Solid waste reclaimed sand as well as preparation method and application thereof

A solid waste and reclaimed sand technology, applied in the field of building materials, can solve the problems of high utilization rate of solid waste, high water absorption rate and high powder content of regenerated sand, and achieve high utilization rate of solid waste and improved comprehensive performance , the effect of low powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

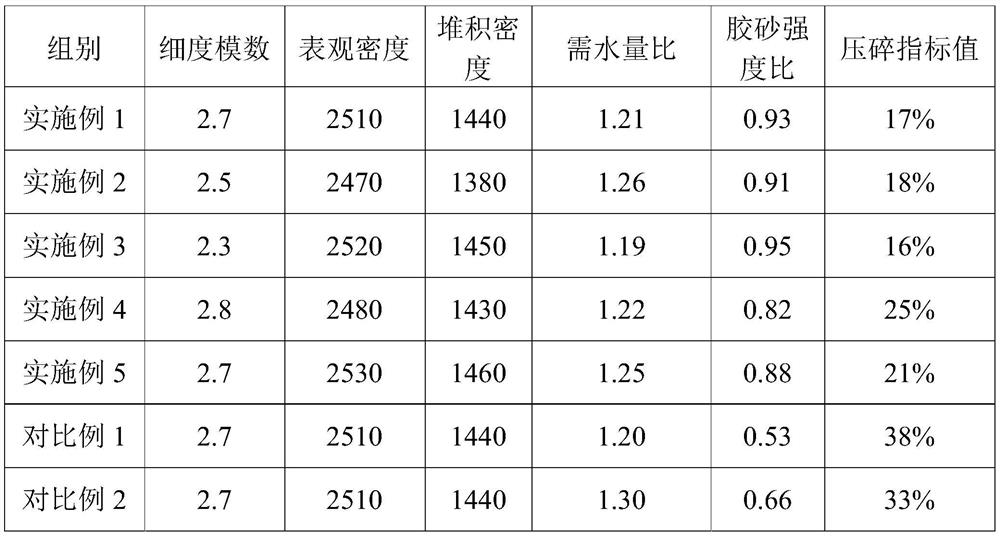

Examples

Embodiment 1

[0049] This embodiment provides a solid waste reclaimed sand, which is composed of the following components by weight ratio: 30 parts of waste concrete, 30 parts of stone powder, 15 parts of cement, 16 parts of fly ash, 0.2 parts of retarder, plasticizer 0.2 parts of water reducing agent, 0.2 parts of water reducing agent, and 40 parts of water. Among them, the cement is P·II 52.5R ordinary Portland cement; the fly ash is F class I fly ash; the retarder is sodium gluconate; the plasticizer is carboxymethyl cellulose; Carboxylic acid superplasticizer.

[0050] Its preparation method is as follows:

[0051] (1) Add solid waste, gelling material, water, retarder, plasticizer and water reducer to the mixer in parts by weight, mix and stir for 10 minutes, and make solid waste slurry;

[0052] (2) Spray-drying the solid waste slurry prepared in step (1) to obtain dry granules with a moisture content of 2.8%;

[0053] (3) Curing the dried granules prepared in step (2) for 28 days ...

Embodiment 2

[0055] This embodiment provides a solid waste reclaimed sand, which is composed of the following components by weight: 80 parts of waste ceramic tiles, 15 parts of cement, 5 parts of slag powder, 8 parts of silica fume, 0.2 parts of retarder, 0.2 parts of plasticizer, 1.2 parts of water reducing agent, 33 parts of water. Among them, the cement is P·O 42.5R ordinary Portland cement; the slag powder is S95 slag powder; the silica fume is silica fume with a 28d activity index of 122%; the retarder is sodium gluconate; the plasticizer is polyvinyl alcohol ; The water reducer is lignosulfonate water reducer.

[0056] Its preparation method is as follows:

[0057] (1) Add solid waste, gelling material, water, retarder, plasticizer and water reducer to the mixer in parts by weight, mix and stir for 30 minutes, and make solid waste slurry;

[0058] (2) Spray-drying the solid waste slurry prepared in step (1) to obtain dry granules with a moisture content of 3.7%;

[0059] (3) Curin...

Embodiment 3

[0061] This embodiment provides a solid waste reclaimed sand, which is composed of the following components by weight: 20 parts of waste mortar, 40 parts of waste concrete, 10 parts of waste tiles, 35 parts of cement, 5 parts of fly ash, metakaolin 8 parts, retarder 0.45 parts, plasticizer 0.38 parts, water reducing agent 1.33 parts, water 38 parts. Among them, the cement is P·II 42.5R ordinary Portland cement; the fly ash is Class I fly ash; the metakaolin is metakaolin with 28d activity index of 108%; the retarder is propylene glycol; the plasticizer is Starch ether; water reducer is polycarboxylate water reducer.

[0062] Its preparation method is as follows:

[0063] (1) Add solid waste, gelling material, water, retarder, plasticizer and water reducer to the mixer in parts by weight, mix and stir for 20 minutes, and make solid waste slurry;

[0064] (2) Spray-drying the solid waste slurry prepared in step (1) to obtain dry granules with a moisture content of 2.2%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com