Rotor spinning melange yarn forming method and device and product

A technology of rotor spinning and color mixing, which is applied in the direction of textiles, papermaking, yarn, etc., can solve the problem of weak control of floating fibers, achieve the effect of improving the mixing effect and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

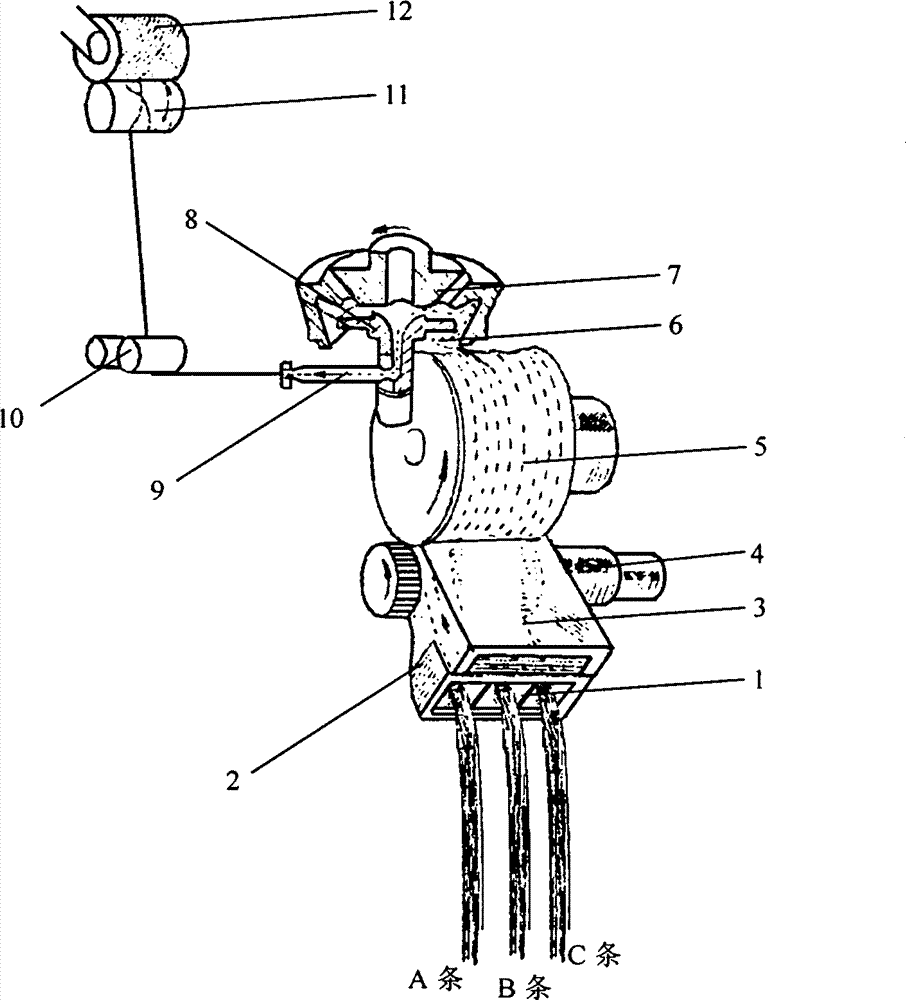

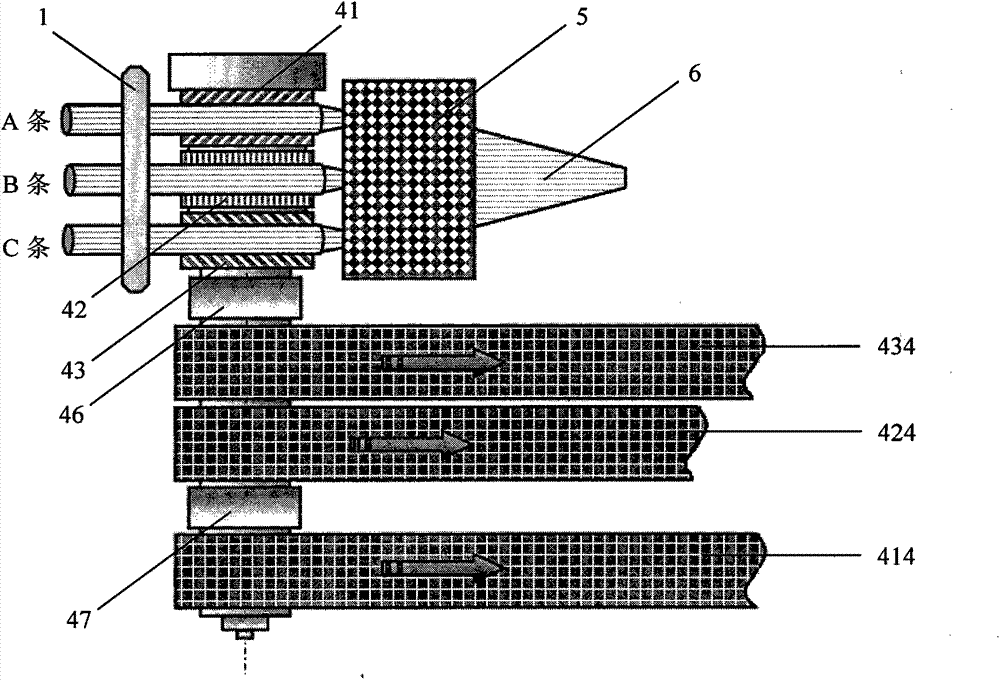

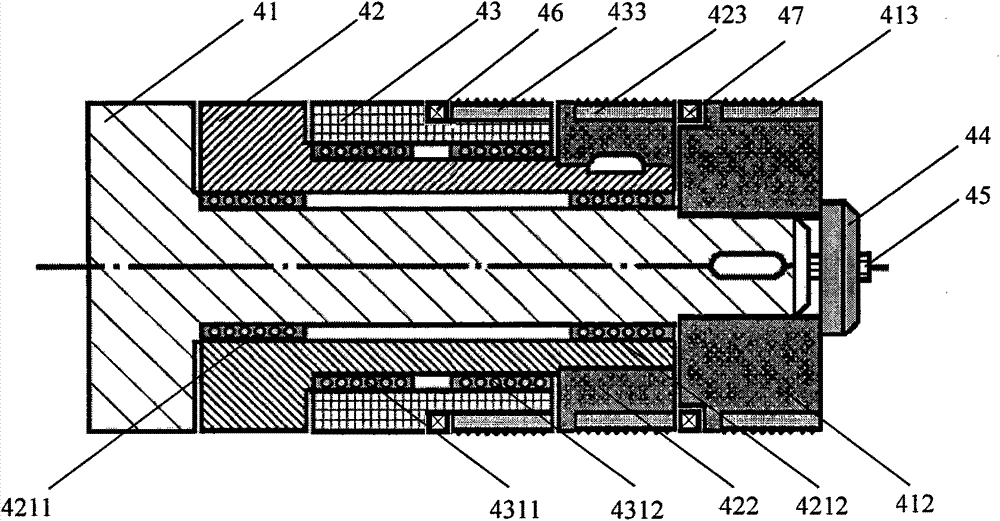

[0017] The fiber sliver refers to the roving sliver or the drawing end sliver, and the fiber is cotton type or wool type. Take feeding three fiber slivers and feeding them in three groups as an example.

[0018] Such as figure 1 , figure 2 As shown, the rotor spinning mixed-color yarn forming method and device of the present invention include the sub-bar 1 on the rotor spinning machine, the bell mouth 2, a set of coaxial flange looper combined feeding roller 4, and the first bearing seat 46. The second bearing seat 47, the feeding plate 3, and related transmission mechanisms and control devices. The coaxial flange looper combined roller includes the first feeding roller 41, the second feeding roller 42, the first feeding roller Three feeding rollers 43, the transmission mechanism includes three stepping motors or servo motors, looper roller bushings and transmission shafts, bearings, toothed pulleys, toothed belts, sprockets, chains, etc., the described The control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com