Well service pump systems and related methods

a well service pump and plunger technology, applied in the direction of piston pumps, borehole/well accessories, surveys, etc., can solve the problems of reducing the stroke length of the plunger, reducing the size of the trailer mounted frac unit, and causing the failure rate of the current frac pump fluid end,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

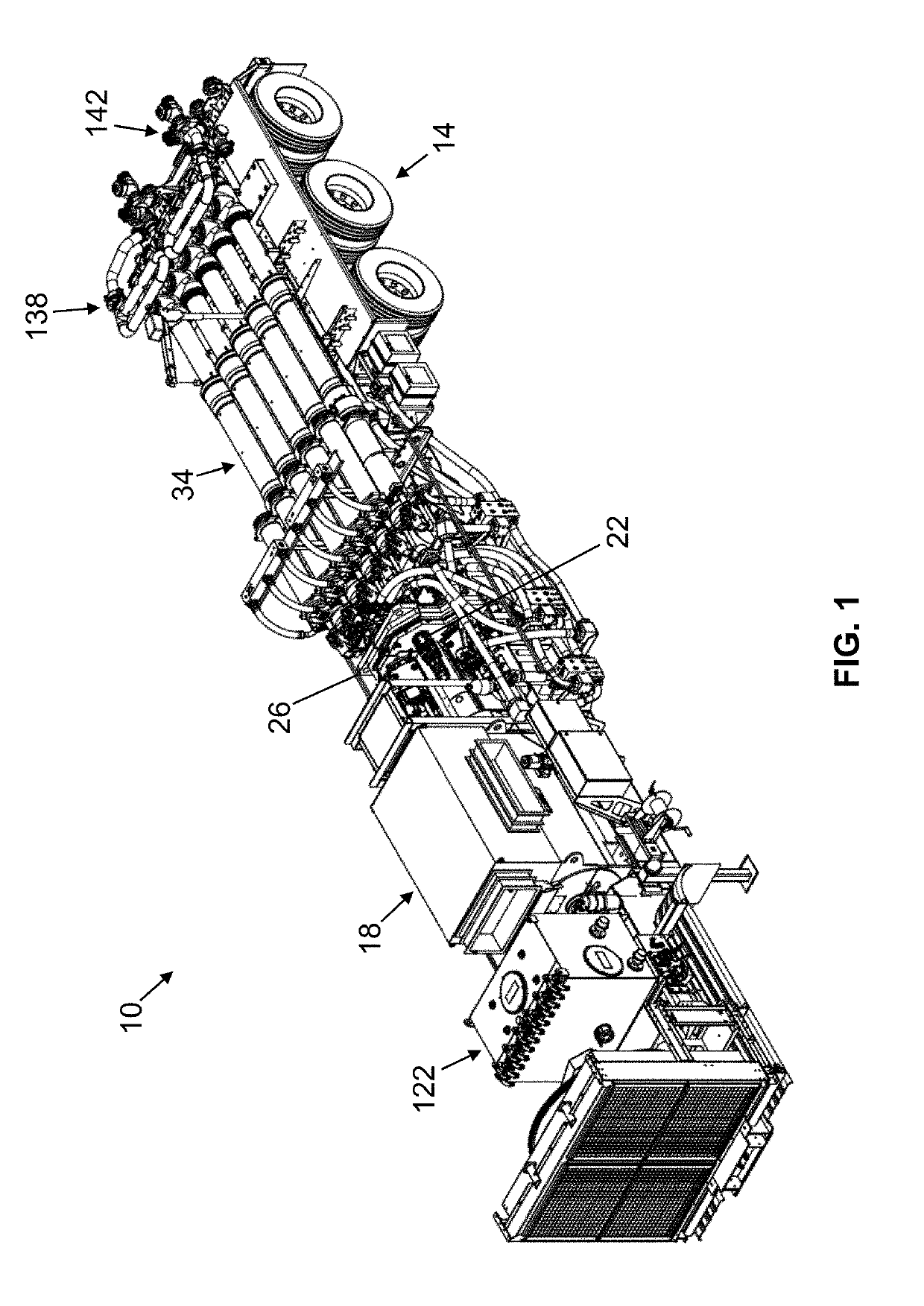

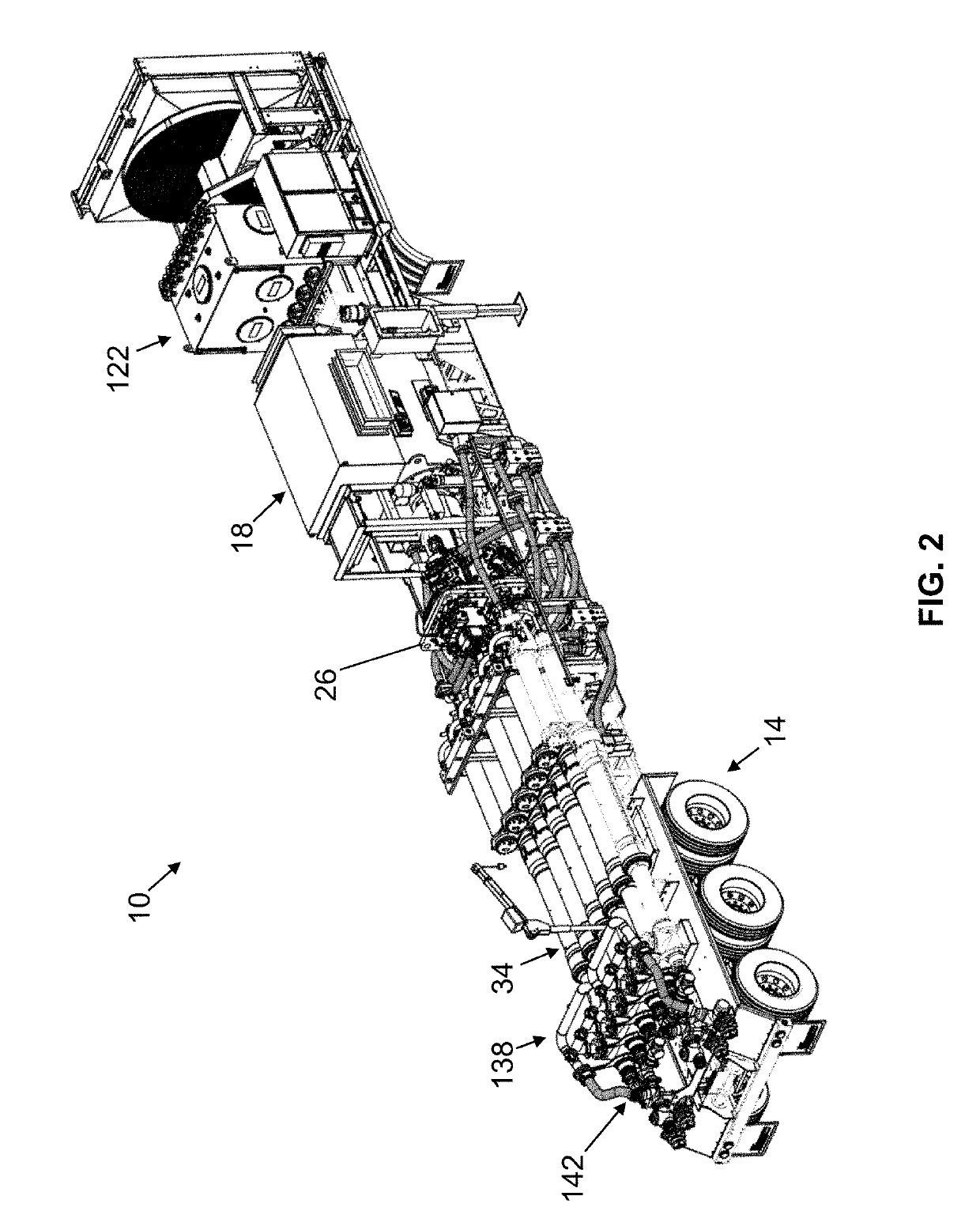

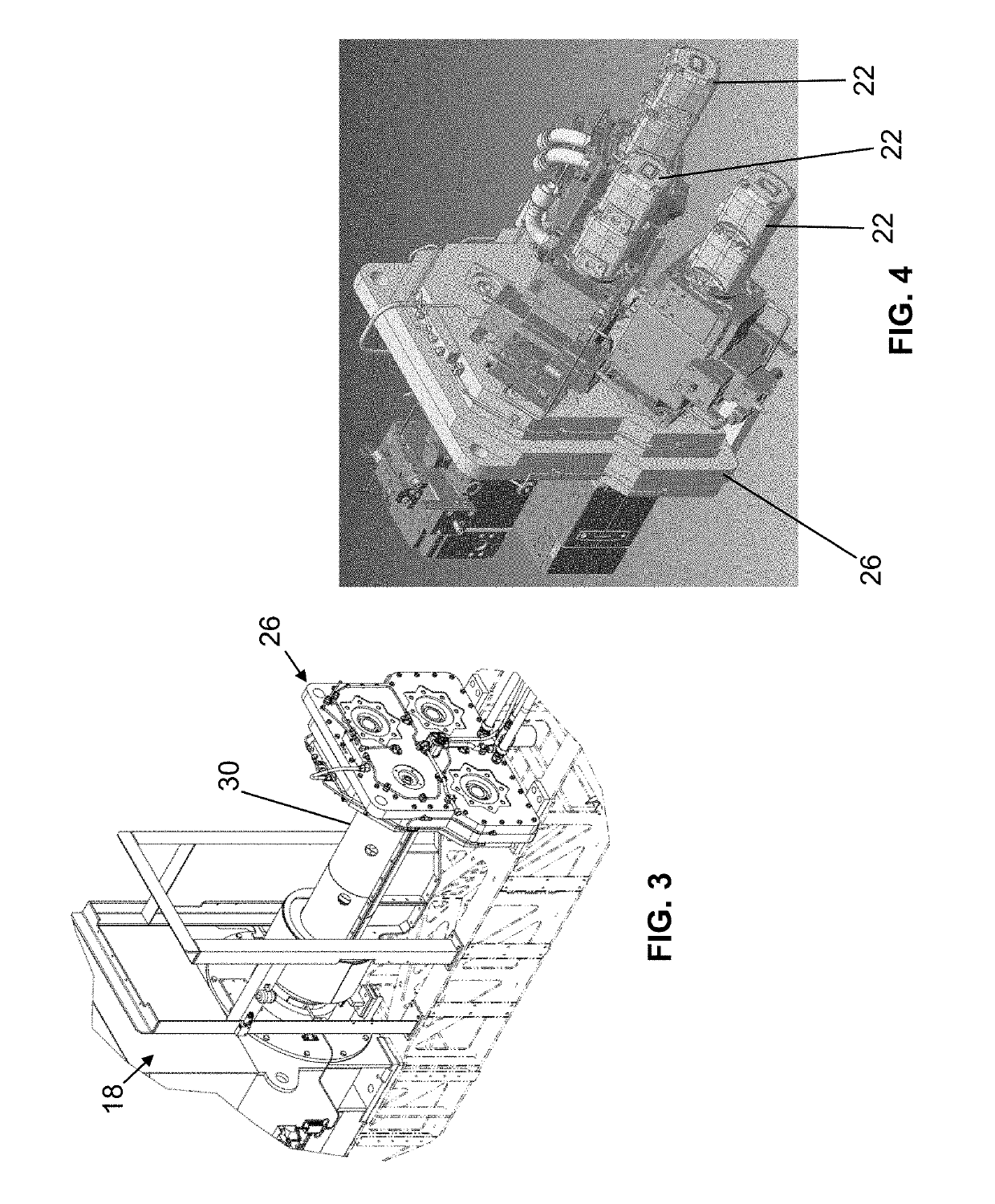

[0033]The following drawings illustrate by way of example and not limitation. For the sake of brevity and clarity, every feature of a given structure is not always labeled in every figure in which that structure appears. Identical reference numbers do not necessarily indicate an identical structure. Rather, the same reference number may be used to indicate a similar feature or a feature with similar functionality, as may non-identical reference numbers. The figures are drawn to scale (unless otherwise noted), meaning the sizes of the depicted elements are accurate relative to each other for at least the embodiment depicted in the figures.

[0034]Referring now to the figures, and more particularly, to FIGS. 1 and 2, shown therein and designated by reference numeral 10 is an embodiment of the present well service pump systems for delivering working fluid at high pressure to a well. As shown, system 10 can be coupled to and carried by a vehicle 14 (e.g., a truck trailer) for transportati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com