Heat pump type closed sludge drying system and control method of same

A sludge drying and closed-type technology, which is applied in heat pumps, dehydration/drying/thickened sludge treatment, refrigerators, etc., can solve the problems of high energy consumption and thermal forced drying, and it is difficult to get large-area push pipes. , high drying temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

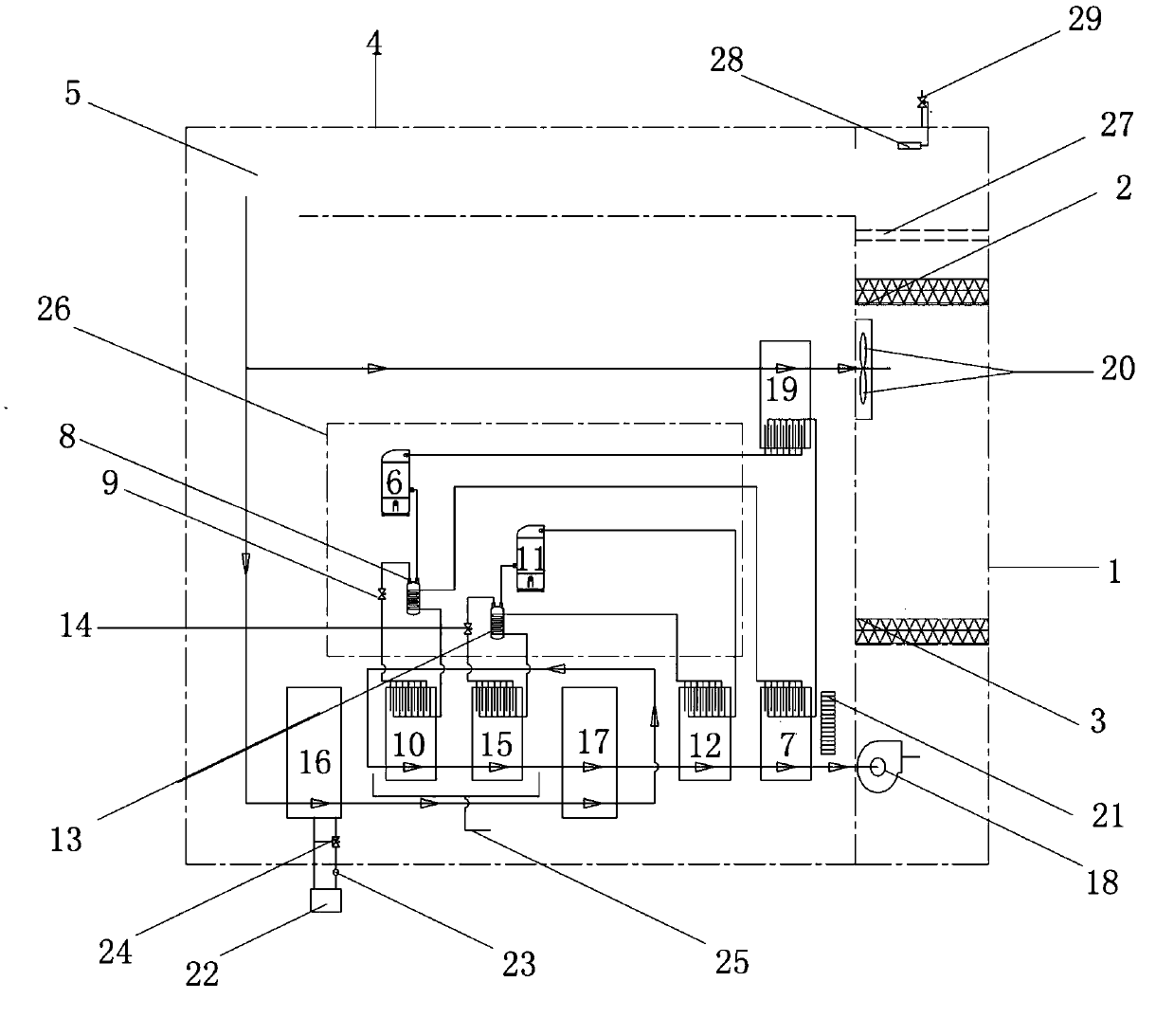

[0089] A heat pump type closed sludge drying system includes a drying room. The drying room is provided with an upper conveyor belt 2 and a lower conveyor belt 3, and a system shell 4 is provided on one side of the drying room. The top of the drying room is connected with the top of the system shell to form a back In the air channel 5, an auxiliary air outlet is formed on the side wall below the upper conveyor belt that is connected to the system housing, and a main air outlet is formed on the side wall below the lower conveyor belt and the system housing is connected to the system housing. The main air outlet is provided with a main blower 18, and the auxiliary air outlet is provided with two auxiliary circulating fans 20.

[0090] The system housing is provided with a first heating circulation system, a second heating circulation system, and an air duct circulation system.

[0091] The first heating cycle system is the No. 1 compressor 6, the sensible heat condenser 19, the No. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com