Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Reduce powder content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

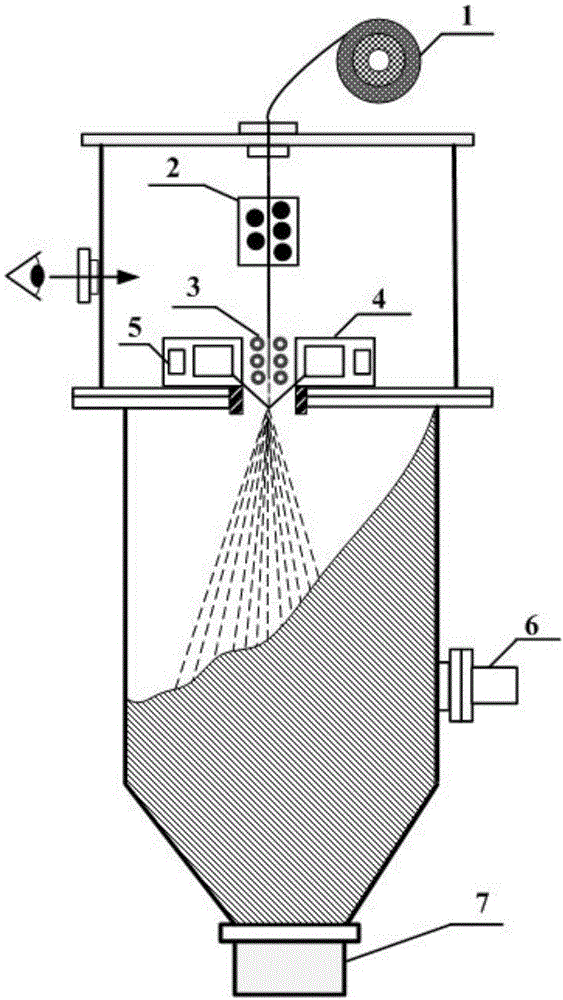

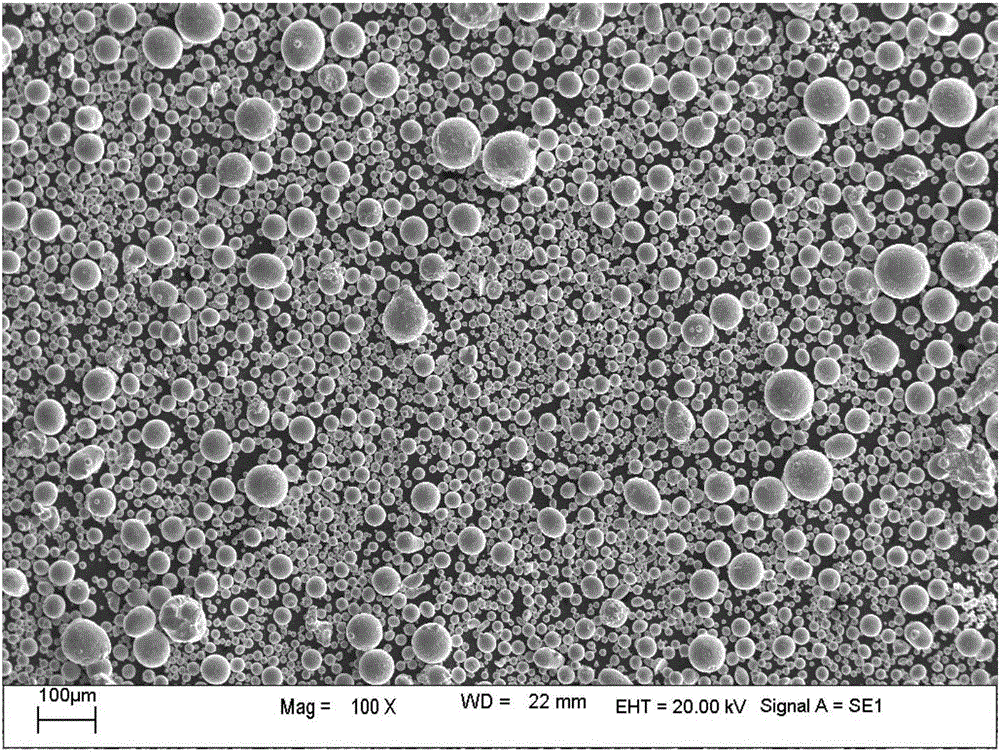

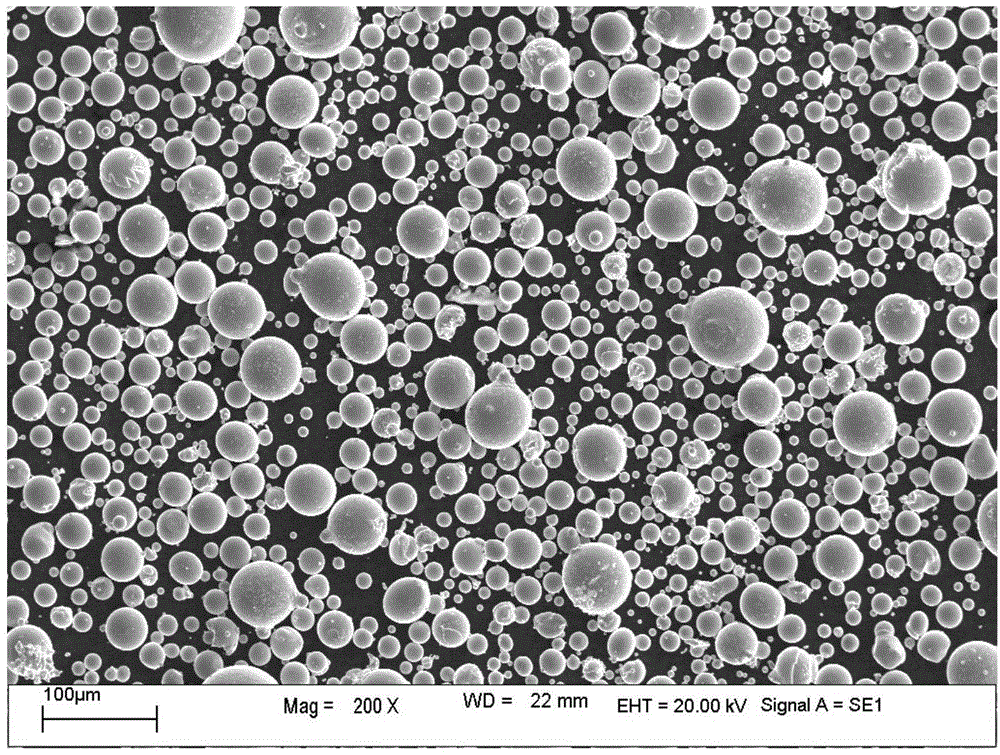

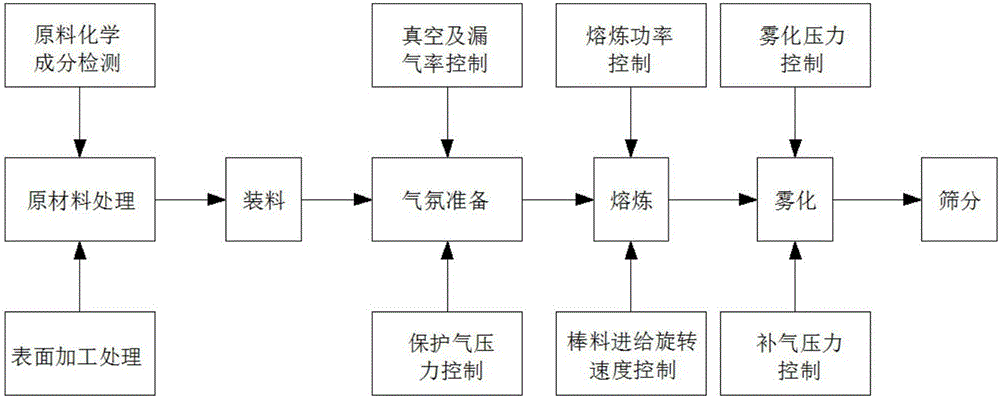

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

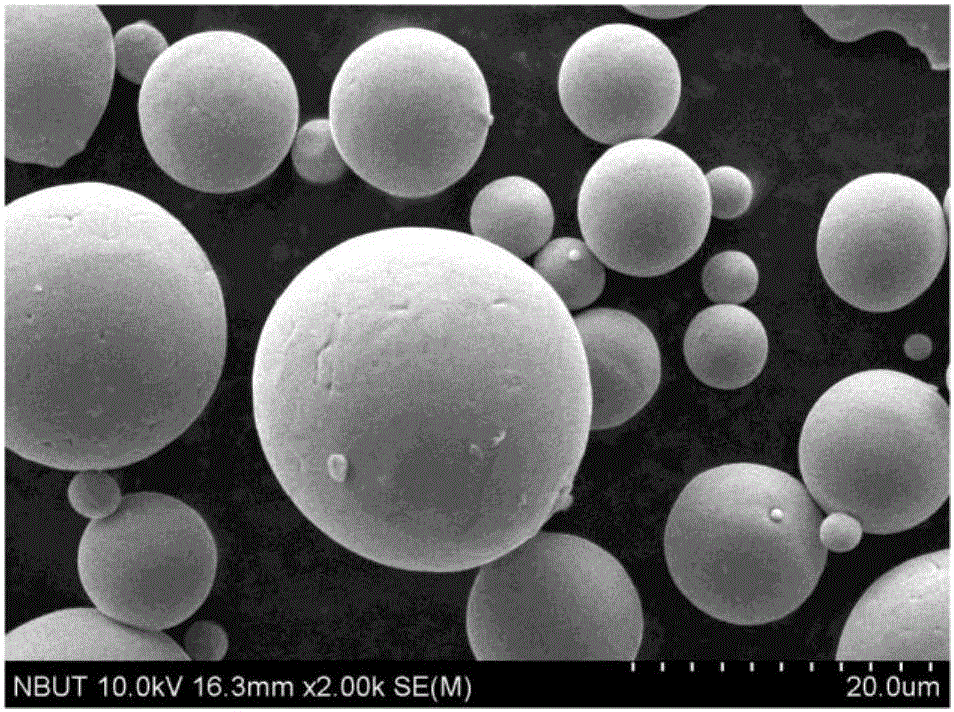

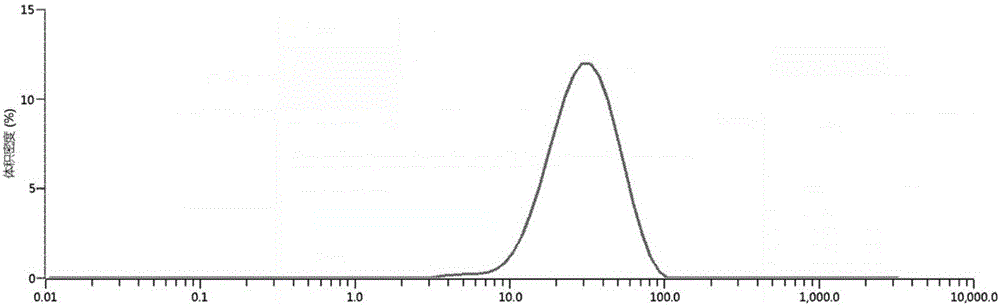

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

Preparation method of titanium alloy powder for 3D printing

ActiveCN106166617AEffective introductionIncrease productivityAdditive manufacturing apparatusTitanium alloyImpurity

The invention discloses a preparation method of titanium alloy powder for 3D printing, and belongs to the technical field of 3D printing / material additive manufacturing. The method comprises the specific steps that raw materials are loaded and clamped after being treated; pre-vacuum-pumping treatment is carried out on a smelting chamber and an atomization furnace, and high-purity argon is introduced into the smelting chamber and the atomization furnace when the vacuum degree reaches 10<-5>-10<-3> Pa; a gate valve is opened, a feeding mechanism is turned on, and bar materials are heated at the temperature of 1550-1700 DEG C; metal molten drop or liquid flow is atomized through a supersonic speed tight coupling gas atomization nozzle, and finally screening is carried out. The preparation method has the advantages that impurities introduced in the smelting and atomization process can be effectively reduced, and it is ensured that power oxygen content is controlled to be below 200 ppm; continuous production can be carried out after bar materials are replaced, and the powder is uniform in granularity, good in degree of sphericity and good in flowability.

Owner:中航迈特增材科技(北京)有限公司 +1

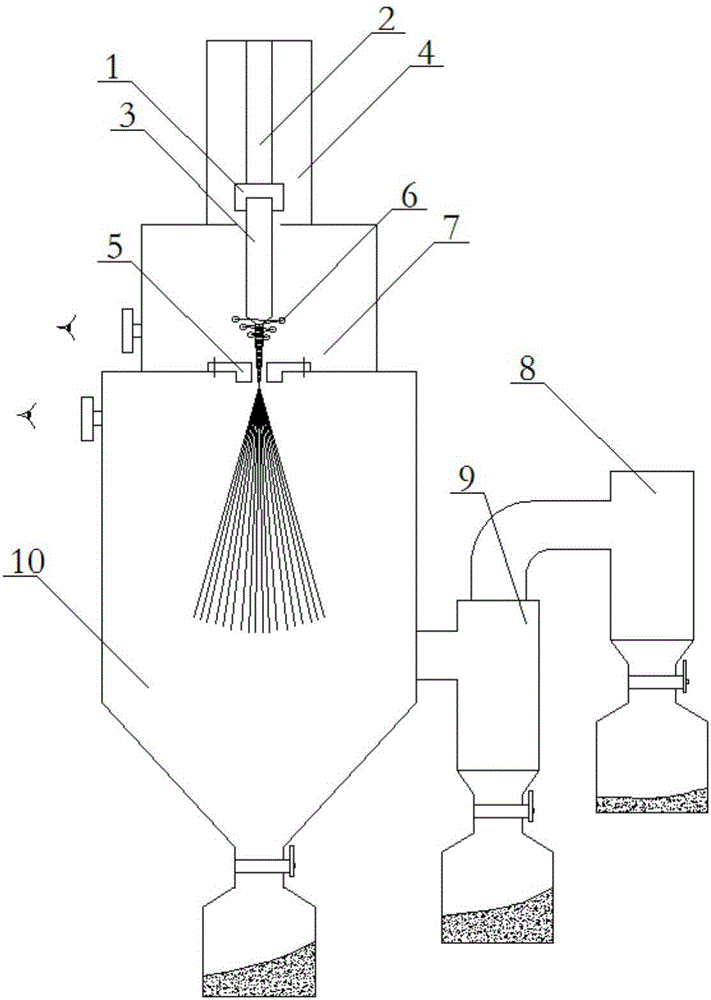

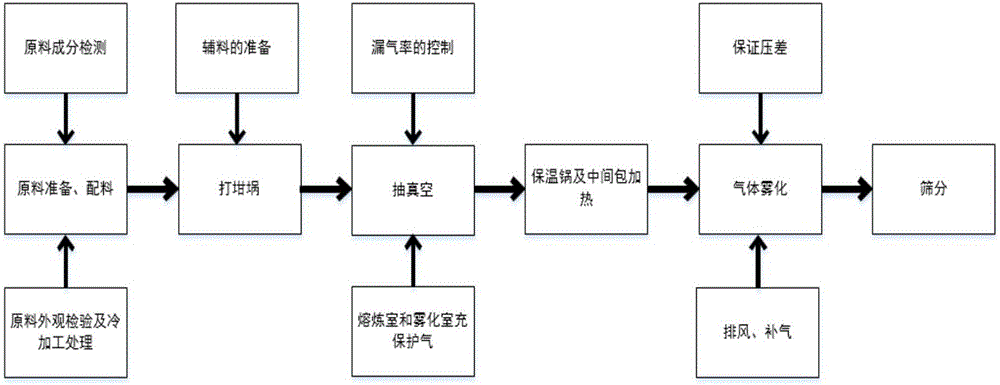

Preparation method of aluminum alloy powder for additive manufacturing

InactiveCN106392089ASmall granularityHigh sphericityAdditive manufacturing apparatusTundishHigh pressure cell

The invention discloses a preparation method of aluminum alloy powder for additive manufacturing, and belongs to the technical field of 3D printing additive manufacturing. The preparation method comprises the steps that impurities in raw materials are removed; a graphite rod is added in a crucible to be roasted at the temperature of 300-500 DEG C; a smelting chamber and an atomization chamber are subjected to vacuum pumping treatment, wherein the vacuum degree reaches 1*10<-4>-1*10<-2> Pa; a heat preservation pot and a tundish are heated; metal liquid flow which perpendicularly drops is broken into small liquid drops through a nozzle with a negative pressure drainage effect under the high pressure of 0.5-6 MPa and high-purity argon, powder is formed through cooling and spheroidizing solidification, and a 5-30 kw high-pressure fan is adopted; and after the temperature is lower than 50 DEG C, screening is carried out under the atmosphere of high-purity argon. The preparation method has the advantages that industrial production can be achieved, the domestic urgent demand for high-performance aeronautical aluminum alloy powder materials is met, and the manufacturing cost is effectively saved.

Owner:中航迈特粉冶科技(北京)有限公司

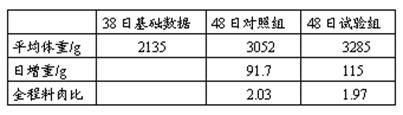

Powdery material of compound feed for broilers and preparation method of powdery material

ActiveCN102326691AHigh energyReduce powder contentAnimal feeding stuffAccessory food factorsBiotechnologySodium bicarbonate

The invention discloses a powdery material of a compound feed for broilers and a preparation method of the powdery material. The powdery material comprises the following raw materials: corn, corn albumen powder, peeled bean pulp, cotton dregs, corn alcohol dregs and soluble substances thereof, chicken and duck oil, soyabean lecithin oil, feather meal, fish meal, mountain flour, calcium hydrogen phosphate, table salt, lysine, methionine, sodium bicarbonate, microecological substances, choline chloride, betaine, complex enzyme, phytase, detoxified toxin, mineral substances and vitamins. The preparation method comprises the following steps of: a, weighing other various raw materials except the powdery raw materials in a weight ratio, and performing coarse crushing by using a 7.0-millimeter crushing sieve; and b, weighing the powdery raw materials in the weight ratio, and mixing the powdery raw materials with the crushed materials in the step a uniformly. The technical scheme provided by the embodiment of the invention has the advantages that: the powdery material of the compound feed for the broilers meets the nutritional requirements of the raised broilers within 7 to 15 days before slaughtering, and the weight of the broilers before the slaughtering exceeds the standard weight.

