Aggregate dust removing device and method used before bin cooling and for asphalt concrete mixing equipment

A technology for asphalt concrete and mixing equipment, which is applied to roads, road repair, roads, etc., can solve the problems of long production cycle, insufficient embedding and cracking, etc., and achieve the effect of saving resources and reasonable layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

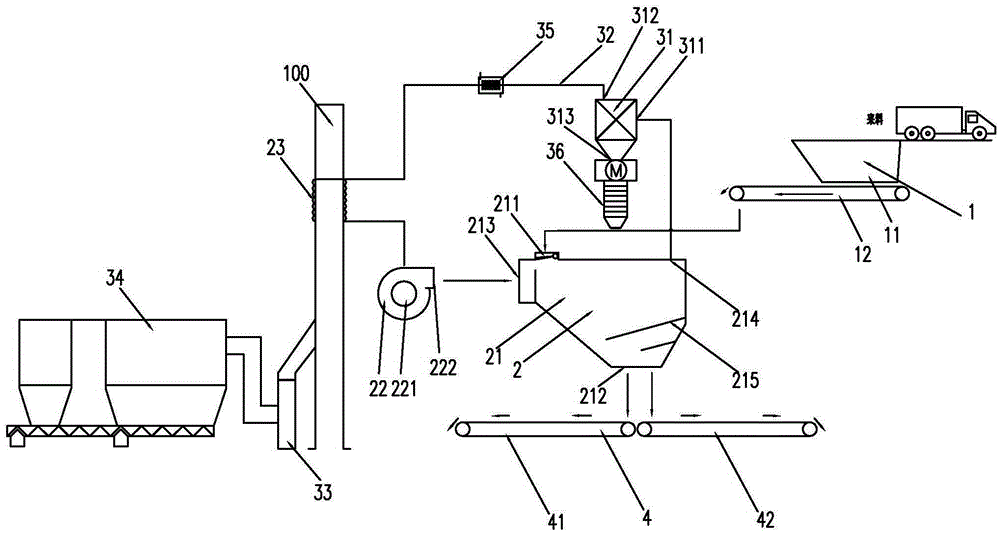

[0022] refer to figure 1 As shown, the aggregate powder removal equipment in front of the cold material silo is installed on the asphalt concrete mixing equipment with the tail gas flue 100, including the aggregate conveying device 1, the winnowing device 2, the dust removal device Device 3 and aggregate conveying device 4.

[0023] The aggregate conveying device 1 includes a collection bin 11 and a feed belt 12, the collection bin 11 is a bucket for unloading aggregates from trucks or loaders, and the feed belt 12 is used to transport the aggregate in the bin 11 to winnowing Device 2 is ready for depowdering.

[0024] The winnowing device 2 comprises a winnowing chamber 21, a blower 22, and an air preheater 23, and the winnowing chamber 21 is provided with a feed inlet 211, a feed outlet 212, an air inlet 213, a dust outlet 214 and a multi-layer screen 215 , wherein the feed port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com