Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Increase flow space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

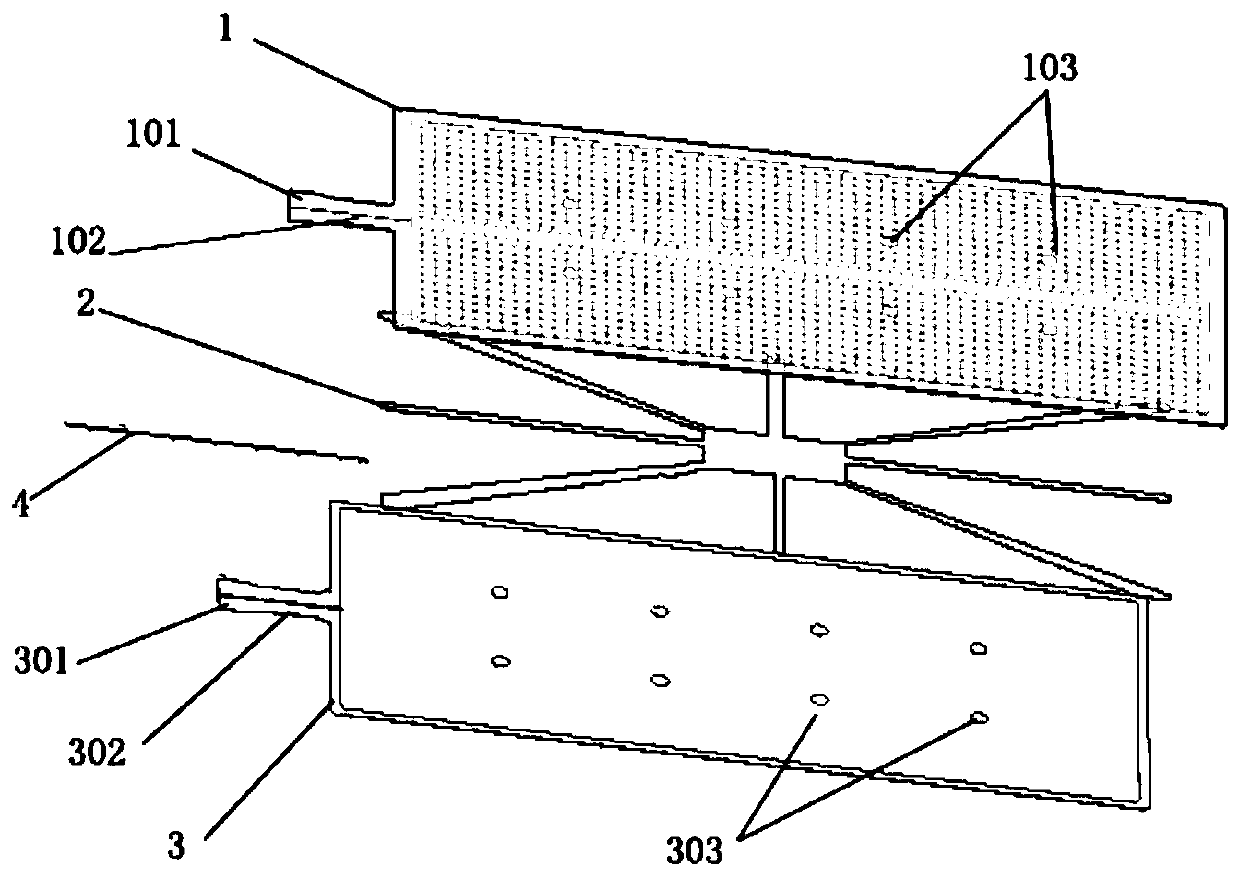

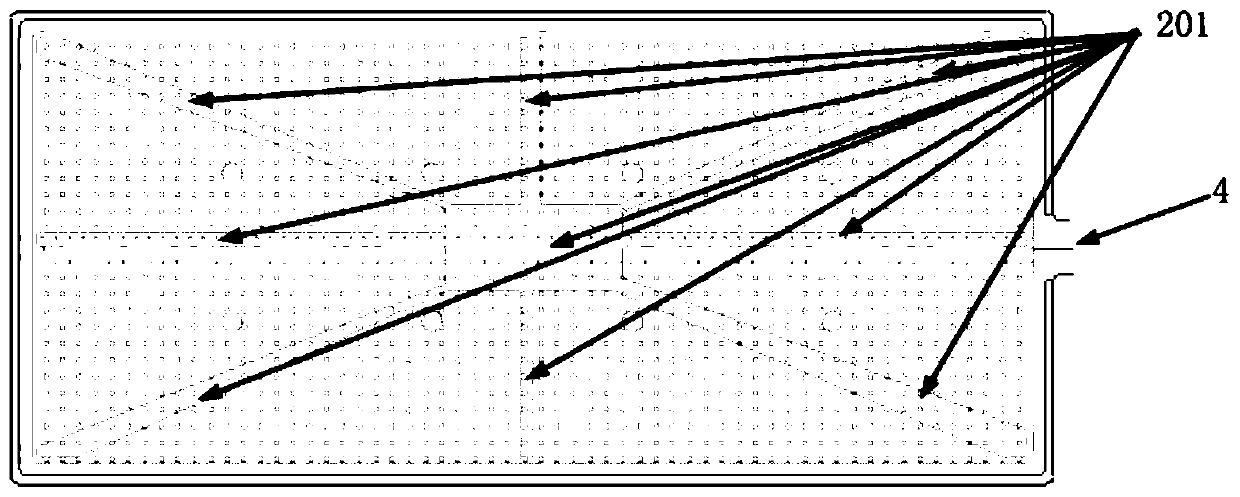

Heat spreader

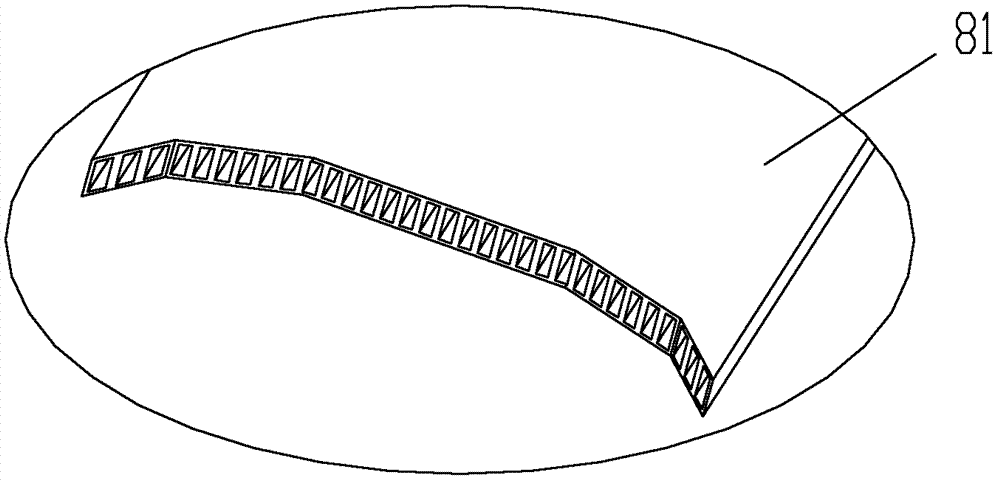

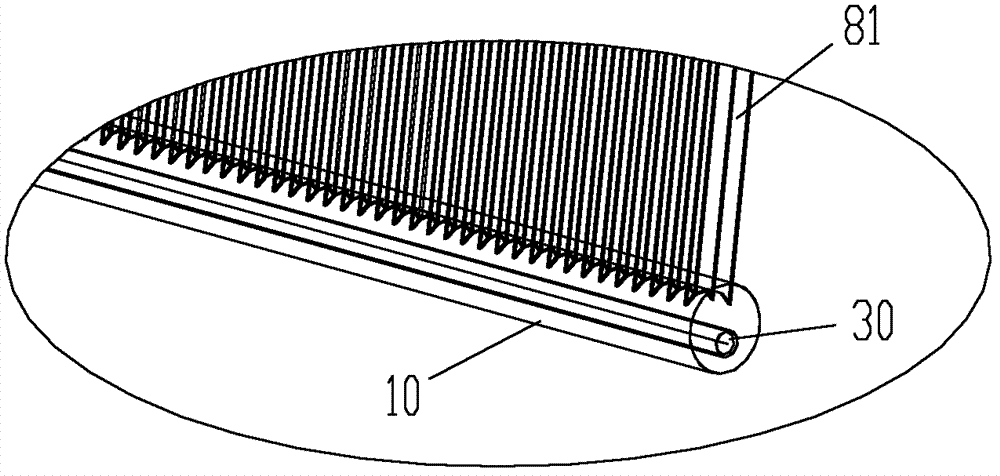

InactiveCN102693949AIncrease flow spaceEvenly distributedSemiconductor/solid-state device detailsSolid-state devicesRefluxWorking fluid

A heat spreader comprises an absorber plate, a heat releasing plate combined with the absorber plate, a first capillary structure on the absorber plate and a second capillary structure on the heat releasing plate, wherein a chamber is formed between the absorber plate and the heat releasing plate; the chamber is filled with a working fluid, and the first capillary structure and the second capillary structure are disposed in the chamber; the first capillary structure comprises several first grooves and second grooves which are arranged parallelly; each of the first grooves extends from one end of the absorber plate to the other end along a vertical direction; each of the first grooves and each of the second grooves are interlaced. Therefore, a gaseous working medium is enabled to simultaneously flow in the first grooves and the second grooves, the flowing space for the gaseous working medium and the contact area thereof with a cover plate are increased, and the heat conduction efficiency is improved due to the reduction of heat transfer resistance and reflux resistance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

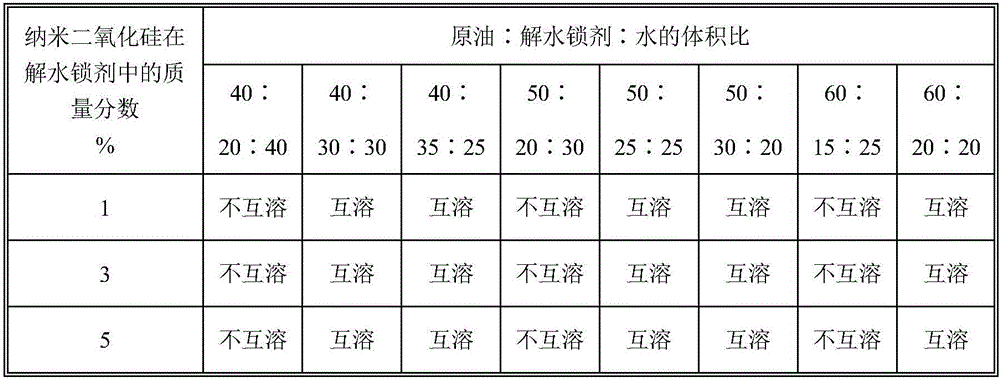

Water lock removal agent for low-water-content oil well

InactiveCN105733543AImprove permeabilityImprove hydrophilicityFluid removalDrilling compositionOil phaseSilicon dioxide

The invention provides a water lock removal agent for removing the water lock damage of a low-water-content oil well.The water lock removal agent is composed of nanometer silicon dioxide and ehtylene glycol monobutyl ether with initial granularity of 15-30 nm, wherein the weight of nanometer silicon dioxide accounts for 1-5% of the total weight.When the volume ratio of the water lock removal agent to water is 1:1, the oil phase and the water phase can be changed into one phase through the water lock removal agent within 6 hours by solubilizing the water phase and the oil phase, and therefore the permeation resistance of the two phases is eliminated; by means of the nanometer silicon dioxide, the hydrophily of rock surfaces can be enhanced, free water is adsorbed to rock surfaces to form water films, and therefore the relative permeation rate of the oil phase is increased, and the permeation start pressure of the oil phase is reduced.For the oil well suffering from water lock damage, the water lock removal agent with the same volume as the leakage volume is injected into a stratum through oil sleeve annulus according to the flushing fluid leakage volume recorded in the flushing work process; by closing the well for 6 hours or above and then opening the well for production, the water lock damage of the low-water-content oil well can be effectively relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

