Molding method for food with round shape

A food forming and circular technology, which is applied in the field of processing and stuffing food, can solve the problems of easy wear, forklift fork can not be effectively supported, and insufficient stability of feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

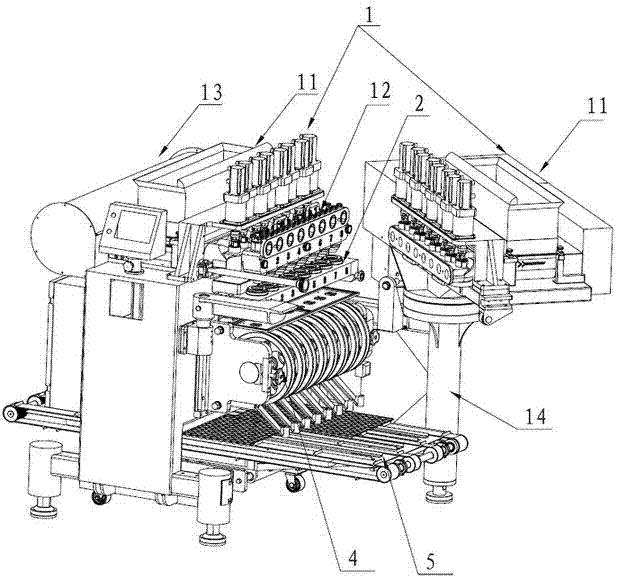

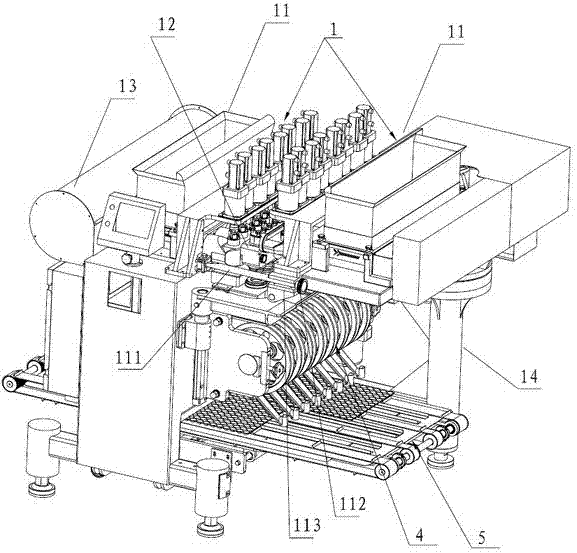

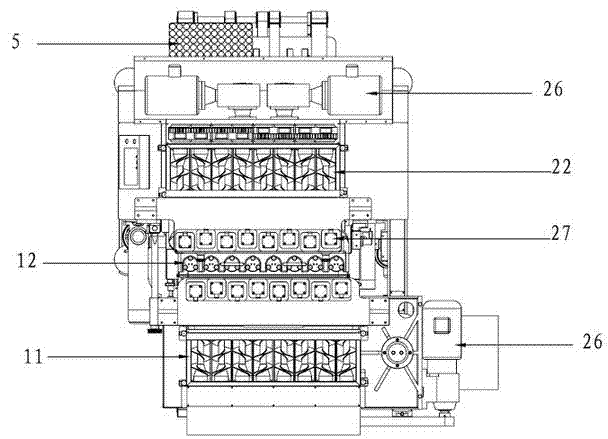

[0077] A method for forming a circular food, comprising the steps of:

[0078] A feeding: Add the skin and stuffing to the feeding assembly 11 of the split feeding system of the round food forming machine;

[0079] B compound: the skin and stuffing in the feeding assembly 11 enter into the skin-stuffing complex 12;

[0080] C cutting: the skin and stuffing output from the skin-stuffing complex 12 are cut off by the retracting and cutting knife assembly 2, and the retracting and cutting knife assembly 2 is connected with the retracting and cutting knife lifting assembly 3, and the retracting and cutting knife assembly 2 is driven by the retracting and cutting knife lifting assembly 3 While realizing the cutting function, do up and down movement;

[0081] D rounding: the cut skin stuffing enters the rounding device 4 for rounding;

[0082] E plate arrangement: the finished product after rounding and forming falls from the rounding device 4 to the plate arrangement component 5;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com