Plant fiber sizing screen powder machine

A plant fiber and grading sieve technology, which is used in sieves, solid separation, and separation of solids from solids by air flow, can solve problems such as affecting product quality, non-standard screening specifications, and short contact time, reducing work. The effect of improving the screening efficiency and pass rate, and increasing the flow space and path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

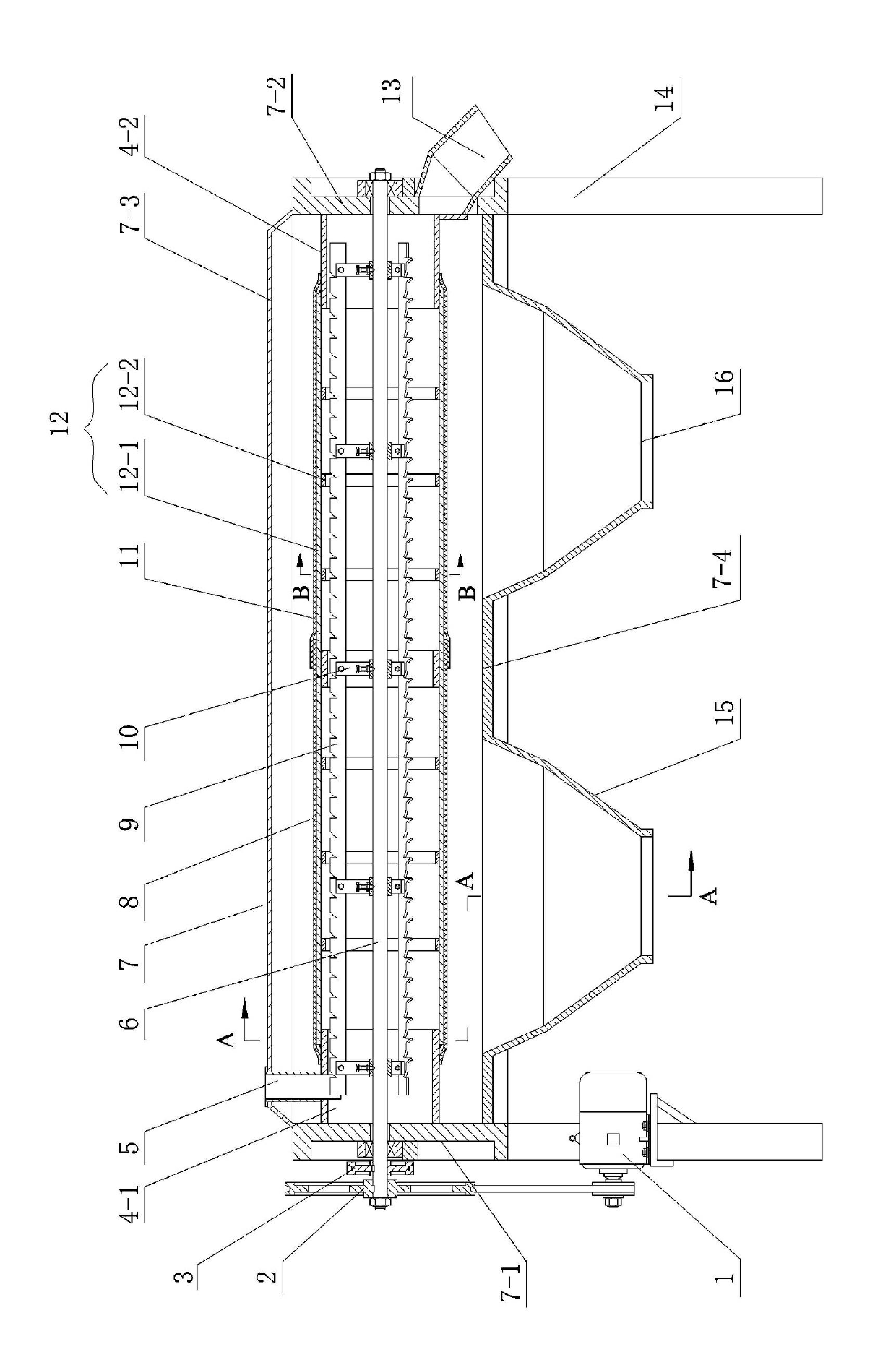

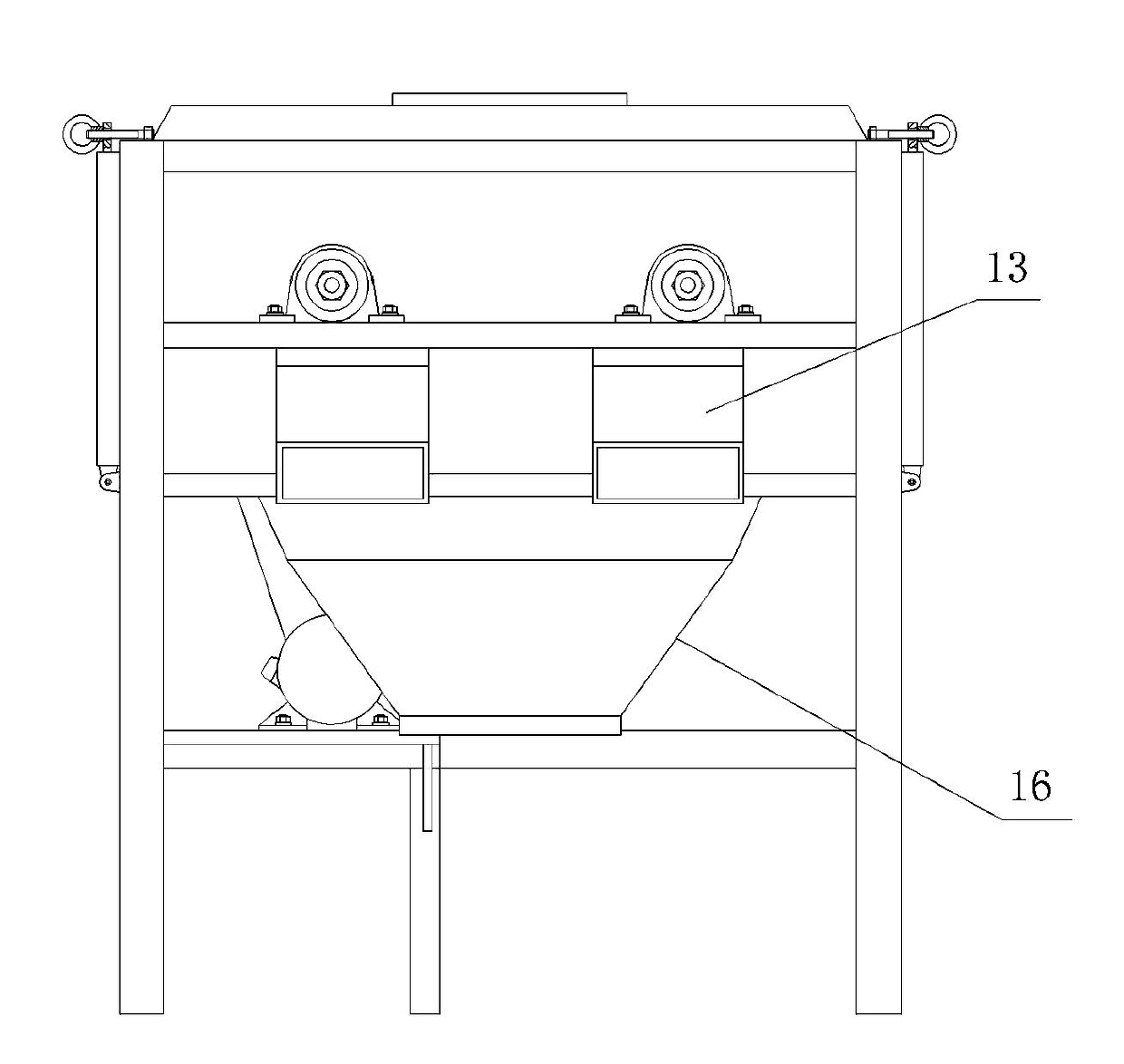

[0034] Embodiment one: Such as figure 1 , Image 6 A kind of plant fiber grading and sifting machine shown, it comprises frame 14, frame 14 upper organic shell 7, and shell 7 is mainly made of front vertical plate 7-1, rear vertical plate 7-2, top shell 7 -3 and the bottom plate 7-4 are enclosed, and the casing 7 is closed on one side and has an openable screen door 17 on one side. Between the front vertical plate 7-1 and the rear vertical plate 7-2 A sieve cylinder is fixed, and the sieve cylinder includes: front and rear end cylinders, a screen mesh frame and a screen mesh. The front end tube 4-1 is welded on the inner side of the front vertical plate 7-1, the rear end tube 4-2 is welded on the inner side of the rear vertical plate 7-2, and a screen frame is fixed between the front end tube 4-1 and the rear end tube 4-2 12. The screen frame 12 is a cylindrical hollow grid structure, the outer ring of the screen frame 12 is tightly covered with a screen, the screen is fix...