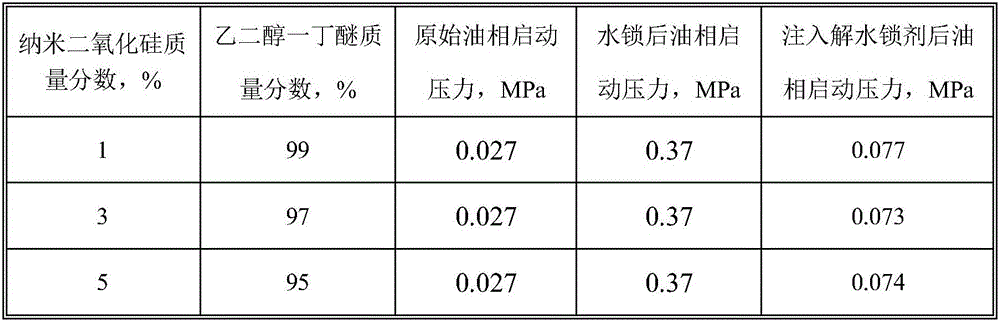

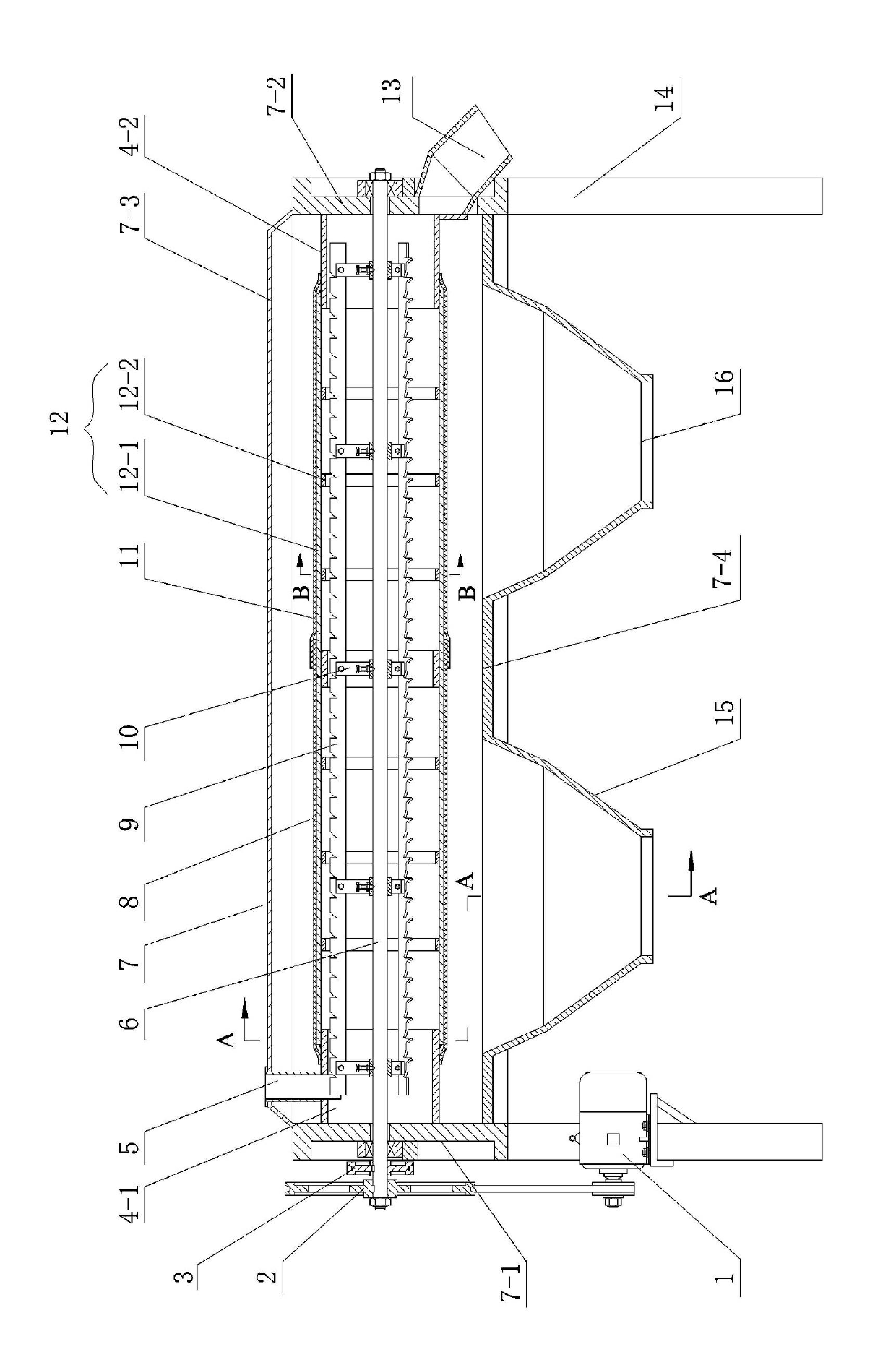

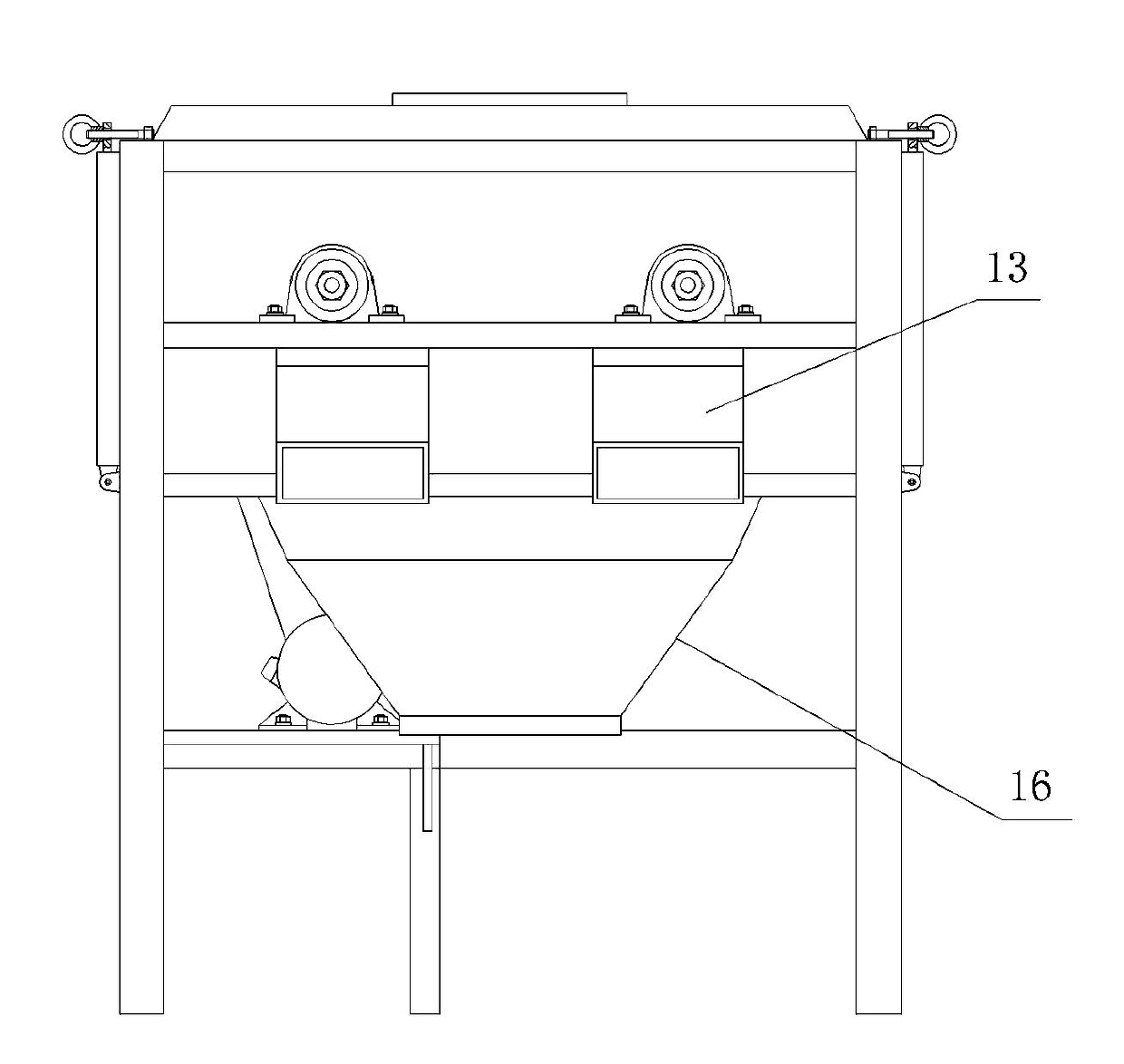

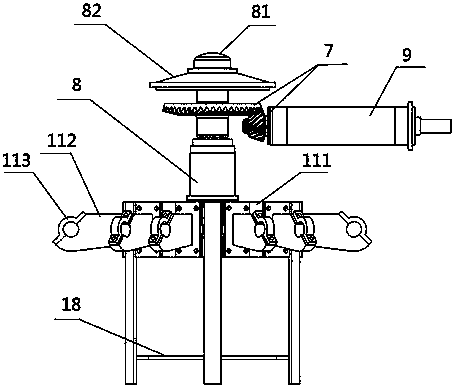

Plant fiber sizing screen powder machine

InactiveCN102652941ALiquidityGood fractionation effectSievingGas current separationMechanical engineeringPlant fibre

The invention discloses a plant fiber sizing screen powder machine, and belongs to the technical field of sifting machines. The plant fiber sizing screen powder machine comprises a rack and a machine shell, wherein the machine shell is formed by a front standing plate, a rear standing plate, a top shell and a bottom plate, and the machine shell is provided with a screen door; a screen drum is fixed between the front standing plate and the rear standing plate, the screen drum comprises front and rear end drums, a screen mesh frame and a screen mesh, the screen mesh comprises a first order screen mesh and a second order screen mesh, and the screen holes of the second order screen mesh are greater than that of the first order screen mesh; and the screen drum is internally provided with a pneumatic conveying device, the upper part of the machine shell is provided with a feeding bin, the lower part of the machine shell is provided with a first order discharge hopper and a second order discharge hopper, and the rear part of the machine shell is provided with a rear discharge port. The plant fiber sizing screen powder machine provided by the invention is used for screening plant fiber power, the structure that a screen drum is fixed and screen mesh is sectionalized is adopted, and the pneumatic conveying device is utilized to deliver powder; and the screening thing uniformly passes in a screening process, the liquidity is strong, the fractionation effect is good, and the output and the quality of the products are notably improved.

Owner:XUZHOU FUYANG ENERGY TECH

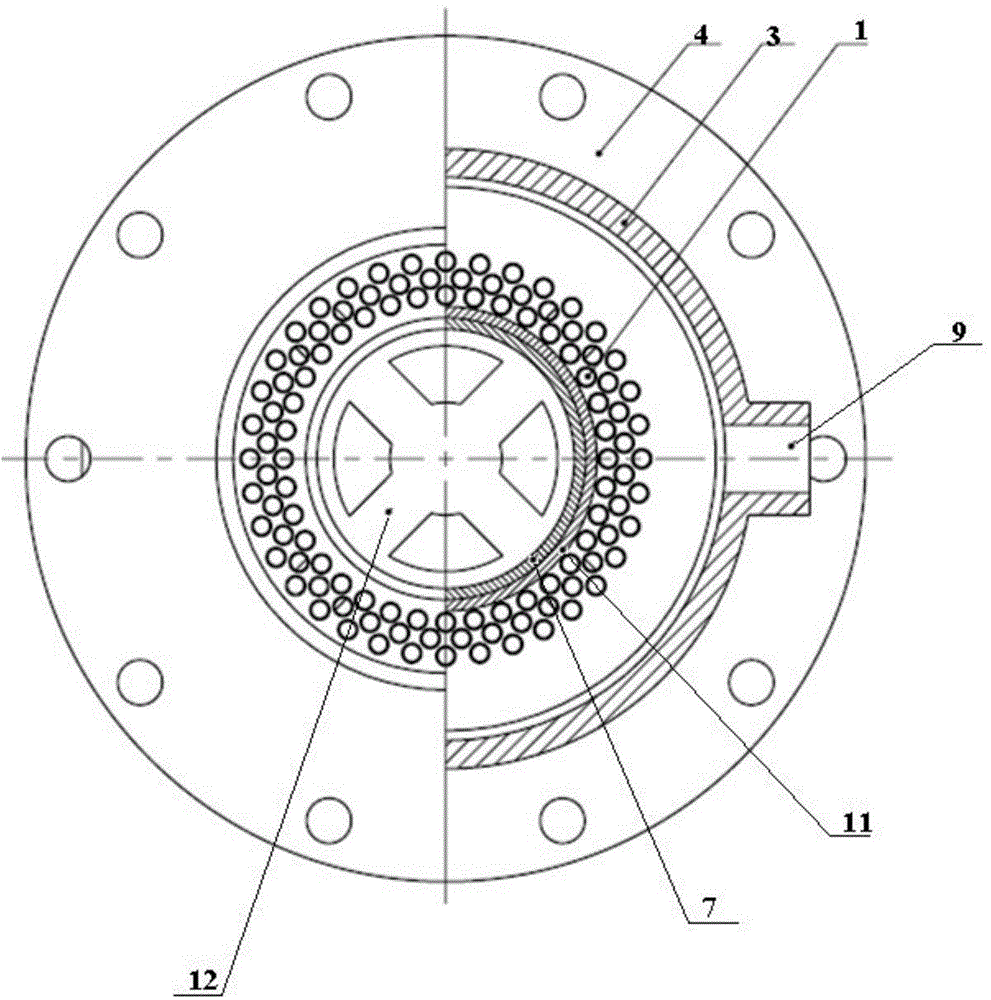

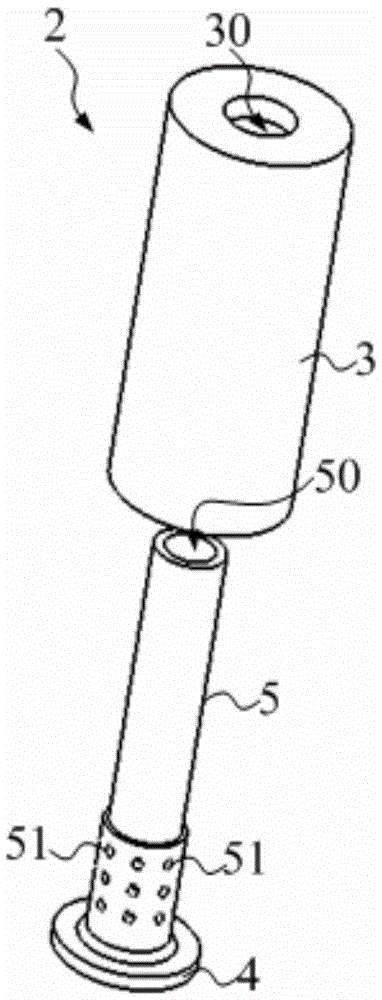

Cold end heat exchanger of free piston type Stirling engine

ActiveCN104595056AIncrease flow spaceImprove heat transfer efficiencyHot gas positive displacement engine plantsEngineeringCooling pipe

The invention belongs to cold end heat exchangers, and particularly discloses a cold end heat exchanger of a free piston type Stirling engine. The cold end heat exchanger comprises cooling pipes, an outer wall and a heat exchanger shell. The heat exchanger shell is composed of an upper heat exchanger shell wall, a lower heat exchanger shell wall and an inner heat exchanger shell wall which are integrally formed. A plurality of cooling pipes are arranged in a cavity defined by the outer wall and the heat exchanger shell, and each of the upper heat exchanger shell wall and the lower heat exchanger wall is provided with a plurality of cooling pipe through holes. The upper end and the lower end of each cooling pipe each penetrate one cooling pipe through hole; and a cooling agent inlet and a cooling agent outlet are formed in the outer wall. Flowing space of cooled working media in a heat exchange area is large, the heat transfer path is clear, and the heat exchange efficiency is high.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