Owner:SHANDONG NEW HOPE LIUHE GROUP

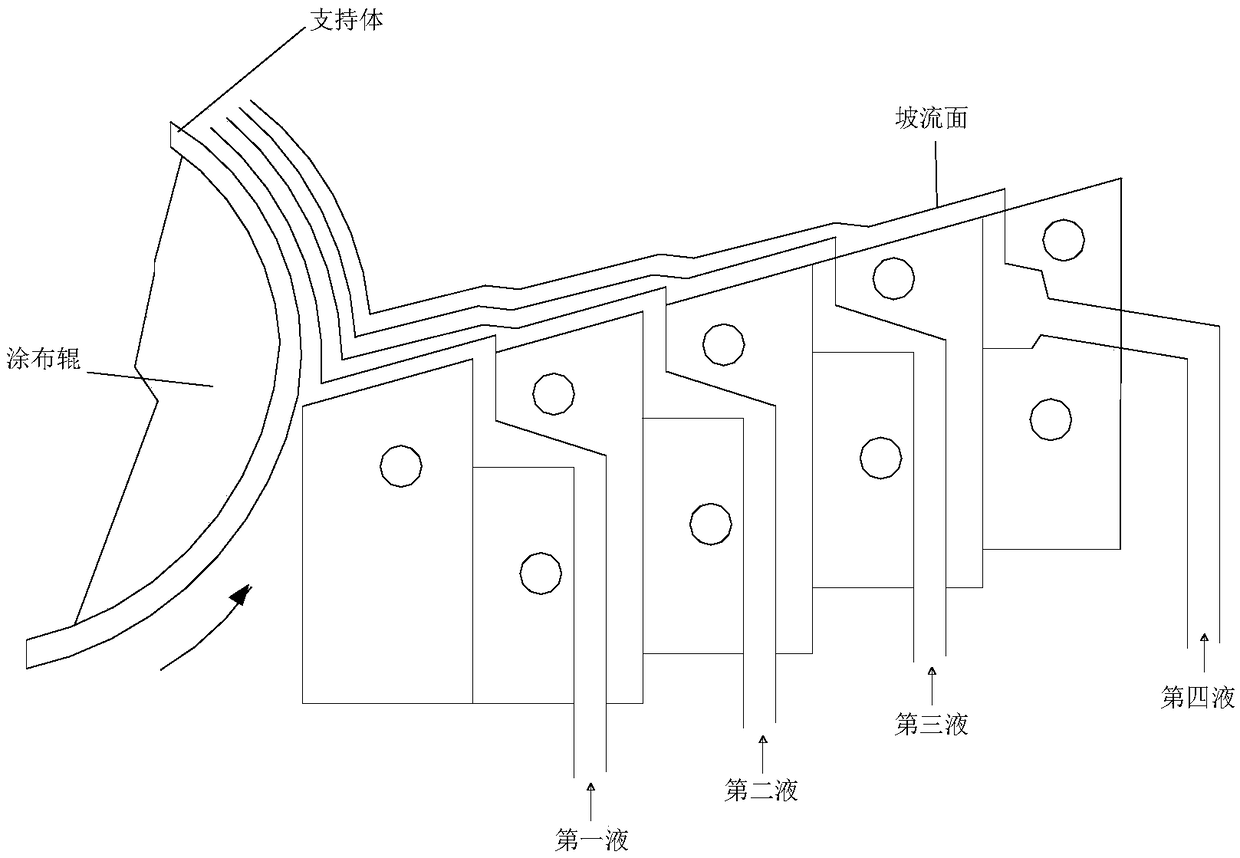

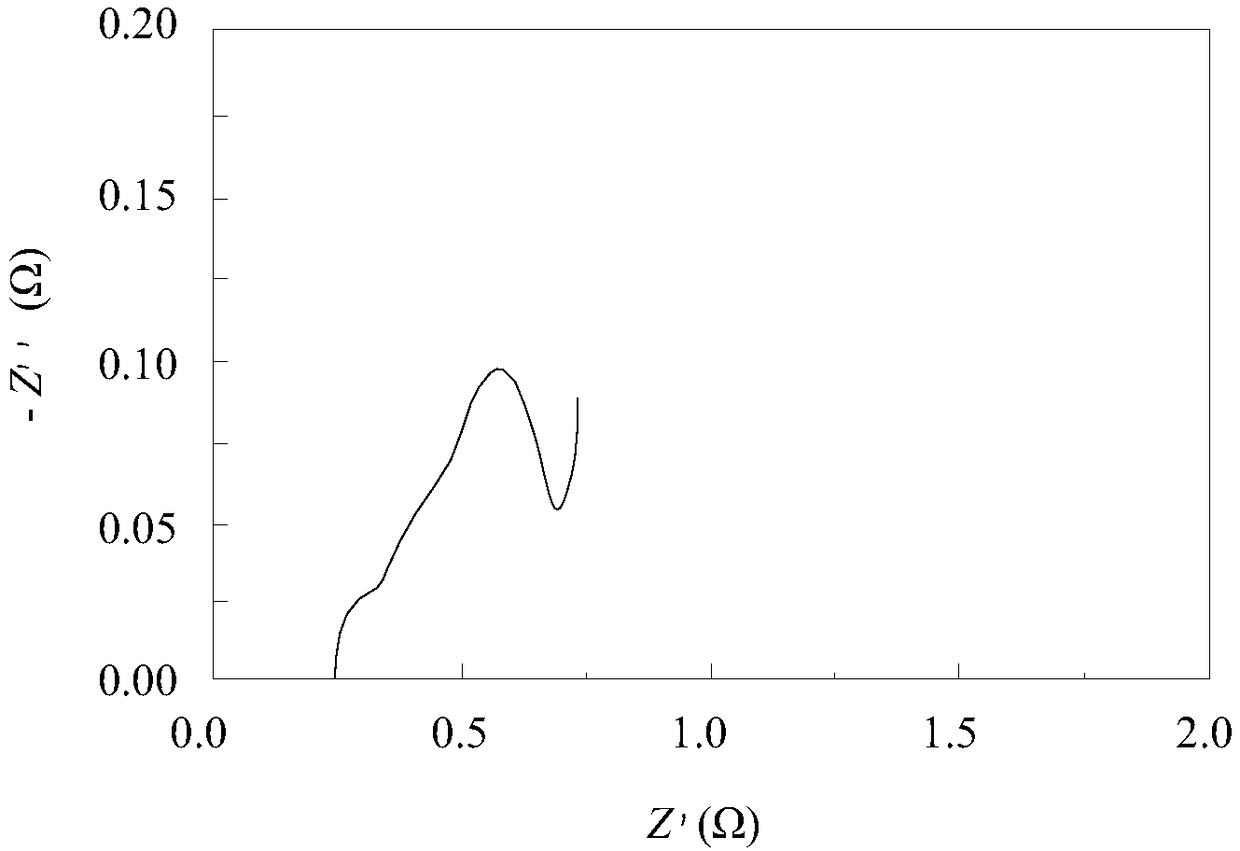

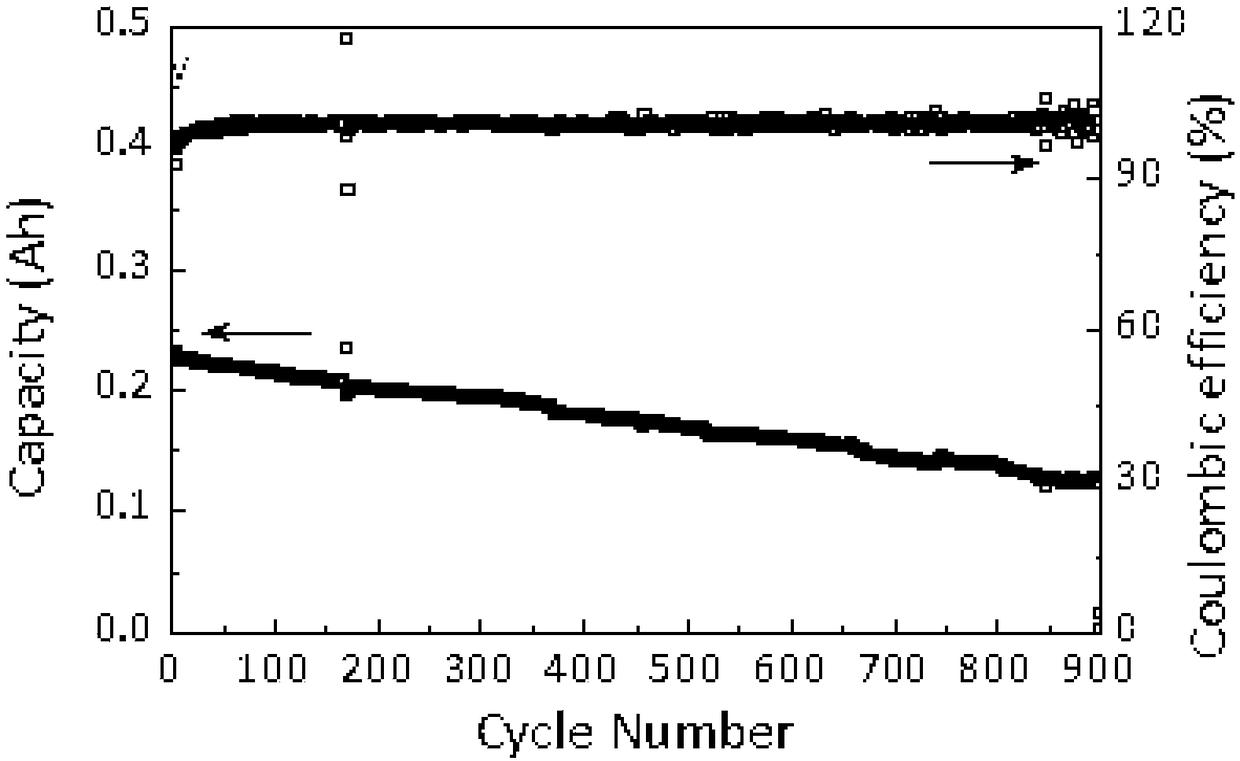

Preparation method for composite electrolyte membrane of solid-state battery

ActiveCN108767311AUniform thicknessPoor uniformity and thickness controlSecondary cellsElectrolyte immobilisation/gelificationComposite electrolytePhysical chemistry

The invention discloses a preparation method for a composite electrolyte membrane of a solid-state battery. By a multi-layer slope flowing coating process, multi-layer organic-inorganic composite electrolyte paste is synchronously coated on a surface of a carrier, and the composite electrolyte membrane of the multi-layer structure solid-state battery can be prepared. The multi-current coating process comprises the following steps of preparing paste of different constituents, allowing the organic-inorganic composite electrolyte paste to downwards flow along a slope flowing current after flowingout of a gap of a coating module according to an arrangement sequence, forming a liquid bridge in a gap between a coating roller and a slope flowing coating module, taking away by the running carrier, forming one or more layers of coating, performing, and stripping the carrier, thereby obtaining the composite electrolyte membrane of the solid-state battery.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

