Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1181results about "Telemotors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

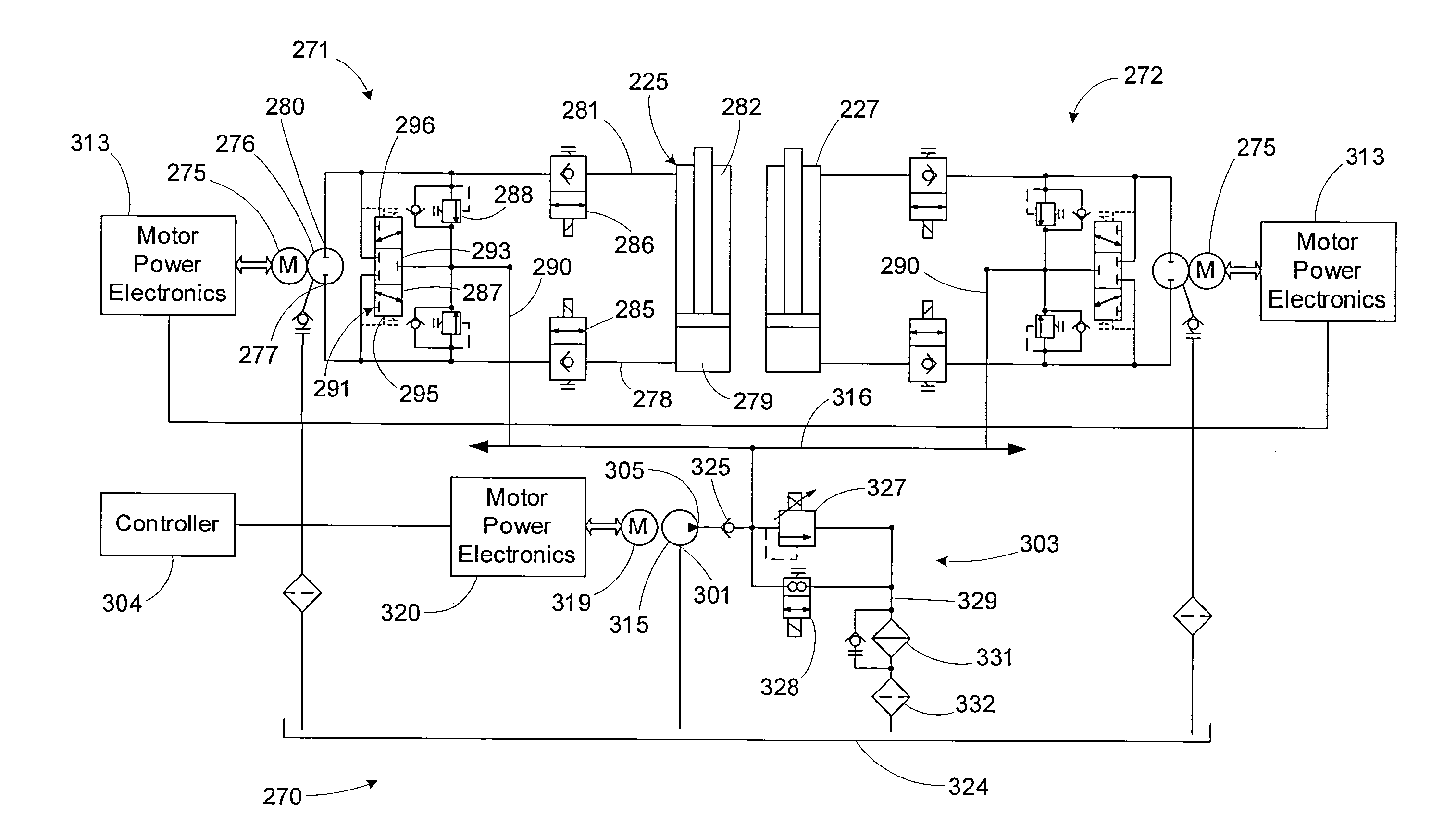

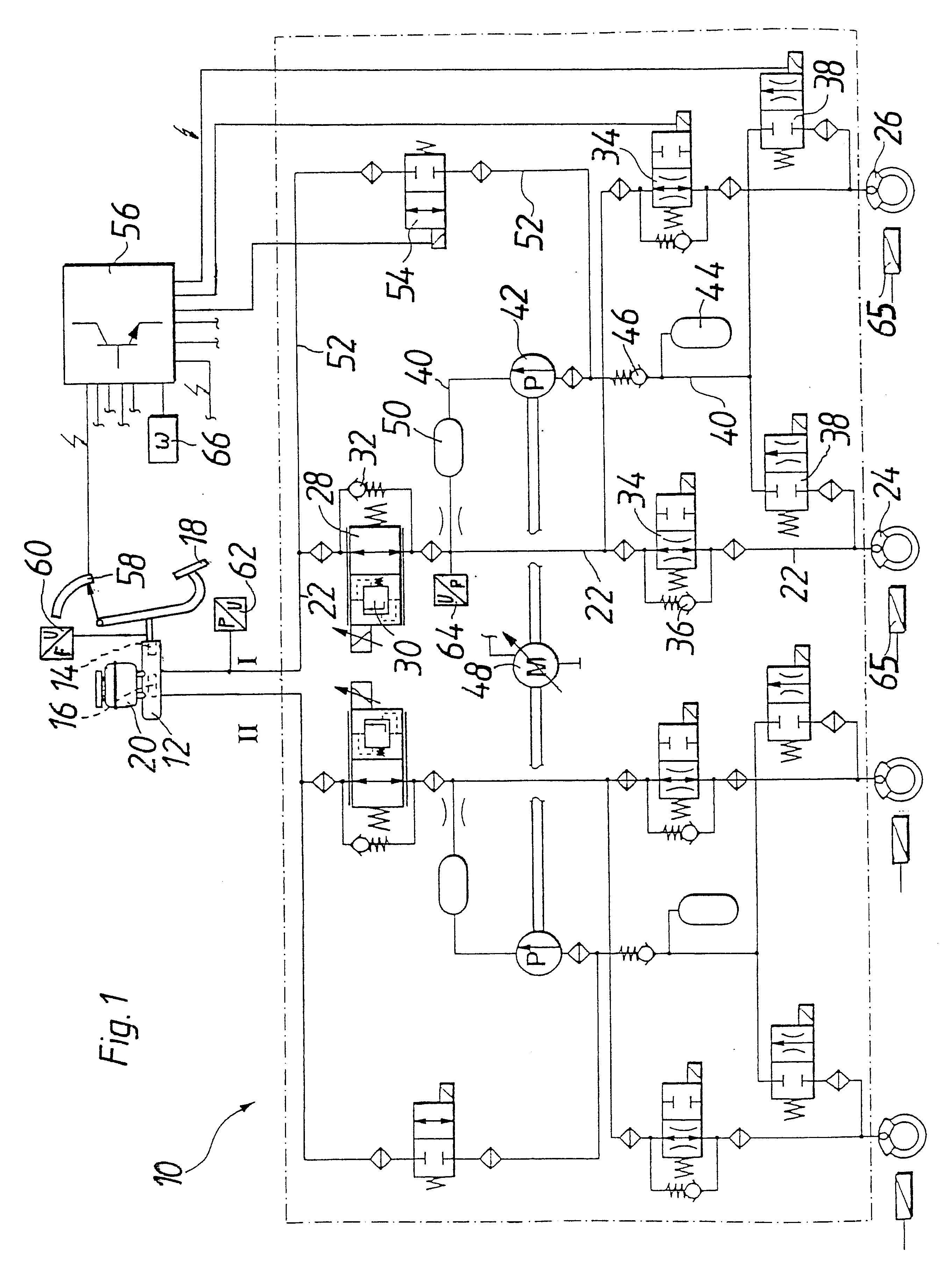

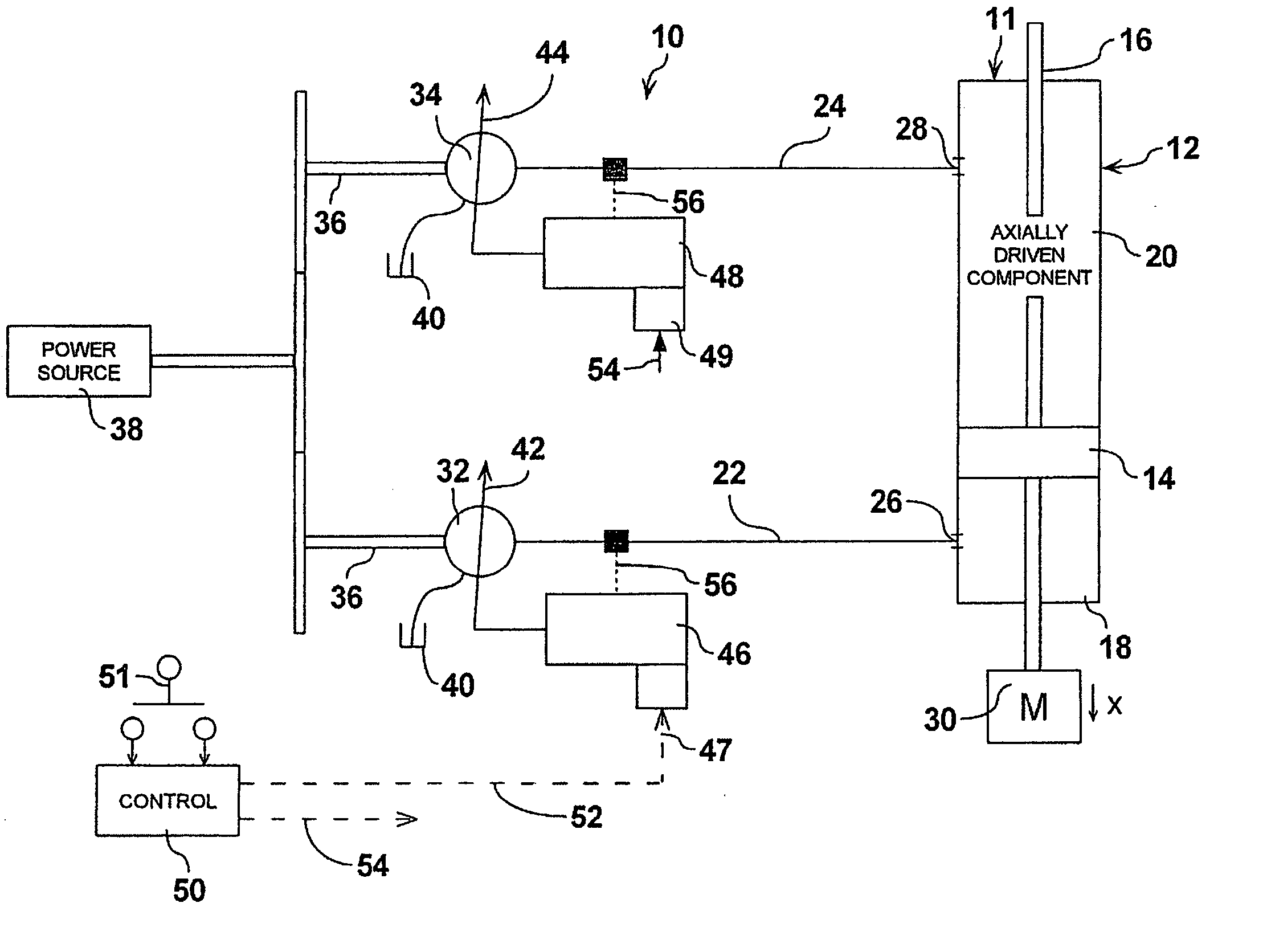

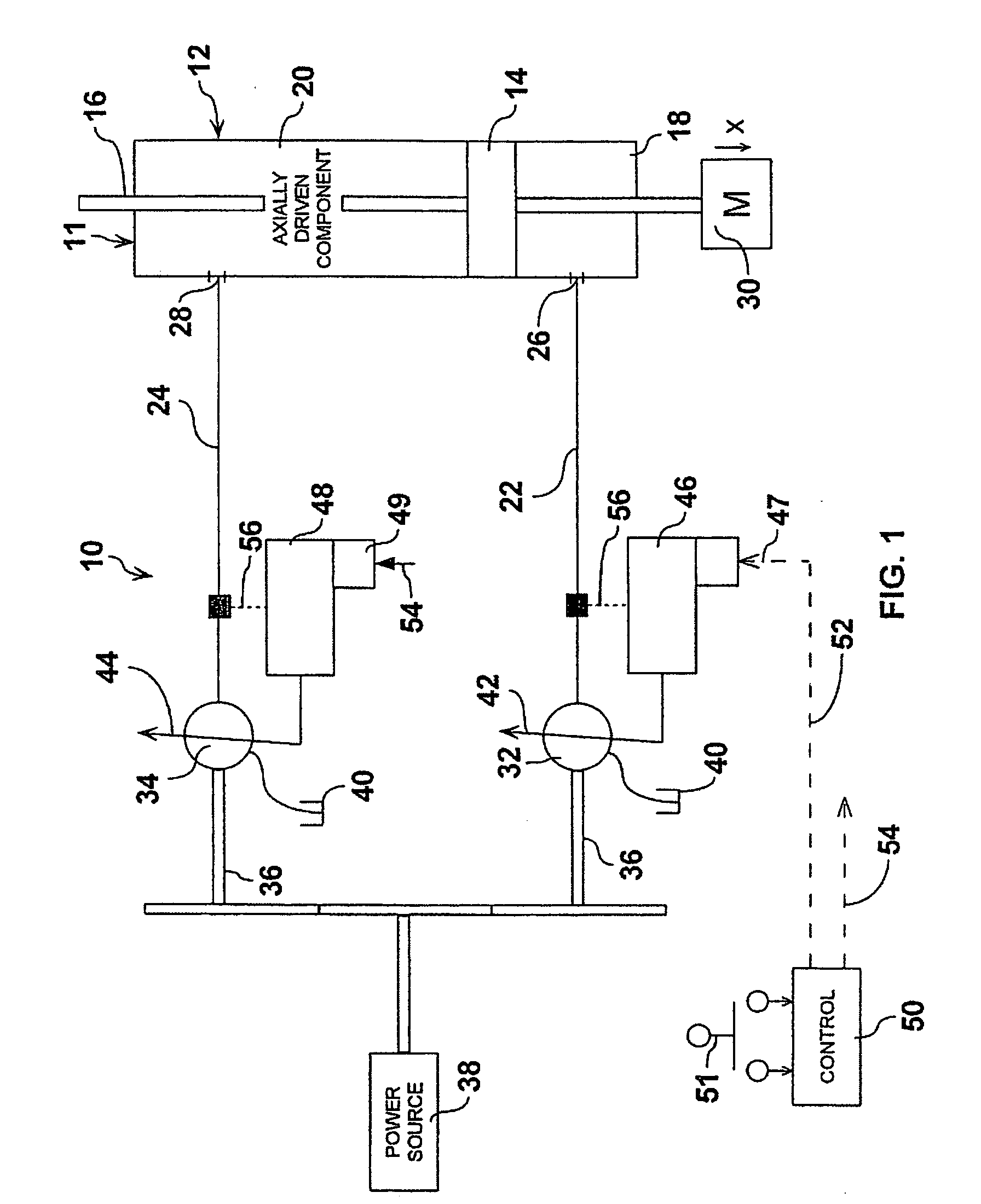

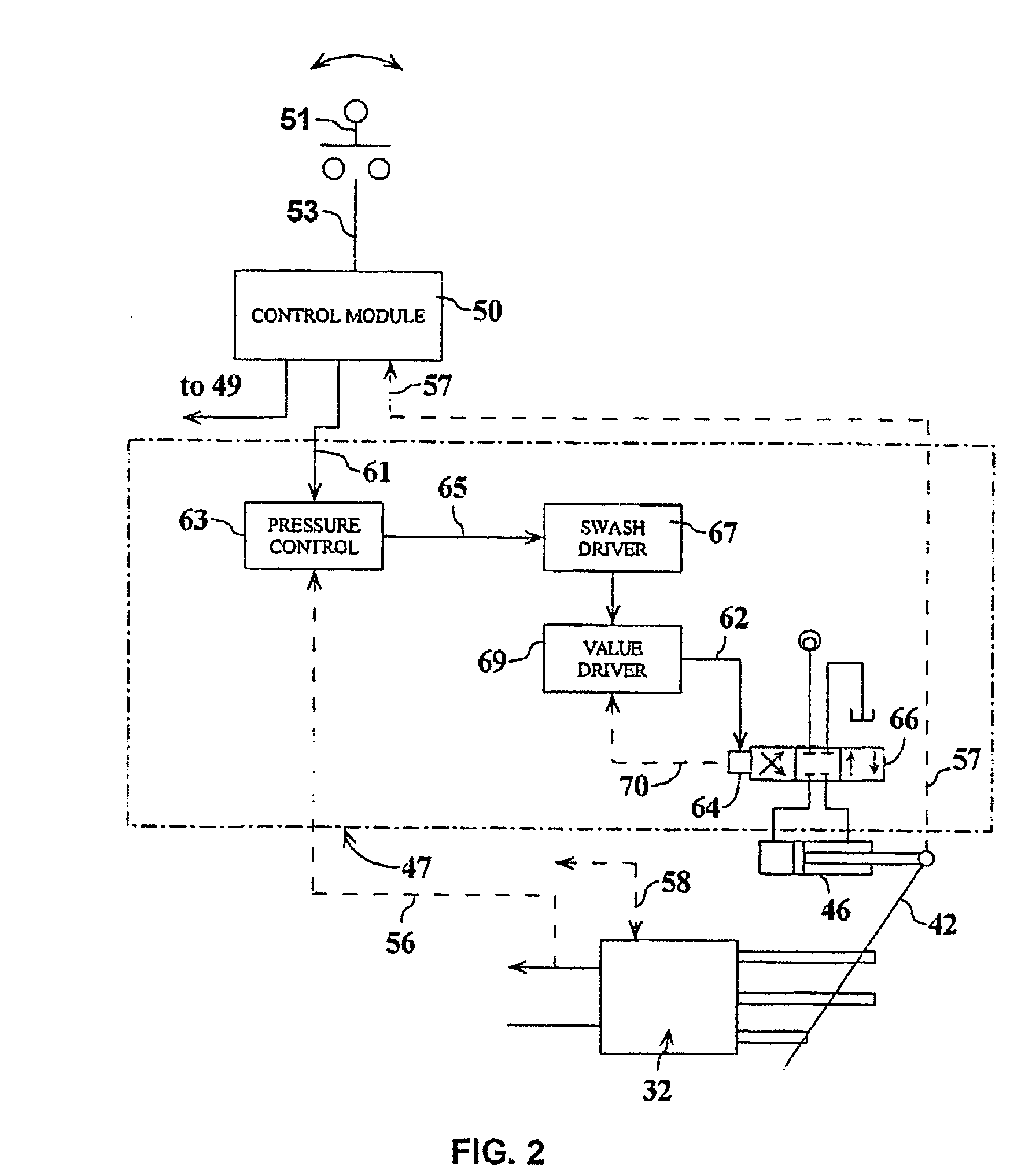

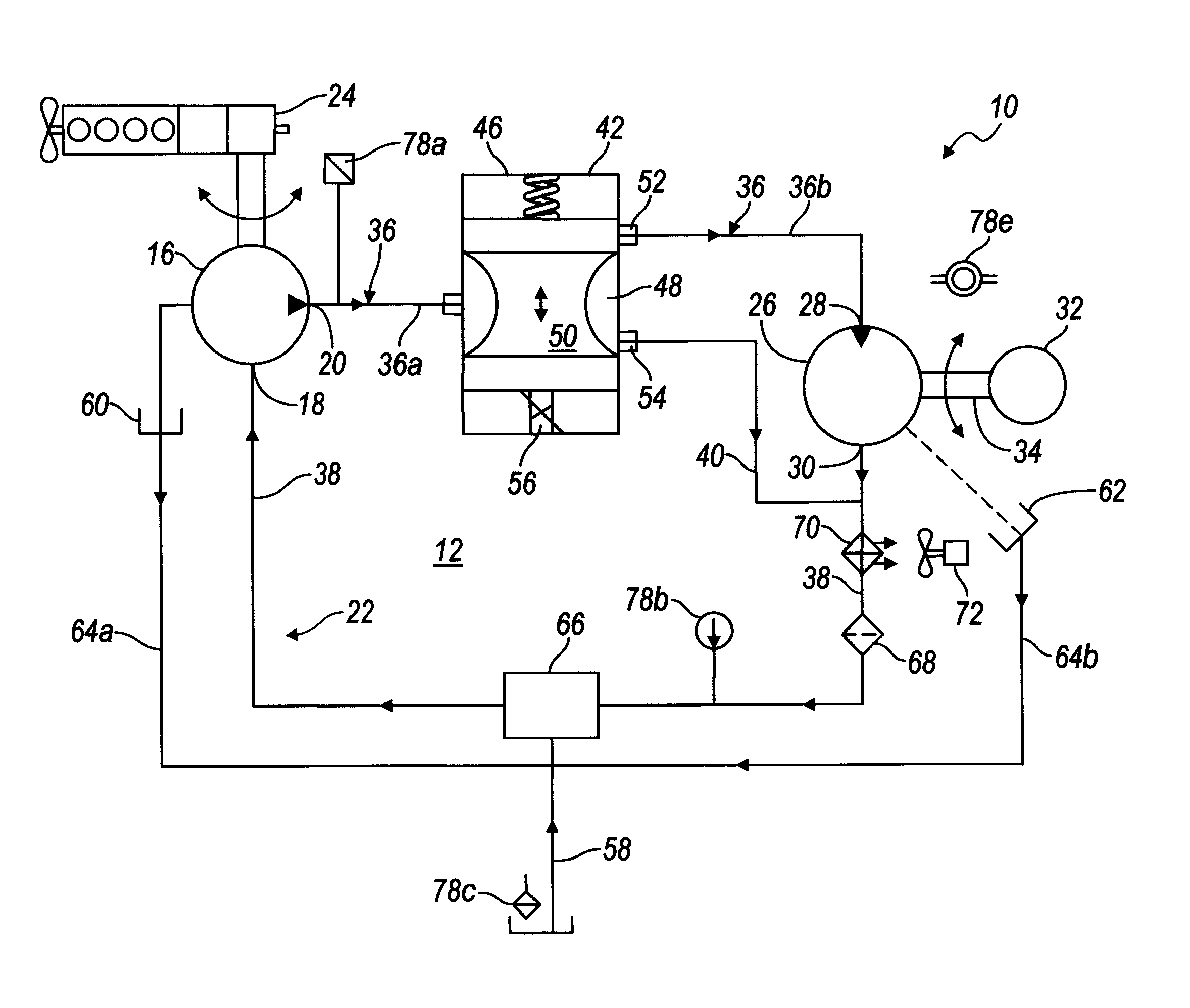

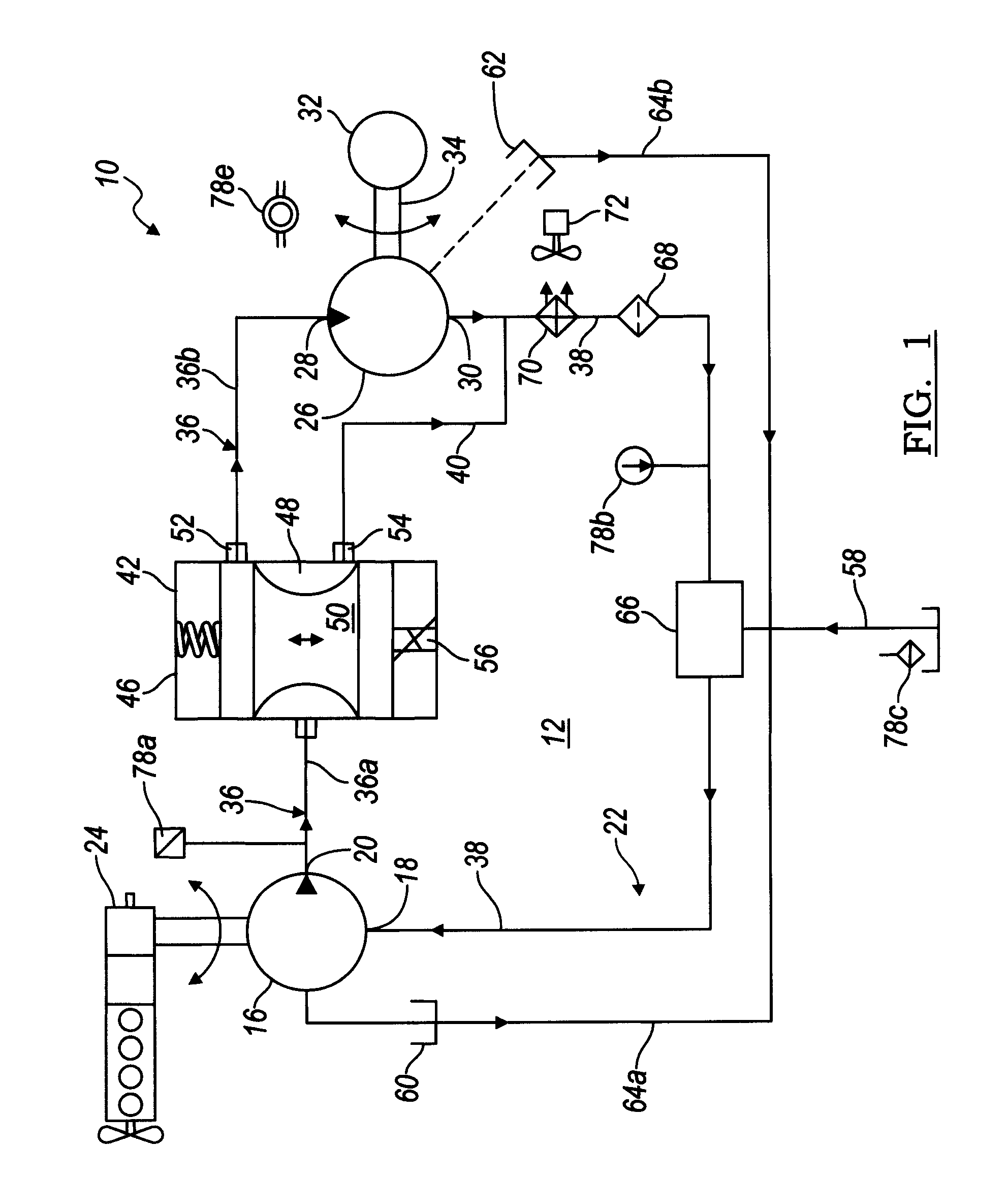

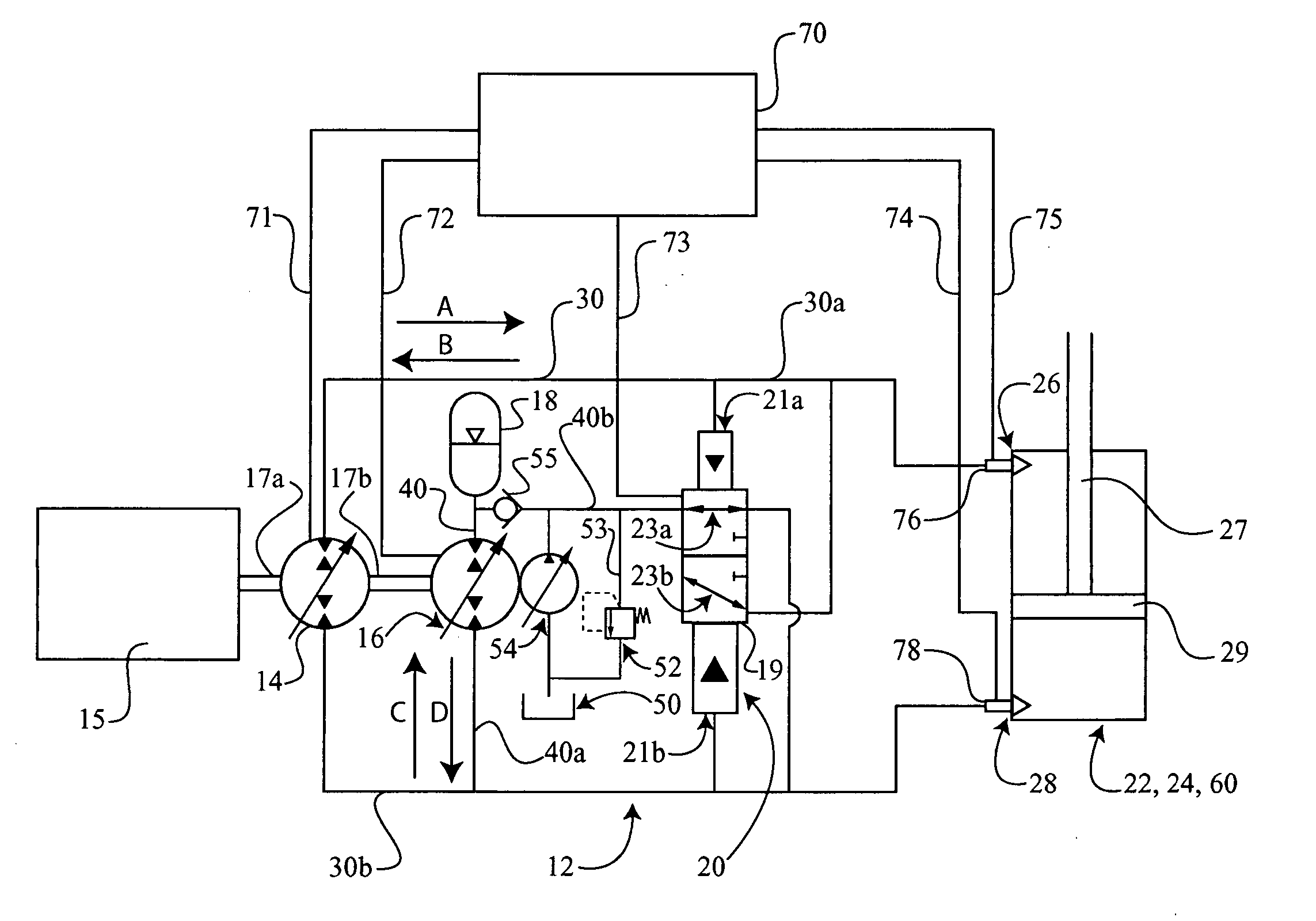

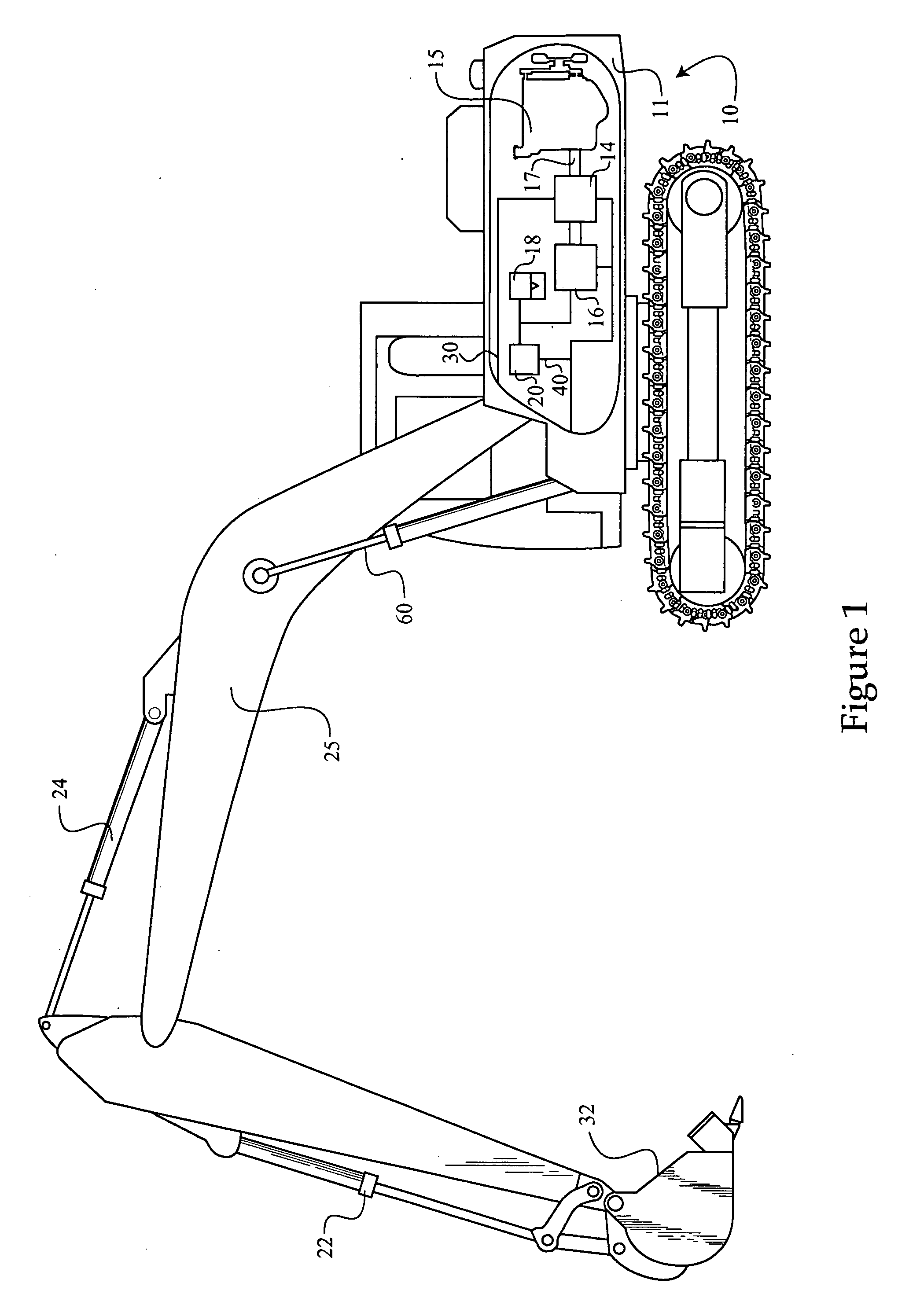

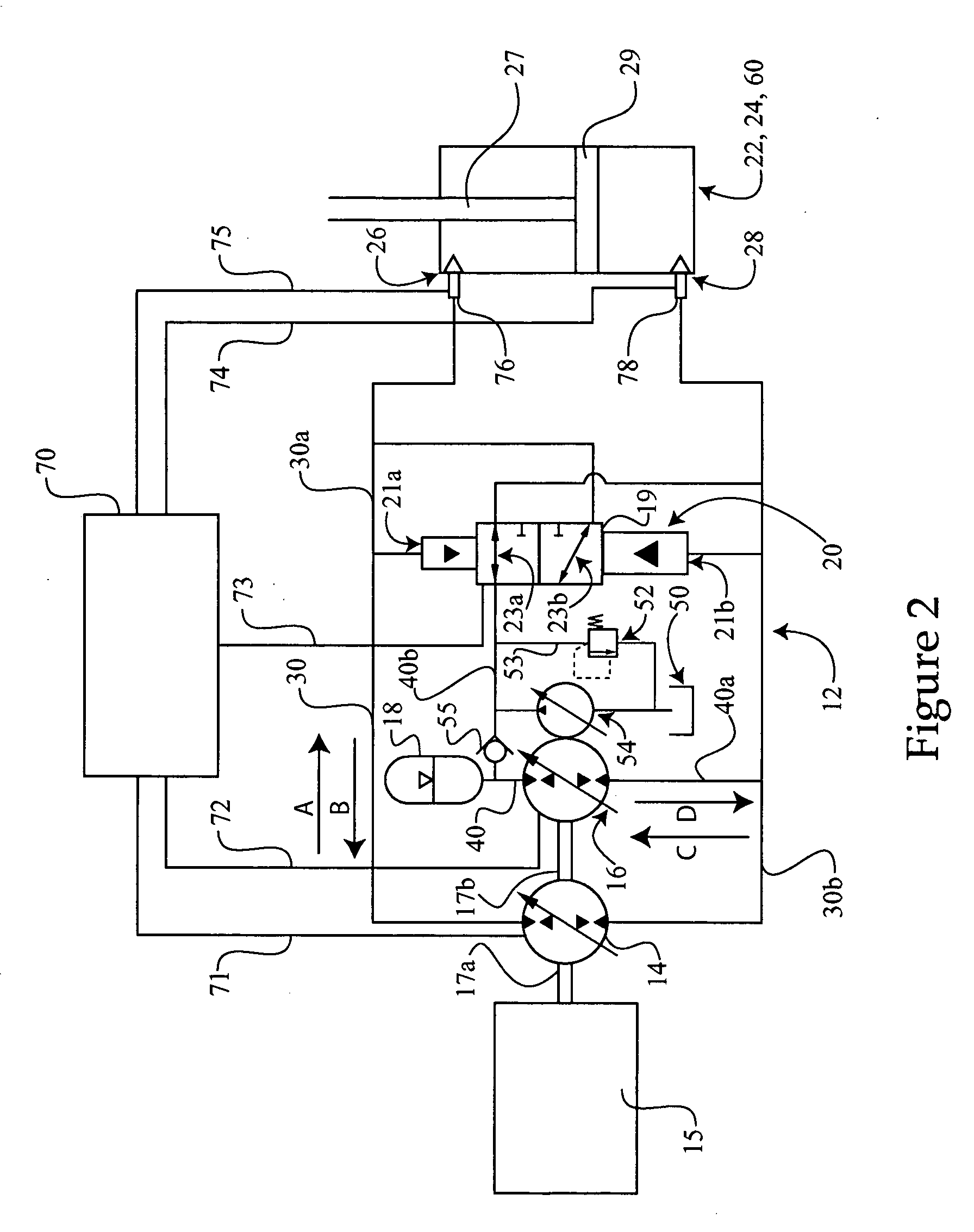

Flow management system for hydraulic work machine

A flow management system capable of providing adjustable hydraulic fluid flow or pressure at a common line to supply bidirectional pumps in electro-hydrostatic actuation systems and conditioning re-circulated hydraulic fluid. The system enables flow sharing between multiple actuation systems and minimization of energy consumption by a power-on-demand approach and / or electrical energy regeneration while eliminating the need for an accumulator. The system has particular application to electro-hydrostatic actuation systems that typically include bi-directional electric motor driven pumps and unbalanced hydraulic actuators connected within closed circuits to provide work output against external loads and reversely recover energy from externally applied loads.

