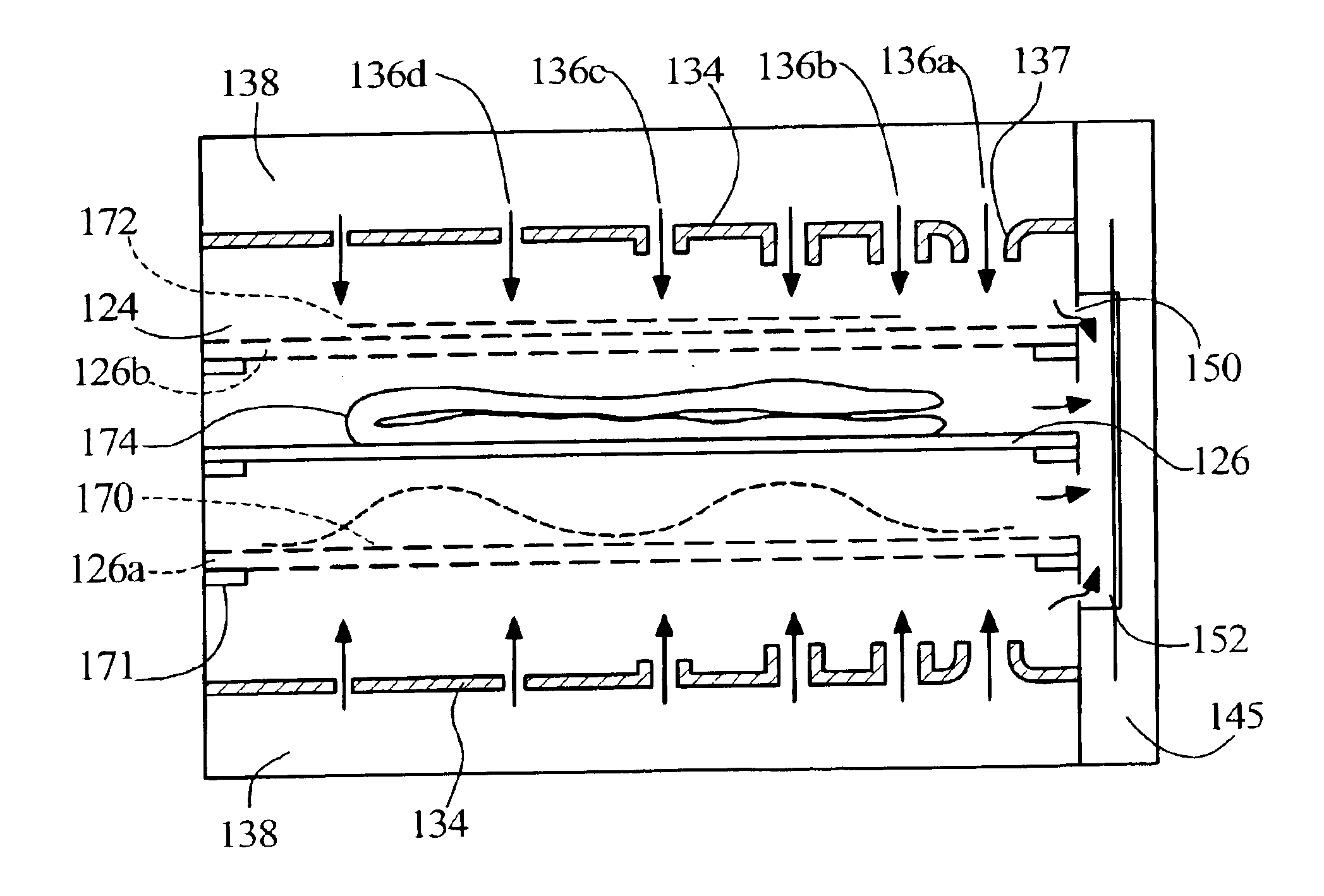

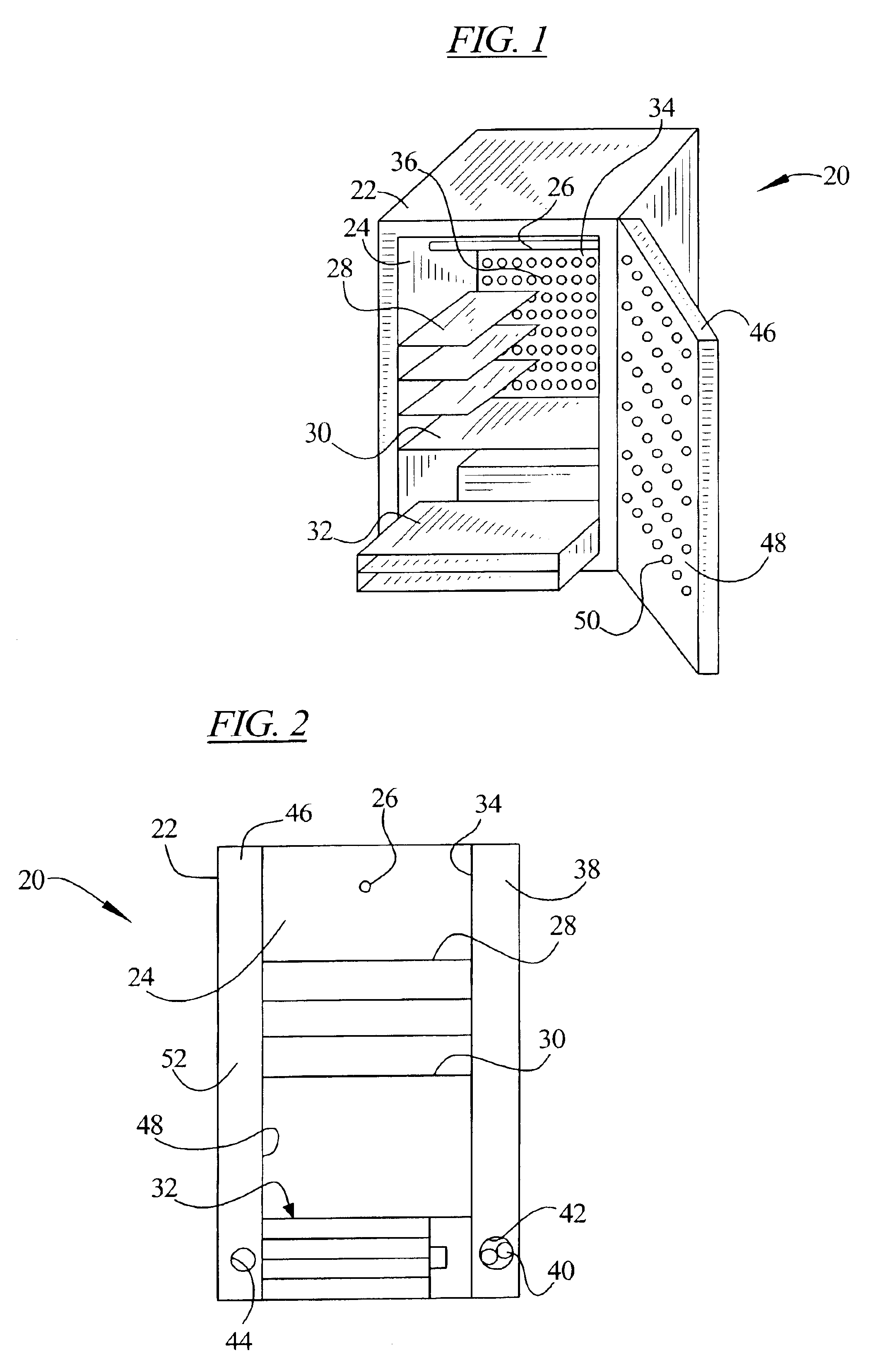

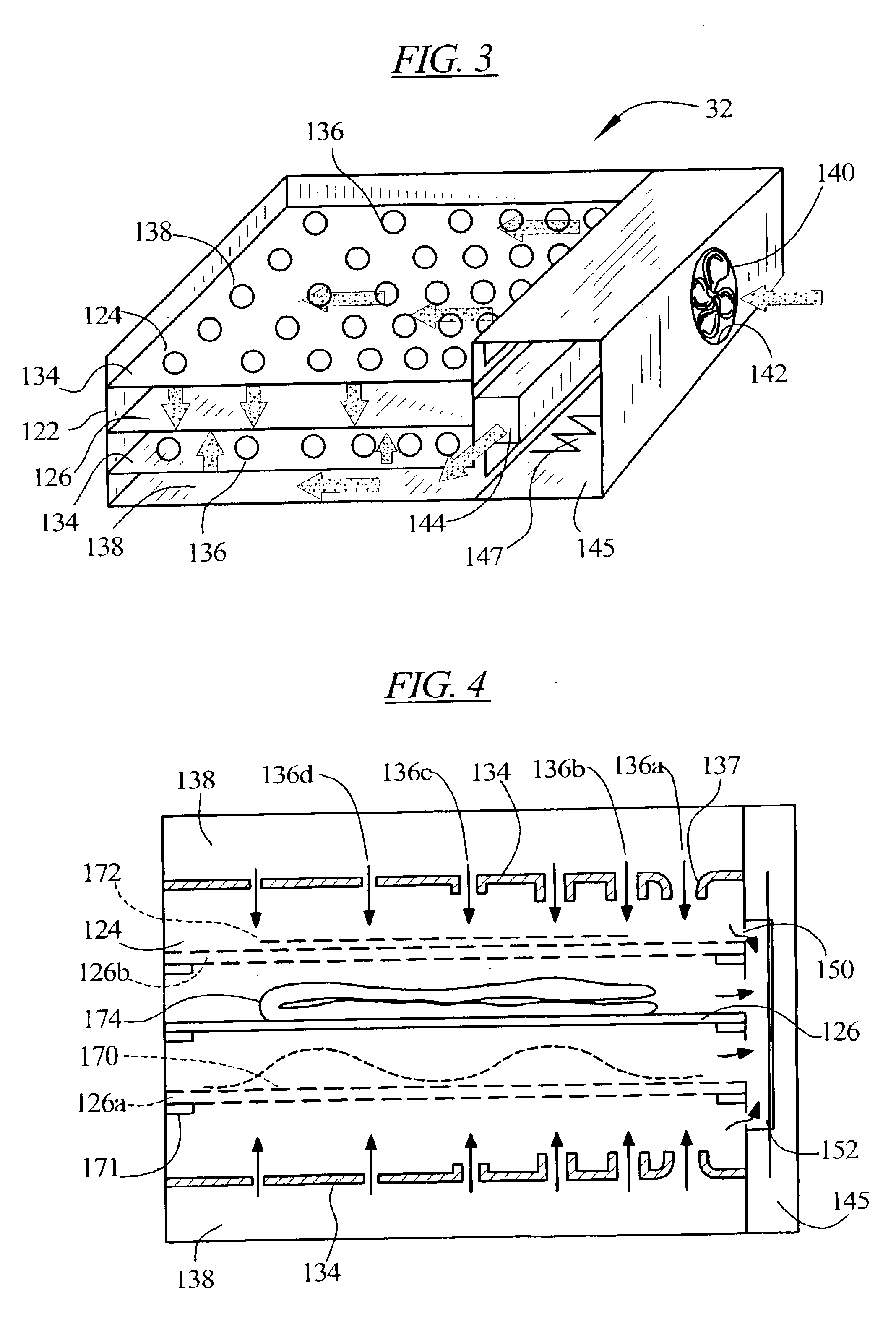

InactiveUS6860032B2Improve performanceIncrease heat transfer rateDrying chambers/containersDrying solid materialsDistributorMaterial Perforation

A stationary dryer, useful as a clothes dryer, is provided comprising a housing enclosing a space and a stationary clothes support located within the space. An air moving device is provided for generating an air flow through the space from an air inlet to an air outlet. An air distributor mechanism comprising a distribution plenum is positioned between the air inlet and the clothes support, with a plenum wall having a plurality of perforations therein. The perforations are sized, shaped and arranged so as to provide jets of air against the clothes support and to equalize an air flow distribution over the clothes support.

Owner:WHIRLPOOL CORP

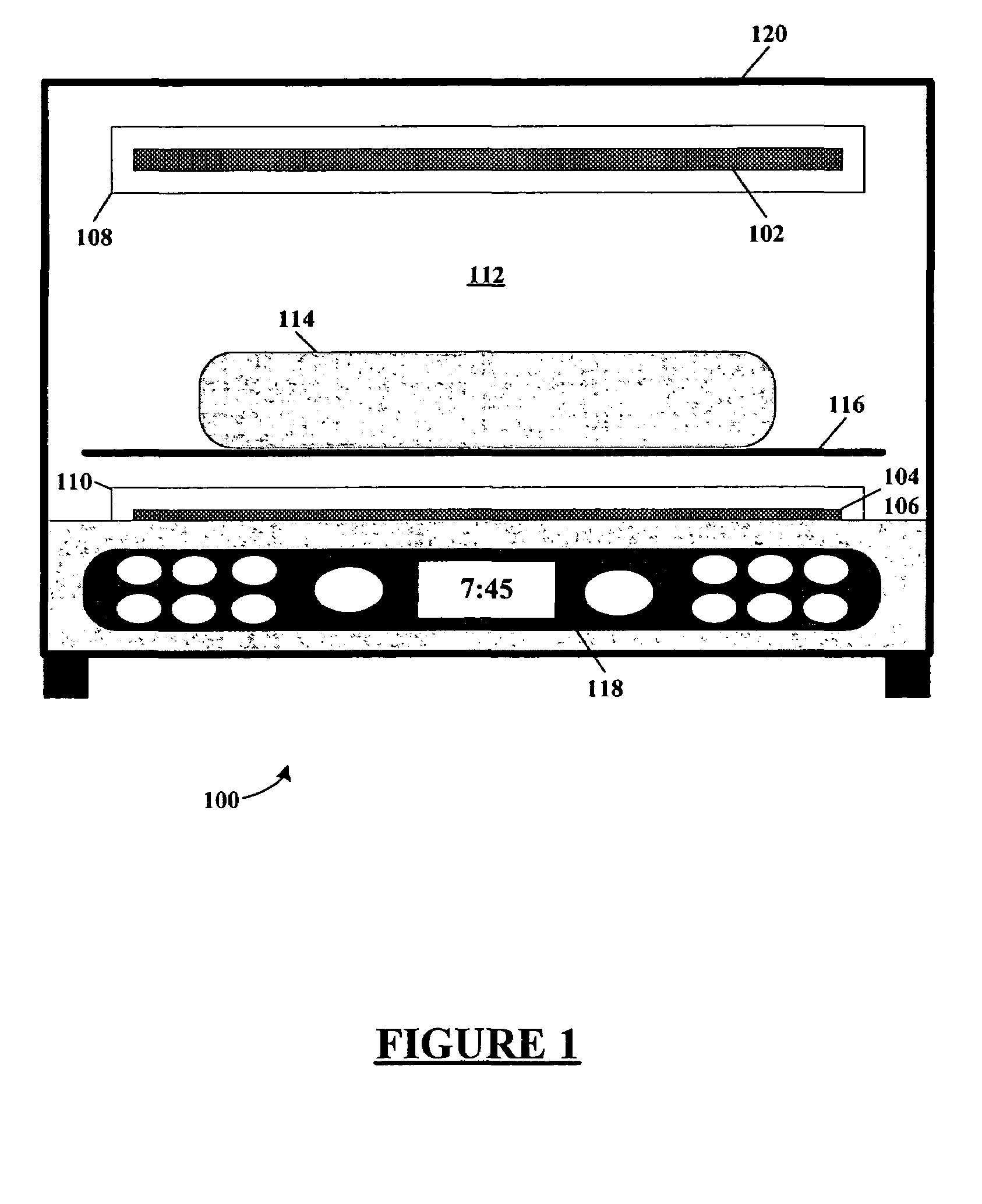

Multi-purpose oven using infrared heating for reduced cooking time

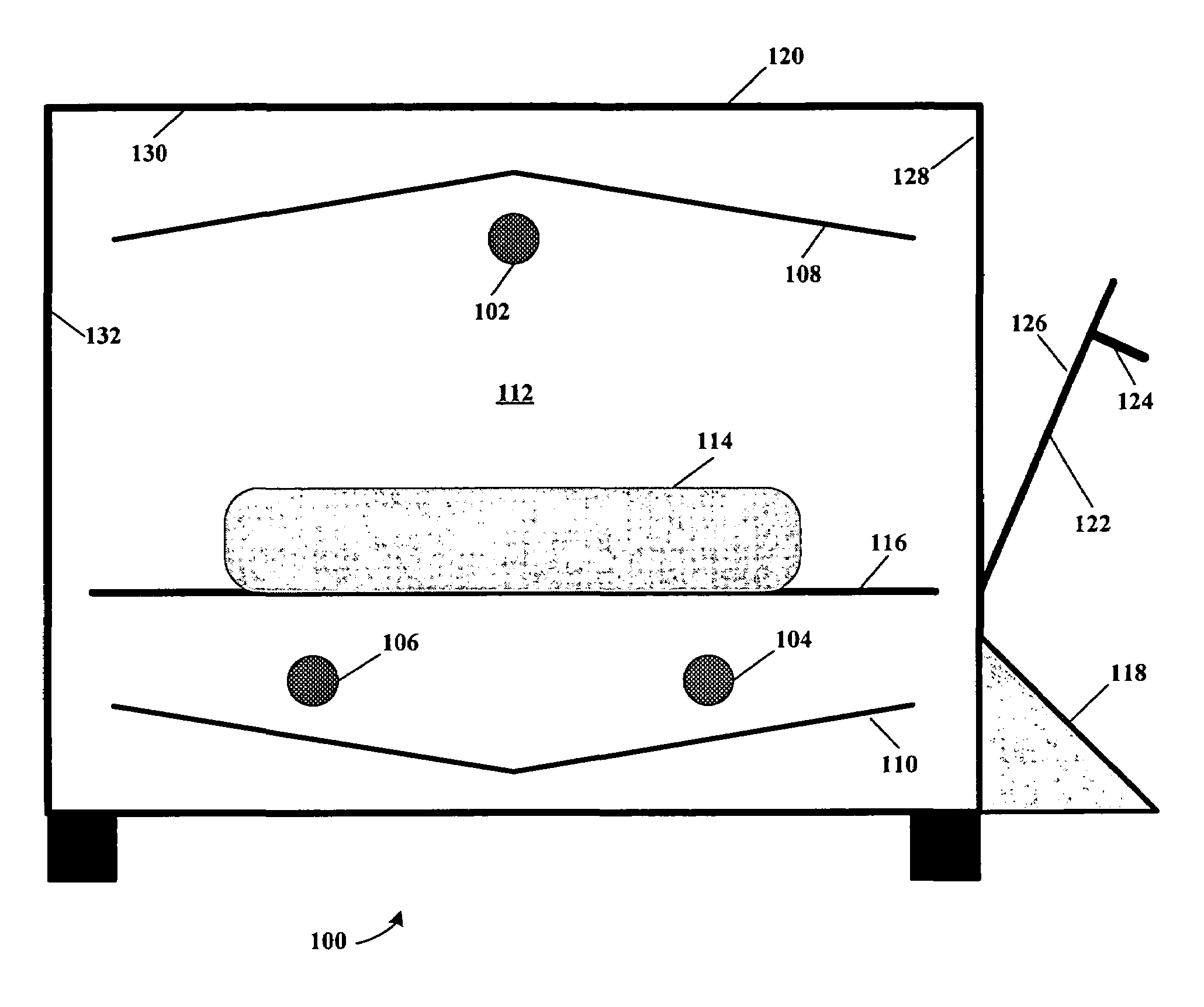

ActiveUS7323663B2High speedEfficient use of powerRadiation pyrometryDomestic stoves or rangesThermal energyRadiant heat

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and re-heats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

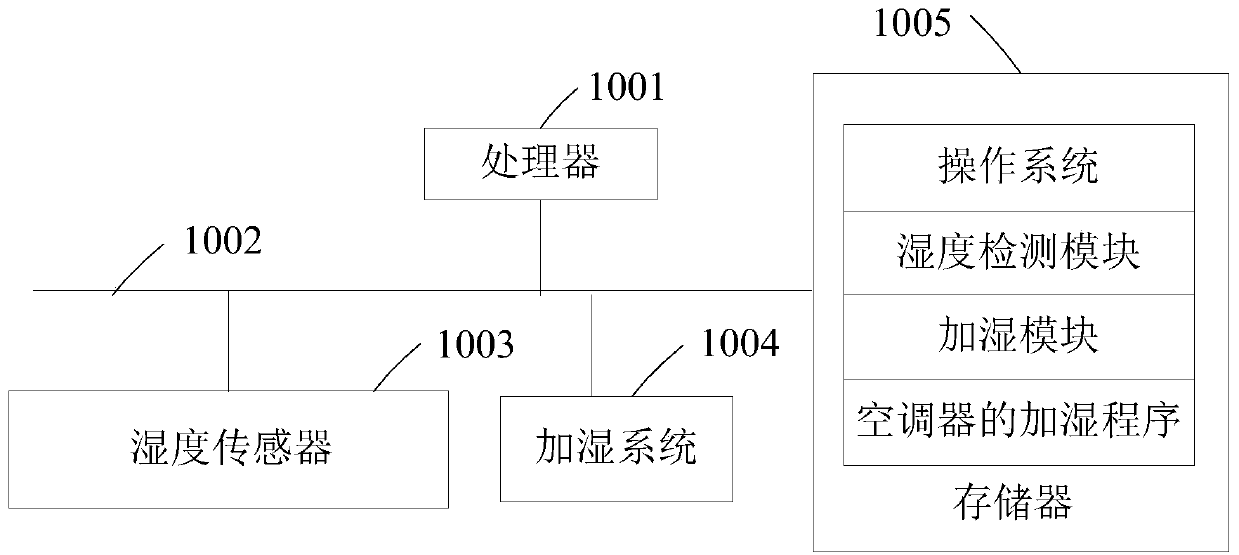

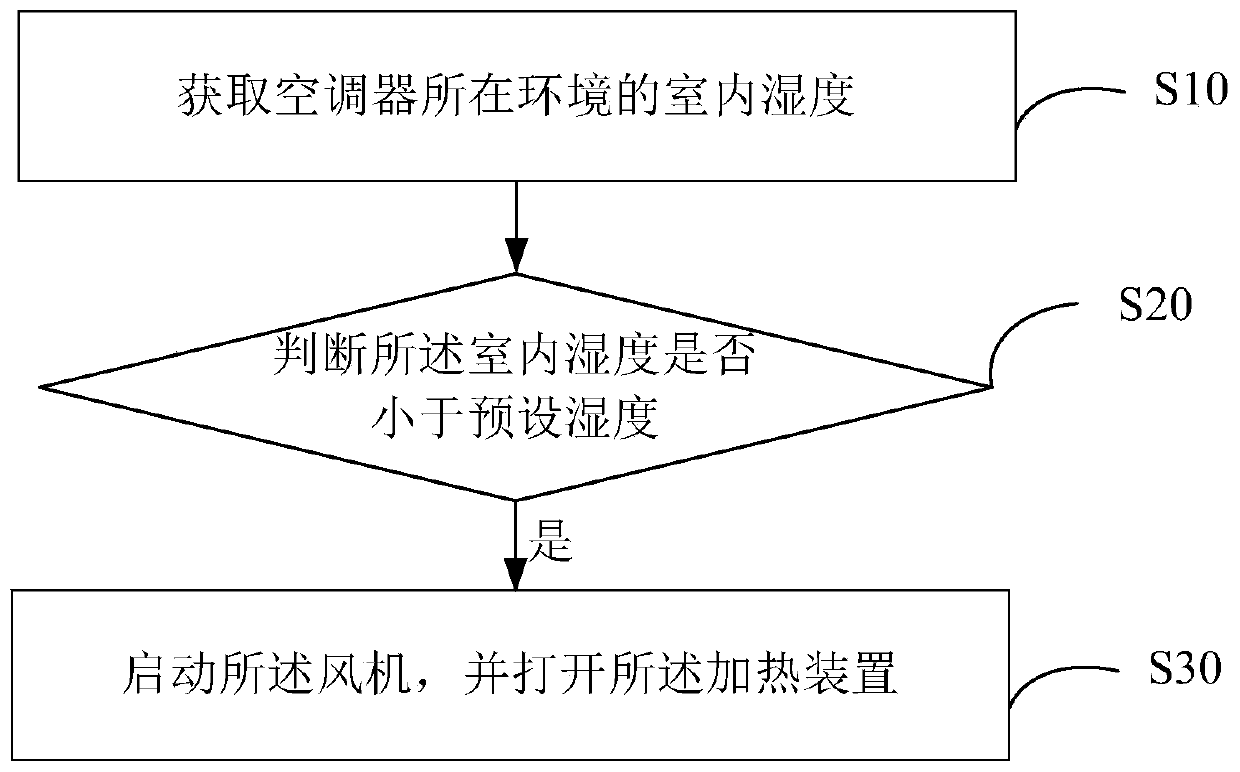

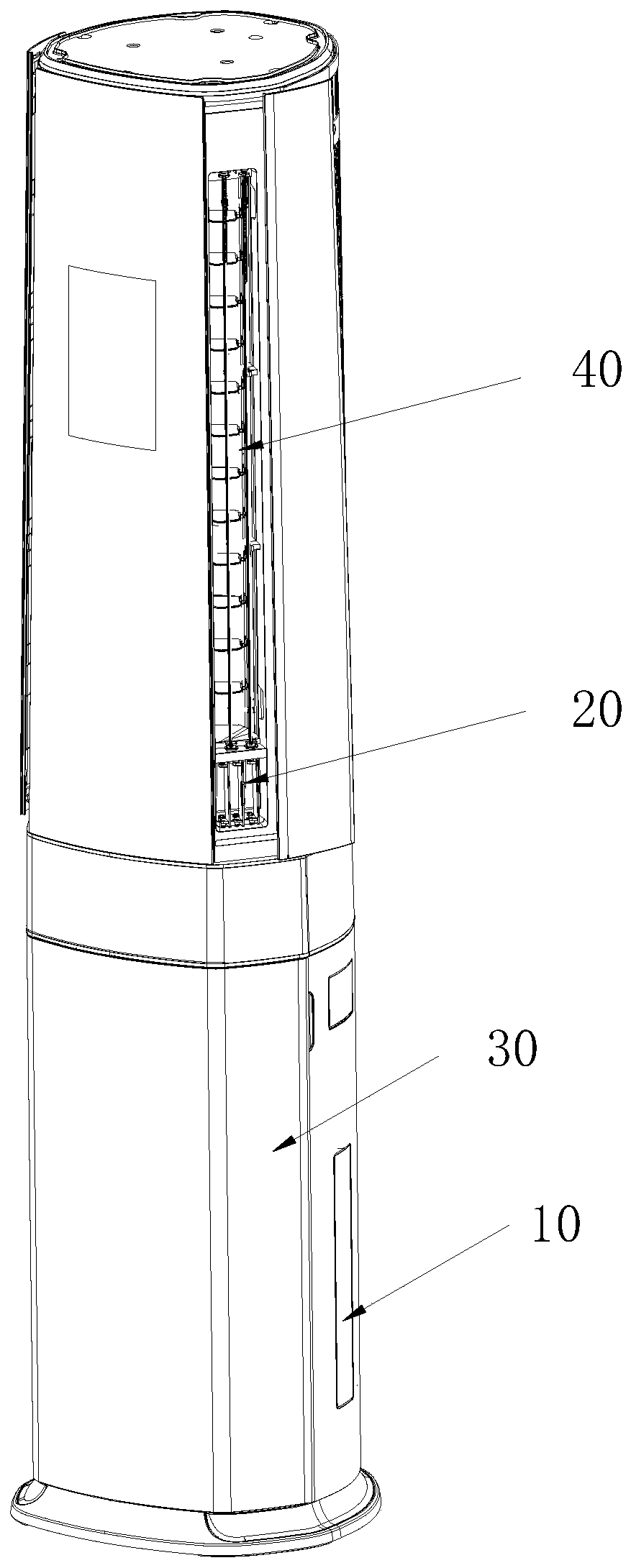

Humidifying method and device of air conditioner, air conditioner and computer readable storage medium

PendingCN109764414AImprove the humidification effectIncrease water evaporation rateMechanical apparatusSpace heating and ventilation safety systemsEvaporationEngineering

The invention discloses a humidifying method of an air conditioner. The air conditioner is provided with a humidifying system, the humidifying system includes a humidifying wind outlet, a humidifyingwind outlet and a humidifying wind channel, the humidifying wind channel communicates with the humidifying wind outlet and the humidifying wind inlet, a draught fan, a humidifying wet film and a heating device located between the humidifying wind inlet and the humidifying wet film are arranged in the humidifying wind channel, the humidifying method of the air conditioner includes the following steps that the indoor humidity of the environment where the air conditioner is located is obtained; and when the indoor humidity is less than a preset humidity, the draught fan is started, and the heating device is opened. The invention further discloses a humidifying device of the air conditioner, the air conditioner and the computer readable storage medium. Air is heated by the heating device, andthe water absorbing capacity of the air is improved. Meanwhile the air with high temperature passes through the humidifying wet film, the rate of water evaporation of the humidifying wet film is accelerated, the moisture content of the air sent from the humidifying wind outlet is increased, and the humidifying effect of the air conditioner is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Method for cooking a food with infrared radiant heat

ActiveUS20080029503A1High speedEfficient use of powerDomestic stoves or rangesElectrical heating fuelThermal energyProcess engineering

An oven using radiant heat at infrared wavelengths optimized for producing rapid and uniform cooking of a wide variety of foods. The infrared oven toasts, bakes, broils, and reheats food at a much faster speed while maintaining high quality in taste and appearance of the cooked food. Optimal infrared wavelengths of the radiant heat sources are used for the best balance of cooking performance, while also reducing the time required to cook the food. Typically short to medium wavelength infrared radiant energy will result in good performance for toasting and browning of food. Medium to long wavelength infrared radiant energy is well suited for delivering more deeply penetrating radiant energy into the food. This deep penetration of radiant infrared heat energy results in a more thorough internal cooking of the food than with conventional methods of conduction and convection cooking.