Embodiment 2

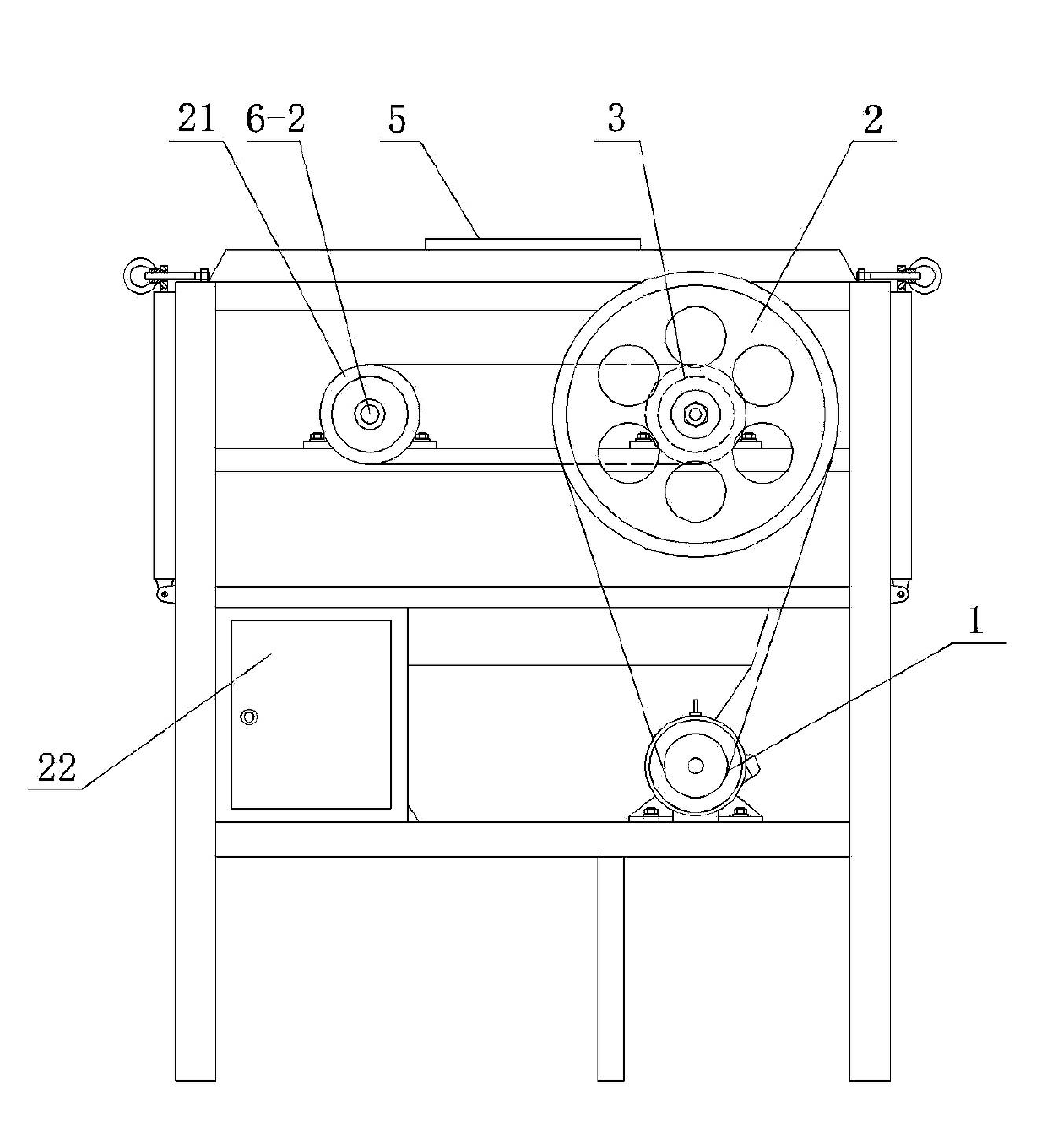

[0042] Embodiment two: Such as figure 1 , figure 2 , image 3 , Figure 4 A kind of plant fiber grading and sifting machine shown, it comprises frame 14, frame 14 upper organic shell 7, and shell 7 is mainly made of front vertical plate 7-1, rear vertical plate 7-2, top shell 7 -3 and base plate 7-4 enclosing form, described casing 7 both sides all have the screen door 17 that can be opened, between described front vertical plate 7-1 and rear vertical plate 7-2, be fixed with two Each screen cylinder includes: front and rear end cylinders, a screen frame and a screen cloth, and the structure of each screen cylinder is the same as the embodiment of a single screen cylinder.

[0043] Such as figure 1 , figure 2 , Figure 4 As shown, two screen drums are arranged in parallel between the front vertical board 7-1 and the rear vertical board 7-2, and each of the screen drums has the air delivery device, and the air delivery device on one of the screen drums The rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com