Owner:PARKER INTANGIBLES LLC

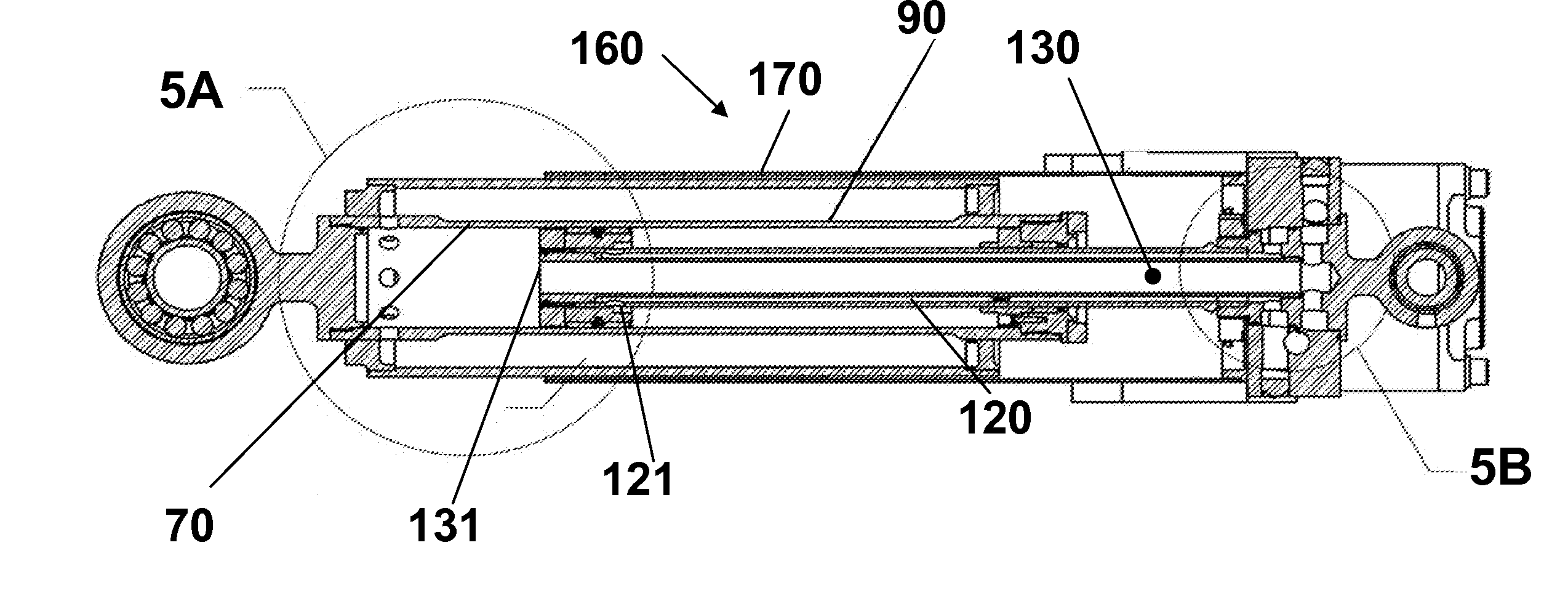

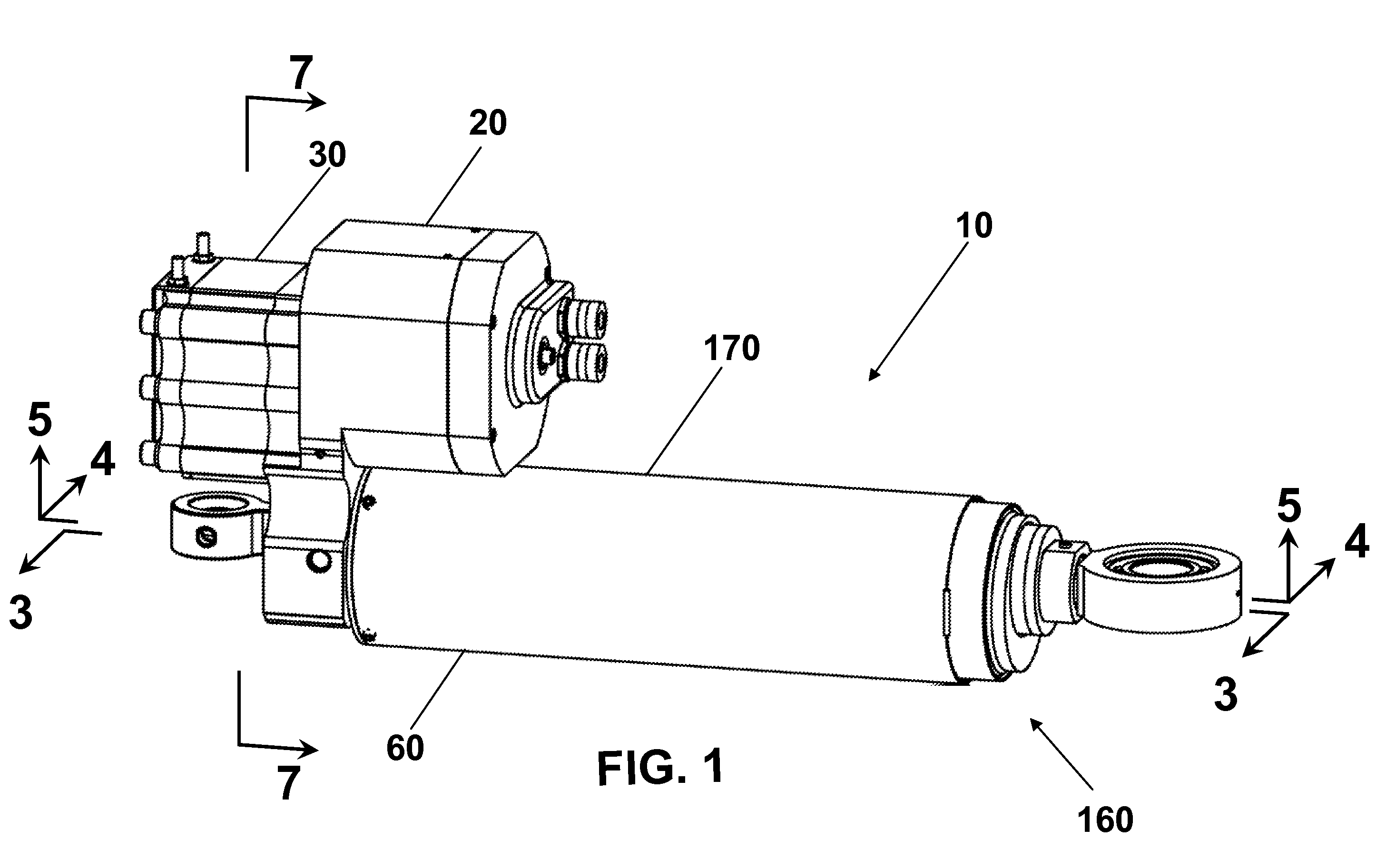

Actuators

Actuators suited for use with, for example, vehicular suspension systems. In some embodiments, the present actuators include a reversible hydraulic pump configured to produce variable hydraulic pressure; a hydraulic cylinder assembly having a cylinder bore, and a piston positioned within the cylinder bore that is axially movable relative to the cylinder bore; and a hydraulic circuit hydraulically coupling the reversible hydraulic pump to the hydraulic cylinder assembly. In these embodiments, actuated axial motion of the piston relative to the cylinder bore is accomplished without the use of check valves, pressure regulating valves, or actively controlled valves.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

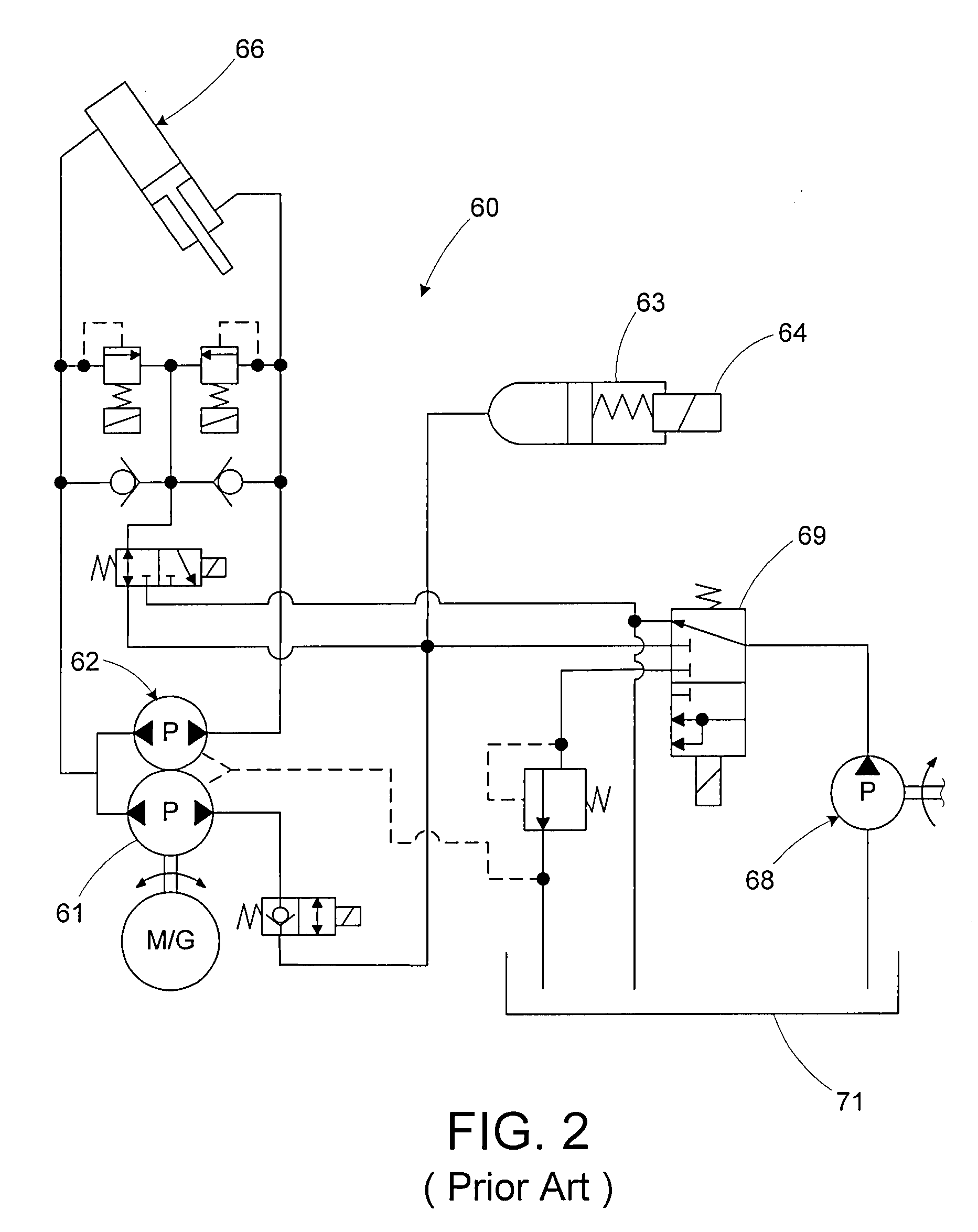

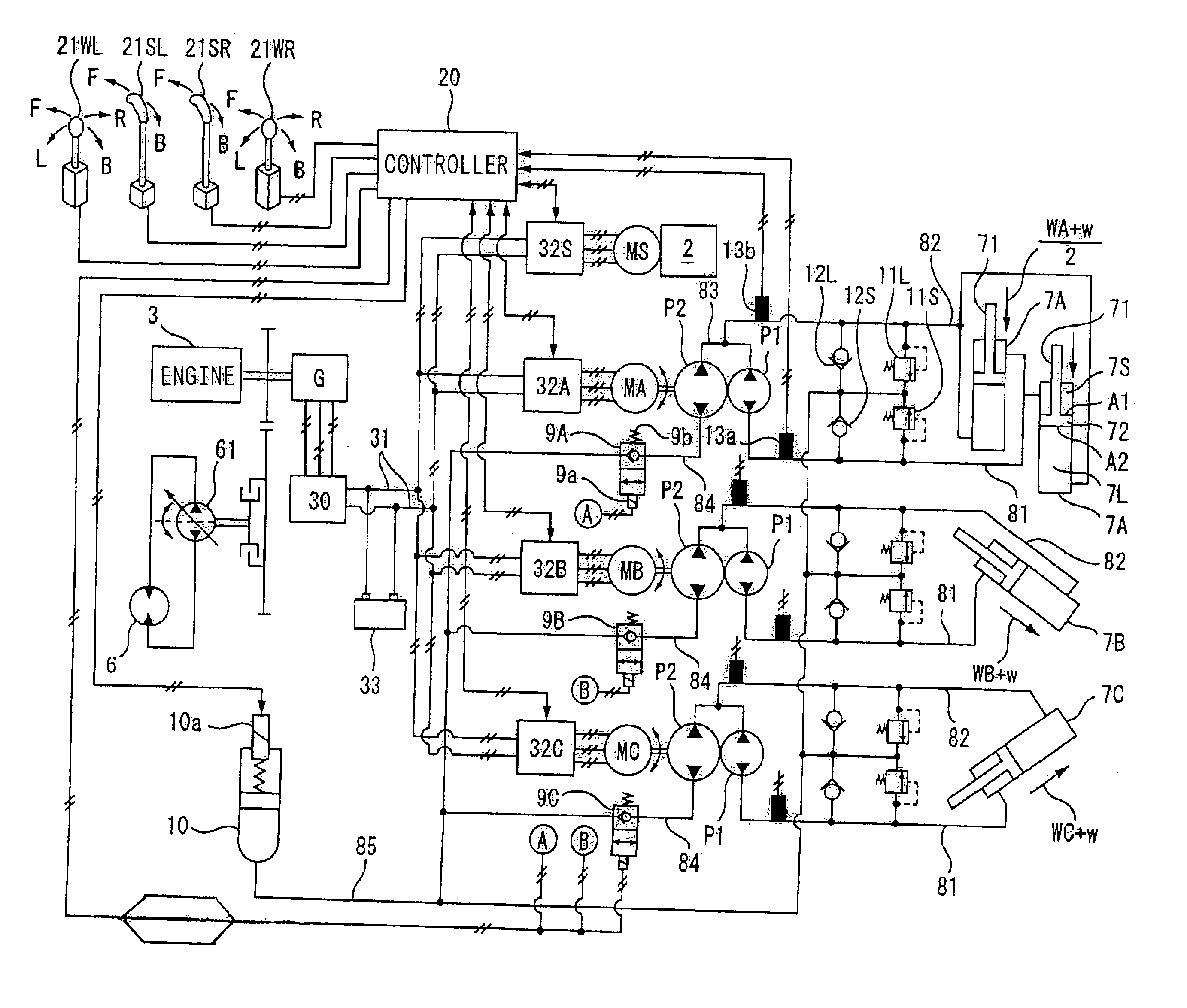

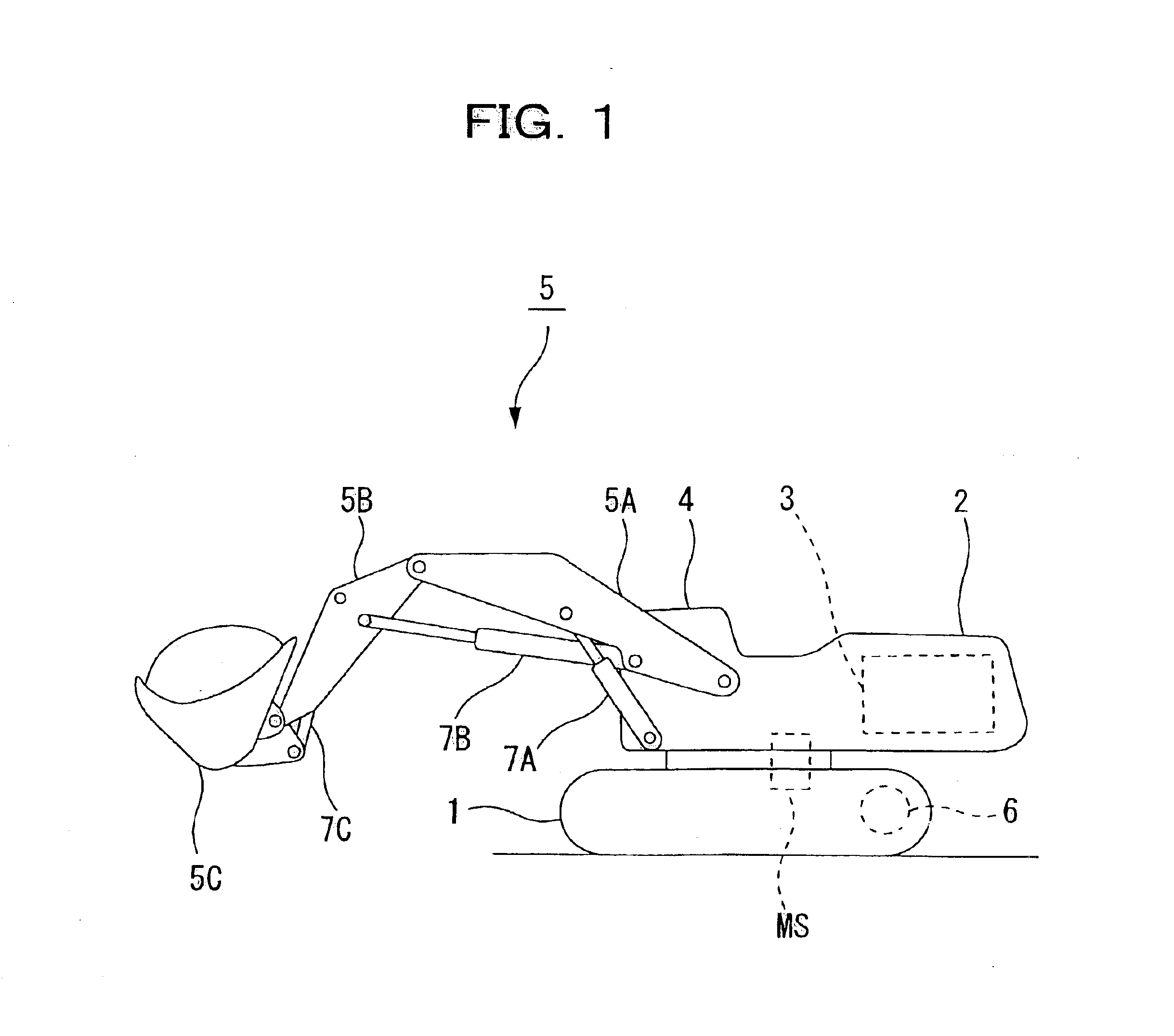

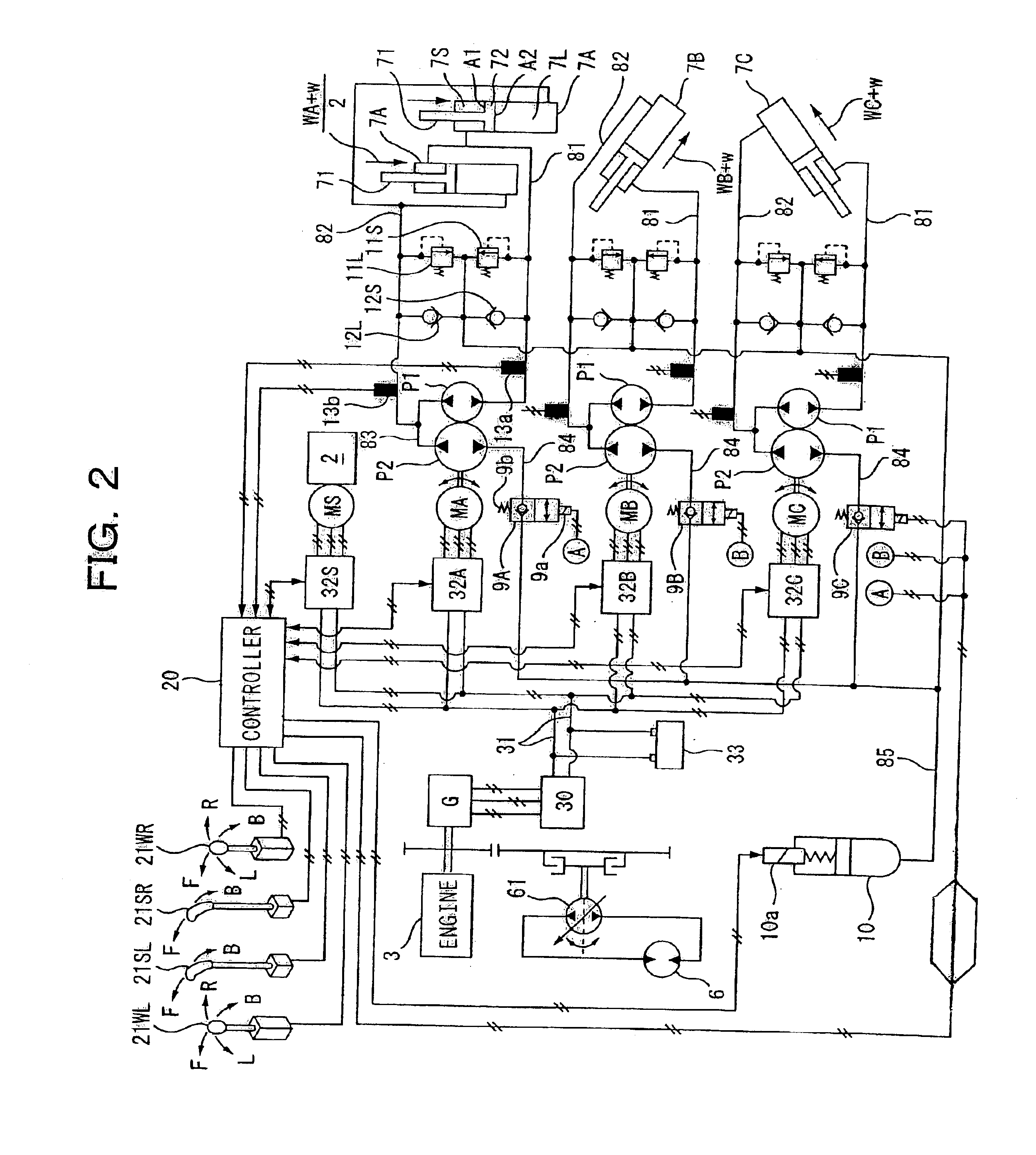

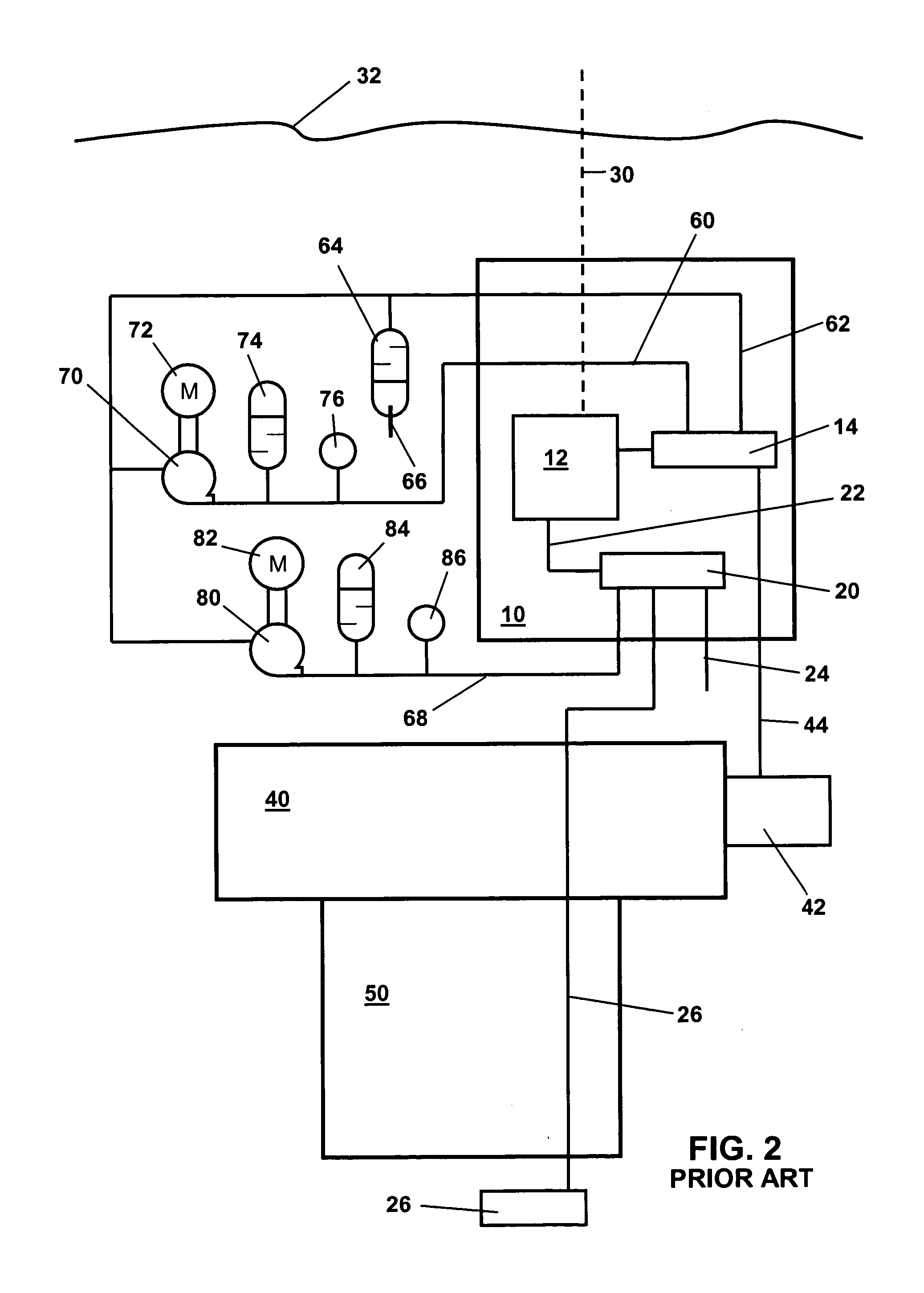

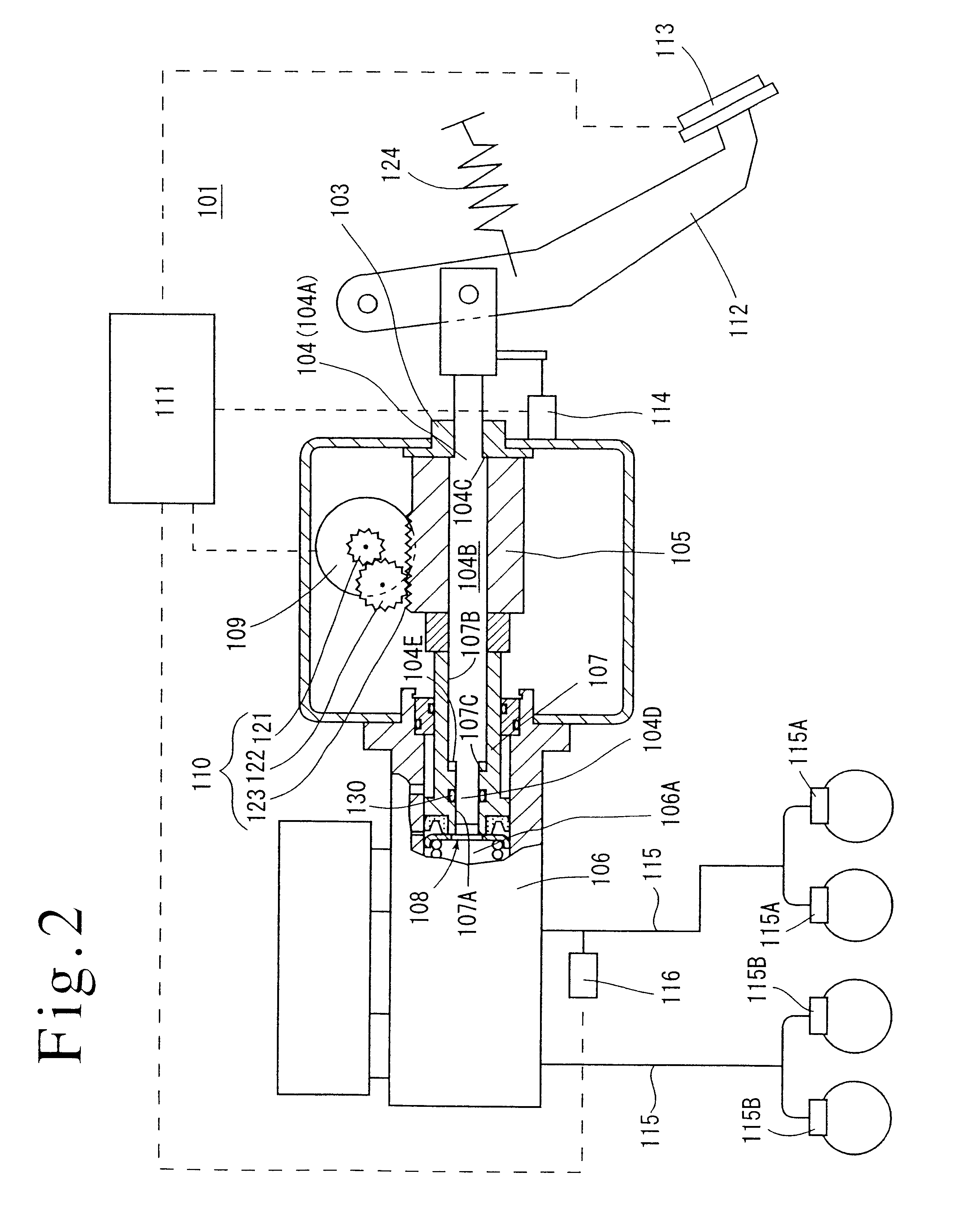

Hybrid machine with hydraulic drive device

A hybrid machine with a hydraulic drive device having hydraulic actuators allowed to operate against and by external loads is provided. To this end, the hybrid machine comprises hydraulic cylinders (7), first hydraulic pumps (P1) connected, with closed circuits, to head side pressure receiving chambers (7S) and bottom side pressure receiving chambers (7L) of the hydraulic cylinders (7), and second hydraulic pumps (P2) connected, with open circuits, to the bottom side pressure receiving chambers (7L) and an external oil chamber (10), wherein the first and second hydraulic pumps (P1, P2) are connected to electric motors (M) so as to be driven.