Owner:APPLICA CONSUMER PRODS

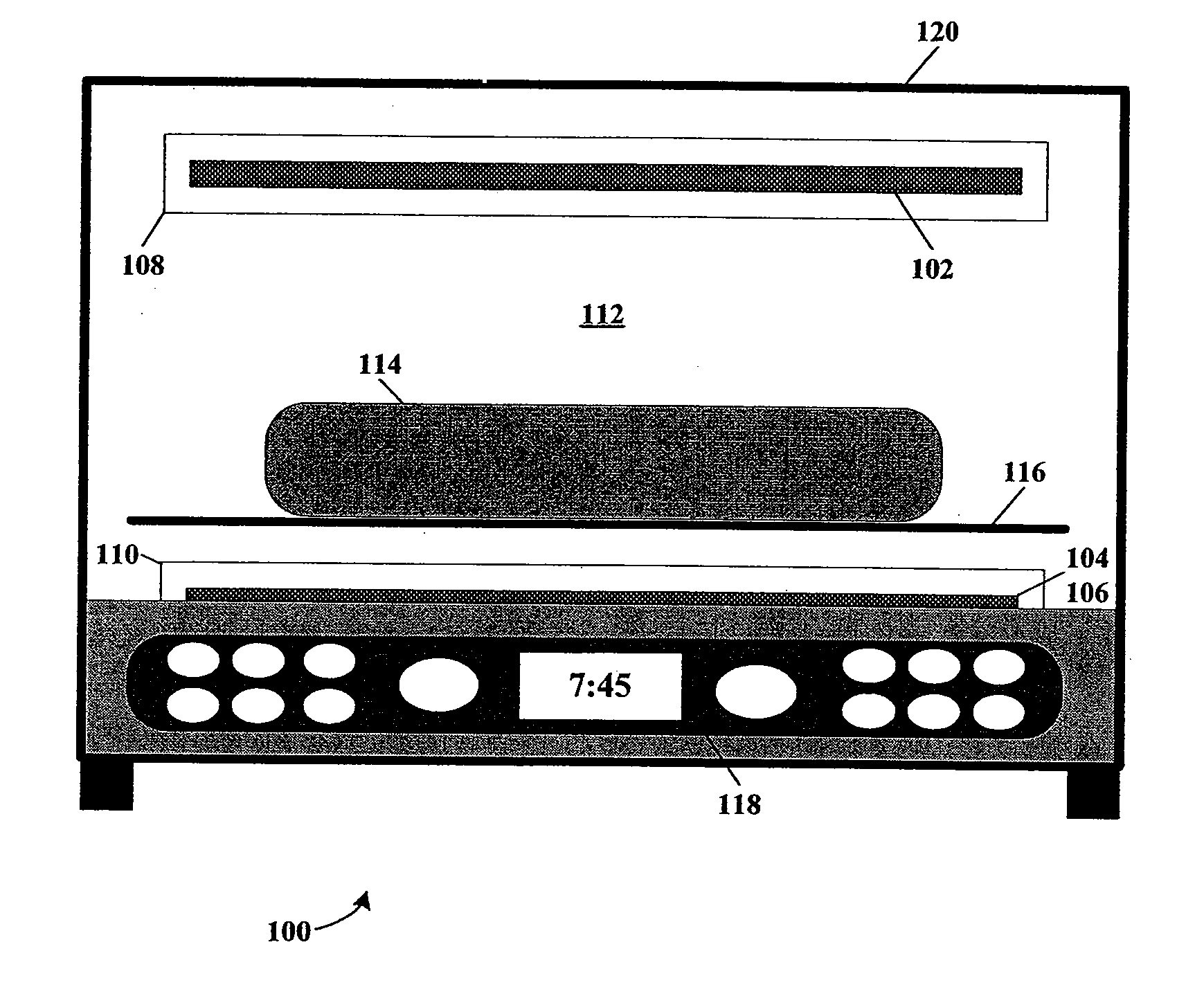

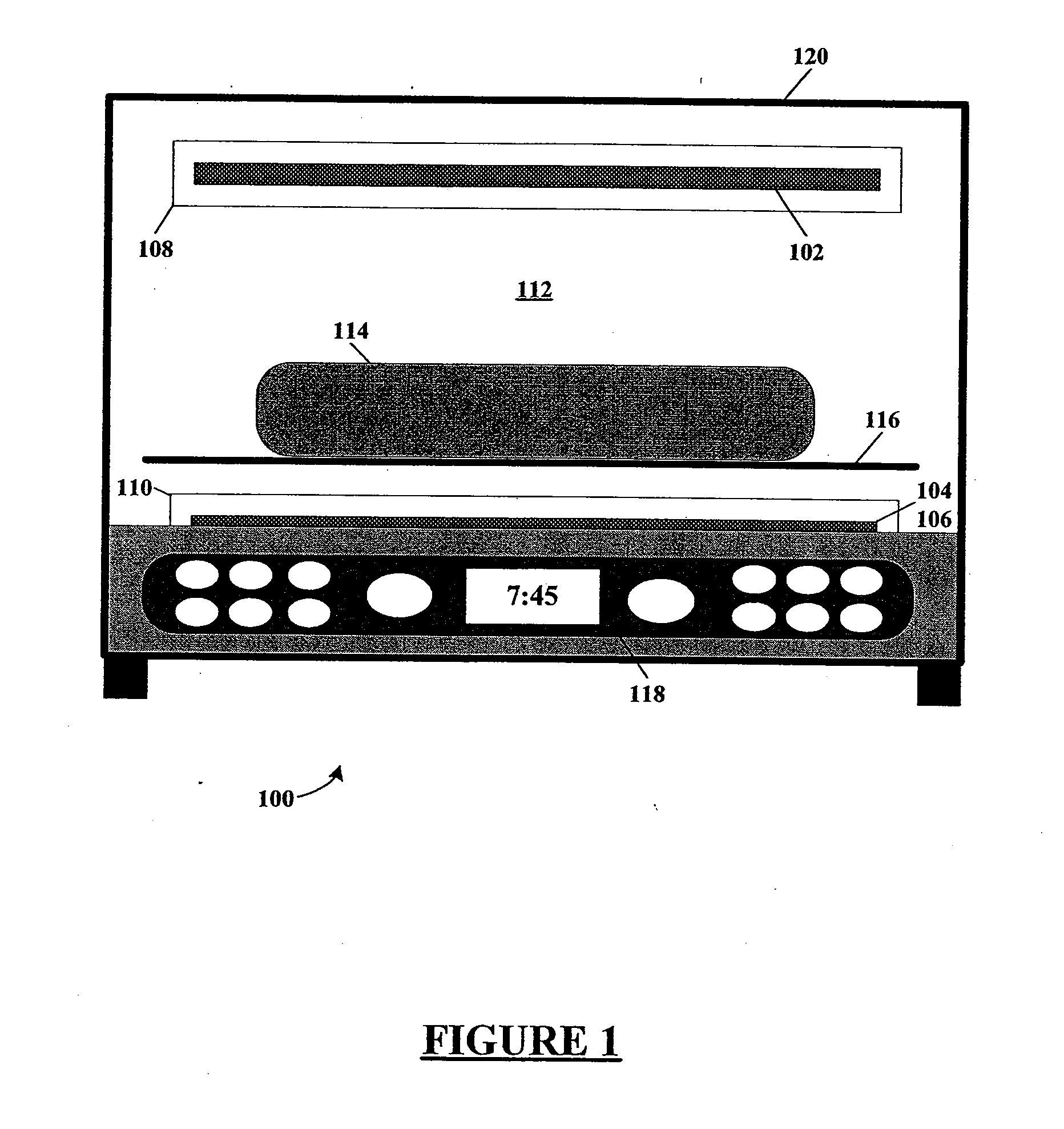

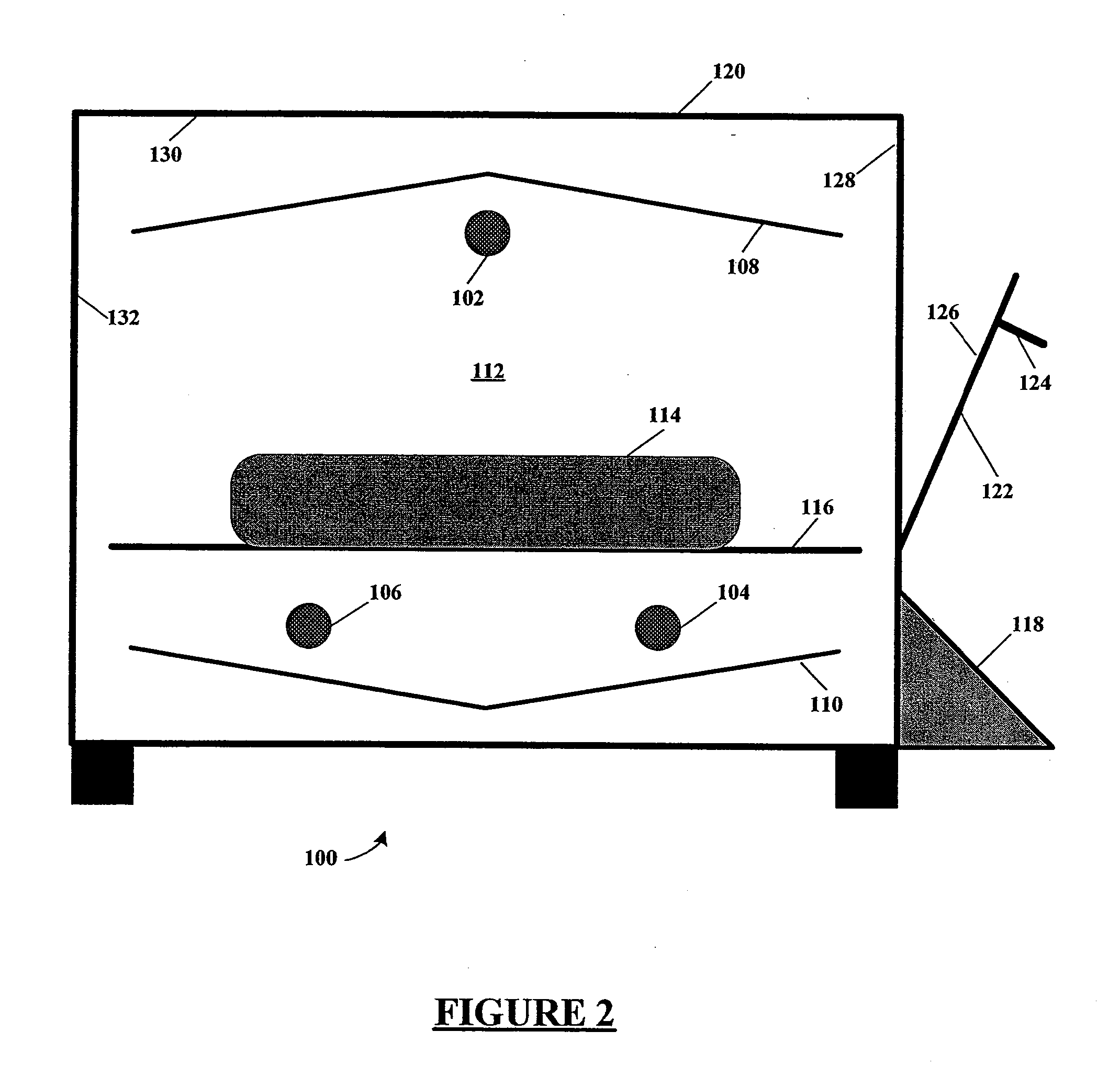

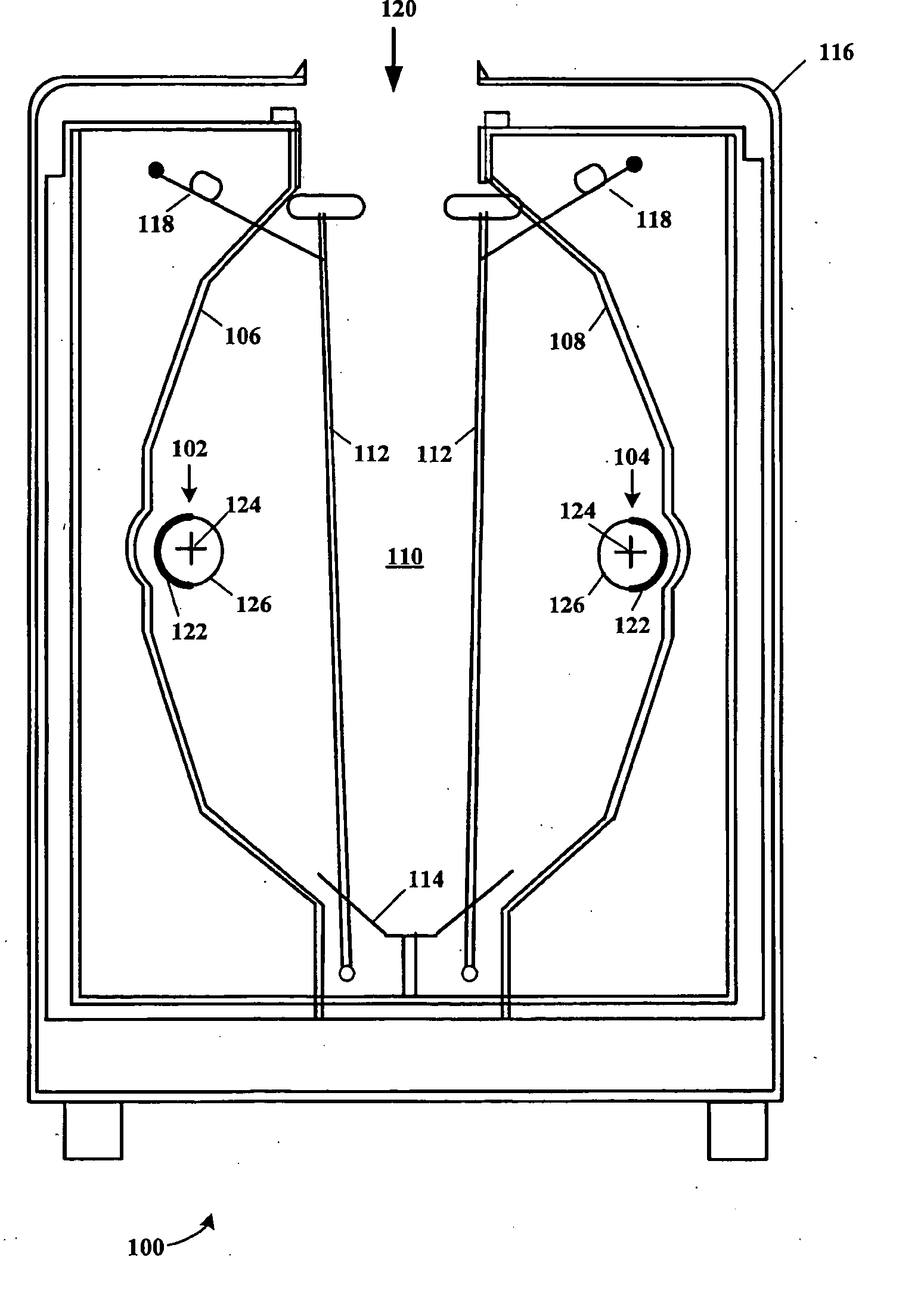

Toaster using infrared heating for reduced toasting time

ActiveUS20050132900A1Faster toastingFaster and even toastingDomestic stoves or rangesDrying solid materials with heatHeat penetrationProcess engineering

A toaster uses radiant heat at infrared wavelengths optimized for producing rapid and uniform toasting of a food product. The infrared wavelengths of the radiated heat are selected for optimum speed and quality (browning and moisture content) of the food product. The selected infrared wavelengths of the radiated heat may also effectively defrost a food product. Defrosting of the food product by the infrared radiated heat adds very little time in obtaining a desired toast color to the food product. A plurality of infrared wavelengths of radiated heat may also be used, wherein the plurality of infrared wavelengths are selected for optimal heat penetration and surface browning of the food product. Shorter wavelengths for browning and slightly longer wavelengths to penetrate the food product for evaporating the moisture therein to allow surface browning by the shorter wavelengths. In addition, the heating energy within the toaster may be further elongated (longer wavelengths) once the infrared radiation is re-radiated off of reflectors within the toaster. The wavelengths of infrared radiated heat may be from about 1 to about 3 microns, and preferably from about 1.96 to about 2.5 microns, and most preferably at about 2.11 microns.

Owner:APPLICA CONSUMER PRODS

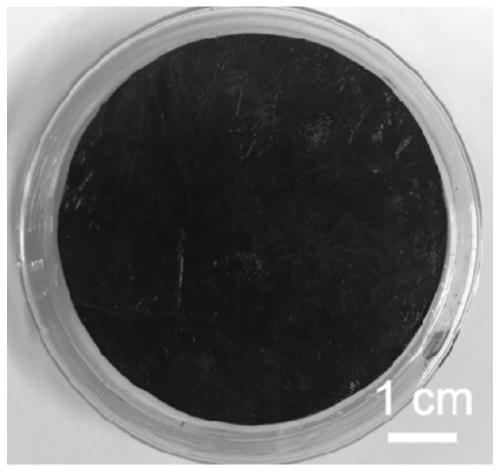

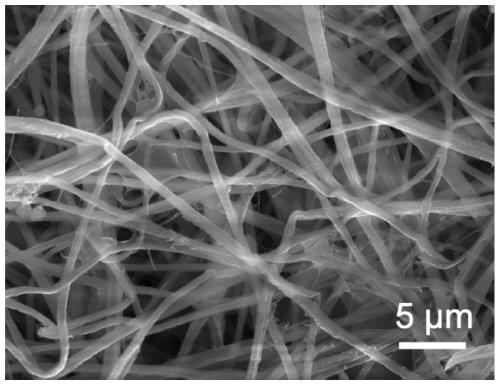

Preparation method of graphene/nanofiber hybrid gel membrane with photo-thermal conversion function

ActiveCN110003509AIncrease water evaporation rateImprove light-to-heat conversion efficiencyCvd grapheneOxide

A preparation method of a graphene / nanofiber hybrid gel membrane with a photo-thermal conversion function relates to a preparation method of a graphene / nanofiber hybrid gel membrane. The invention aims to solve the problem that existing photo-thermal conversion materials have low evaporation velocity and low photo-thermal conversion efficiency during the seawater desalination process. The preparation method comprises the following steps: 1, preparation of gel fiber; 2, preparation of graphene oxide sheets; and 3, preparation of the hybrid gel membrane. The preparation method is used for preparation of the graphene / nanofiber hybrid gel membrane with the photo-thermal conversion function.