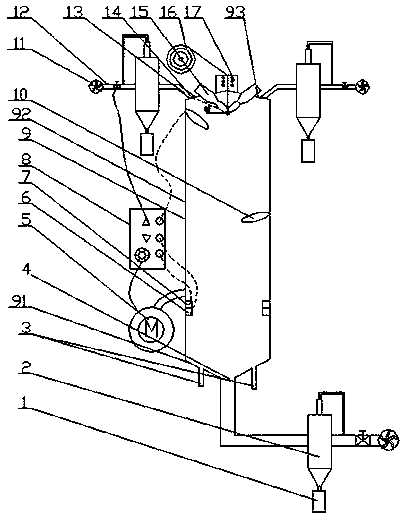

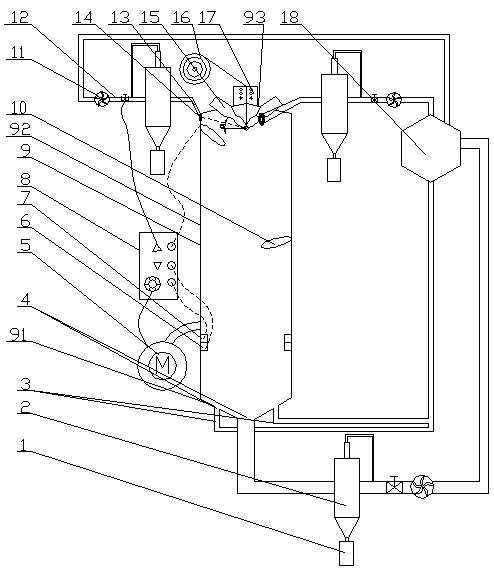

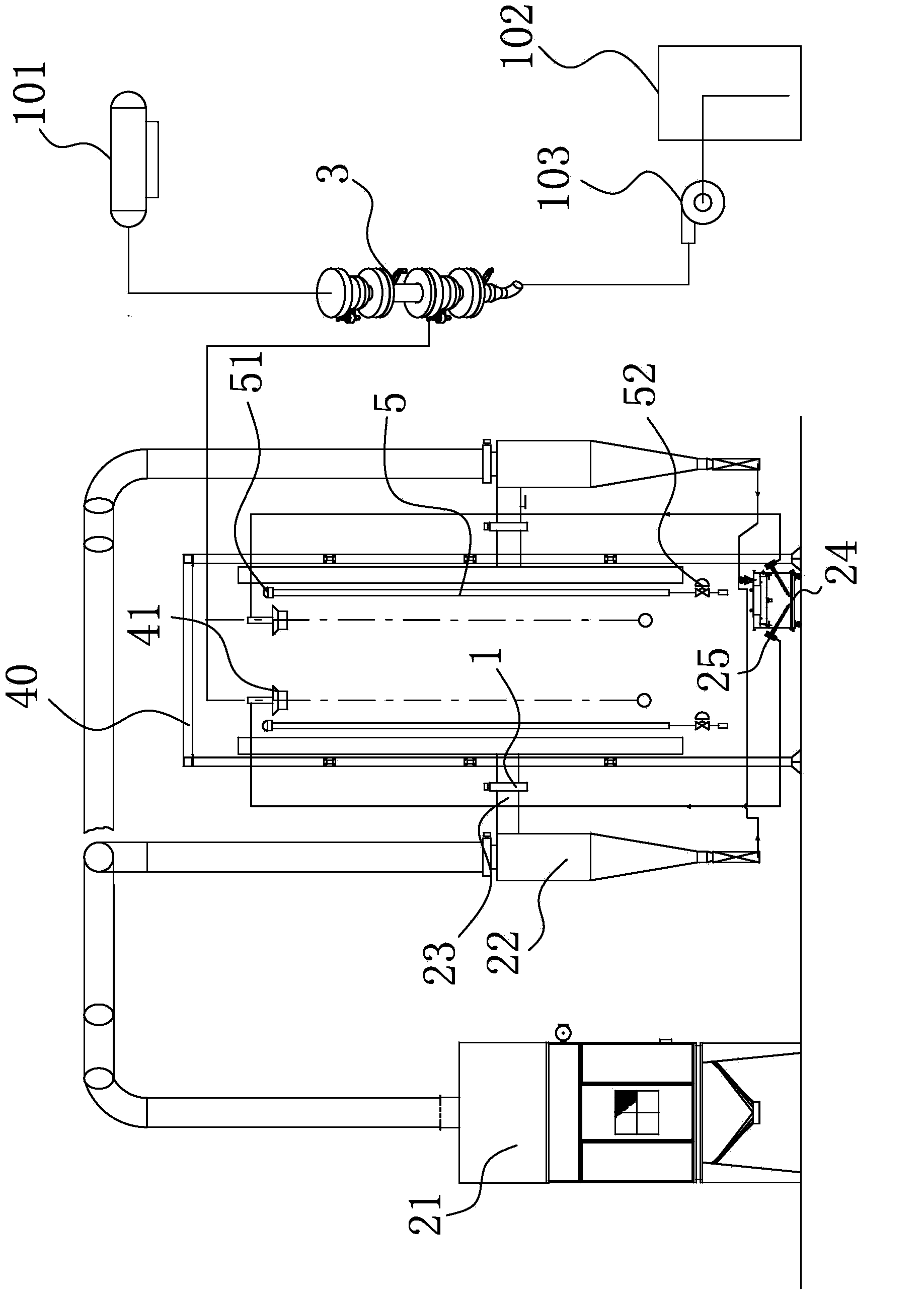

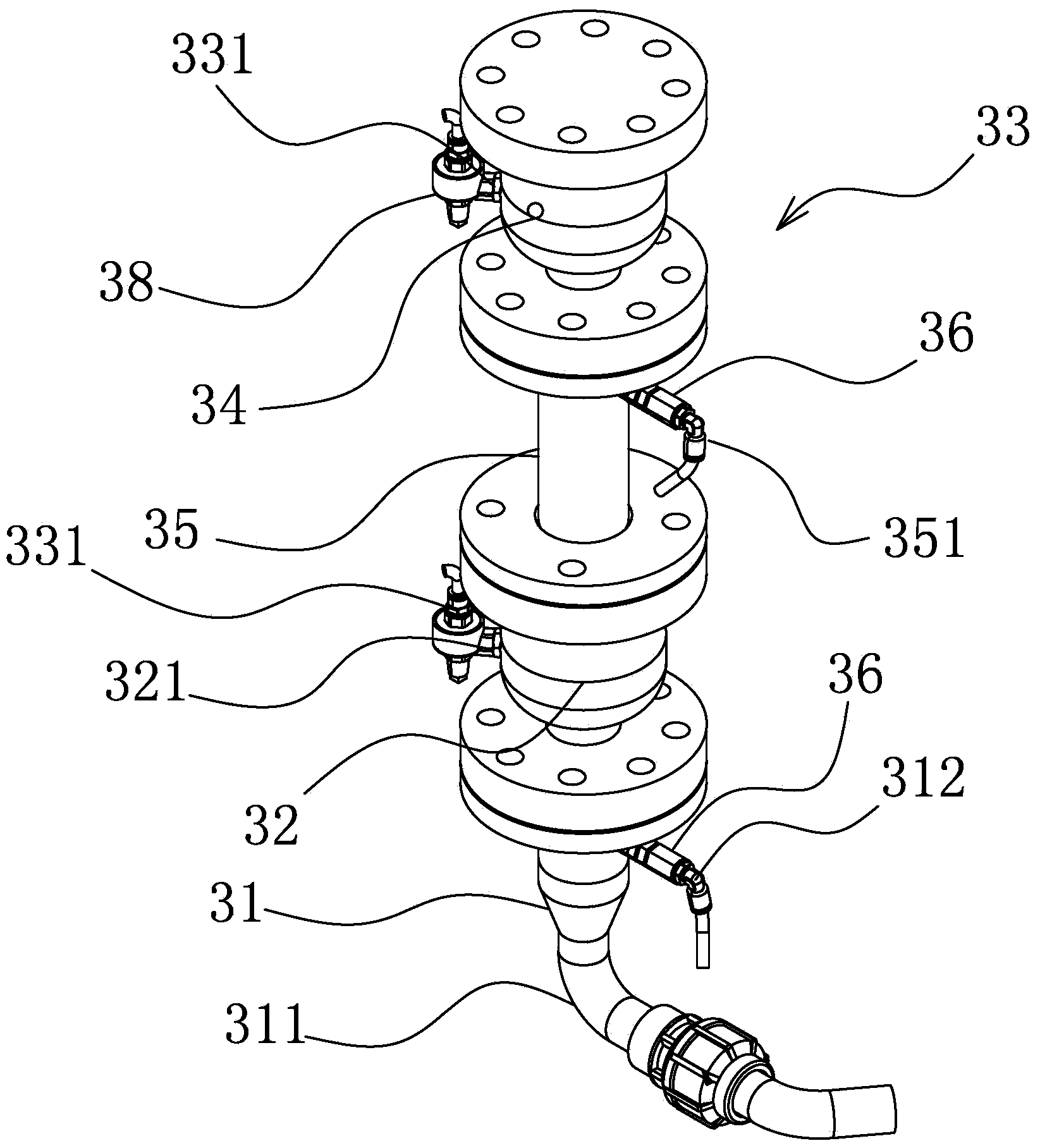

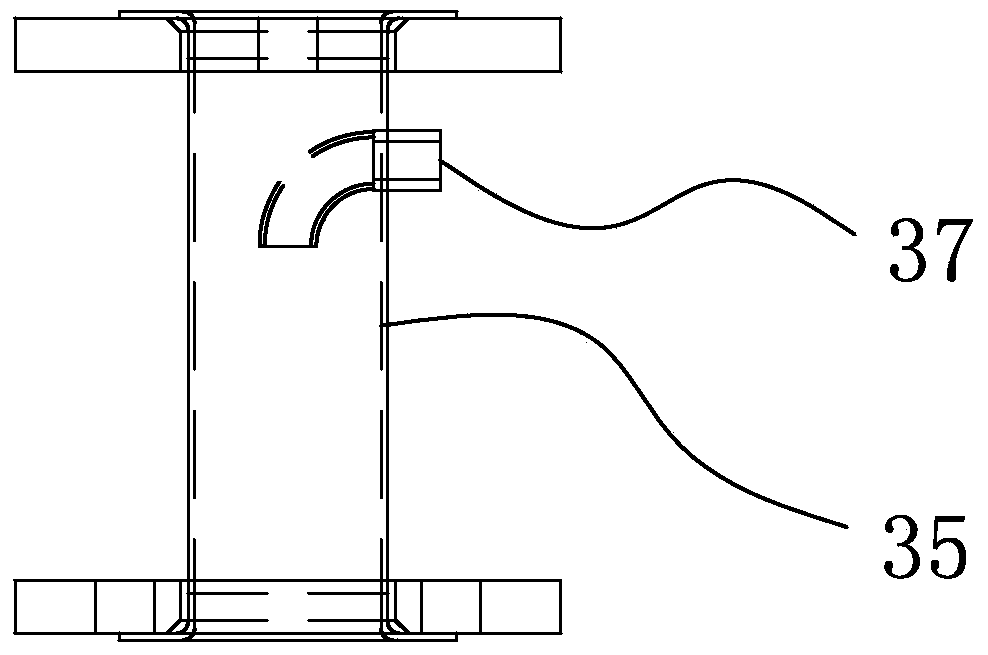

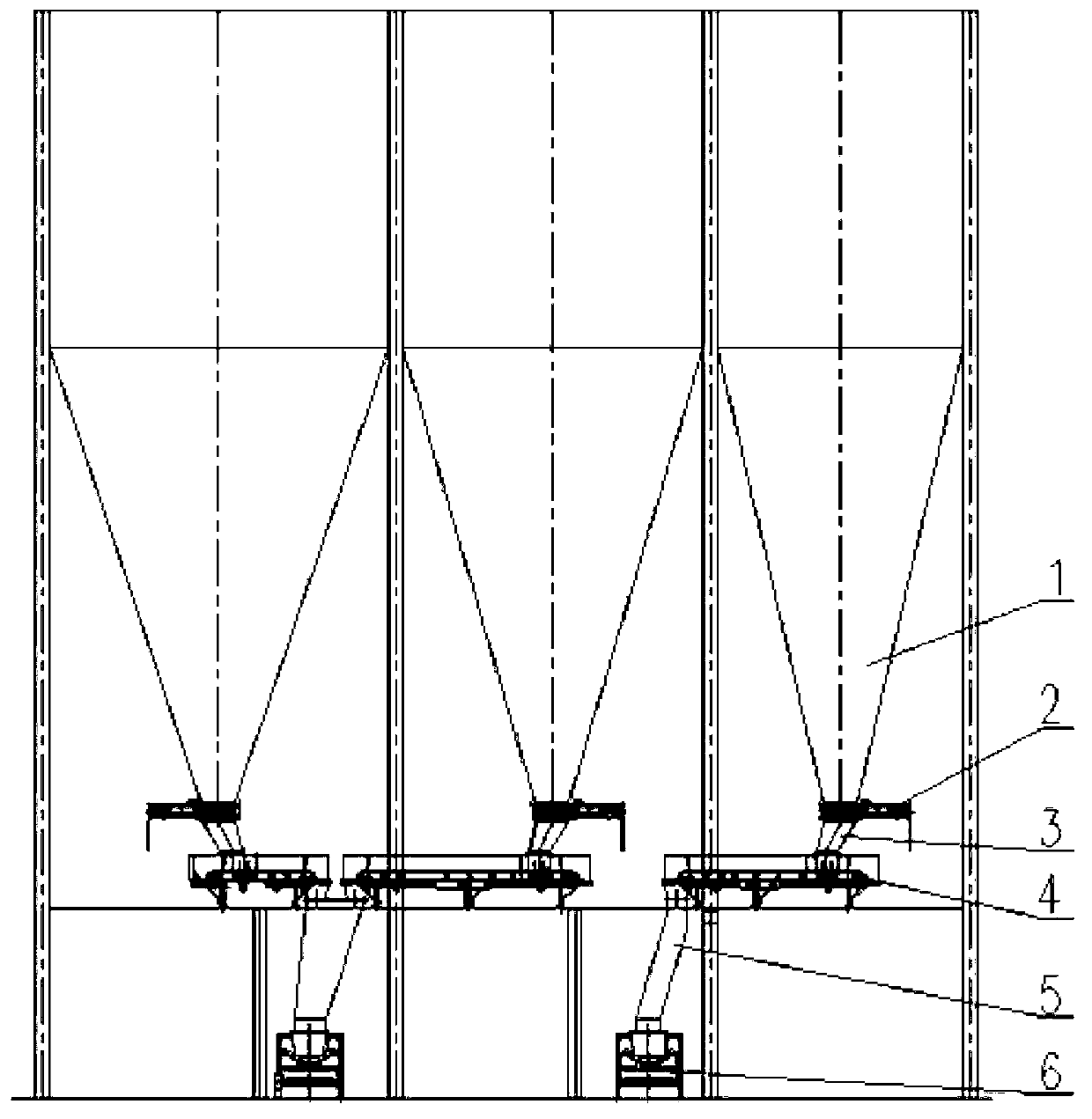

Metal atomization pulverizing equipment with low satellite sphere content

ActiveCN107661983AIncrease heat exchange rateReduce the chance of satellite formationGranularityTower

The invention provides metal atomization pulverizing equipment with low satellite sphere content. The metal atomization pulverizing equipment comprises a metal feeding mechanism, an atomization device, an atomization tower and a powder separation device, wherein the metal feeding mechanism is connected with the atomization device; the atomization device is mounted at the top of the atomization tower; a main powder outlet is formed in the bottom of the atomization tower; the main powder outlet is communicated with the powder separation device; no less than three powder outlet holes are formed in the upper end or a sealing end of a side wall of the atomization tower; the powder outlet holes are formed in the periphery of an atomization powder output and coke collection region at the bottom of the atomization device; the powder outlet holes are connected with the powder separation device through a powder output pipeline. The metal atomization pulverizing equipment with the low satellite sphere content, provided by the invention, is simple in structure and convenient to use; metal atomization powder prepared by the equipment has uniform and small granularity, high spherical degree, good flowability and low satellite sphere content, and performance requirements on various types of metal powder in the market can be met; the equipment is low in manufacturing cost and is convenient forbatch production; urgent requirements on high-performance metal powder at home and abroad can be met.

Owner:HUNAN TIANJI SMART MATERIAL TECH CO LTD

High-fiber edible oat bran powder, peeled oat grains and preparation methods thereof

The invention relates to high-fiber edible oat bran powder and also relates to peeled oat grains; the invention further relates to preparation methods of the high-fiber edible oat bran powder and the peeled oat grains; and the invention belongs to the technical field of grain and food raw material processing. A vertical sand-roller rice mill is utilized to carry out 4-6 times of peelings; the sieve plates are all punched sieves whose forward tilt angles are 10 degrees and sieve holes are 25mm multiplies 0.9mm; the sand rollers are all flat-sheet emery sand rollers whose diameters are 250mm and linear velocities are 13.7m / s; the flat-sheet emery sand rollers utilized in the first and second peelings are of No. 30 and the flat-sheet emery sand rollers utilized in the third and fourth peelings are of No. 36; a pneumatic three-way dial-plate valve is turned on / off, so as to control whether to perform the fifth and sixth peelings, wherein the flat-sheet emery sand roller utilized in the fifth peeling is of No. 46 and the flat-sheet emery sand roller utilized in the sixth peeling is of No. 60; electric current of each vertical sand-roller rice mill is maintained at 17-18 amperes; and the final peeling rate is up to 80-85%. By utilizing the preparation methods, the peeling of the oats can be softly performed in a layer-by-layer way, so that the qualities of the bran powder and the peeled oats are thereby ensured.

Owner:NINGXIA JIADAO HALAL FOOD

Improved vertical type section bar electrostatic spraying and coating device

ActiveCN103831182AFull gas-solid mixingImprove spray qualityLiquid spraying plantsMaterial storageMixing chamber

The invention provides an improved vertical type section bar electrostatic spraying and coating device, and belongs to the technical field of spraying devices. The improved vertical type section bar electrostatic spraying and coating device solves the technical problems that in the prior art, power outlet is not uniform, and the spraying effect is poor. The improved vertical type section bar electrostatic spraying and coating device comprises a coating machine, a compressed air system and a spraying material storage tank, a sprayer mechanism is arranged in the coating machine, the compressed air system is connected with the sprayer mechanism, and the spraying material storage tank is connected with the sprayer mechanism through a material conveying mechanism. The improved vertical type section bar electrostatic spraying and coating device further comprises a gas-solid mixer which comprises a powder feed chamber internally provided with a cavity, a feed port is formed in one end of the powder feed chamber, the other end of the powder feed chamber is detachably connected with a mixing chamber, a first gas inlet and the like are formed in the side wall of the powder feed chamber, and the sprayer mechanism can rise and fall in the vertical direction. Full gas-solid mixing can be conducted on powder entering the coating machine in advance, large-grained powder is fully scattered into small-grained powder, and therefore spraying quality is improved.

Owner:ZHEJIANG MINGQUAN INDAL COATING

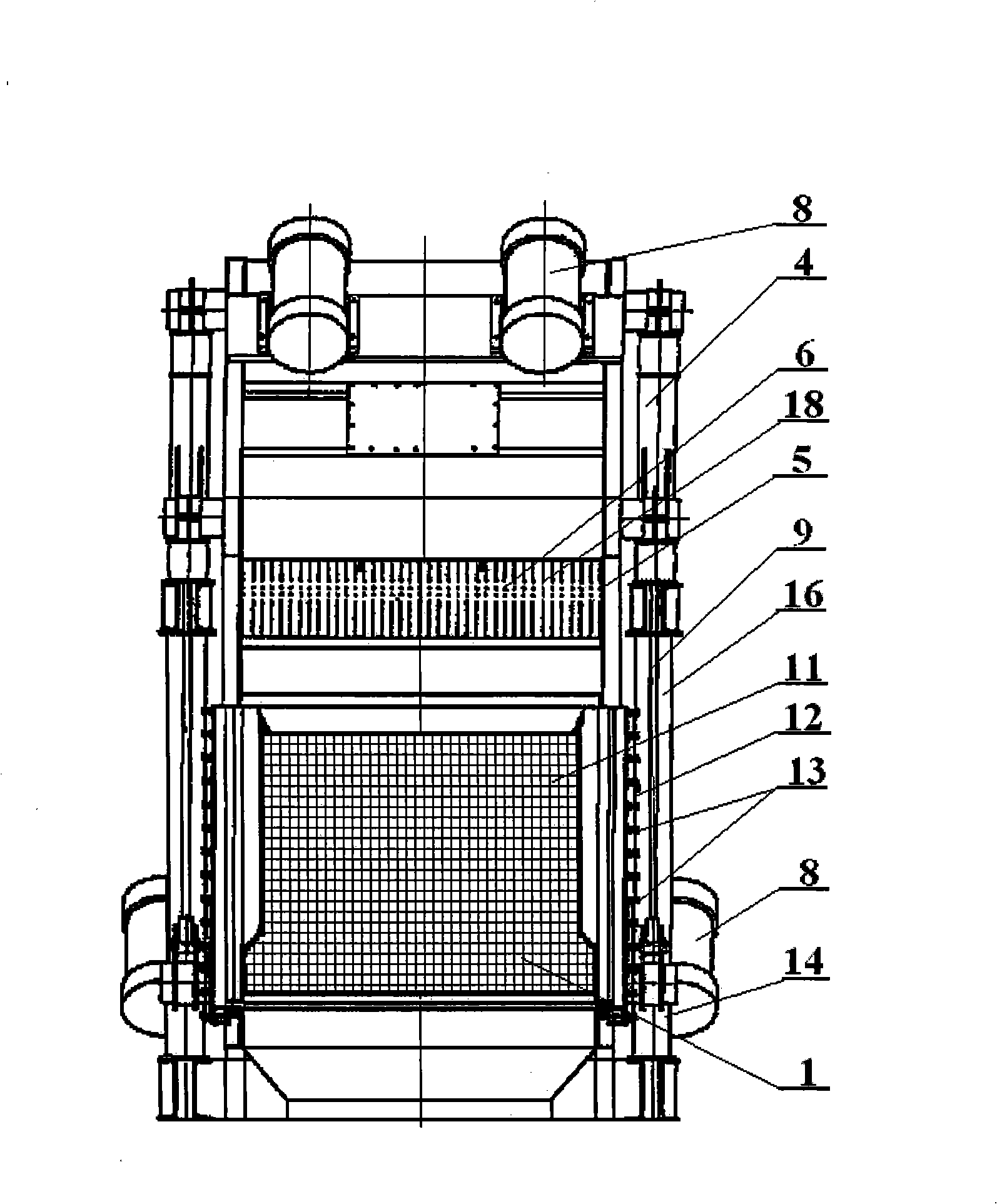

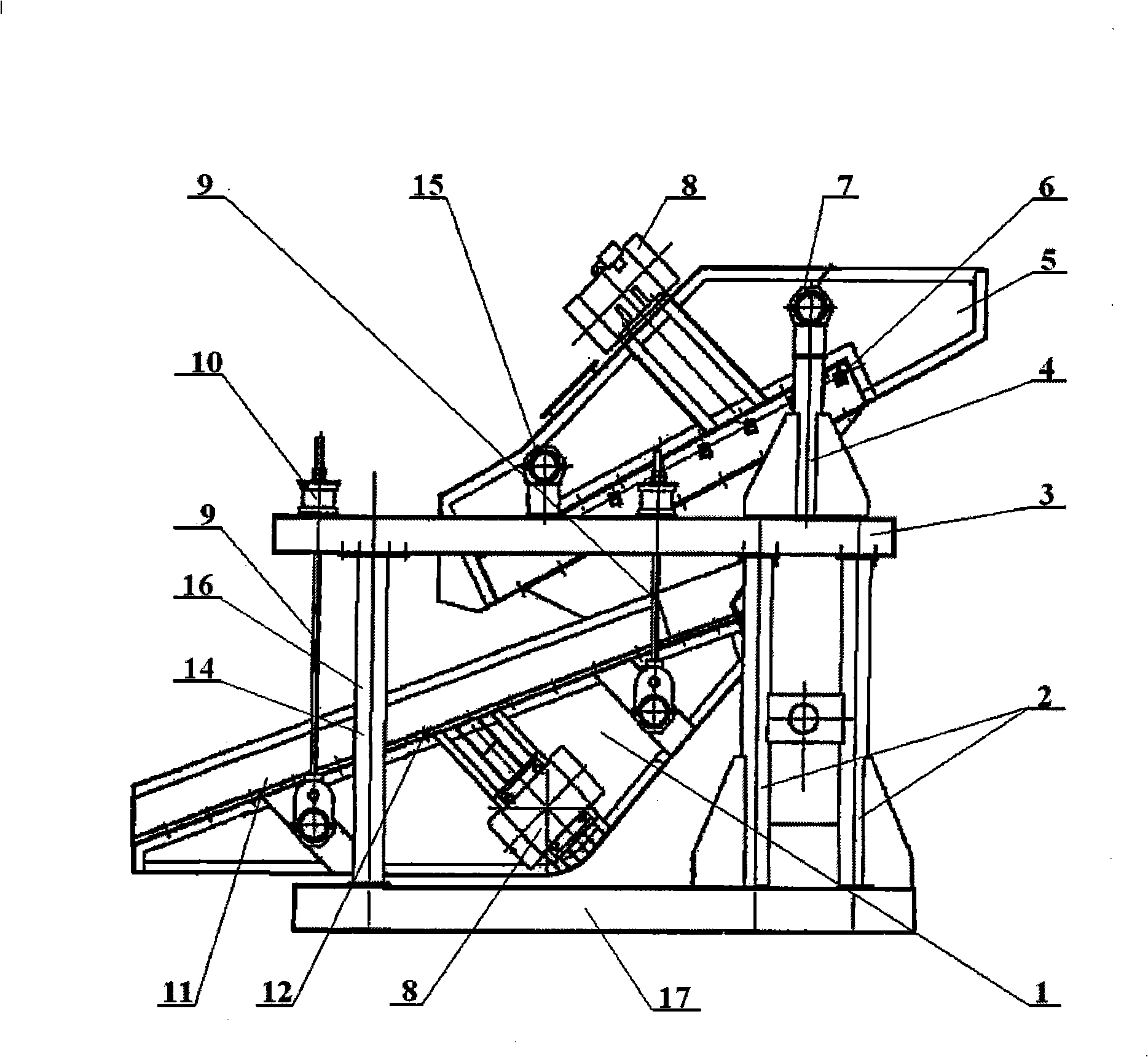

Combination vibration sieve

The invention discloses a combined vibration sieve, wherein a coarse sieve surface (6) of a coarse vibration sieve (5) is a sieve mesh formed by a plurality of suspended self-cleaning elastic coarse sieve bars (18) which are uniformly spaced at a certain distance and in a mounting direction oblique upwards or downwards to the coarse sieve surface (6). By adopting the technical proposal, the combined vibration sieve has reasonable structure and high safety and reliability, solves the problems of low screening efficiency and poor screening quality in the prior art, improves the efficiency of screening lump ores, particularly the lump ores with a high water content, minimizes the dust content of screened lump ores and the proportion of lump ores in the powdered ores after screening, further meets the requirements for lump ores in blast furnace production, increases the utilization coefficient of the blast furnace and reduces the production costs.