Owner:KOMATSU LTD

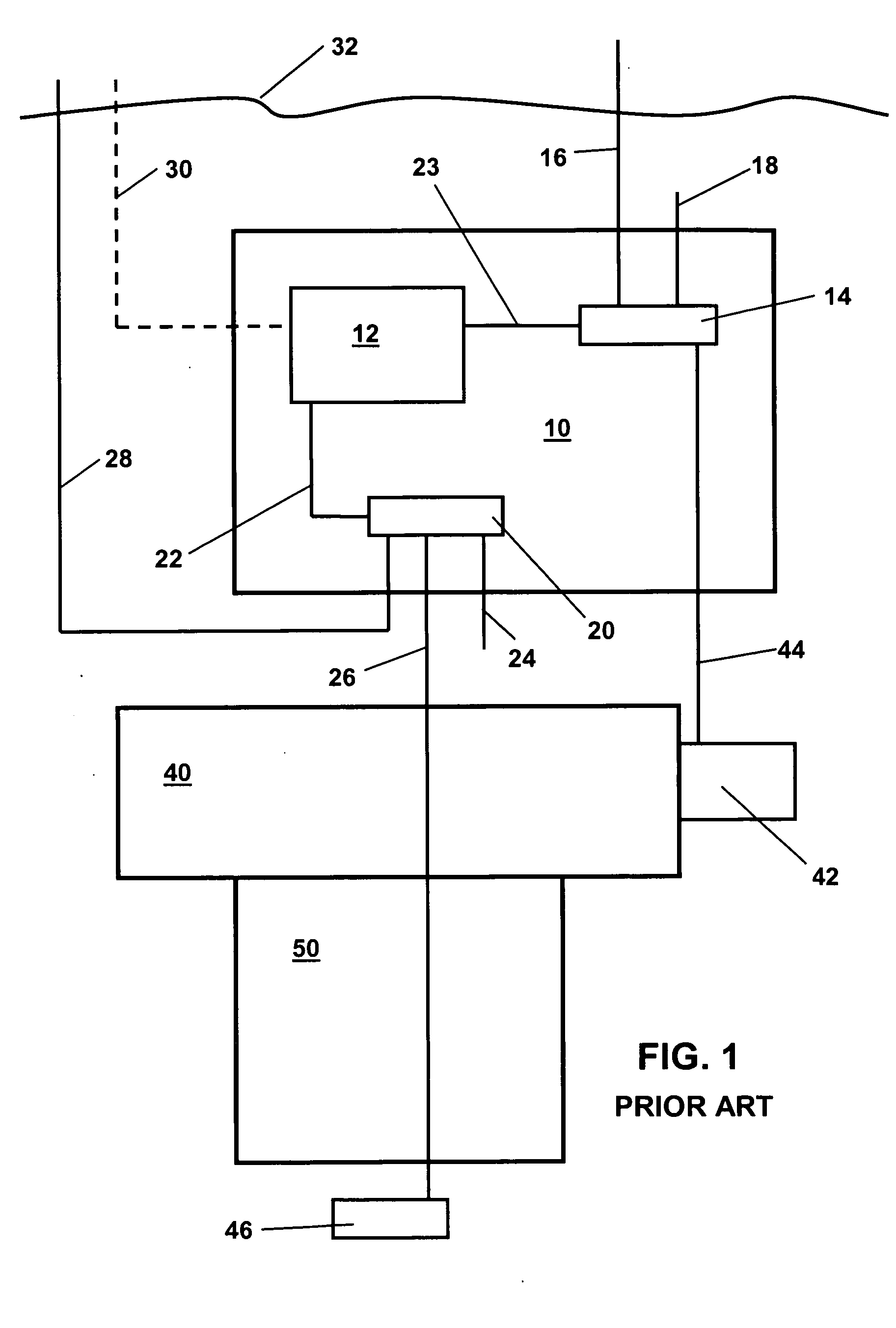

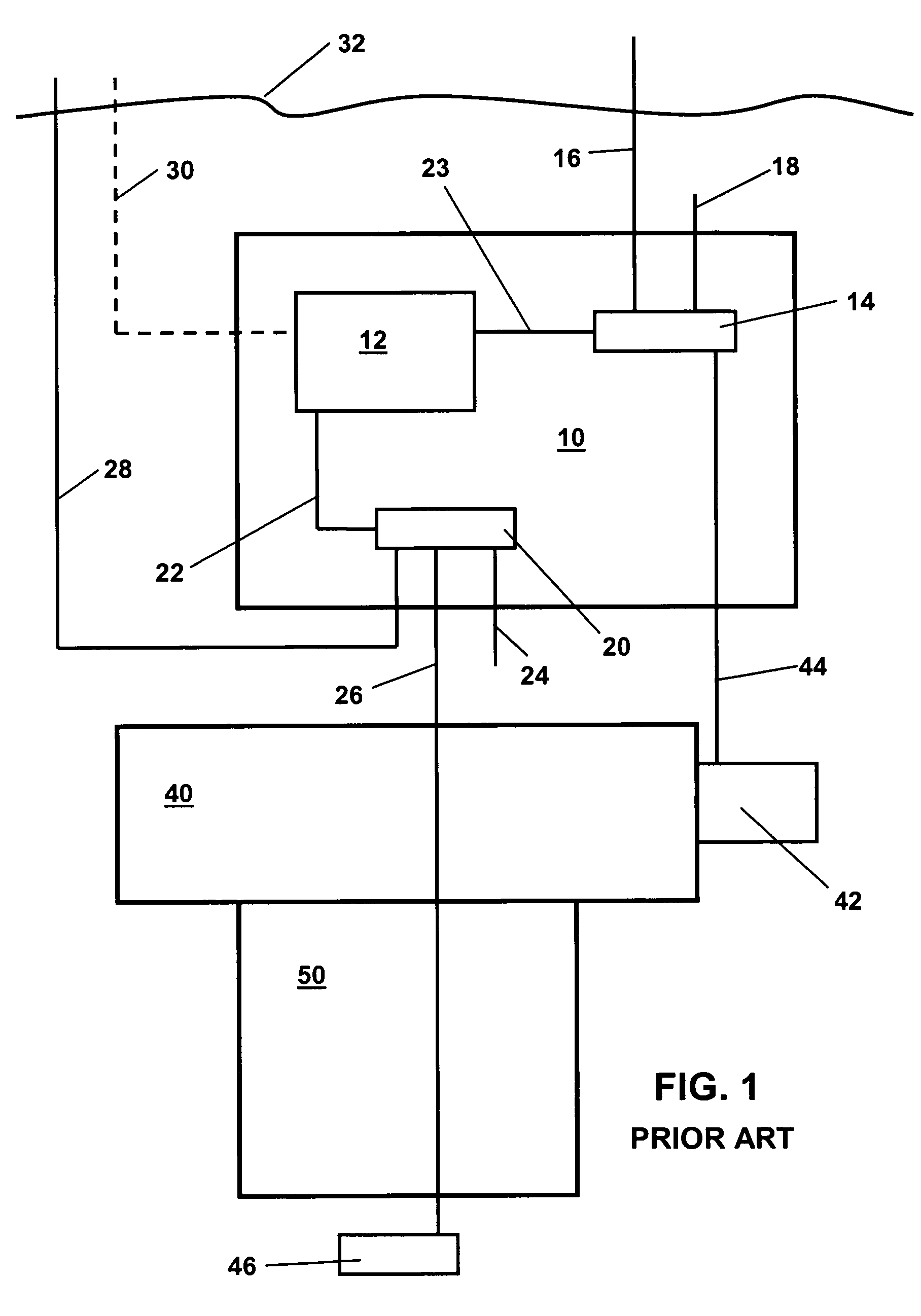

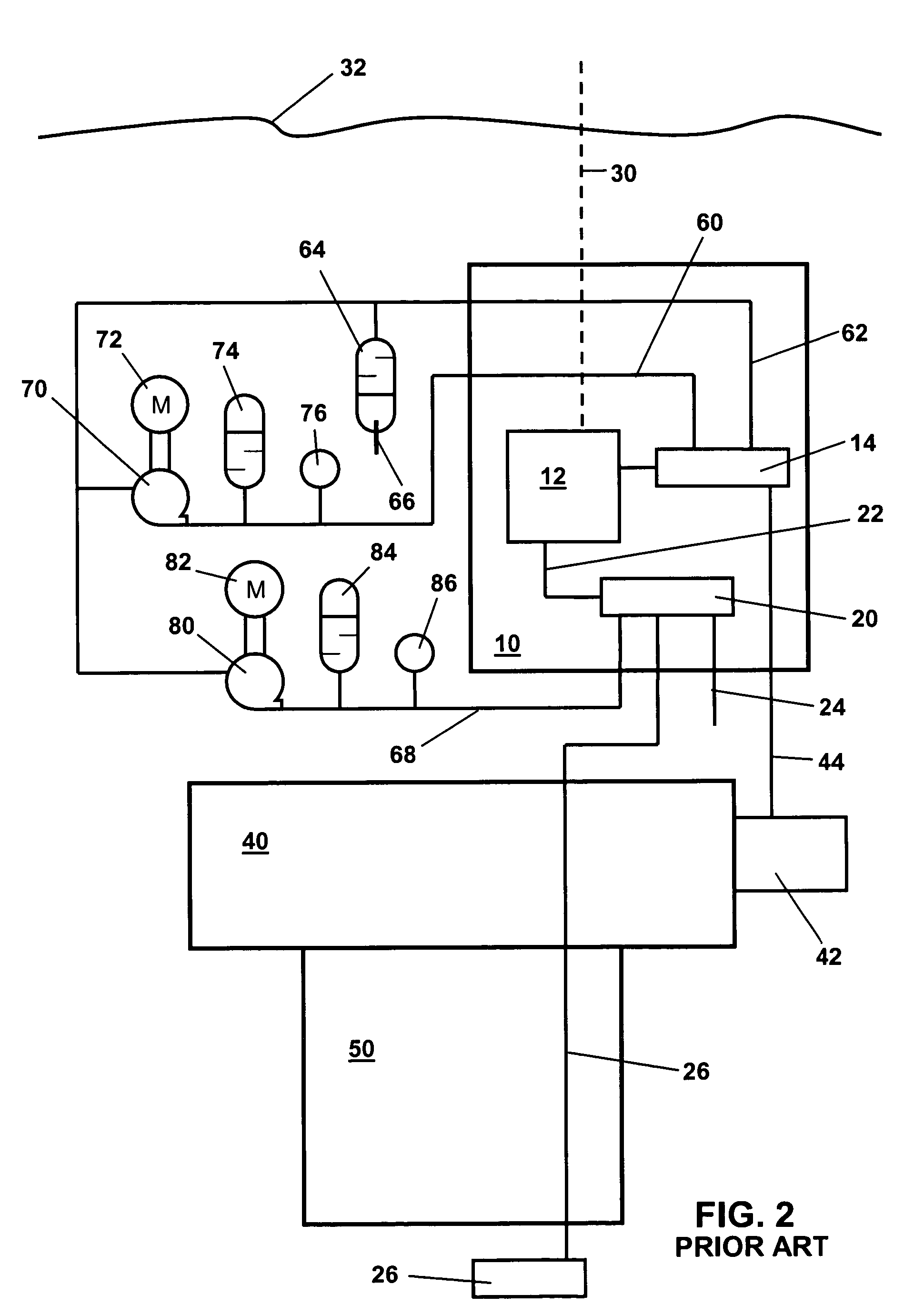

System for controlling a hydraulic actuator, and methods of using same

The present invention is directed to a system for controlling a hydraulic actuator, and various methods of using same. In one illustrative embodiment, the system comprises a first hydraulic cylinder, an isolated supply of fluid provided to the first hydraulic cylinder, the isolated supply of fluid positioned in an environment that is at a pressure other than atmospheric pressure, an actuator device coupled to the first hydraulic cylinder, the actuator device adapted to drive the first hydraulic cylinder to create the sufficient pressure in the fluid, and at least one hydraulic line operatively intermediate the first hydraulic cylinder and the hydraulic actuator, the hydraulic line supplying the sufficient pressure in the fluid to the hydraulic actuator in the remote locale.

Owner:FMC TECH INC

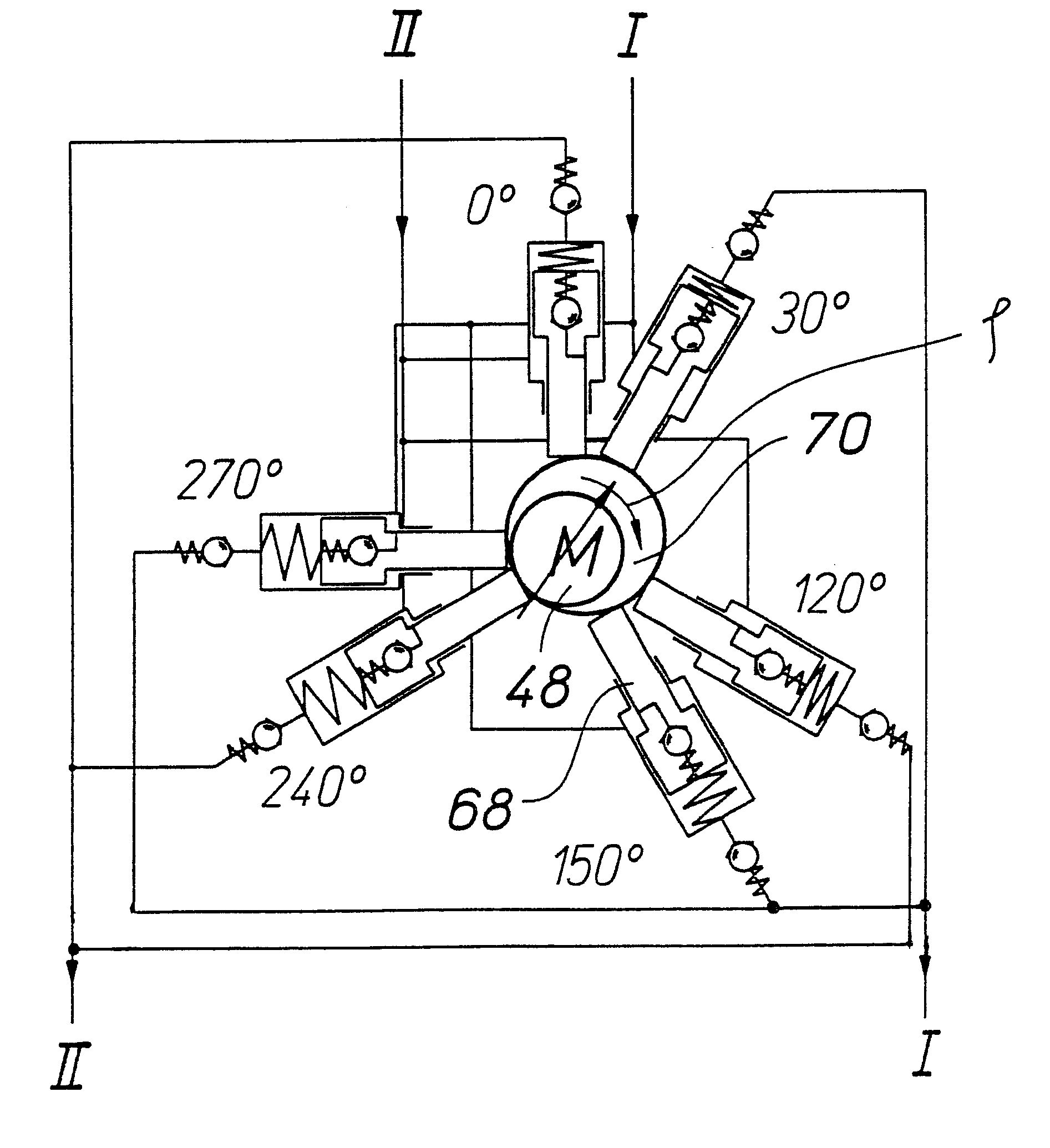

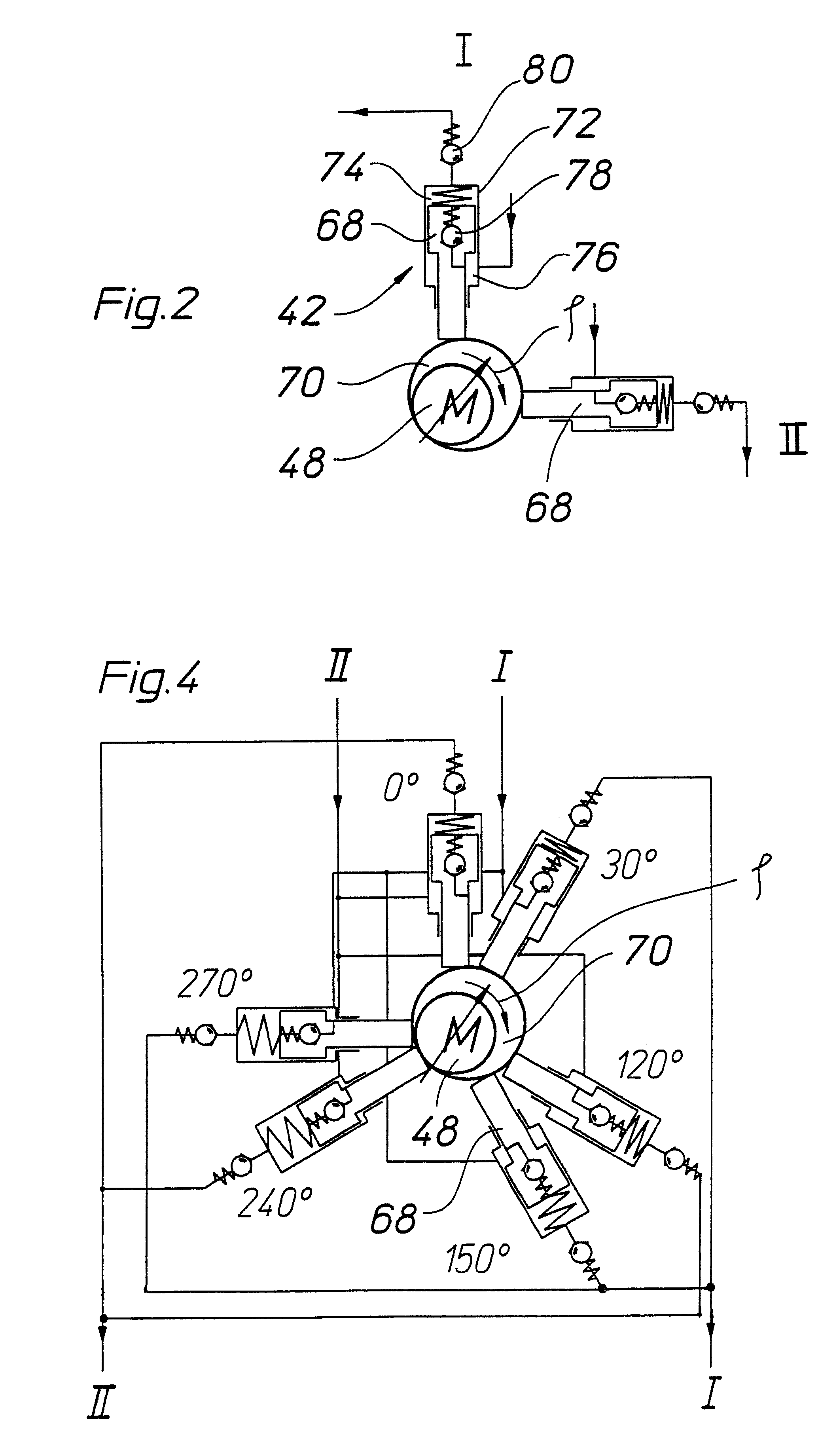

Hydraulic braking system for automobiles

The invention relates to a vehicle hydraulic brake system with electrohydraulic brake boosting by a piston pump. In order to reduce pressure pulsations on an intake side of the multi-piston pump, the brake system embodies a multi-piston pump, for example, as a six-piston pump with stepped pistons that are driven with an alternating phase shift of 30° and 90° in relation to one another. The phase shift of the drive of the stepped pistons is selected so that the intake volume flows have a uniform phase shift, by which the total intake volume flow of the multi-piston pump has a reduced amplitude of the pressure pulsation, which reduces the repercussions on a master cylinder.

Owner:ROBERT BOSCH GMBH

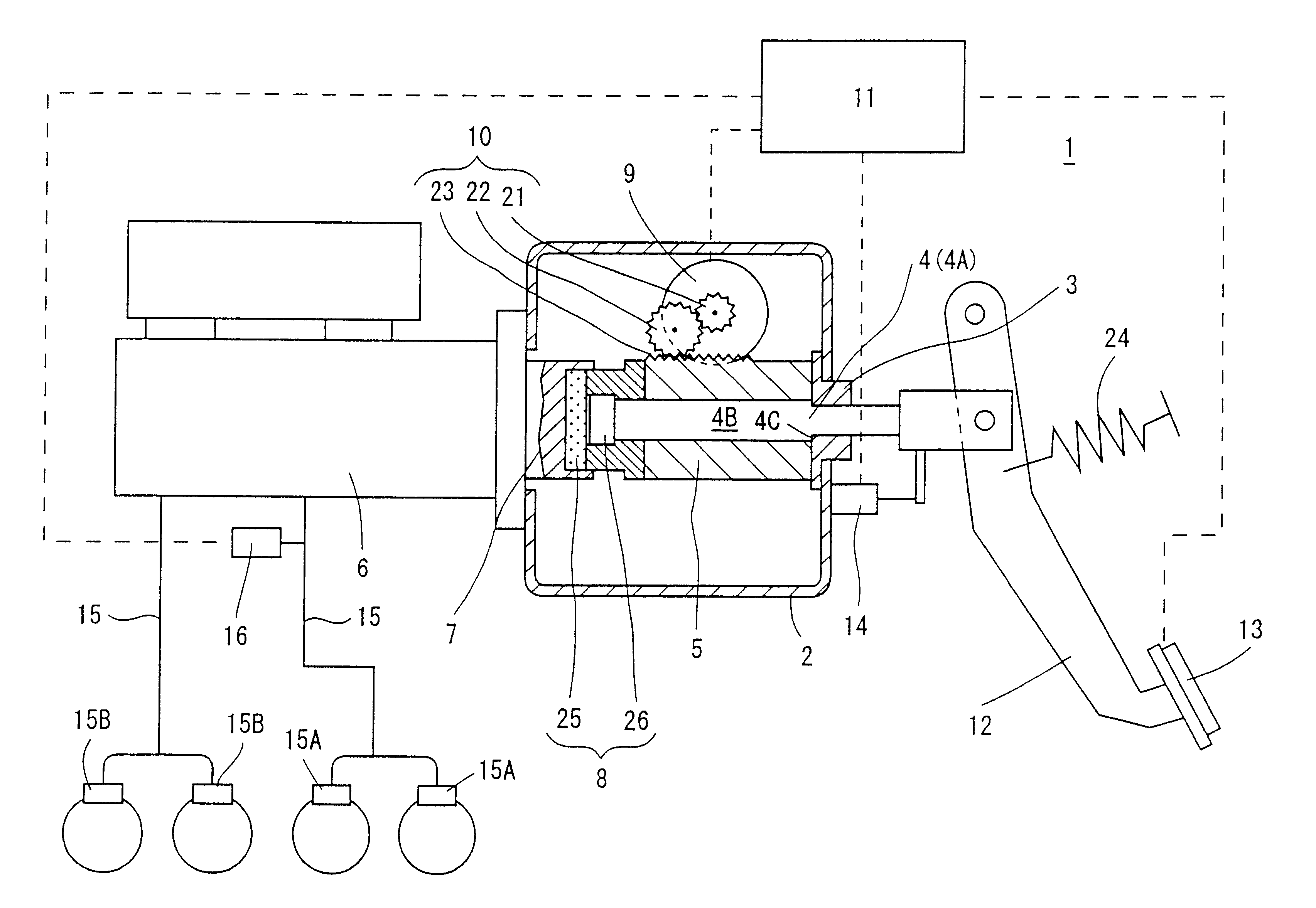

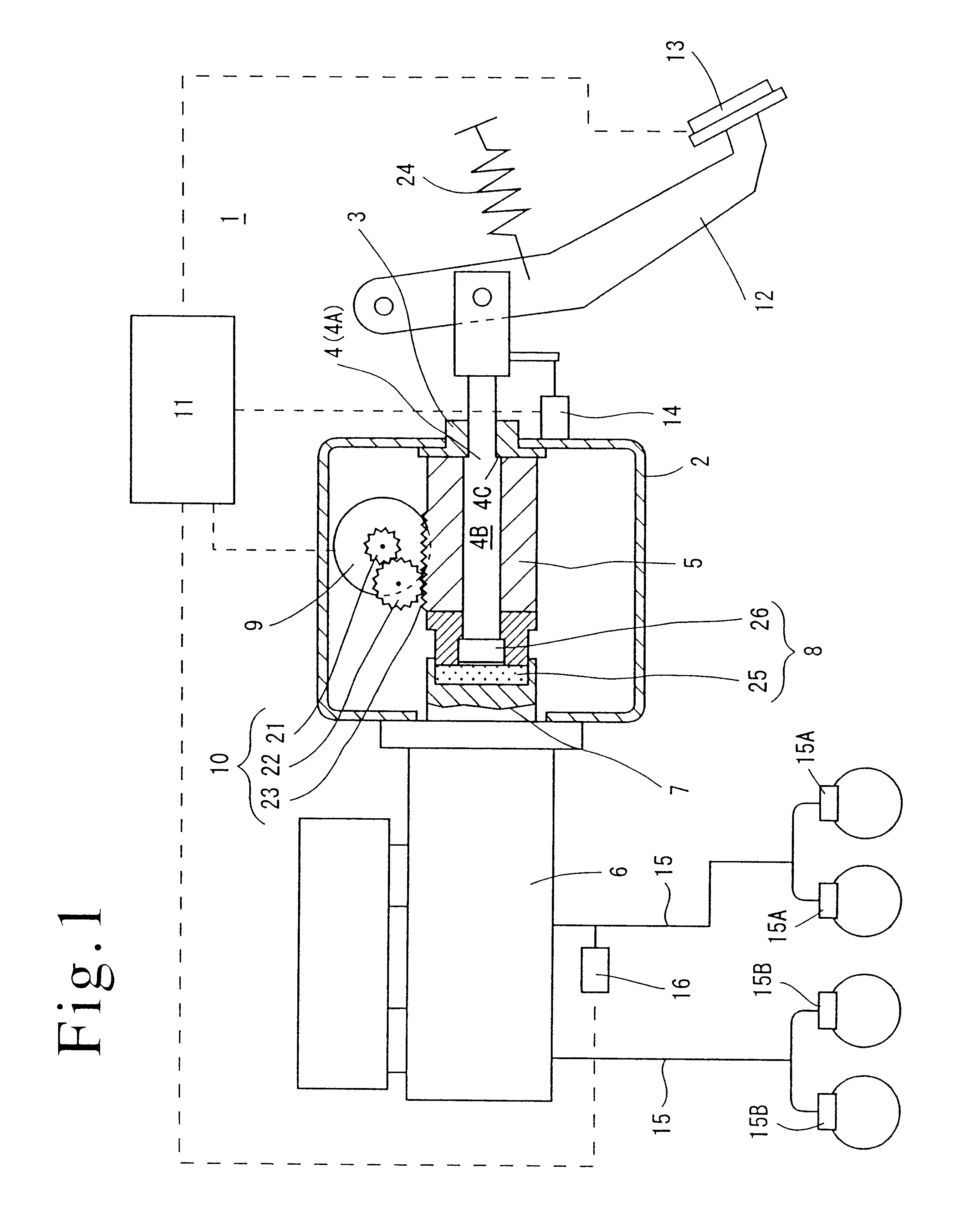

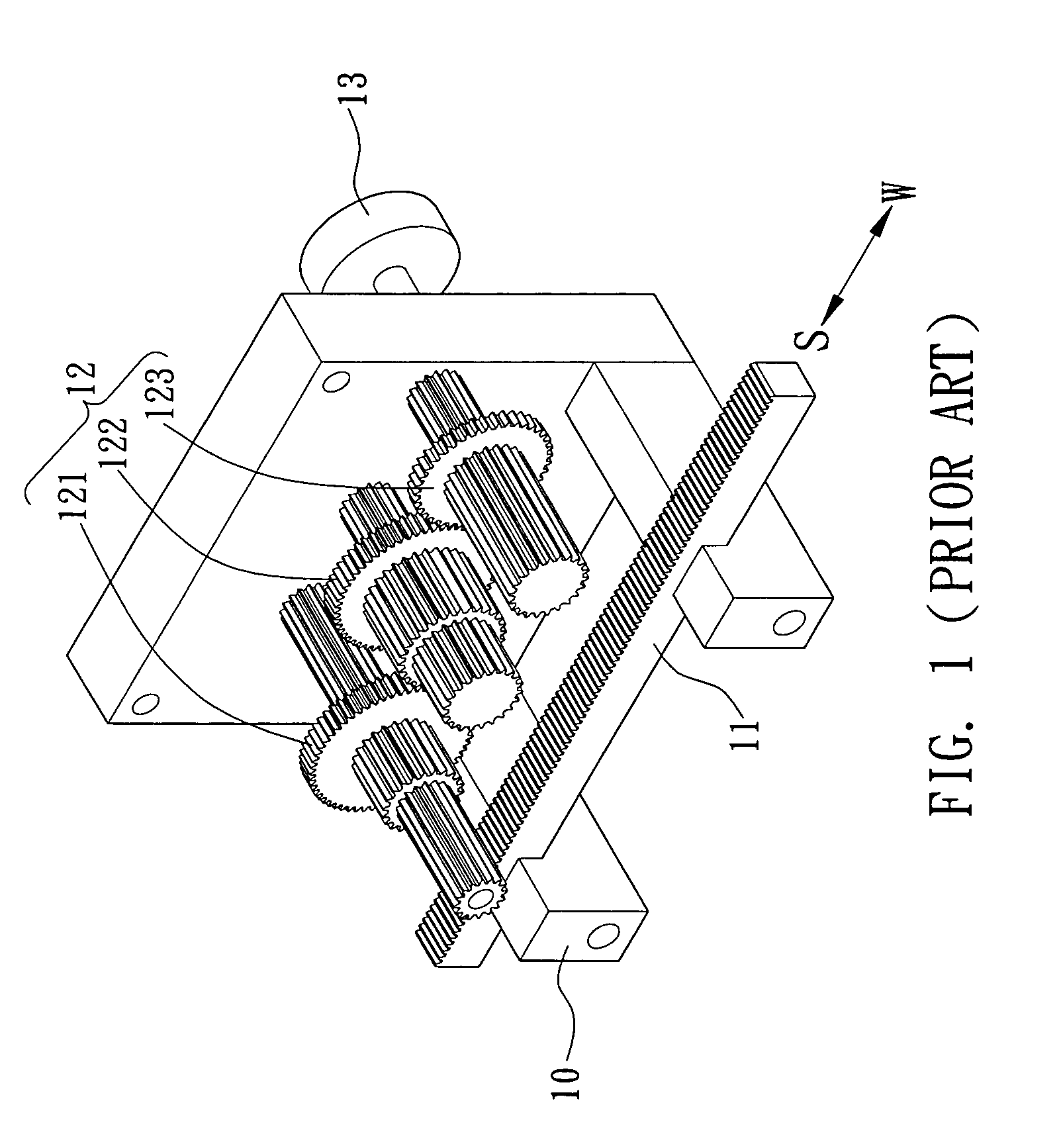

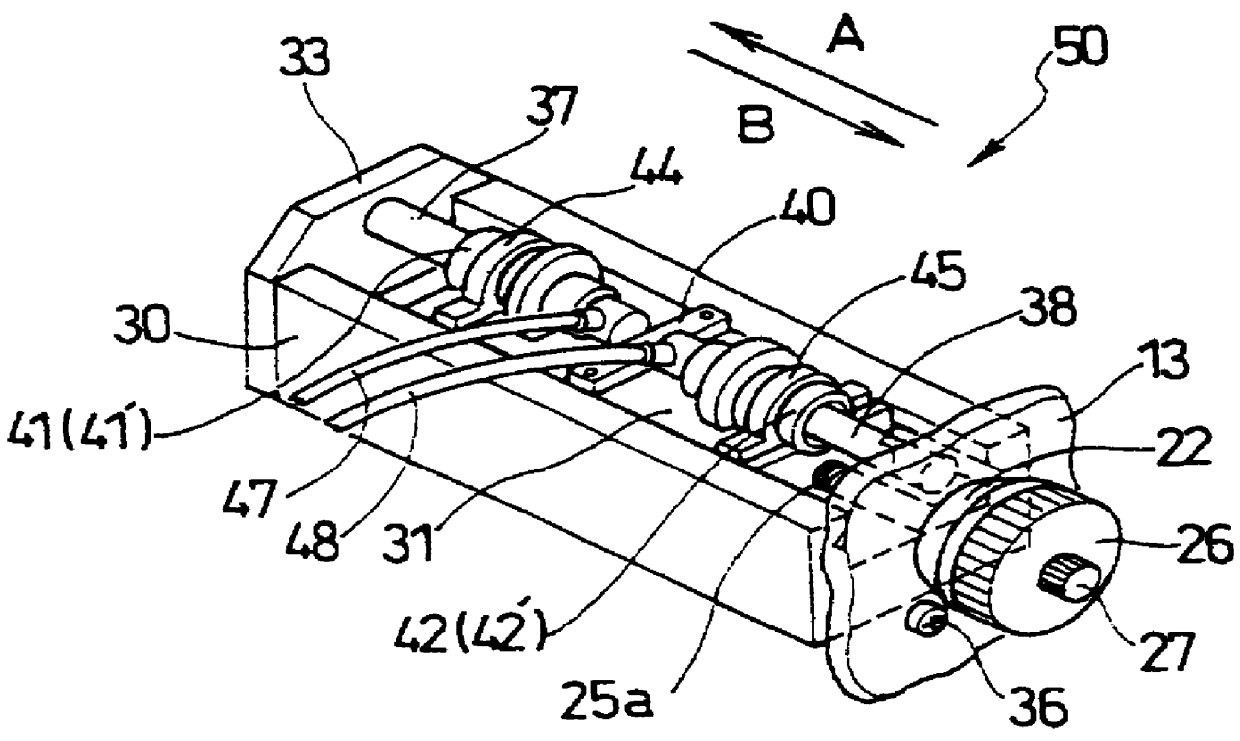

Electrically driven brake booster

InactiveUS6634724B2Reduce weightEasy constructionServomotor componentsRotary clutchesLinear motionMaster cylinder

An electrically driven brake booster (1) includes an input member (4) disposed in operative association with a brake pedal (12), an output member (5) disposed in operative association with the master cylinder (6), and drive transmitting device (10) for translating a rotating motion of a motor (9) into a linear motion to be transmitted to the output member (5). The drive transmitting device (10) comprises a rack (23) formed on the output member (5), and pinions (21, 22) disposed in operative association with the motor (9) and in meshing engagement with the rack (23). Also, reaction transmitting device (8) which transmits a brake reaction to the input member (4) and the output member (5) at a given proportion is provided. In comparison to conventional drive transmitting device, the drive transmitting device (10) of the present invention has a simple construction, a reduced weight and a better transmission efficiency. The provision of reaction transmitting device allows a correct brake control to be achieved on the basis of a brake reaction.

