Experimental device and method for measuring rock mechanics parameters under action of ultrasonic wave and chemistry

A technology of rock mechanical parameters and chemical action, applied in the direction of applying stable tension/compression to test the strength of materials, preparation of test samples, etc., can solve the problem of changes in tensile strength, compressive strength and shear strength. Lack of or hinder the promotion and application of ultrasonic oil recovery technology to achieve the effect of flexible use, less equipment and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

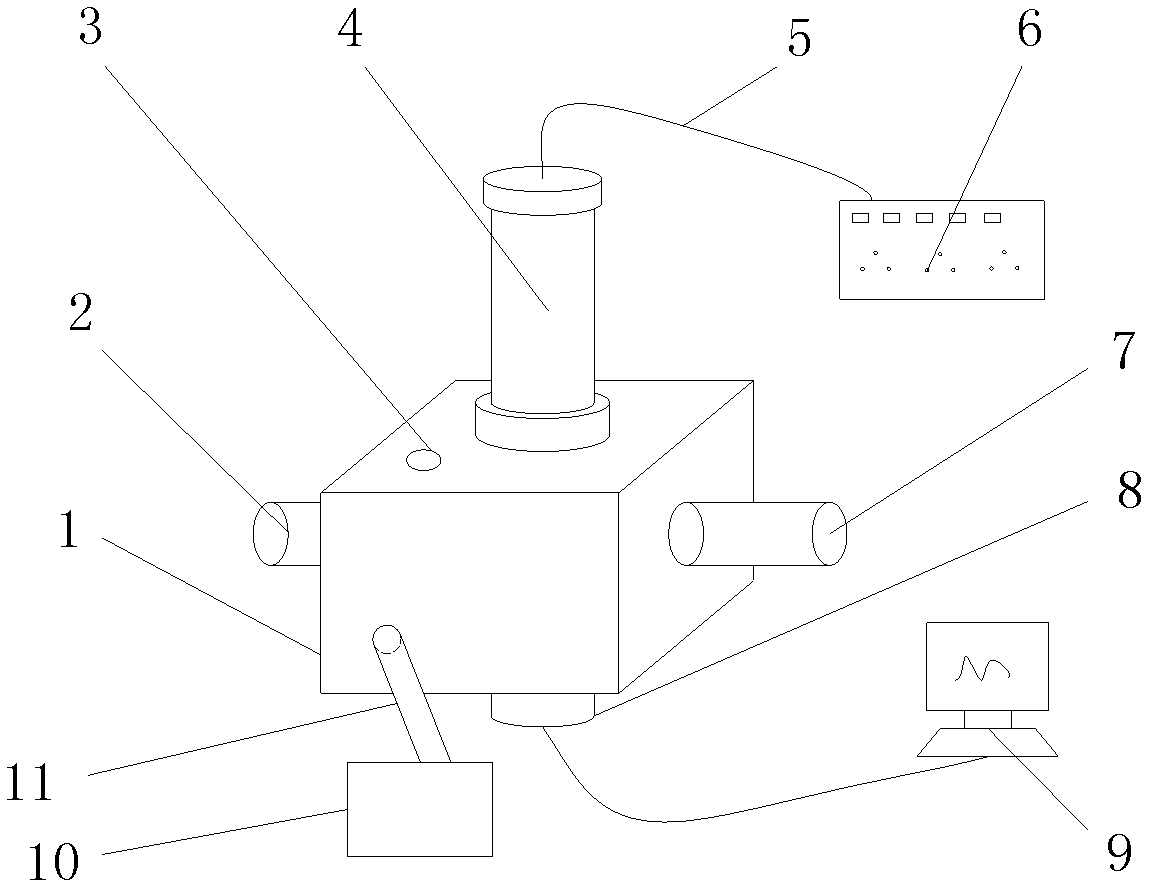

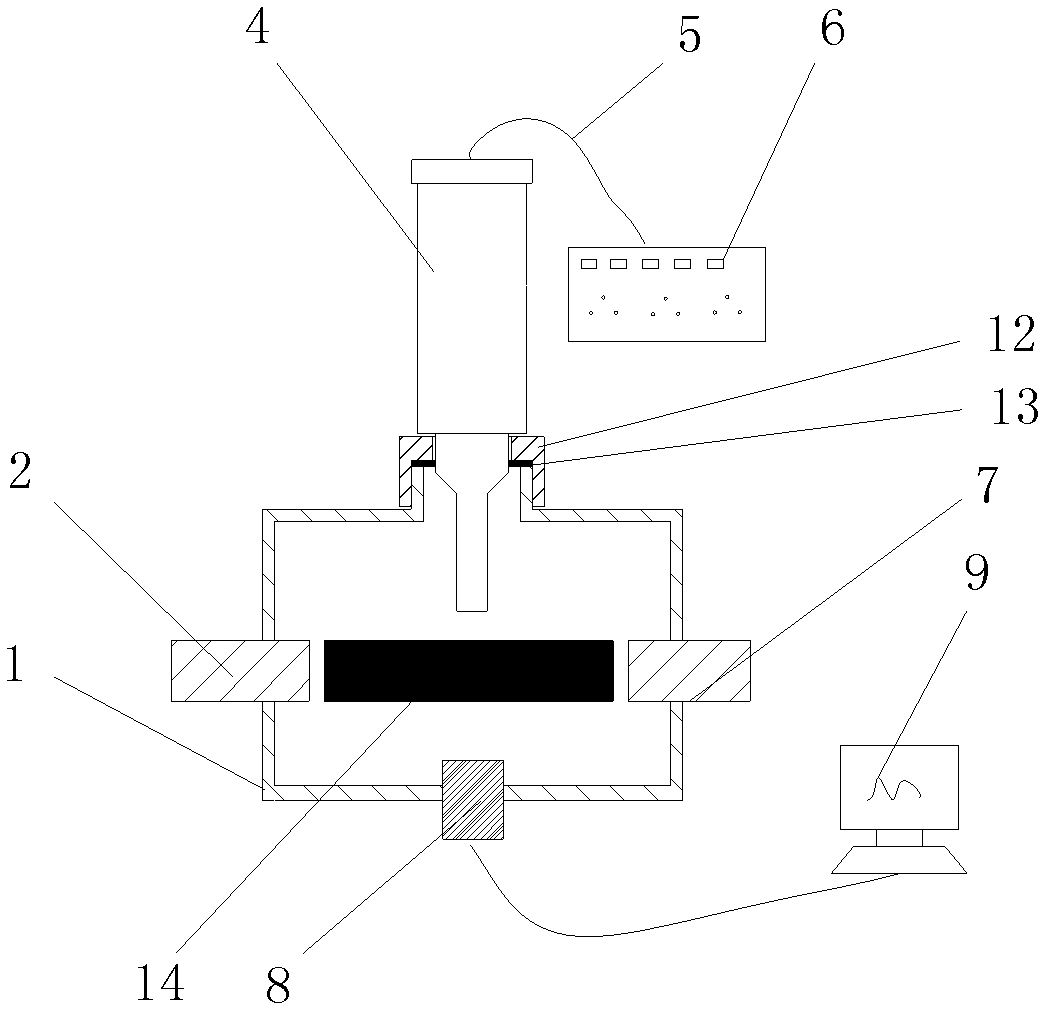

[0047] Such as figure 1 , figure 2 and image 3 The experimental device for measuring rock mechanics parameters under the action of ultrasonic waves and chemicals includes a rock mechanics testing machine, a hydraulic pressure booster 10, a closed box 1 for placing the rock core 14 to be tested, and an airtight box for the rock core 14 to be tested. The ultrasonic transducer 4 for ultrasonic treatment, the ultrasonic generator 6 connected with the ultrasonic transducer 4, the pressure detection unit 16 for real-time detection of the overlying pressure on the tested rock core 14, and the ultrasonic transducer respectively An ultrasonic power detector 8 and an ultrasonic amplitude measuring instrument 15 for real-time detection of the ultrasonic power and amplitude of the transducer 4 acting on the tested rock core 14 . The rock mechanics testing machine carries out symmetrical loading on the rock core 14 to be tested from the left and right sides through the left loading sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com