Owner:MAANSHAN IRON & STEEL CO LTD

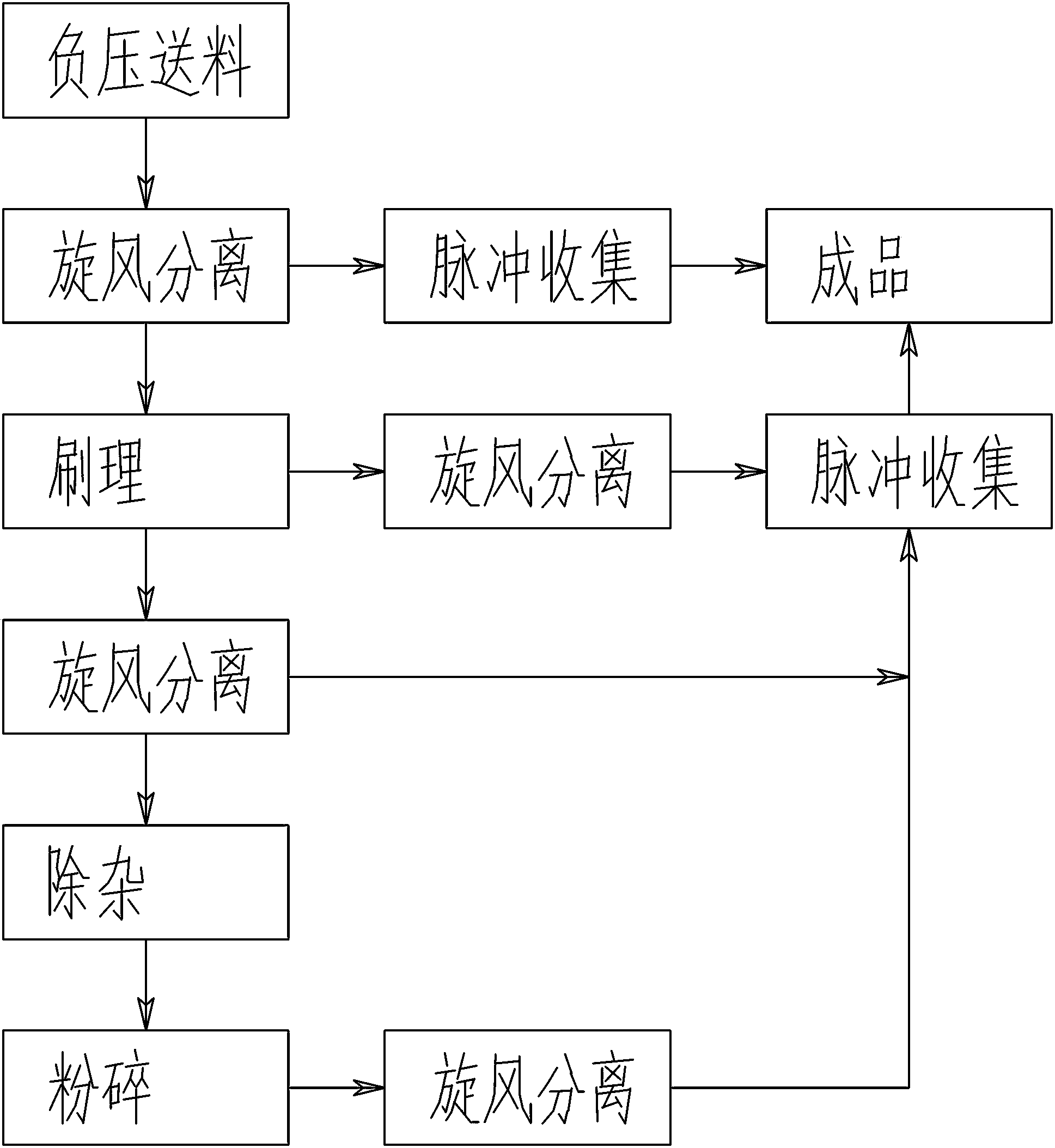

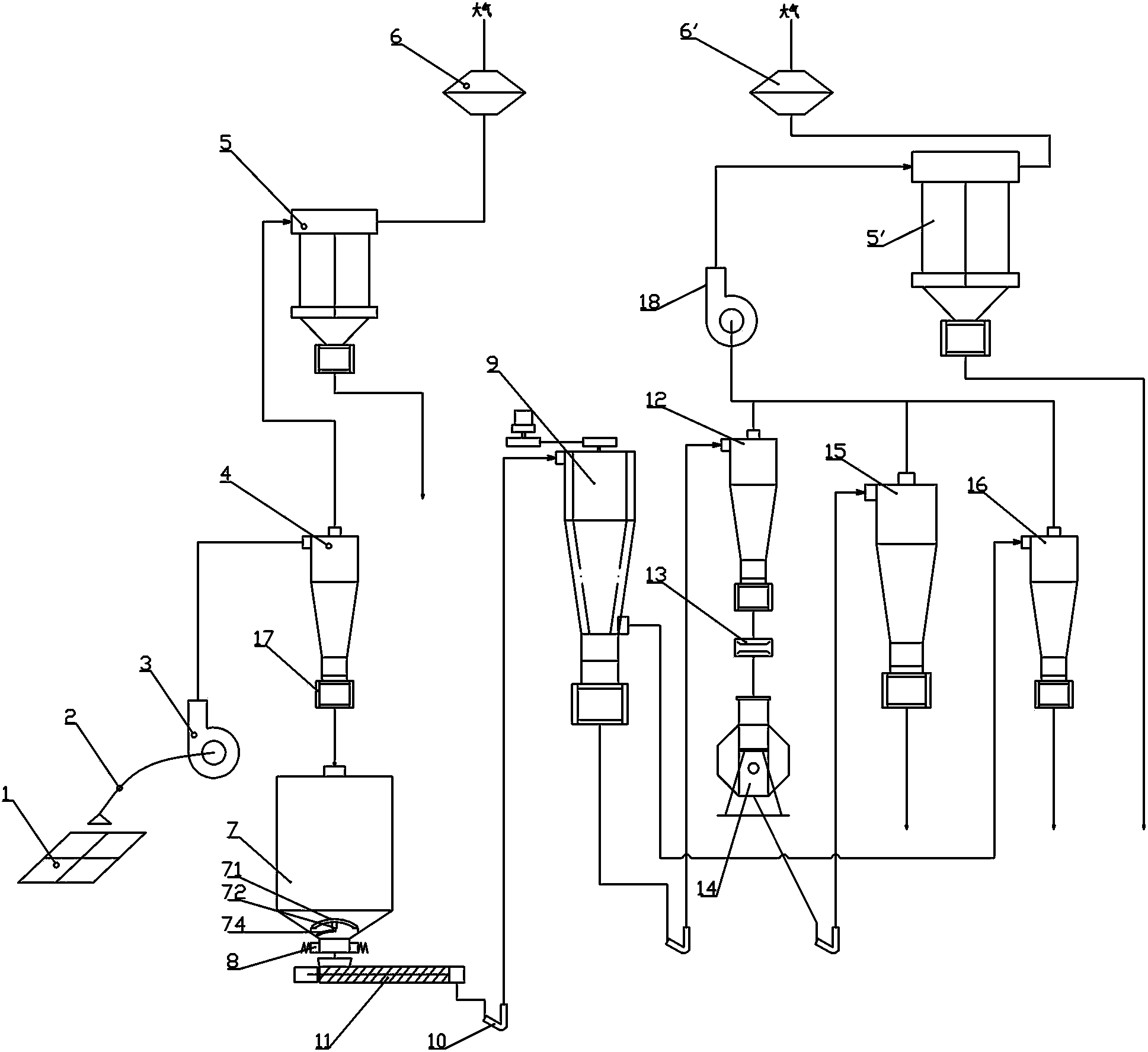

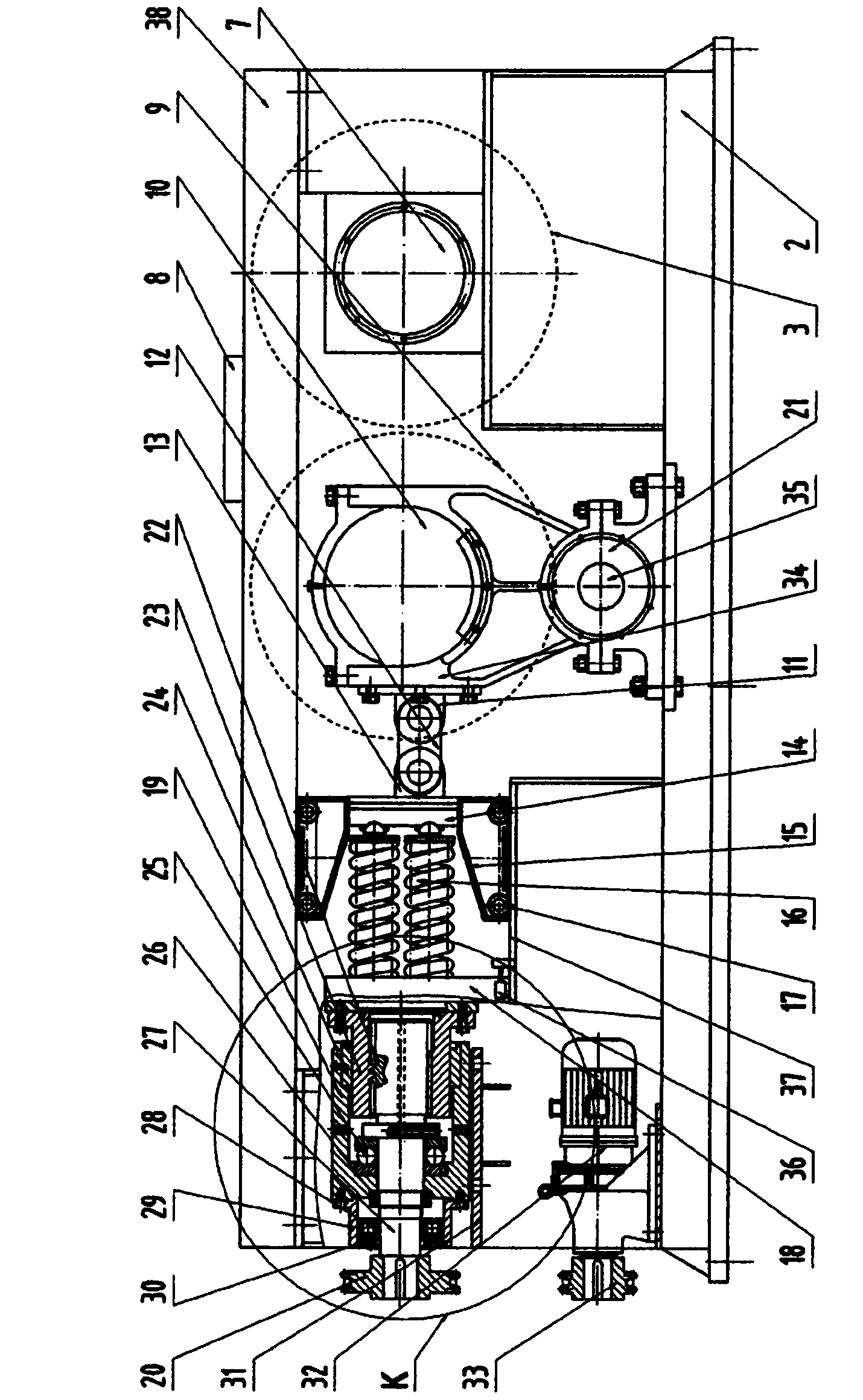

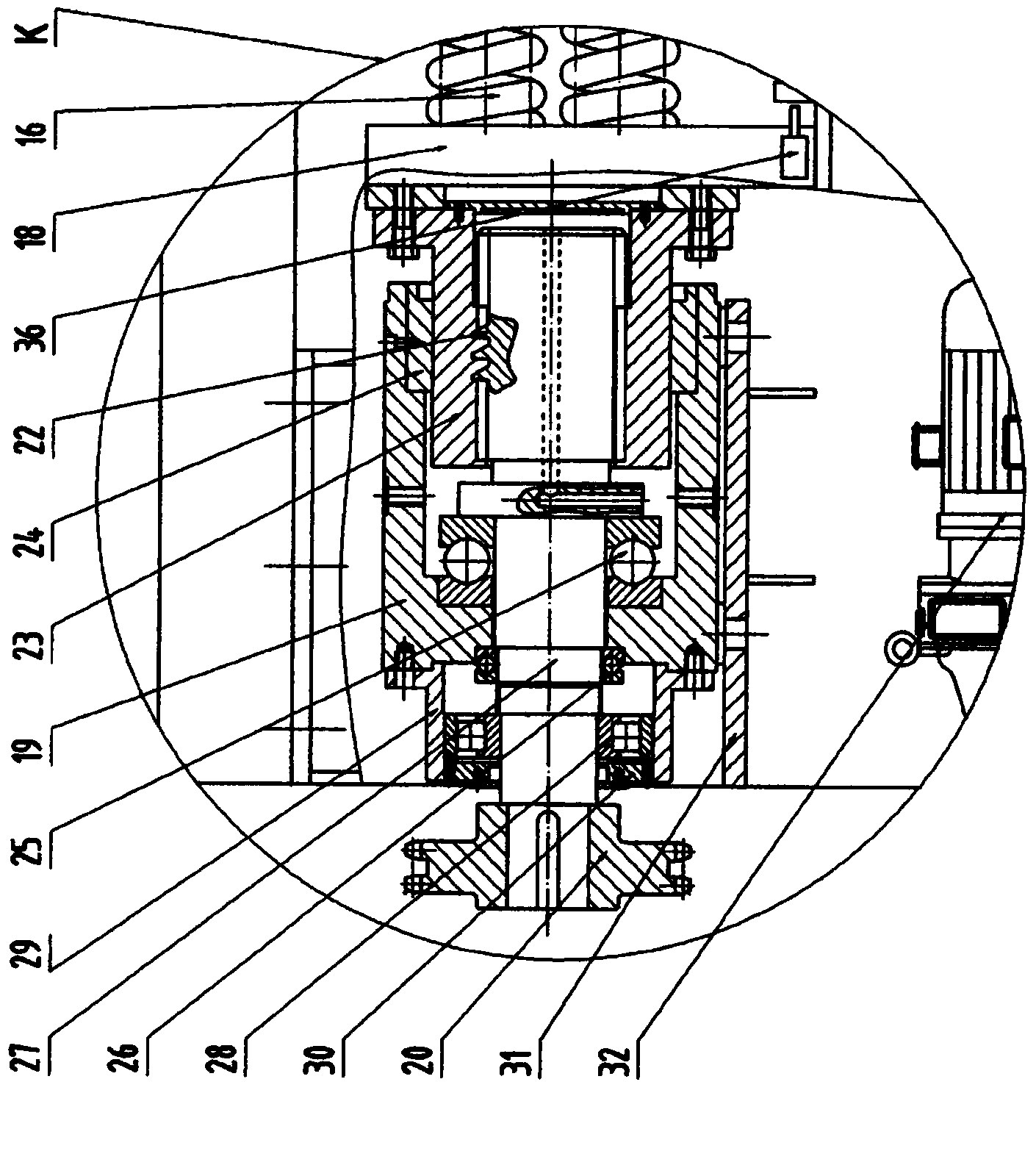

Spore powder collection method, spore powder collection apparatus and brushing machine

InactiveCN103396939AReduce powder contentEasy to separateSievingBioreactor/fermenter combinationsSporeCyclonic separation

The invention discloses a spore powder collection method, a spore powder collection apparatus and a brushing machine. The spore powder collection method comprises the following steps: a fungi bed is sent into a first cyclone separator by a sucking conveying material-collector, and a light material is collected by a pulse deduster to obtain spore powder; a heavy material is conveyed to the brushing machine, and a fine material screened by the brushing machine is sent into a fourth cyclone separator; a thick material screened by the brushing machine is sent into a second cyclone separator; a heavy material separated by the second cyclone separator is sent into a pulverizer, and a pulverized material is sent into a third cyclone separator; and the light material of each cyclone separator is conveyed to a pulse deduster via a blower fan by negative pressure, and the spore powder is collected by the pulse deduster. According to the method, a segmented multistage separation manner comprising first, cyclone separation, then kneading and brushing screening, again, cyclone separation, and cyclone separation of the heavy material after pulverizing is used to ensure that the collected spore powder can reach 160-180 billion / g, the living spore rate reaches 85-90%, and spore extracted from residue is only 400 million / g, so that separating extraction is very sufficient.

Owner:当阳市森林病虫害防治检疫站

Rapeseed peeling and separating process

InactiveCN1644667ALow skin contentGuaranteed separation effectFatty-oils/fats productionHuskRapeseed

Rapeseed peeling process achieves control of water content between 7-9%. It is carried out by: sorting them with multi-grade screen, using peelers with different roller gaps to peel them simultaneously, and separating continently. Either the rate of the kernels in the husks or the rate of the husks in the kernels is <3%, so that qualities of kernels and husks are increased, so are the oil products. It is used industrially.

