Energy-saving travelling type hydraulic transport machine

A kind of moving machinery and walking technology, which is applied in the field of energy-saving walking hydraulic handling machinery, which can solve the problems of limited potential energy recovery, short landing process time, inability to adapt to changes in potential energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

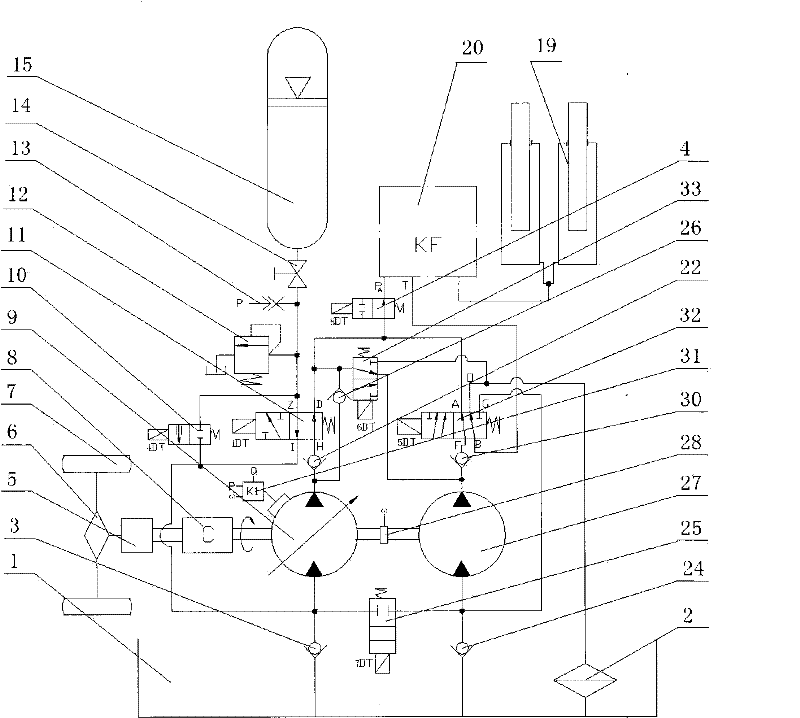

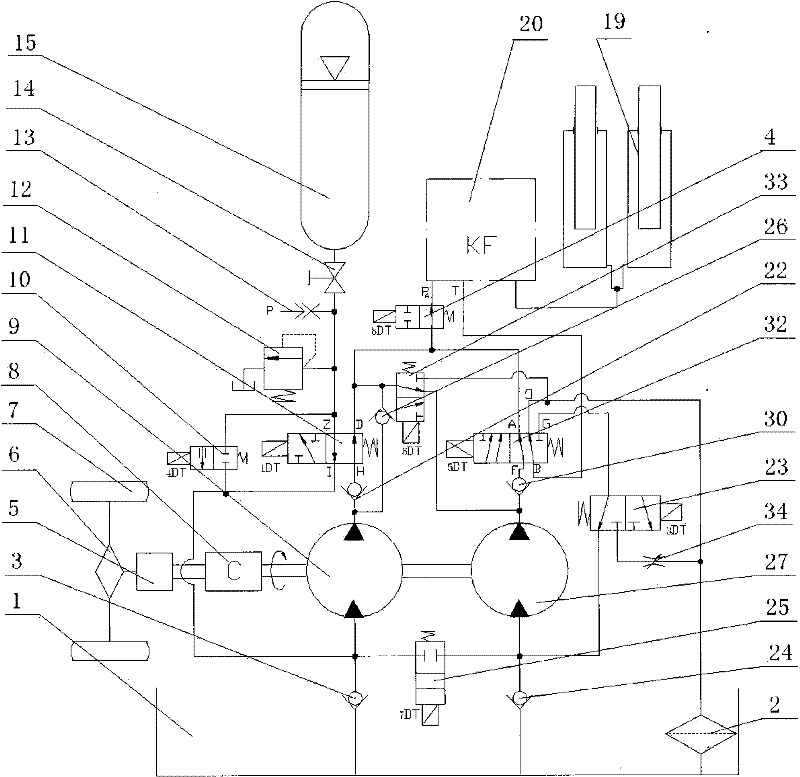

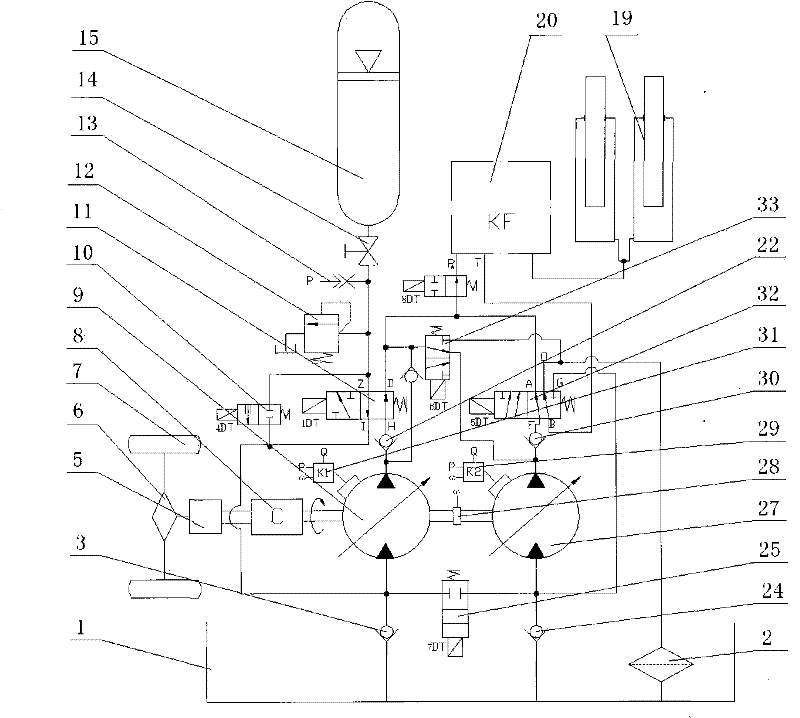

[0043] Now in conjunction with the accompanying drawings to illustrate the specific implementation of the present invention, the combined system of the variable pump and the quantitative motor is shown in figure 1, is a better adaptive solution, which can automatically adapt to potential energy recovery under different working conditions. When the driver uses power machinery (diesel engine or electric motor) 8 to drive the variable oil pump 9 to drive the lifting cylinder 19 to lift heavy objects, if the driver controls the machine Carry out the lowering operation, in the process of lowering the heavy object, the oil in the lower chamber (rodless chamber) of the lifting cylinder 19 is pressed to the unblocked (flow resistance adjusted to the minimum) return of the control valve group 20 by the gravity of the heavy object. Oil channel T, at the same time, 1DT and 5DT are energized, the reversing valves 11 and 32 are reversing, and the pressured return oil passes through the B po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com