Supersonic speed gas atomization sprayer

A gas atomization and supersonic technology, which is applied in the direction of spraying devices, spraying devices, safety devices, etc., can solve the problems of small entrainment effect, large droplet diameter, easy blockage of spray holes, etc., and achieve low working water pressure, Enhance the effect of secondary atomization and pipeline requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

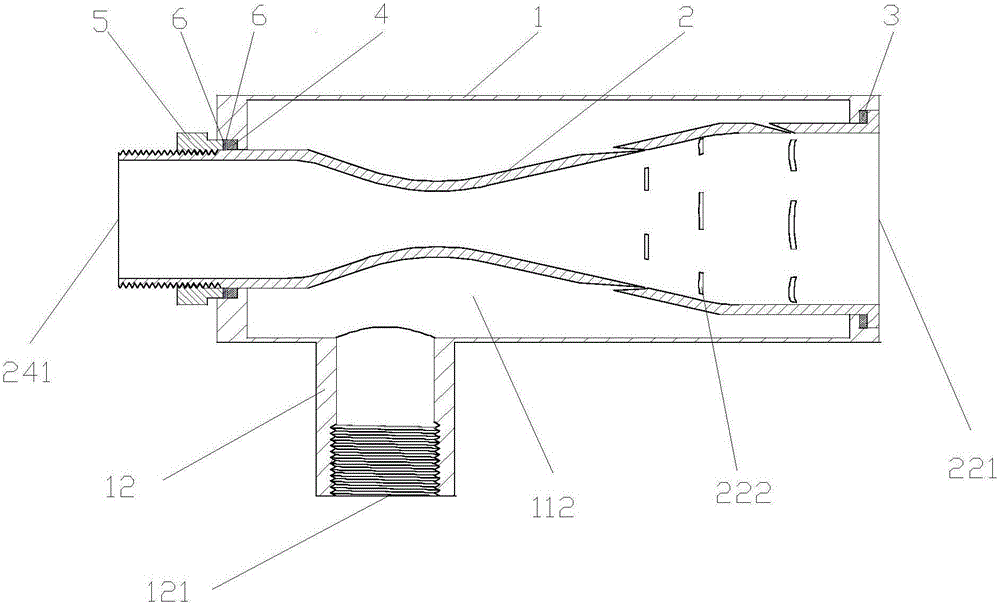

example 1

[0026] Example 1: if image 3 , Figure 4 As shown, when the air supply pressure is not high, the air flow velocity is not enough to reach supersonic speed, or high subsonic speed, it is suitable to adopt the first type of liquid film annular seam (222) to uniformly distribute the inner nozzle (2), Laval scaling Between the pipe throat (212) and the spray outlet (221), there is a dense liquid film annular seam (222), and the liquid film annular seam (222) opens toward the spray outlet (221), wherein the liquid film annular seam starts from Laval There are 3 layers distributed from the zoom pipe throat (212) to the spray outlet (221); the first layer is evenly distributed with 6 flat small annular seams in the zoom section of the Laval zoom pipe (21), and the annular seams are connected to the inner spray pipe (2) The included angle of the axis is 45°; the second layer also has 6 flat small holes evenly distributed in the zoom section of the Laval zoom tube (21), and the inclu...

example 2

[0027] Example 2: if Figure 5 , Image 6 As shown, when the supply pressure is high, the air flow velocity can reach supersonic speed, which is the second type of liquid film circular seam spiral distribution inner nozzle pipe (2), in the Laval scaling pipe throat (212) to the spray outlet (221 ), there is a liquid film annular seam (222), wherein the liquid film annular seam (222) is distributed with 2 layers; the first layer is evenly distributed with 6 flat annular seams in the expansion section of the Laval zoom tube (21), in the form of Helically distributed, the angle between the annular seam and the axis is 90°; the second layer is evenly distributed with 6 flat annular seams in the cylindrical section of the nozzle outlet, which is helically distributed, the helix has the same direction of rotation, and the helix angle depends on the working wind pressure Definitely, the included angle of the axis between the annular seam and the inner nozzle pipe (2) is 90°, and the...

example 3

[0028] Example 3: if Figure 7 , Figure 8 As shown, when the air supply pressure is very high, the air flow velocity can reach hypersonic speed, which is the third type of liquid film circular seam spiral "eight" distribution, between the throat (212) of the Laval zoom tube and the spray outlet (221) Between them, there are liquid film annular seams (222), wherein the liquid film annular seams (222) are distributed with 2 layers; the first layer is evenly distributed with 6 flat annular seams in the expansion section of the Laval zoom tube (21), in the form of a helix The angle between the annular seam and the axis is 90°; in the second layer, six flat annular seams are evenly distributed in the cylindrical section of the nozzle outlet, and they are helically distributed in the opposite direction. 90°, and the circumferential seam of the second layer of liquid film is staggered by 30° in the circumferential direction; in this way, two layers of water film will be formed duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com