Owner:DIESEL KIKI CO LTD

Cylinder driving system and energy regenerating method thereof

InactiveUS6912849B2Improve energy efficiencyReduce in quantityFluid couplingsServomotorsHydraulic cylinderHydraulic pump

A cylinder driving system capable of reducing the number of hydraulic devices and the amount of energy loss and an energy regenerating method thereof are provided. To this end, the system includes i) a hydraulic cylinder, ii) a hydraulic pump having three suction / discharge ports of a first port for supplying oil to a bottom chamber of the hydraulic cylinder or draining oil from the bottom chamber, a second port for draining oil from a head chamber of the hydraulic cylinder or supplying oil to the head chamber, and a third port for draining oil from a tank or supplying oil to the tank, the suction rate or the discharge rate in the first port being the sum of the respective discharge rates or suction rates in the second port and the third port, and iii) a driving source for driving the hydraulic pump.

Owner:KOMATSU LTD

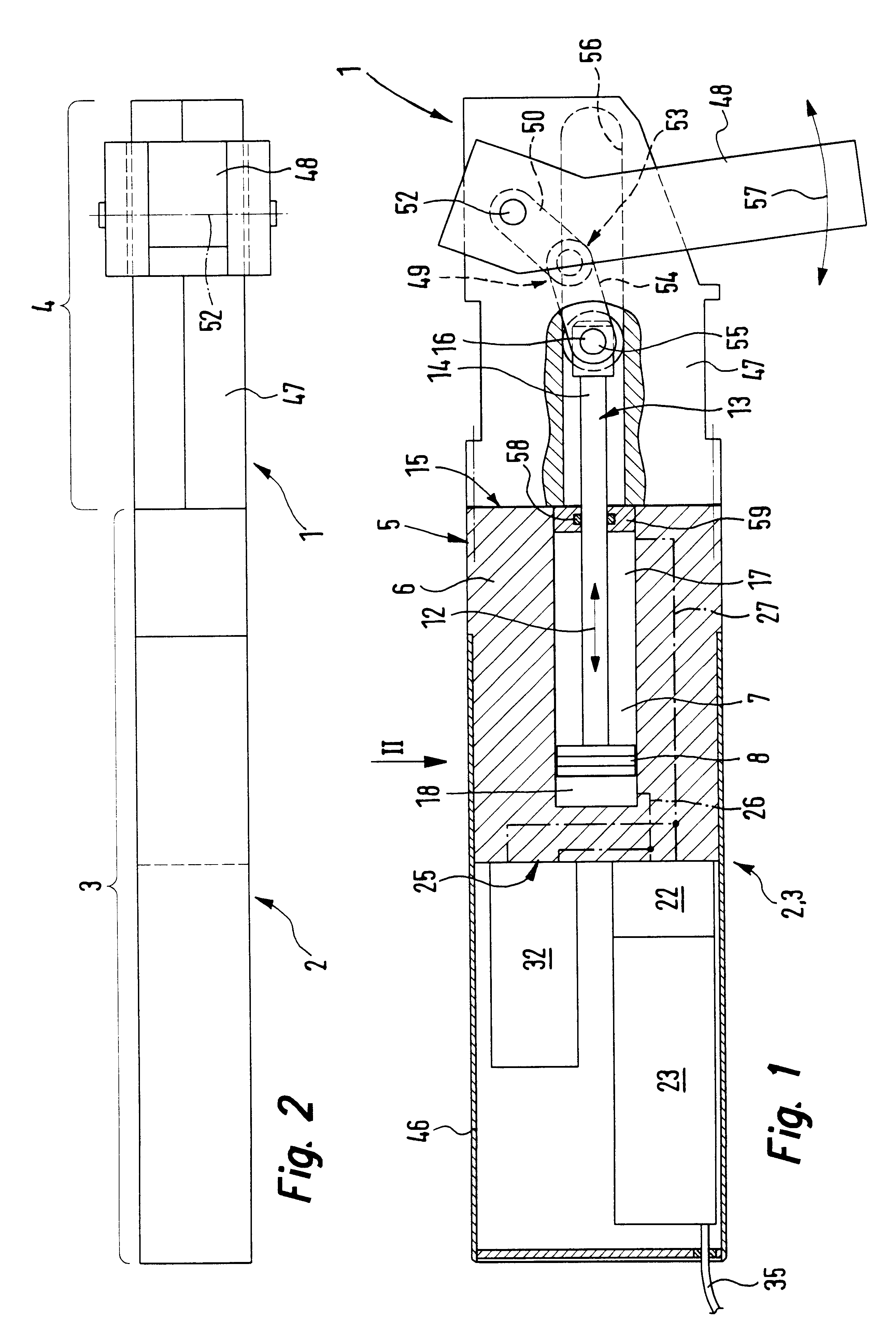

Drive device

InactiveUS6543223B2Easy to driveReduce needFluid couplingsServomotor componentsHydraulic pumpHydraulic circuit

A drive device comprising a closed hydraulic circuit which has a hydraulic drive adapted to be actuated by hydraulic medium and has a hydraulic pump responsible for the supply and removal of the hydraulic medium to and from the hydraulic drive. For the operation of the hydraulic pump an electric motor is provided. The activation of the hydraulic drive is controlled by the operational state of the hydraulic pump.

Owner:FESTO AG & CO KG

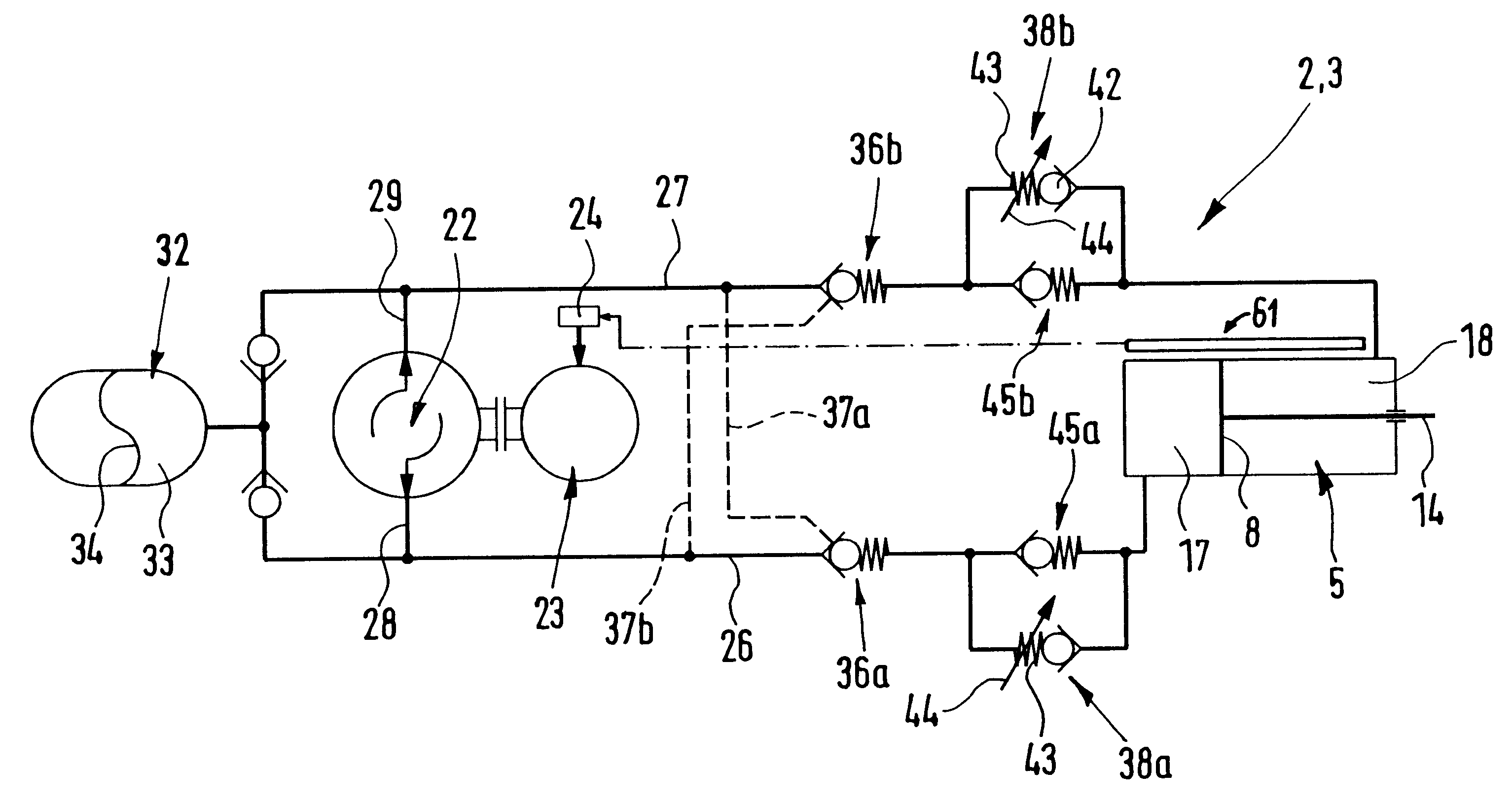

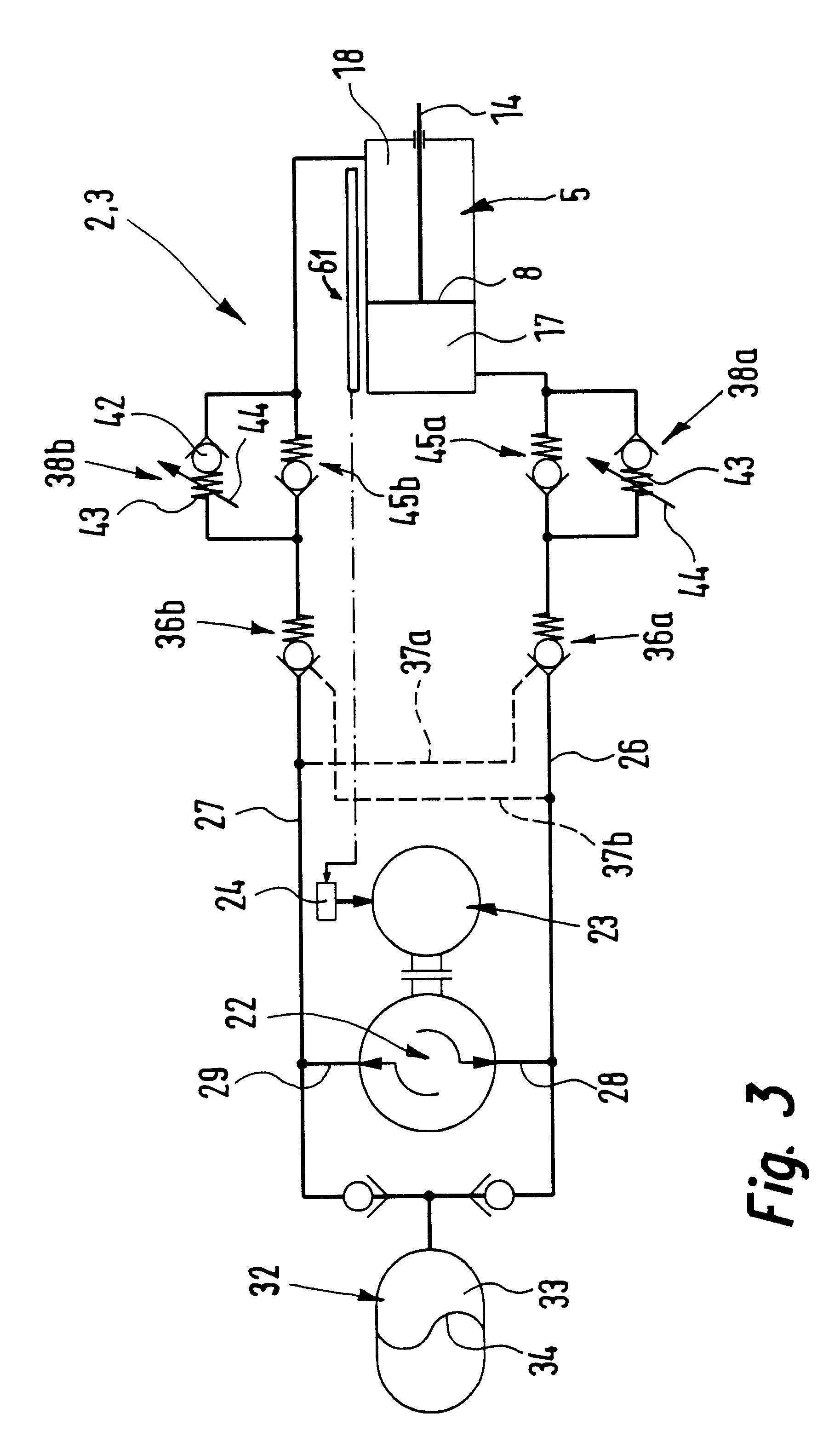

Hydraulic drive system

InactiveUS20060156713A1Keep the pressureReduce forceFluid couplingsAccumulator installationsBattery chargeEngineering

A hydraulic drive system for an actuator uses a pair of pressure compensated hydraulic machines to control flow to and from the drive chambers of the actuator by varying the controlled pressure of one of the machines. The machines are mechanically coupled to permit energy recovery and charge an accumulator to store supplies energy. The drive system may be combined with other services including a transmission for incorporation in a vehicle. The transmission uses a pressure compensated supply and torque control of the wheels.

Owner:CONCENTRIC ROCKFORD

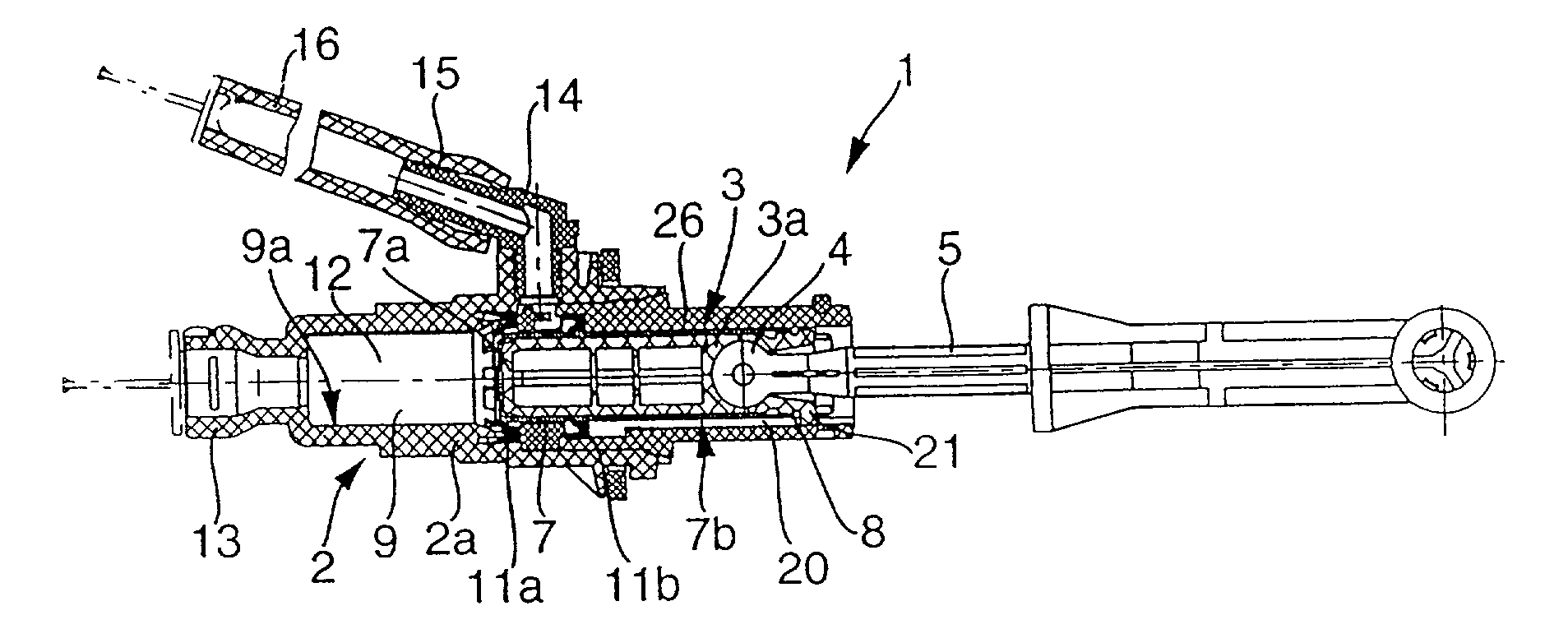

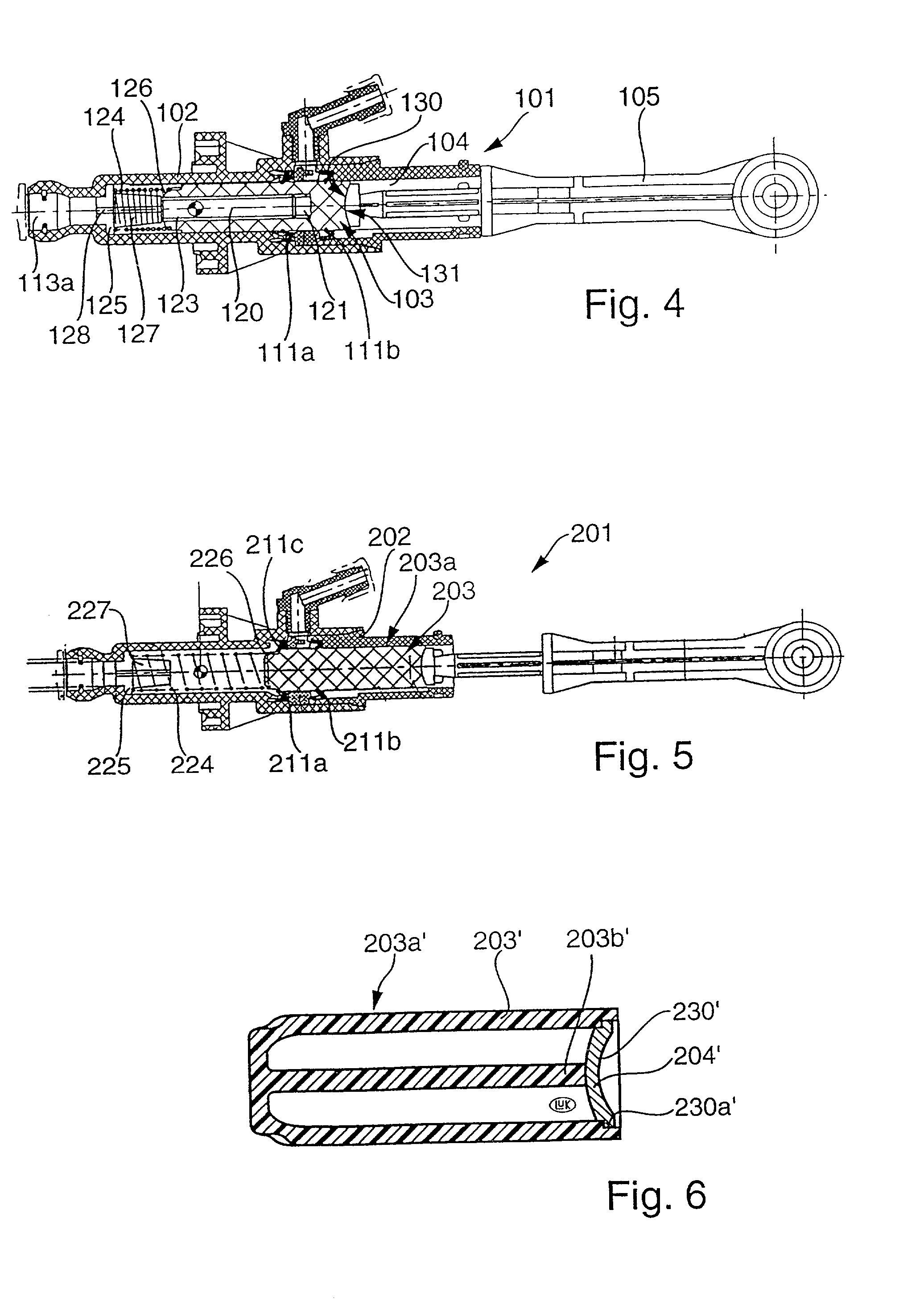

Master cylinder for use in power trains of motor vehicles

InactiveUS20020116924A1Satisfactory operationAvoid spreadingPiston ringsRotary clutchesMaster cylinderControl theory

A master cylinder for use in the power train of a motor vehicle to actuate the brakes or the friction clutch is designed to avoid the generation of screeching noise and / or the transmission of stray movements to the piston rod in response to shifting of the piston relative to the housing and relative to the sealing element(s) between the piston and the housing. This can be accomplished by causing the piston to turn relative to the housing and the sealing element(s) during axial movement in the housing and / or by installing one or more dampers between the piston and the housing and / or between the piston and the piston rod. The dampers can constitute separately produced parts and / or specially configured and / or finished surfaces provided on the piston and contacting the housing and / or the sealing element(s). The invention also relates to improvements in the configuration and / or the material(s) of the piston.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