Owner:HARBIN INST OF TECH +2

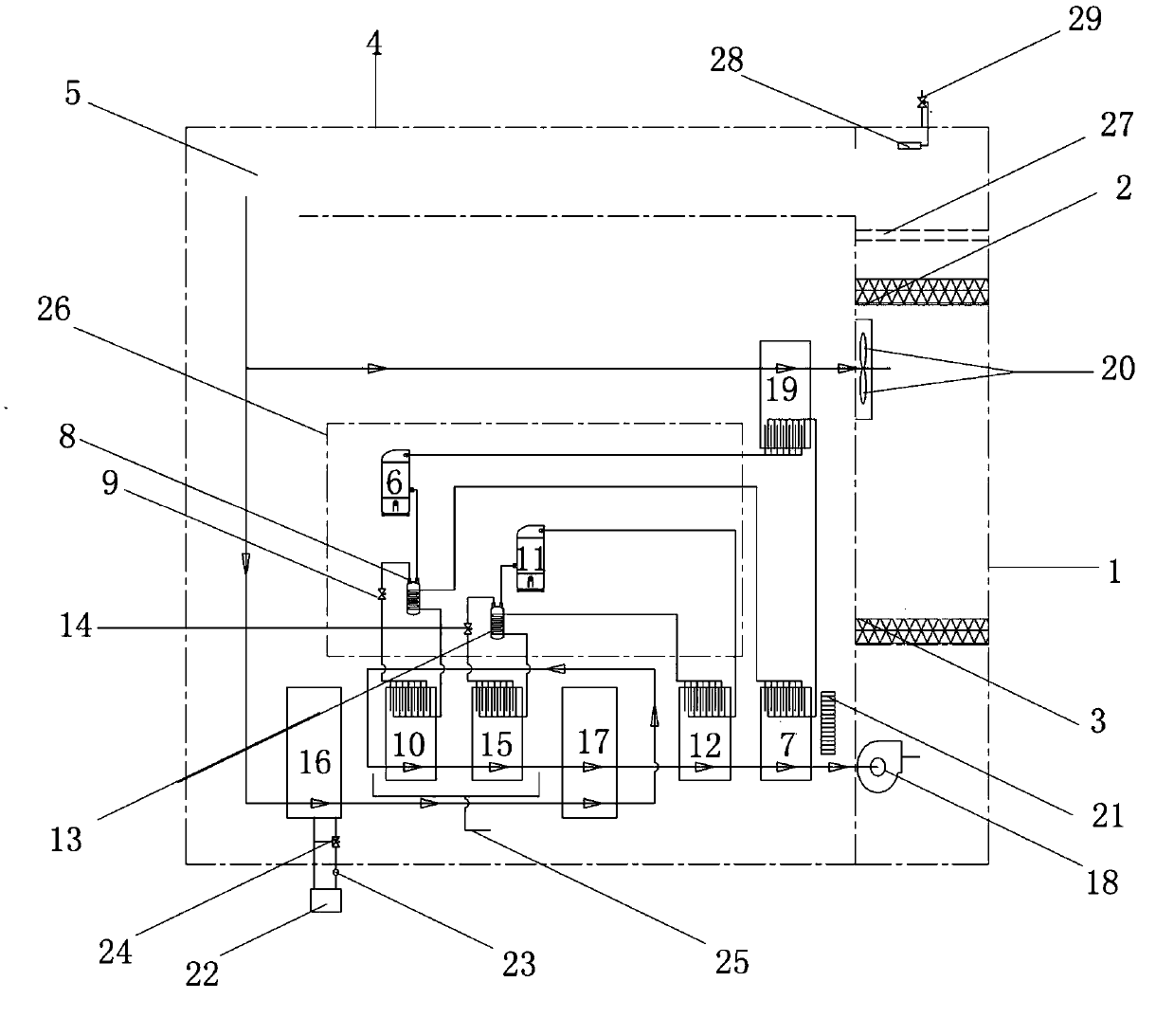

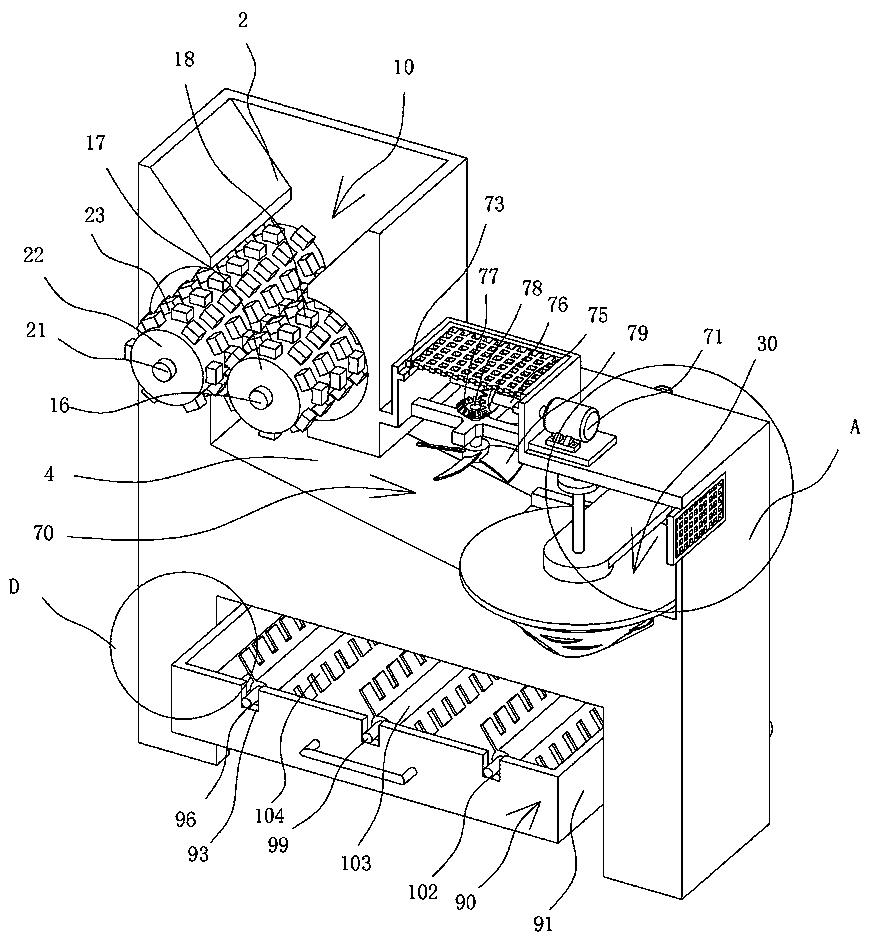

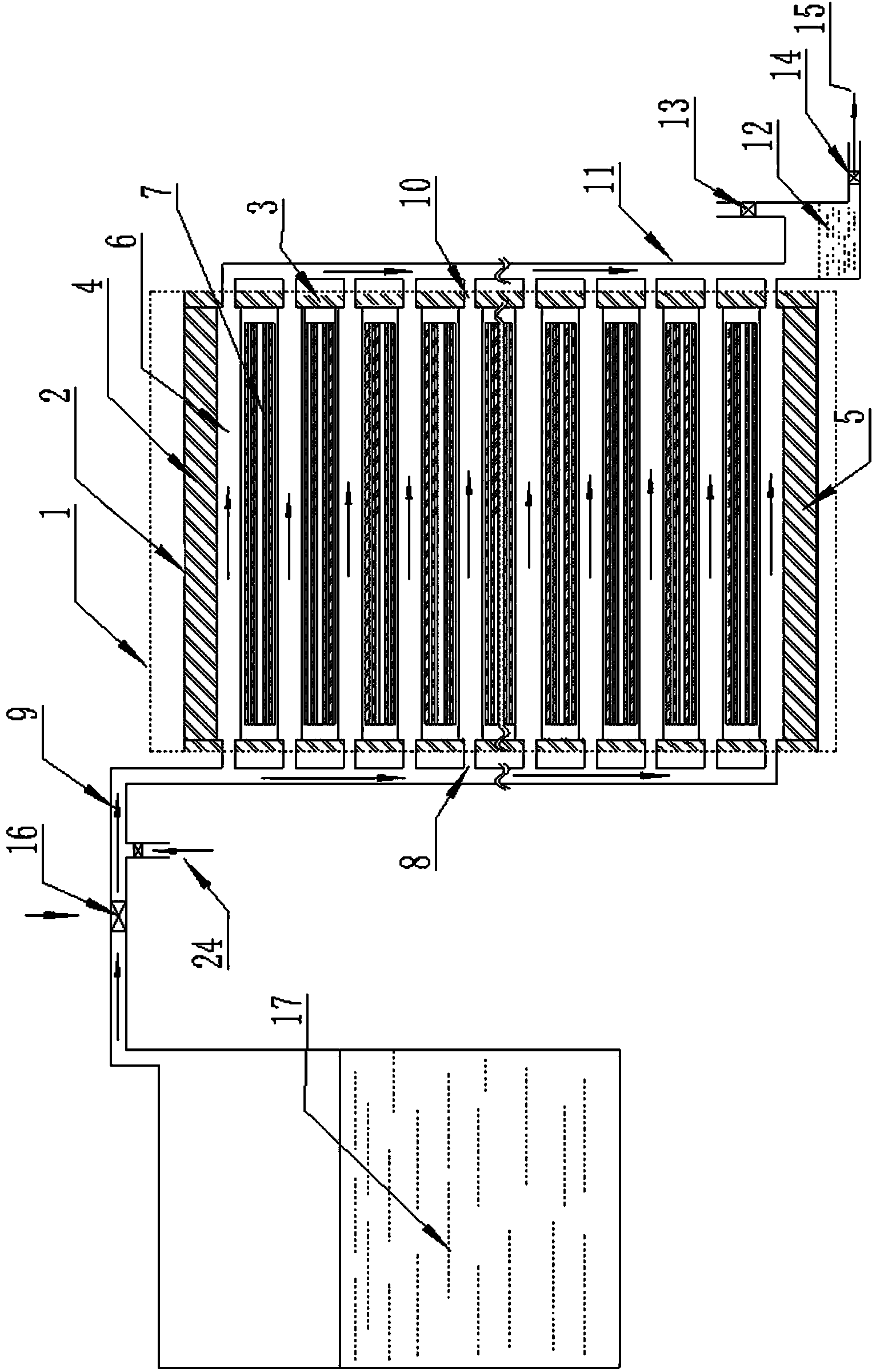

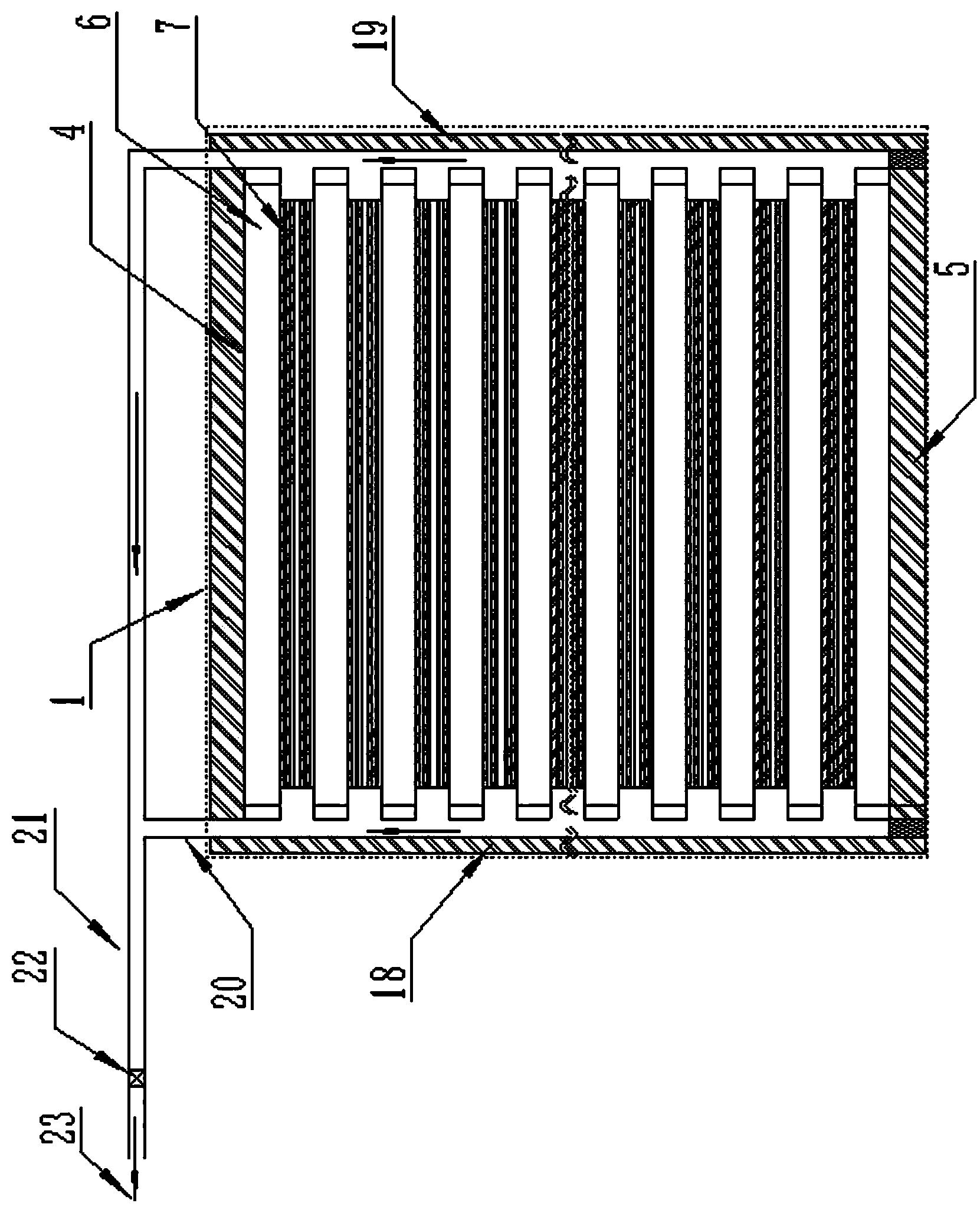

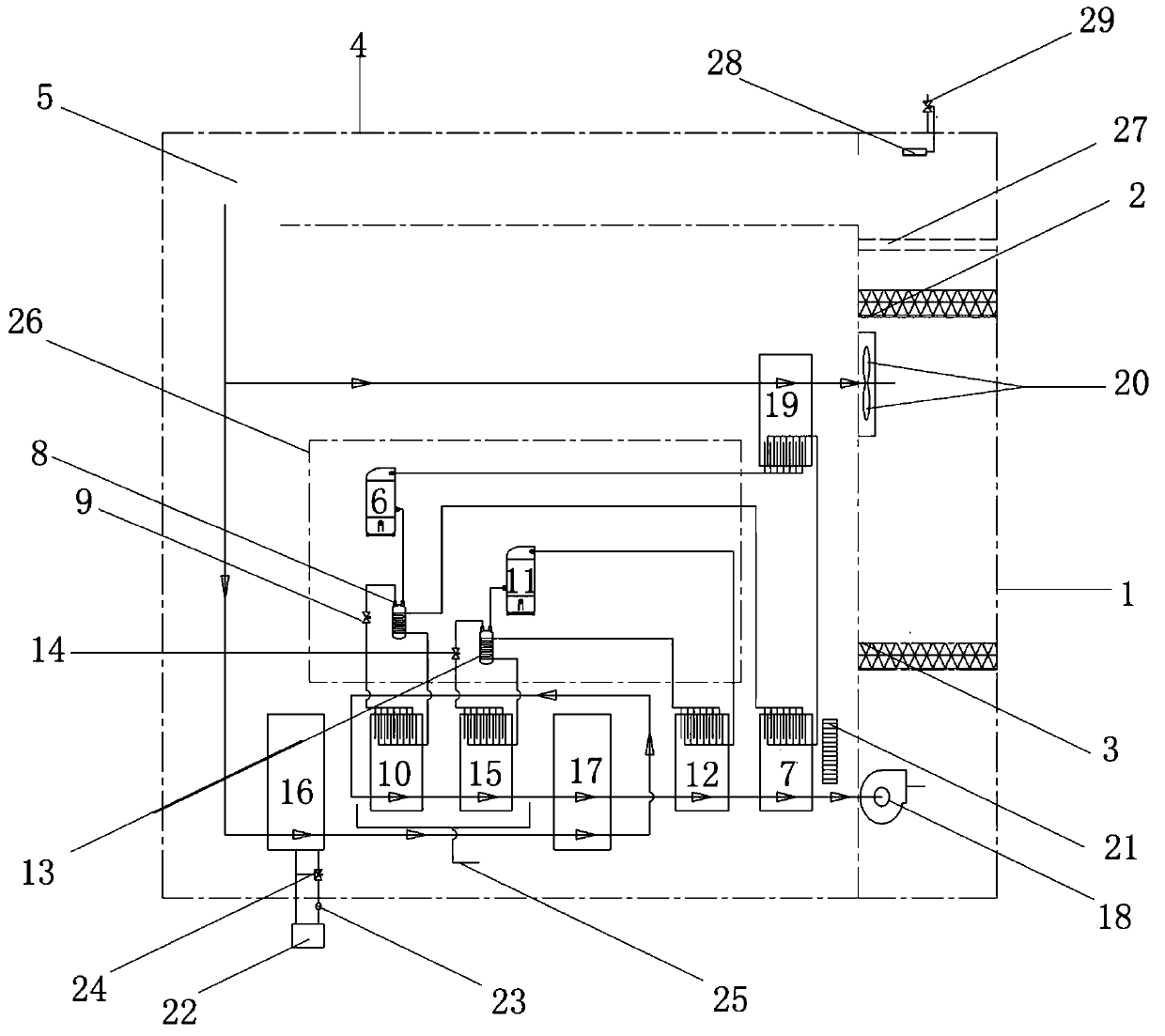

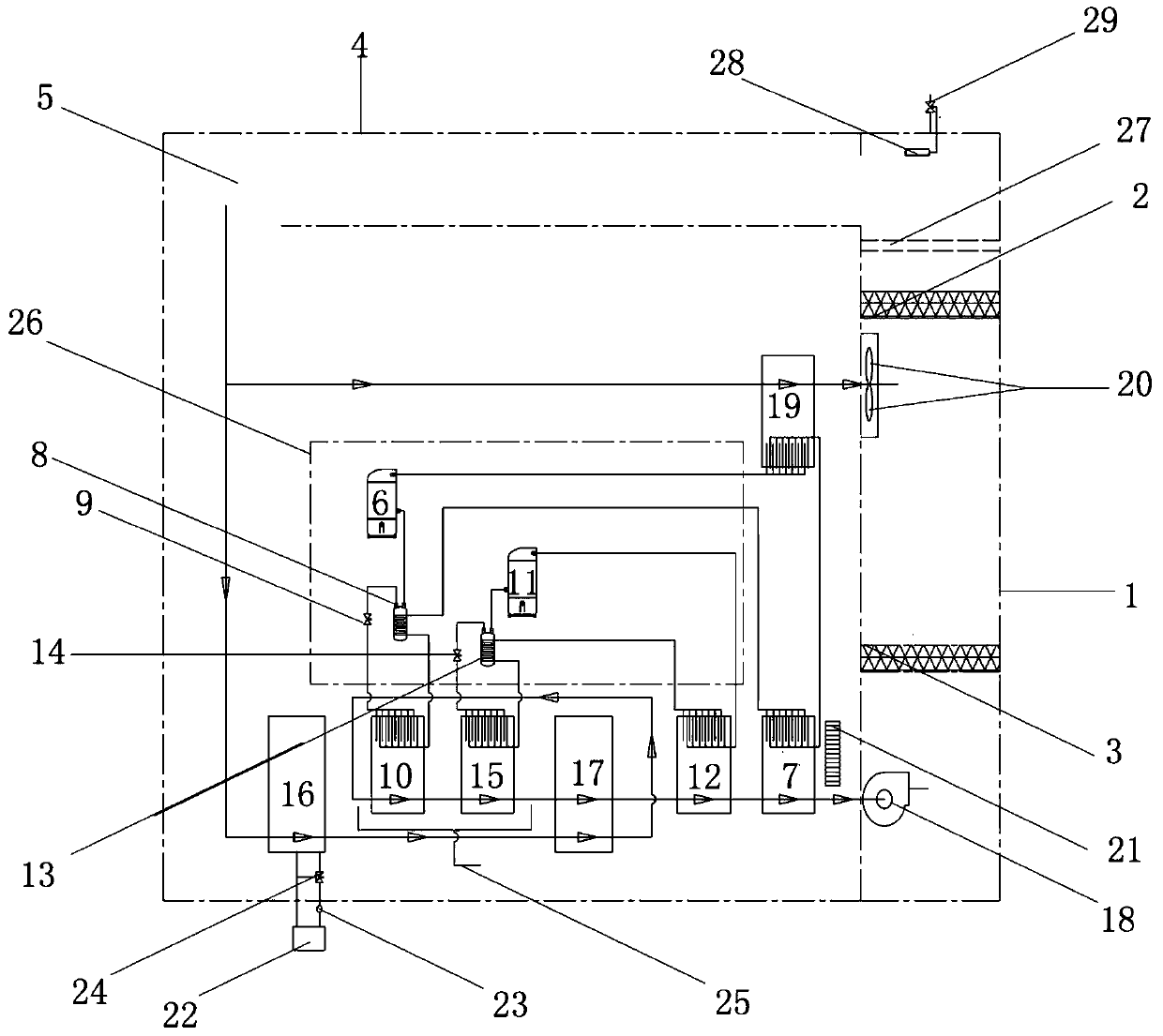

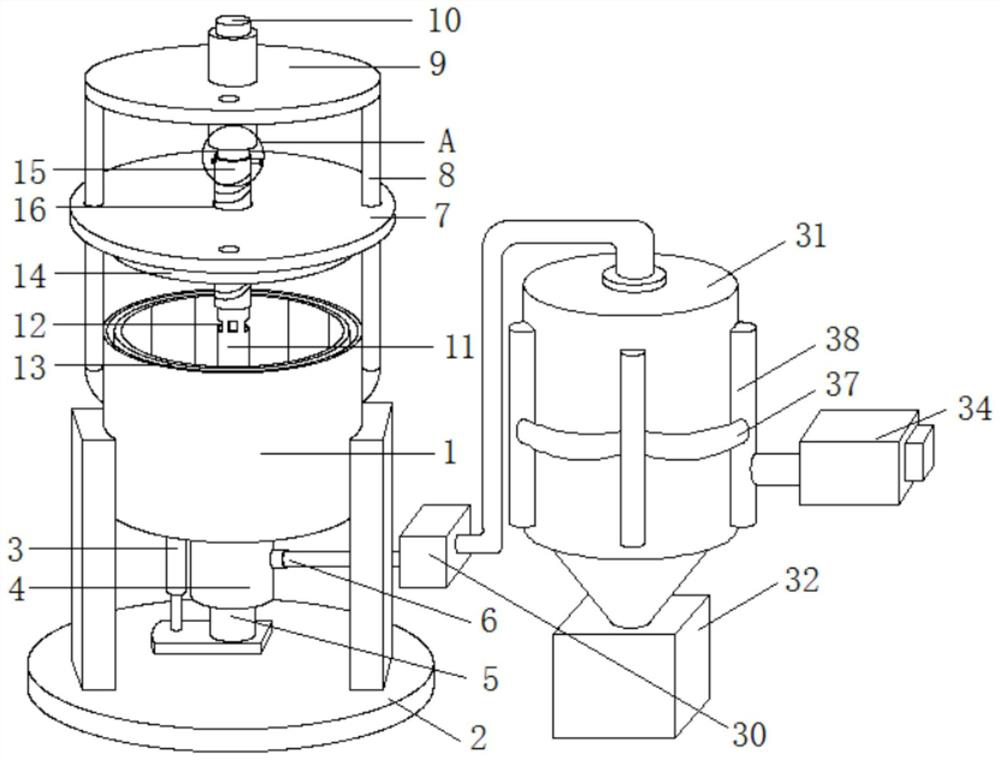

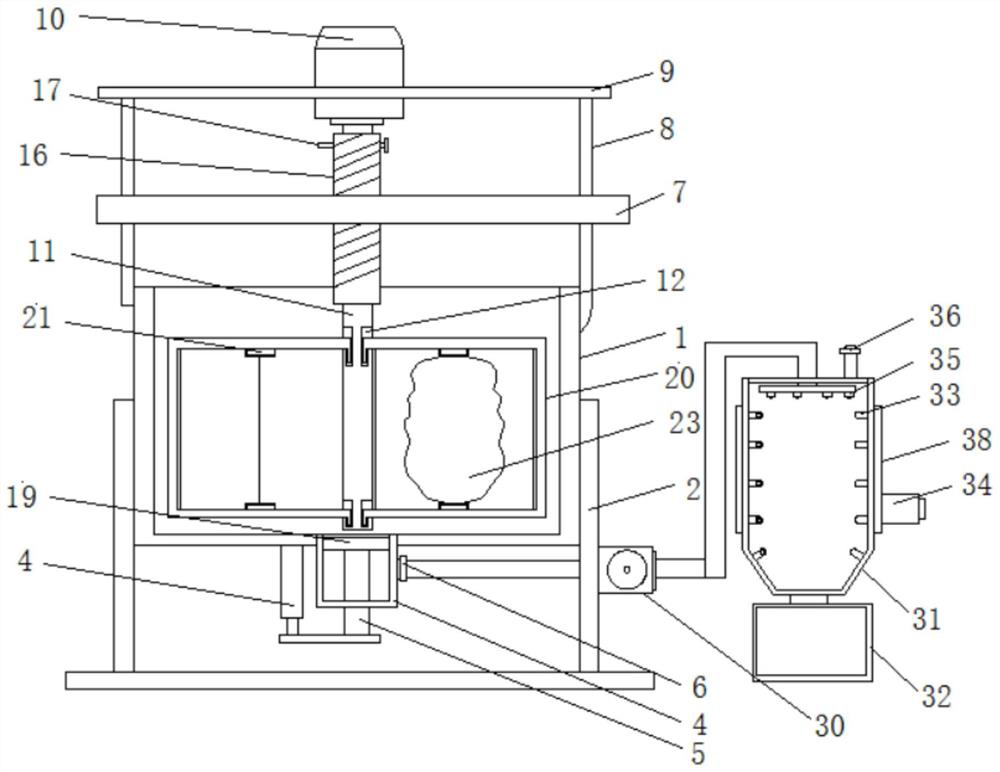

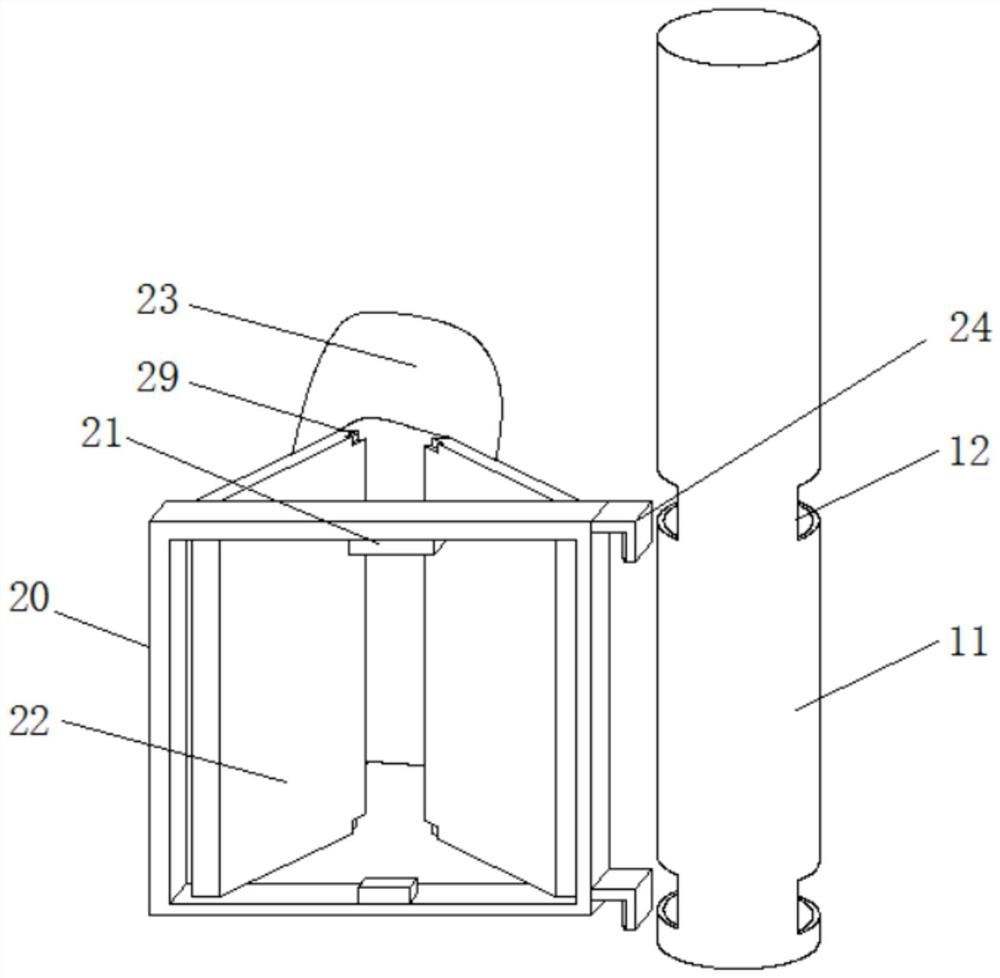

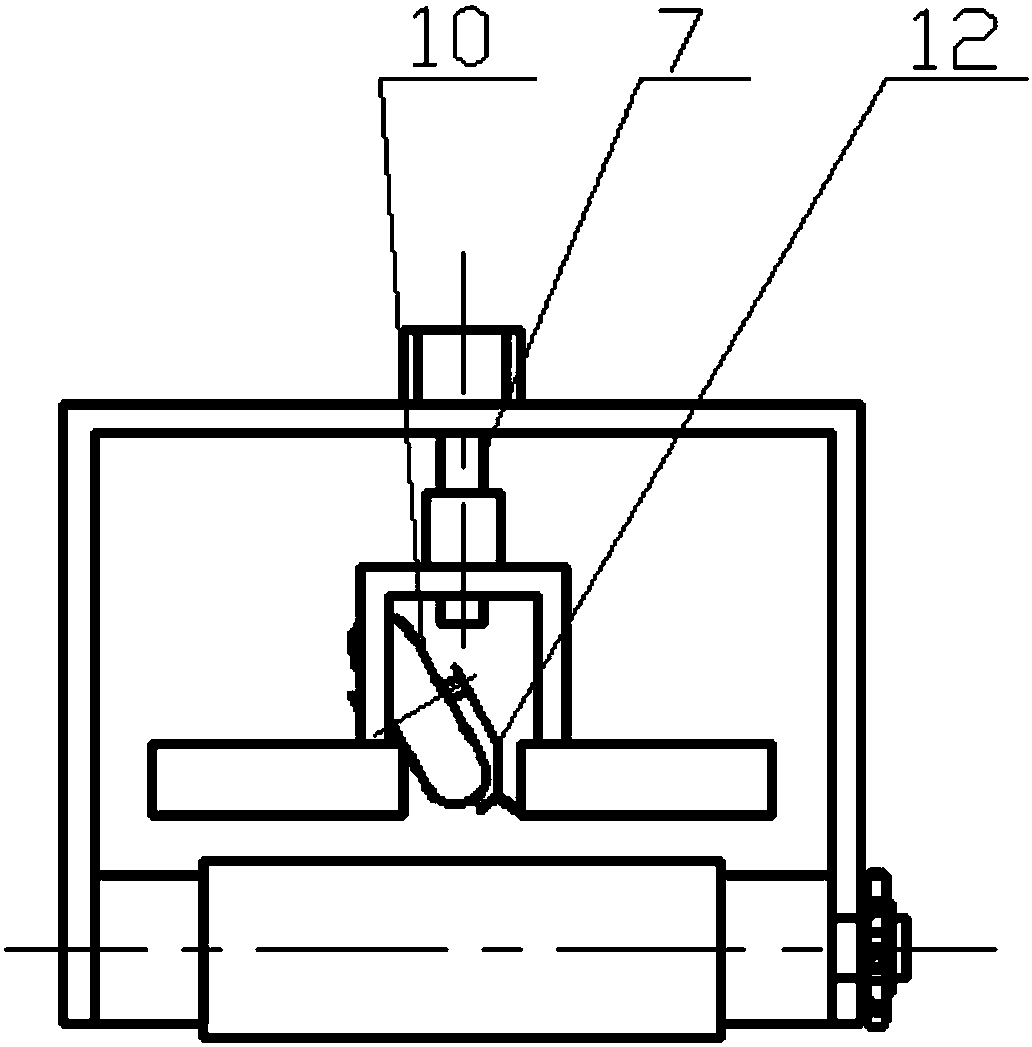

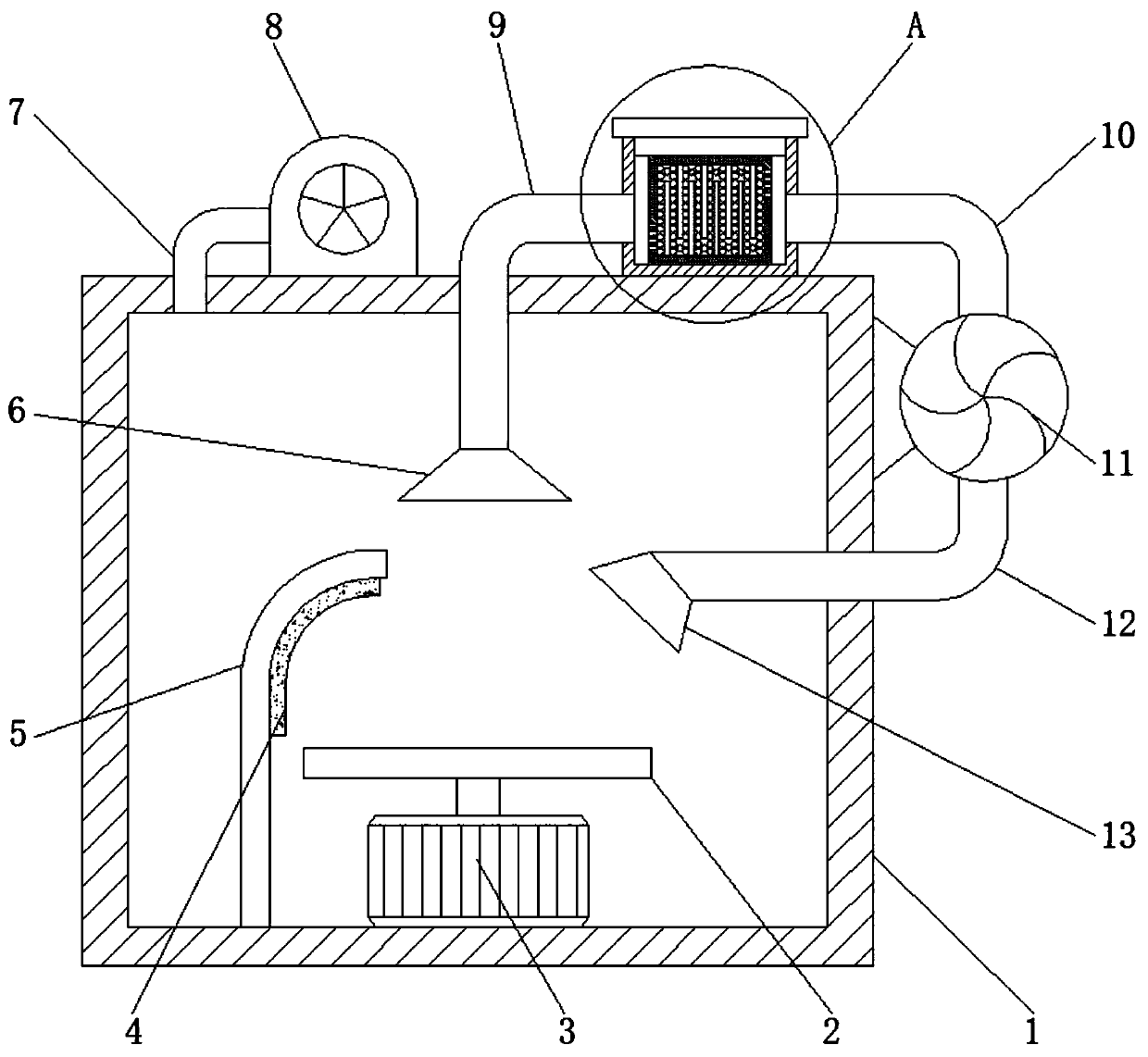

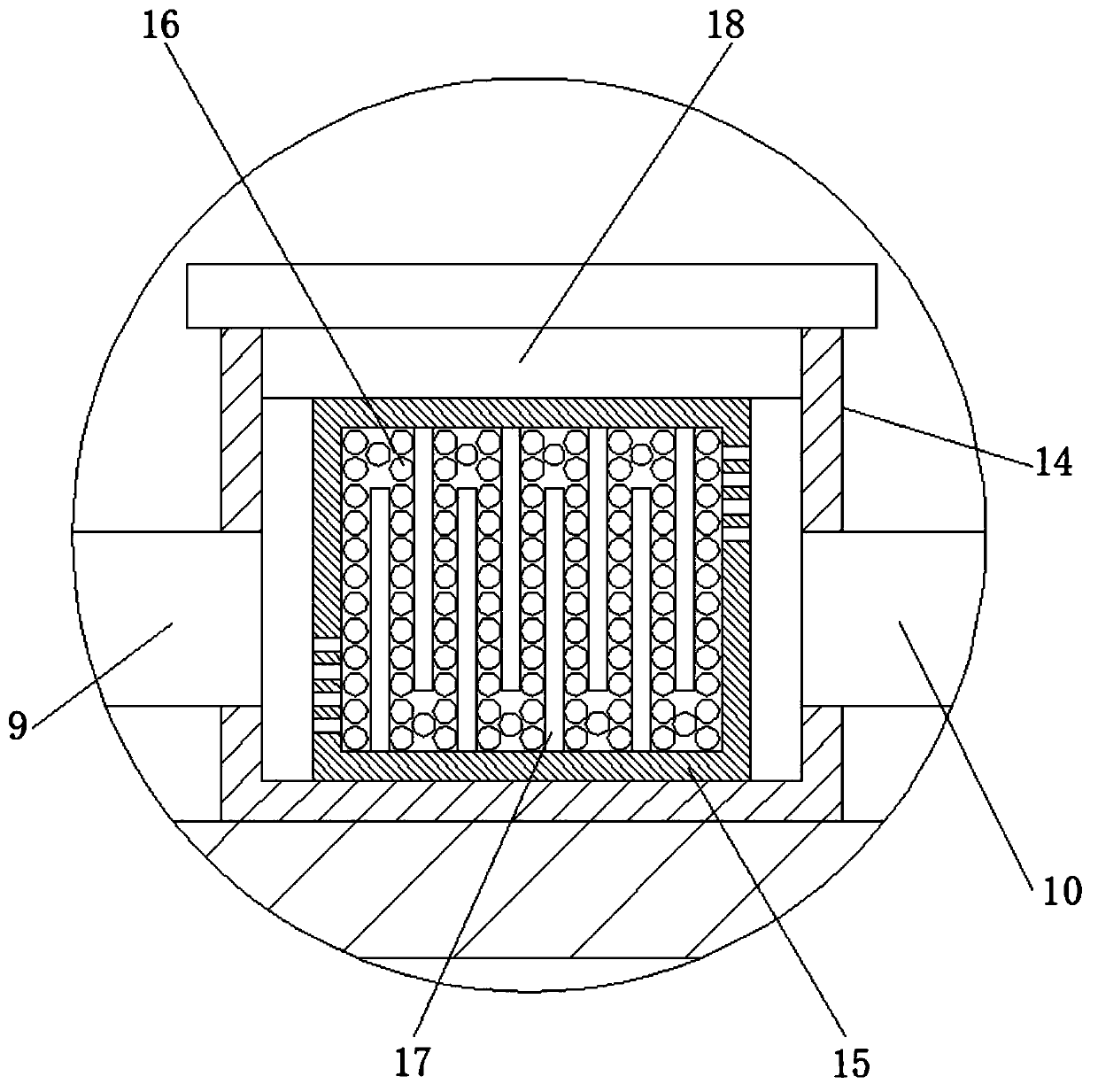

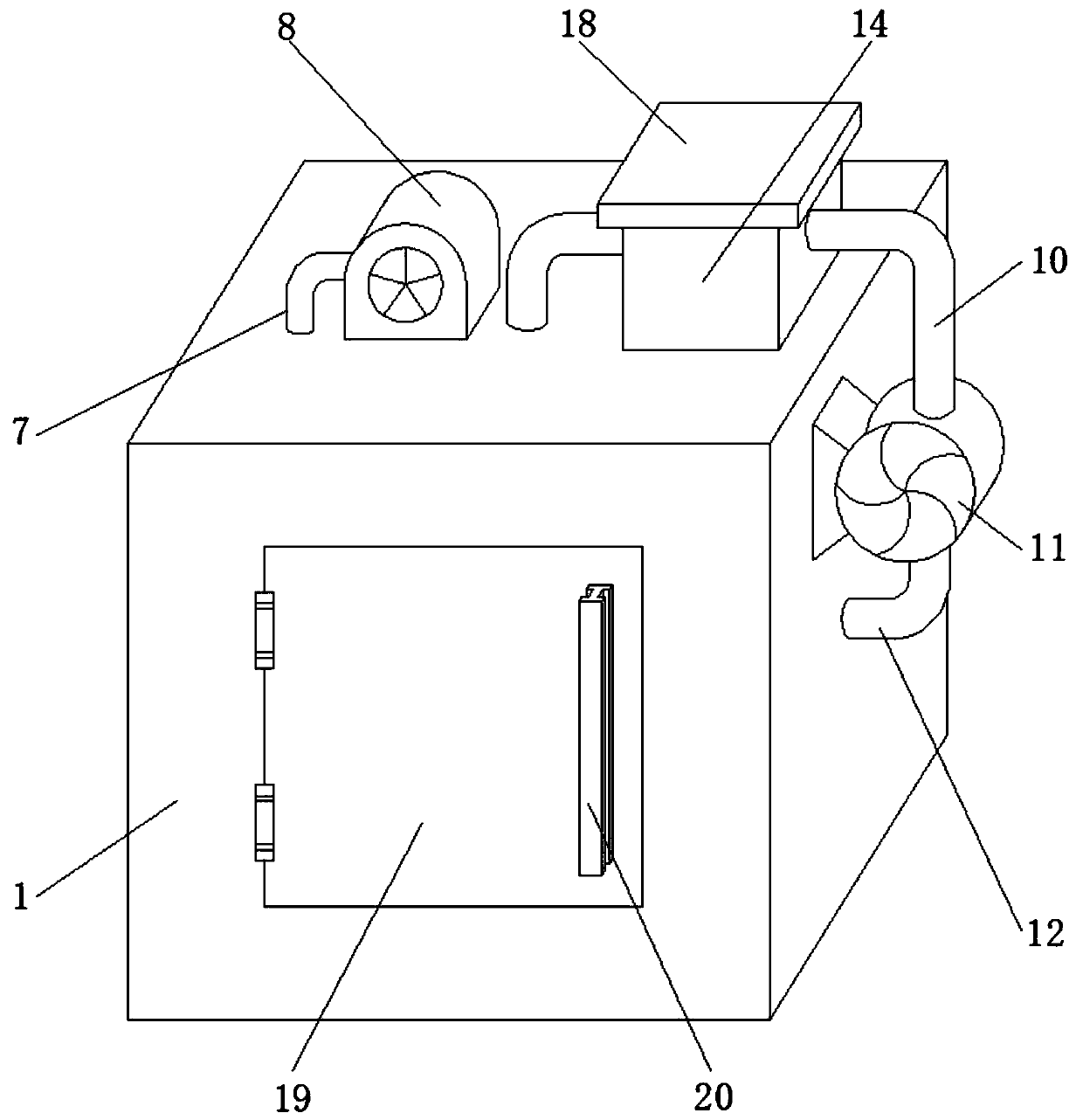

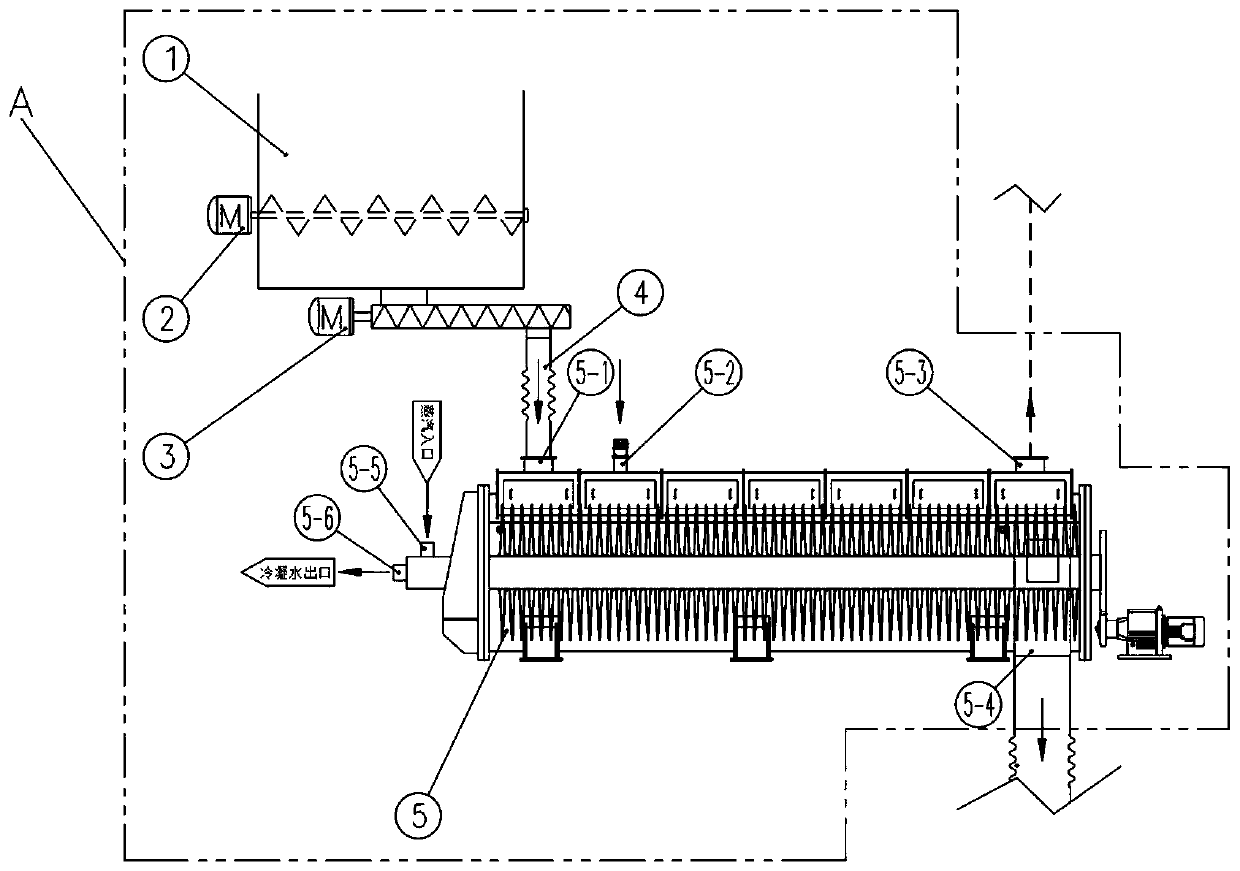

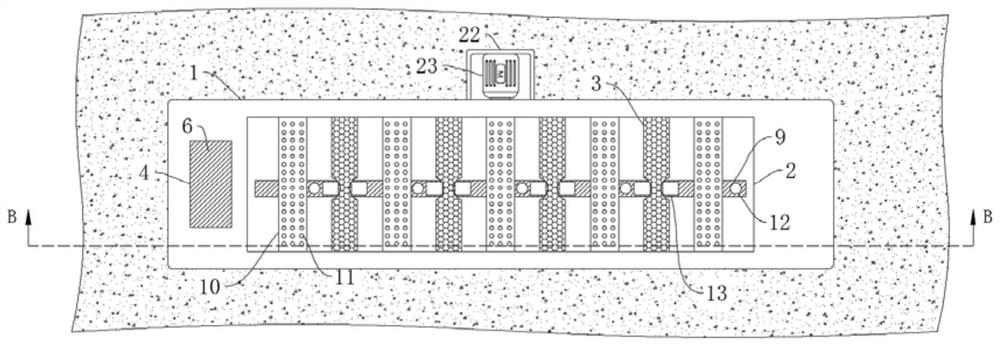

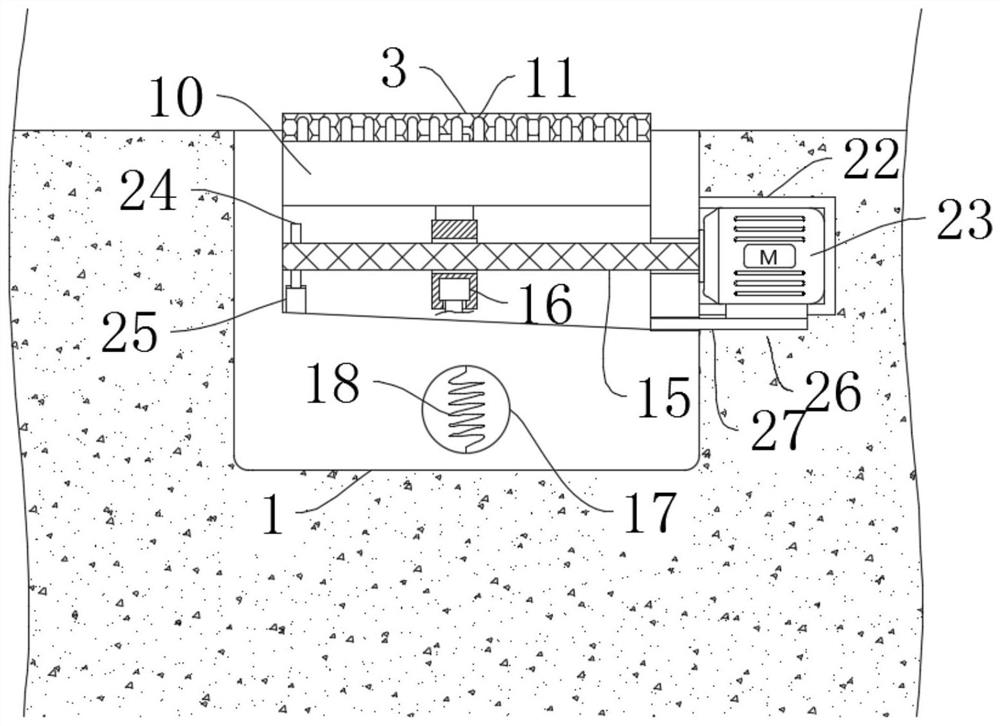

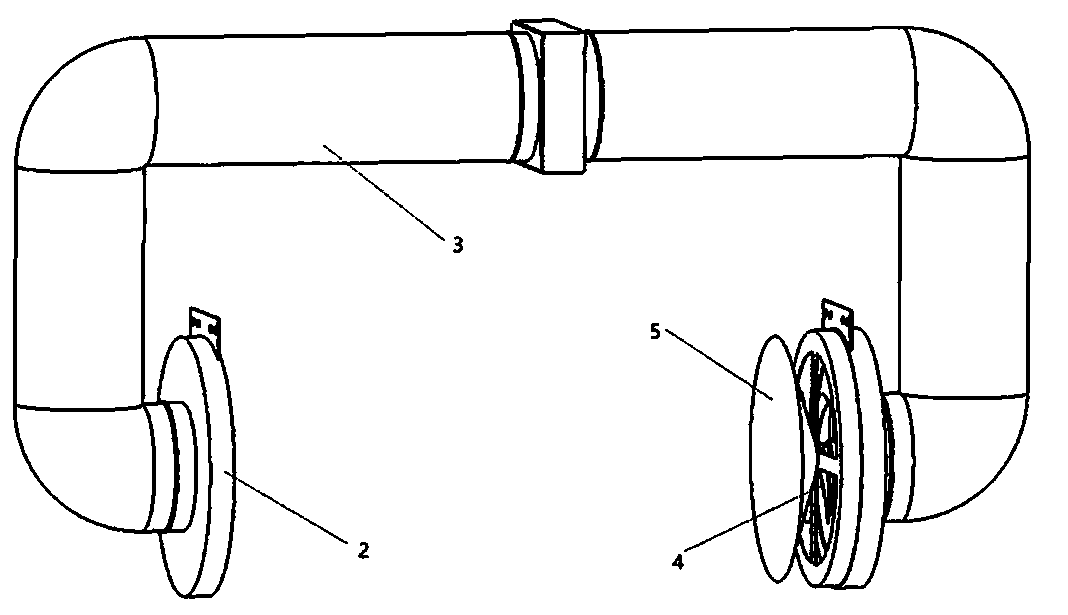

Heat pump type closed sludge drying system and control method of same

ActiveCN109553270AAvoid corrosionIncrease water evaporation rateSludge treatment by de-watering/drying/thickeningHeat pumpsEnvironmental resistanceSludge

A heat pump type closed sludge drying system comprises: a drying room (1), an upper conveyor belt (2) which is arranged on the upper part of the drying room and used for conveying sludge, and a lowerconveyor belt (3) which is arranged on the lower part of the drying room and used for conveying sludge. The heat pump type closed sludge drying system also comprises a system housing (4) at one side of the drying room (1), where the top of the drying room and the top of the system housing are connected to form an air return channel (5). A main air supply port, connected with the system housing, isformed in the side wall where the lower part of the lower conveyor belt is connected with the system housing. The system also includes a first heating circulation system, a second heating circulationsystem and an air flue circulation system that are arranged inside the system housing. The sludge drying system and the control method of same are energy-saving, environment-friendly and high-effective.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

Method for toasting a food product with infrared radiant heat

ActiveUS20080044167A1Faster toastingFaster and even toastingDomestic stoves or rangesDrying solid materials with heatThermal energyHeat penetration

