Automatic machining device of anti-theft door frame and control system thereof

A technology for processing devices and anti-theft doors, applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve problems such as poor surface finish, high labor costs, and low efficiency, so as to avoid bumps and post-processing, reduce errors, and improve overall quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

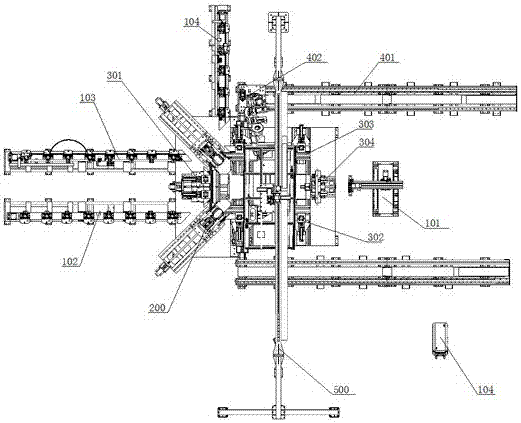

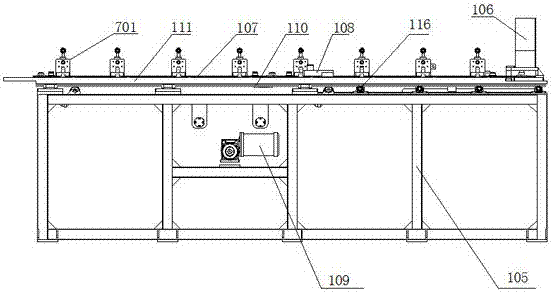

[0050] Example 1, such as Figure 1-7 As shown, the present invention provides an automatic processing device for an anti-theft door frame, including a feeding mechanism 100, a cutting mechanism 200, an assembly platform 300, a welding mechanism 400, a blanking mechanism 500 and a control mechanism. The assembly platform 300 is quadrilateral, The feeding mechanism 100, the cutting mechanism 200, the welding mechanism 400, and the unloading mechanism 500 are arranged around the assembly platform 300. The material loading mechanism 100 transports the frame profiles to the assembly platform 300 in a manner of vertically and horizontally intersecting and four sides are separately fed. The platform 300 is used to fix the frame profile and move the frame profile on the assembly platform 300 so that the cutting mechanism 200 and the welding mechanism 400 can obtain processing positions. The cutting mechanism 200 is used to process the frame profile on the assembly platform 300, and th...

Embodiment 2

[0077] Example 2, such as Figure 2-7 As shown, in order to make the robot working platform more reasonable, this embodiment combines and arranges two sets of automatic processing devices for anti-theft door frames, sharing a set of welding mechanism, laser cutting mechanism and lower gear loading components, and adopts the mode of staggered production , forming a streamlined automatic processing line.

[0078] An automatic processing device for an anti-theft door frame is provided, comprising a feeding mechanism 100, a cutting mechanism 200, an assembly platform 300, a welding mechanism 400, a blanking mechanism 500 and a control mechanism arranged symmetrically to the axis of the lower gear feeding assembly 101. The assembly platform 300 is in the shape of a quadrilateral, and the loading mechanism 100, the cutting mechanism 200, the welding mechanism 400, and the unloading mechanism 500 are arranged around the assembly platform 300. Platform 300, the assembly platform 300 ...

Embodiment 3

[0079] Embodiment 3, the present invention provides an automatic processing device for an anti-theft door frame, including a feeding mechanism 100, a cutting mechanism 200, an assembly platform 300, a welding mechanism 400, a blanking mechanism 500 and a control mechanism, and the assembly platform 300 is quadrilateral , the feeding mechanism 100, the cutting mechanism 200, the welding mechanism 400, and the unloading mechanism 500 are arranged around the assembly platform 300, and the feeding mechanism 100 transports the frame profile to the assembly platform 300 in a way of vertically and horizontally intersecting and feeding independently on four sides. The assembly platform 300 is used to fix the frame profile and move the frame profile on the assembly platform 300 so that the cutting mechanism 200 and the welding mechanism 400 obtain processing positions. The cutting mechanism 200 is used to process the frame profile on the assembly platform 300, and the welding The mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com