Owner:莫惠春

Special granular laying hen summer feed and preparation method therepf

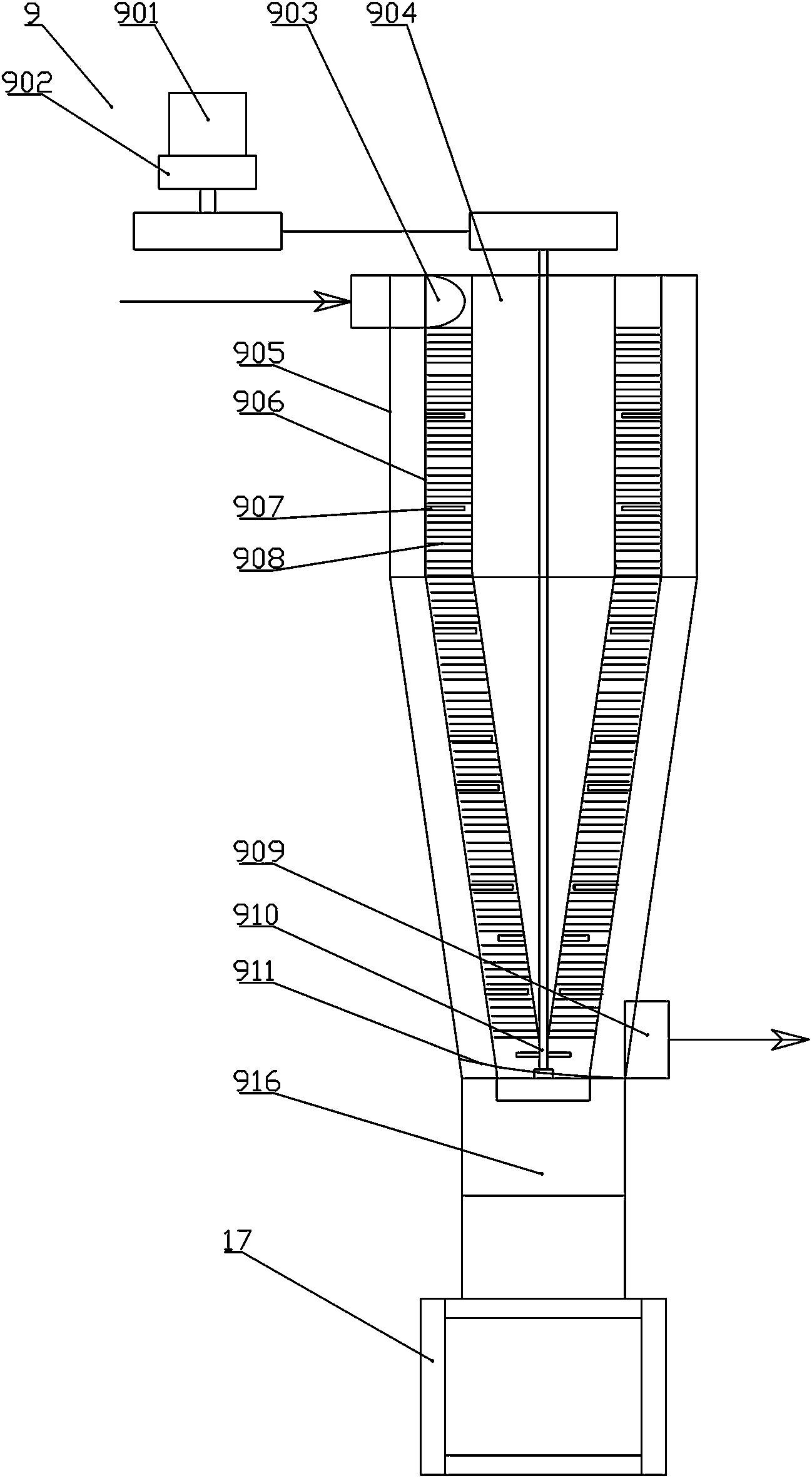

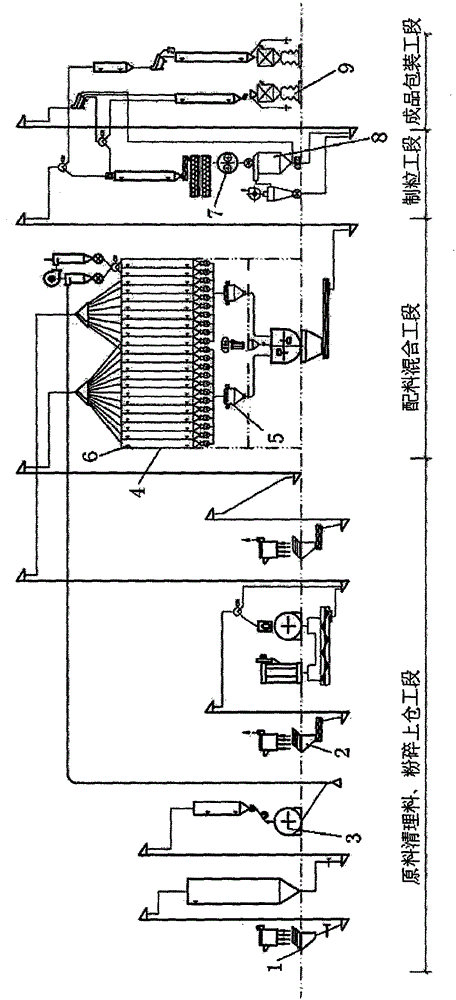

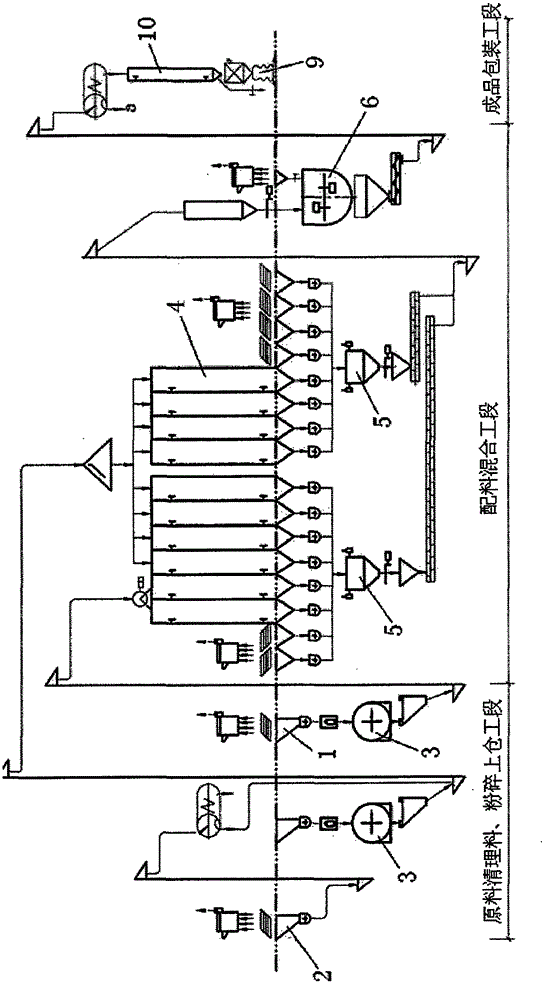

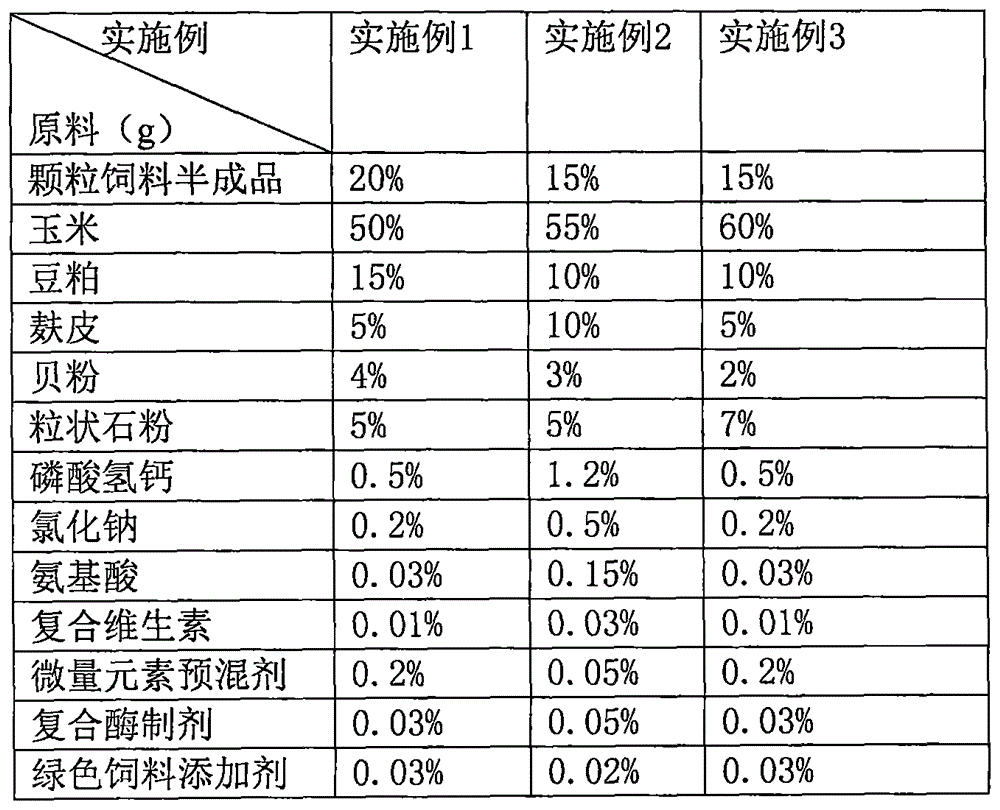

The present invention relates to a special granular laying hen summer feed and a preparation method thereof, wherein the special granular laying hen summer feed comprises the following raw materials by weight: 15-30% of a granular feed semi-finished product, 50-65% of corn, 10-20% of soybean meal, 0-10% of bran, 0-5% of shell powder, 5-10% of granular stone powder, 0.5-2% of calcium hydrogen phosphate, 0.2-0.5% of sodium chloride, 0.03-0.15% of amino acids, 0.01-0.03% of compound vitamins, 0.05-0.2% of a trace element premix, 0.01-0.05% of a compound enzyme preparation, and 0.01-0.03% of a green feed additive. The preparation method comprises: 1) preparing a granular feed semi-finished product; and 2) preparing the special material. The technical problems solved by the special feed of the present invention comprise good feed sensation, low powder content, more intake by laying hen and high feed intake. According to the present invention, the partial raw material in the feed is subjected to granulation aging so as to improve the feed utilization rate; the dust in the feed production and breeding environment is reduced, and the feed product quality is improved; and the feed intake is improved by more than 10% so as to improve the whole production performance of the laying hen in the summer.

Owner:HEBEI LESHOU FARMING GRP CO LTD

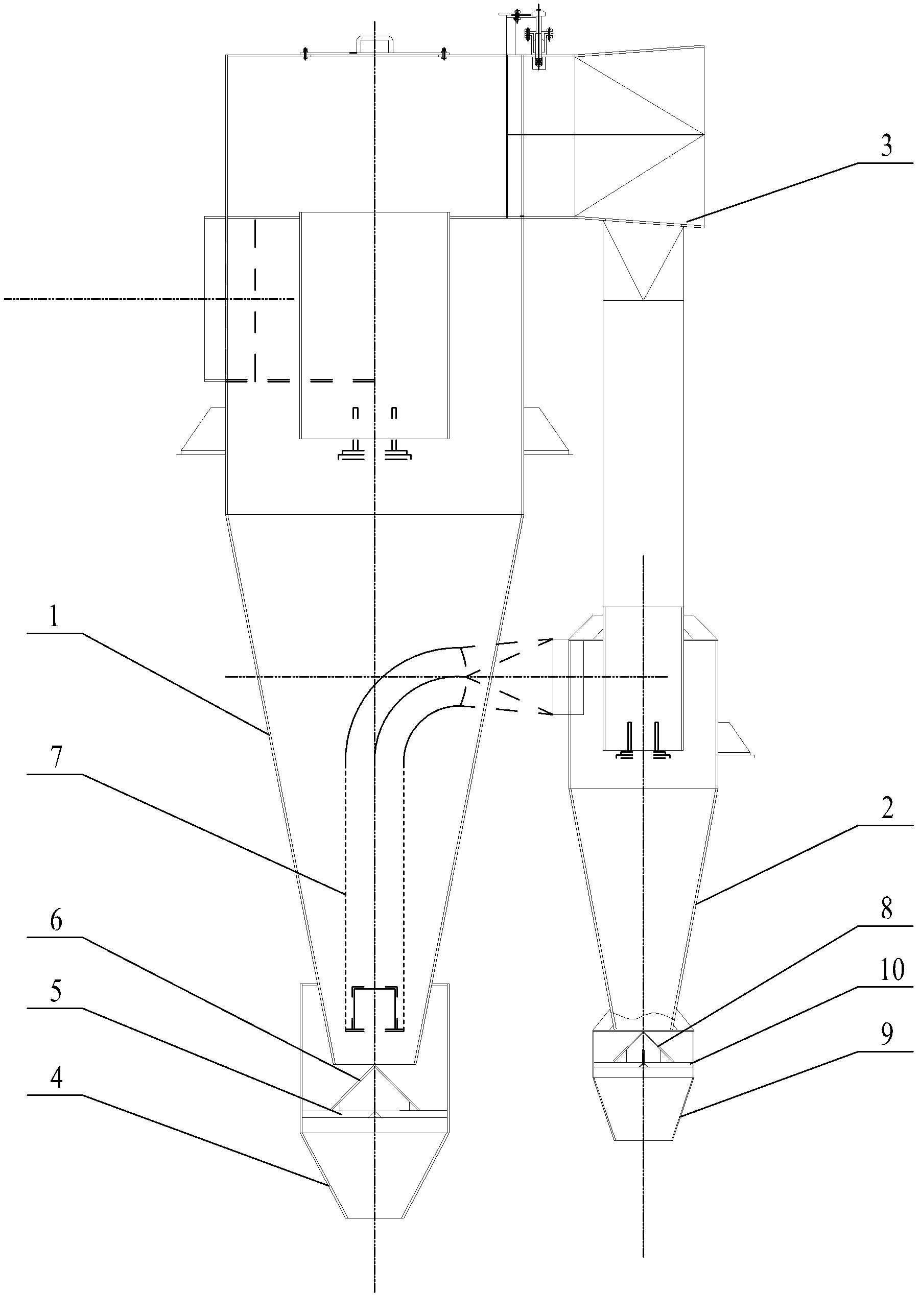

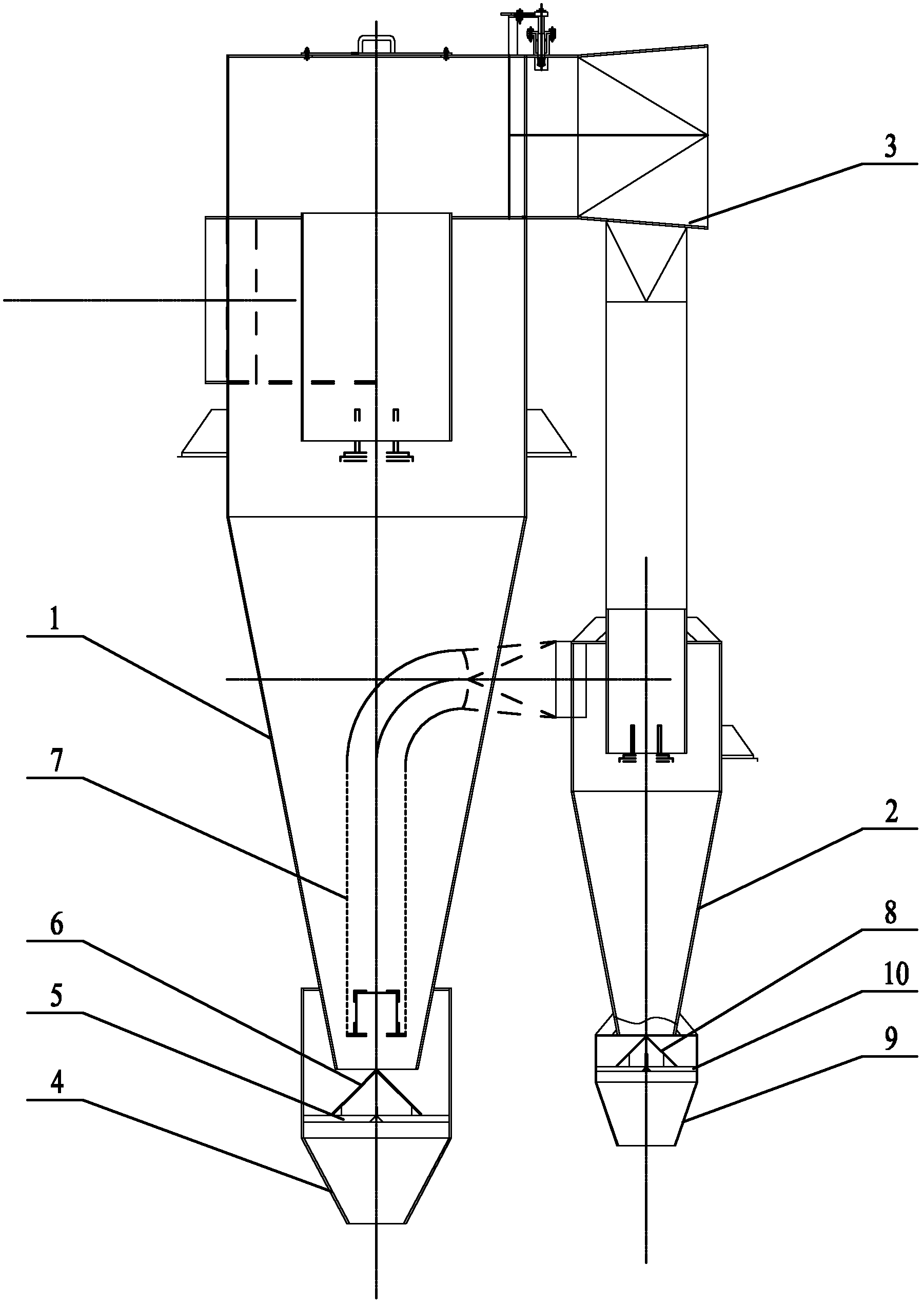

High-efficiency dust collection cyclone separator group

ActiveCN102600997AImprove efficiencyMeet safe operation requirementsReversed direction vortexCycloneEngineering

The invention relates to a high-efficiency dust collection cyclone separator group. A plurality of front cyclone separators are in parallel connection, a rear dust hopper is connected to a dust outlet of a rear cyclone separator, a front mounting frame is fixed into a front dust hopper, a front conical funnel cap is fixedly mounted on the front mounting frame, air inlet pipes are parallelly connected onto an air inlet of the rear cyclone separator, the number of the air inlet pipes is matched with that of the front cyclone separators, an air inlet end of each air inlet pipe is arranged insidethe bottom end of a lower conical cylinder of the corresponding front cyclone separator, a rear mounting frame is fixed into the rear dust hopper, and a rear conical funnel cap is fixedly mounted on the rear mounting frame. Secondary entrainment of fine dust at dust discharge ports of the front cyclone separators is eliminated, and the powder content of exhaust gas exhausted through a central pipe in the middle of the rear cyclone separator is greatly decreased. The efficiency of the cyclone separator group can be 3-5% higher than that of a conventional cyclone separator, and the dust collection efficiency of the cyclone separator group is ensured to be higher than 95%.

Owner:WUXI HUATONG ELECTRIC POWER EQUIP

Method for making wheat flour for extracting vital gluten

ActiveCN103028457AReduce powder contentGuaranteed qualityGrain huskingGrain polishingProcess engineeringWheat flour

The invention belongs to the processing field of flour production and particularly relates to a method for making wheat flour for extracting vital gluten. The method for making the wheat flour for extracting the vital gluten comprises the following steps of: wheat pre-washing, wheat washing and water adjusting, pure wheat flour grinding, flour mixing and post processing, wherein the pure wheat flour grinding step comprises skin grinding, core grinding, dreg grinding and tail grinding. A skin grinding system comprises a primary skin grinding port and a secondary skin grinding port. The method is characterized in that the speed ratio of the secondary skin grinding port in the skin grinding system is 2:1, namely that the speed ratio of a fast roller to a slow roller is 2:1; and grinding rollers adopted in the core grinding system, the dreg grinding system and the tail grinding system are all matt surface rollers, and the speed ratio of the matt surface rollers is 1.25:1. The wheat flour for the vital gluten, produced by the technical method meets the quality requirement for extracting the vital gluten, few gluten proteins and starch particles are destroyed, gluten is easily formed, and the separating yield rate of the vital gluten is increased by 0.8% more or less. Power consumed by the flour making method is about 5% less than power consumed by a traditional method, so that the energy saving effect is remarkable.