A toaster uses radiant heat at infrared wavelengths optimized for producing rapid and uniform toasting of a food product. The infrared wavelengths of the radiated heat are selected for optimum speed and quality (browning and moisture content) of the food product. The selected infrared wavelengths of the radiated heat may also effectively defrost a food product. Defrosting of the food product by the infrared radiated heat adds very little time in obtaining a desired toast color to the food product. A plurality of infrared wavelengths of radiated heat may also be used, wherein the plurality of infrared wavelengths are selected for optimal heat penetration and surface browning of the food product. Shorter wavelengths for browning and slightly longer wavelengths to penetrate the food product for evaporating the moisture therein to allow surface browning by the shorter wavelengths. In addition, the heating energy within the toaster may be further elongated (longer wavelengths) once the infrared radiation is re-radiated off of reflectors within the toaster. The wavelengths of infrared radiated heat may be from about 1 to about 3 microns, and preferably from about 1.96 to about 2.5 microns, and most preferably at about 2.11 microns.

Owner:APPLICA CONSUMER PRODS

Air-drying method for improving quality of alfalfa

InactiveCN102228132AIncrease flow spaceHigh trafficDrying solid materials with heatAnimal feeding stuffLoss ratePositive interaction

The invention discloses an air-drying method for improving the quality of alfalfa. The method comprises the following steps of: 1) ridging; 2) selecting materials and treating; and 3) air-drying. The method has the advantages that: 1, the ridging increases the air flow space on the bottom of a grass layer; 2, the fracture of stalks accelerates the evaporation rate of the moisture in the stalks, so that the drying time is shortened; 3, the combination of field ridging and fracturing and air-drying of the stalks has a positive interaction effect on the loss of the moisture of fresh alfalfa forage; 4, the loss rate of the moisture of the fresh alfalfa forage is remarkably and negatively correlative with the residual amount of crude proteins in green hay; 5, the aims of accelerating the drying of the alfalfa, uniformly drying and improving the quality of the green hay are fulfilled; and 6, operation steps are simple and easy, the drying cost is low, and the efficiency is high.