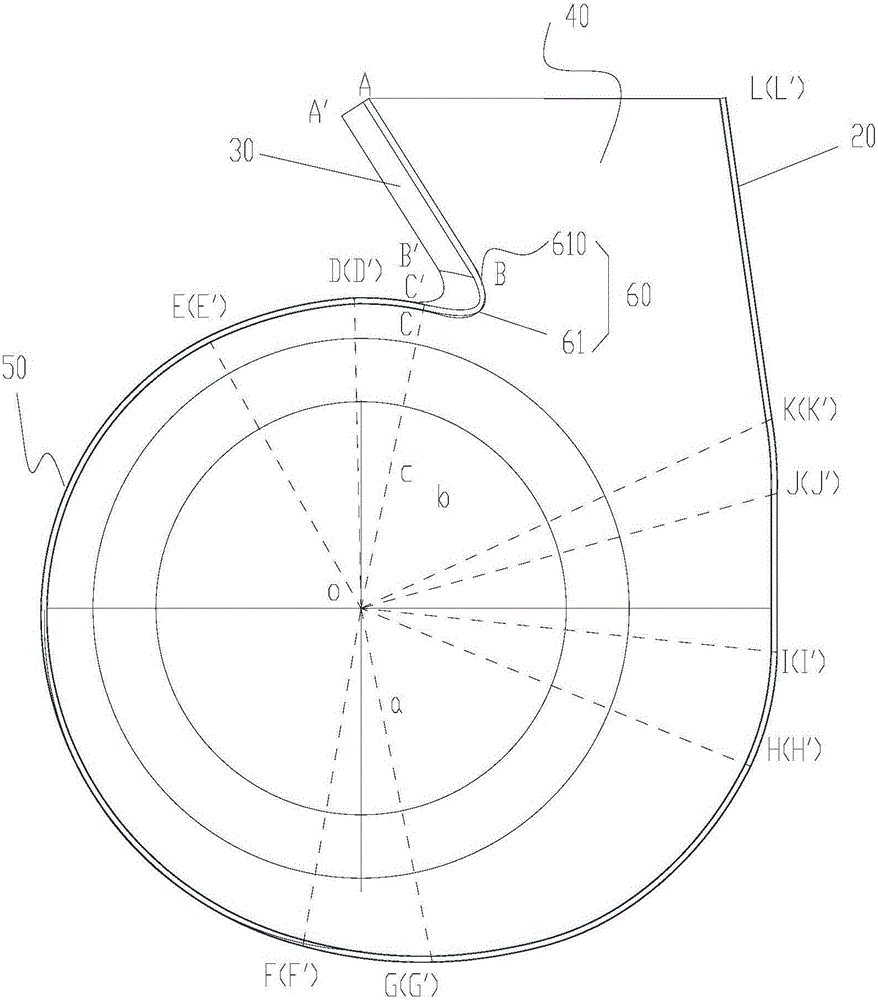

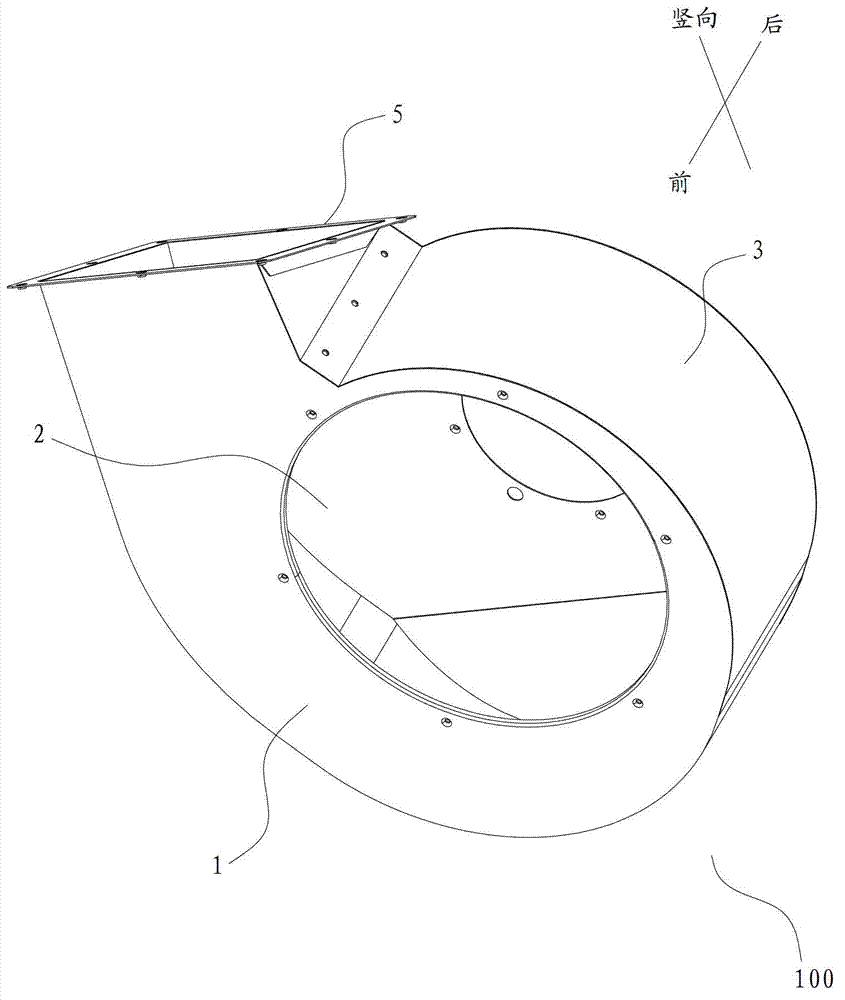

Fan, fan volute and air conditioner

The invention provides a fan, fan volute and an air conditioner. The fan volute comprises a bottom plate and side plates, wherein the side plates are connected to the bottom plate; an air flue is formed between the bottom plate and the side plates; the outlet of the air flue is provided with a pressure diffusing section; the side plates comprise the first side plate and the second side plate which correspond to the pressure diffusing section; and the second side plate and the bottom plate form an acute-angle included angle on the plane. The second side plate in the pressure diffusing section is inclined by certain angle, so that flowing space, in the fan volute, of a fluid is increased, and turbulence generated when gas enters the fan is reduced, and therefore, the purpose of reducing noises is realized.

Owner:GREE ELECTRIC APPLIANCES INC

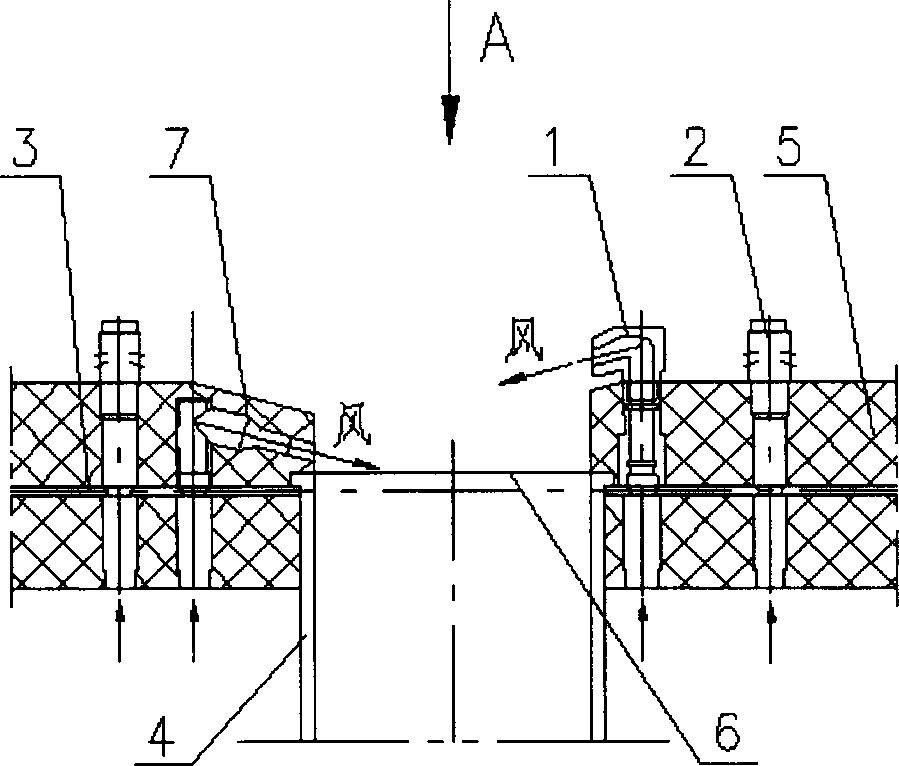

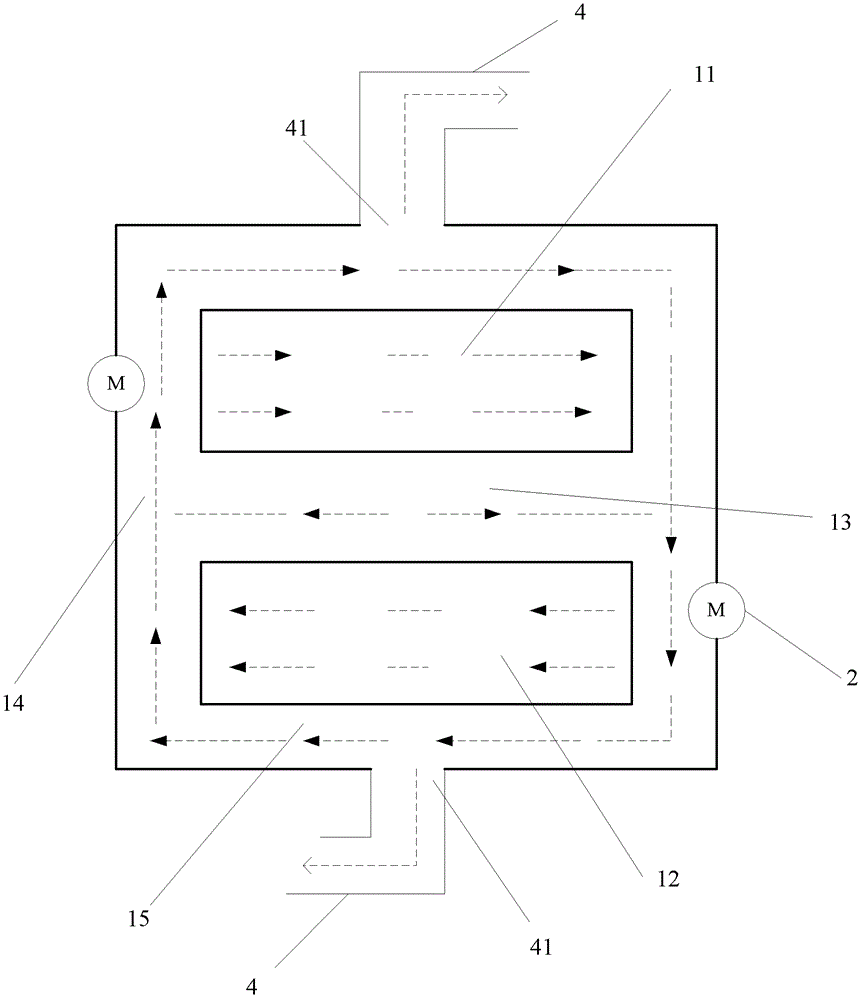

Flash-evaporation and condensation integrated seawater desalinization device

ActiveCN101973596AReduce usageLow costGeneral water supply conservationSeawater treatmentSteam pressureDesalination

Owner:ZHEJIANG UNIV

Air-drying method for improving quality of alfalfa

InactiveCN102228132AIncrease flow spaceHigh trafficDrying solid materials with heatAnimal feeding stuffLoss ratePositive interaction

The invention discloses an air-drying method for improving the quality of alfalfa. The method comprises the following steps of: 1) ridging; 2) selecting materials and treating; and 3) air-drying. The method has the advantages that: 1, the ridging increases the air flow space on the bottom of a grass layer; 2, the fracture of stalks accelerates the evaporation rate of the moisture in the stalks, so that the drying time is shortened; 3, the combination of field ridging and fracturing and air-drying of the stalks has a positive interaction effect on the loss of the moisture of fresh alfalfa forage; 4, the loss rate of the moisture of the fresh alfalfa forage is remarkably and negatively correlative with the residual amount of crude proteins in green hay; 5, the aims of accelerating the drying of the alfalfa, uniformly drying and improving the quality of the green hay are fulfilled; and 6, operation steps are simple and easy, the drying cost is low, and the efficiency is high.

Owner:GANSU AGRI UNIV

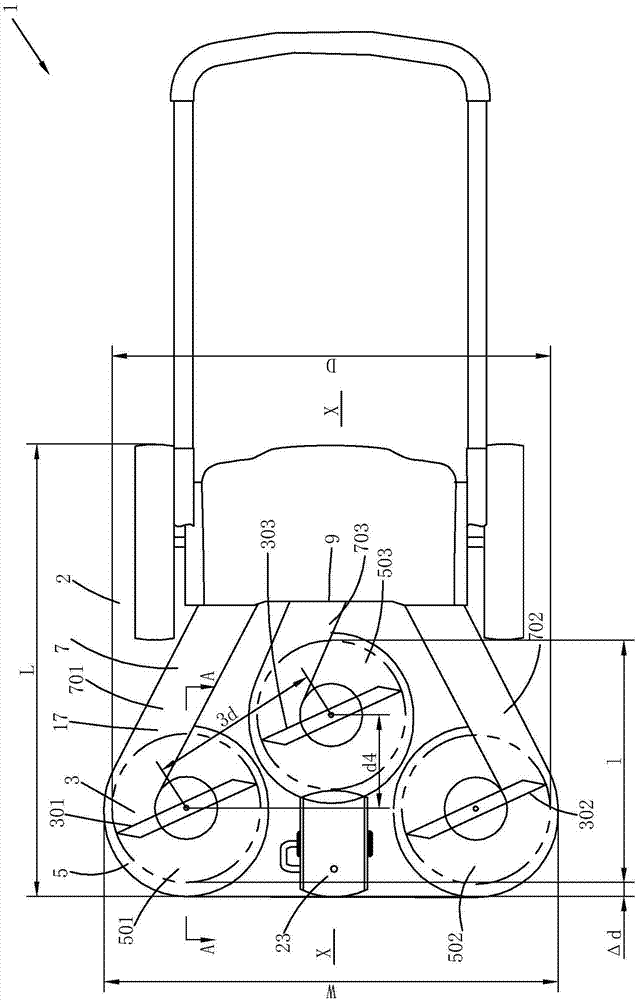

Mowing machine

The invention relates to a mowing machine. The mowing machine comprises a shell body, a cutting motor and a plurality of cutting members, wherein the cutting motor is mounted on the shell body and is used for providing a driving force; and the cutting members are driven by the cutting motor to rotatably perform mowing operation. The mowing machine further comprises a plurality of cutting chambers and at least one grass discharging passage, wherein the cutting chambers correspond to the cutting members and are independent of one another; and the at least one grass discharging passage correspond to the cutting chambers and communicate with the cutting chambers. The mowing machine has the beneficial effects that through arranging an independent cutting chamber for each cutting member, the grass discharging efficiency of the multi-cutting-member mowing machine is increased.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Reactor external reactor vessel cooling (ERVC) system three-dimensional simulation experiment apparatus and reactor external reactor vessel cooling (ERVC) system three-dimensional simulation experiment method

ActiveCN108389635AIncrease water injection cooling capacityIncrease flow spaceNuclear energy generationCooling arrangementThree dimensional simulationVertical plane

The invention provides a reactor external reactor vessel cooling (ERVC) system three-dimensional simulation experiment apparatus and a reactor external reactor vessel cooling (ERVC) system three-dimensional simulation experiment method. The experiment apparatus comprises an injection water storage circuit, an experiment main circuit, a cooling water secondary circuit and a descending circuit, wherein the experiment main circuit comprises a reactor pit simulation body, a pressure container simulation body, a thermal insulation layer simulation body, a cavity body and a heating module, the cooling water secondary circuit comprises a heat exchanger and a cooling pipeline, the descending circuit comprises a natural descending circulation pipeline and a forced descending circulation pipeline, and the vertical plane of a steam-water mixture flowing path is perpendicular to the input pipeline of the injection water storage circuit or an included angle is formed between the vertical plane of asteam-water mixture flowing path and the input pipeline of the injection water storage circuit. With the experiment apparatus and the experiment method of the present invention, the ERVC experimentsunder the natural circulation condition and the forced circulation condition can be achieved by simulating the ERVC process of the actual external reactor vessel, and the water injection flow and thewater injection undercooling can be well adjusted by combining the three-dimensional water supply flow path, such that the ERVC capacity of the reactor and the safety margin of the critical heat fluxdensity on the outer wall of the pressure vessel can be improved.