Owner:BINZHOU ZHONGYU FOOD

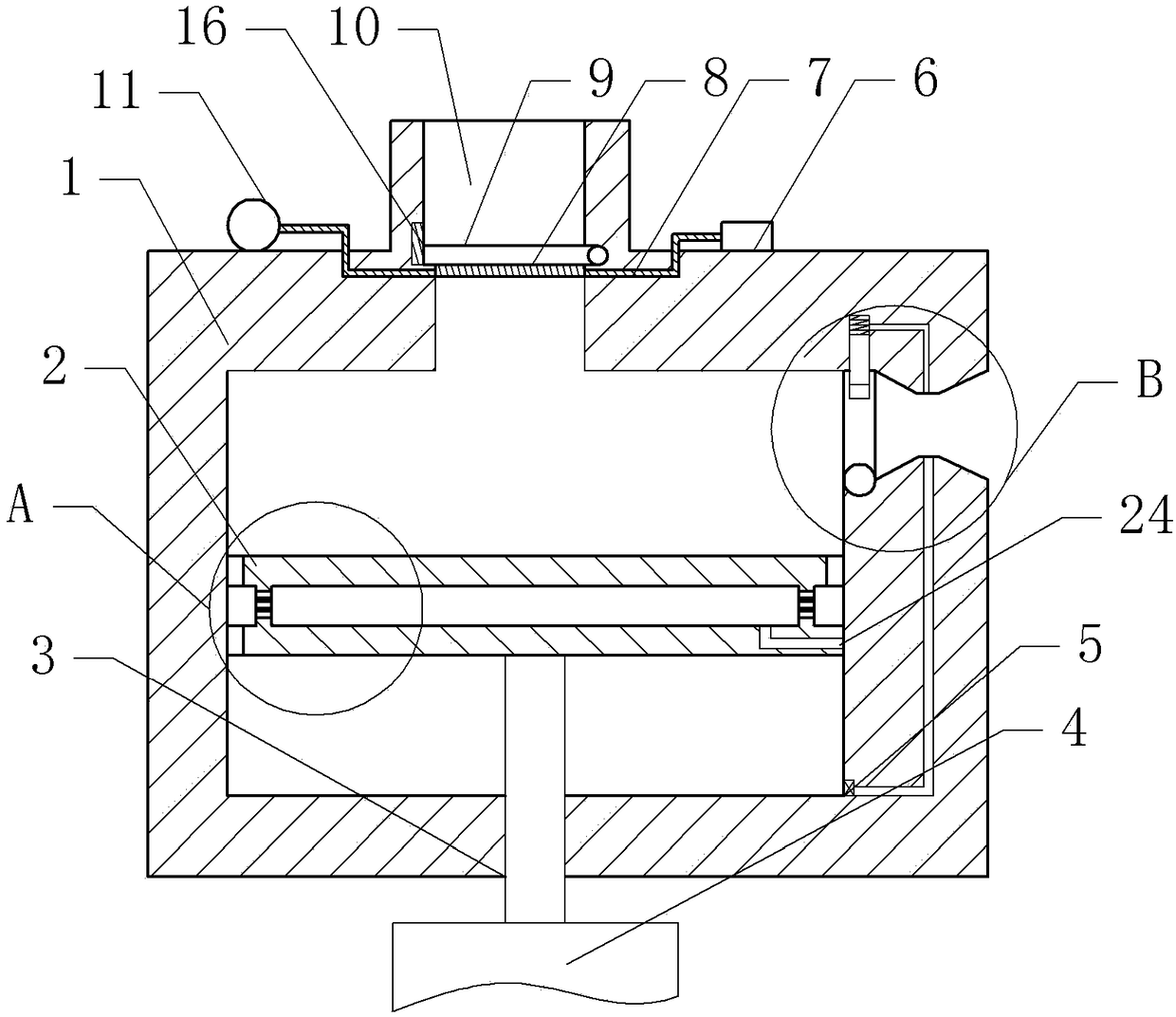

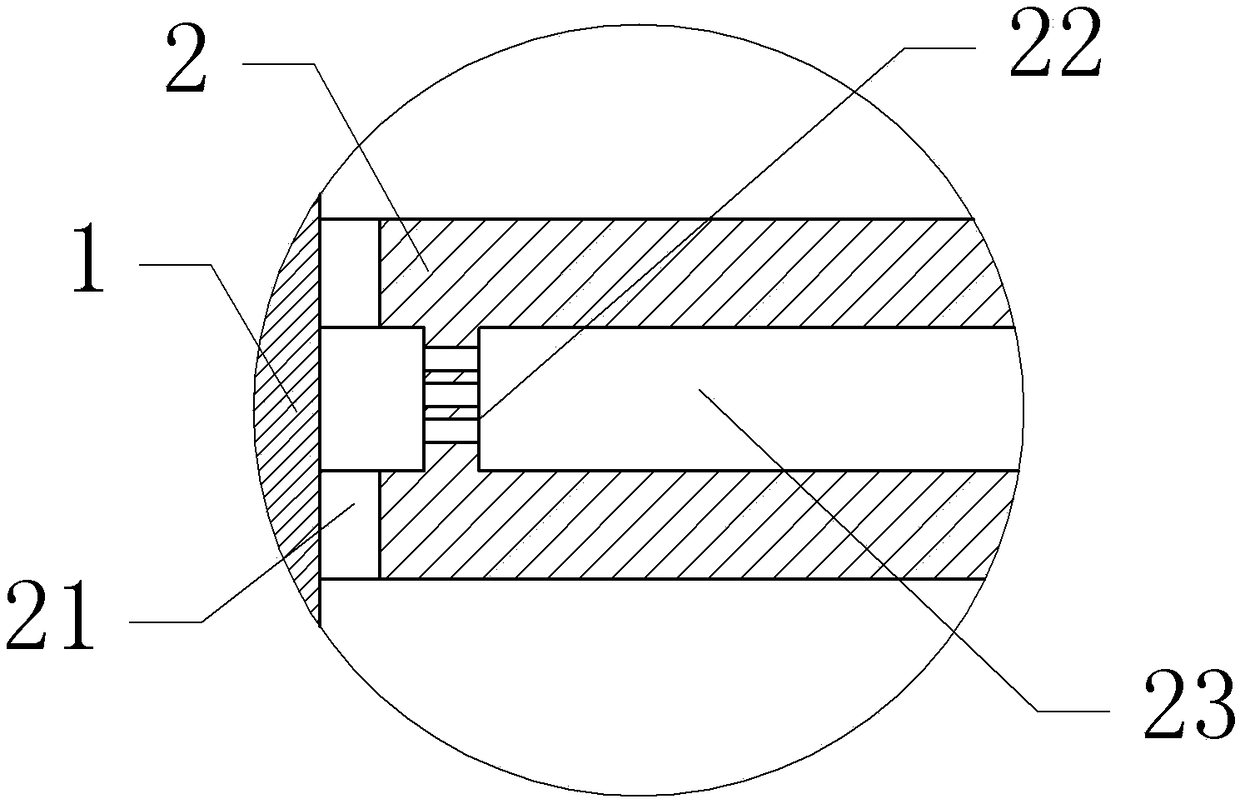

Single-driving-roller clearance-free sand maker

ActiveCN103447113AReduce powder contentIncrease sand forming rateGrain treatmentsEngineeringPower component

The invention discloses a single-driving-roller clearance-free sand maker, and relates to the technical field of crushing equipment. The single-driving-roller clearance-free sand maker is composed of a rack 2, a power device, a movable roller 9, a fixed roller, a fixed roller bearing seat 7 and a pressure regulating device; the pressure regulating device comprises a pressure regulating power component, a pressure regulating component, a pressure regulating and applying component, a pressure regulating guide component and a pressure regulating transmission component. The single-driving-roller clearance-free sand maker has the characteristics of simple structure, convenience in maintaining, low running cost, long running cycle, high sand formation rate and the like, can be used for preparing sands for construction by utilizing materials including sand stones, cobblestones and the like, also can be used for front breaking and grinding of a grinding system, and can be widely applied to the fields including construction, construction materials, mines and the like.

Owner:湖南宇晖重工机械有限公司

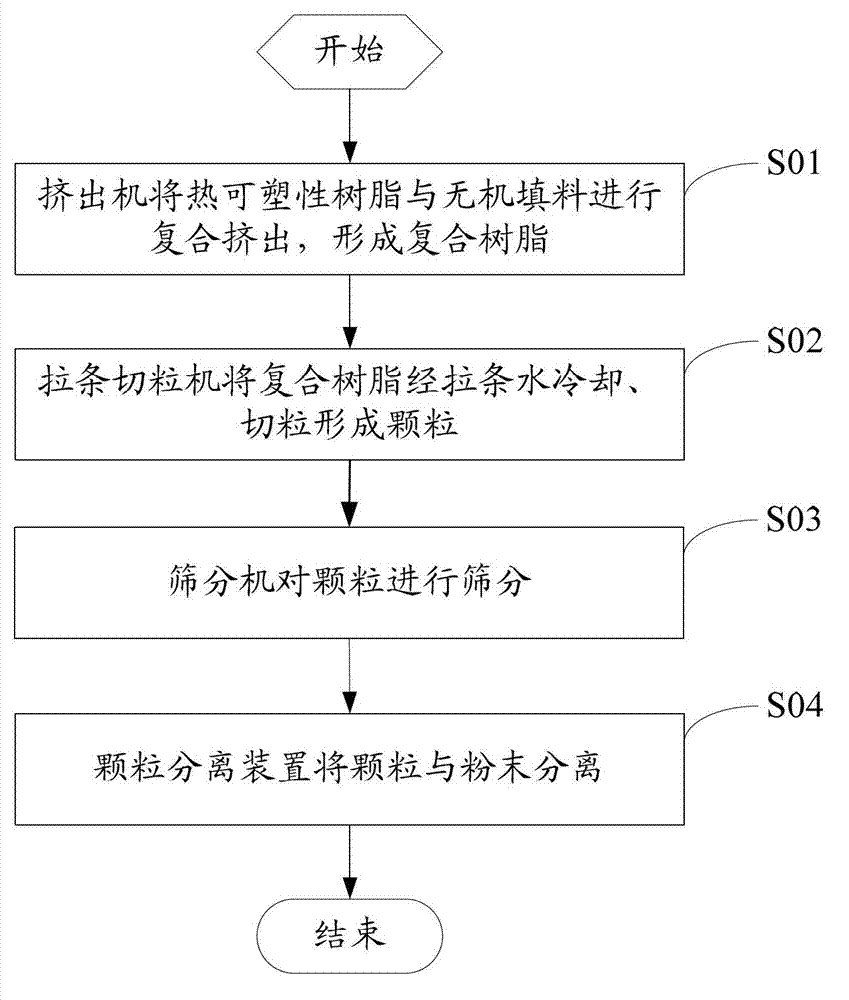

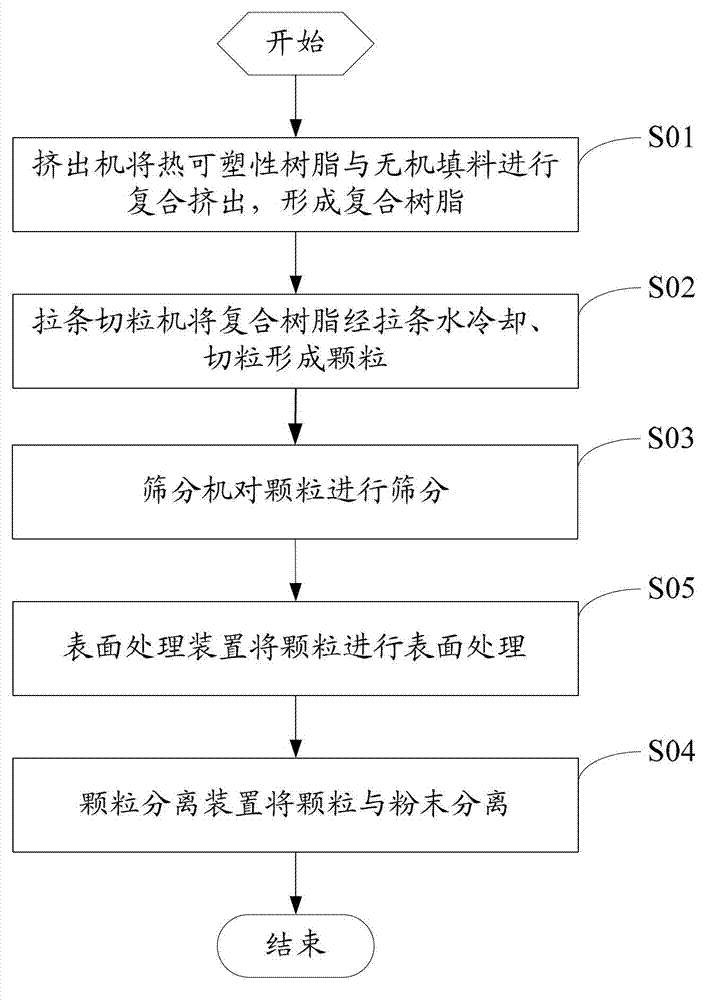

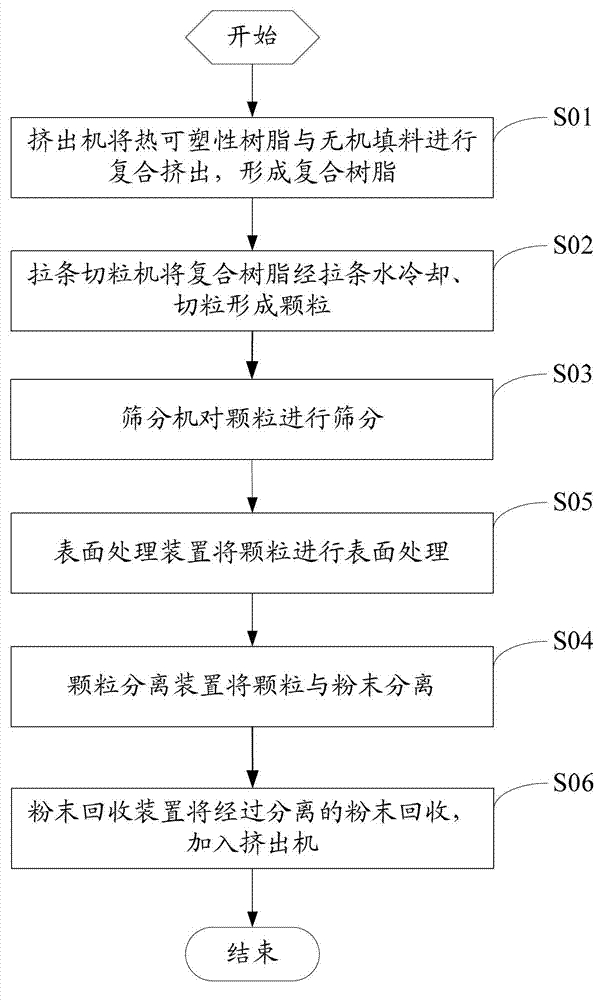

Thermoplastic resin granulation method and device thereof

ActiveCN102729353AReduce powder contentSolve the problem of powderCoatingsResin-Based CompositeWater cooling

The present invention discloses a thermoplastic resin granulation method and a device thereof. The method comprises the following steps: carrying out composite extruding on a thermoplastic resin and an inorganic filler with an extruder to form a composite resin; carrying out bracing water cooling and granulation on the composite resin with a bracing granulation machine to form particles; screening the particles with a screening machine; and separating the particles from the powder with a particle separation device. According to the thermoplastic resin granulation method of the present invention, bracing water cooling, granulation and screening are sequentially performed, and then the particle separation device is adopted to separate the particles from the powder, such that the powder content in the particles is reduced, the powder problem of the downstream injection molding plant during the production process is effectively solved, and the production efficiency and the yield are improved.

Owner:东丽塑料(深圳)有限公司

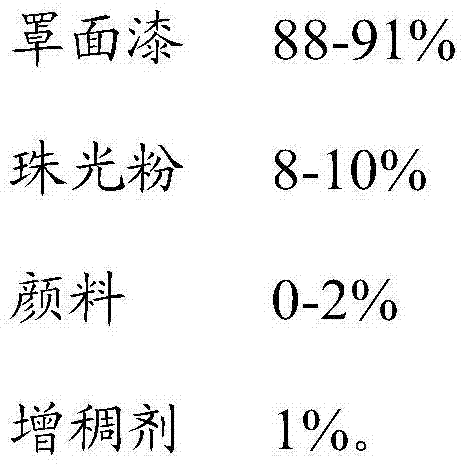

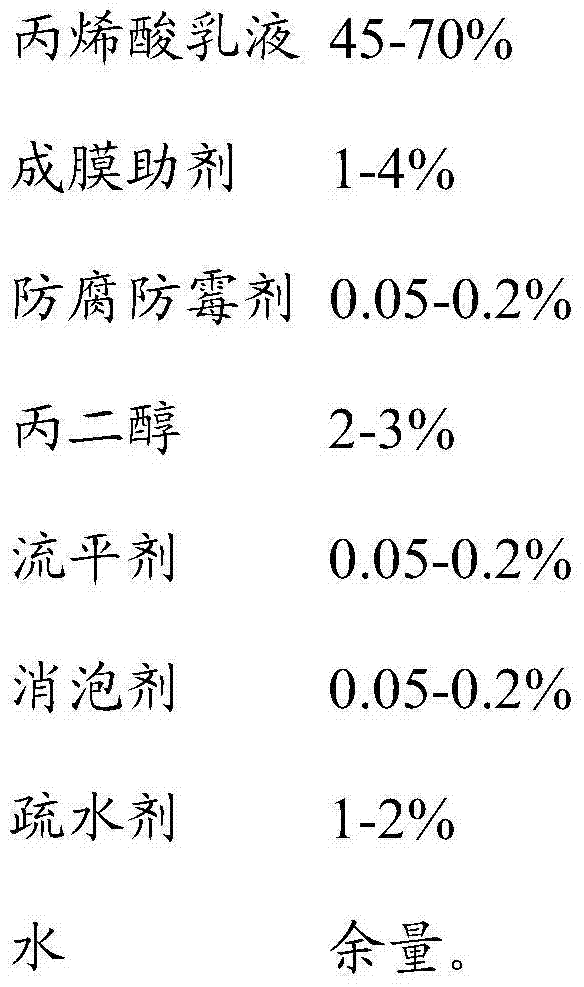

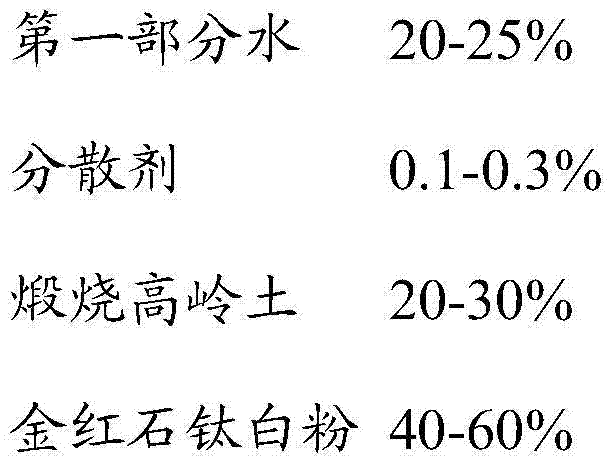

Super-weather-proof water-based metallic paint and preparation method thereof

InactiveCN104725962AIncrease coverageReduce powder contentAntifouling/underwater paintsPaints with biocidesWater basedCalcium silicate

The invention discloses a super-weather-proof water-based metallic paint, and belongs to the field of a water-based paint. The super-weather-proof water-based metallic paint comprises the following components in percentage by weight: 88-91% of finish-coat paint, 8-10% of pearl powder, 0-2% of pigment and 1% of a thickener. The invention further discloses a preparation method of the super-weather-proof water-based metallic paint. The super-weather-proof water-based metallic paint has favorable hiding power, excellent contamination resistance and self-cleaning function, excellent pain film property, high weather resistance, scrubbing resistance, ageing resistance, scratch resistance, rice color, rich metallic color, obvious quality and good gloss effect; the paint is applicable for inner and outer wall surfaces and metal surfaces, calcium silicate board surfaces and other decorative material surfaces, the application scope is wide. The preparation method is easy to implement, the three wastes are avoided during the production process, and so the preparation method is environmentally friendly and safe.

