Dual-motor driven computerized sewing machine

A dual-motor-driven, lockstitch sewing machine technology, applied in the direction of cloth feeding mechanism, sewing equipment, sewing machine components, etc., can solve the problem of vibration affecting the staff and the environment, and achieve high speed, easy mass production, and reduction of transmission noise and vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

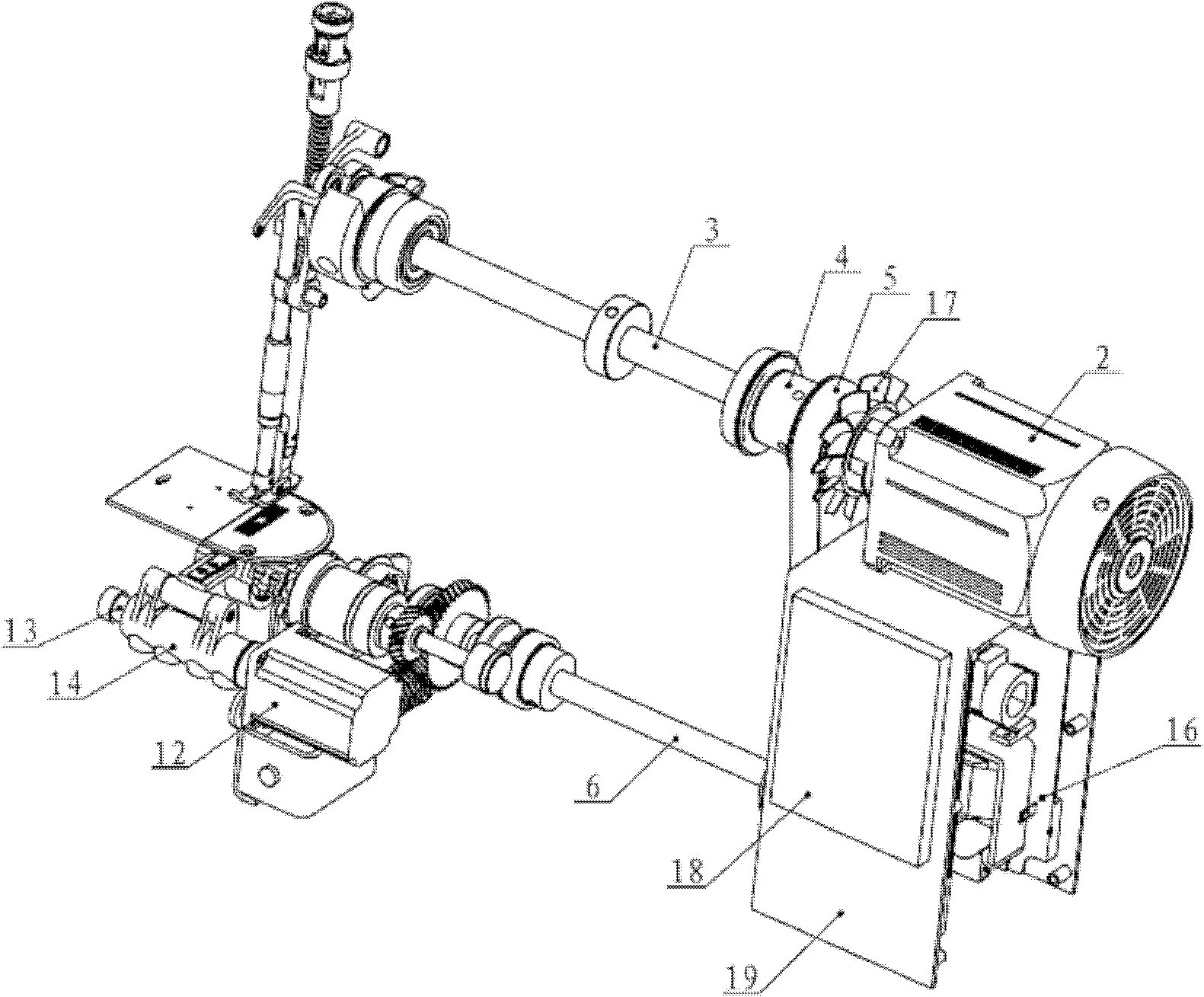

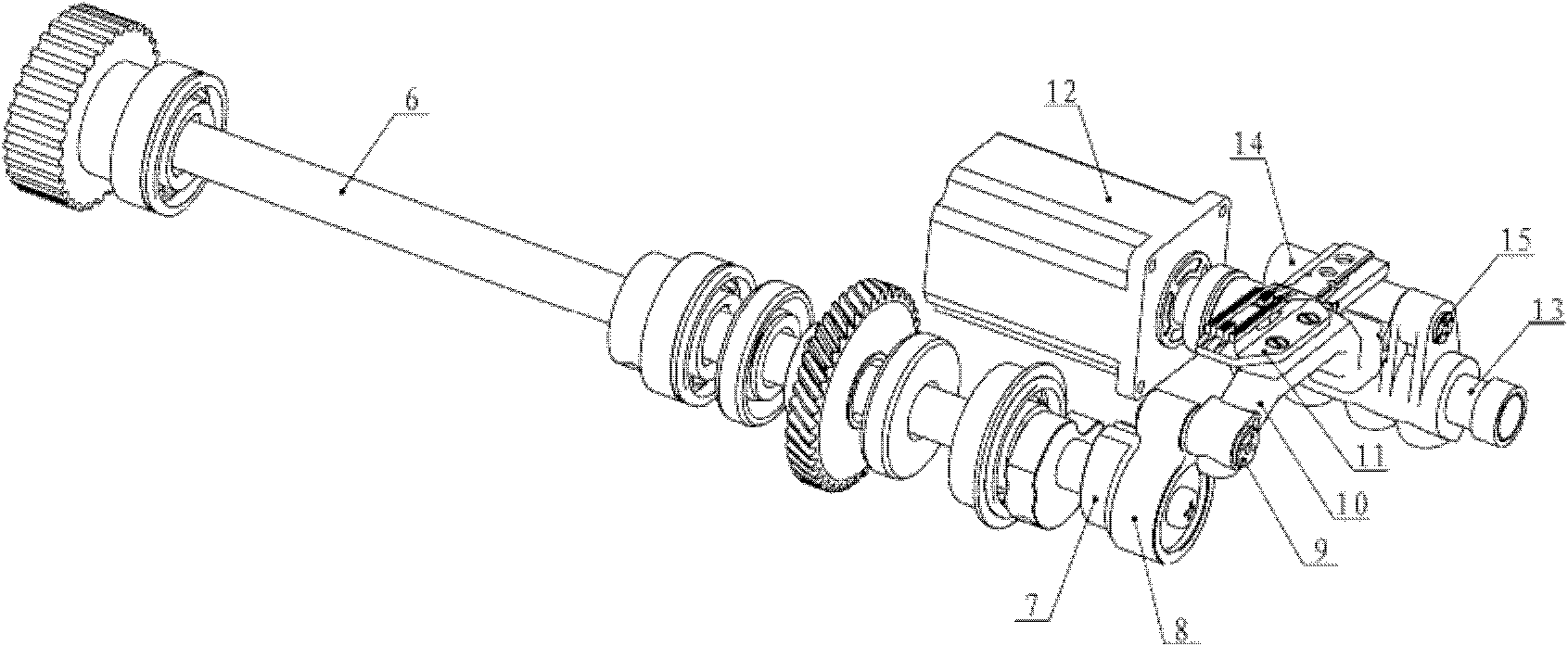

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a double-motor-driven computer lockstitch sewing machine includes a body 1, a circuit control board 16, a main servo motor 2, and a cooling fan 17 mounted on a main shaft 2; The shaft 6 is connected by transmission; the end of the lower shaft 6 is equipped with a tooth-lifting eccentric wheel 7 through a bearing, and the outer bearing is inserted into a tooth-lifting crank 8; the tooth-lifting crank 8 is connected to the cloth feeding frame 10 through a tooth-lifting connecting pin 9; the cloth feeding frame 10 The cloth feed dog 11 is installed on the top; the cloth feed servo motor 12 is fixed with screws through the assembly pin and the bearing; the drive shaft of the cloth feed servo motor 12 and the assembly pin 13 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com