Owner:LINGDONG NUCLEAR POWER +4

Forming mould for flange forging and forging method

PendingCN110116183AIncrease flow spaceIncrease spatial mobilityForging/hammering/pressing machinesWheelsForgeMaterials science

The invention provides a forming mould for flange forging. The forming mould comprises a forming upper mould and a forging lower mould, wherein a forming bin is arranged above the forming lower mould;the forming upper mould is movably mounted in the forming bin; a lower mounting slot is formed in the bottom of the forming bin; the lower mounting slot penetrates through the lower surface of the forming lower mould; a lower mould core is embedded into the lower mounting slot; an upper mounting slot is formed in the forming upper mould in a penetrating mode; an upper mould core is mounted in theupper mounting slot; an upper groove is formed in the lower surface of the upper mould core; a lower groove is formed in the upper surface of the lower mould core; the upper groove and the lower groove are spherical arc-shaped slots; and the curvature of the arc surface of the upper grove is the same with that of the arc surface of the lower groove; the forming upper mould, the forming lower mould, the upper mould core and the lower mould core are closed to define a forming cavity; and the forming cavity is positioned in the upper groove and the lower groove to define a spherical cylindricalstructure. The forming mould solves the problem that an existing forming mould causes a formed forge piece to crack or fold as a result of a too great flange size and quick material flow, and is suitable for flanges with relatively great sizes.

Owner:常州市丰乐精锻有限公司

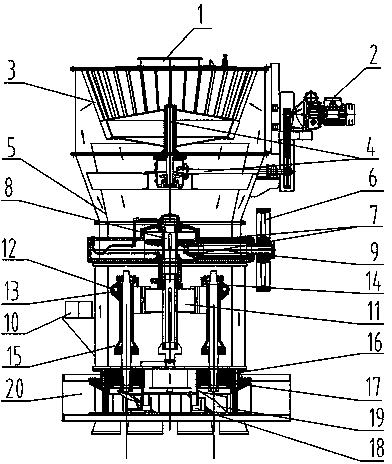

Energy-saving low-carbon environment-friendly European-type grinding machine

The invention relates to an energy-saving low-carbon environment-friendly European-type grinding machine comprising an analytical machine on the upper part of a host machine, wherein the lower part of the host machine comprises an upper machine body, a middle machine body and a lower machine body; a discharge hole is formed in the top end of the upper part of the main machine; an airflow isolation loop is arranged on the lower part of the host machine; fine powder sending space is formed between the airflow isolation loop and the machine bodies of the lower part of the host machine; a feeding hole is installed in the outer side of the middle machine body; an air inlet is arranged in the lower machine body; a main shaft transmission device is installed in the middle machine body; the main shaft transmission device comprises a host machine belt wheel and a belt wheel transmission shaft; the host machine belt wheel is installed at the outside of the middle machine body; one end of the belt wheel transmission shaft is connected with the host machine belt wheel; the other end of the belt wheel transmission shaft is engaged with the other conical gear of the main shaft; a combined-type grinding roller lifting frame is installed on the main shaft; a cross arm shaft is installed on the combined-type grinding roller lifting frame; the upper end of a long-arm grinding roller shaft assembly is suspended on the cross arm shaft to form a movable fulcrum; a grinding roller capable of performing autogiration is installed at the lower end of the long-arm grinding roller shaft assembly; and a grinding ring with the position corresponding to that of the grinding roller is installed on the lower machine body. The energy-saving low-carbon environment-friendly European-type grinding machine is high in grinding efficiency, convenient to examine and repair and install, and long in service life, and a finished product produced by the energy-saving low-carbon environment-friendly European-type grinding machine is wide in particle size range.

Owner:上海建冶路桥机器设备有限公司

Transformer respirator

InactiveCN107808748AAvoid pollutionIncrease flow spaceTransformers/inductances coolingRespiratorTransformer oil

The invention provides a transformer respirator. The transformer respirator comprises a silica gel cylinder for storing silica gel particles, an upper cover arranged on the upper side of the silica gel cylinder, a breathing disc arranged on the lower side of the silica gel cylinder, an inner oil cup and an outer oil cup, wherein the inner oil cup and the outer oil cup are arranged on the lower side of the breathing disc and used for storing transformer oil; the transformer respirator is characterized by also comprising an extending oil cup fixed on the upper side of the breathing disc and communicated with the inner oil cup and a separation net arranged on the upper side of the extending oil cup and used for bearing the silica gel particles, the separation net is arranged inside the silicagel cylinder, the separation net and the extending oil cup are arranged at an interval, and the area of the cross section of the extending oil cup is larger than the area of the cross section of theinner oil cup. According to the transformer respirator, the problem that silica gel in an existing respirator is contaminated by splashed transformer oil is solved; the flowing space of the transformer oil is increased, and the silica gel contamination problem caused by rapid rising of the transformer oil level caused when the temperature of a transformer changes is effectively solved.

Owner:STATE GRID CORP OF CHINA +1

Transferring point dust suppression device and method

The invention relates to a transferring point dust suppression device and method. The device is arranged at the transferring position of an upper-stage belt and a lower-stage belt. The device comprises a discharge pipe, an ultrasonic smoke nozzle, a dust suppression cover, baffle plates, a return pipe, a sealing part and a dust blocking curtain. An induced airflow calculation method is invented, aformula for calculating the size of the induced airflow in different working conditions and devices is provided, guidance is provided for reasonably setting the parameters such as the fogdrop particles and the spraying volume of the ultrasonic smoke nozzle, and the purpose of reducing the dust suppression energy consumption is achieved. Ultrasonic waves are used for generating frog so that the space of the discharge pipe can be humidified, in cooperation with the flow blocking effect of the baffle plates and the dust blocking curtain and the pressure relief effect of the return pipe, dust carried in the airflow settles under the gravity effect, the combination probability of the frog and dust is improved through kinetic energy of the induced airflow, and the dust removal effect is improved. The transferring point dust suppression device and method are suitable for dust suppression of the bulk material belt conveying and transferring process without special requirements on the materialmoisture content, such as dust suppression of the belt conveying processes such as coal, iron ore, building quarrying, sintering and gravel loading and unloading.

Owner:天津矿嘉科技有限公司

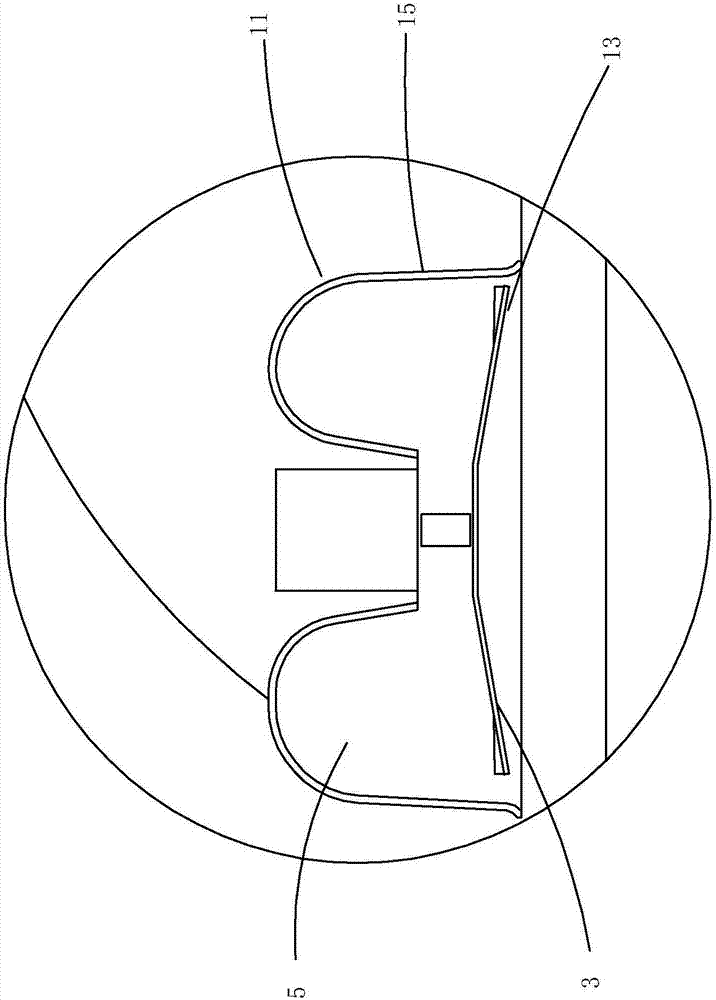

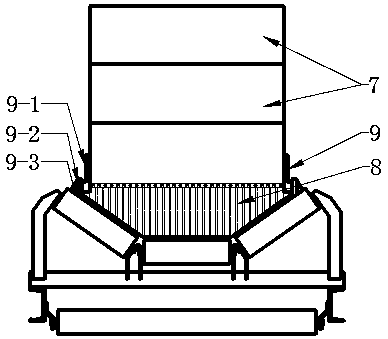

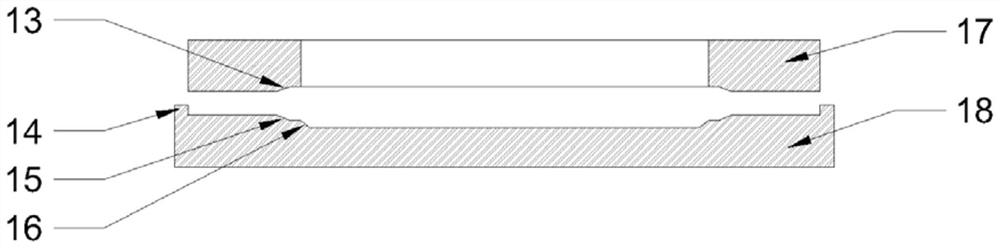

Ultra-thin vapor chamber and manufacturing process thereof

PendingCN111220013AGuaranteed reflowIncrease the flow space of saturated steamIndirect heat exchangersEngineeringPipe

The invention discloses an ultra-thin vapor chamber and a manufacturing process thereof. The vapor chamber comprises a cover plate, a bottom plate and a porous capillary structure arranged between thecover plate and the bottom plate; a plurality of supporting columns are fixedly connected to the inner side wall of the cover plate, and a plurality of buckling parts corresponding to the supportingcolumns are arranged on the inner side wall of the bottom plate; a first protruding part is fixedly arranged at the end of one side of the cover plate, and a first groove is formed in the inner wall of the first protruding part; a second protruding part is fixedly arranged at the end of one side of the bottom plate, a second groove is formed in the inner wall of the second protruding part, and a vacuumizing pipe / liquid injecting pipe is welded between the first groove and the second groove in a penetrating mode; and the porous capillary structure is a special-shaped porous capillary structure, and the porous capillary structure is in an asterisk shape or other shapes. According to the ultra-thin vapor chamber which is large and thin, when the total thickness of products is smaller than 0.4 mm, it is guaranteed that the saturated steam flowing space is increased by 30 %-50 %, and the overall heat dissipation performance can be improved by 30% or above.

