Ultra-thin vapor chamber and manufacturing process thereof

A vapor chamber and ultra-thin technology, applied in the field of heat conduction materials, can solve problems such as the limitation of heat dissipation efficiency, and achieve the effect of improved heat dissipation performance and reliable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

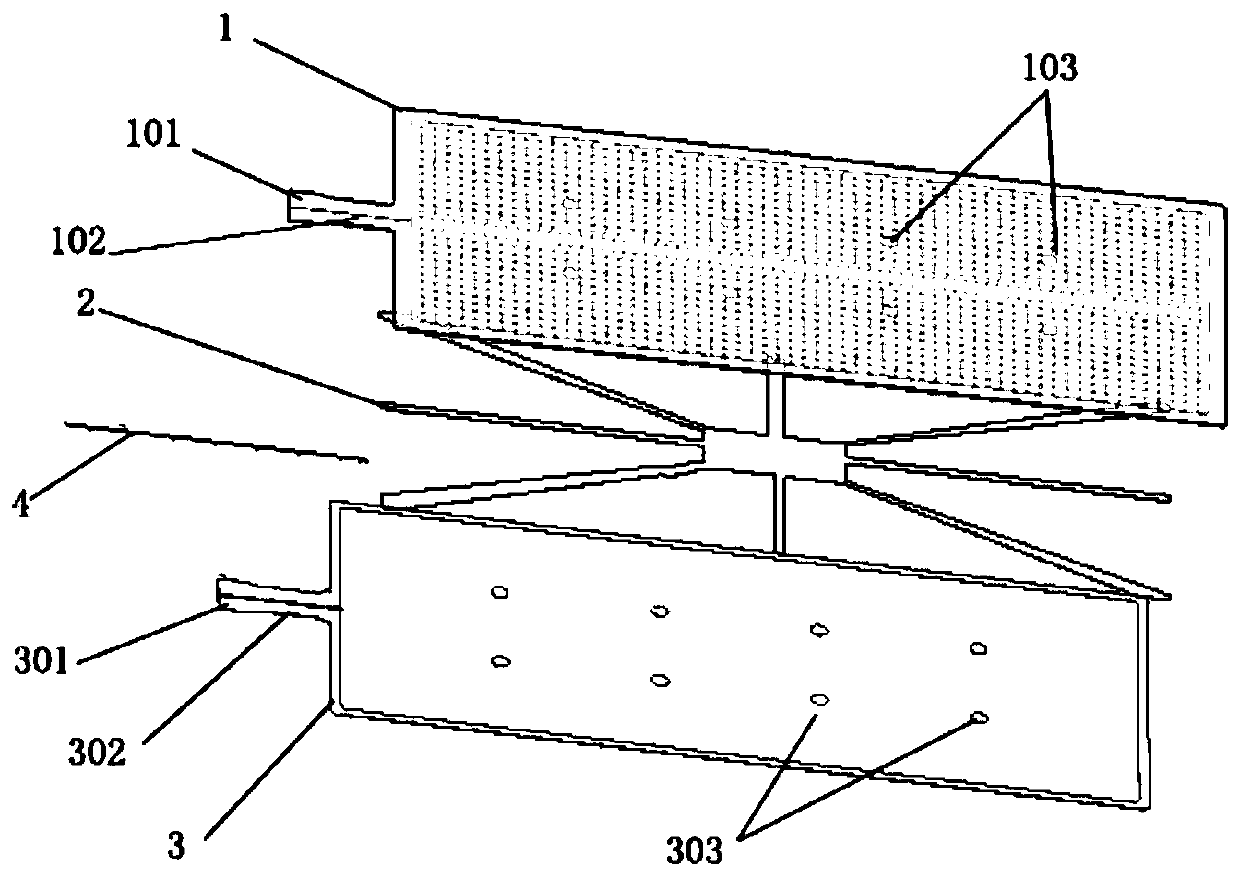

[0029] An ultra-thin temperature chamber, comprising a cover plate 1, a bottom plate 3 and a porous capillary structure 2 arranged between them. The cover plate 1 is rectangular, and a plurality of cylindrical support columns 103 are fixed on the inner wall. The cover plate 1 acts as a sealing and heat dissipation surface. Heat dissipation. The shape of the base plate 3 is the same as that of the cover plate 1 , and a plurality of fastening portions 303 corresponding to the support columns 103 are provided on the inner sidewall of the base plate 3 . The cover plate 1 and the bottom plate 3 are made of copper and its copper alloy, iron, carbon steel, aluminum and its alloy or polymer materials such as Saigang, the thickness of the cover plate is 0.03-0.35mm, and the thickness of the bottom plate is 0.03-0.25mm; the supporting column has a diameter of 103 The longitudinal length is 0.2-1mm, mainly to strengthen the structural strength and the liquid return path.

[0030] One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com