Gas atomization preparing method for micro spherical metal powder and equipment thereof

A metal powder and gas atomization technology, which is used in metal processing equipment, transportation and packaging, etc., can solve the problems of low atomizing gas pressure, low rotation speed of the rotating disk, and complex overall design of the atomizing equipment, and achieves narrow particle size distribution. Good sphericity, the effect of increasing the characteristic surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

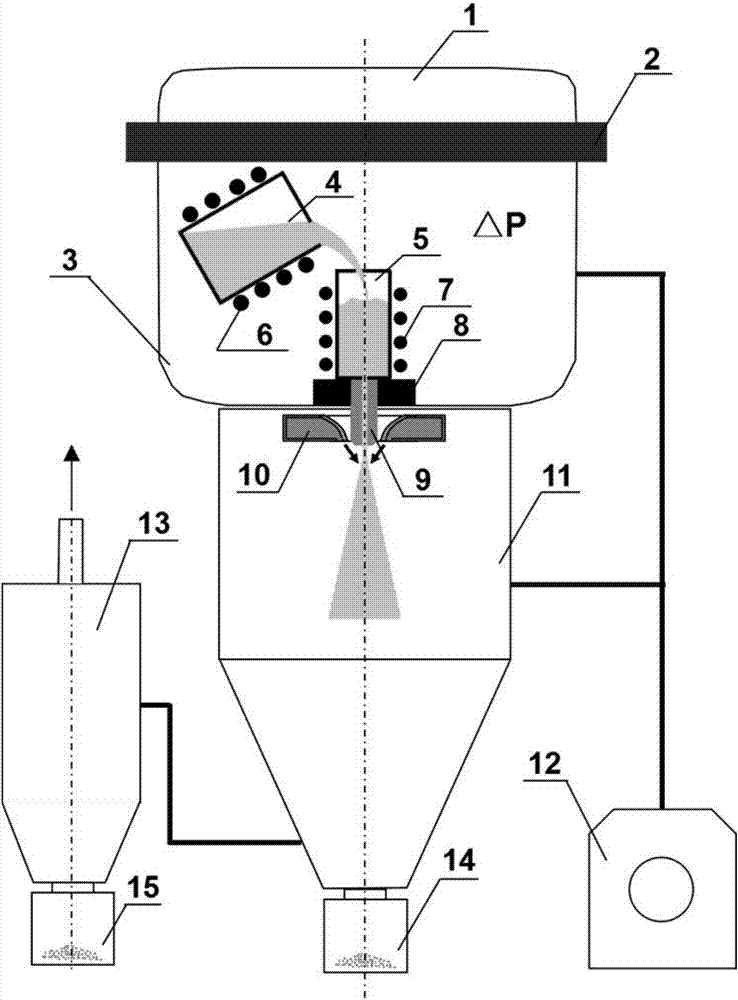

[0057] Example: fine spherical AlSi 10 Preparation of Mg alloy powder

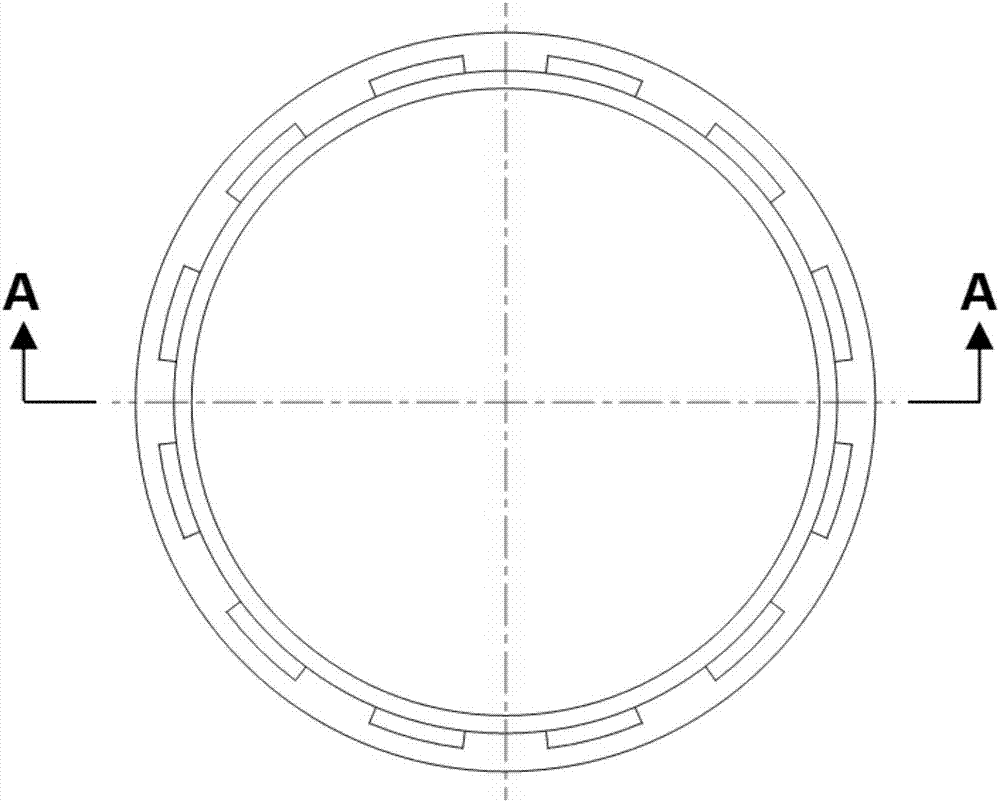

[0058] The smelting furnace adopts intermediate frequency induction heating, and the material of the smelting crucible 4 is graphite. The holding furnace is