Owner:深圳威铂驰热技术有限公司

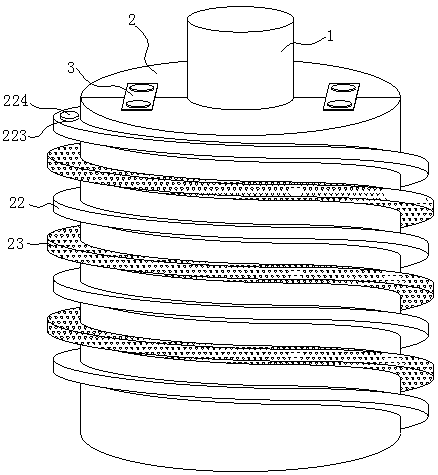

Phase-change heat dissipation motor shell and motor applying same

PendingCN110061586ATemperature dynamic balanceImprove cooling effectCooling/ventillation arrangementSupports/enclosures/casingsHeat sinkStator

The invention provides a phase-change heat dissipation motor shell and a motor applying the same. The phase-change heat dissipation motor shell comprises a motor body and a motor shell, wherein the motor body comprises a rotor assembly, a rotating shaft and a stator assembly; one end of the rotating shaft is fixedly connected with the rotor assembly through a bearing; the rotor assembly is arranged in the stator assembly in a sleeved mode; the stator assembly is arranged inside the motor shell in a sleeved mode; and spiral phase-change cooling fins are fixedly connected to the surface of the stator assembly. The invention relates to the field of motors. According to the phase-change heat dissipation motor shell and the motor applying the same, the integrated spiral heat dissipation structure is used, and compared with an existing independent heat dissipation fins, the flowing space of the phase-change working medium is large, the heat dissipation continuity is enhanced, and meanwhile,the heat dissipation effect of the traditional fan-shaped heat fins is enhanced on the basis, and the consumable material of the machine shell is saved, so that the problems that the heat dissipationcontinuity of a common phase-change heat dissipation motor is poor, the heat dissipation effect is continuously reduced along with the increase of temperature, and the phase-change working medium is poor in liquidity and small in space elasticity and phase-change working medium loss occurs easily can be solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

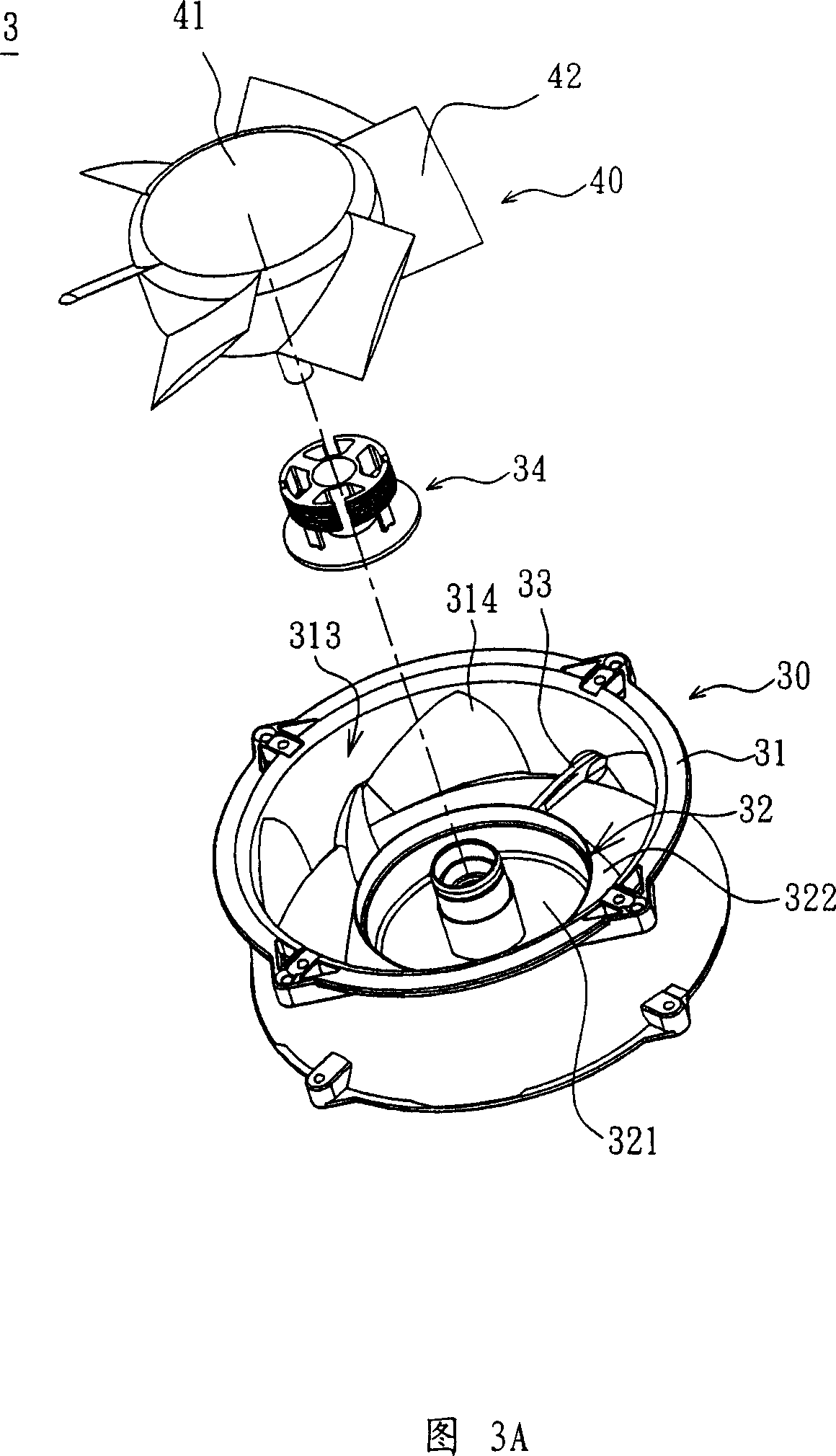

Fan and its frame

InactiveCN1940308AIncrease wind pressureIncrease air volumePump componentsPump installationsImpellerEngineering

There is disposed a fan, which includes a fan frame and an impeller. The fan frame has a frame body, a base and at least one support member. There is at least a deflector part on the inside wall of the frame body. The base is disposed in the frame body and has a bottom part and a supercharging part set on the periphery of the bottom. The support member is set between the frame body and the supercharging part of the base and the impeller is disposed in the frame body and is supported by the base.

Owner:DELTA ELECTRONICS INC

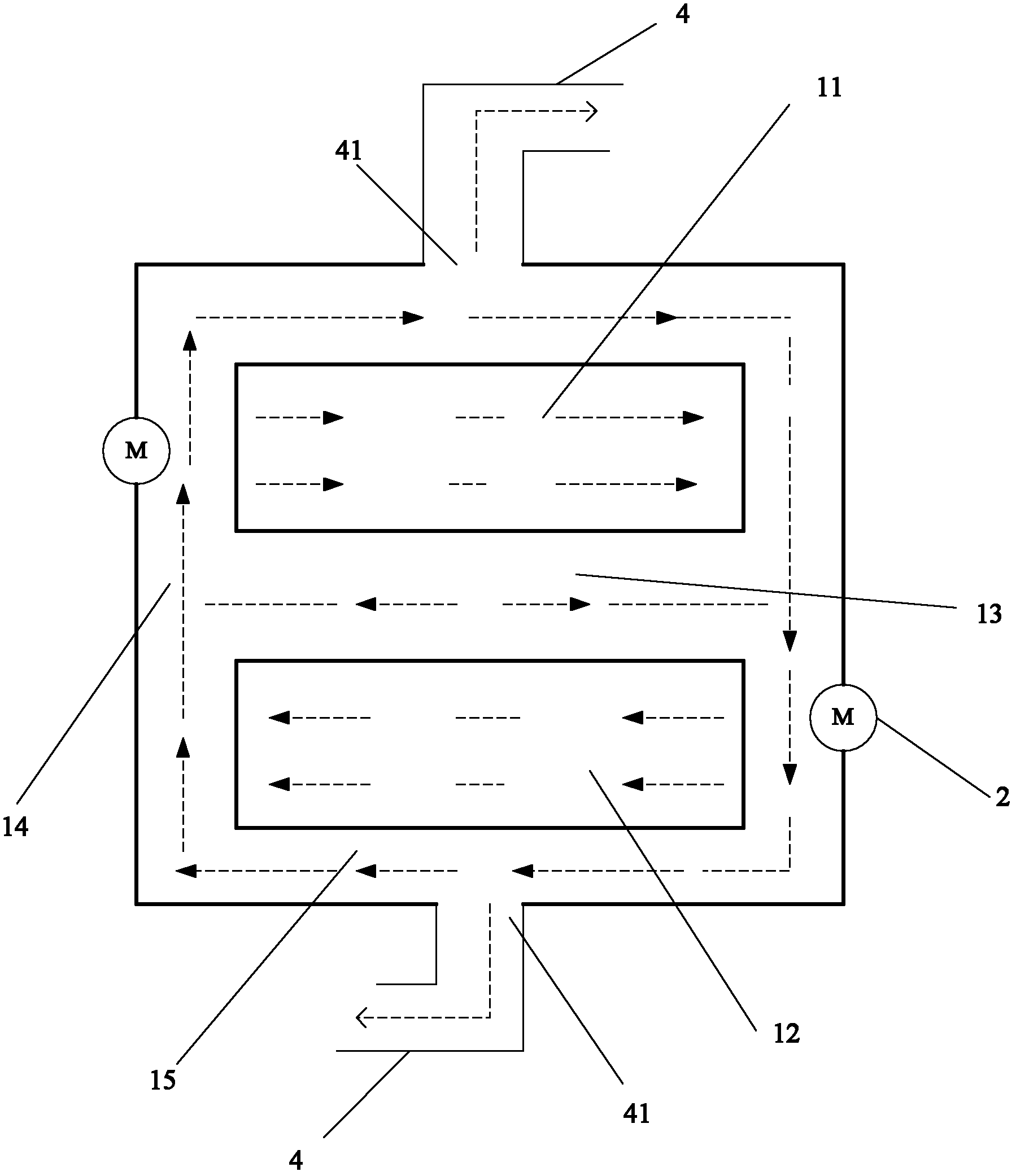

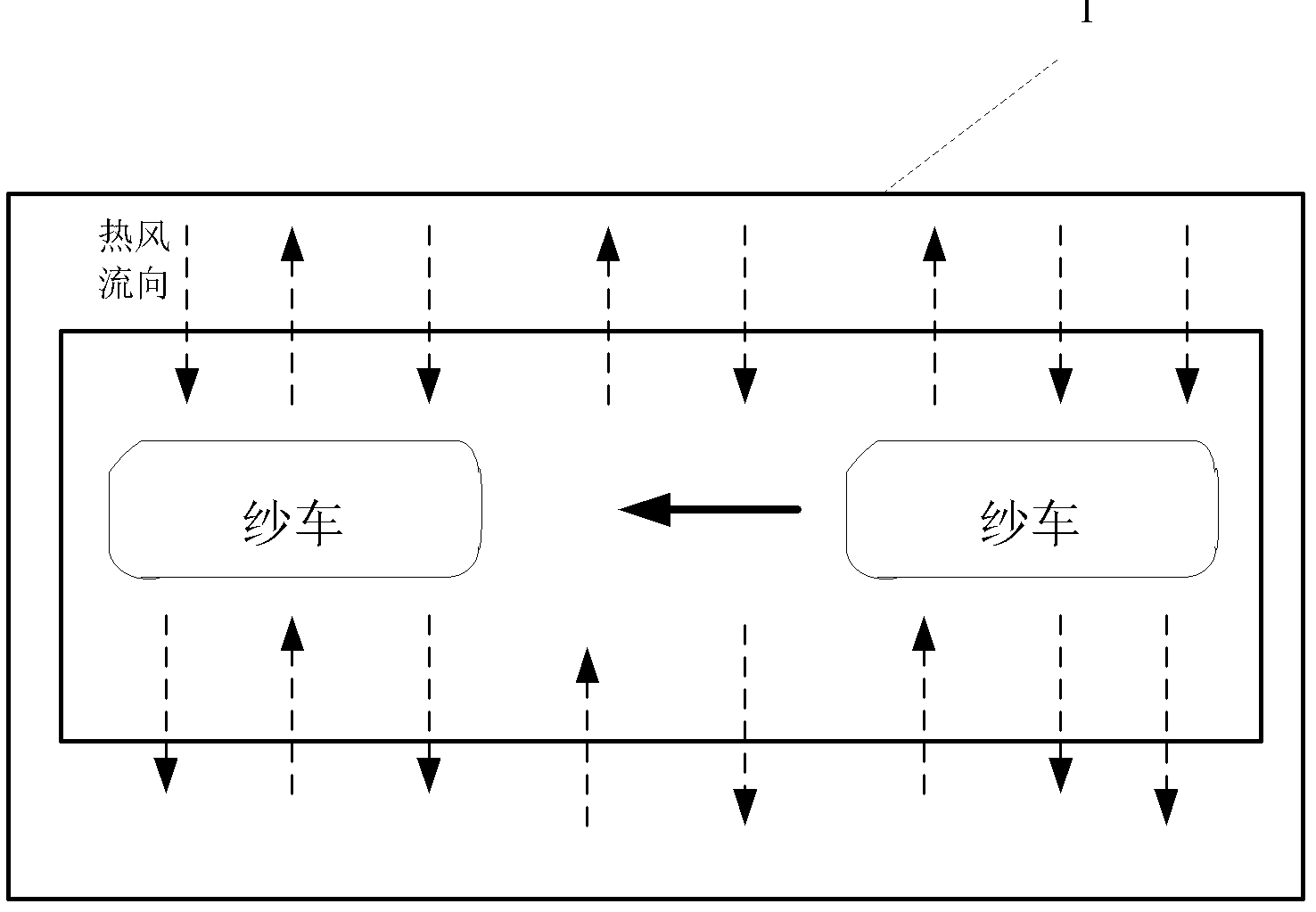

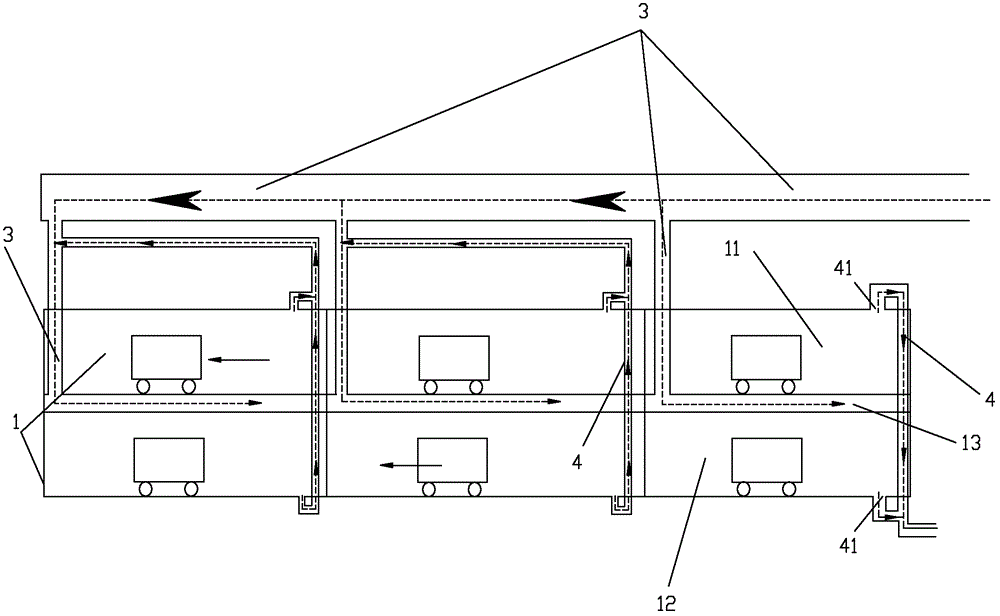

Tunnel type drying device

The invention discloses a tunnel type drying device, which comprises a furnace body, a hot air supply system, a hot air supply pipeline, a dehumidifying fan and a dehumidifying pipeline, wherein a first drying cavity and a second drying cavity are formed in the furnace body; the first drying cavity is positioned over the second drying cavity; a suspension interlayer is formed between a bottom plate of the first drying cavity and a top plate of the second drying cavity; a vertical hot air channel is formed between the side walls of the first drying cavity and the second drying cavity and the side wall of the furnace body; the vertical hot air channel is communicated with the suspension interlayer; horizontal hot air channels are formed between a top plate of the first drying cavity and a top plate of the furnace body as well as between a bottom plate of the second drying cavity and a bottom plate of the furnace body; the horizontal hot air channels are communicated with the vertical hot air channel; the hot air outlet of the hot air supply pipeline is formed in the suspension interlayer; and hot air is output from the hot air outlet. By adopting the drying device, hot air can flow better in the drying process, and the drying efficiency is increased on the premise of lowering the hot energy consumption.