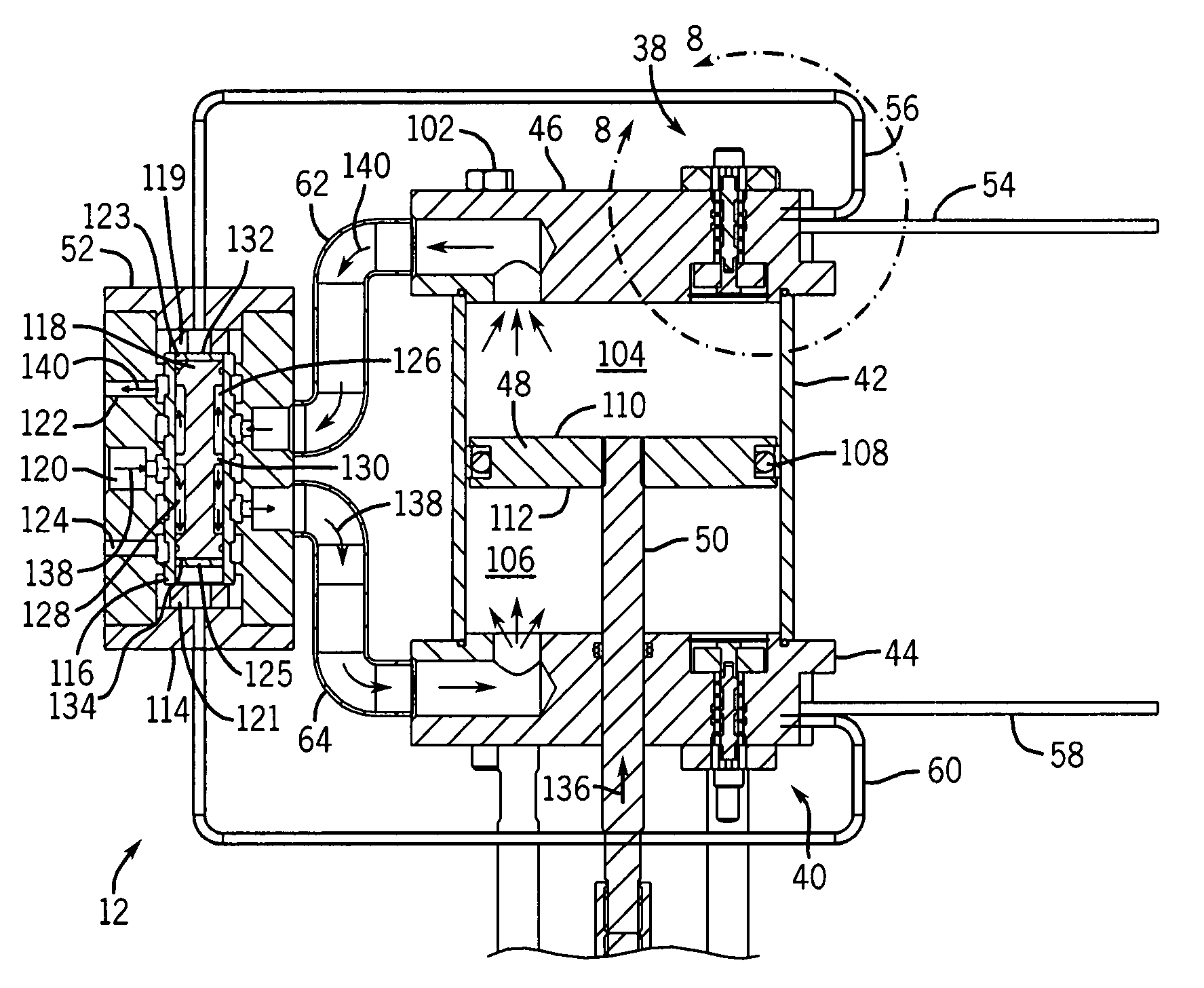

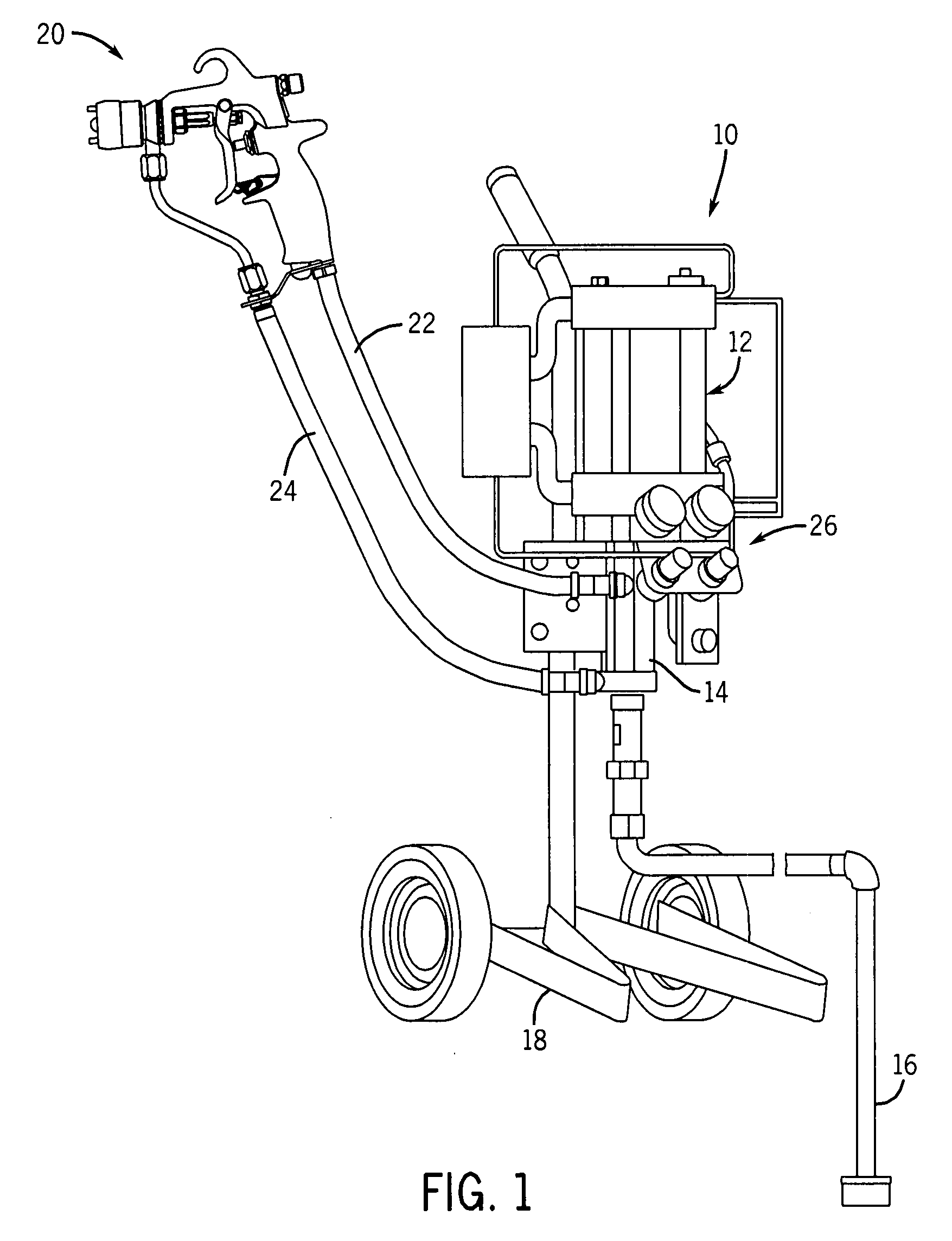

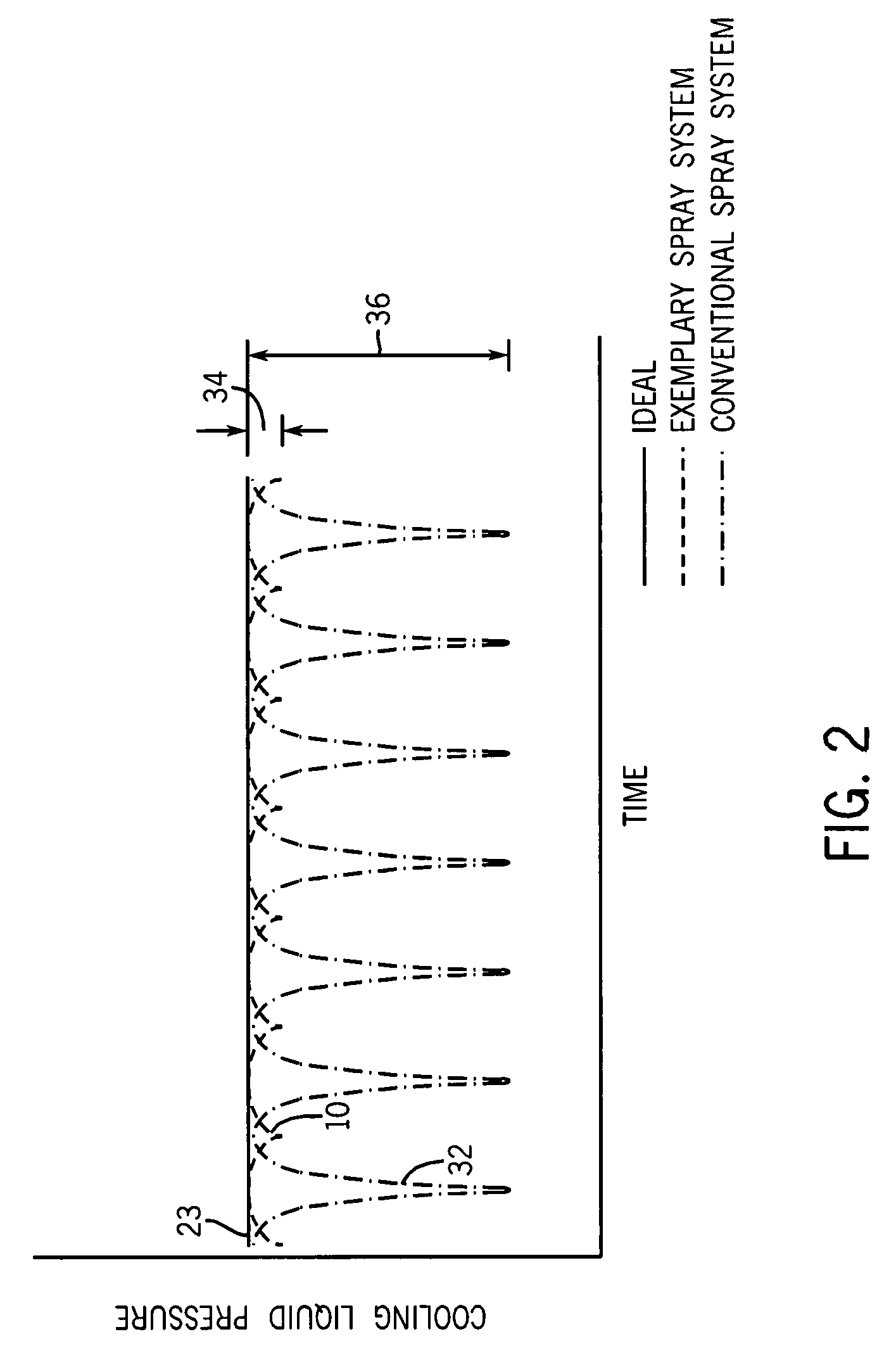

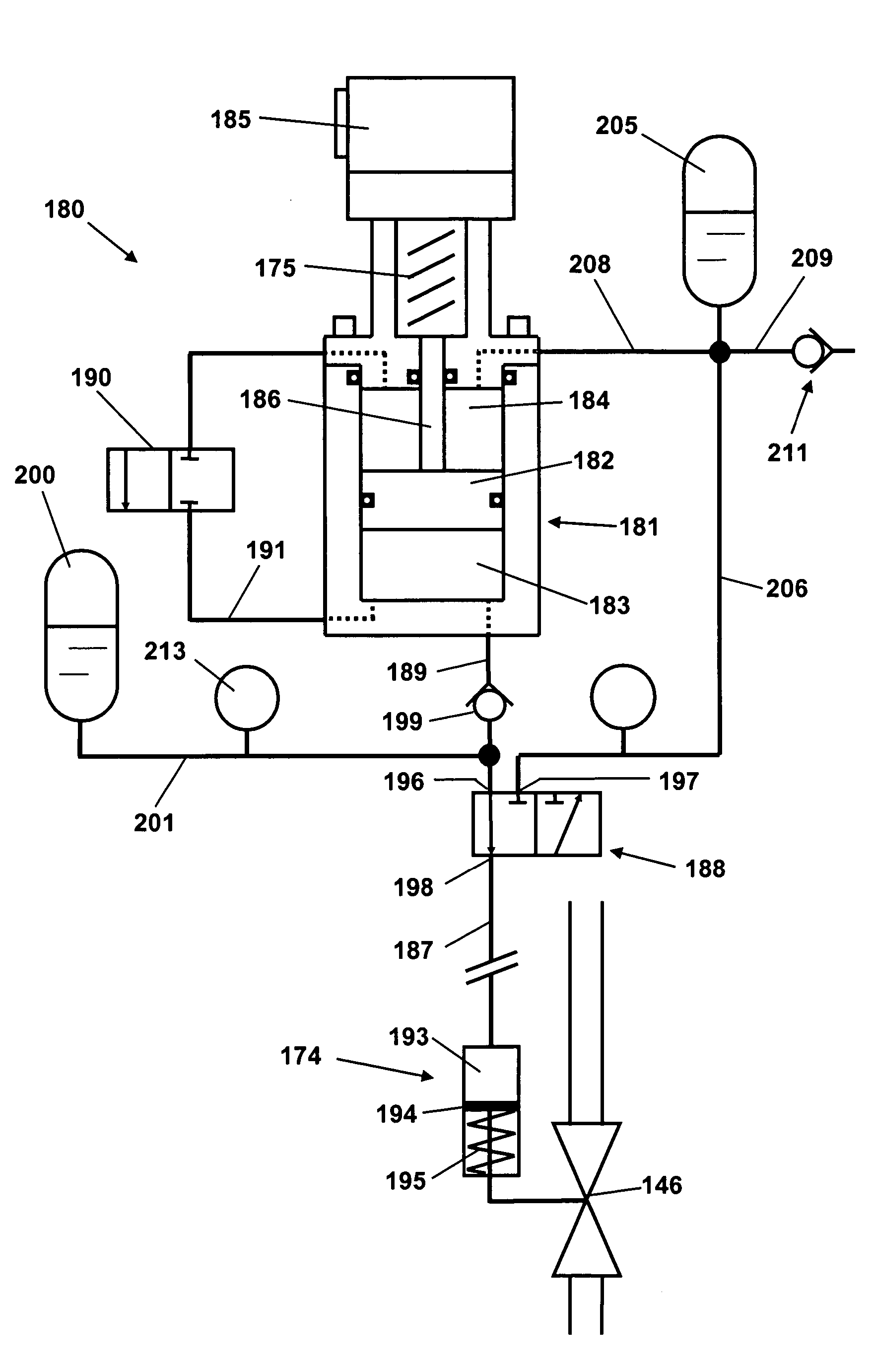

Magnetically sequenced pneumatic motor

A pneumatic motor having a piston and a magnetically actuated valve. The magnetically actuated valve may be adjacent the piston and, in some embodiments, include a spool valve.

Owner:CARLISLE FLUID TECH INC

System for controlling a hydraulic actuator, and methods of using same

The present invention is directed to a system for controlling a hydraulic actuator, and various methods of using same. In one illustrative embodiment, the system comprises a first hydraulic cylinder, an isolated supply of fluid provided to the first hydraulic cylinder, the isolated supply of fluid positioned in an environment that is at a pressure other than atmospheric pressure, an actuator device coupled to the first hydraulic cylinder, the actuator device adapted to drive the first hydraulic cylinder to create the sufficient pressure in the fluid, and at least one hydraulic line operatively intermediate the first hydraulic cylinder and the hydraulic actuator, the hydraulic line supplying the sufficient pressure in the fluid to the hydraulic actuator in the remote locale.

Owner:FMC TECH INC

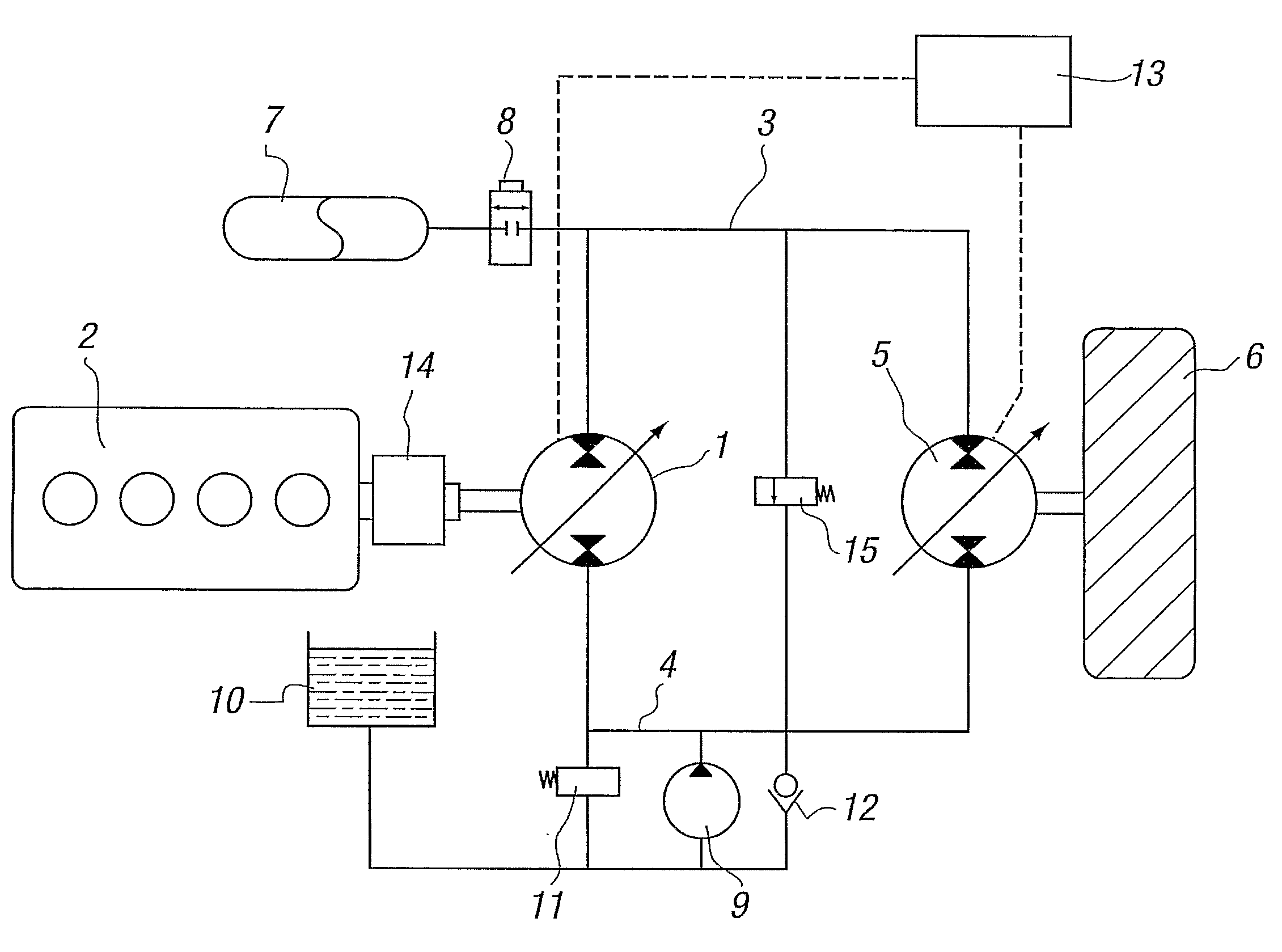

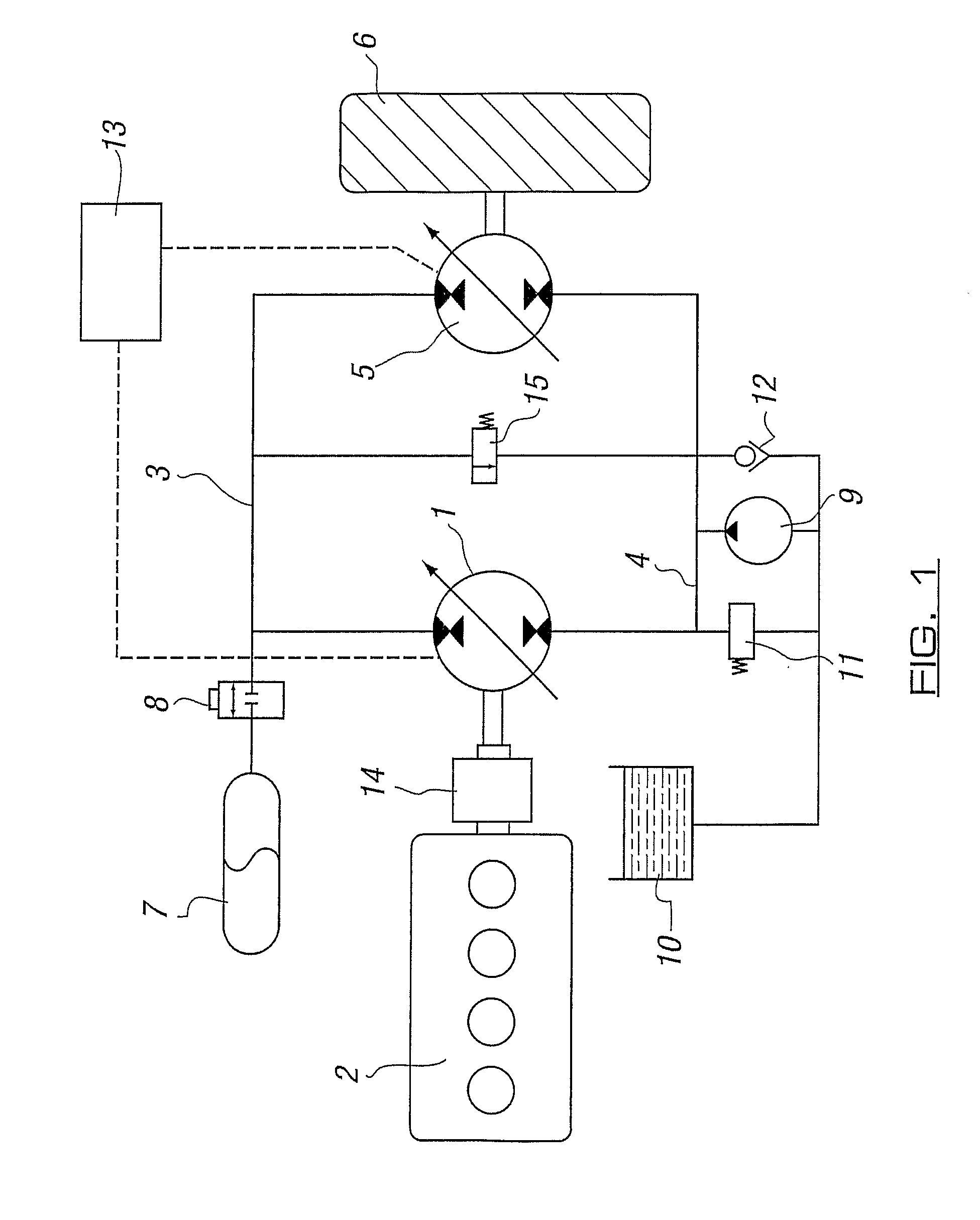

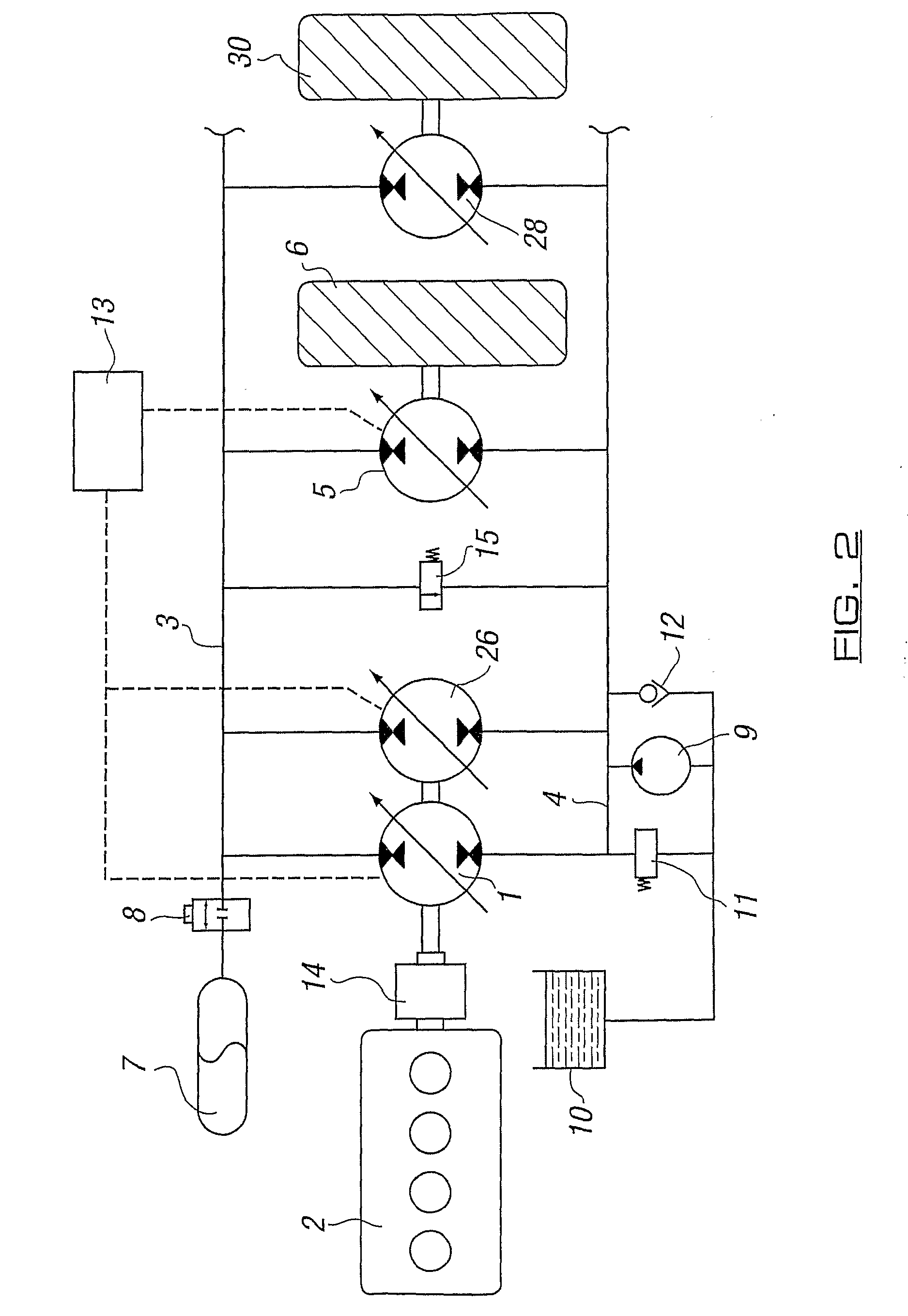

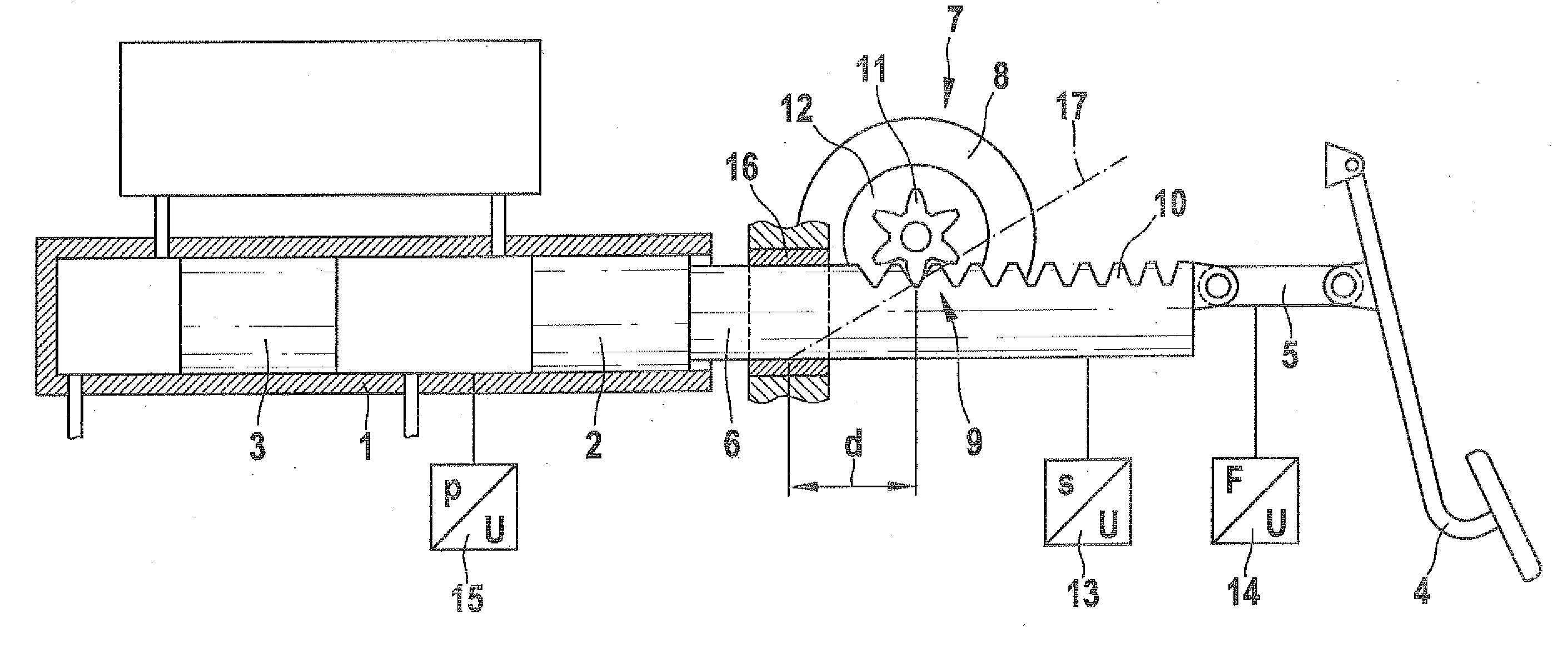

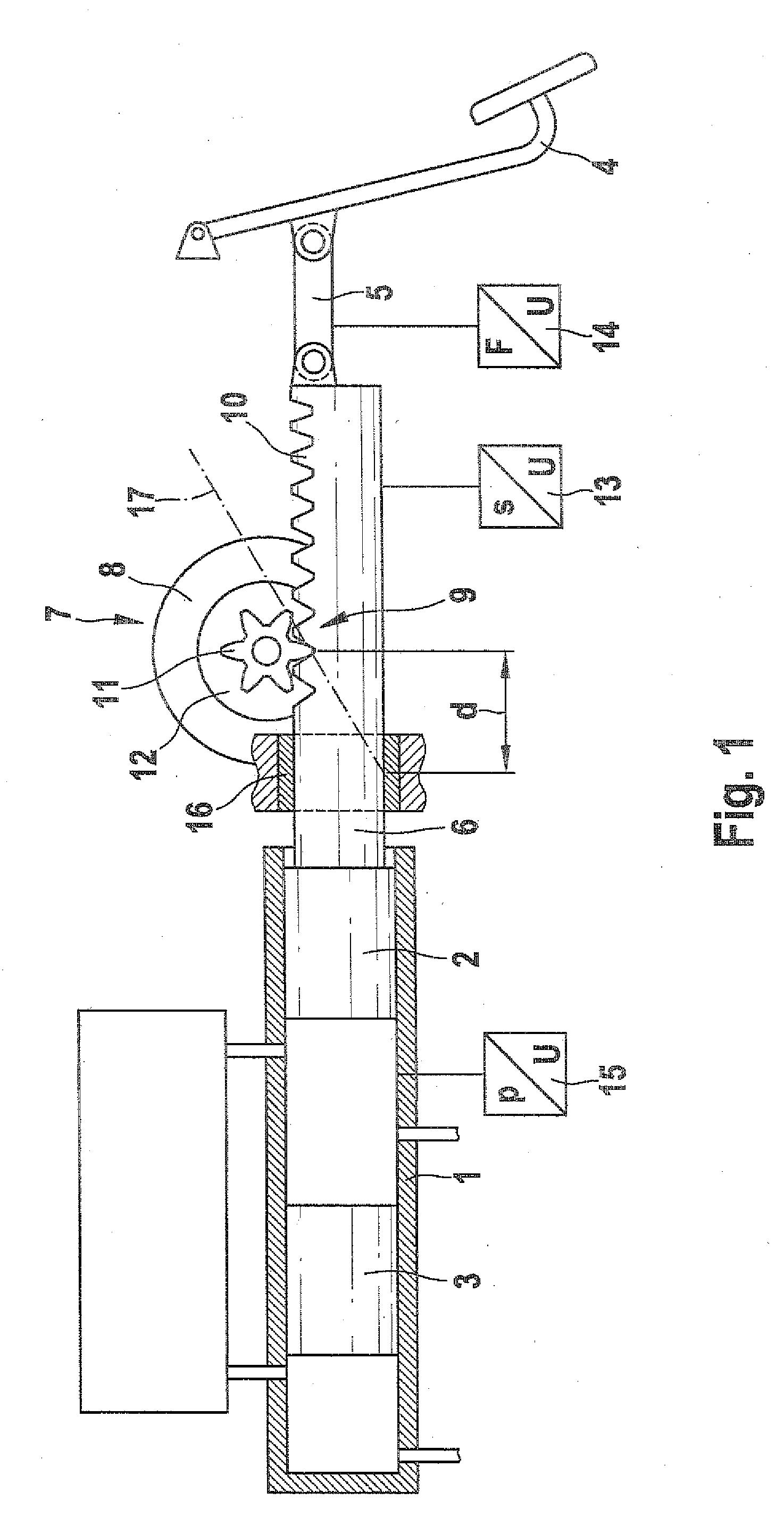

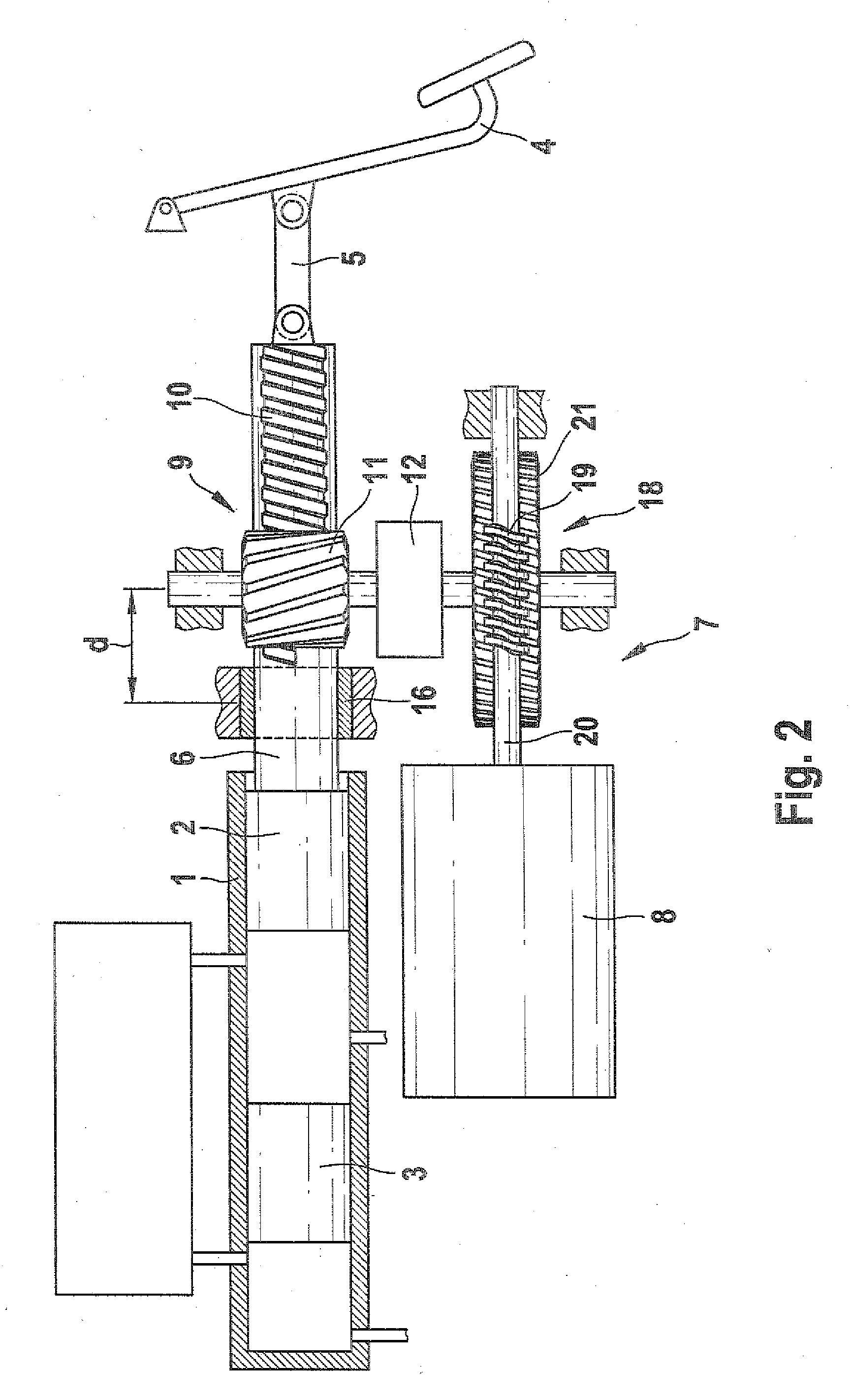

Hydrostatic regenerative drive system

InactiveUS20090210120A1Hydraulic connection is simplifiedAvoid the needDigital data processing detailsTelemotorsHigh pressurePressure controlled ventilation

A variable transmission comprises a first fluid working machine (1) for connection to a prime mover (2), a second fluid working machine (5) for connection to a mechanical load (6) and a fluid system linking the first and second working machines, the fluid system having a high-pressure side (3) and a low-pressure side (4) each connected to both said first and said second fluid working machines (1, 5), a fluid accumulator (7) on the high-pressure side, a means to admit fluid from the reservoir to the low-pressure side and a pressure control valve to maintain the correct pressure in the low-pressure side, wherein the second fluid working machine (5) includes chambers of variable volume having electronically controllable valves such that each of said chambers has pumping, motoring and idling modes of operation, and the second fluid working machine (5) is operable to both source fluid to and sink fluid from each of said high-pressure side (3) and said low-pressure side (4).

