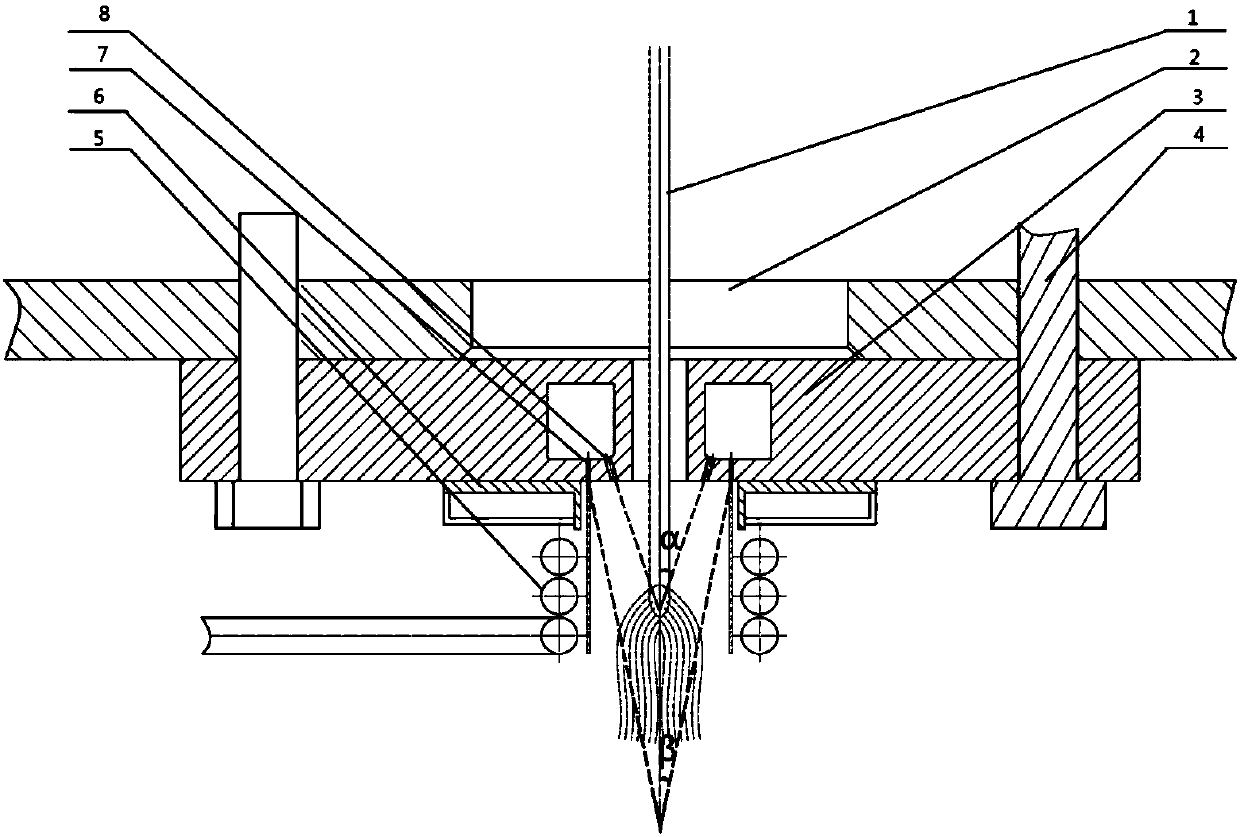

Device and method for continuously preparing titanium or titanium alloy powder for 3D printing through gas atomization

A 3D printing and gas atomization technology, which is applied in the field of powder metallurgy and atomization to prepare titanium or titanium alloy powder. Production efficiency issues, heat loss reduction, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