Owner:CHONGQING POLYCOMP INT

Volute, fan with same and exhaust hood

ActiveCN103711730AEnsure consistencySpeed up the flowDomestic stoves or rangesPump componentsAir volumeEngineering

The invention discloses a volute which comprises a front plate, a rear plate and a surrounding plate. The front plate and the rear plate are parallel to each other in the front-back direction, and an inclined face plate which is inclined towards a space between the front plate and the rear plate is formed on the lower portion of one of the front plate and the rear plate at least; the surrounding plate is connected between the front plate and the rear plate and comprises a first helical surface section, a second helical surface section and a curved surface section, the second helical surface section corresponds to the first helical surface section, the curved surface section is connected between the first helical surface section and the second helical surface section, corresponds to the inclined face plates, and is deviated from helical surfaces to be outwardly protruded, and the first helical surface section and the second helical surface section are located on the helical surfaces. The volute has the advantages that the outwardly protruded curved surface section is reasonably arranged on the surrounding plate, so that a flowing space of airflow inside a fan can be enlarged, flow fields in the volute can be uniformly distributed, the air volume and the air pressure of an exhaust hood can be increased, and noise can be effectively lowered. The invention further discloses the fan with the volute and the exhaust hood.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

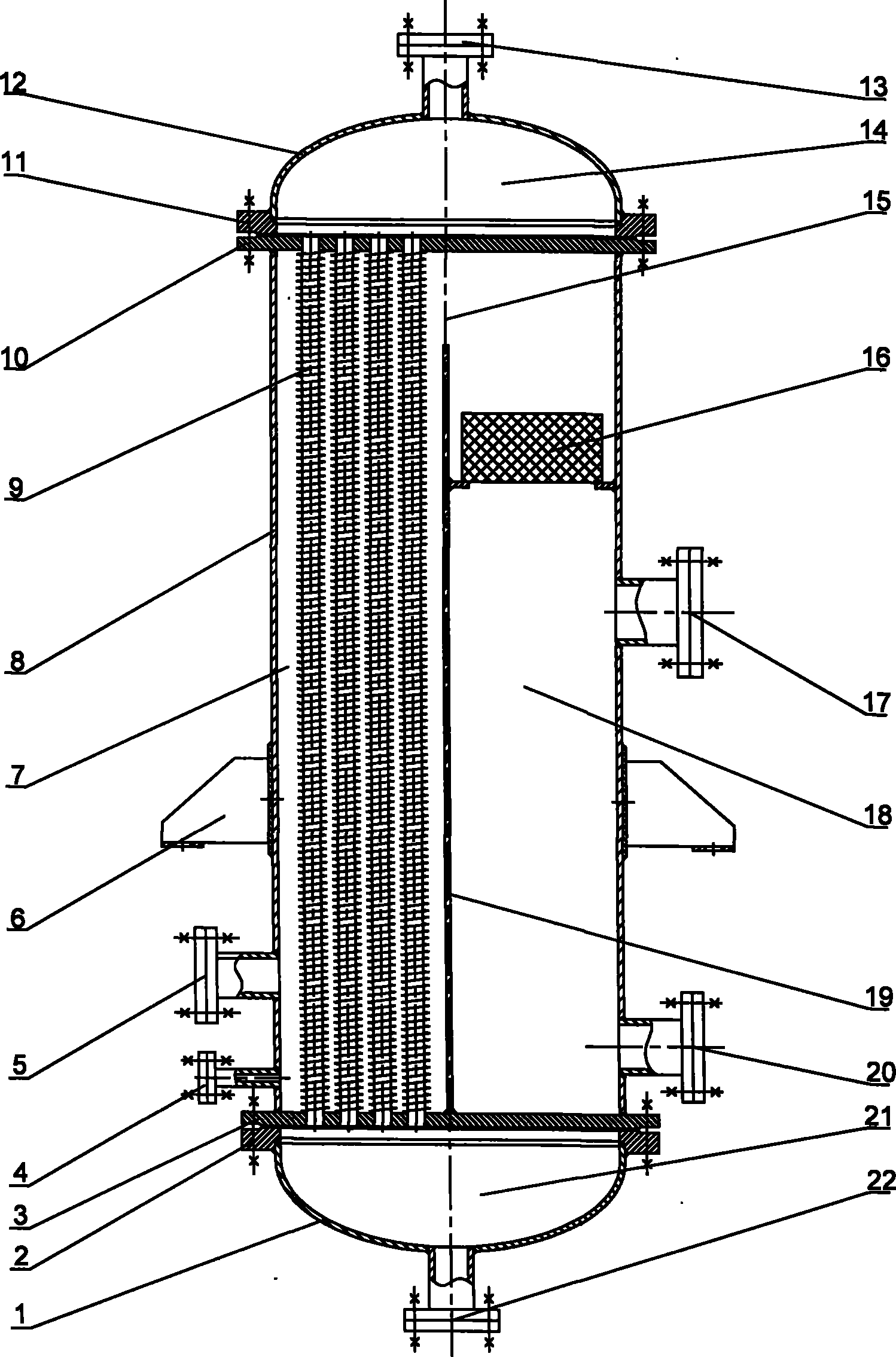

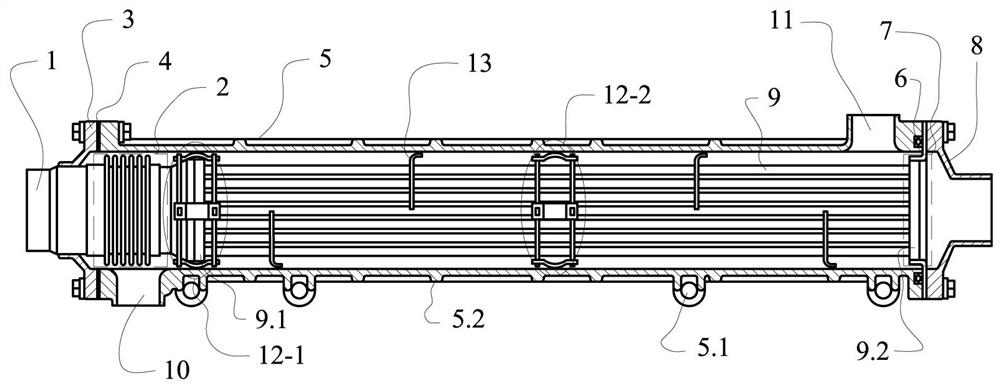

Cast shell type EGR cooler

PendingCN112577341ARaise the natural frequencyPlay the role of radial supportHeat exhanger sealing arrangementHeat exchanger casingsWater flowPipe

The invention relates to a cast shell type EGR cooler. An air inlet connector is connected with a telescopic structure with a corrugated pipe and a sleeve, the outer circumference of the telescopic structure is fixedly connected with an input end flange cover, and the input end flange cover is in bolted connection with one end of a cast pipe shell through an input end sealing gasket. The other endof the pipe shell is in bolted connection with a fixing structure and an output end flange cover with an output pipe connector through an output end sealing ring. The telescopic structure is welded to and connected with a pipe plate at one end of a pipe bundle, and a pipe plate at the other end of the pipe bundle is welded to and connected with the fixing structure. According to the cast shell type ERG cooler, the fixing structure is arranged at one end of the pipe bundle, the telescopic structure is arranged at the other end of the pipe bundle, the problem of dislocation between the pipe shell and the pipe bundle due to thermal expansion and cold contraction is solved, axial displacement compensation is conducted on a heat exchange core through a flexible structure of a double-layer corrugated pipe in the telescopic structure, the influence of thermal expansion and cold contraction on the heat exchange core is reduced, the double-layer corrugated pipe is placed at an air inlet end and combined with a shell water inlet structure, the water flow space is increased, and water flow uniformity is guaranteed.

Owner:渭南美益特发动机减排技术有限公司

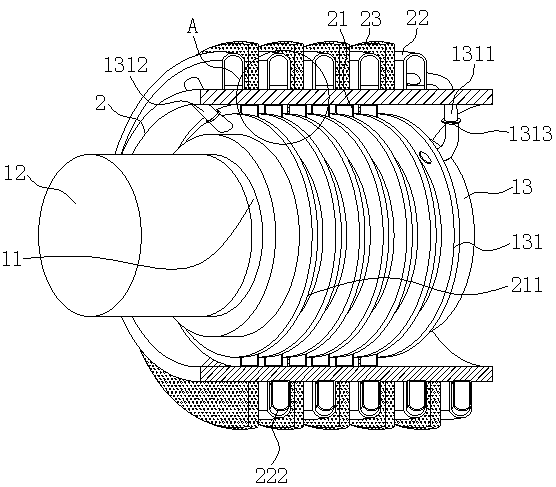

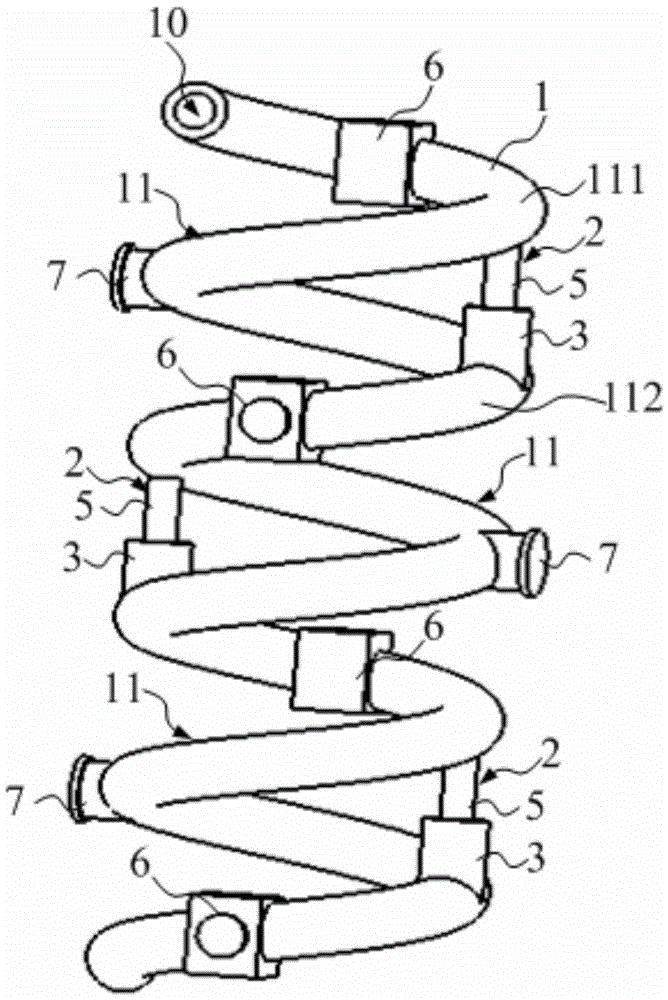

Automobile, ECU of automobile, suspension system, spring damping device and control system

ActiveCN106838097AIncrease flow spaceGood shock absorbing effectSpringsLiquid based dampersPistonEngineering

The invention provides an automobile, an ECU of the automobile, a suspension system, a spring damping device and a control system. The spring damping device comprises a spiral spring and the damper. A spring inner cavity extending to the two ends of the spring line in the spiral direction is formed in the spring line of the spiral spring. The damper comprises a working cylinder provided with a piston cavity, a piston slidably located in the piston cavity, and a guide rod connected with the piston and provided with a guide rod cavity. The piston cavity is divided into a first cavity and a second cavity by the piston, the first cavity is defined by the piston and the guide rod, and the guide rod cavity or the second cavity communicates with the first cavity. The spring inner cavity comprises at least one working section in the spiral section. The damper connected to the spring line is arranged outside the working section. The length direction of the guide rod is parallel to the axial direction of the spiral spring. The guide rod cavity and the second cavity communicate with the working section. Flowing fluid is contained in the working section. According to the technical scheme, the spring damping device is small in occupied space and has good buffering and damping performance, and arrangement difficulty is lowered.