Owner:GANSU AGRI UNIV

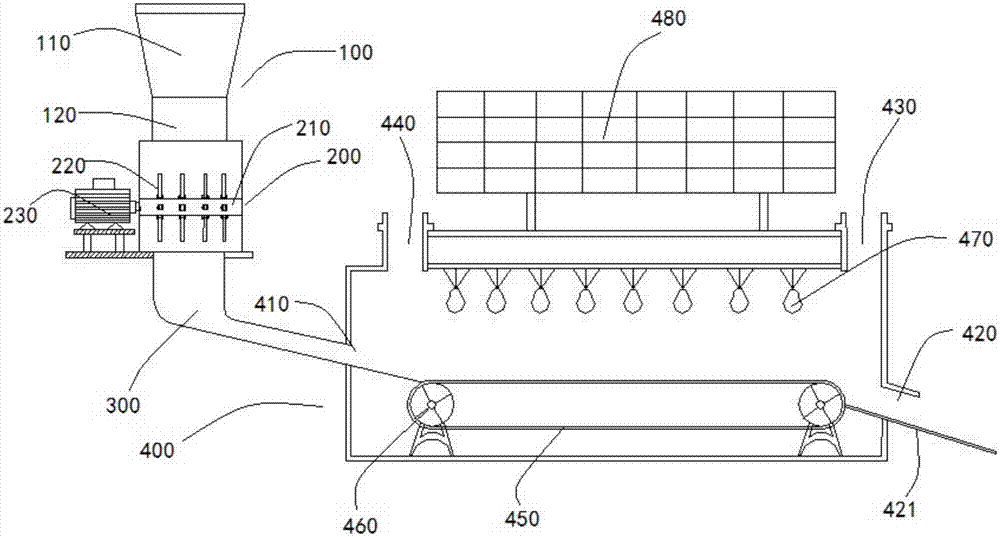

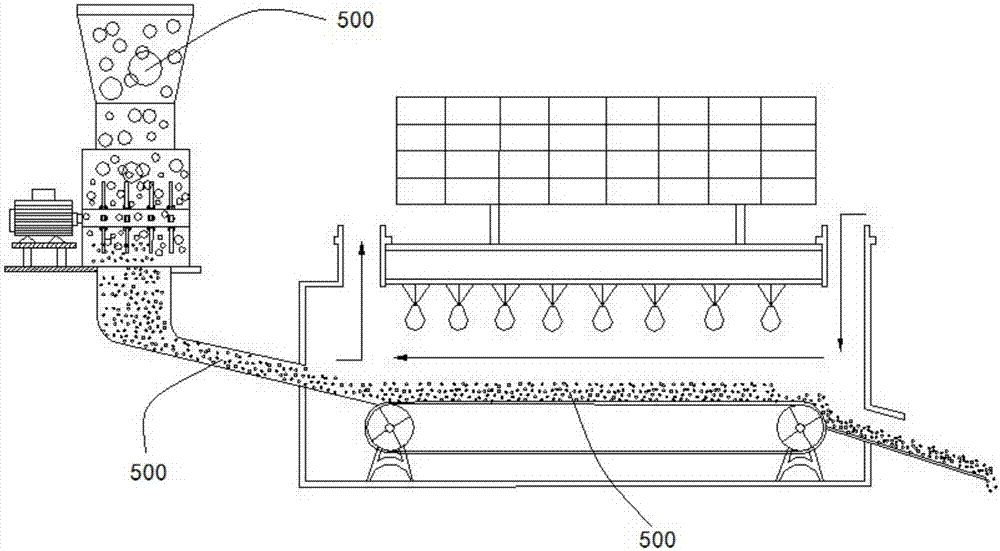

Environment-friendly energy-saving type solid waste treatment device

InactiveCN106918198AFast dryingImprove efficiencyDrying machines with progressive movementsGrain treatmentsFertilizerDrive motor

The invention discloses an environment-friendly energy-saving type solid waste treatment device, and relates to the field of solid waste treatment equipment. The device comprises a feeding mechanism, a breaking mechanism, a first pipeline and a drying mechanism which are sequentially connected in series, the drying mechanism comprises an upper cover, a lower cover, a left wall and a right wall, the drying mechanism is a hollow cavity, a feeding opening is formed in the left wall, and is connected with the first pipeline, the right wall is provided with a discharging opening, the upper cover comprises an air inlet and an air outlet, the drying mechanism internally comprises a conveying belt used for conveying fertilizer and a driving wheel used for driving the conveying belt, the driving wheel is connected with a drive motor and is driven by the drive motor, an electronic radiation infrared heater is arranged on the inner side of the upper cover of the drying mechanism, and is located above the conveying belt, and a solar cell panel providing energy for the electronic radiation infrared heater is arranged on the outer portion of the upper cover of the drying mechanism. The problem that during existing solid waste treatment, incineration or landfill efficiency is poor is solved.

Owner:成都君华睿道科技有限公司

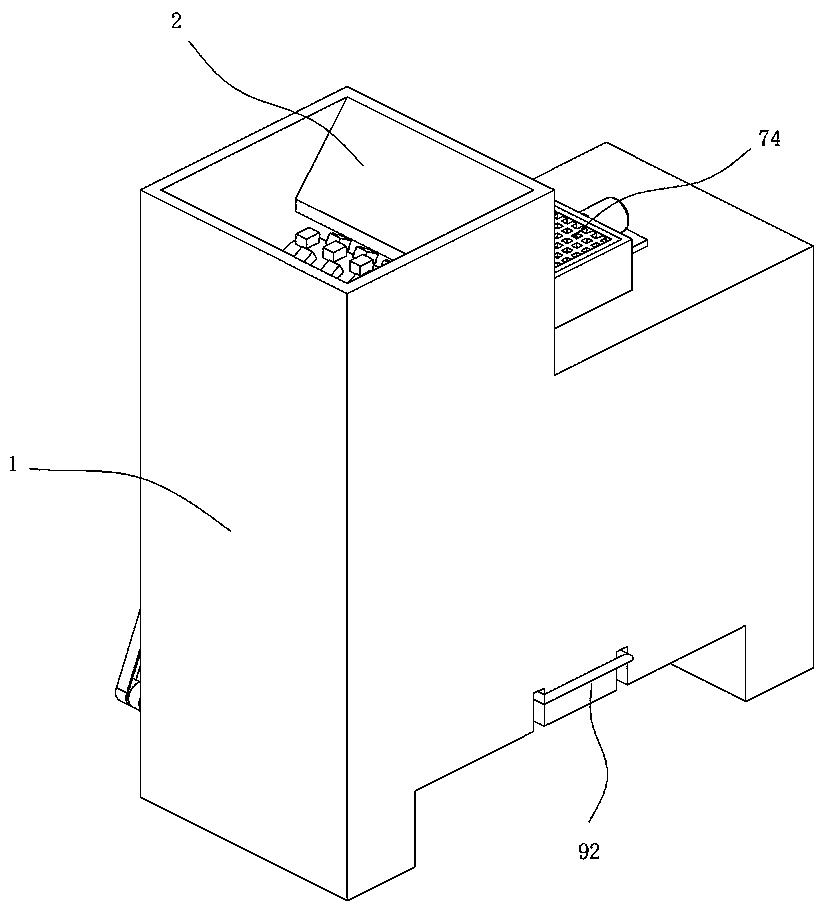

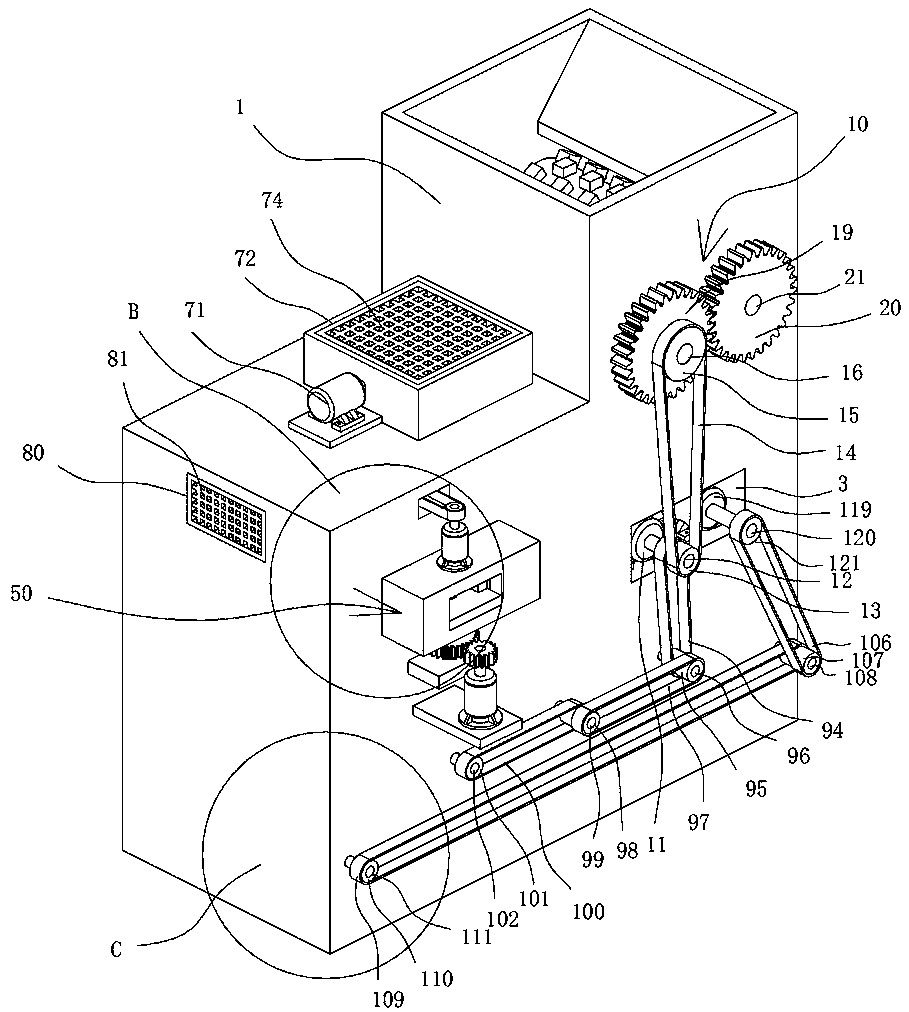

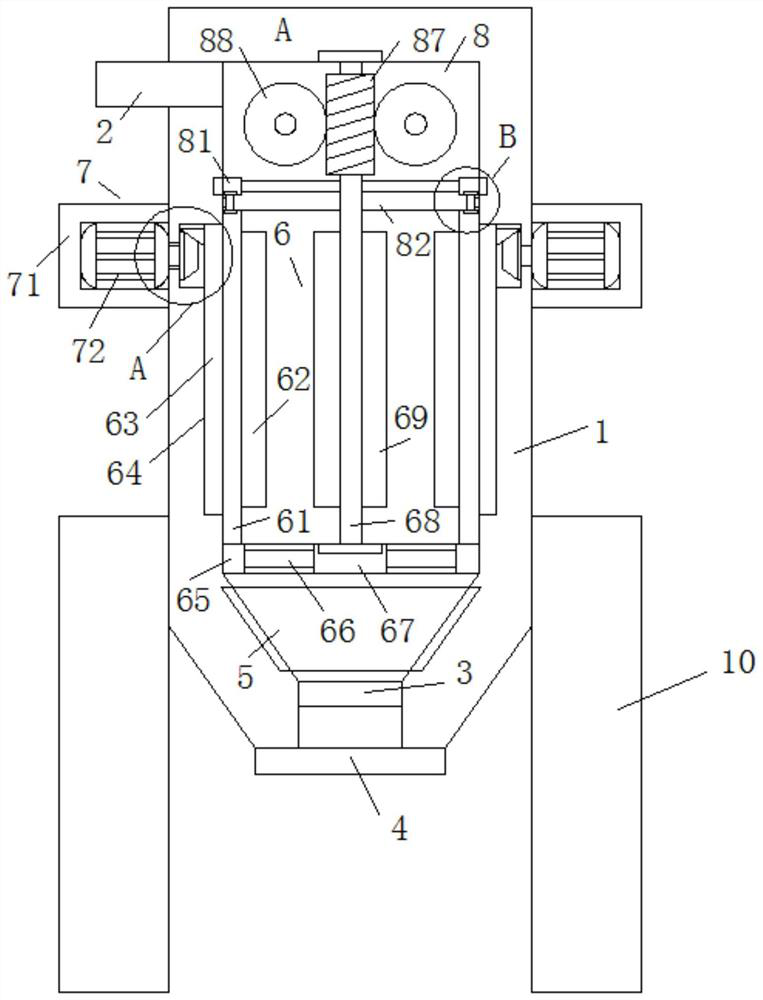

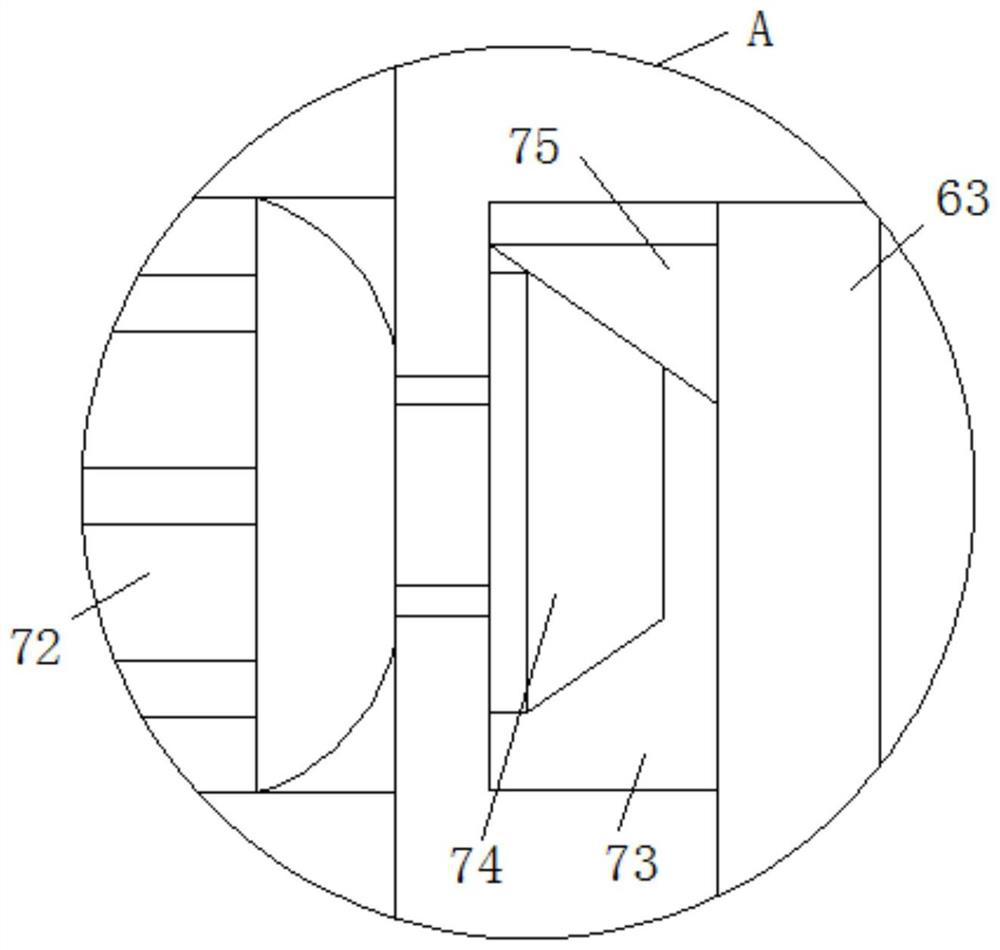

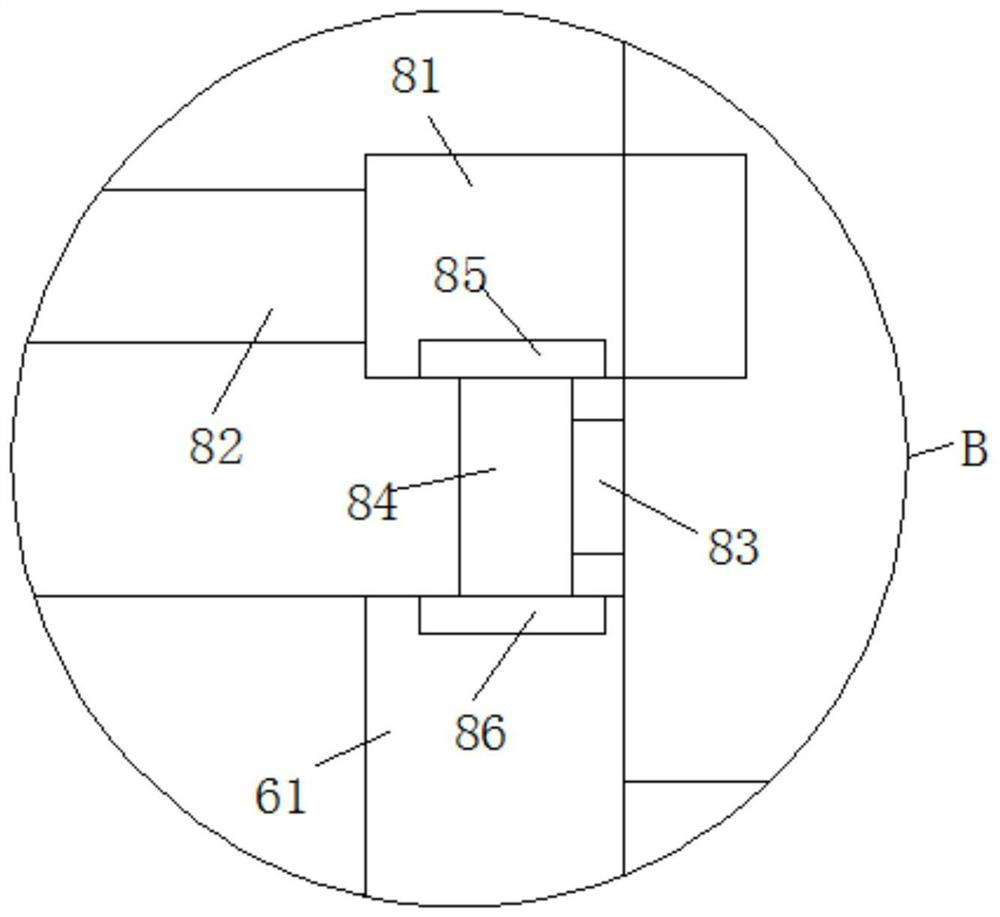

Efficient traditional Chinese medicine smashing equipment

ActiveCN111282645AReduce loadImprove crushing efficiencyRotary stirring mixersTransportation and packagingMedicinal herbsPharmacy medicine

The invention discloses efficient traditional Chinese medicine smashing equipment. The equipment comprises a rack. The upper end of the rack is provided with a feeding port, the lower side of the feeding port is provided with a crushing mechanism, and the middle of the rack is provided with a slide. The right end of the slide is provided with a smashing mechanism, the middle of the smashing mechanism is provided with an adjustment assembly with a particle size adjustment function, and the middle of the rack is provided with a drying mechanism. The lower end of the rack is provided with a storage mechanism with a stirring function, the front end of the storage mechanism is provided with a lifting assembly, and the front end of the rack is provided with a power cavity. The efficient traditional Chinese medicine smashing equipment has the advantages that the smashing mechanism with a smashing gap adjustment function is used for smashing the crushed medicinal material through a rotatable smashing head, the height of the smashing head is controlled to adjust the minimum size of medicine particles, and the application range of the equipment is enlarged.

