Air-drying method for improving quality of alfalfa

An alfalfa, quality technology, applied in the direction of drying solid materials, lighting and heating equipment, furnaces, etc., can solve problems such as poor drying uniformity of stems and leaves, and achieve the effect of accelerating the loss rate, reducing the loss of crude protein, and reducing respiration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The drying method for improving the quality of alfalfa includes the following steps:

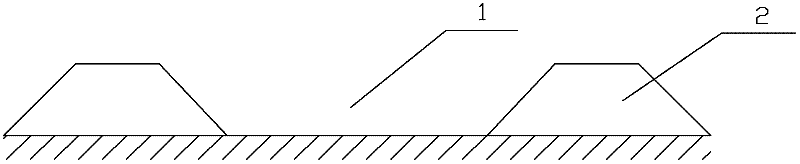

[0025] 1) Ridging: The surface of the field is treated with furrows and ridges. The cross-section of the ridge is trapezoidal, the height of the ridge is 8-10 cm, the width of the bottom of the ridge is 21 cm, the width of the top of the ridge is 5 cm, the width of the ridge is 24 cm, and the bottom angle of the trapezoidal cross-section of the ridge is 45~50°;

[0026] 2) Material selection and treatment: alfalfa ( Medicago sativa L . Eureka) as the material. After mowing at the initial flowering stage, the alfalfa stalks should be slightly flattened until they are just cracked and no sap will flow out;

[0027] 3) Drying: Place the alfalfa strips selected and treated in step 2) on the ridge of step 1) for drying. The alfalfa strips are placed on the ridge along the vertical direction of the ridge, the thickness of the grass layer is 10-12cm, and the drying time is 10 hours.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com