Owner:SAIC MOTOR

Oil filling pipe assembly of passenger vehicle

InactiveCN103057402AAvoid early jumping the gun and backsprayImprove flow spacePipe supportsFlexible pipesFuel oilBackflow

The invention discloses an oil filling pipe assembly of a passenger vehicle. A guide device is also arranged in an oil filling pipe; a plurality of gun barrel limiting blocks are arranged at intervals in the circumferential direction of the inner wall above a direct connection pipe; the gun barrel limiting blocks comprise connection ends used for fixing the inner wall of the direct connection pipe; and the relative ends of the connection ends of the gun barrel limiting blocks define a guide space which is provided for a gun barrel to penetrate into and is coaxial with the direct connection pipe. When an oil gun is inserted for filling oil, the guide device can be used for limiting the gun inserting position to avoid the problems of advance gun jumping and reverse spraying caused by incorrect operation; at the same time, the oil filling length at the straight end of the oil filling pipe is increased, so that the flowing space of oil liquid in the oil filling process is enlarged, the time of collision between the oil liquid and the inner wall of the oil filling pipe is delayed, and the possibility of backflow of fuel oil is reduced; and due to the design of a bent pipe, the impact force of the oil liquid on the pipe wall due to the change of the flowing direction of the oil liquid is effectively reduced, and the possibility of backflow of the fuel oil is further reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

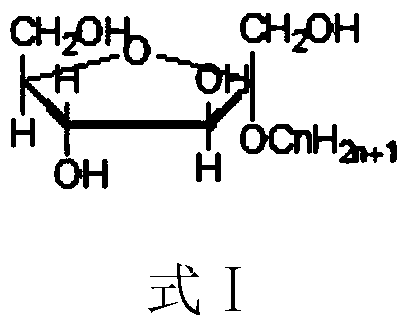

Water blocking releasing agent for oil and gas reservoirs and preparation method thereof

The invention provides a water lock releasing agent for oil and gas reservoirs, wherein the chemical agent comprises cationic polyacrylamide, alkyl glycoside, glycol ether substances and nano crystalline cellulose, the nano crystalline cellulose accounts for 1-3% of the total mass, and the glycol ether substances account for 25-40% of the total mass. The cost of the water lock releasing agent is relatively low; production process is simple, raw material sources are wide, the water lock releasing agent can be obtained by direct mixing; the water lock releasing agent is simple in use method, isprepared from the raw materials safe to the environment, and has excellent effects of reducing surface tension and solubilizing, so that the flowing resistance caused by the fact that water enters anoil layer and immerses into a stratum can be eliminated or reduced, crude oil and natural gas can easily flow to the bottom of a well, and the oil-gas yield is increased.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

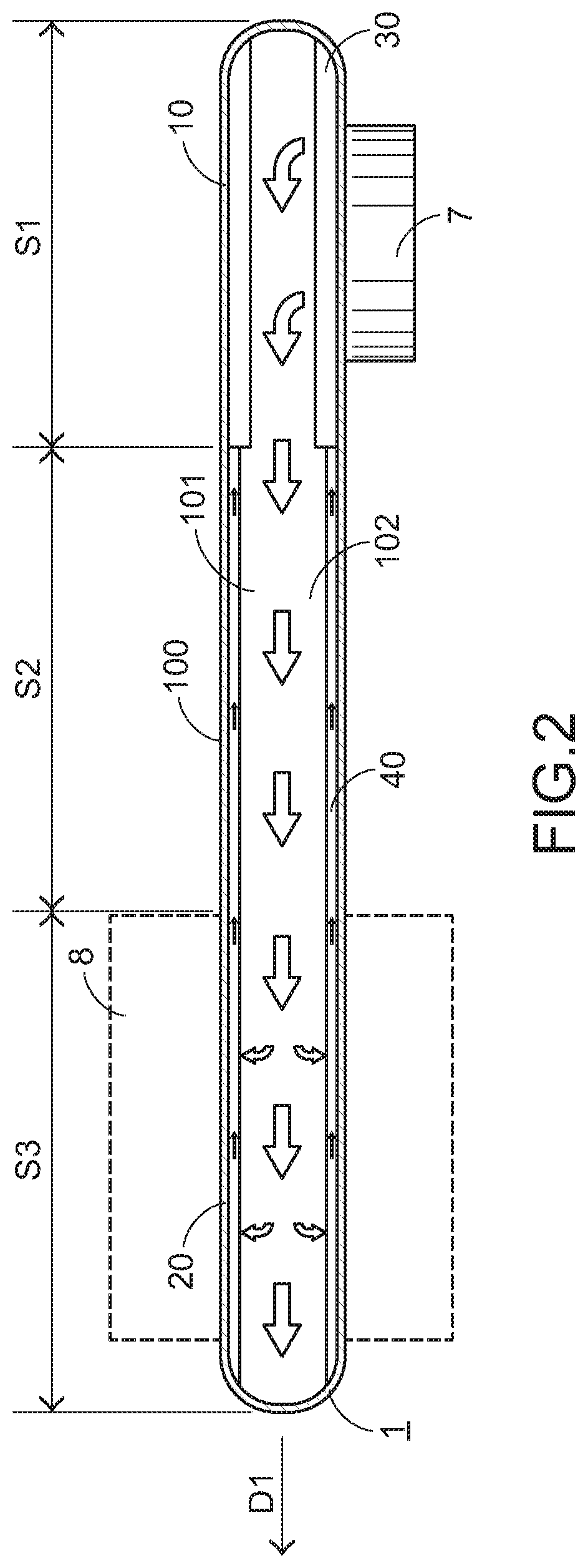

Composite-type heat type

ActiveUS20200248970A1Increase flow spaceIncrease return speedIndirect heat exchangersWorking fluidCapillary Tubing

A composite-type heat pipe includes a working fluid, a first capillary structure, a second capillary structure and a pipe body. The first capillary structure has a smooth surface. The second capillary structure has plural trenches. The pipe body accommodates the working fluid. The pipe body includes a first section and a second section. The second section is connected with the first section. The first capillary structure is formed on a first inner wall of the first section. The second capillary structure with the trenches is formed on a second inner wall of the second section. The trenches extend along an axial direction of the pipe body.

Owner:AURAS TECH

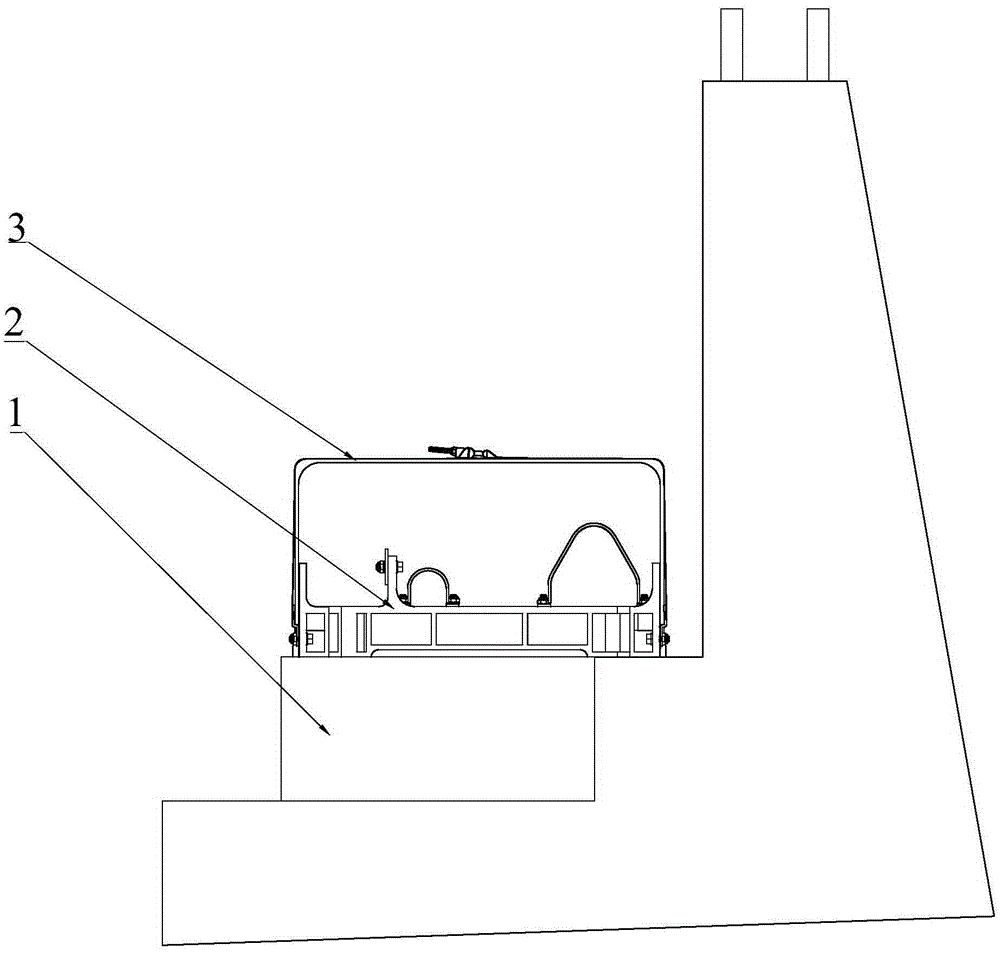

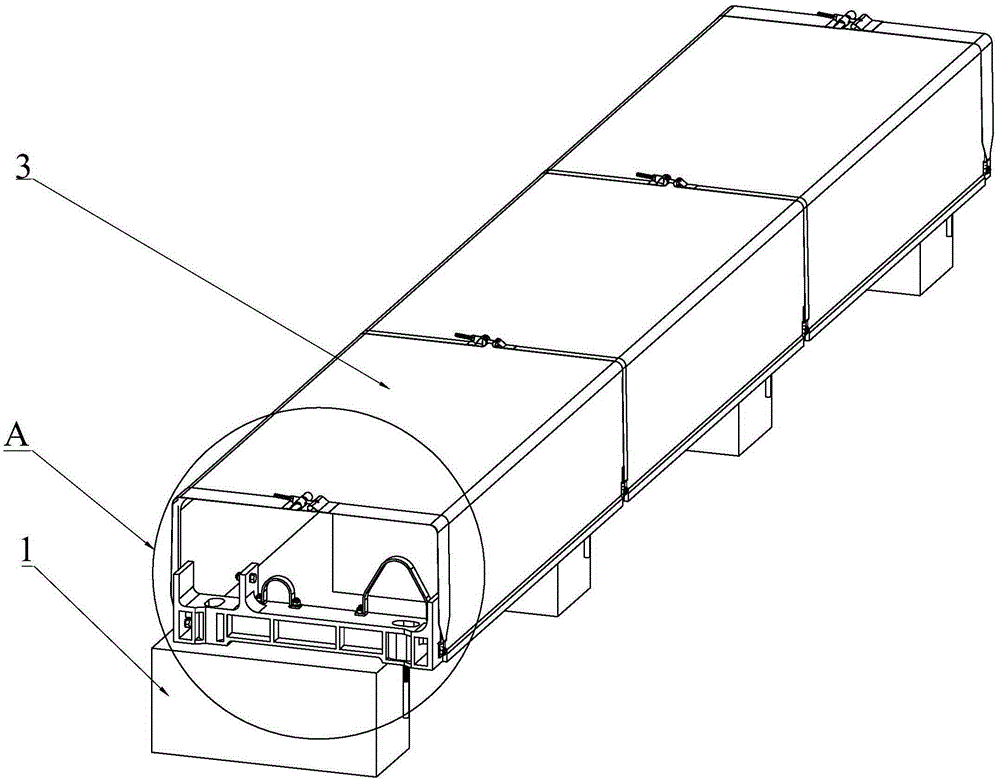

Cable trough combination for rail transit system

The invention discloses a cable trough combination for a rail transit system, and aims to provide a cable trough combination which is sunproof, rainproof, good in heat-dissipating and waterproof effect, and convenient and fast to use, install and maintain and is used for the rail transit system. The cable trough combination is characterized by comprising multiple connected cable trough combination units, and each cable trough combination unit comprises multiple cable trough supports arranged at intervals and an inverted-U-shaped cable trough cover used for shielding the cable trough supports and provided with openings in the two ends, wherein the cable trough supports are located in the cable trough cover and connected with the cable trough cover, the weight and the size of an installed device in the first step are reduced, installation is more convenient and easy to adjust, the installation accuracy is greatly improved in a narrow space particularly, the probability of reinstallation caused by mismatching installation is reduced, the working efficiency is improved, and follow-up overhauling and maintaining are facilitated.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

Hydrogen fuel cell, preparation method of hydrogen fuel cell, clamp for preparing hydrogen fuel cell and use method of clamp

ActiveCN112151828AReduce thermal deformationImprove deformation resistanceFinal product manufactureWater management in fuel cellsHydrogen fuel cellStructural engineering

The invention provides a hydrogen fuel cell, a preparation method of the hydrogen fuel cell, a clamp for preparing the hydrogen fuel cell and a use method of the clamp. The hydrogen fuel cell comprises an anode plate, a five-layer membrane electrode assembly and a cathode plate which are sequentially stacked, the five-layer membrane electrode assembly comprises a five-layer membrane electrode anda sealing structure arranged along the outer edge of the five-layer membrane electrode, and the sealing structure comprises an upper outer-layer frame, an upper inner-layer frame, a lower inner-layerframe and a lower outer-layer frame which are arranged in a stacked mode. The clamp comprises an upper clamp plate and a lower clamp plate, wherein the upper clamp plate is provided with a protrudingstructure and a stepped slope and is embedded with the lower clamp plate. According to the invention, the thicknesses of the inner-layer frames are different, and the thicker inner-layer frame is arranged on the cathode side, so that the drainage capacity of a cathode is enhanced, and water logging can be effectively reduced; the clamp is used for double-layer frame sealing and integrated packaging, the forming process is simple, the overall deformation resistance is high, and damage to membrane electrode materials and structures due to overpressure, dislocation and other problems in the forming process can be effectively reduced.