Owner:海南诚耕健康产业有限公司

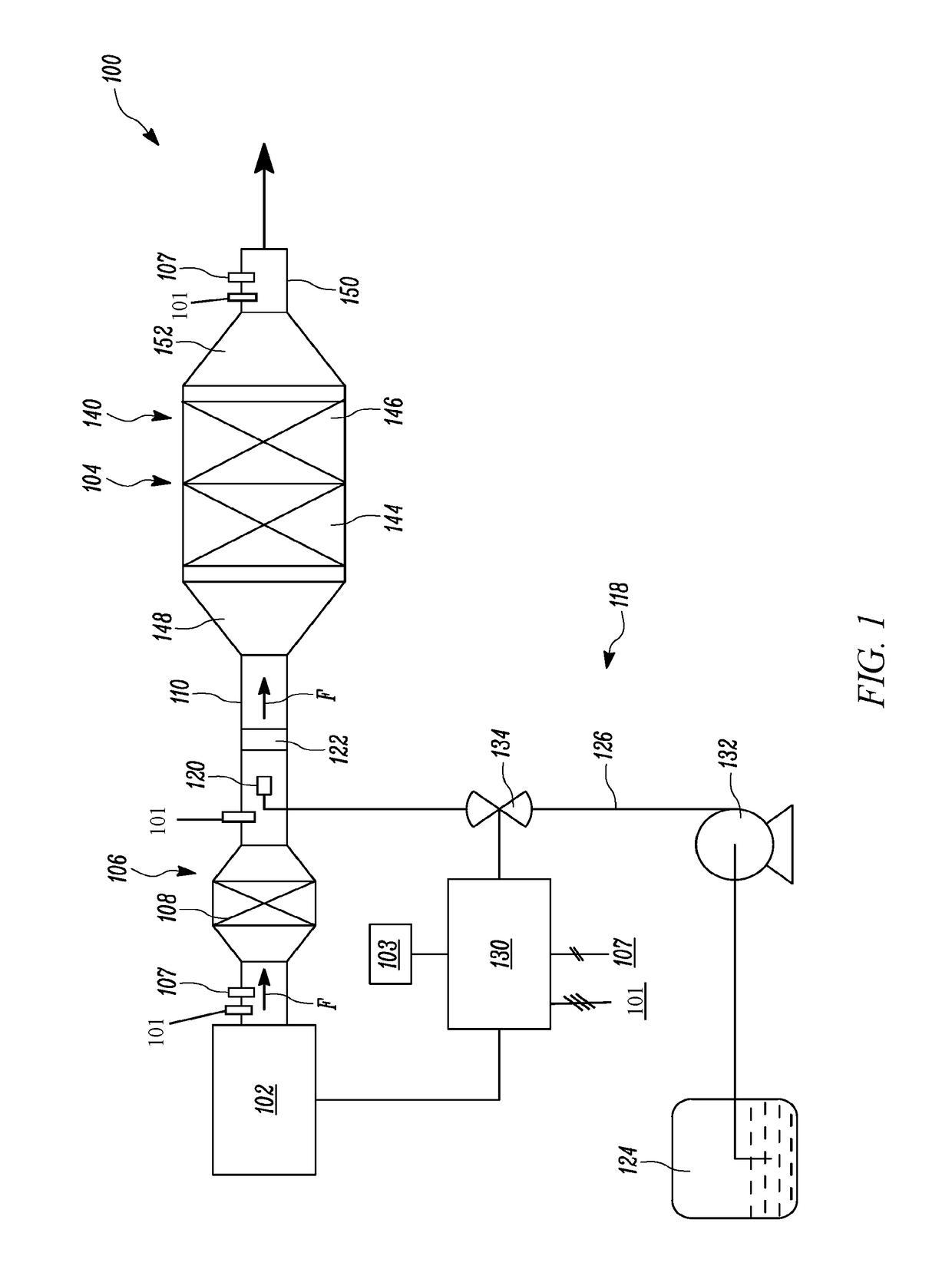

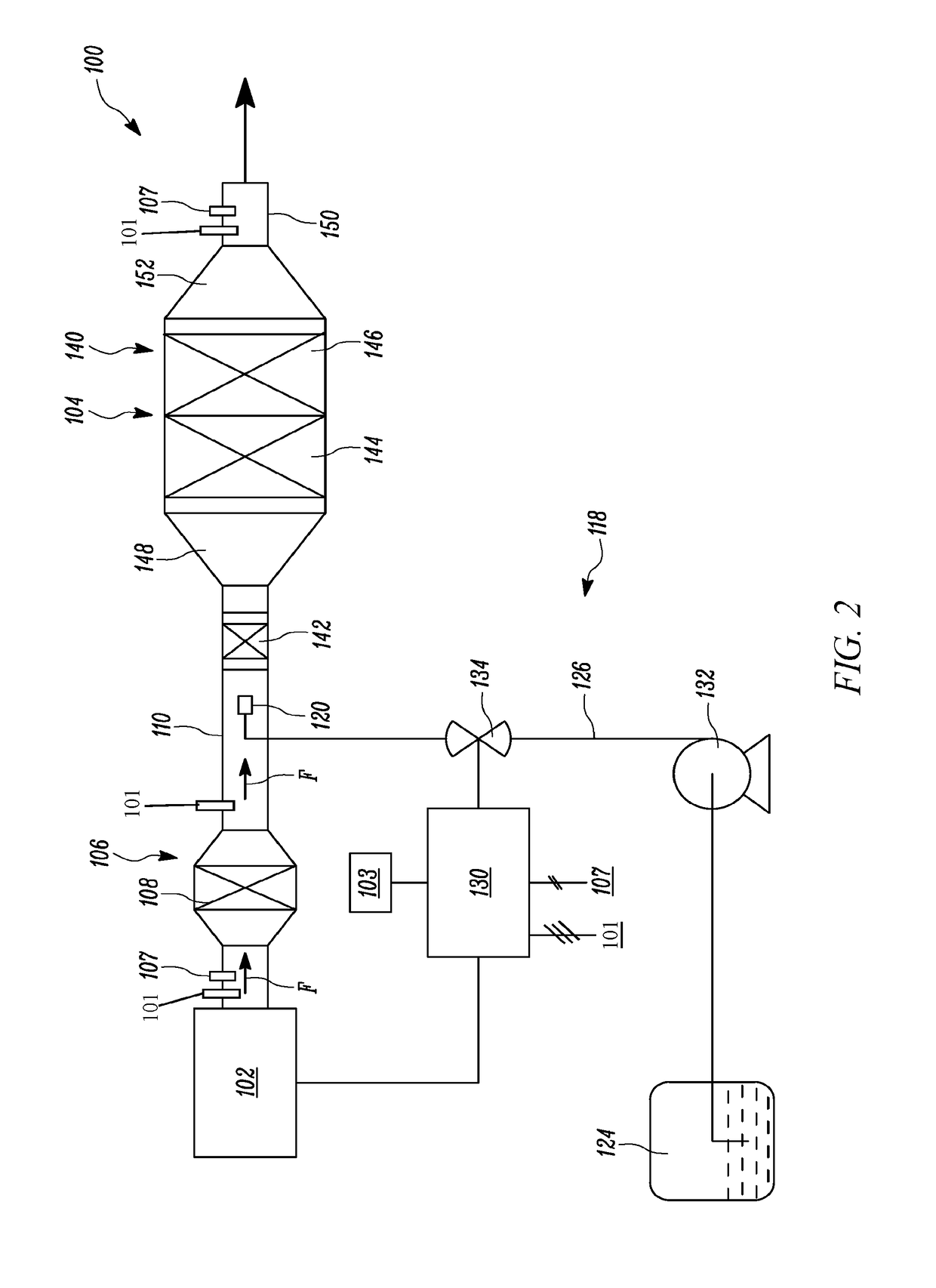

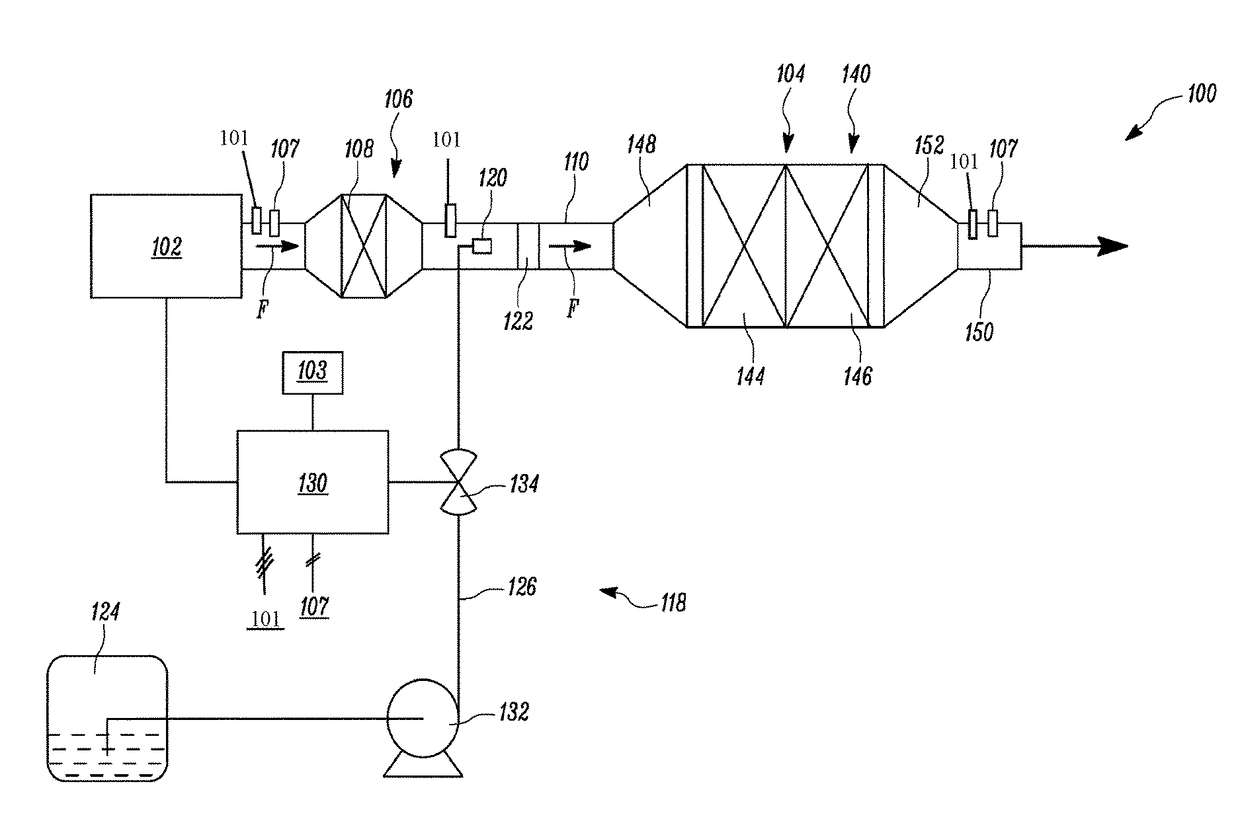

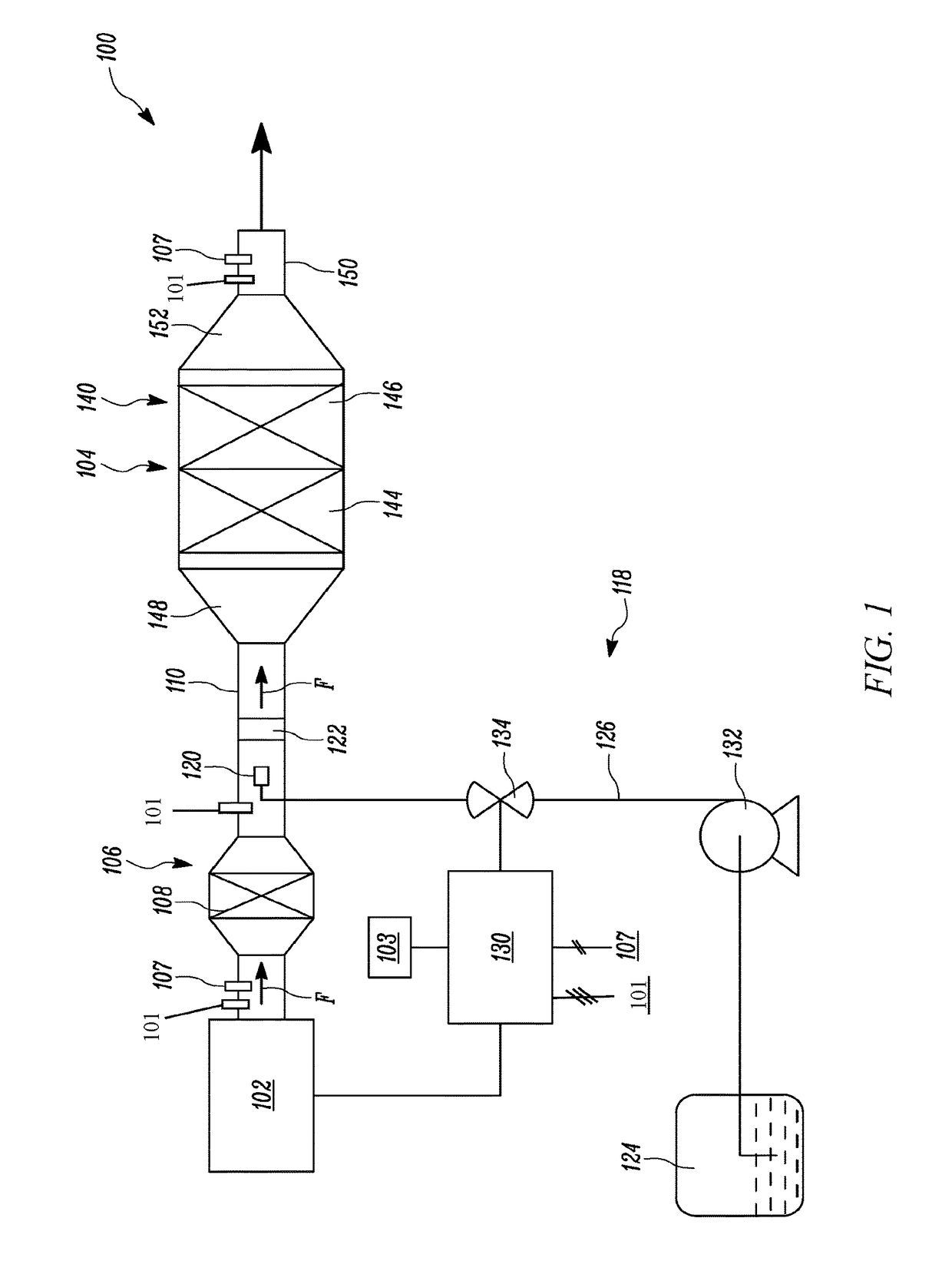

System, apparatus, and method to address unwanted def-based deposits in diesel exhaust system

ActiveUS20170292430A1Increase heightImprove heat transfer performanceGas treatmentInternal combustion piston enginesEvaporationDiesel exhaust fluid

An exhaust system for a diesel engine is provided. The exhaust system includes a component body with a surface, and a surface treatment disposed on some of the surface or all of the surface. The surface treatment is disposed so as to receive Diesel Exhaust Fluid (DEF) injected into the exhaust system during operation of the diesel engine. The surface treatment facilitates increased heat transfer to the received DEF to promote water evaporation and urea thermolysis of the received DEF.

Owner:CATERPILLAR INC

System, apparatus, and method to address unwanted DEF-based deposits in diesel exhaust system

ActiveUS9890682B2Improve heat transfer performanceSimple structureGas treatmentInternal combustion piston enginesEvaporationDiesel exhaust fluid

An exhaust system for a diesel engine is provided. The exhaust system includes a component body with a surface, and a surface treatment disposed on some of the surface or all of the surface. The surface treatment is disposed so as to receive Diesel Exhaust Fluid (DEF) injected into the exhaust system during operation of the diesel engine. The surface treatment facilitates increased heat transfer to the received DEF to promote water evaporation and urea thermolysis of the received DEF.

Owner:CATERPILLAR INC

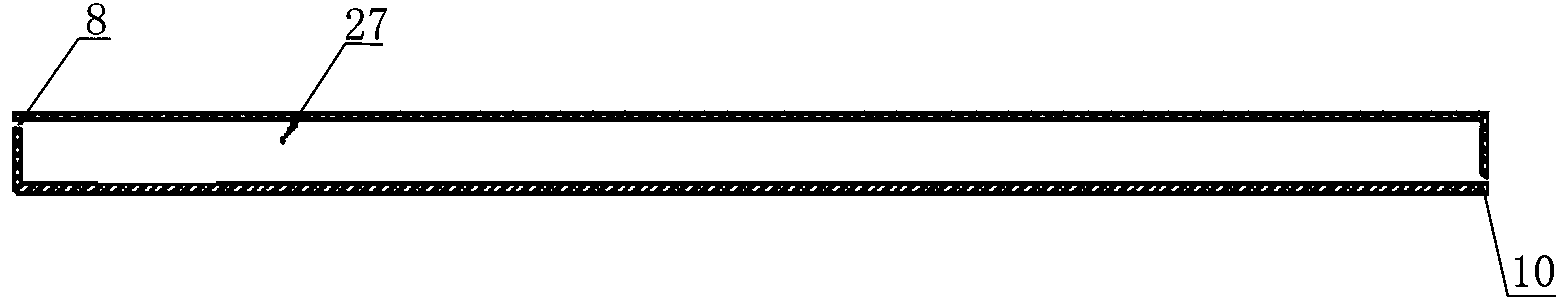

Steam direct pressure type drying device of veneer materials

InactiveCN104006634AFast dryingReduce heat lossDrying gas arrangementsDrying machines with local agitationLiquid waterWater storage tank

The invention discloses a steam direct pressure type drying device of veneer materials. The steam direct pressure type drying device of the veneer materials comprises a drying oven, a steam boiler and a steam air supply pipe connecting the drying oven and the steam boiler. A horizontally arranged drying frame is arranged in the drying oven, the top layer and the bottom layer of the drying frame are an upper pressure bearing limiting plate and a lower pressure bearing limiting plate which are made of steel plates respectively, a connecting rod is arranged between the limiting plates and fixedly connected with the limiting plates, enclosed hollow heating plates made of stainless steel sheets are arranged between the limiting plates at intervals in parallel, the side edges of all layers of heating plates are fixedly connected with the connecting rod, a steam inlet connecting pipeline is arranged on the same side face of the heating plates and is communicated with the boiler steam air supply pipe, a gas-liquid inlet connecting pipeline is arranged on the other side face of the heating plates and is communicated with a gas-liquid water outlet pipe, and the gas-liquid water outlet pipe is communicated with a water storage tank. According to the steam direct pressure type drying device of the veneer materials, the heat energy for drying the materials is transmitted to the materials through the steam and is separated from the materials only through a thin layer of stainless steel sheet, and pressure is directly provided by the steam, so that a mechanism for providing pressure and energy consumption are omitted, the device is compact in structure, and the defects that an existing device is high in manufacturing cost and large in energy consumption are overcome.

Owner:黄达宏

Method for improving production efficiency of rice cracker employing microwave and hot air combined drying

InactiveCN104431802AIncrease productivitySpeed up evaporationFood shapingFood preparationMicrowaveProcess engineering

The invention discloses a method for improving production efficiency of a rice cracker employing microwave and hot air combined drying, and belongs to the technical field of processing of rice puffed leisure foods. The method has the characteristics that formed green bodies of the rice cracker adopt a novel microwave and hot air combined drying process; rapid rise of internal temperature of the rice cracker is achieved by using the characteristics of internal microwave heating and high heating rate; meanwhile, the balance of mass and heat transfer of the green bodes in the drying process is enhanced by adopting forced convective drying of hot air; the moisture in the green bodies is rapidly and uniformly reduced to 12%-15% required for late baking from about 40% under the combined drying action; the drying time is shortened to tens of minutes from several hours, and thus the target of improving the production efficiency of the rice cracker is achieved; in addition, the microwave drying has a certain puffing effect on materials; the puffing degree of the rice cracker can be further improved; the product quality of the rice cracker is finally improved, and therefore, through the method for drying the green bodies of the rice cracker employing the microwave combined with hot air, so that the drying time can be shortened; the energy consumption for production is reduced; and the product quality is improved.

Owner:FUWA GROUP

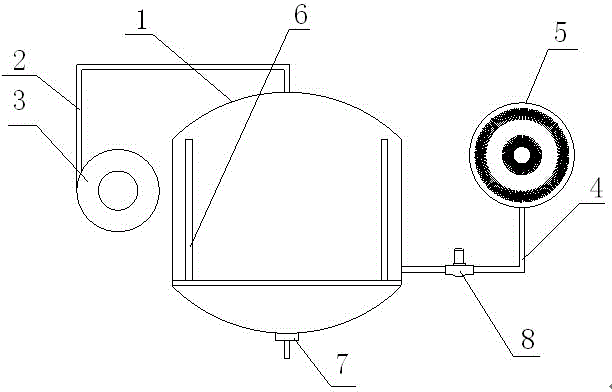

Heat pump type closed sludge drying system

PendingCN110028219AAvoid corrosionReduce operating powerSludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention relates to a heat pump type closed sludge drying system, which comprises a drying room (1), an upper layer conveying belt (2) arranged on the upper portion of the drying room and used for conveying sludge, and a lower layer conveying belt (3) arranged on the lower portion of the drying room and used for conveying sludge, wherein the heat pump type closed sludge drying system furthercomprises a system shell (4) arranged on one side of the drying room, the top portion of the drying room is connected to the top portion of the system shell to form a wind return channel (5), a main wind supply port is formed on the side wall, connected to the system shell, below the lower layer conveying belt, and is connected to the system shell, the heat pump type closed sludge drying system further comprises a first heat generation circulation system, a second heat generation circulation system and a wind channel circulation system, and the first heat generation circulation system, the second heat generation circulation system and the wind channel circulation system are arranged in the system shell. According to the present invention, the heat pump type closed sludge drying system hasadvantages of energy saving, environmental protection, high efficiency and the like.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

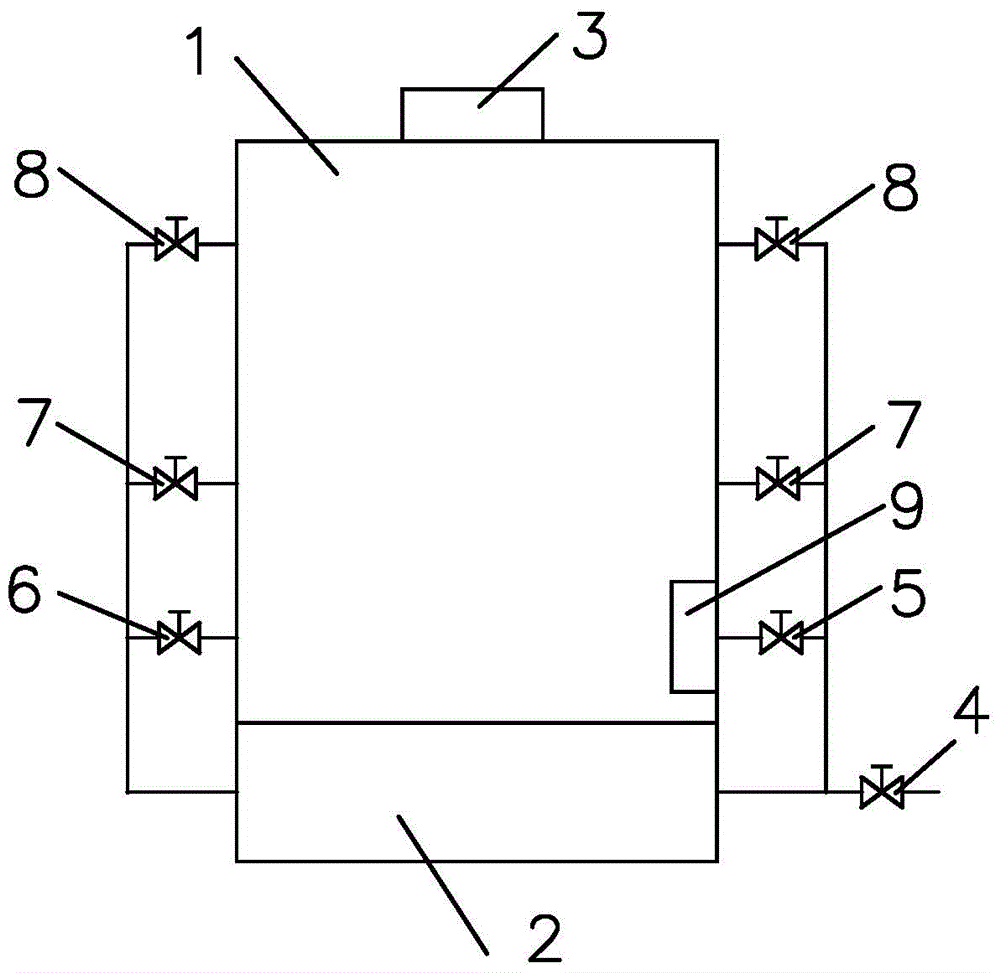

Negative pressure drying device

InactiveCN104958059AIncrease water evaporation rateImprove drying efficiencyTextiles and paperFootwear cleanersEngineeringMoisture

The invention relates to the field of drying devices, in particular to a negative pressure drying device. The negative pressure drying device comprises a box body. A negative pressure pump is arranged below the box body and connected to a controller on the box body. The box body is communicated with the air inlet end of the negative pressure pump through a valve. The box body is internally provided with a plurality of sets of convection holes corresponding to one another in position. The convection holes in the same set are correspondingly connected to the air inlet end and the air outlet end of the negative pressure pump through valves respectively, and an annular circulating channel is formed. The air outlet end of the negative pressure pump is connected to an exhaust port in the box body through a valve. The controller is sequentially connected with valves in the box body and controls the valves. The drying device for clothes, shoes and life articles provides a vacuum negative pressure drying area, increases the moisture evaporation rate of the clothes and improves the drying efficiency.

Owner:GUANGXI UNIV

Methods and means to collect water vapors

InactiveUS20070090202A1Increase water evaporation rateIncrease condensation rateLiquid surface applicatorsGeneral water supply conservationSprinkler systemCollection system

Owner:HSIA CHIH YU

Extracting and processing device for traditional Chinese herbal solution and preparation method for Chinese patent medicine

ActiveCN112717545APrevent outflowUniform stirring and mixingSolid solvent extractionFiltration circuitsPharmaceutical drugProcess engineering

The invention relates to the field of processing of traditional Chinese medicines, in particular to an extracting and processing device for a traditional Chinese herbal solution. The extracting and processing device comprises a storage mechanism, a driving mechanism, a conveying mechanism and a concentrating mechanism,wherein the upper end of the storage mechanism is connected with the driving mechanism; the lower end is connected with the concentrating mechanism through a transportation mechanism; the storage mechanism comprises a preparation kettle, a sealing cover, a top plate, a plurality of sliding rods annularly arranged on the outer side of the preparation kettle and an electric heating wire arranged on the inner wall of the preparation kettle; an opening is formed in the upper end of the preparation kettle; the sealing cover seals the opening; the top plate is arranged at the upper end of the sealing cover; and the upper ends of the plurality of sliding rods penetrate through the sealing cover and are connected with the bottom periphery of the top plate. Compared with the prior art, the extracting and processing device of the invention has the following advantages: a herbal residue filtering and purifying speed is higher, efficiency is higher, suspended solids in liquid and large-diameter herbal residues can be conveniently, rapidly and synchronously filtered, and the problems that during medicine purification, heating and purifying time is long and medicine effect is prone to being damaged by continuous high temperature are solved.