Owner:ARTEMIS INTELLIGENT POWER

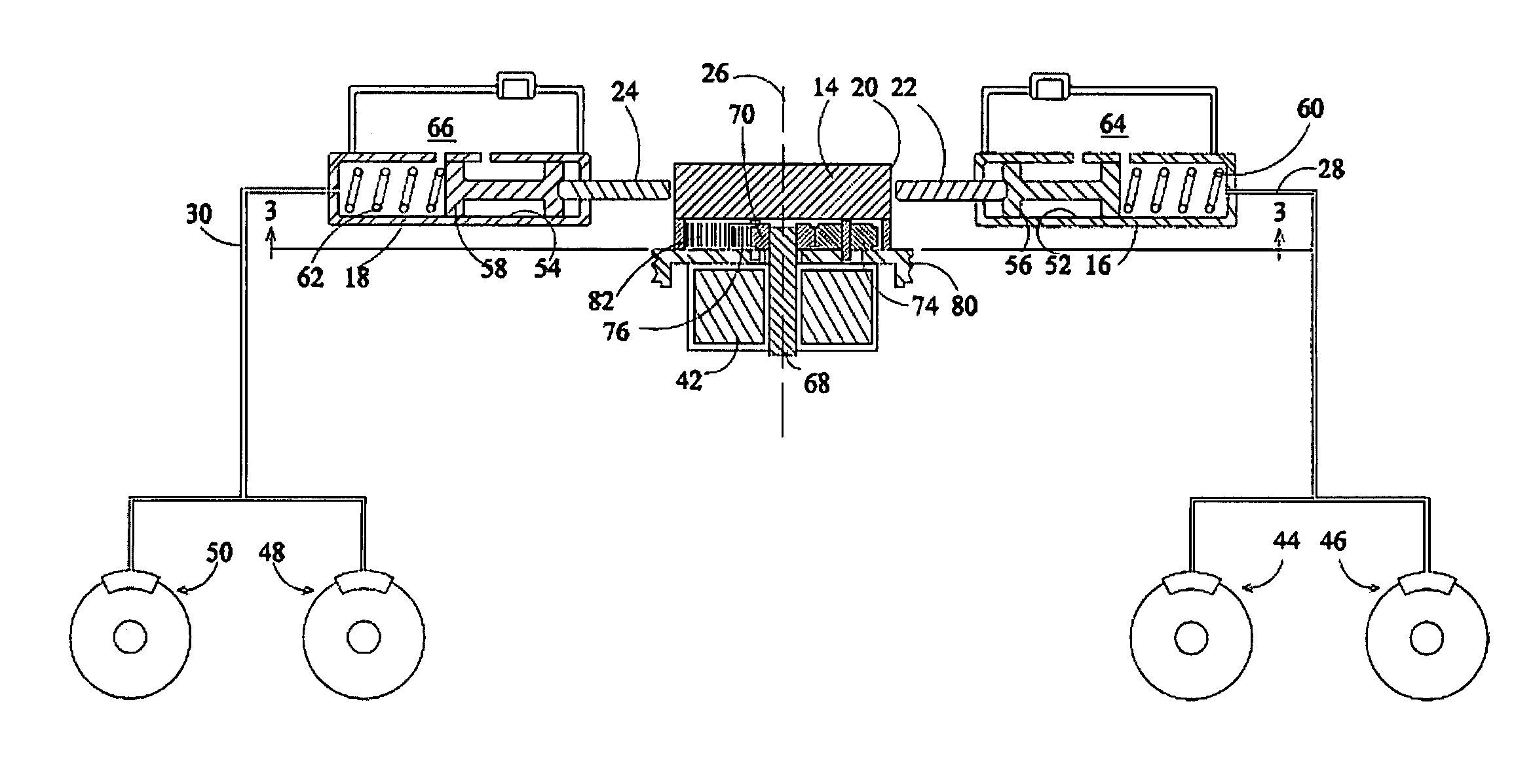

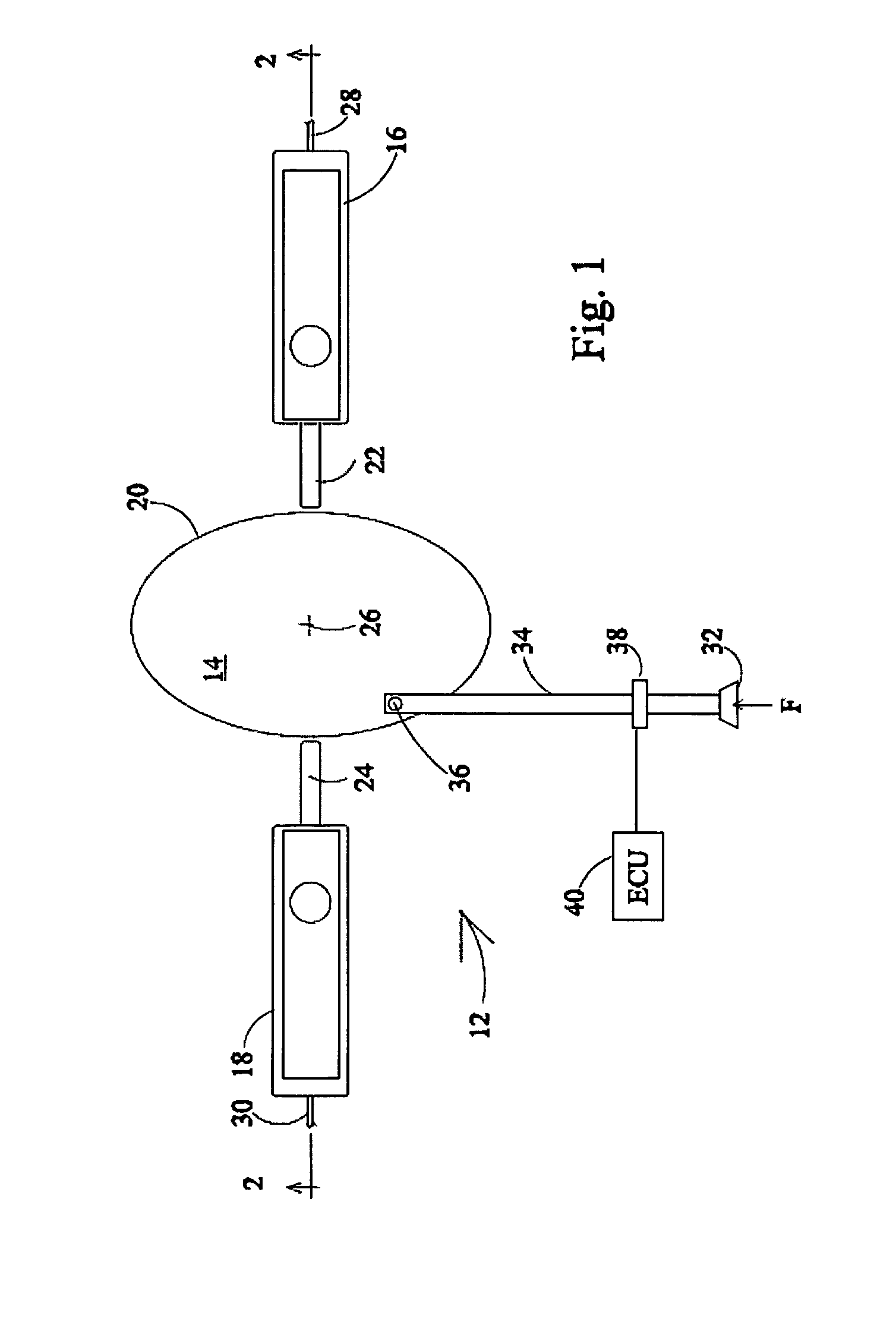

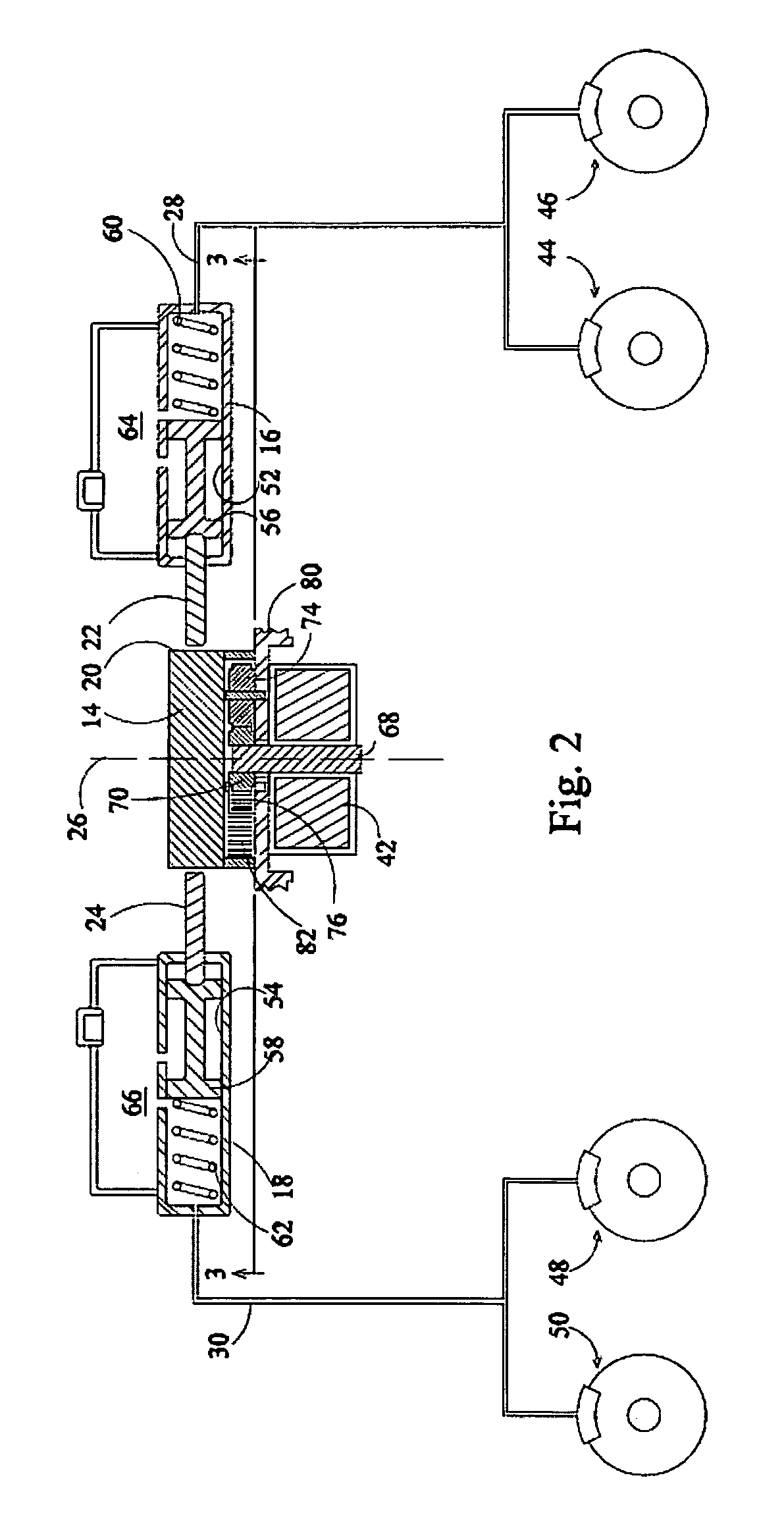

Eccentric cam brake booster

ActiveUS8069662B1Reduce noiseIncrease buff effectRotary clutchesFoot actuated initiationsPower flowMaster cylinder

An electric power booster (12) where driver command is monitored by a transducer (38) on an input rod (34). This signal is converted to the appropriate voltage / current and operates an electric motor (42). The motor output shaft (68) is connected to a planetary gear reducer (72) appropriately sized to provide no more than + / −1 / 4 turn of an eccentric cam (14). Two master cylinders (16, 18) power piston rods (22, 24) ride diametrically opposed on the cam surface (20). As the cam rotates the piston rods are forced out pressurizing the respective hydraulic circuits and thereby providing fluid to each brake circuit (28, 30). In the event of power failure as well as to augment the output of the motor, the input rod is mechanically linked directly to the cam offset from the center allowing the driver to manually rotate the cam thereby pressurizing the brake circuits.

Owner:ROBERT BOSCH CORP +1

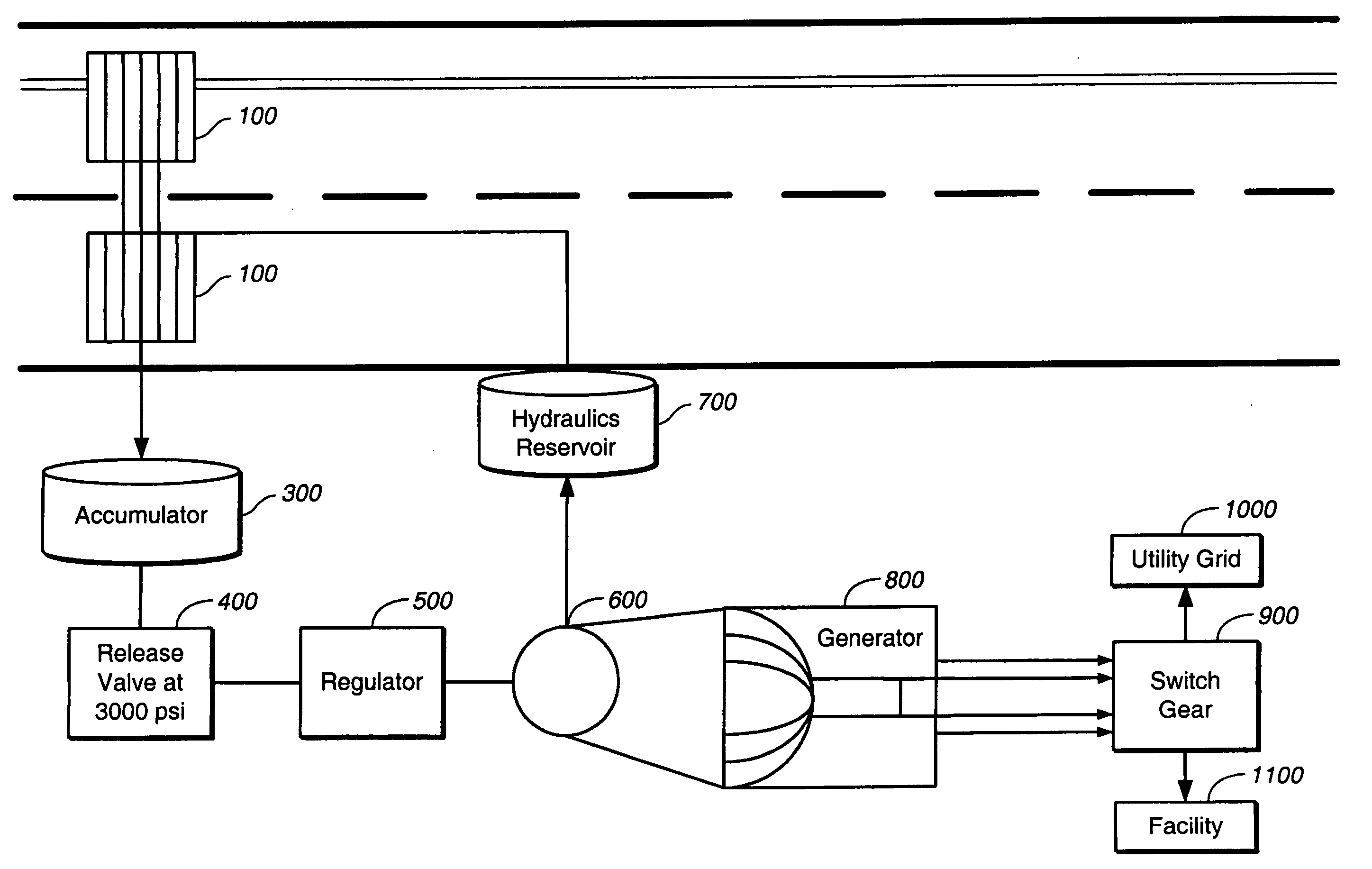

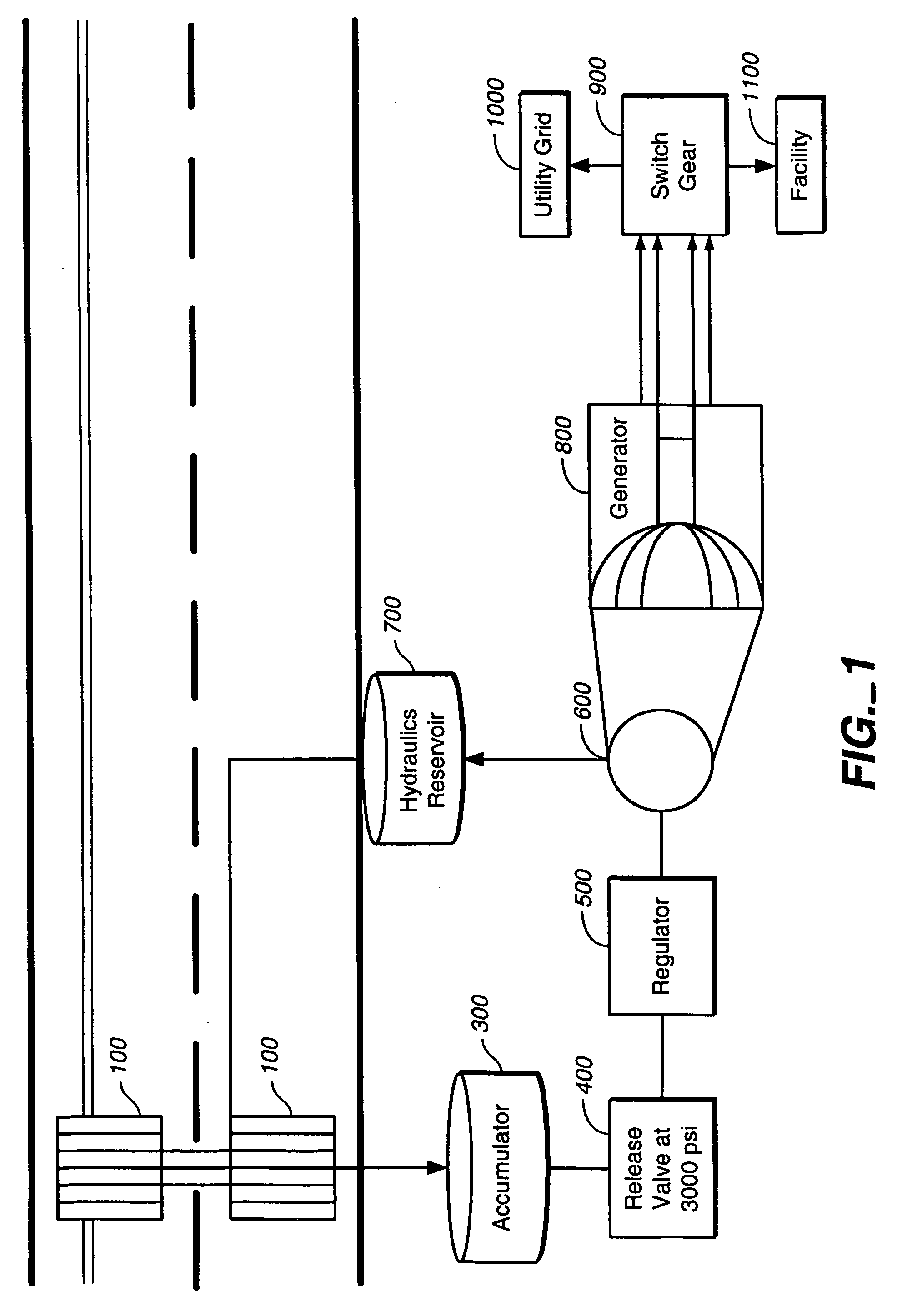

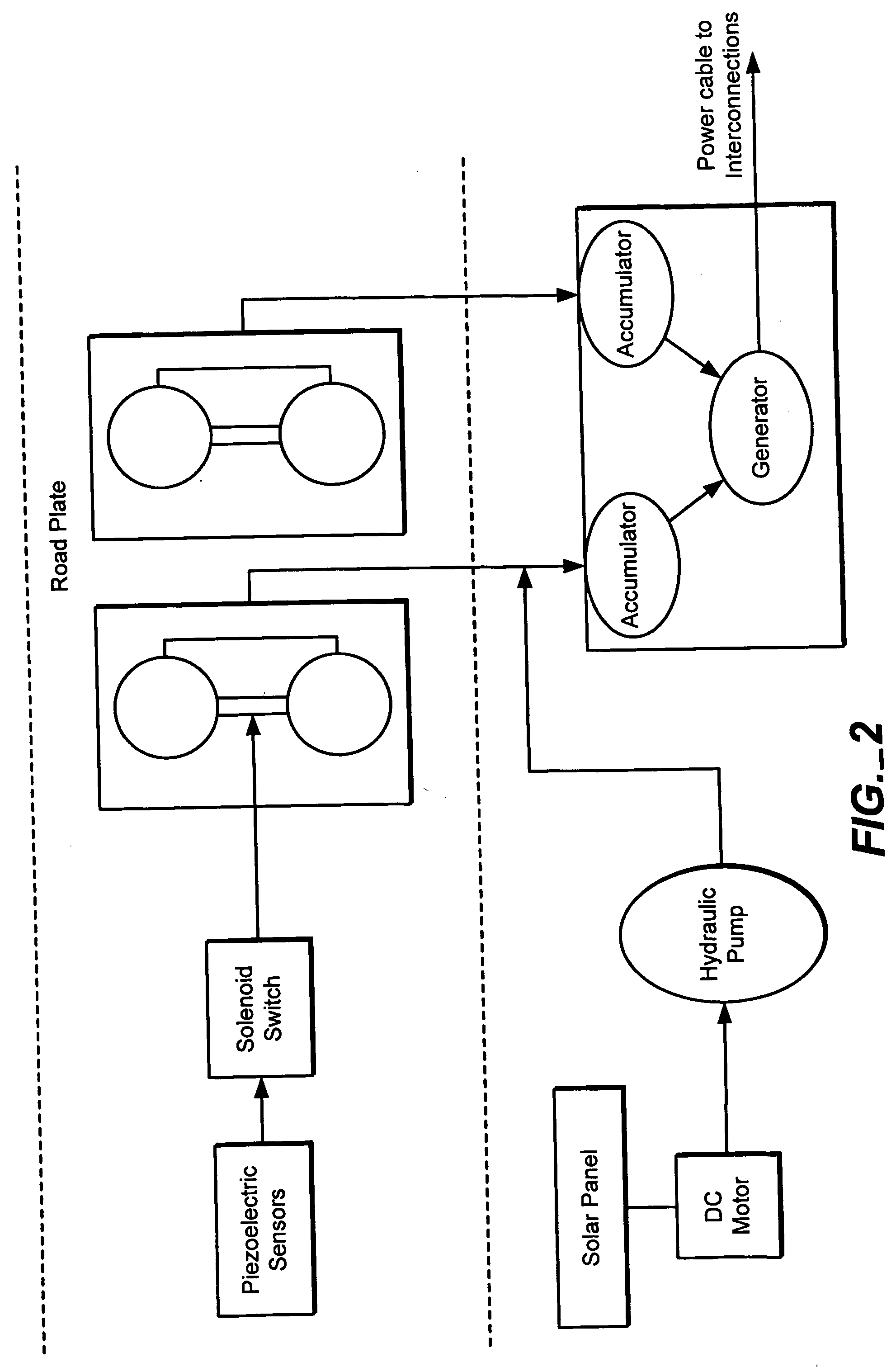

System and method for electrical power generation utilizing vehicle traffic on roadways

The present invention relates to methods and systems for power generation including a method and system for electrical power generation by utilizing forces due to vehicle weights from traffic on roadways. An embodiment of the invention uses multiple compressible hydraulic cylinders of different types, the cylinders used being dynamically selected responsive to the various weights of the vehicles presenting.