heated by a graphite heating body, and the material of the holding crucible 5 is graphite. The material of the diversion nozzle 9 is graphite, and the outlet aperture is 1.5 mm. Stainless steel ring hole atomizer: Φ0.8×20, that is, the inner diameter of the nozzle hole is 0.8mm, and the number of nozzle holes is 20. Adopt mechanical pump-Roots pump two-stage vacuum system. A two-stage cyclone separation system is used.

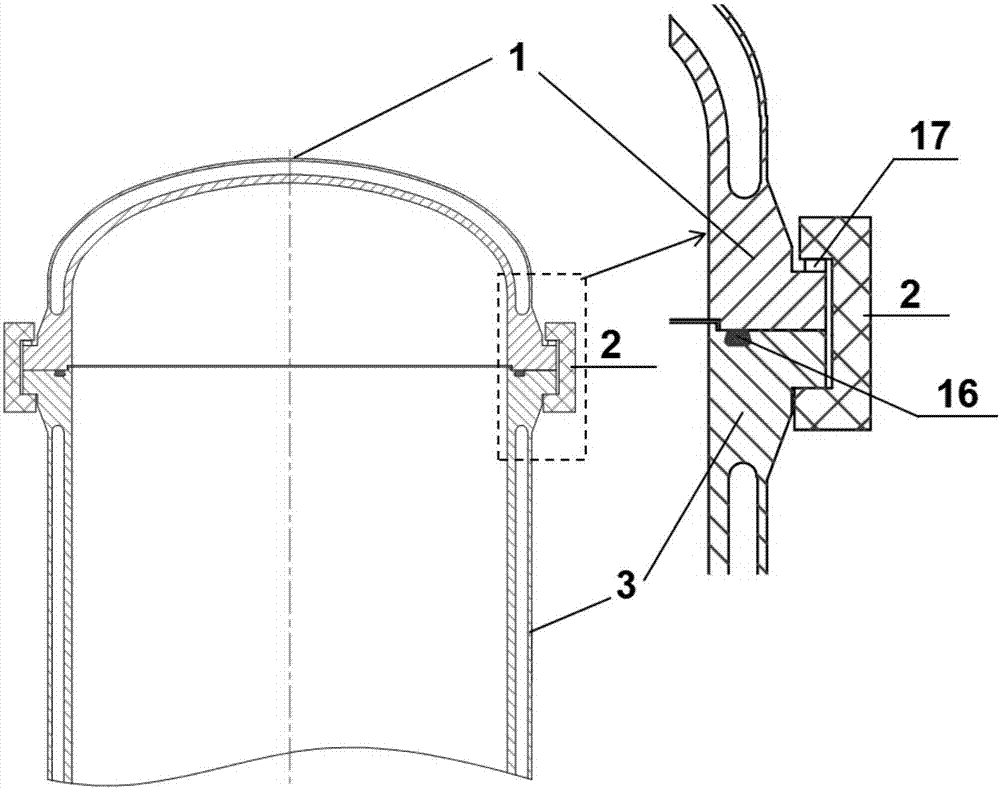

[0059] Weigh AlSi 10 10 kilograms of Mg alloys are added in the melting crucible 4 . The furnace cover 1 and the furnace body 3 are tightly closed, and the vacuum is evacuated to 10 - 1 Pa. The metal pressure ring 2 is hydraulically driven, so that the protruding teeth at the upper end of the metal pressure ring are aligned wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com