Non-blast furnace iron making device feeding system and method

A non-blast furnace and material distributing device technology, which is applied in the field of feeding system of non-blast furnace ironmaking equipment, can solve the problems of blocking the gas passage in the furnace and poor furnace production, and achieve the effect of reducing the powder content and eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

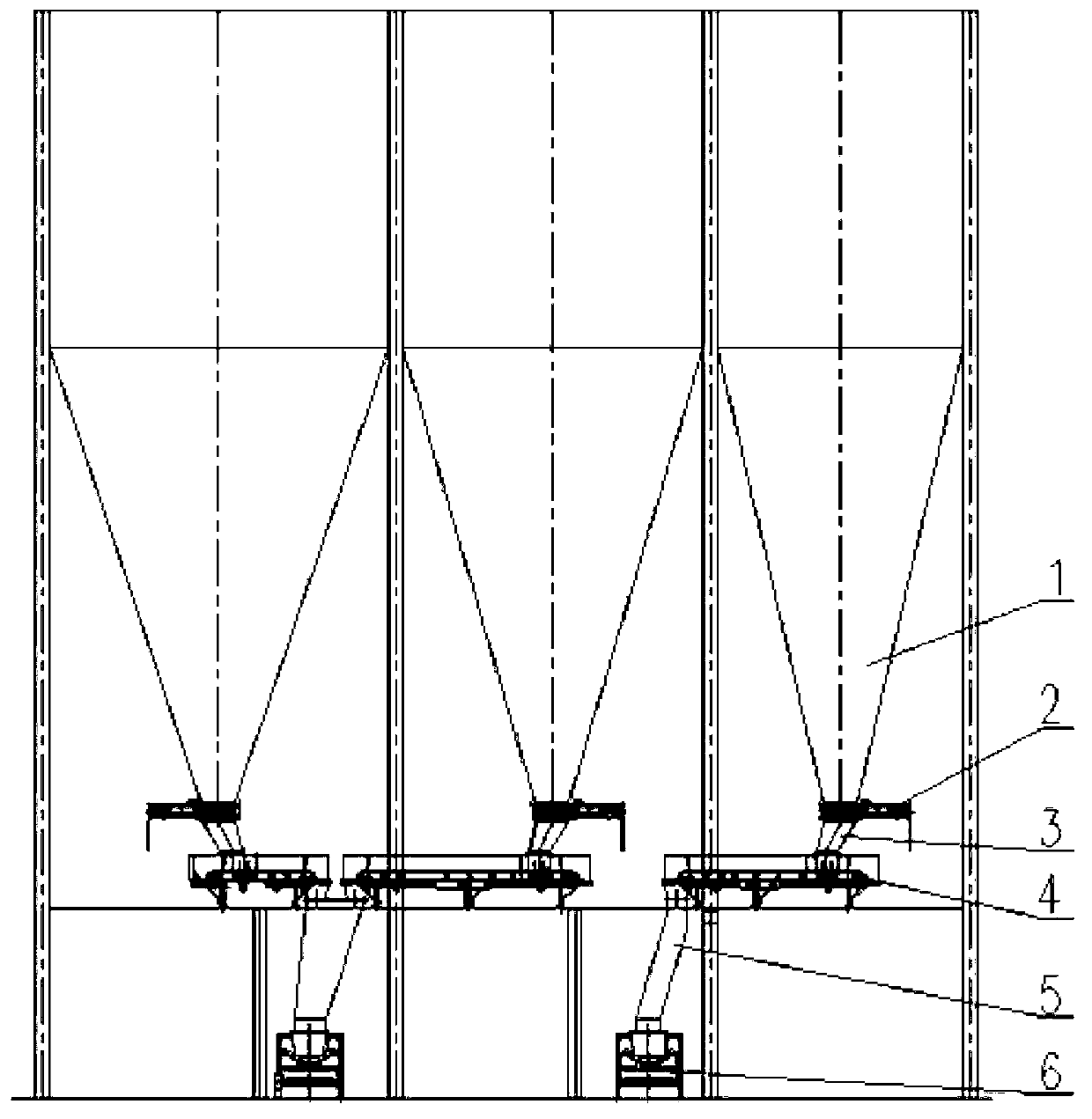

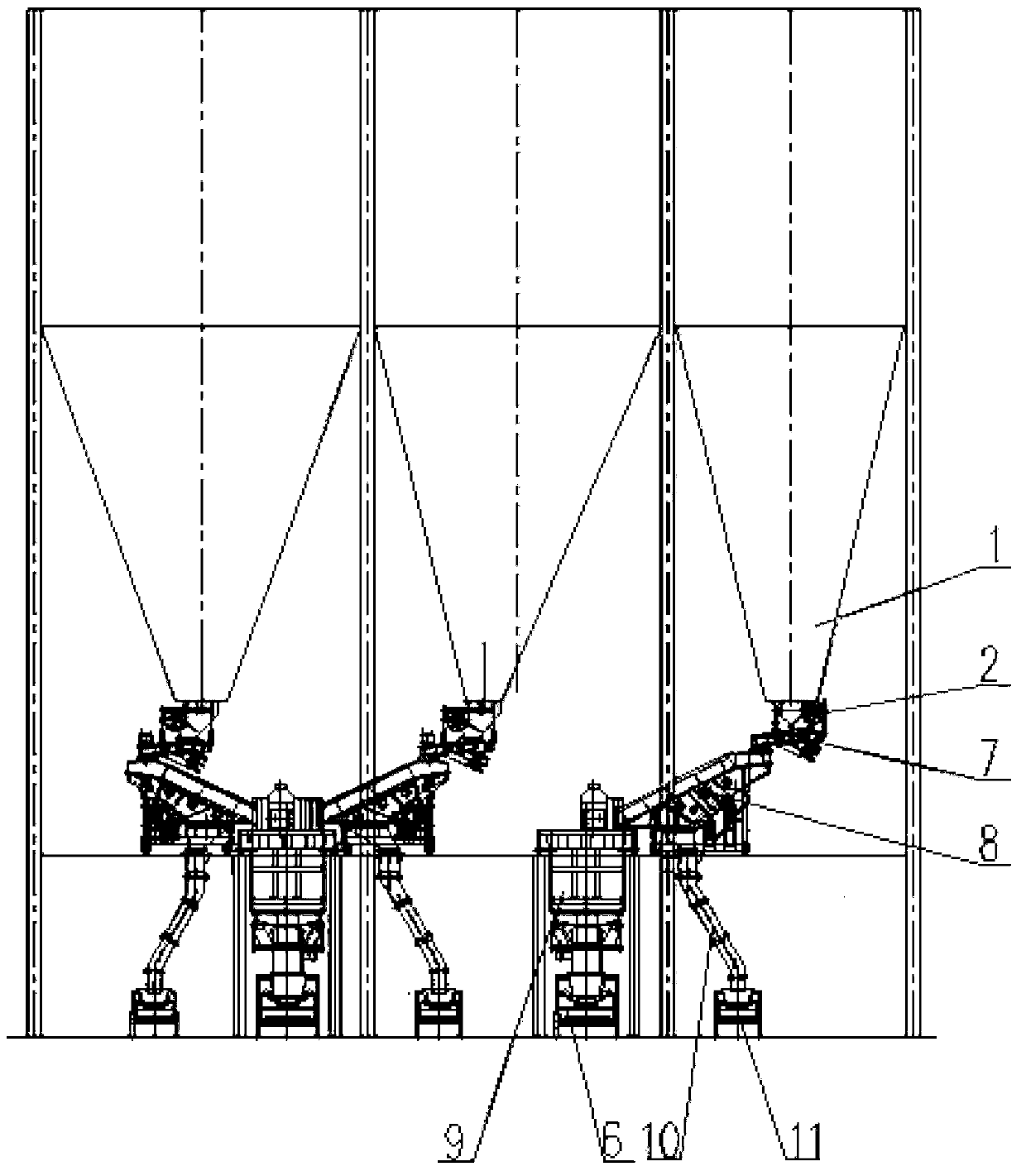

[0019] The following will combine figure 2 The non-blast furnace ironmaking device charging system and method provided by the present invention are described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can understand the It is modified and polished.

[0020] Please refer to figure 2 , the present embodiment provides a non-blast furnace ironmaking device feeding system, comprising a material trough 1, a discharge gate 2, a conveyor belt conveyor 6 under the trough, a vibrating feeder 7 and a vibrating screen 8, the material trough 1 The discharge gate 2 is connected to one end of the vibrating feeder 7, the other end of the vibrating feeder 7 is connected to the vibrating screen 8, and the conveying belt conveyor 6 under the trough is located in the vibrating screen. Below the sieve 8, the raw material enters the vibrating feeder 7 after passing through the trough 1 and the discharge gate 2 in turn,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com