Owner:KENNEY TERRY DOUGLAS

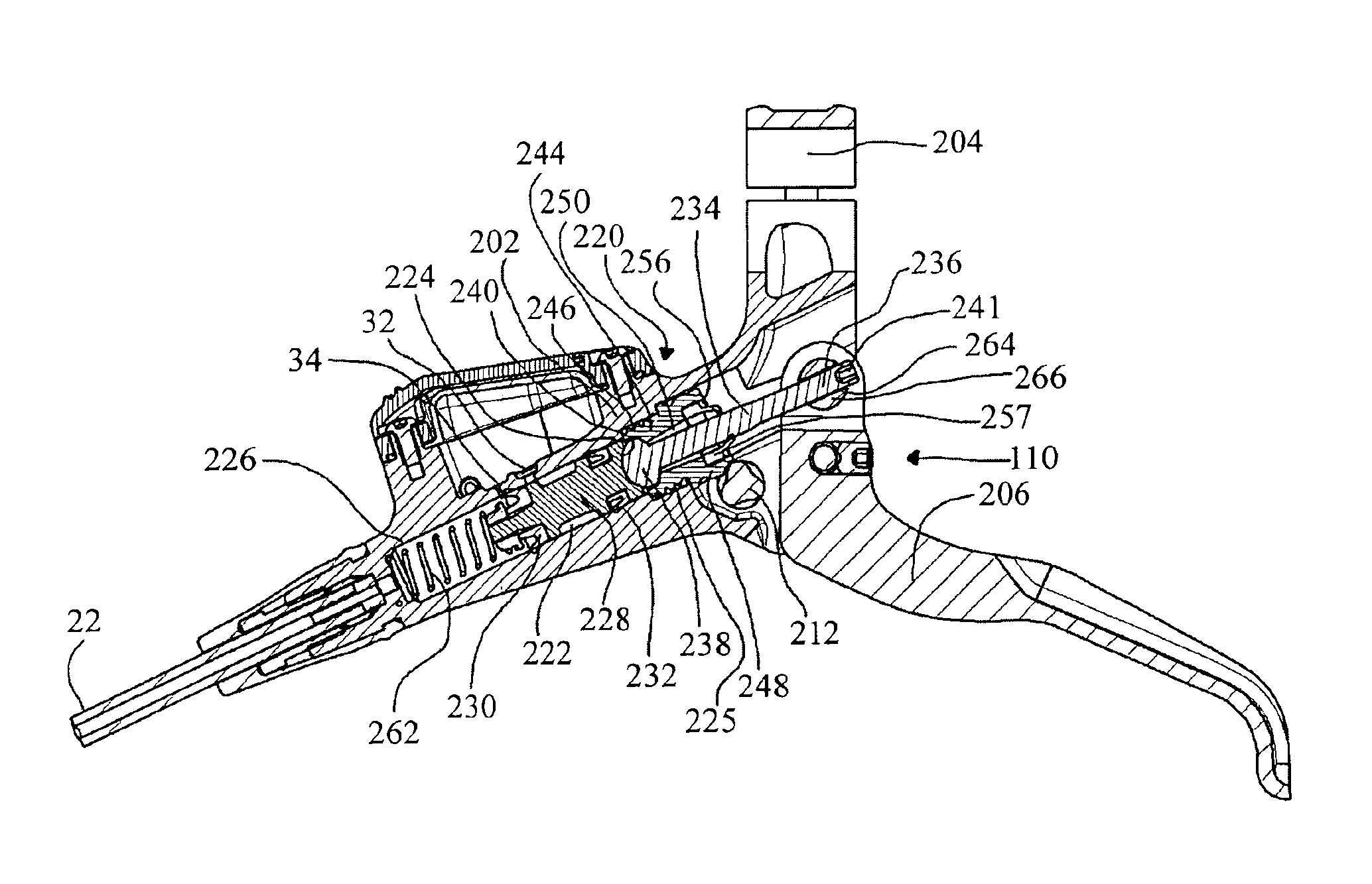

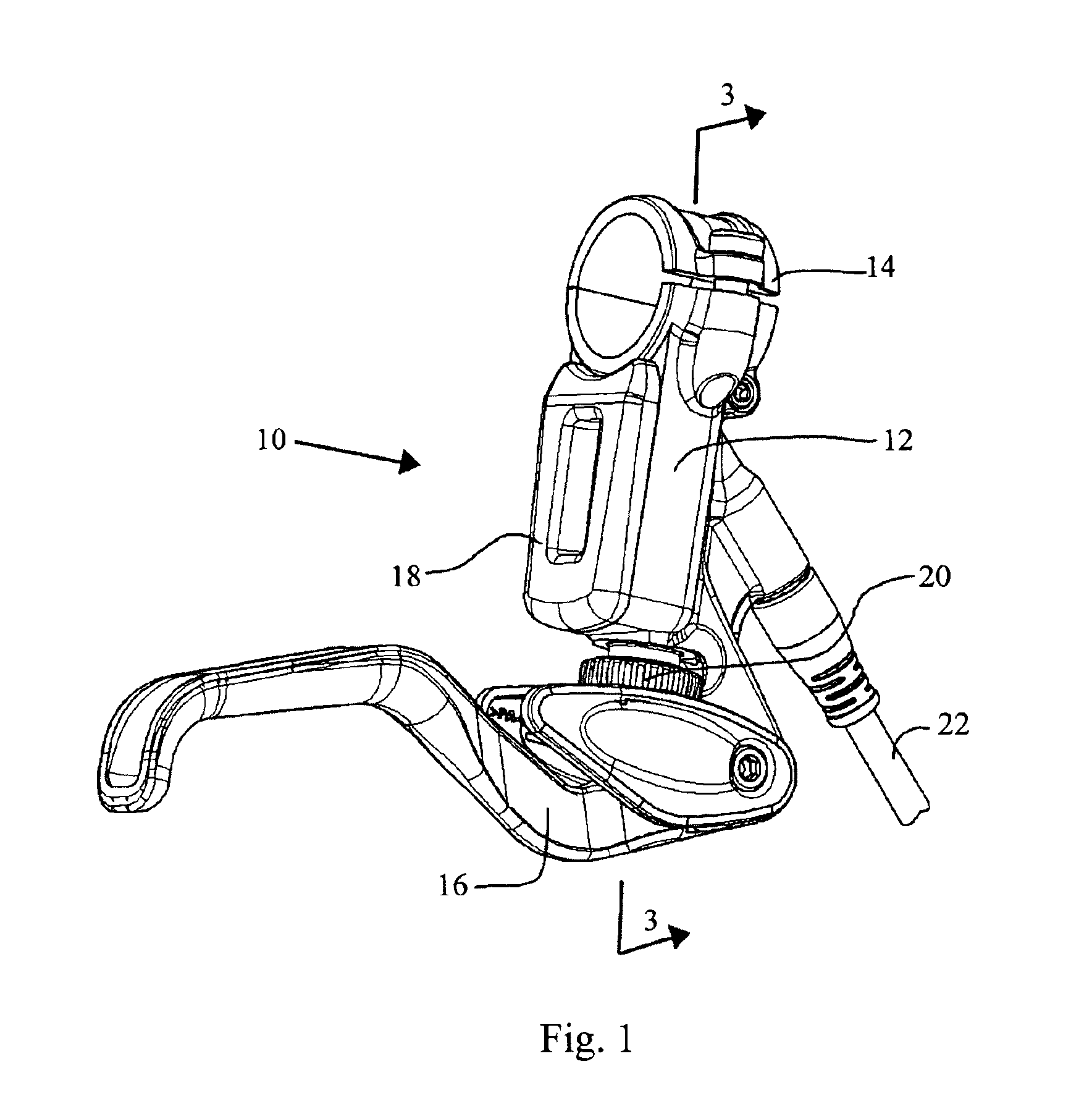

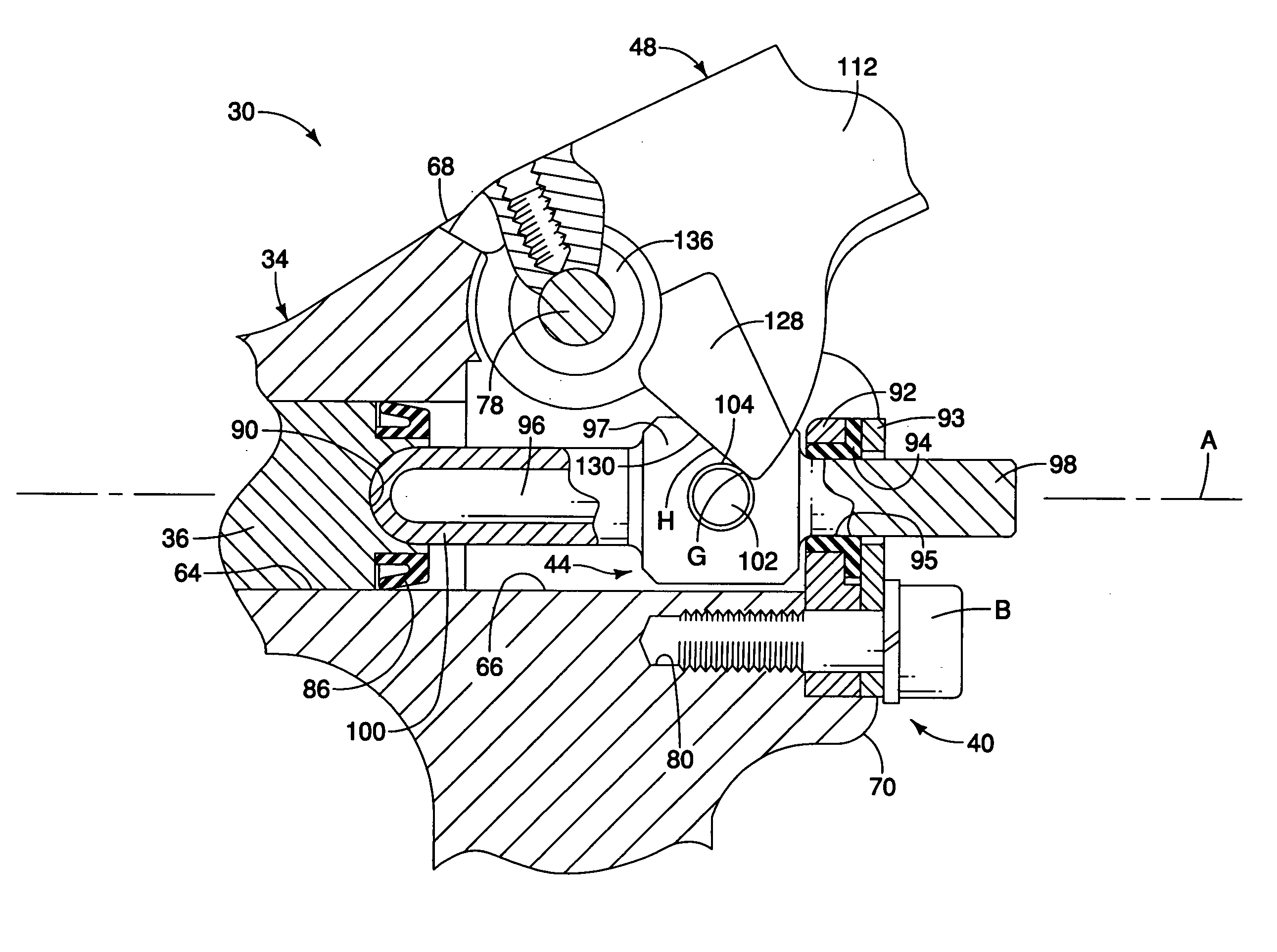

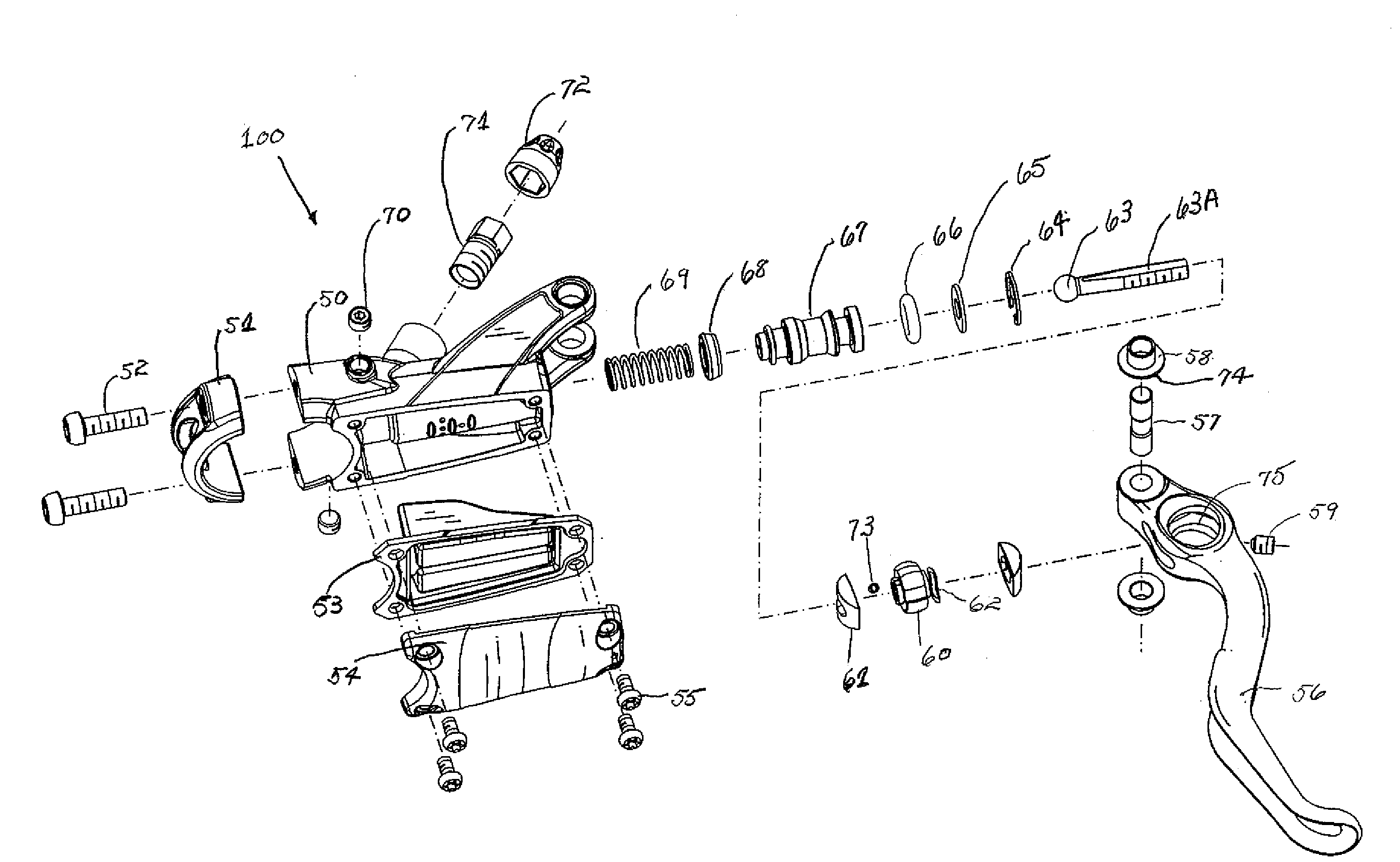

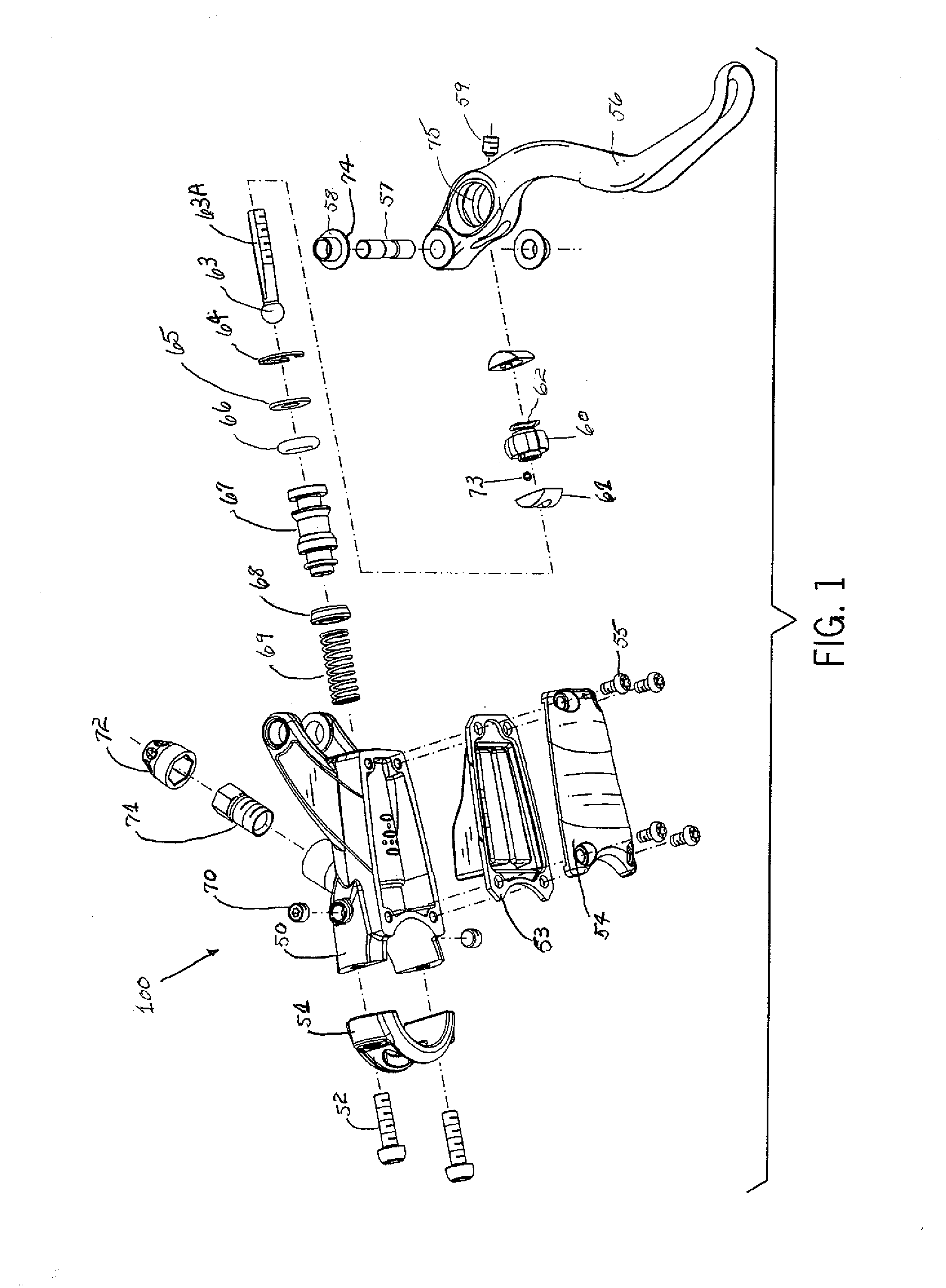

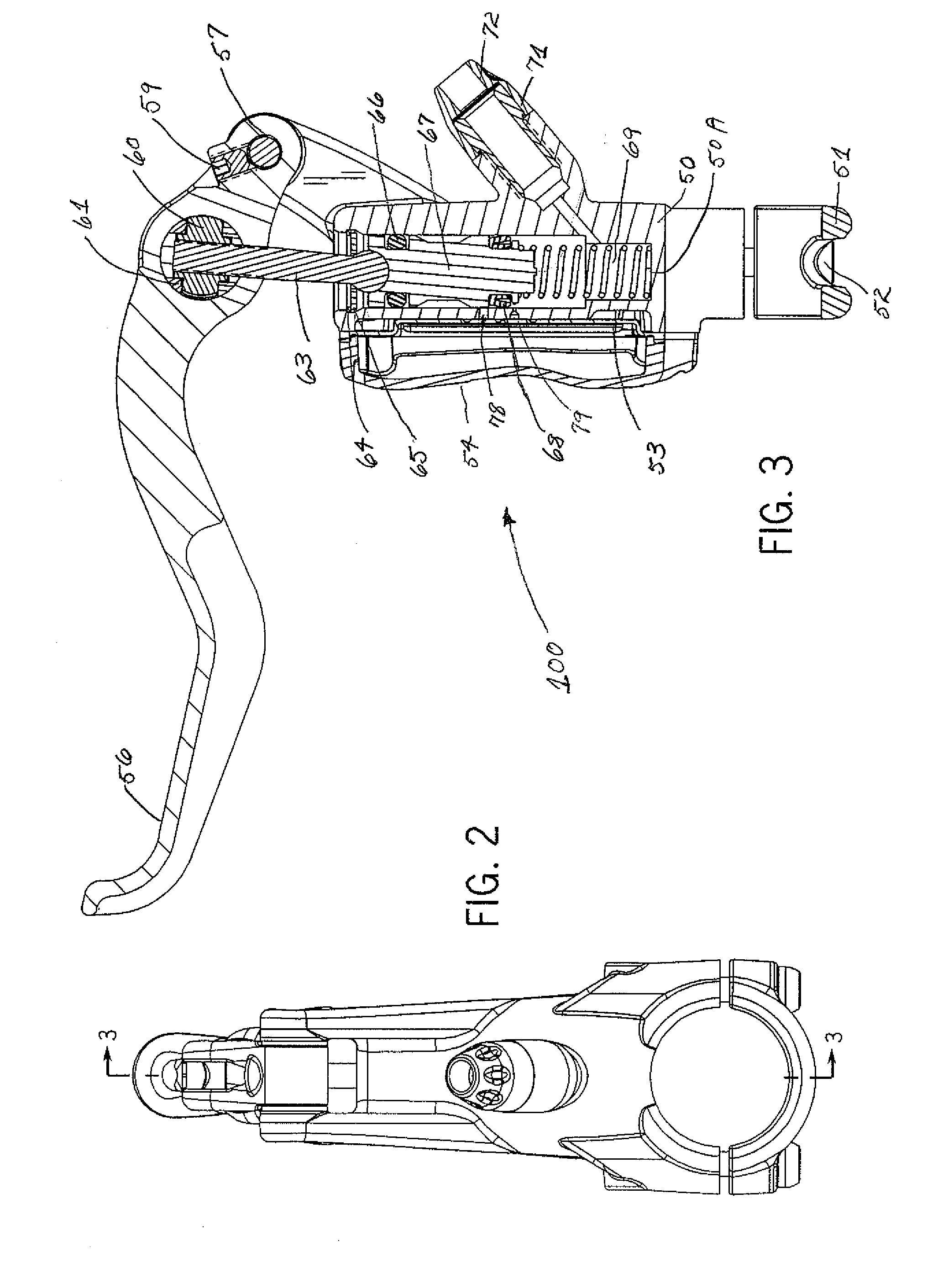

Reach adjustment mechanism for a master cylinder lever of a hydraulic disc brake

InactiveUS6957534B2Prevent unwanted changesIncreasing costControlling membersRotary clutchesRest positionMaster cylinder

A master cylinder for a hydraulic disc brake includes a housing defining a cylinder, the cylinder having a first and second end along its axis. A piston is received in the cylinder and has a radial seal between the piston and the cylinder. A lever is pivotably associated with the housing for pivoting between a rest position and an actuated position relative to the housing. A push rod is operatively associated with the piston and the lever to move the piston axially within the cylinder as the lever is actuated between the rest and actuated positions. A threaded engagement between a first end of the push rod and the lever is configured to cause movement of the rest position of the lever relative to the housing when a rotating force is applied to the push rod causing axial rotation of the push rod. An indexing structure is operatively associated with the push rod for providing index axial rotation of the push rod upon application of the rotating force to the push rod causing axial rotation of the push rod.

Owner:SRAM CORPORATION

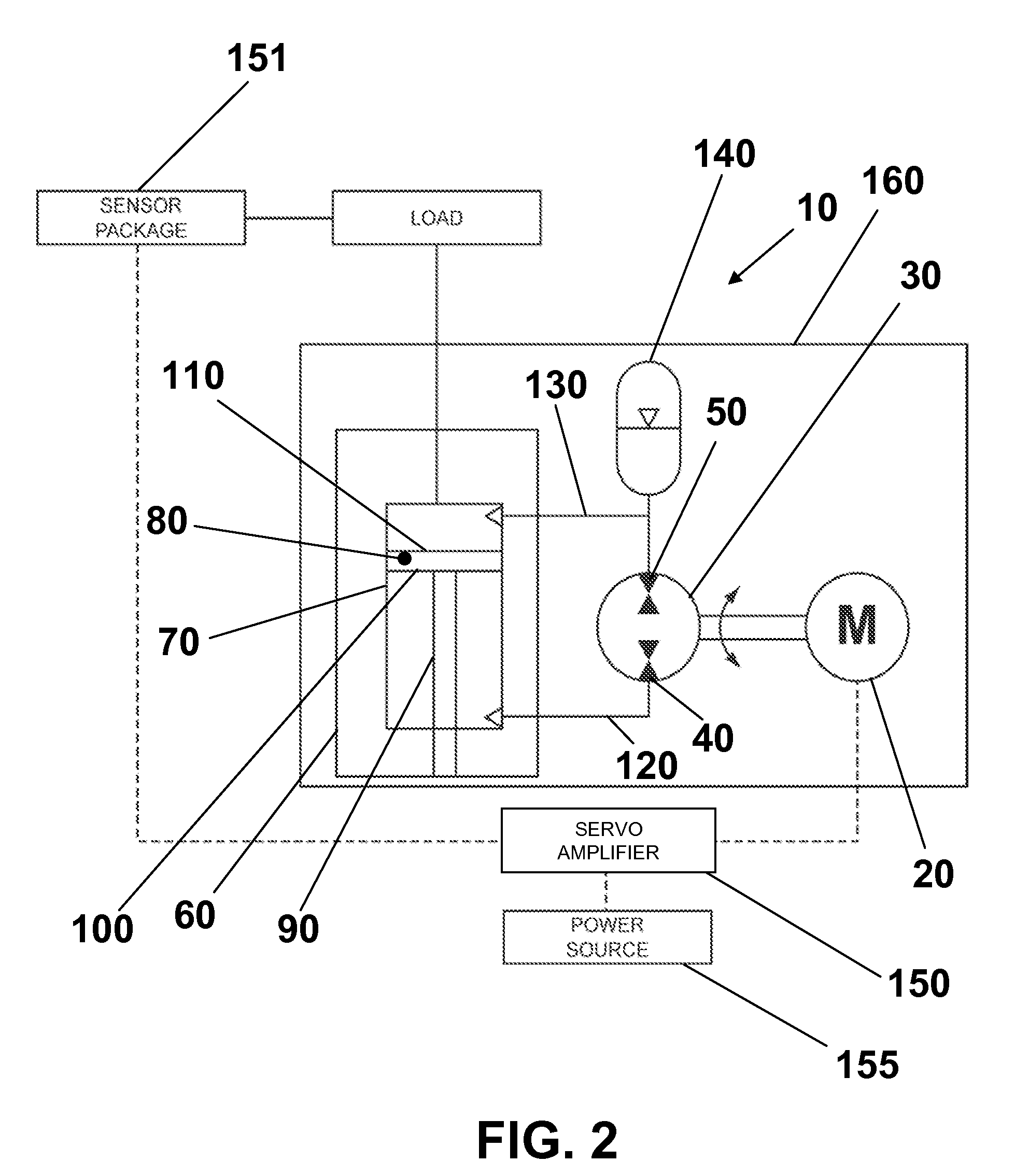

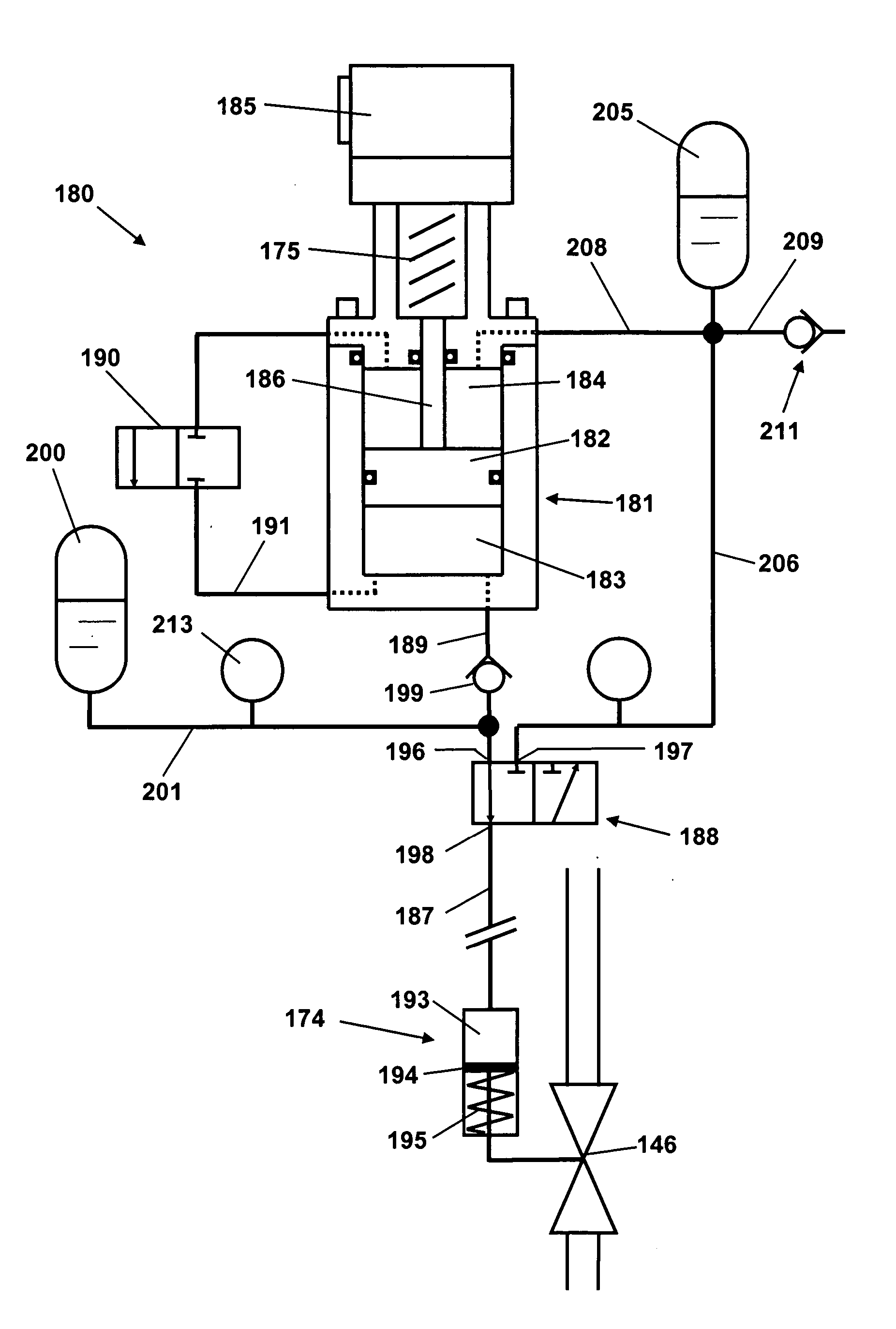

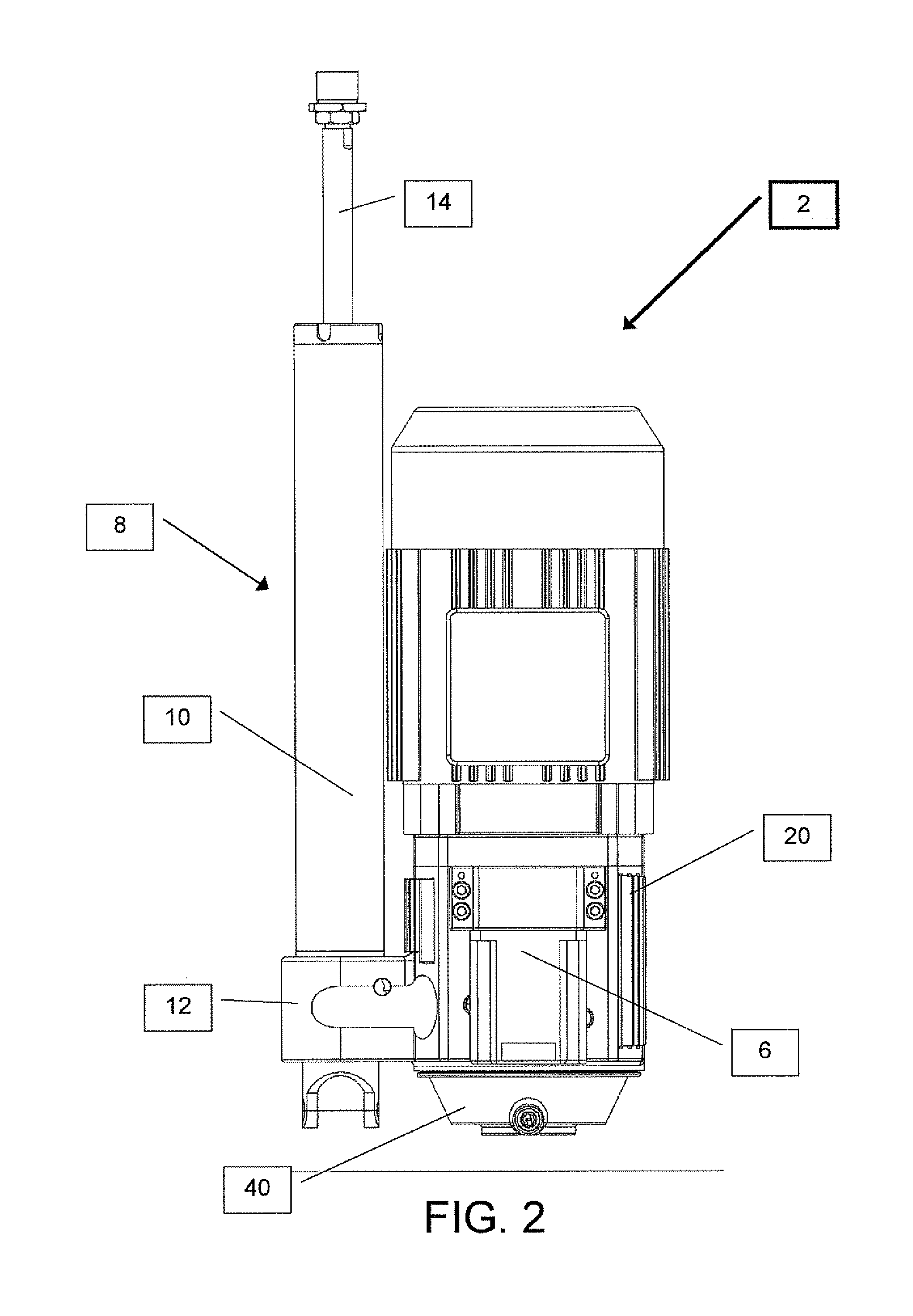

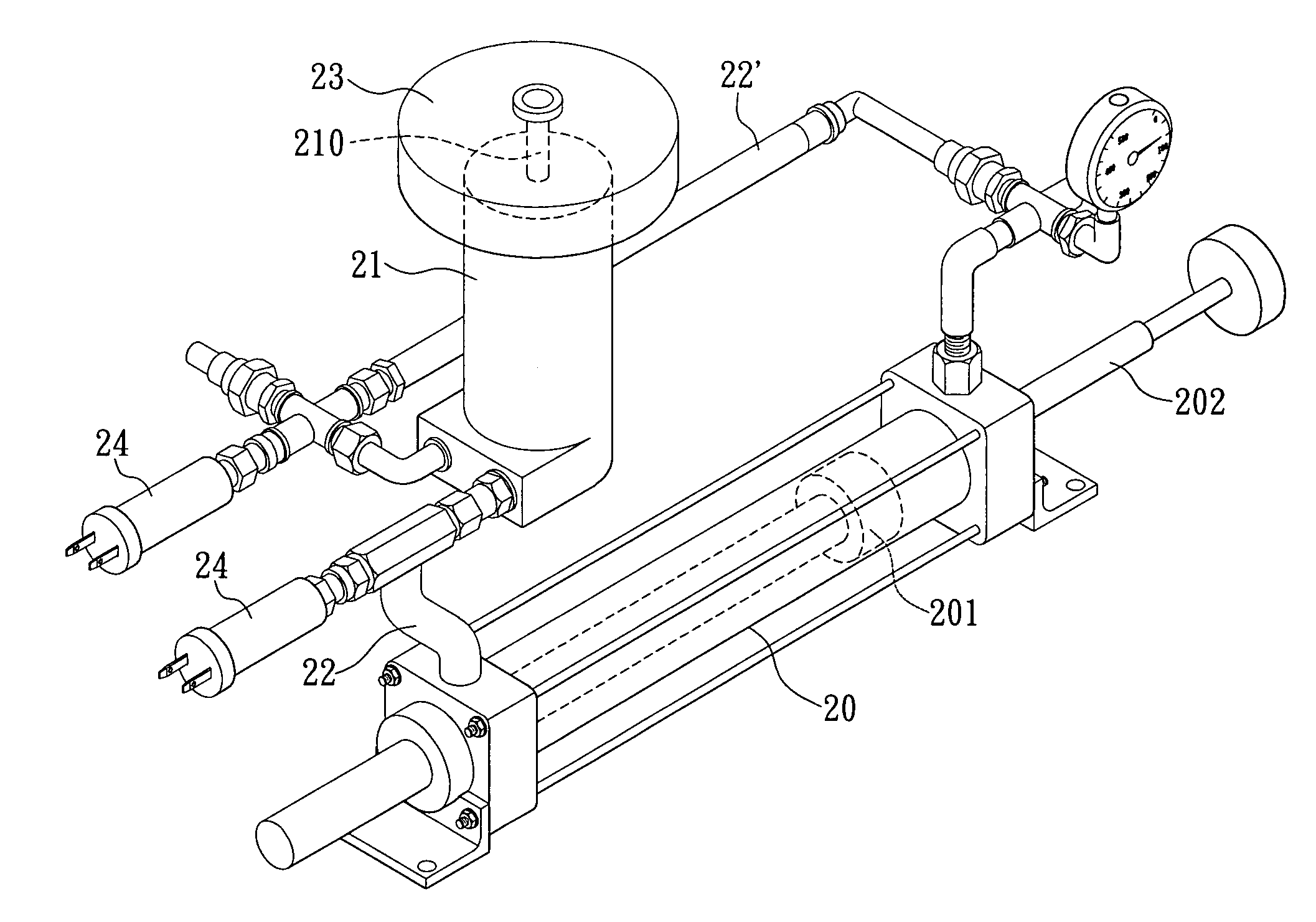

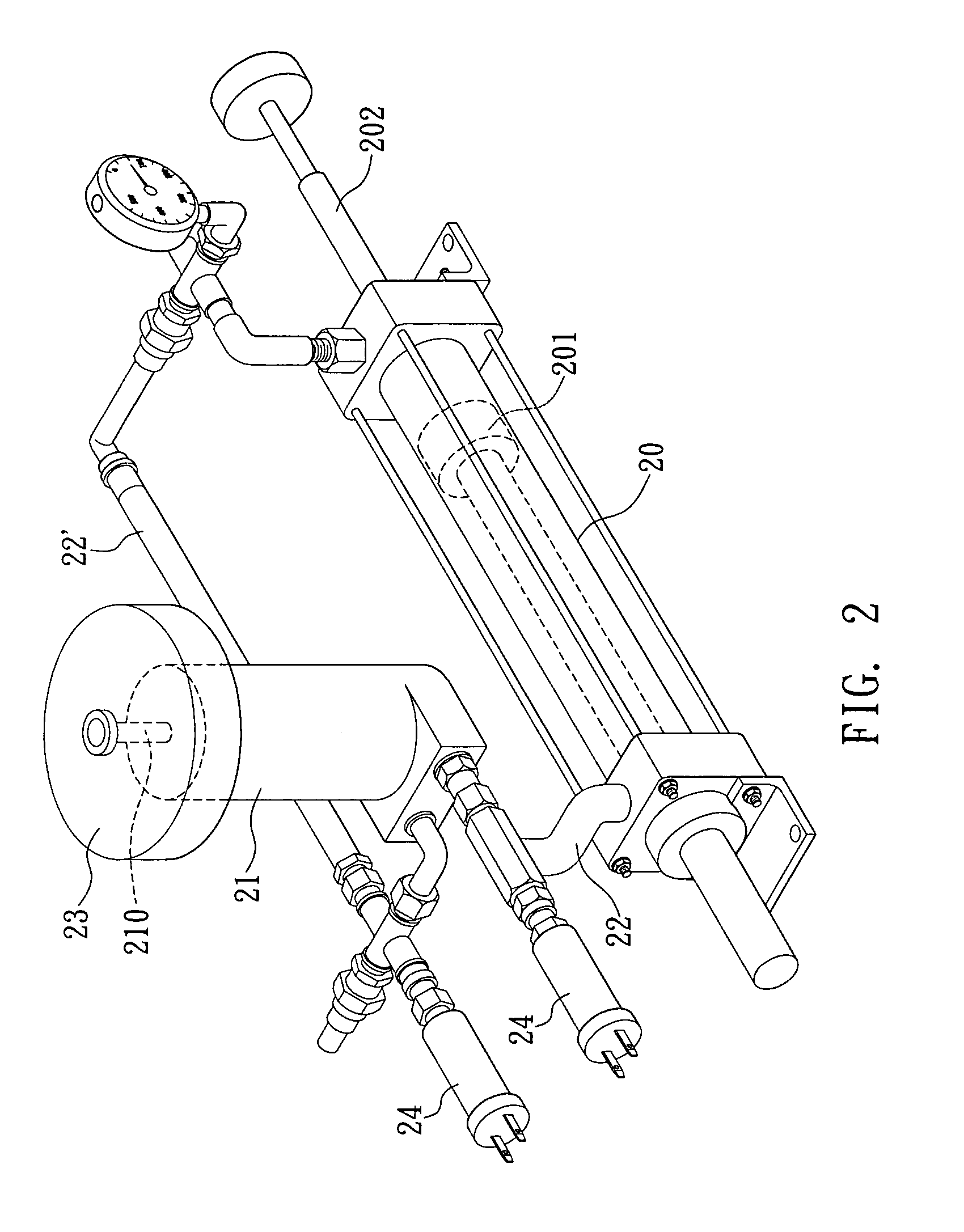

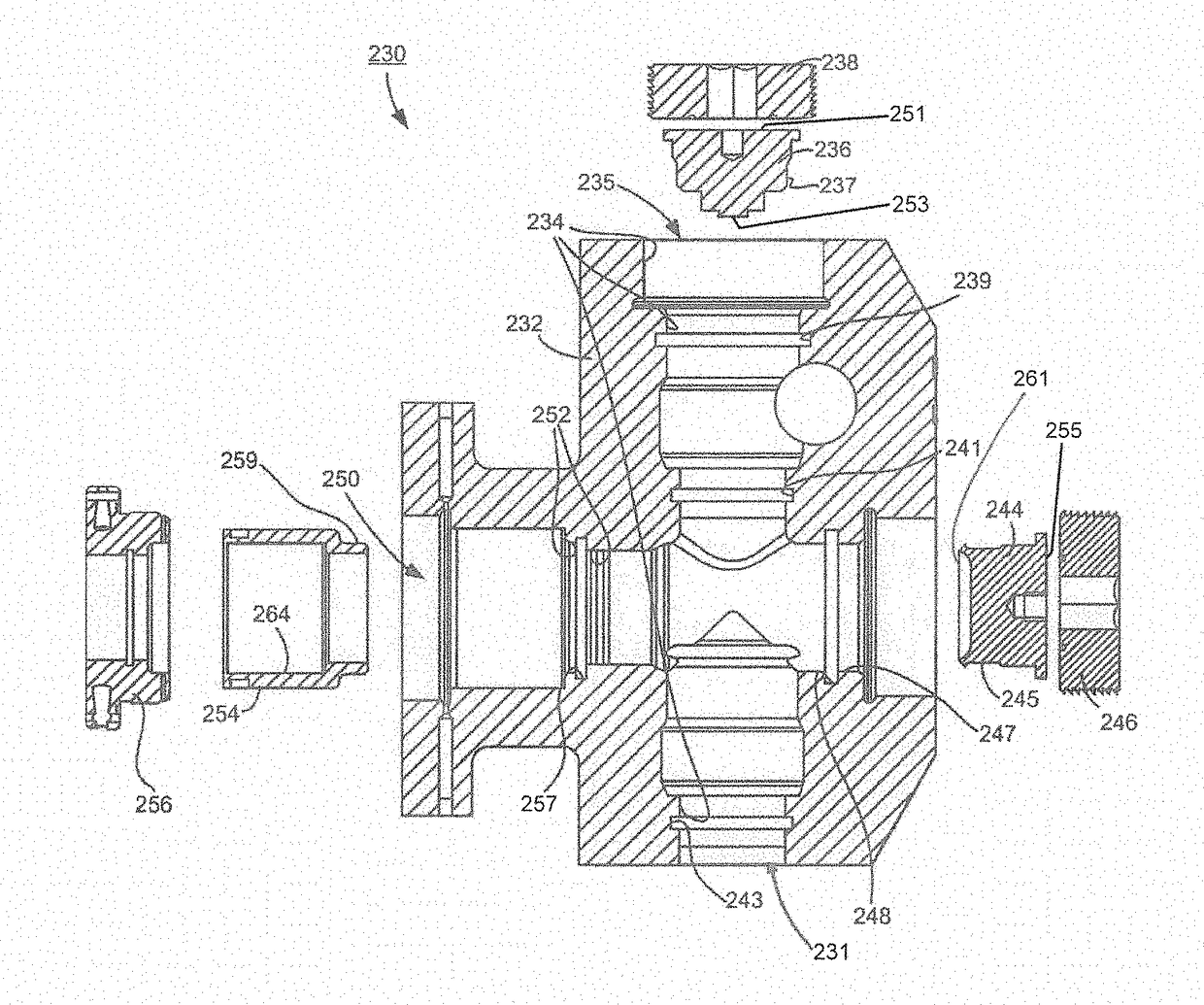

Self-Contained Hydraulic Actuator System

The hydraulic linear actuator system of the present invention includes a pump that is configured to rotate in a single direction at a substantially constant velocity. Both the direction and flow rate of fluid through the system is controlled by adjusting the positional relationship between the stator and the rotor of the pump. This positional relationship is adjustable between a forward flow state, a non-flow state and a reverse flow state. The hydraulic linear actuator is responsive to the flow of fluid through the system so as to be displaced in a first direction by the forward flow state of the pump and in a second direction by the reverse flow state of the pump.

Owner:A A TECH & I P +1

Electromechanical brake booster

InactiveUS20100126167A1Little strengthReduce the risk of injuryBraking action transmissionRotary clutchesFreewheelMaster cylinder

The invention relates to an electromechanical brake booster for a master brake cylinder of a hydraulic vehicle braking system. The invention provides to configure the brake booster such that it preferably includes a switchable freewheel, which enables an actuation of the master brake cylinder without any movement of the electric motor of the brake booster. The invention further provides to configure the brake booster such that it includes a mechanical gear having a variable transmission ratio, which has a high path transmission at the beginning of an actuation of the master brake cylinder, and a force transmission that rises with increasing actuation. A variable gear ratio is possible using a rack and pinion gear, the toothed rack of which has a soothing with a pitch that changes across the length of the toothed rack. A further possibility of a mechanical gear having a variable ratio is a toggle lever mechanism.