Owner:FAW JIEFANG AUTOMOTIVE CO

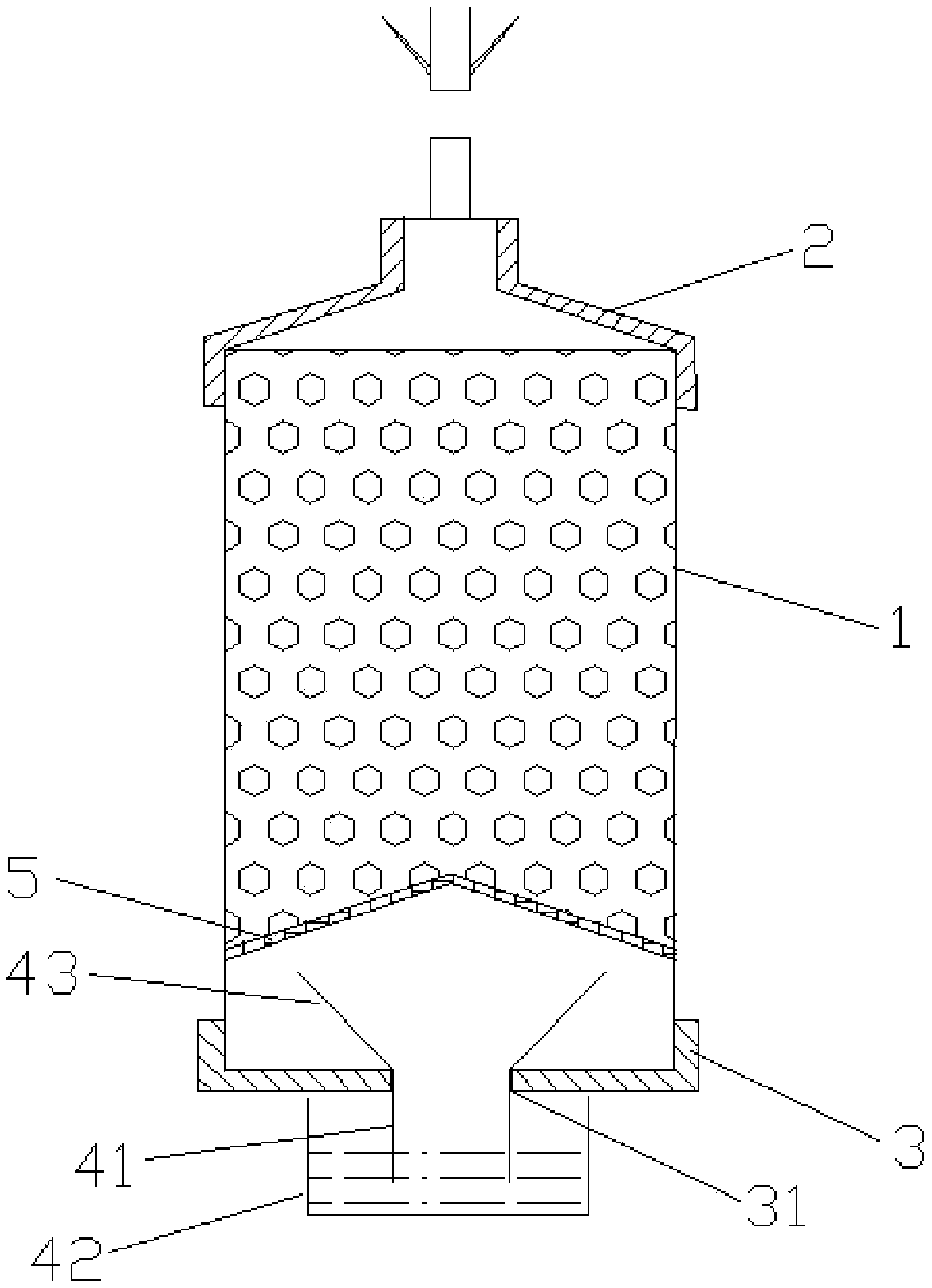

Liquid separation device and air conditioner comprising liquid separation device

InactiveCN103363732AIncrease distanceImprove stabilityFluid circulation arrangementEngineeringRefrigerant

The invention provides a liquid separation device and an air conditioner comprising the liquid separation device. The liquid separation device comprises a first liquid collection tube and a liquid separation tube, wherein the two end faces of the first liquid collection tube are closed; a plurality of tube wall outlets are formed in a tube wall of the first liquid collection tube in a length direction; the liquid separation tube is arranged in the first liquid collection tube; one end of the liquid separation tube stretches out of one end face of the first liquid collection tube; and the liquid separation tube is eccentrically arranged in the first liquid collection tube. With the adoption of the technical scheme, the liquid separation tube is eccentrically arranged in the liquid collection tube, so that a distance between the liquid separation tube and an inner wall of the liquid collection tube is increased, a larger flowing space is provided for gas and liquid phase refrigerants flowing out of the liquid separation tube, the liquid separation stability of the gas and liquid phase refrigerants is improved, the gas and liquid phase refrigerants entering the liquid collection tube are more uniformly distributed into microchannel tubes, and furthermore a utilization ratio of a heat exchange area of a microchannel heat exchanger is increased.

Owner:GREE ELECTRIC APPLIANCES INC

Slag falling system of garbage boiler

The invention discloses a slag falling system of a garbage boiler. The slag falling system comprises a square-opening directional hood, a columnar hood or a mushroom-type hood, an air distributing plate, a slag falling pipe, a casting material and a slag outlet and also comprises a duckbill-type directional hood, wherein the duckbill-type directional hood, the square-opening directional hood and the mushroom-type hood are distributed on the outer side of the slag outlet from inside to outside in a layered manner; the square-opening directional hood and the duckbill-type directional hood are distributed at the near position close to the slag outlet at an interval in a staggering manner and form a step shape with up-down fall; the mushroom-type hood is distributed on the outer side of the slag outlet; the duckbill-type directional hood is completely buried in the casting material, while the square-opening directional hood and the mushroom-type hood extend out of the surface of the casting material; all the hoods are vertically inserted into opened holes of the air distributing plate. The slag falling system disclosed by the invention has the beneficial effects that the duckbill-type directional hood, the square-opening directional hood and the mushroom-type hood are combined and distributed, so that the flowing space of furnace slag is enlarged, the winding probability of iron wires at a slag falling port is reduced, the fluidization air quantity of the outlet is increased, and the whole device is beneficial to forming good working condition with uniform fluidization and disturbance at the upper part and smooth drainage and deslagging at the lower part.

Owner:南通万达能源动力科技有限公司

Wave-shaped applying structure

InactiveCN101013237AAvoid enteringIncrease flow spacePrinted circuit aspectsThin material handlingWave shapeParticle packing

The invention relates to a wave-shaped coating structure, including the S / R coating layer coating on the TAB / COF, and the said S / R coating layer installed a number of concave parts to make the edge wave shape. The said concave part width is 1~10 lead line unit, and in the shape of rectangular, trapezoidal, U-shape or V-shape. The invention places a number of concave parts at the edge of S / R coating layer, making the S / R coating layer edge forming wave shape, and the region without coating S / R coating layer in the wave-shape edge forms a space which can exclude ACF particles when pressing, to increase the flow space of ACF particles, and reduce ACF particle packing, and ultimately avoid TAB / COF lead line short circuit.

Owner:BOE TECH GRP CO LTD +1

Tunnel type drying device

The invention discloses a tunnel type drying device, which comprises a furnace body, a hot air supply system, a hot air supply pipeline, a dehumidifying fan and a dehumidifying pipeline, wherein a first drying cavity and a second drying cavity are formed in the furnace body; the first drying cavity is positioned over the second drying cavity; a suspension interlayer is formed between a bottom plate of the first drying cavity and a top plate of the second drying cavity; a vertical hot air channel is formed between the side walls of the first drying cavity and the second drying cavity and the side wall of the furnace body; the vertical hot air channel is communicated with the suspension interlayer; horizontal hot air channels are formed between a top plate of the first drying cavity and a top plate of the furnace body as well as between a bottom plate of the second drying cavity and a bottom plate of the furnace body; the horizontal hot air channels are communicated with the vertical hot air channel; the hot air outlet of the hot air supply pipeline is formed in the suspension interlayer; and hot air is output from the hot air outlet. By adopting the drying device, hot air can flow better in the drying process, and the drying efficiency is increased on the premise of lowering the hot energy consumption.

Owner:CHONGQING POLYCOMP INT

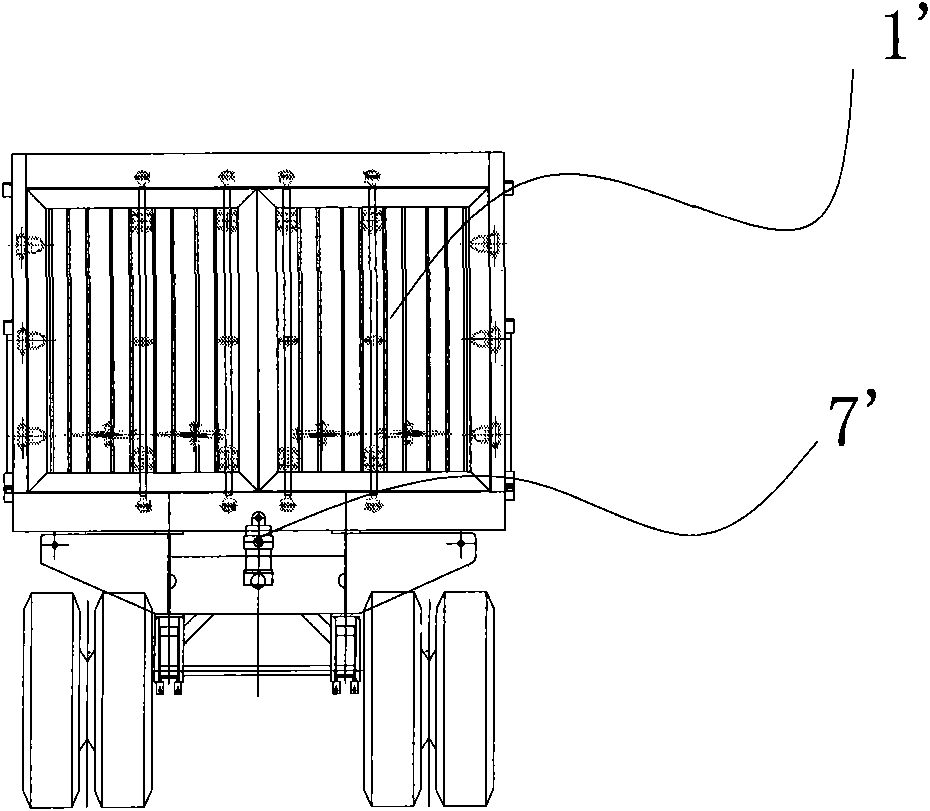

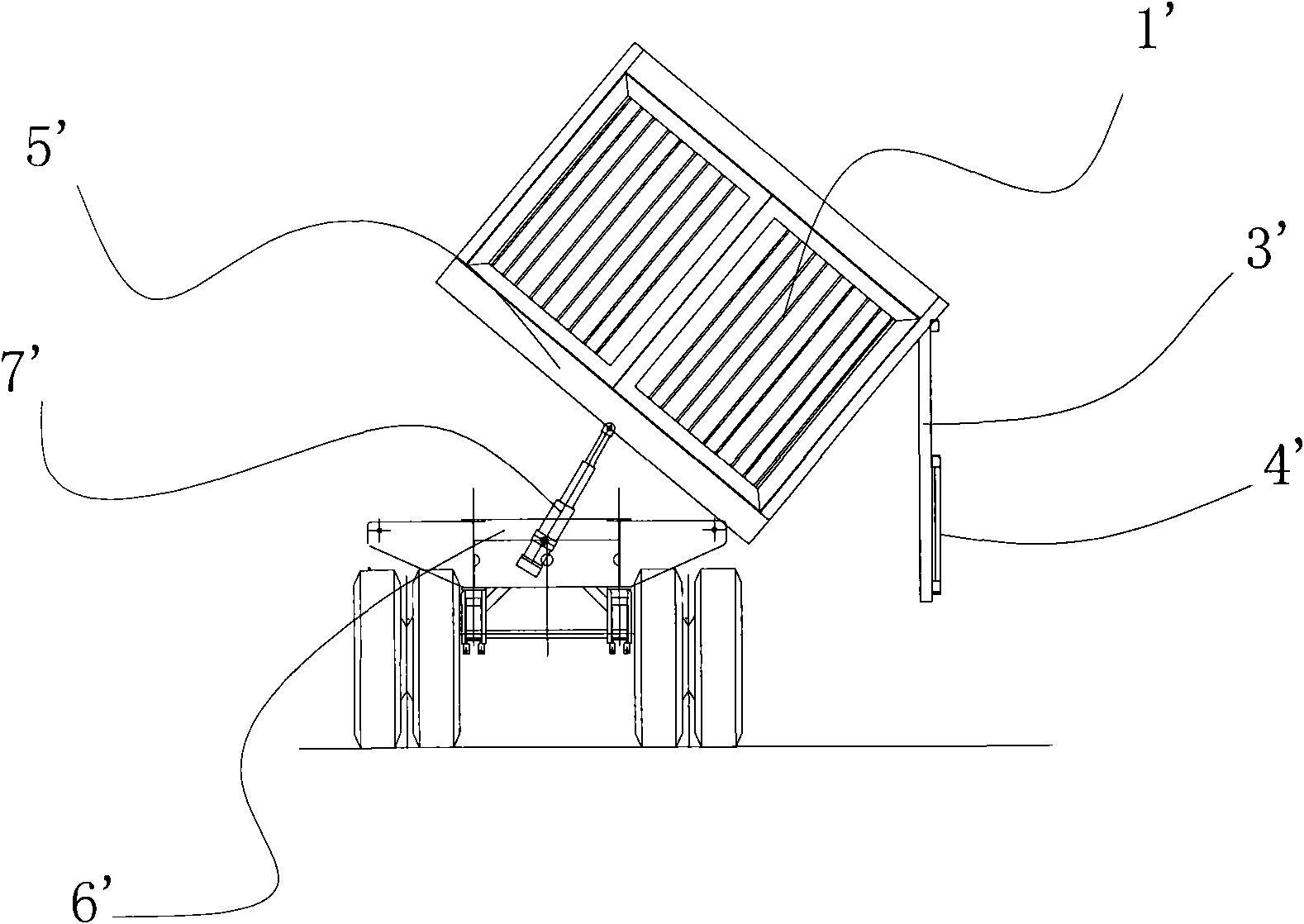

Side dumping car

InactiveCN101624028ANot easy to influenceEasy to controlVehicle with tipping movementBiomedical engineering

The invention relates to a side dumping car comprising a lower rack and a compartment body, wherein the compartment body is arranged on the lower rack and can turn towards both sides. The compartment body can be divided into a plurality of sections of independent compartment bodies, each section of independent compartment body in the independent compartment bodies comprises each section of independent upper rack and each section of independent compartment arranged on each section of independent upper rack, the top corner ends of the front end wall and the back end wall of each independent compartment are at least provided with two side compartment door power elements used for respectively operating the opening and closing of two side compartment doors at both sides of the compartment, and at least one compartment power element operating the lifting of the compartment is arranged on the lower rack at the front end or / and the back end of each independent compartment. In the side dumping car, each section of compartment body can independently dump goods towards any one side and also can dump the goods towards one side simultaneously, and any two sections or a plurality of sections of compartment bodies also can be combined to dump the goods towards the same side; in addition, the problem of the deformation of the upper rack also can be solved simultaneously.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com