Preparation method for composite electrolyte membrane of solid-state battery

A solid electrolyte, electrolyte membrane technology, applied in electrolyte, electrolyte immobilization/gelation, secondary battery and other directions, can solve the problems of complex device, harsh preparation conditions, increased process difficulty and production cost, etc., to reduce steps, The effect of uniform distribution and simple simultaneous coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

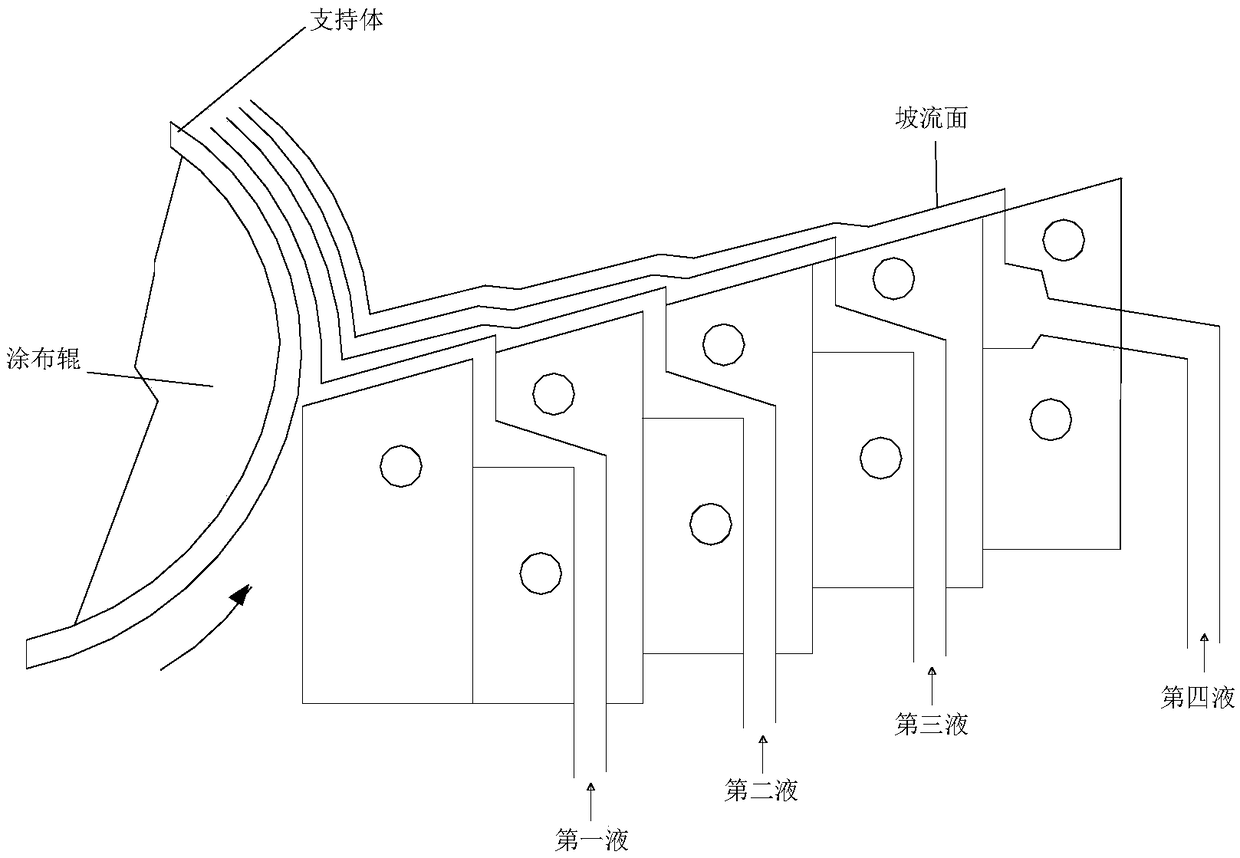

[0040] A preparation method for a composite electrolyte membrane of a solid-state battery, which is through a multi-layer slide coating process, and the PET carrier is coated with No. 1 (formation layer 1) and No. 2 slurry (formation layer 2), and No. 1 The slurry is in contact with the PET surface, and after the coating is dried and shaped, the PET carrier is peeled off. The multi-flow coating process is as follows: the organic-inorganic composite electrolyte slurry flows out from the slit of the coating die and flows down along the slope flow surface, and then forms a gap between the coating roller and the slide coating die. The liquid bridge is taken away by the running carrier to form a multi-layer coating, and after drying, the composite electrolyte membrane of the solid-state battery is obtained.

[0041] The coating speed is 1m / min, two layers are coated, the drying temperature is 70°C, the drying time is 5min, and the total thickness of the dry film is 15μm.

[0042] ...

Embodiment 2

[0044] The difference from Example 1 is:

[0045] The coating speed is 10m / min; the number of coating layers is 1; the coating thickness is 5 μm; the drying temperature is 40°C.

[0046] The organic-inorganic composite electrolyte slurry includes the following five raw materials: lithium lanthanum zirconium oxide, lithium hexafluorophosphate, polyvinylidene fluoride, polyethylene oxide, ethylene carbonate, and the mass ratio of the five raw materials is 5:1:1:1:0.1 Mix in dimethylformamide, and ball mill at 300 rpm for 1 hour to obtain organic-inorganic composite electrolyte slurry.

Embodiment 3

[0048] The difference from Example 1 is:

[0049] The coating speed is 30m / min; the number of coating layers is 10; the coating thickness is 100 μm; the drying temperature is 100°C.

[0050] The organic-inorganic composite electrolyte slurry includes the following five raw materials: lithium lanthanum zirconium oxide, lithium hexafluorophosphate, polyvinylidene fluoride, polyethylene oxide, ethylene carbonate, and the mass ratio of the five raw materials is 5:1:1:1:0.1 Mix in dimethylformamide, and ball mill at 300 rpm for 1 hour to obtain organic-inorganic composite electrolyte slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com