Owner:GUANGZHOU ZUODANSHI PAINT

Device and method for reducing powder content of lump ore

The invention relates to a device and method for reducing the powder content of a lump ore. The device and method for reducing the powder content of the lump ore mainly solve the technical problems ofhigh powder content and difficult screening of an existing blast furnace ironmaking lump ore. The device for reducing the powder content of the lump ore comprises a sintering machine, a sintering machine air bellow, a sintering flue gas pipeline, a lump ore belt conveyor, and a lump ore bin. The device for reducing the powder content of the lump ore is characterized in that the device further comprises an induced draft fan, a baking furnace, a flue gas hood, a silo, a lump belt conveyor, a vibrating screen riddler, an undersize belt conveyor, a dedusting belt conveyor, and a feeding belt conveyor, wherein the flue gas hood communicates with the sintering flue gas pipeline; the induced draft fan communicates with a gas outlet pipe of the baking furnace through the sintering flue gas pipeline; an electrostatic precipitator is arranged on the sintering flue gas pipe between the induced draft fan and the gas outlet pipe of the baking furnace; and an electric gate valve is arranged on thesintering flue gas pipeline between the gas outlet pipe of the sintering flue gas pipeline and a gas inlet pipe of the baking furnace. The device for reducing the powder content of the lump ore has low manufacturing and operating costs.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Full-extruded chicken compound feed and preparation method thereof

InactiveCN102488112AImprove digestibilityImprove ripenessFood processingAnimal feeding stuffAnimal scienceEconomic benefits

The invention is prepared by the steps of selecting corn, wheat, bean pulps, cottonseeds and other raw materials, performing secondary smashing and full-extruded treatment, and spraying liquid zymin and the like according to a heat-sensitivity principle. Nutrient substance including protein, amylum and the like in full-extruded feed is loose in structure, thereby facilitating contact of the feed and the zymin and enabling the feed to be easily digested. Intestinal canals of chickens fed with the full-extruded feed are healthy, simultaneously, ammonia gas concentration gain / feed ratio and death rate in henhouses are reduced, and economic benefit of cultivation is increased.

Owner:TONGWEI

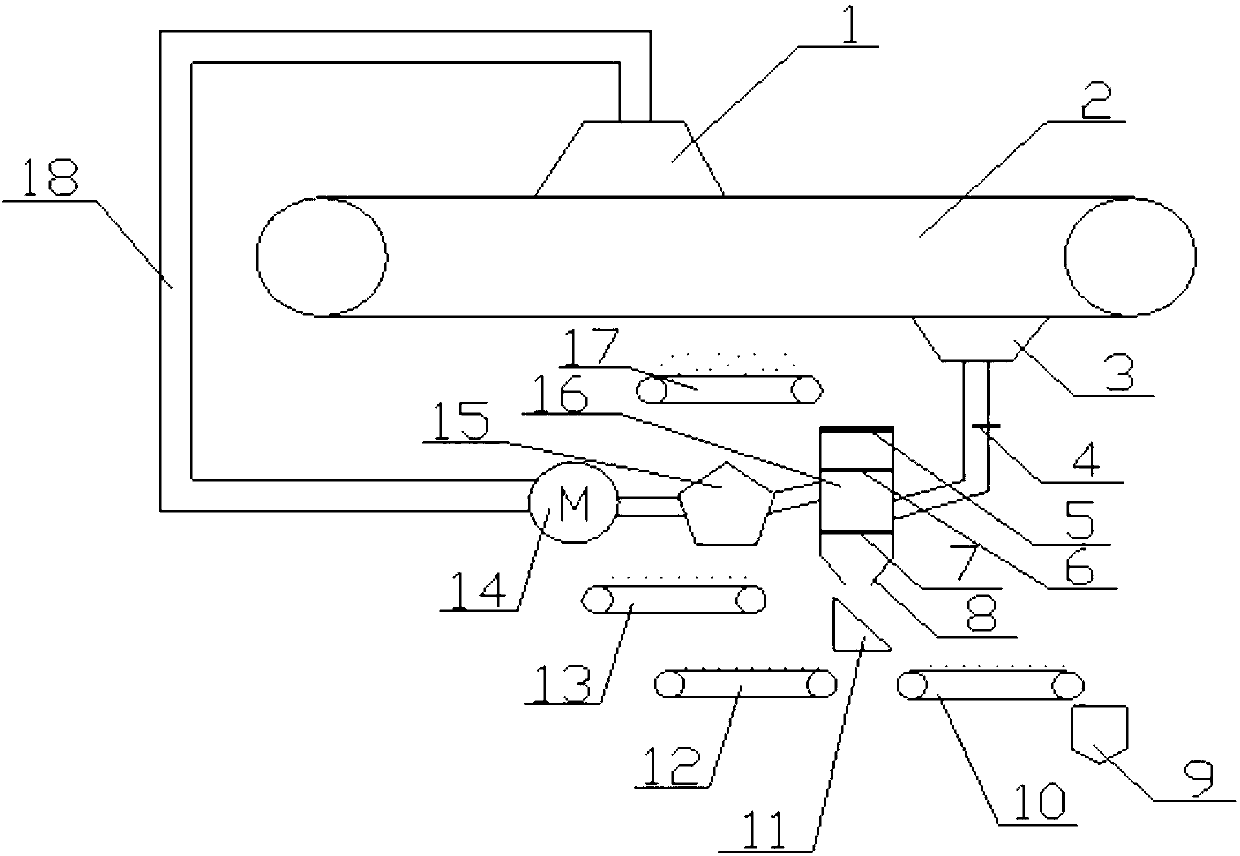

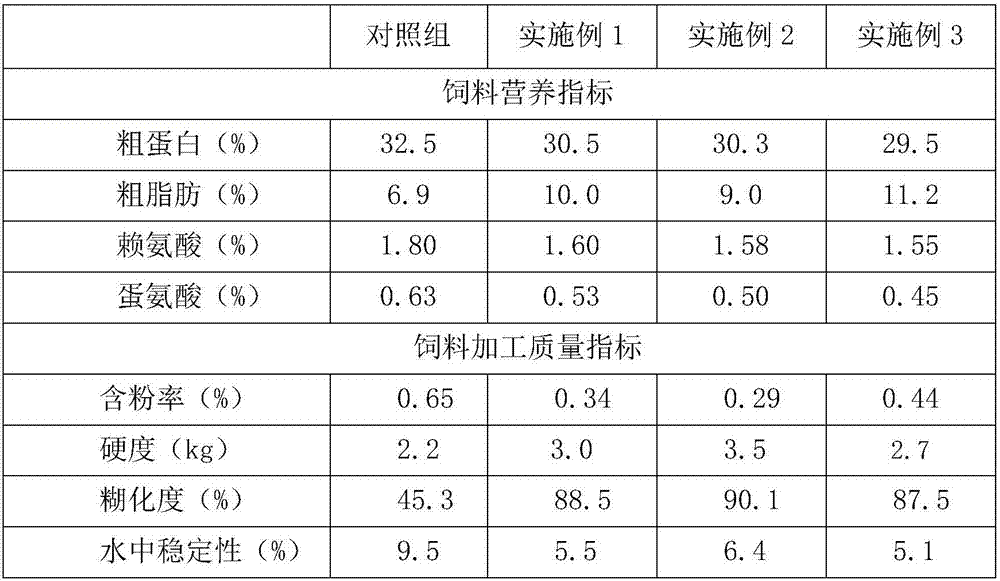

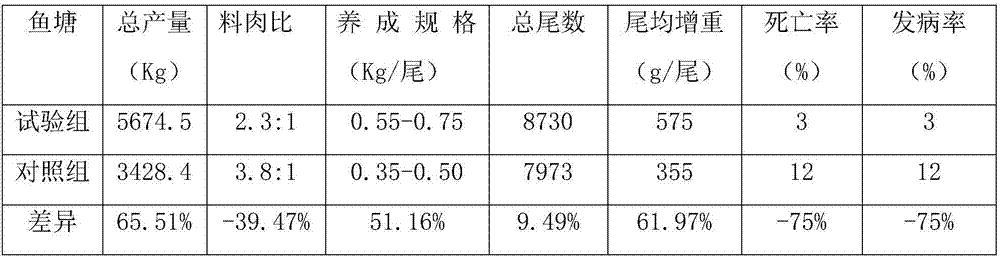

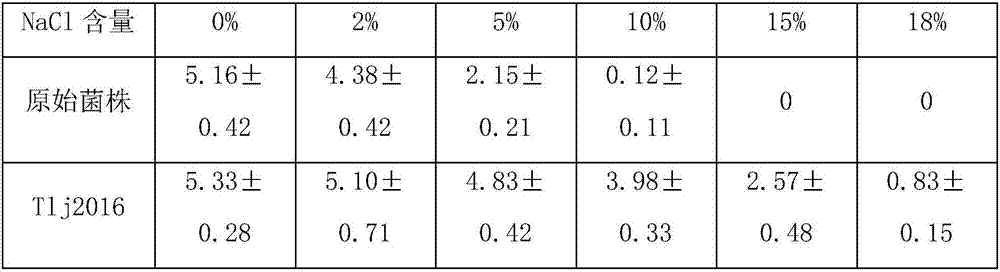

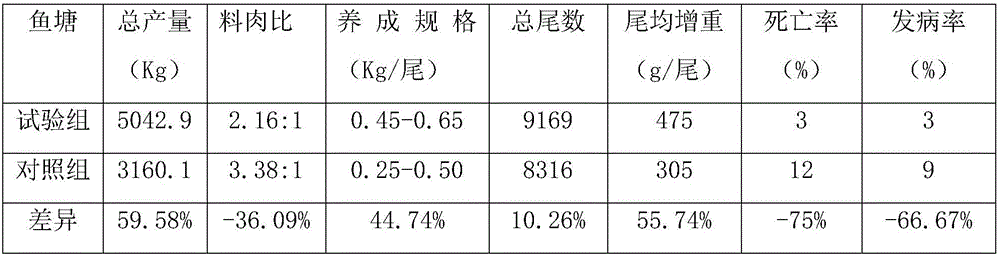

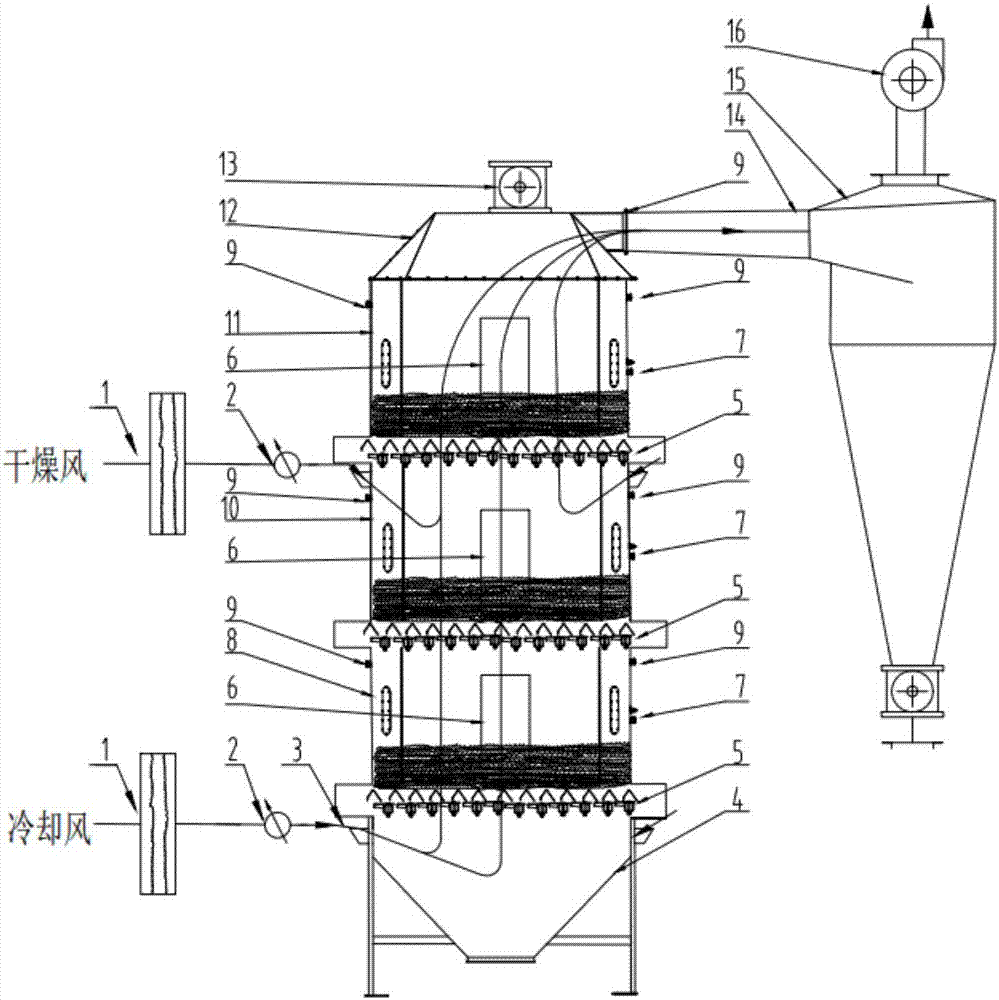

High-fat crucian curing compound feed and processing technology

InactiveCN107494894AImprove immunityHigh yieldFood processingClimate change adaptationBiotechnologyWeight gaining

The invention discloses a high-fat crucian curing compound feed and a processing technology. Fermented astragalus has high scientific compounding prebiotic property and is capable of obviously improving the body immunity and liver functions; platycodon grandiflorum is capable of effectively reducing the incidence of hyperlipidemia and hyperglycemia symptoms and is effectively improving excessive deposition of fat in liver, spleen and muscle tissues, so that the adaptability of crucian on a high-fat feed is improved, and healthy growth of the crucian is promoted; fish meal is replaced with terrestrial animal protein raw materials, composite grease is compounded scientifically, and by matching different fat raw materials, the crucian growth speed is improved, the feed coefficient is reduced, the body form of the fish is improved, and health of the liver and gall is protected; and a carnitine and cholate degradation inhibitor can achieve the effects of increasing emulsification, digestion and absorption of the fat, promoting biliary secretion and protecting the liver and increasing choleresis and contributes to protecting the health of the liver and gall. Feed tests show that under the conditions that the crude protein content of daily ration is reduced by 2-3% and the crude fat content is increased by 2.1-4.3%, the weight gain rate of the crucian can be increased by 10.99% or more, the feed coefficient is reduced by 12.4% or more, the liver and gall are healthy and normal.

Owner:LIAONING WELLHOPE AGRI TECH

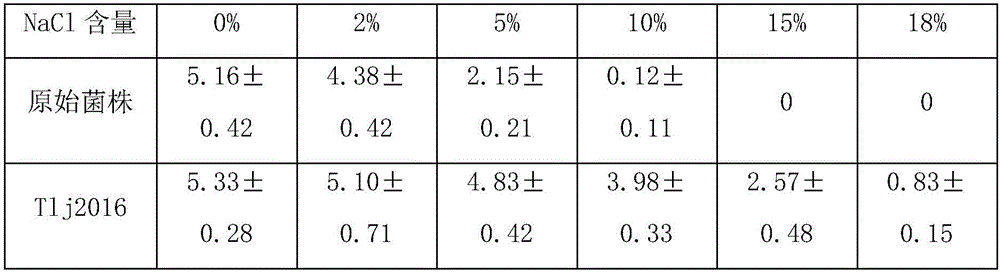

Silurus asotus feed phagostimulant and preparation method thereof

InactiveCN107348229AOptimized formulaImprove antioxidant capacityFood processingClimate change adaptationSoluble fiberArtemisia carvifolia

The present invention discloses a silurus asotus feed phagostimulant and a preparation method thereof, and belongs to the technical field of feed additive preparations. Based on nutritional requirements of silurus asotus and water body environment, and combining food intake characteristics, a formula of raw materials is optimized. The silurus asotus feed phagostimulant scientifically combines compound flavor peptides greatly improving palatability and feed utilization rate, having a relatively strong anti-oxidation effect and eliminating free radicals; an accharomyces cerevisiae culture having functional characteristics of being strong in nutrition, biological activity, oxidation resistance, etc.; a high-calcium cerasus humilis extract effectively supplementing calcium, iron and soluble fibers, having a strong embedding effect and prolonging a shelf life; artemisia carvifolia seed powder significantly improving antifreeze effects and stability, improving water resistance and gloss, and enhancing and promoting palatability; and wheat malt powder providing rich nutrients, bioactive substances and plant enzyme sources. Finally, the prepared silurus asotus feed phagostimulant is strong in phagostimulant and good in production performances.

Owner:田岗

Quantitative gas detection device

ActiveCN108225856AReduce testing costsImprove detection efficiencyWithdrawing sample devicesParticle suspension analysisDiffusionEngineering

The invention relates to the technical field of gas detection, and discloses a quantitative gas detection device. The quantitative gas detection device comprises a machine frame, a detection box and adriving mechanism, wherein the driving mechanism is positioned under the detection box; the interior of the detection box is slideably connected with a piston plate; the lower part of the piston plate is connected with a piston rod; the piston rod is fixedly connected with the driving mechanism; a detection passage, a battery and a detection lamp are arranged at the upper part of the detection box, the battery and the detection lamp are respectively electrically connected with a conducting wire, a detection plate is arranged in the detection passage and is hinged to the detection box, a firstadhesive layer is arranged at the lower part of the detection plate and is in contact with two conducting wires, and a second adhesive layer is arranged on the detection passage; an air intake passage is arranged at one side of the detection box, a blocking plate is arranged in the air intake passage, the other end of the blocking plate is provided with a groove, an air cavity is arranged in thedetection box above the groove, a limiting block is arranged in the air cavity, and a spring is arranged at the top part of the limiting block; the air intake passage is provided with a shrinkage section, a throat pipe section and a diffusion section, an air pipe is arranged at the throat pipe section, and the air cavity is communicated with the air intake passage through the air pipe. The quantitative gas detection device has the advantages that the structure is simple, and the detection gas can be quantitatively detected.