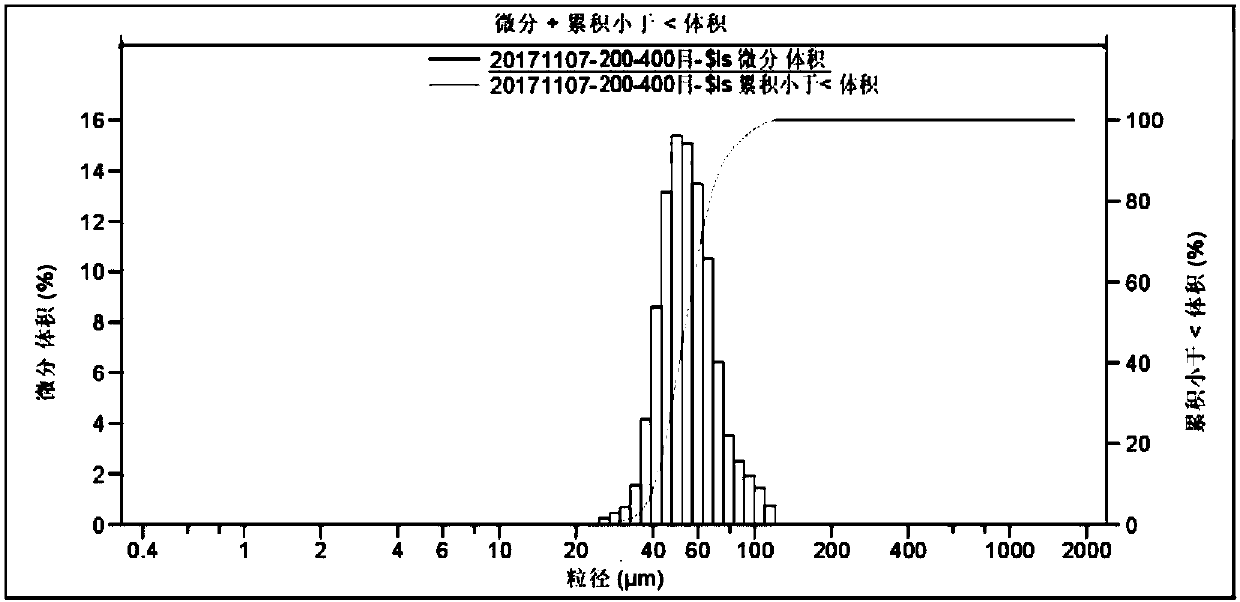

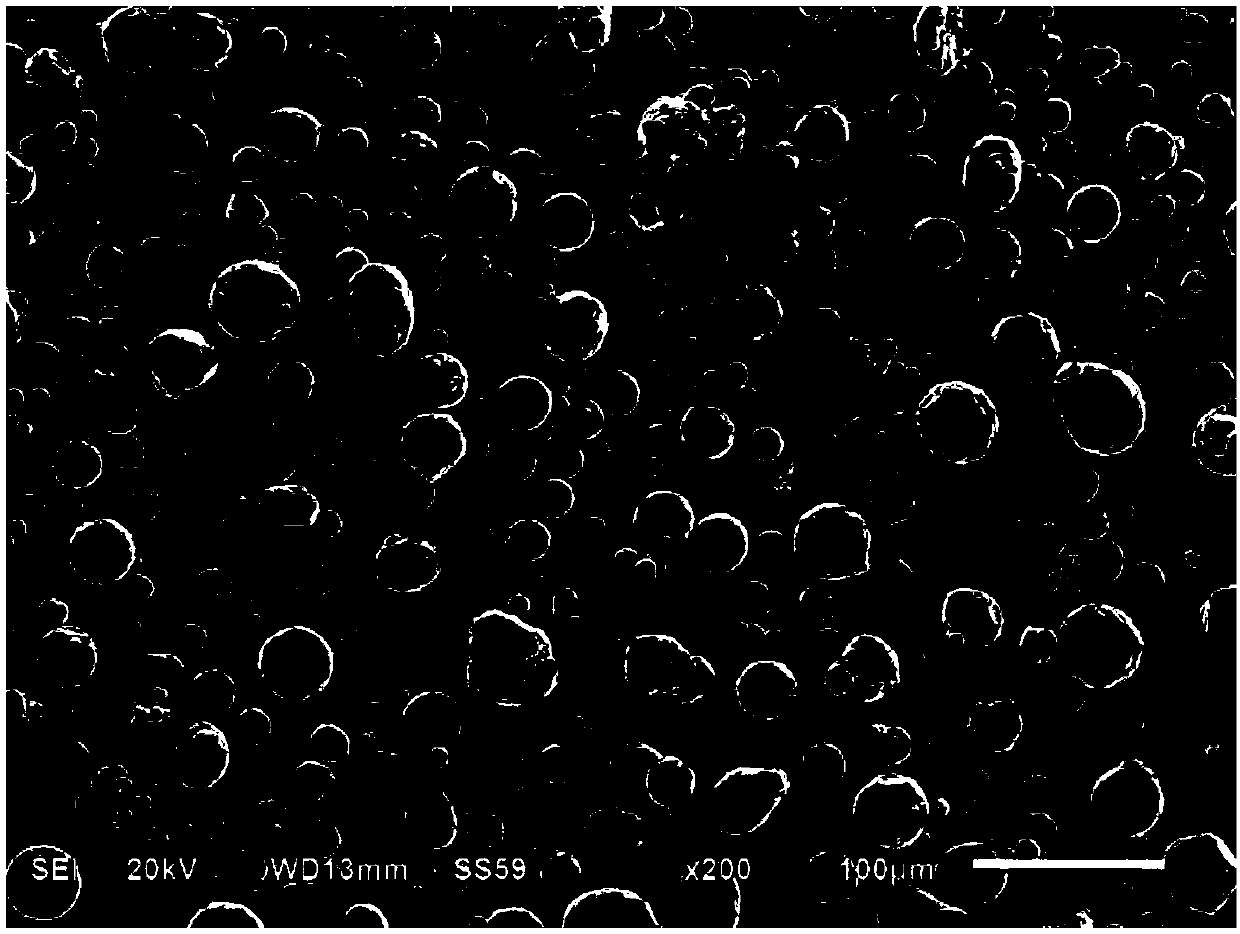

[0045] Select commercially pure titanium (CP-Ti) wire with a diameter of 3 mm as the wire material, and turn on the titanium and titanium alloy wire feeding equipment at a feeding speed of 20 mm / s. Set the main atomizing airflow nozzle of the spray pan and the auxiliary protective airflow nozzle of the spray pan at the same level. First, vacuum the entire set of atomization equipment, and the internal pressure of the equipment is 2.0 × 10 -3 Pa, and then rush into the protective argon gas, the internal pressure of the equipment is 0.04MPa, and then repeat the above operation once. Turn on the cooling water of the electromagnetic shielding ring system, and turn on the cooling water of the high-frequency induction coil system. After the titanium wire enters the high-frequency induction coil, turn on the high-frequency induction power supply. When the superheat of the titanium liquid reaches 300±20k, turn on the atomization spray pan, set the pressure of the main atomization spr...

Embodiment 2

[0047] Titanium alloy (TC4) wire with a diameter of 3 mm was selected as the wire material, and the titanium and titanium alloy wire feeding equipment was turned on at a feeding speed of 20 mm / s. Set the main atomizing airflow nozzle of the spray pan and the auxiliary protective airflow nozzle of the spray pan at the same level. First, vacuum the entire set of atomization equipment, and the internal pressure of the equipment is 2.0×10 -3 Pa, and then rush into the protective argon gas, the internal pressure of the equipment is 0.04MPa, and then repeat the above operation once. Turn on the cooling water of the electromagnetic shielding ring system, and turn on the cooling water of the high-frequency induction coil system. After the titanium wire enters the high-frequency induction coil, turn on the high-frequency induction power supply. When the superheat of the titanium liquid reaches 300±20k, turn on the atomization spray plate. The pressure of the main atomization spray pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com