Owner:江尔成

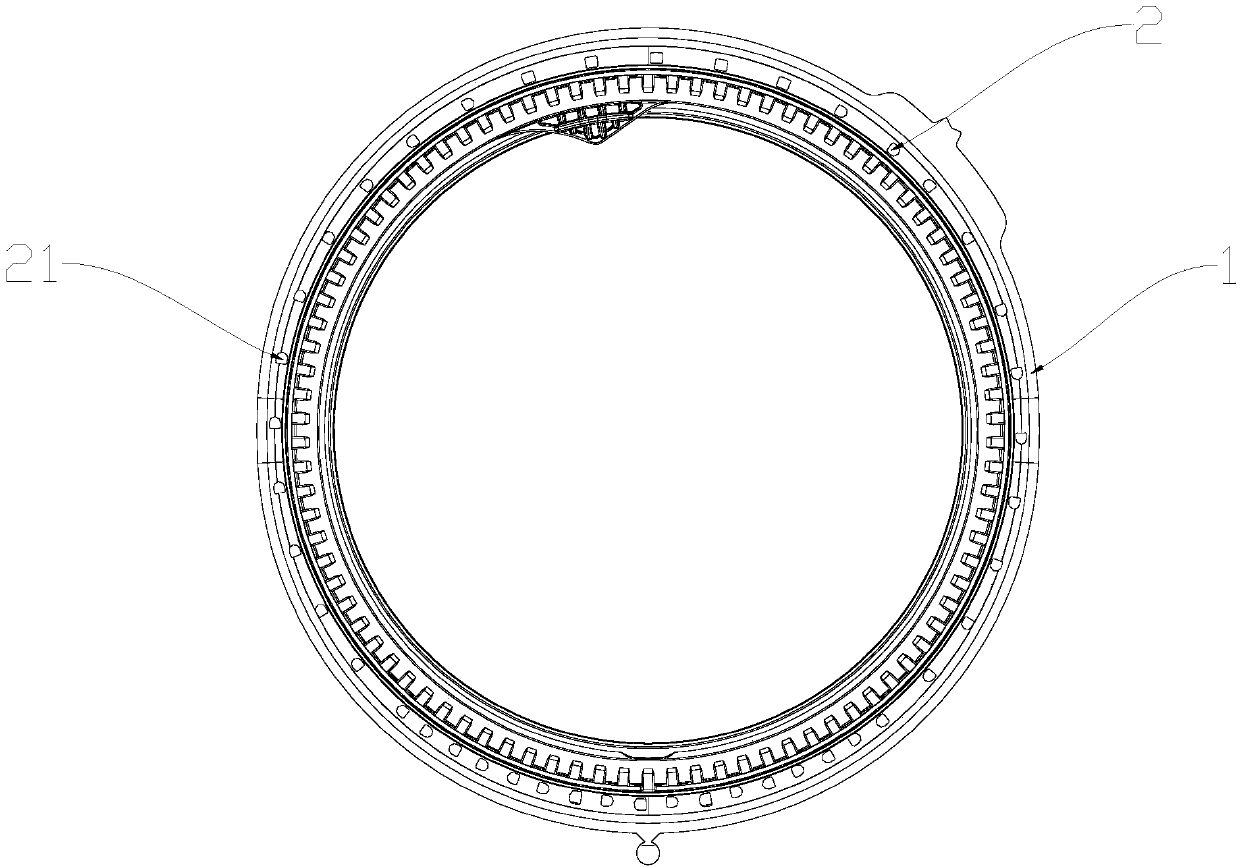

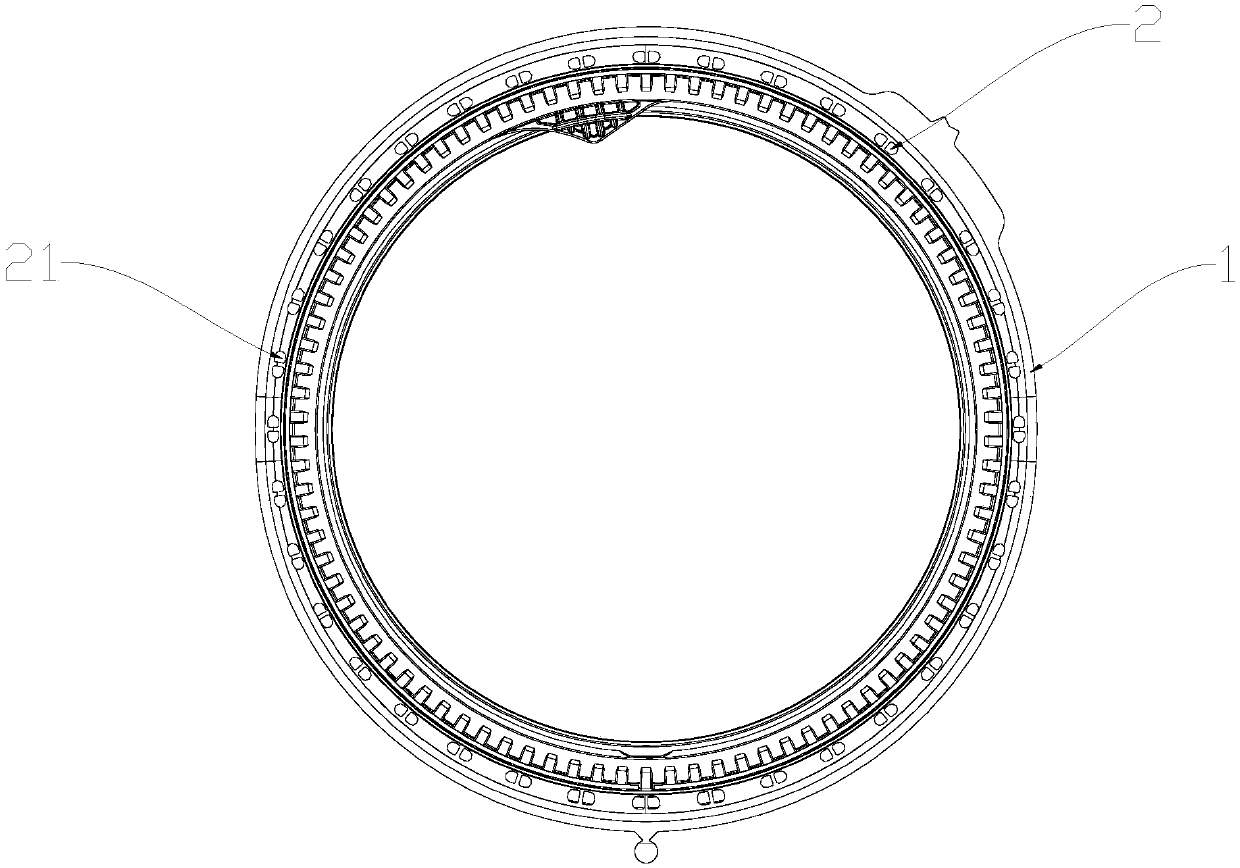

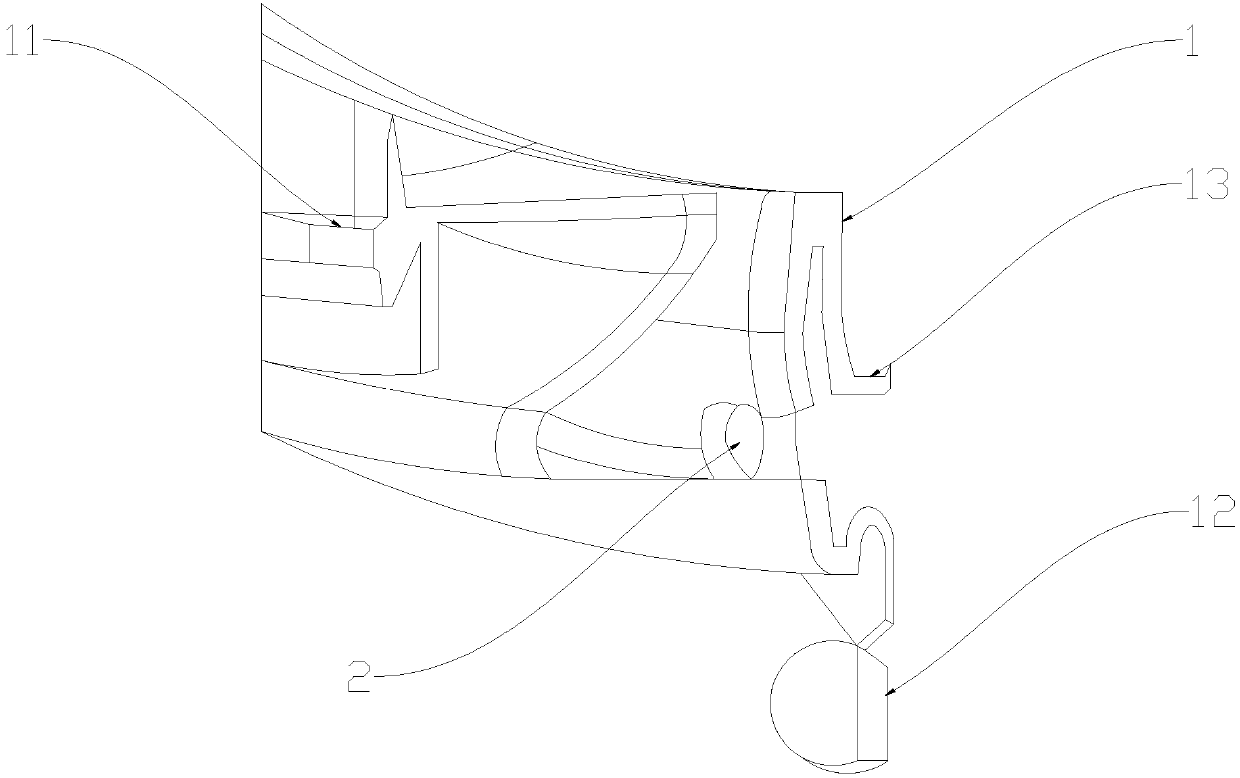

Ventilation structure for clothing treatment equipment and clothing treatment equipment

ActiveCN110093745AAvoid wet conditionsAvoid odorOther washing machinesTextiles and paperForeign matterEngineering

The invention relates to the technical field of clothing treatment equipment, and specifically provides a ventilation structure for the clothing treatment equipment and clothing treatment equipment, aiming at solving the problem that the window mats of existing clothing treatment equipment are prone to odor and bacteria. Therefore, the clothing treatment equipment comprises a box body, an outer cylinder fixed in the box body and an inner cylinder rotatably contained in the outer cylinder; a clothing throwing port is arranged on the box body; a window mat is arranged between the clothing throwing port and the outer cylinder; the ventilation structure includes ventilation holes, which are arranged on the window mat so that when the inner cylinder rotates, the air flow passes through the ventilation holes to air-dry the interior of the window mat. The clothing treatment equipment of the present invention includes the ventilation structure. The invention adopts the above ventilation structure to air-dry the window mat in the form of ventilation, avoids the foreign matter accumulated in the window mat to produce odor and breed bacteria, avoids secondary pollution to the cleaned matter,avoids influence on the health of the user, and improves the user's use experience.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

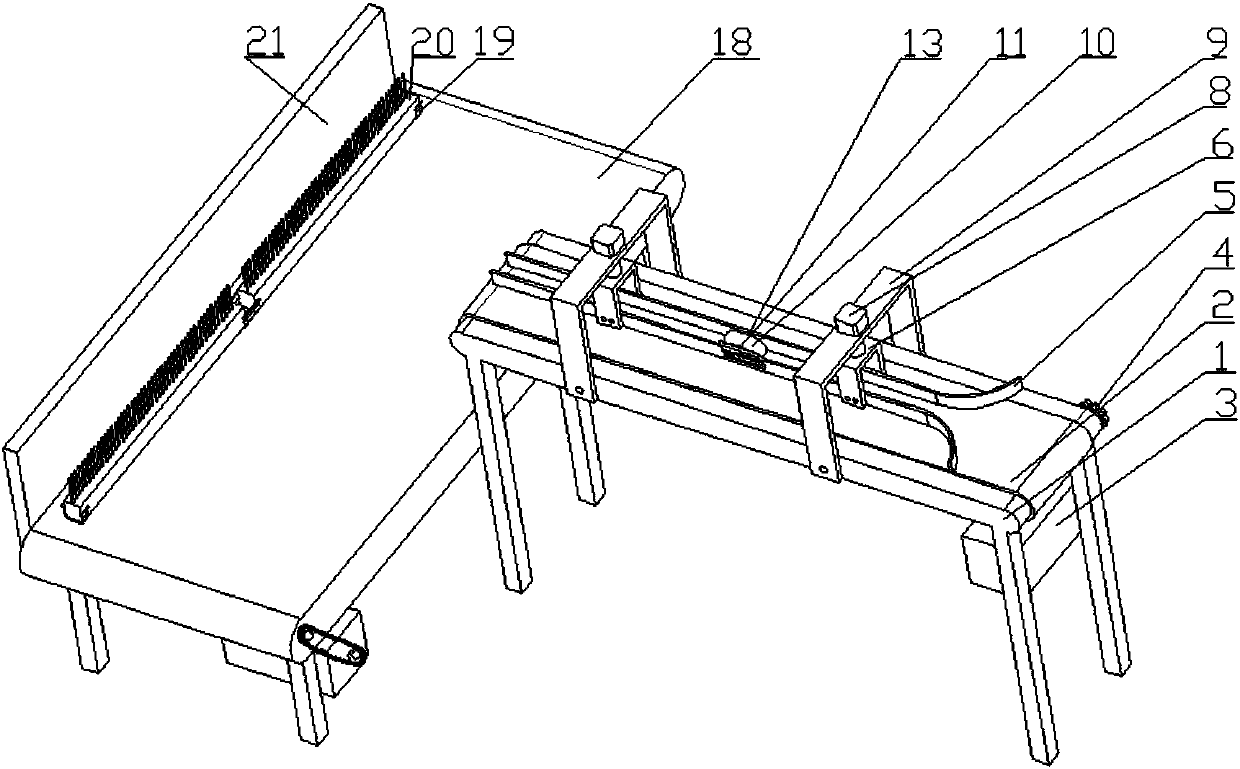

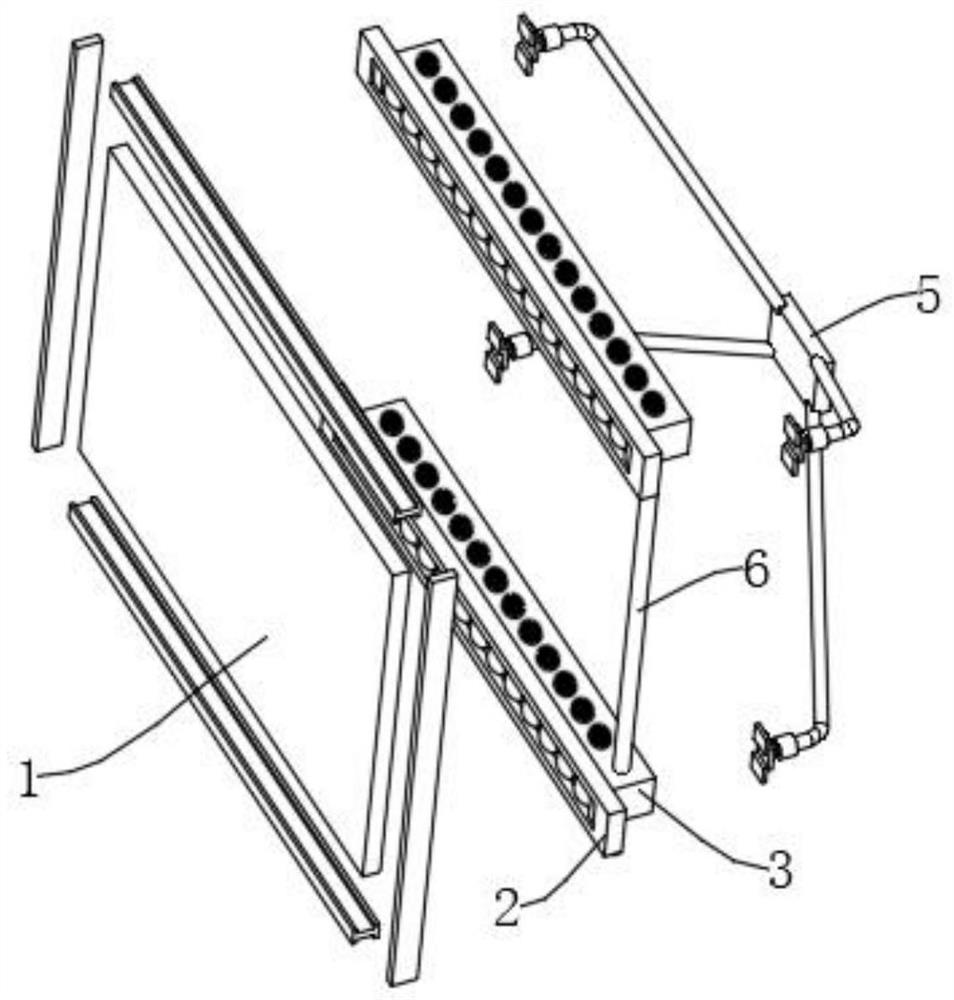

Fresh tobacco leaf stalk sectioning and orderly-clamping device and sectioning and clamping method thereof

The invention discloses a fresh tobacco leaf stalk sectioning and orderly-clamping device and a sectioning and clamping method thereof. Leaf stalks and tobacco leaves are different in flue-curing degree, and accordingly the flue-curing quality is affected. The fresh tobacco leaf stalk sectioning and orderly-clamping device comprises a positioning adjusting assembly, a first belt conveying mechanism, guiding plates, a compressing contour wheel, a Y-shaped cutter, a photoelectric sensor, a second belt conveying mechanism, a fastener, a tobacco clamp and a baffle. The Y-shaped cutter begins to cut main veins from the end faces of tobacco leaf stalks, and the compressing contour wheel is adjusted through a spring to adapt to the different height situations at different positions of the tobaccoleaf main veins. Sectioned tobacco leaves are throwed and conveyed through the first belt conveying mechanism, and leaf stalks fall between two adjacent clamping columns of the tobacco clamp after being in contact with the baffle; when n tobacco leaves are stacked between the two adjacent clamping columns, the tobacco clamp is stepped for one station; when the tobacco clamp is full of tobacco leaves, a motor is driven to stop rotating, the tobacco clamp is taken down and put in a flue-curing room, then a new tobacco clamp is clamped on two fasteners located at an upper tobacco leaf clamping station. The fresh tobacco leaf stalk sectioning and orderly-clamping device achieves automatic and orderly clamping of fresh tobacco leaves and makes the leaf stalk flue-curing time approximate to leaf flue-curing time.

Owner:西安智财全技术转移中心有限公司

Distillation dehydration device for lubricating oil production

PendingCN113337305AStir wellIncrease water evaporation rateLubricating oils distillationHydrocarbon dewateringProcess engineeringFan blade

The invention discloses a distillation dehydration device for lubricating oil production. The device comprises a distillation box, wherein the lower end of the distillation box is provided with a discharge port, a sealing plug is clamped in the discharge port, the side wall of the upper end of the distillation box is fixedly connected with a feed pipe, and the inner wall of the lower end of the distillation box is fixedly connected with a heating plate. A group of supporting columns are fixedly connected to the outer side of the lower end of the distillation box, and a stirring mechanism is arranged in the distillation box and located in the middle position of the distillation box. Beneficial effects of the device are that: a linkage gear drives a linkage rotating shaft to rotate and through transmission of a worm and a turbine, an exhaust rotating shaft of an exhaust mechanism is driven to rotate, so that exhaust fan blades can rotate, the outward exhaust efficiency of the distillation box is improved, evaporated water vapor can be quickly discharged, and the condition that the water vapor drops into lubricating oil again after being condensed in the distillation box is avoided.

Owner:江苏朗斯汽车用品有限公司

Drier

InactiveCN104634071AReduce consumptionSimple structureDrying gas arrangementsDrying solid materialsEvaporationPulp and paper industry

A drier comprises a drying box, a support, a draught fan and an air heater. The draught fan is connected with the top of the drying box through an exhaust pipe. The air heater is connected with one side of the drying box through an air inlet pipe. The support is fixedly connected into the drying box. A drainer is fixedly connected to the bottom of the drying box. The drier has the advantages that the structure is simple, the negative pressure air flow type drying is adopted, the evaporation speed of water on objects to be dried is greatly increased, the energy consumed for drying is reduced, and popularization is easy.

Owner:昆山利丘家用电器有限公司

Freeze-drying equipment for food processing

InactiveCN110836571AHeating evenlyIncrease water evaporation rateDrying solid materials without heatDrying chambers/containersHeat AvoidanceProcess engineering

The invention discloses a freeze-drying equipment for food processing. The freeze-drying equipment comprises a freeze-drying box, the inner wall of the bottom part of the freeze-drying box is connected with a motor through bolts, one end of an output shaft of the motor is provided with a rotary table, the outer wall of the top part of the freeze-drying box is provided with a fixing frame, the outer wall of one side of the fixing frame is provided with a heating plate, the outer wall of the top part of the freeze-drying box is connected with a vacuum pump through the bolts, the outer wall of one side of the vacuum pump is provided with an air extraction pipe, one end of the air extraction pipe communicates with the freeze-drying box, the outer wall of one side of the freeze-drying box is provided with a fixing port, and the inner wall of the fixing port is rotationally connected with a box door through a hinge. According to the freeze-drying equipment for food processing, the uniform heating of food is realized, the evaporation rate of moisture in foods is effectively accelerated, the use effect is better, the heat energy loss is avoided while the moisture is absorbed, the requirements of energy conservation and environmental protection are met, meanwhile, a water absorption resin which is located between baffle plates fully absorbs the moisture, the dehydration effect is better, and the freeze-drying effect of the equipment is further improved.

Owner:耒阳市刘燕酿制生物科技有限公司

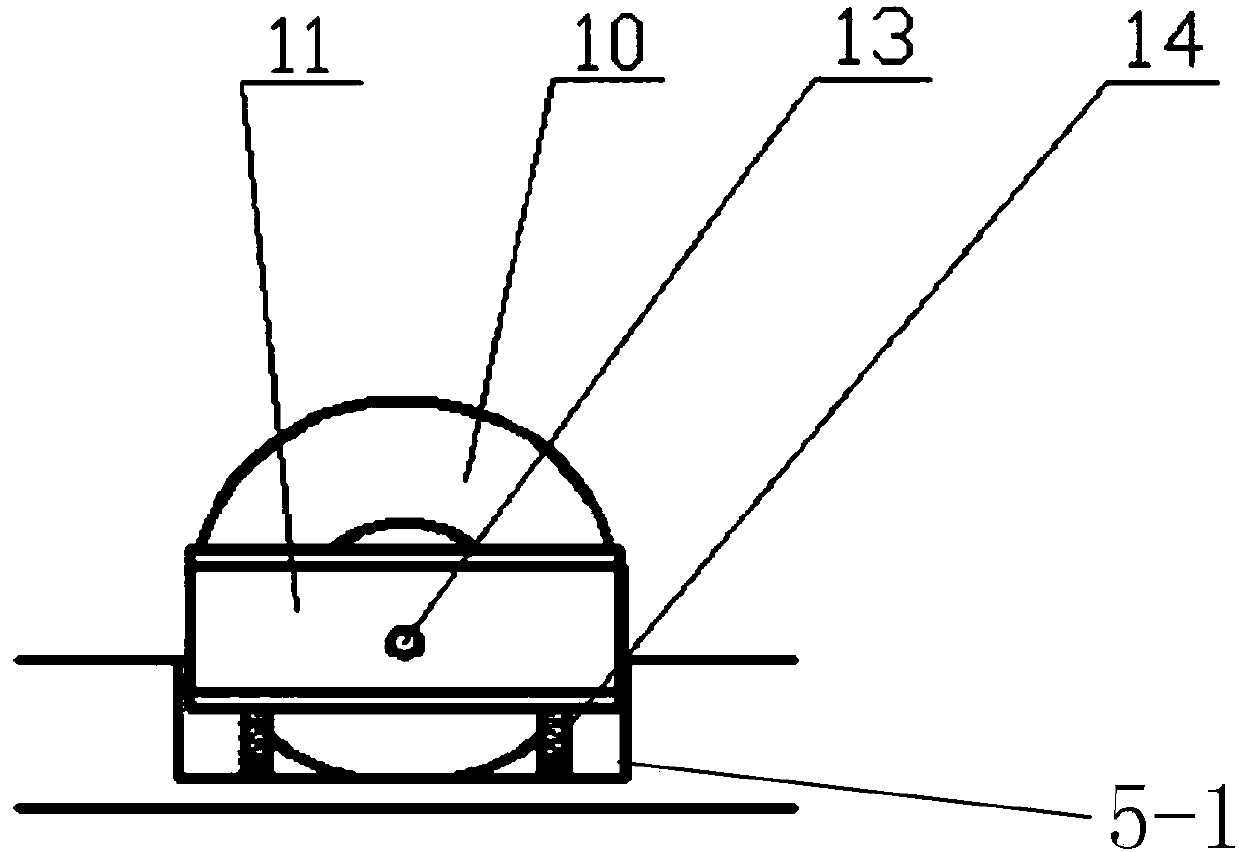

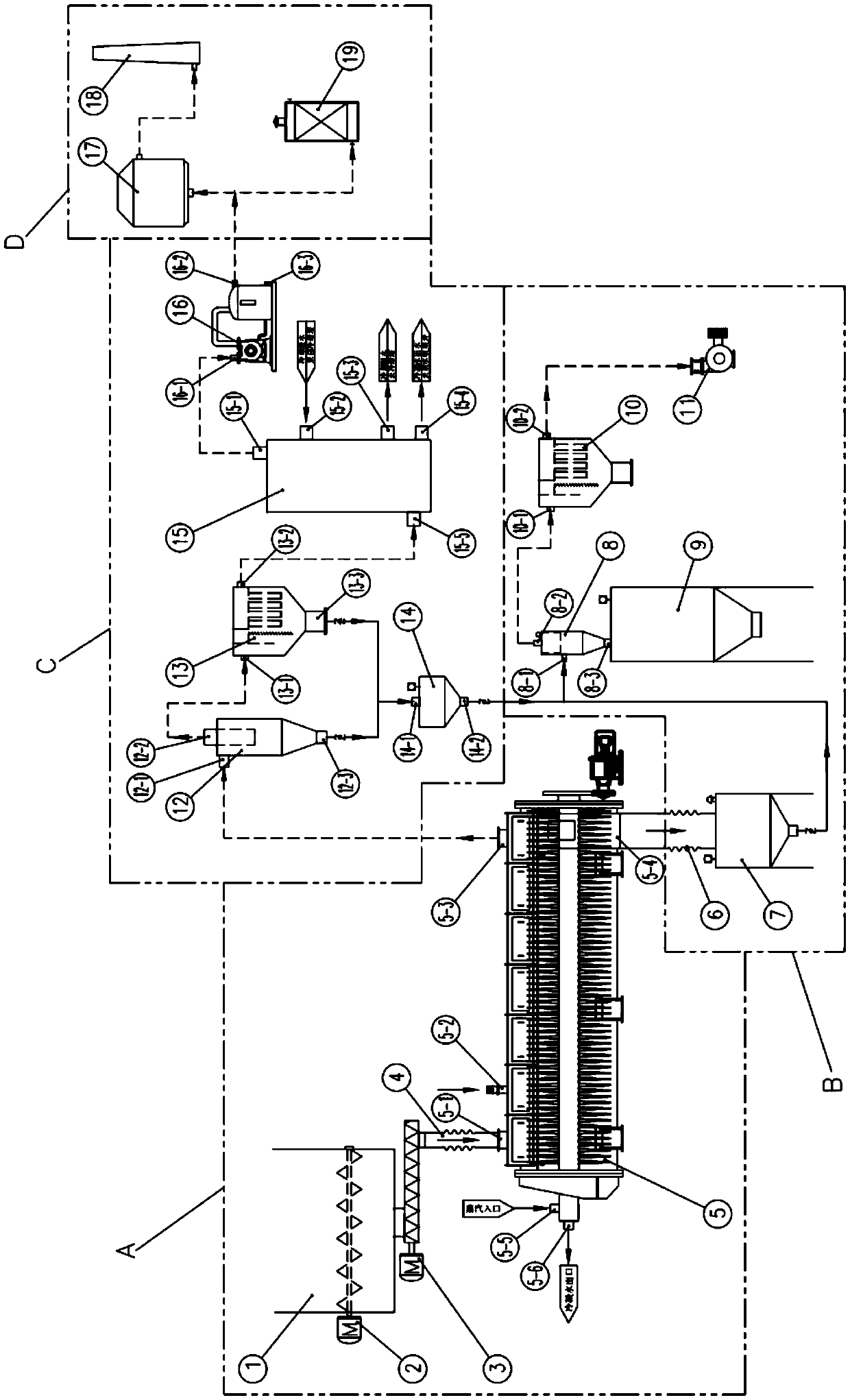

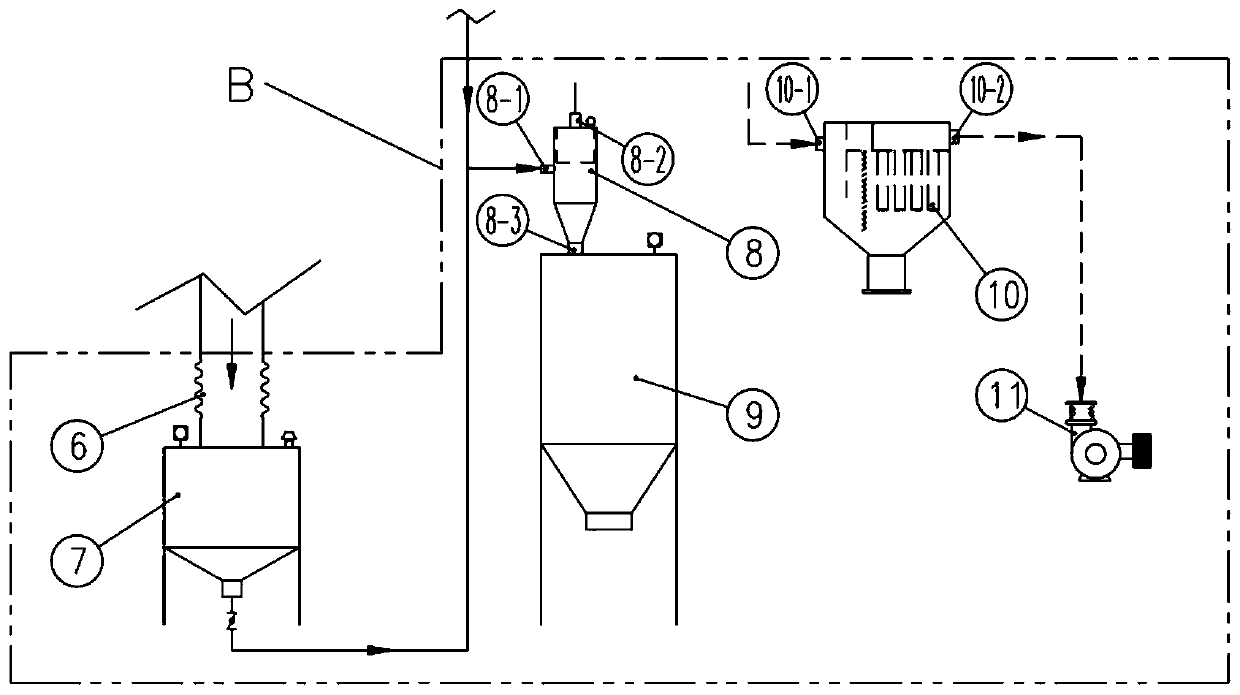

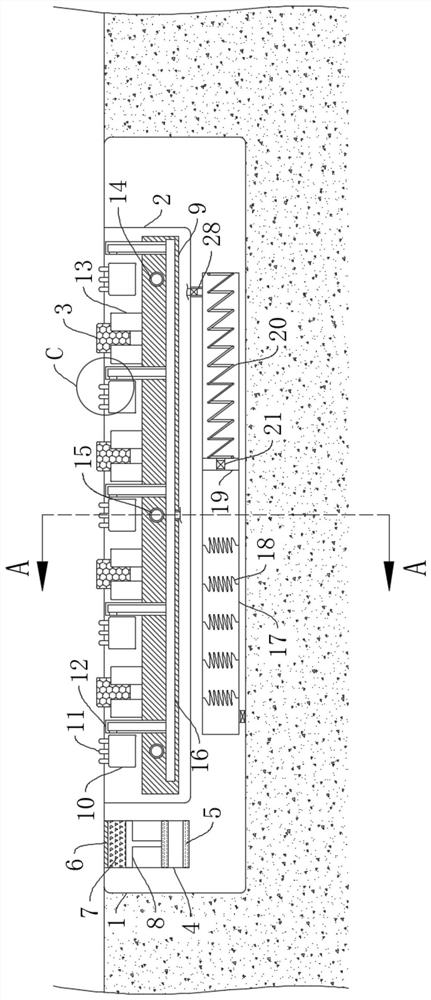

Low-vacuum sludge drying system

PendingCN111470749ALower boiling pointIncrease water evaporation rateCombination devicesSludge treatment by de-watering/drying/thickeningSludgeBaghouse

The invention discloses a low-vacuum sludge drying system, and relates to the technical field of sludge drying. The system comprises a wet sludge bin, an arch breaking device, a conveying device, a feeding flexible connecting section, a low-vacuum sludge drying device, a discharging flexible connecting section, a buffer bin, a vacuum conveying device, a dry sludge bin, an efficient bag type dust removal device, a Roots blower, a cyclone dust removal device, an efficient bag type dust remover, a storage bin, a condenser, a vacuum system, an incineration device, a chimney and a deodorization device, wherein the arch breaking device is mounted on the wet sludge bin. The low-vacuum sludge drying system provided by the invention is of a fully-sealed structure, the sludge drying device is subjected to space air exhaust through the vacuum system, so that a certain negative pressure state is formed in the sludge drying device, and sludge drying is carried out in the negative pressure state environment; not only is the boiling point temperature reduced, but also the water evaporation speed is increased; and the overall operation energy consumption of the equipment is directly reduced, so that the energy-saving effect is achieved.