Owner:重庆博创知识产权运营有限公司

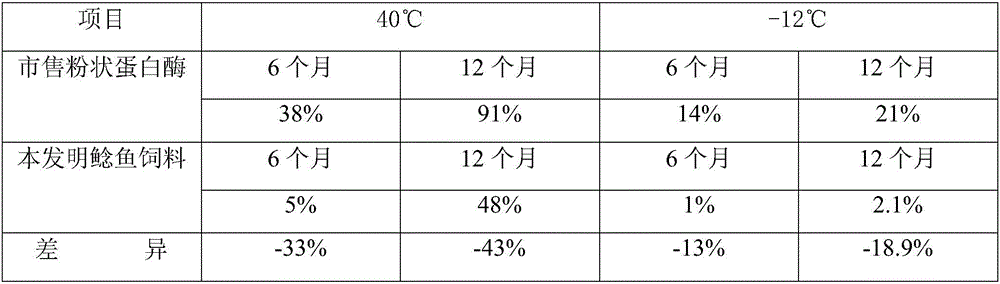

Catfish feed compound enzyme and preparation method thereof

InactiveCN106615692AImprove digestibilityIncrease production capacityClimate change adaptationAnimal feeding stuffWater qualitySoluble fiber

The invention discloses a catfish feed compound enzyme and a preparation method thereof. The preparation method of the catfish feed compound enzyme is characterized by taking nutritional requirement of the catfish and the water environment as the basis, optimizing the raw material formula, combining digestion characteristics of the catfish and scientifically compounding a wine making yeast culture material with functional characteristics such as high nutrition performance, high biological activity, high oxidation resistance and the like, a calcium fruit extract capable of effectively supplementing calcium, iron and soluble fiber, providing powerful embedding effect and prolonging the quality guarantee period of the feed compound enzyme, wormwood seed powder capable of obviously improving anti-freezing effect and stability of the feed compound enzyme, improving water resistance and glossiness of the catfish feed and reducing powder content in the feed, a palatable agent capable of greatly improving palatability and digestion rate of the feed, and wheat malt flour capable of providing rich nutrient materials, biological active materials and plant enzyme sources to finally obtain the catfish feed compound enzyme capable of obviously enhancing digestion rate and parturition performance of the catfish, reducing the feed coefficient, preventing water pollution and maintaining high water quality.

Owner:田岗

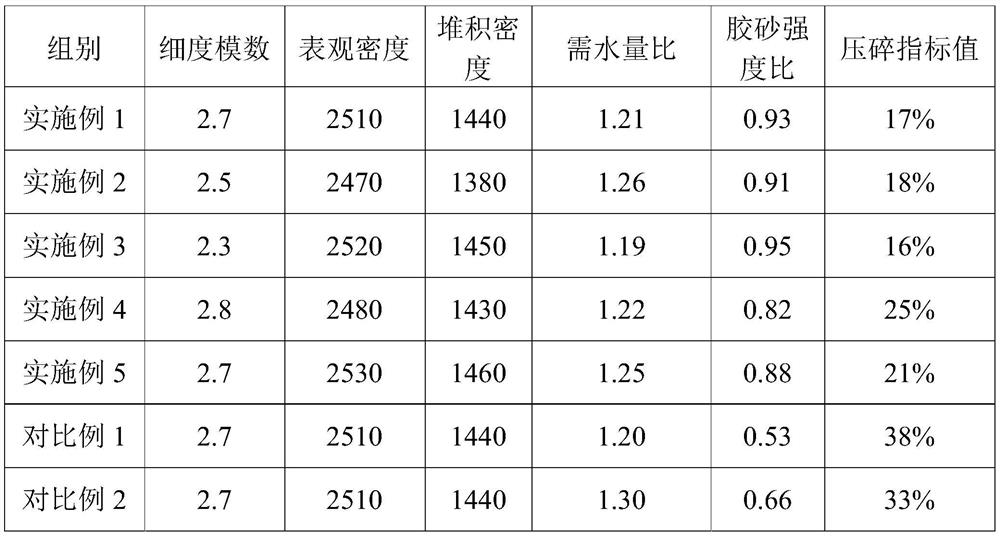

Solid waste reclaimed sand as well as preparation method and application thereof

ActiveCN112408829AImprove liquidityHigh strengthSolid waste managementPlasticizerProcess engineering

The invention relates to solid waste reclaimed sand as well as a preparation method and application thereof. The solid waste reclaimed sand is prepared from the following raw materials in parts by weight: solid waste, a cementing material, water, a retarder, a plasticizer and a water reducing agent. The solid waste is creatively mixed with the cementing material, the retarder, the plasticizer, thewater reducing agent and the water, wherein the novel solid waste reclaimed sand is obtained through a series of treatment, and the reclaimed sand has the advantages of being small in water absorption rate, low in powder content, good in fluidity, high in strength and high in solid waste utilization rate; therefore, the defects of traditional solid waste reclaimed sand are overcome, and the comprehensive performance of the reclaimed sand is improved. The preparation method of the solid waste reclaimed sand is simple and easy to operate, and is very suitable for large-scale industrial production.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Non-blast furnace iron making device feeding system and method

InactiveCN103344118AReduce powder contentEliminate the effects ofCharge manipulationScreening effectEnergy consumption

The invention provides a non-blast furnace iron making device feeding system and method. The feeding system comprises a material groove, a material discharge gate, a material belt conveyor under the groove, a vibrating feeder and a vibrating screen, raw materials sequentially pass through the material groove and the material discharge gate and then enter the vibrating feeder, vibration feeding is achieved through the vibrating feeder, therefore, the raw materials are distributed on the vibrating screen, powder materials in the raw materials are screened out through the vibrating screen, the screened raw materials enter a material distributing device on the top of a furnace through the material belt conveyor under the groove, and feeding is achieved. The vibrating screen and the vibrating feeder are introduced, the vibrating screen and the vibrating feeder are used together to screen the raw materials, the vibrating feeder is adopted so that the materials can be loosened, the screening effect is facilitated, and the vibrating screen is used for screening and removing the powder materials from the materials. According to the non-blast furnace iron making device feeding system and method, the content of powder materials entering a vertical reduction furnace is reduced, and the problem that the productivity, the energy consumption and the operability of the whole system are seriously influenced due to the high content of the powder materials in the raw materials in the vertical reduction furnace is solved.

Owner:上海宝锋工程技术有限公司

Mulberry leaf extract fish feed adhesive, and preparation method and application of mulberry leaf extract

ActiveCN111084301AReduce powder contentReduce pulverization rateAnimal feeding stuffYerba santa extractHorticulture

The invention discloses a mulberry leaf extract fish feed adhesive, and a preparation method and application of mulberry leaf extract. The mulberry leaf extract is taken as an aquatic feed adhesive soas to perform the functions of lowering the powder content, the pulverization rate and the dissolve-loss ratio of the feed and prolonging the shape-preserving time of the feed in water, the absorption of nutrient ingredients by fishes and shrimps is not affected, an adhesion effect is good, and water stability is good. A new purpose of mulberry leaves is developed, a traditional mulberry leaf utilization structure is improved, the comprehensive utilization potential of the mulberry leaves is performed, waste materials are recycled, and the economic and social benefit of the mulberry leaves can be improved. The invention has a very important meaning and has the advantages of low cost, a small use amount, wide sources, no toxicity and convenience in processing.

Owner:NEIJIANG NORMAL UNIV

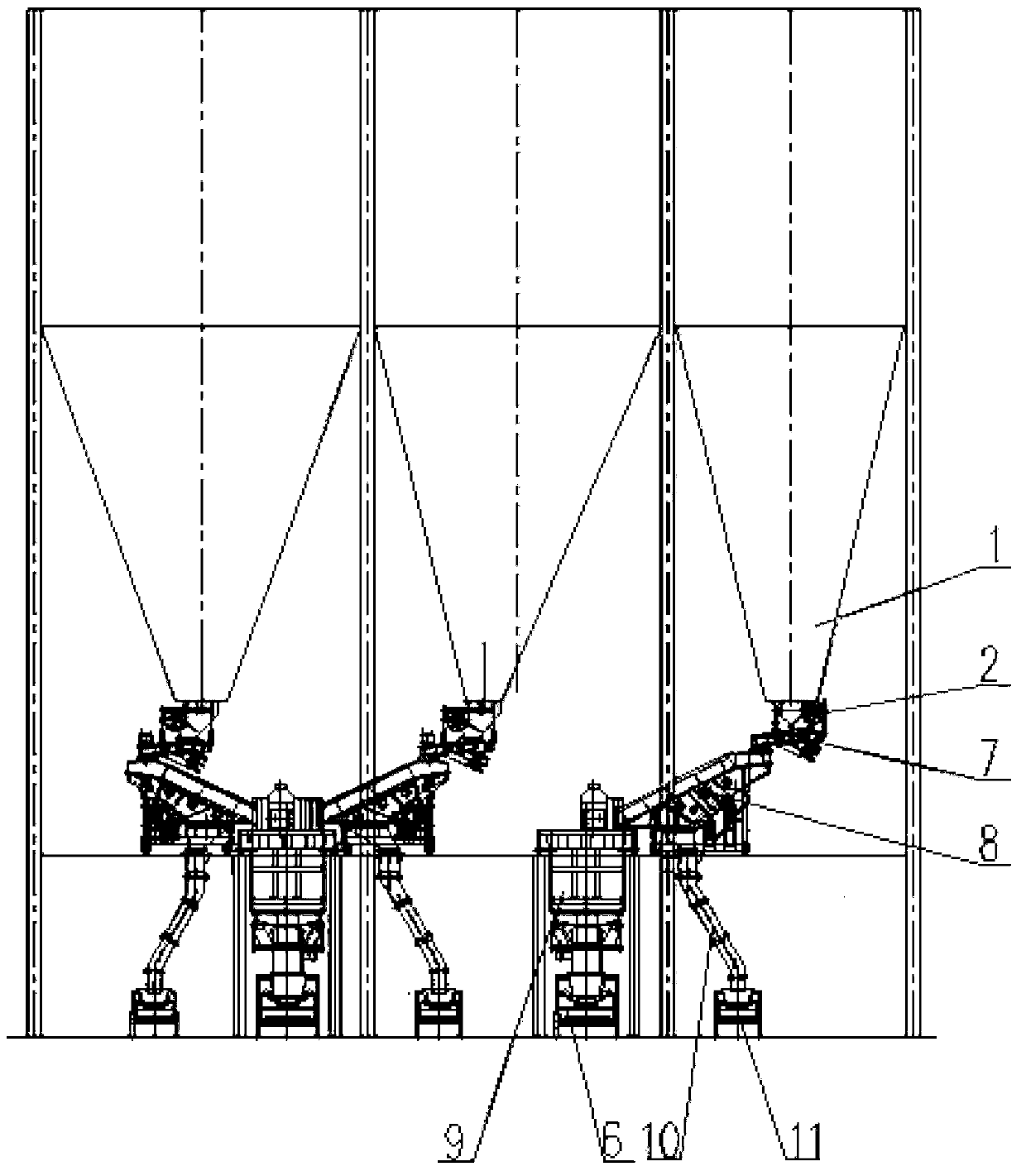

Drying and cooling system for production of cured powdery feed

PendingCN107990653AStrong penetrating powerImprove efficiencyFeeding-stuffDomestic cooling apparatusAir volumeCounter flow

The invention provides a drying and cooling system for production of cured powdery feed. A cooling tank of a cooler is divided into multiple layers, a turning plate type discharge mechanism as well asan upper material level device and a lower material level device for controlling material layer height is arranged independently on each tank layer, and an independent compressed air blowing system is arranged on each tank layer. The drying and cooling system is provided with a cooling air inlet pipe and a drying air inlet pipe, and steam heat exchangers and automatic doors capable of controllingtemperature and air volume are mounted on the pipes respectively. Compared with the conventional counter-flow type pellet feed cooler, the drying and cooling system has the advantages that penetrating power of cooling air is strong, the cooling air can be contacted uniformly with the powdery feed, and the cooling efficiency is increased greatly; the powdery feed on each layer can play a filter role, so that powder return rate is reduced; the system has integrated cooling and drying function and is applicable to all weather conditions.

Owner:FEED RESEARCH INSTITUTE CHINESE ACADEMY OF AGRICULTURAL SCIENCES

High-yield catfish feed attractant and preparation method thereof

InactiveCN106805007AIncrease profitOptimized formulaFood processingClimate change adaptationFlavorWater environment

The invention discloses a high-yield catfish feed attractant and a preparation method thereof and belongs to the technical field of feed additive preparation. The high-yield catfish feed attractant and the preparation method thereof have the advantages that the nutritional requirements of catfish and water environments are combined with the ingestion features of the catfish to optimize a raw material formula, raw materials are scientifically compounded to greatly increase palatability and feed utilization rate, and the attractant comprises compound flavor peptide which has high anti-oxidation effect and is capable of removing free radicals; the high-yield catfish feed attractant contains saccharomyces cerevisiae culture with functional features such as high nutrition, high bioactivity and high oxidation resistance, Prunus Humilis Bunge extract which can effectively supplement calcium, iron and soluble fibers, has a powerful embedding effect and can prolong shelf life, wormwood seed powder which can evidently increase an anti-freezing effect and stability, increase water resistance and glossiness, enhance and promote palatability and lower powder content, and wheat malt powder which can provide rich nutritional substances, bioactive substances, fragrant substances and plant enzyme sources; the prepared high-yield catfish feed attractant is high in palpability and good in production performance.

Owner:田岗

Aggregate dust removing device and method used before bin cooling and for asphalt concrete mixing equipment

The invention relates to the field of aggregate dust removal before bin cooling and for asphalt concrete mixing equipment, in particular to an aggregate dust removing device and method used before bin cooling and for the asphalt concrete mixing equipment. The aggregate dust removing device used before bin cooling and for the asphalt concrete mixing equipment comprises an aggregate conveying device, a drying roller, a winnowing device and a dust remover. The winnowing device comprises a winnowing chamber and an air blower; the winnowing chamber is provided with a feed port, a discharge port, an air inlet and a dust suction port, the feed port is communicated with the drying roller, the discharge port is used for discharging screened aggregate, the air inlet is communicated with the air blower, and the dust suction port is connected with the dust remover; the air blower is provided with an air inlet and an air outlet, the air inlet is connected with the dust remover, and the air outlet is connected with the air inlet of the winnowing chamber. Meanwhile, the air blower blows clean air in the dust remover to blow dust of the aggregate in the winnowing chamber. According to the invention, the dust content of the aggregate for asphalt concrete is greatly lowered, waste is avoided, resources are saved, the arrangement is reasonable, and secondary pollution is avoided.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

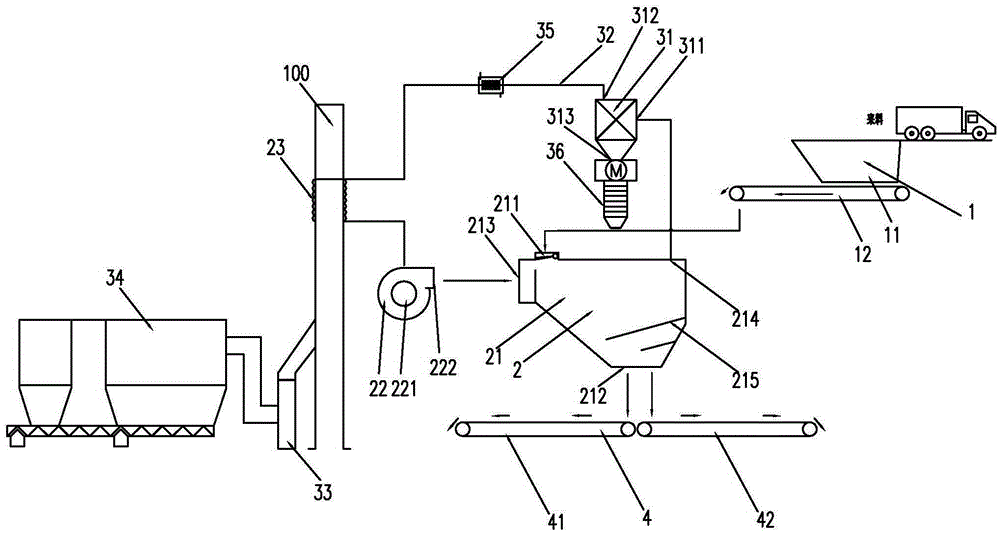

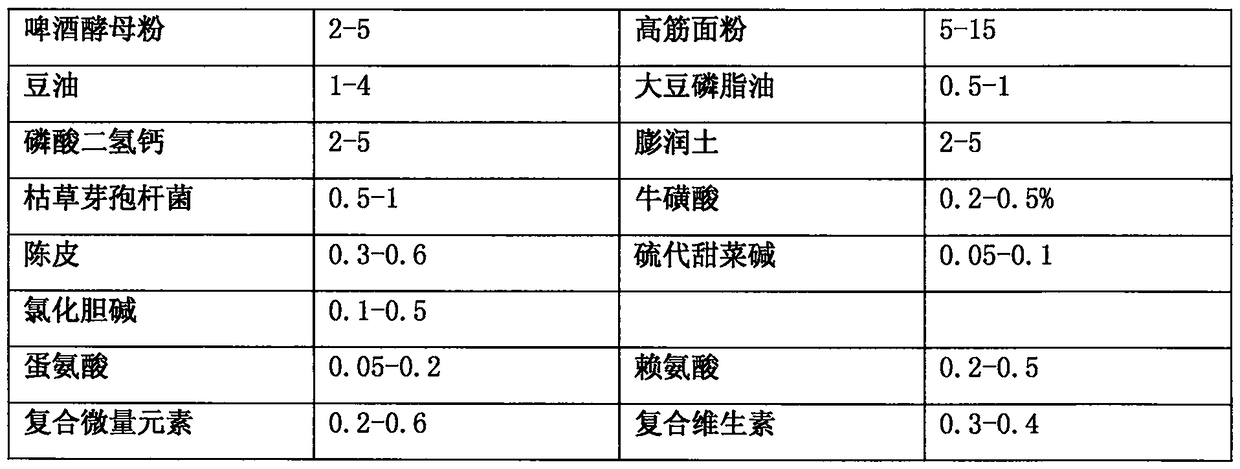

Environmental-friendly mixed culture fish feed capable of strengthening food calling properties and preparation method of environmental-friendly mixed culture fish feed

InactiveCN108201024AImprove digestion and absorption rateIncrease contact areaFood processingClimate change adaptationAnimal scienceTaurine

The invention discloses an environmental-friendly mixed culture fish feed capable of strengthening food calling properties. The environmental-friendly mixed culture fish feed is prepared from the following raw materials in percentage by weight: 10-15% of soybean meal, 15-30% of rape seed cakes, 5-15% of cottonseed meal, 2-10% of corn alcohol meal, 2-8% of pig internal organ powder, 2-8% of fish meal, 2-5% of beer yeast powder, 5-15% of high-gluten flour, 1-4% of soybean oil, 0.5-1% of soybean phospholipid oil, 2-5% of calcium dihydrogen phosphate, 2-5% of bentonite, 0.5-1% of bacillus subtilis, 0.2-0.5% of taurine, 0.3-0.6% of dried orange peel, 0.05-0.1% of sulfobetaine, 0.1-0.5% of choline chloride, 0.05-0.2% of methionine, 0.2-0.5% of lysine, 0.2-0.6% of composite trace elements and 0.3-0.4% of composite vitamins. The feed can improve the food calling properties and the digestibility, reduce the powder, and reduce the waste of feeds.

Owner:淮安禾丰饲料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com