Owner:上海净泥新能源科技有限公司

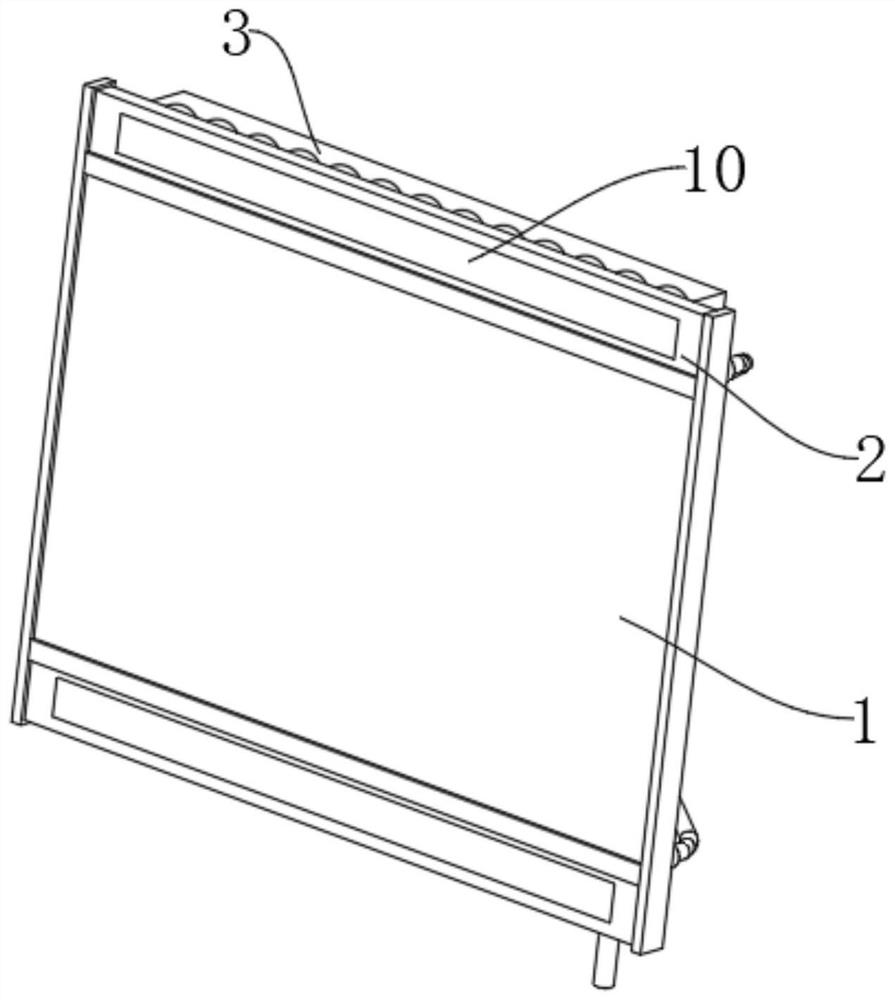

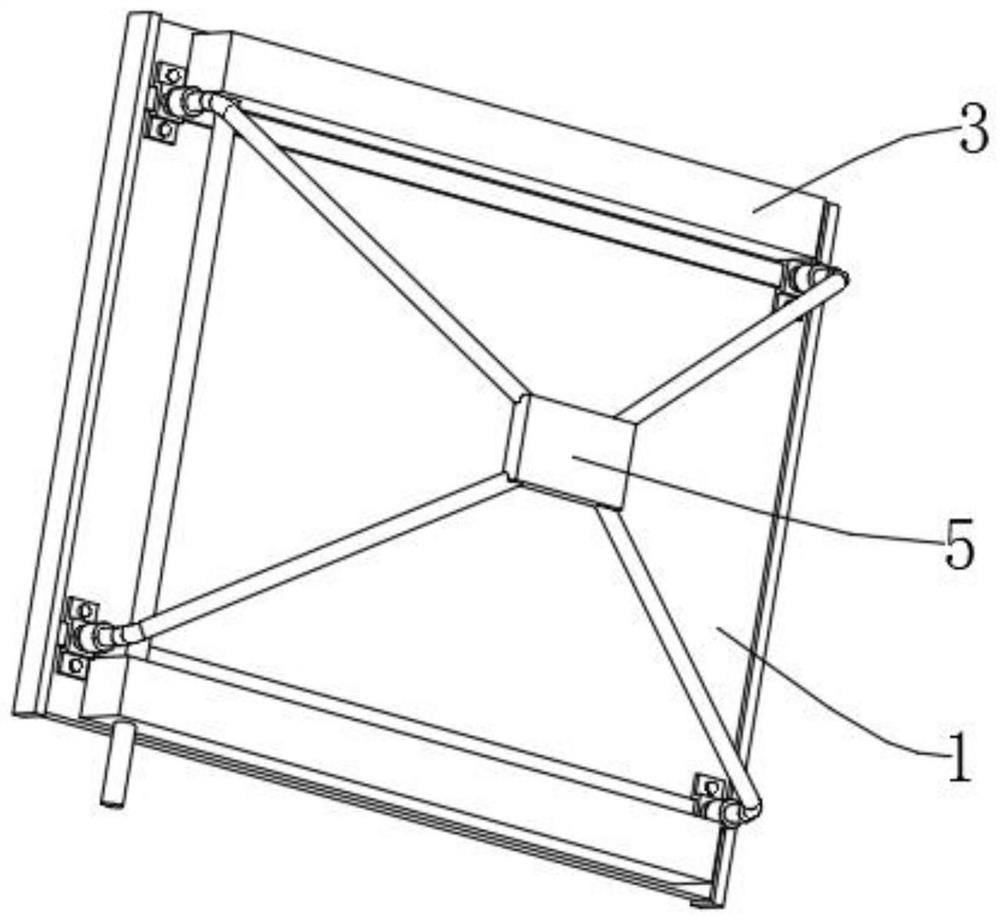

Indoor humidifying building curtain wall utilizing illumination energy gathering

InactiveCN112503781AReduce the use effectAchieve direct thermal conversionSolar heating energyWallsWater vaporMechanical engineering

The invention discloses an indoor humidifying building curtain wall utilizing illumination energy gathering in the technical field of building curtain walls. The indoor humidifying building curtain wall comprises a glass curtain wall and a mounting frame body, wherein heat collecting panels are mounted on the upper side and the lower side of the glass curtain wall; the back surfaces of the heat collecting panels are connected with a humidity keeping box; light rays are gathered in the heat collecting panels through convex lenses; the heat collecting panels are matched with a light gathering cover to heat collecting pipes; an evaporation bracket is arranged in the humidity keeping box; the inner side of the humidity keeping box is divided into an evaporation cavity on the upper layer and awater storage cavity on the lower layer by the evaporation bracket; and a water absorption evaporation block is placed on the evaporation bracket. According to the indoor humidifying building curtainwall, the heat collecting panels are assembled on the upper side and the lower side of a traditional glass panel, the heat collecting panels can continuously supply heat to the humidity keeping box, when time goes on, the light rays irradiate into the heat collecting panels from different directions, light gathering and heating can still be carried out, the evaporation speed of water in a sponge block is increased by the heat, so that the water vapor is evaporated from an evaporation opening of a cover body, the indoor space is humidified, and the indoor humidity is kept.

Owner:赵艳荣

A manufacturing process of peach wood hollow screen

ActiveCN107199614BMoisture-proof and anti-corrosionImprove densification performanceScreensDecorative surface effectsManufacturing technologyDistillation

The invention discloses a manufacturing technology of a hollowed-out peach wood screen. The technology is characterized by comprising the steps as follows: (1) material selection is performed as follows: a peach tree with the tree age being 20 years or above is selected as a machining material; (2) board sawing is performed as follows: a peach wood board is 1.8-2 cm thick; (3) heating and boiling in saline water are performed as follows: the board is immersed in water with the sodium chloride concentration ranging from 0.7% to 1% for heating and boiling; (4) high-pressure fumigation is performed as follows: the board is vertically placed on a distillation layer of a pressure cooker, a preservative is added, and high-temperature fumigation is performed; (5) softening in an acid and a base is performed as follows: the board is immersed in a sodium hydroxide solution and a hydrochloric acid solution respectively for soaking treatment; (6) drying is performed as follows: the board is vertically placed in a drying box, and a drying technology is performed; (7) hollowing-out engraving is performed as follows: the hollowed-out screen is engraved; (8) waxing is performed as follows: the screen is coated with wood wax by the aid of a soft brush and is coated repeatedly for 3-4 times. With the technology, the content of moisture in the peach wood board can be reduced, the anti-corrosion and moisture-proof performance can be improved, and the engraving performance and the smoothness of the peach wood board can be improved.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

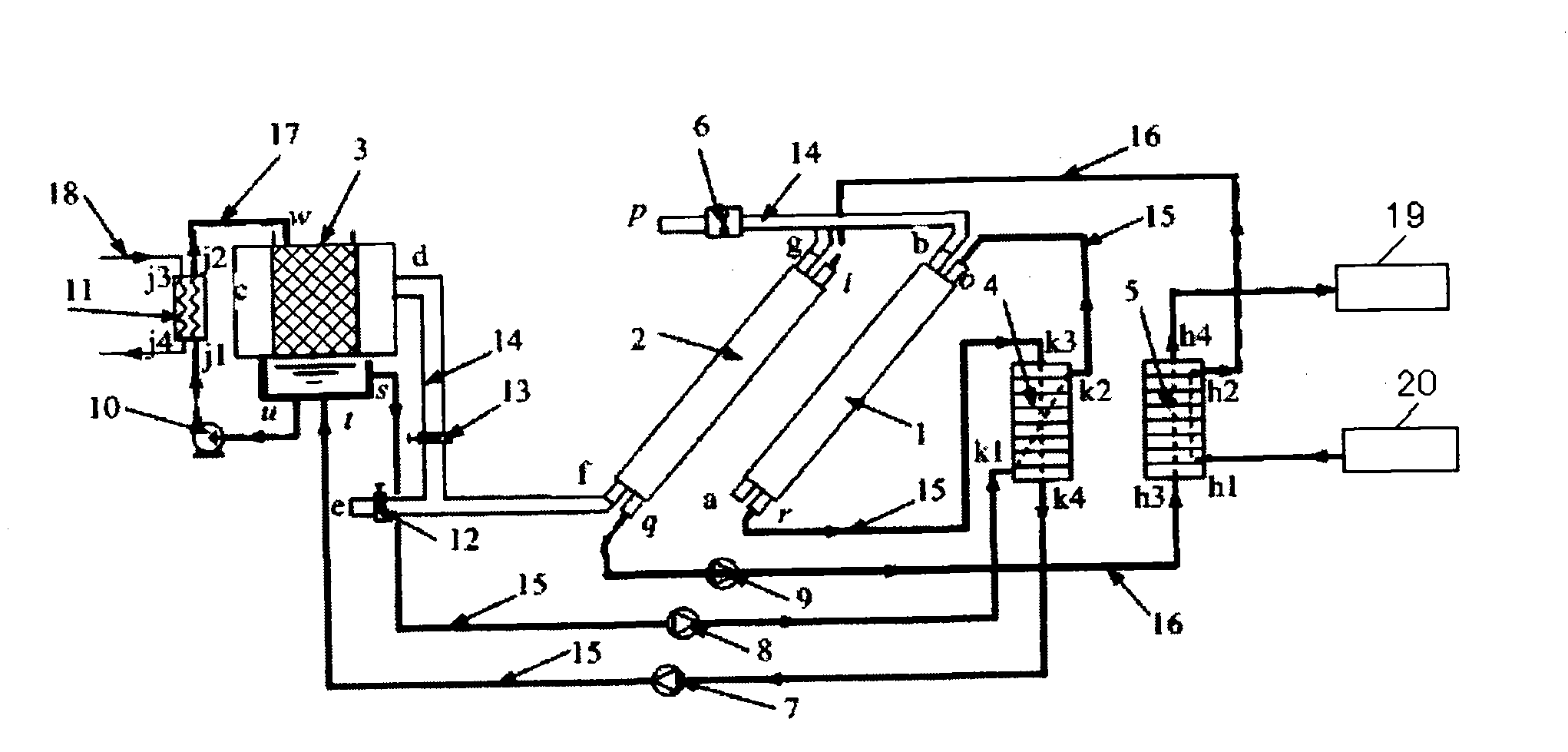

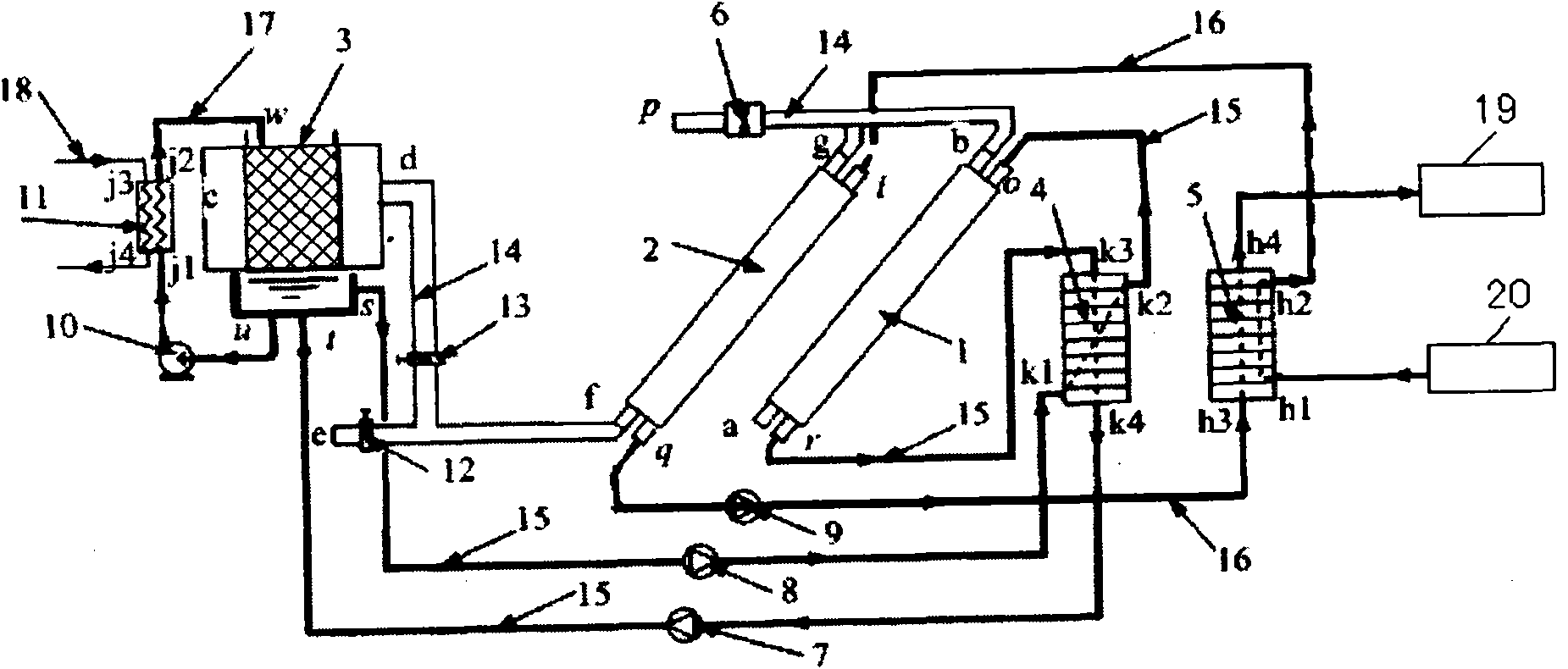

Solar air pretreatment staged solution heat collection regeneration device

InactiveCN101900389AEfficient regenerationImprove energy storage capacitySolar heat devicesAir conditioning systemsHigh concentrationAir cycle

The invention relates to a solar air pretreatment staged solution heat collection regeneration device which comprises an air circulation loop and a solution circulation loop. The device has the following technical effects: 1) utilizing the high-efficient regeneration of a first-stage heat collection / regenerator to carry out compensation on the low-efficient regeneration of a second-stage heat collection / regenerator; 2) utilizing outdoor air to carry out the first-stage regeneration on low-concentration solution, and then using the low-concentration solution after the first-stage regeneration to carry out pre-dehumidification on the outdoor air, wherein the dry air after the dehumidification can realize the effective regeneration of high-concentration solution in the second-stage heat collection / regenerator and improve the energy storage capacity of the high-concentration solution; and 3) the prominent advantage of the solar air pretreatment staged solution heat collection / regeneration device is the effect of improving the water evaporation rate of the high-concentration solution by sacrificing the water evaporation rate of the regeneration of the low-concentration solution under the conditions of high humidity and low solar radiation, thereby being particularly applicable to areas having the weather with high humidity in southern China.

Owner:NANCHANG UNIV

Landing opening anti-skid passage for subway station

The invention discloses a landing opening anti-skid passage for a subway station. The landing opening anti-skid passage for the subway station comprises a pedal; a water collecting tank is arranged on the upper wall of the pedal; a plurality of fixing rods are fixedly connected to the inner wall of the water collecting tank; a plurality of protruding blocks are fixedly connected to the upper walls of the multiple fixing rods; a plurality of sponge strips are fixedly connected to the inner wall of the water collecting tank; a control mechanism is arranged on the pedal; and the control mechanism comprises a groove formed in the upper wall of the pedal. According to the landing opening anti-skid passage for the subway station, people can be prevented from slipping down, travel safety of people in rainy days is guaranteed, the water absorption effect of the sponge strips can also be improved, the protruding blocks are kept dry, the situation that the friction force between the protruding blocks and a shoe sole is reduced due to the fact that water stains are attached to the surfaces of the protruding blocks for a long time is avoided, and therefore the anti-slip effect of the protruding blocks is guaranteed; and meanwhile, a motor can be cooled, the motor temperature is prevented from being too high, the motor is protected, and the service life of the motor is prolonged.

Owner:廖青连

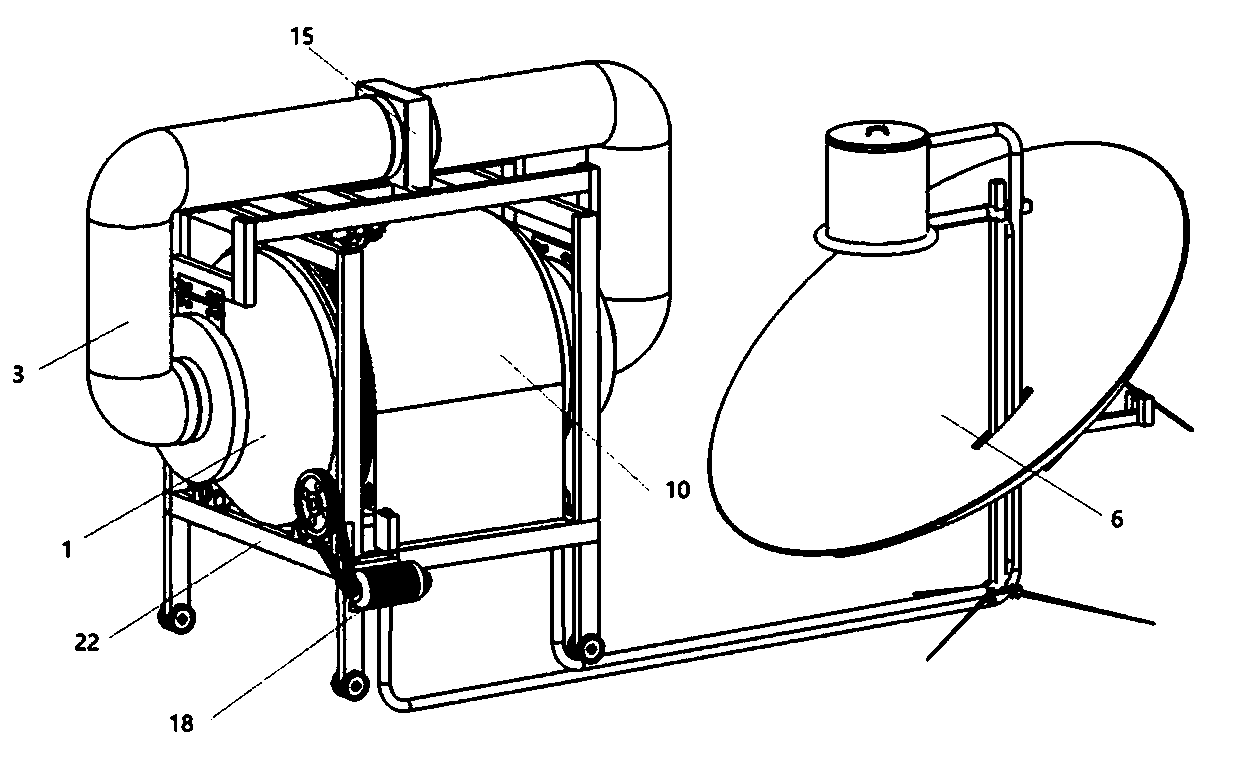

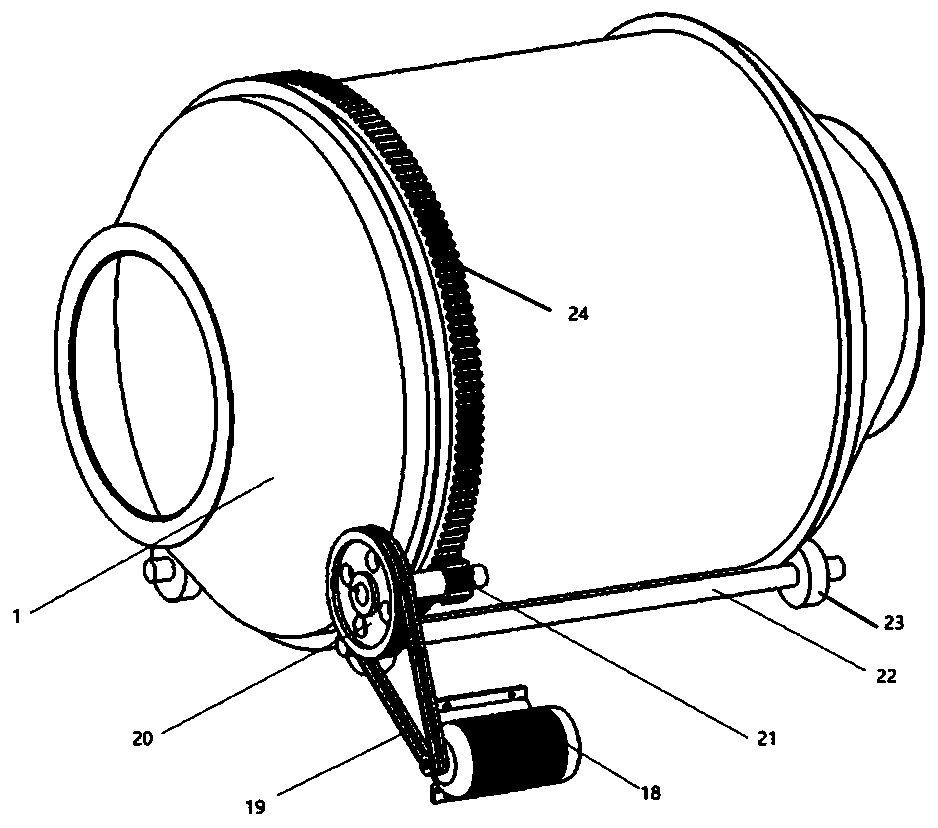

Pulp dryer

PendingCN111207575AAchieve flippingFully contactedSolar heating energyDrying gas arrangementsProcess engineeringMechanical engineering

The invention discloses a horizontal dryer. The horizontal dryer comprises a roller assembly, a circulating air supply assembly, a heating assembly and a dehumidifying assembly. The horizontal dryer can achieve the effects of improving the drying speed of equipment, reducing the energy loss and reducing the energy requirement, and has certain guiding significance for enriching the types of dryersand improving the quality of the dryers.

Owner:刘超山

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com