Owner:ROBERT BOSCH GMBH

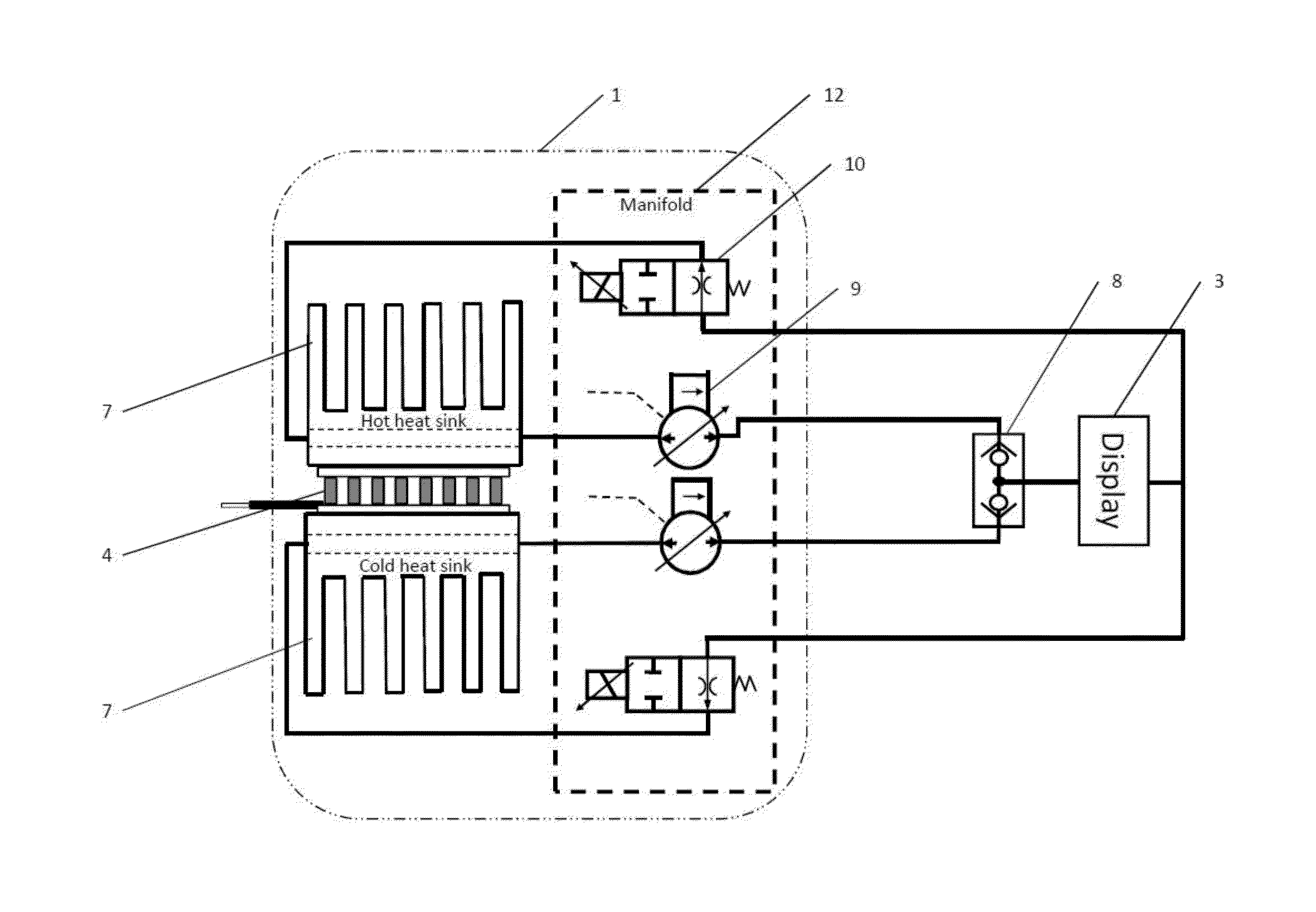

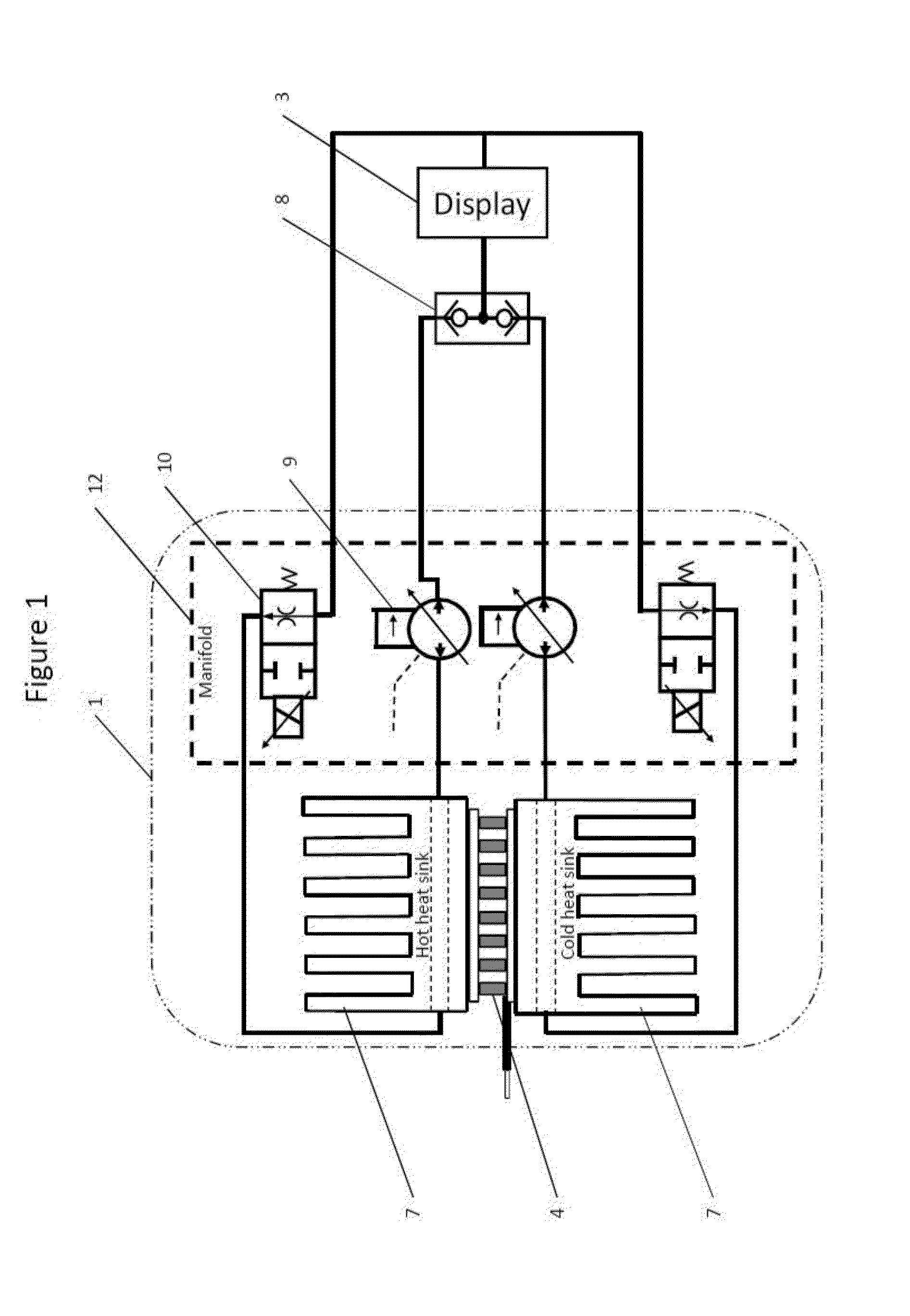

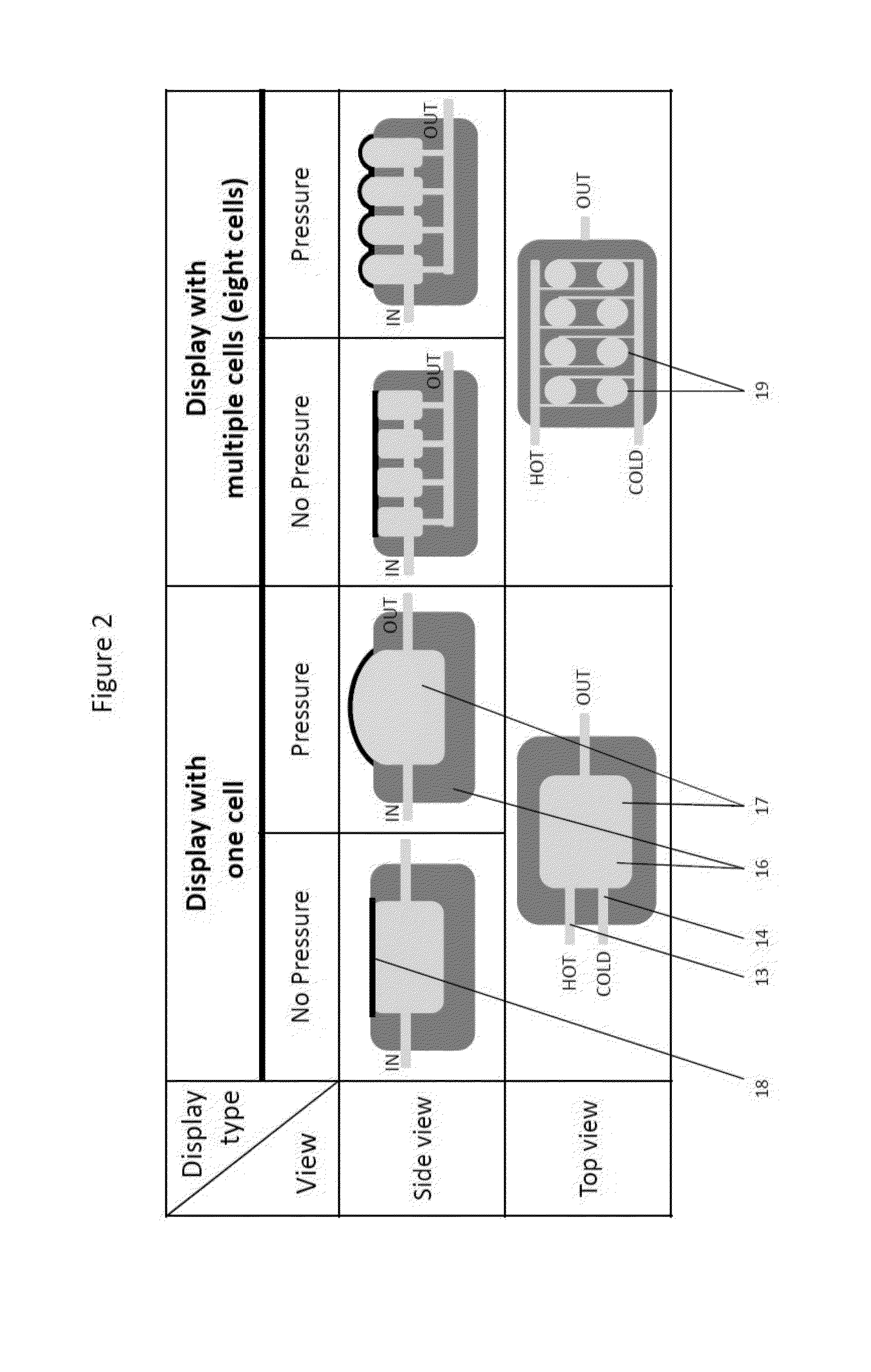

Multimodal Haptic Device, System, and Method of Using the Same

ActiveUS20160238040A1Increased haptic fidelityPneumatic massageVibration massageDisplay deviceClosed loop

A multimodal haptic device operating as a closed-loop system, the device including a pipeline configured to allow a closed-loop flow of a fluid medium, a manifold operatively connected to the pipeline, the manifold having a pump and a valve to control and regulate a flow of the fluid medium along the pipeline, and a display unit operatively connected to the pipeline, the display unit having a tactile display and a valve operatively connected to the tactile display for regulating an efflux of the fluid medium from the tactile display into the pipeline.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

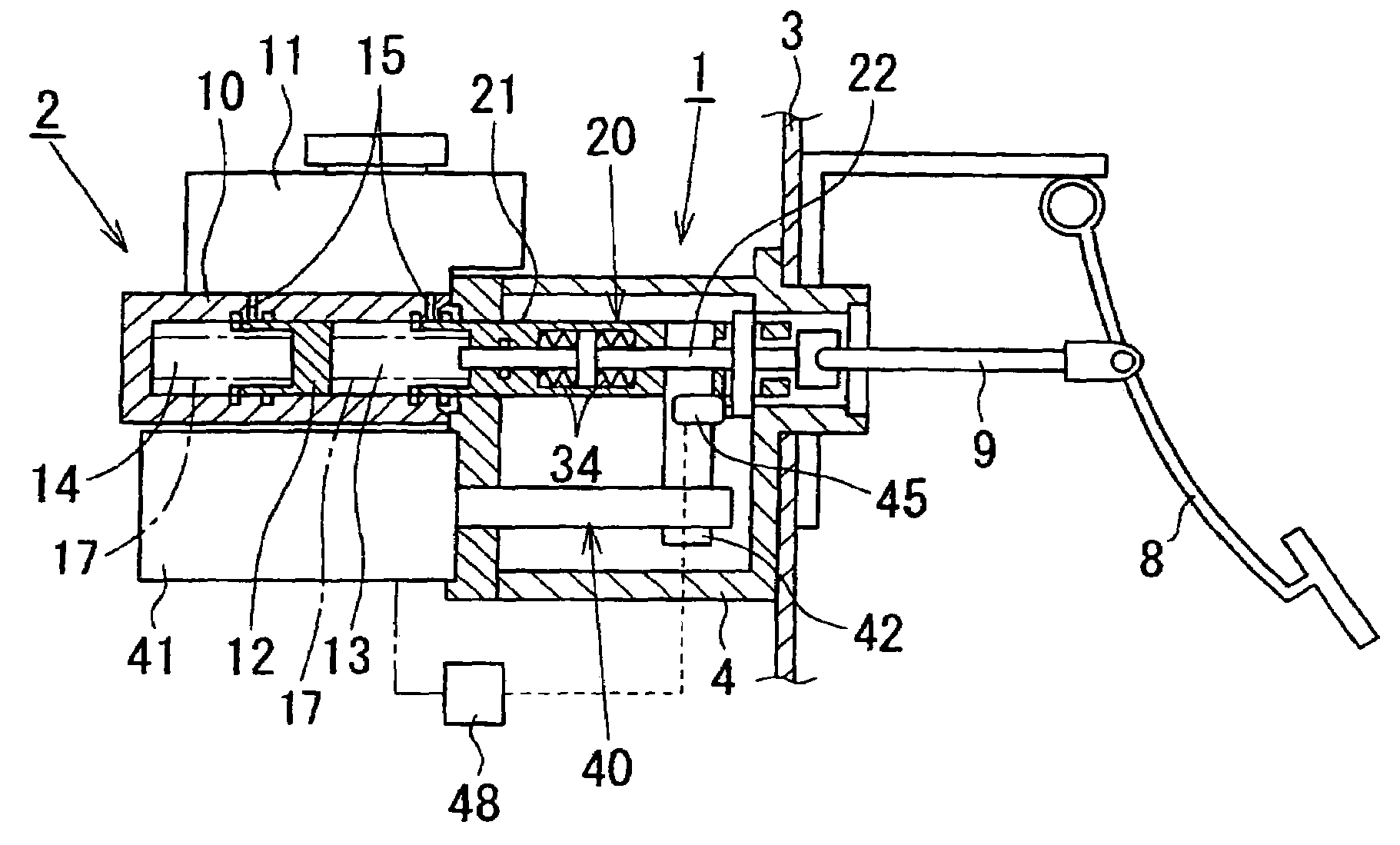

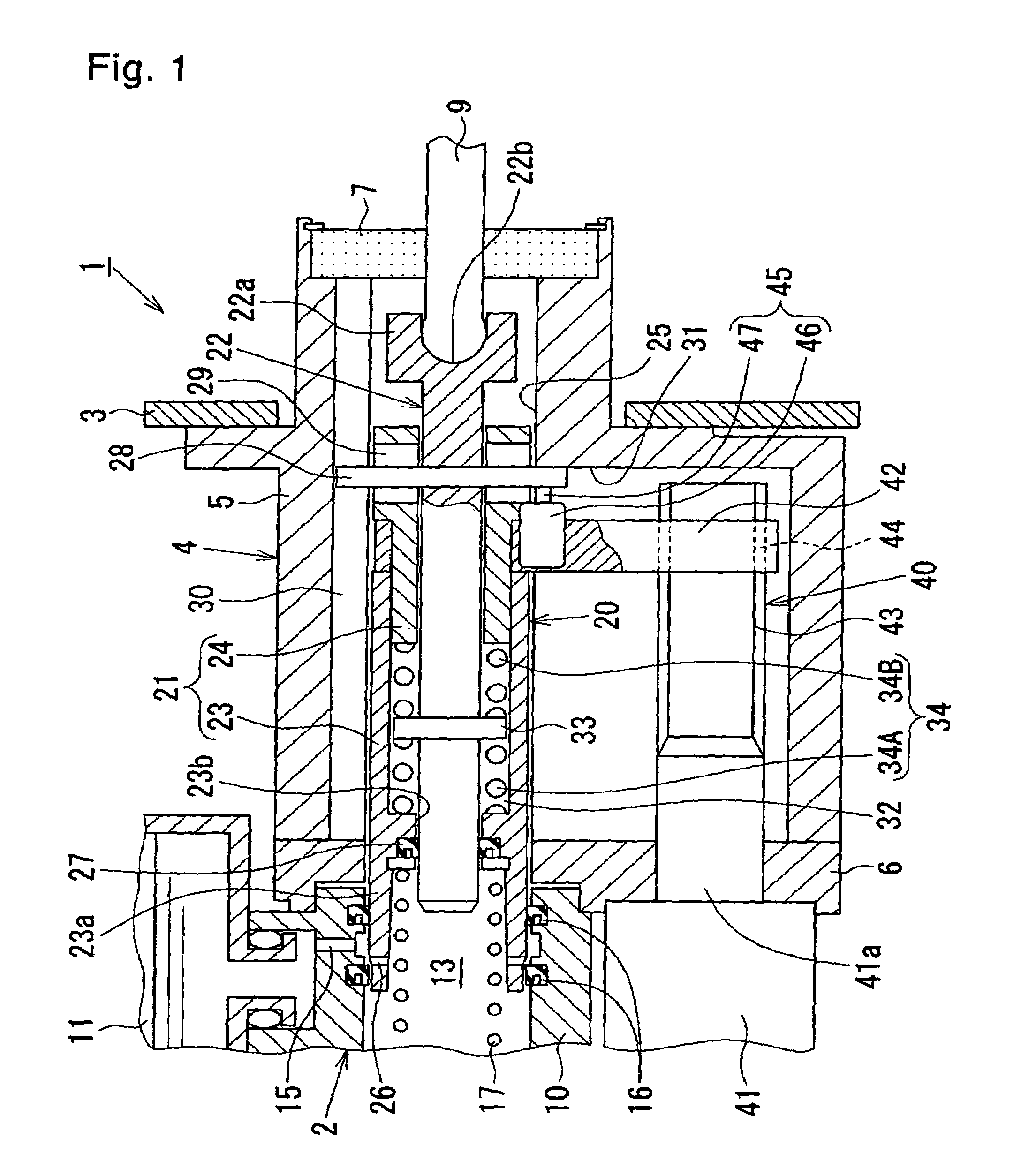

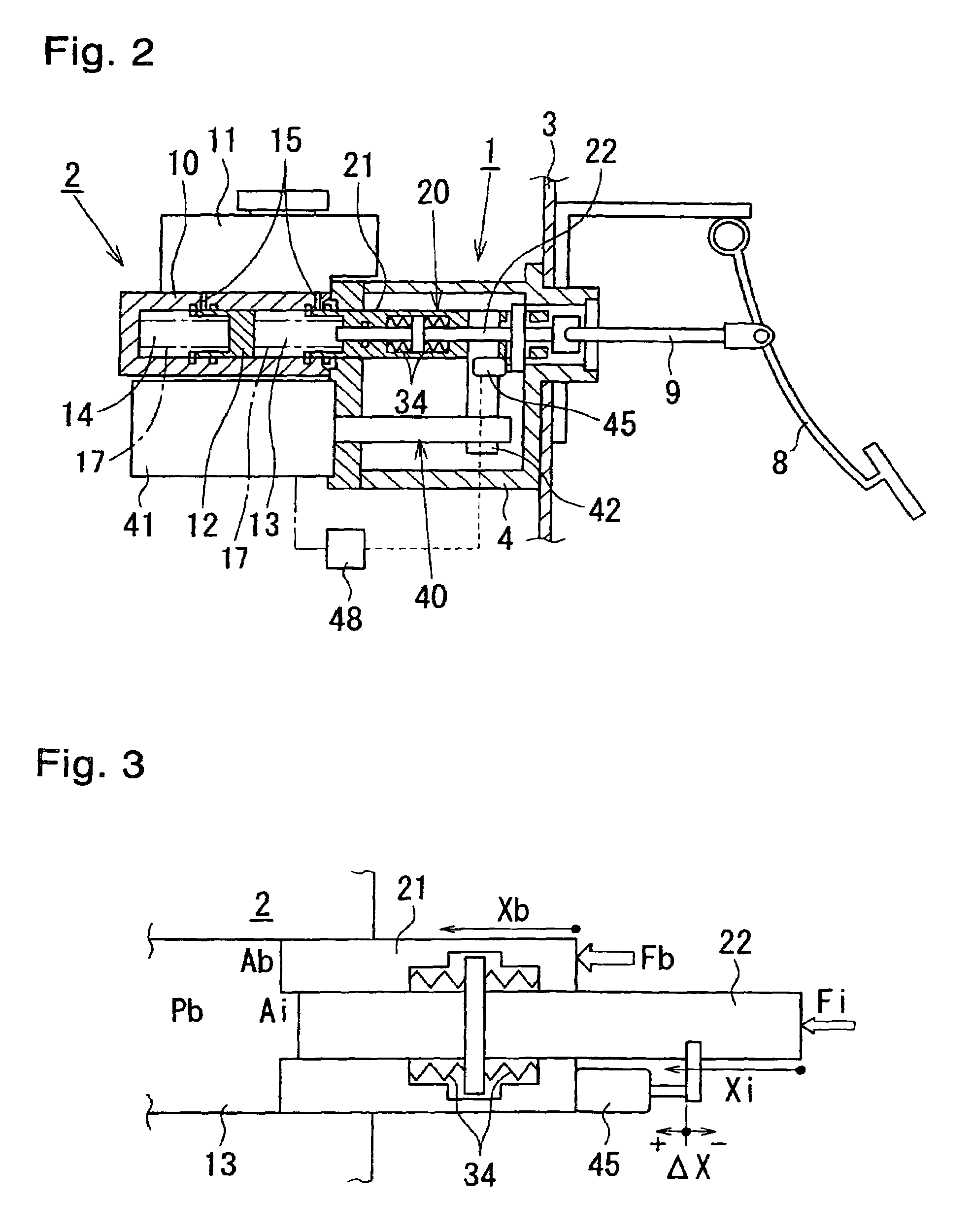

Electrically actuated brake booster

ActiveUS7367187B2Boost ratio can be increased and decreasedEnsure operabilityBraking action transmissionRotary clutchesRelative displacementActuator

An electrically actuated brake booster capable of obtaining a desired boost ratio for a given input pressure when an electric actuator is activated as a boost source, so as to ensure a desired operability of a brake pedal. The electrically actuated brake booster comprises: an input piston 22 to which an input thrust is applied through an input rod 9 that moves in coordination with operation of a brake pedal 8; and a booster piston 21 to which a booster thrust is applied by an electric actuator 40 that uses an electric motor 41 as a drive source, such that the input piston 22 and the booster piston 21 are disposed to be movable relative to each other but are normally maintained in a neutral position of relative displacement by means of springs 34. While an amount of relative displacement between the pistons 21 and 22 is determined by the potentiometer 45, the electric motor 41 is controlled to adjust the amount of relative displacement to a predetermined value. At the same time, a reaction force acting on the input piston 22 resulting from a hydraulic brake pressure is offset by urging forces of the springs 34 to thereby obtain a desired level of boost ratio.

Owner:HITACHI ASTEMO LTD

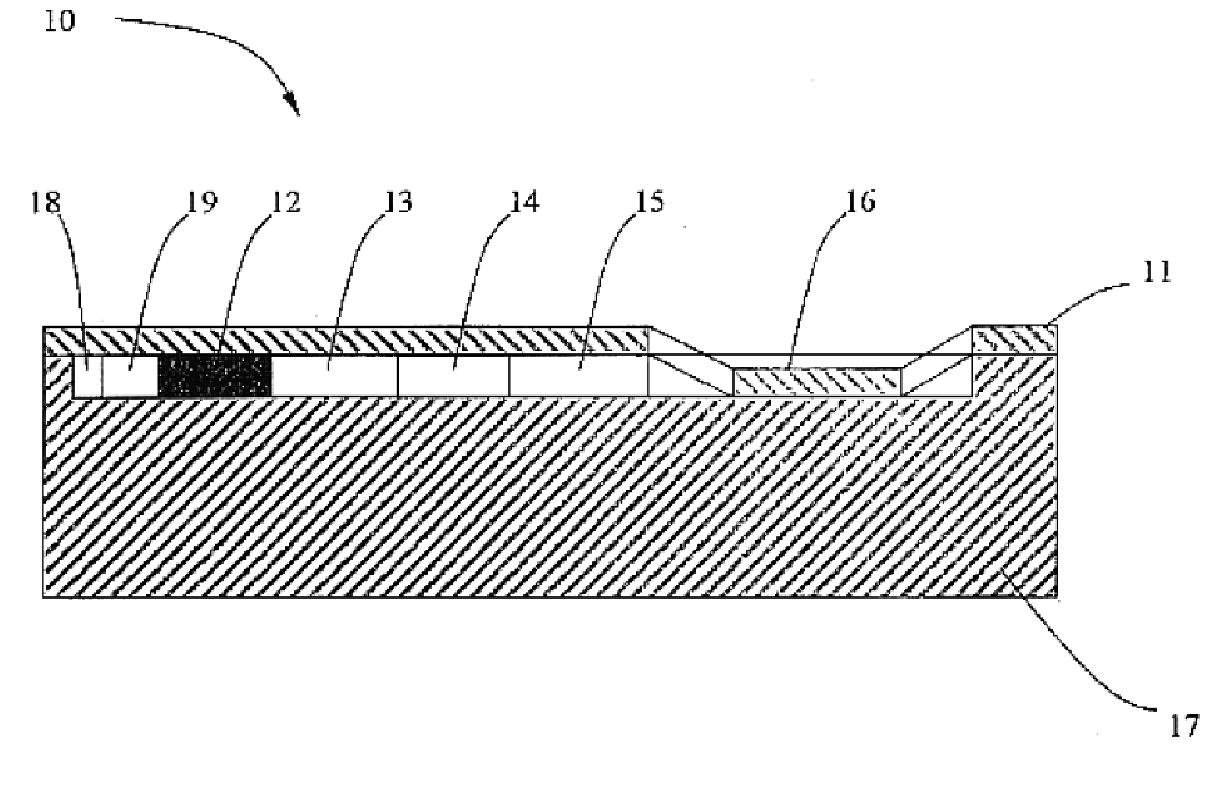

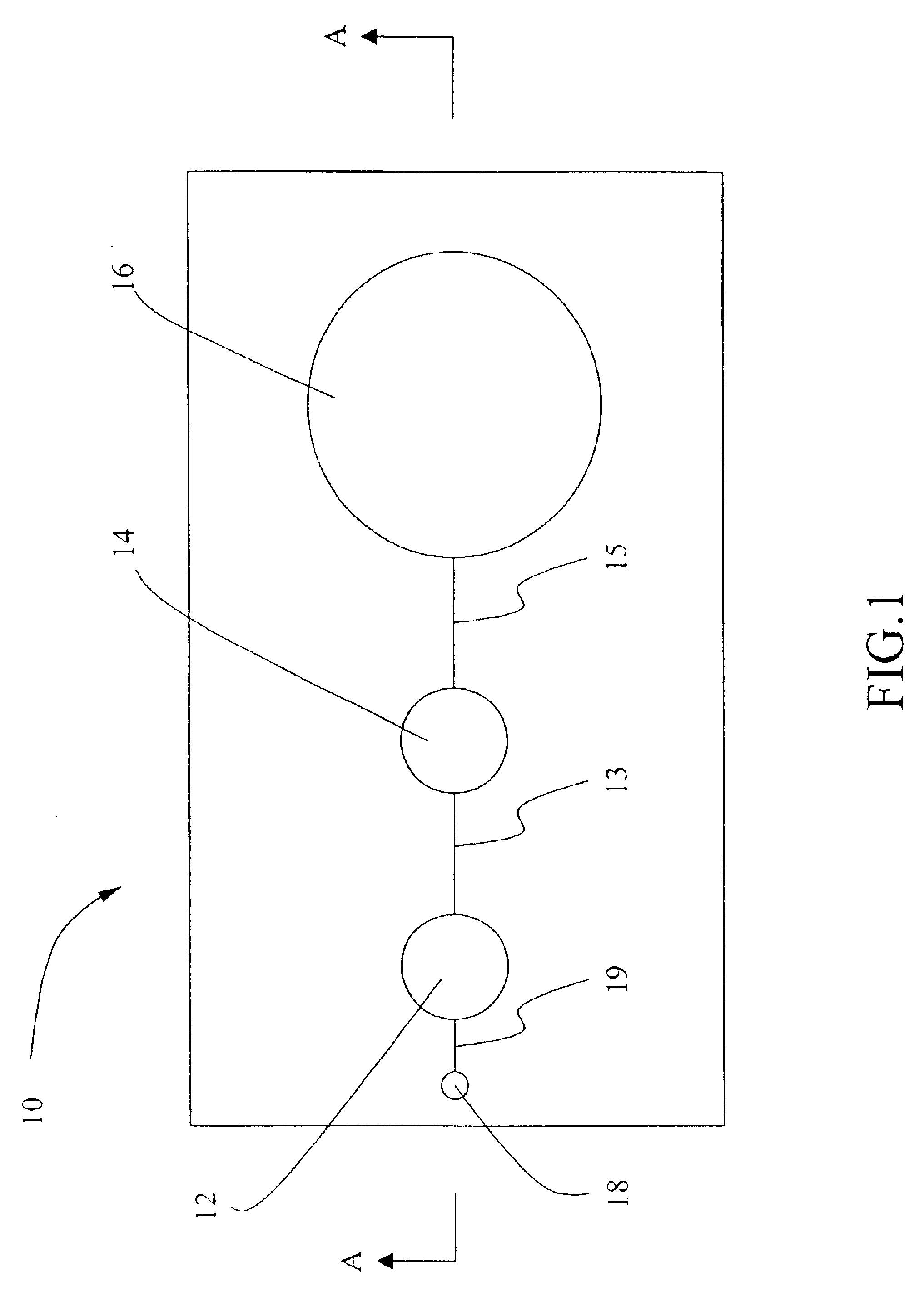

Partially closed microfluidic system and microfluidic driving method

InactiveUS6843263B2Extend fluid flowing distanceEasy to manufactureCircuit elementsRotary clutchesEngineering

This specification disclosed a partially closed microfluidic system and a fluid driving method. The microfluidic system is comprised of a substrate with microfluidic elements and a thin film. A feature of this structure is that the thin film is elastic and deformable. It has a single opening corresponding to a vent hole on the substrate, thus forming a partially closed microfluidic system. The substrate is designed to have several positions for micro fluid elements and deformable chambers and uses micro channels to form a complete network. Since the thin film is elastic and deformable, one is able to impose a pressure on the thin film above the deformable chambers in this partially closed microfluidic system to drive the fluid into motion. Once the pressure is released, the fluid flows back to its original configuration.

Owner:IND TECH RES INST

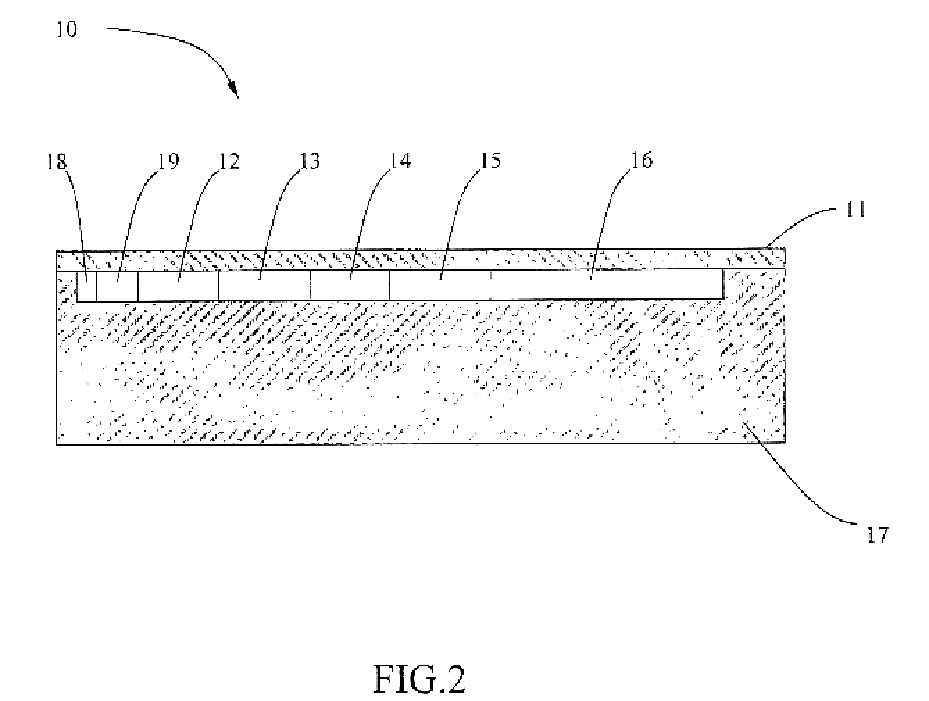

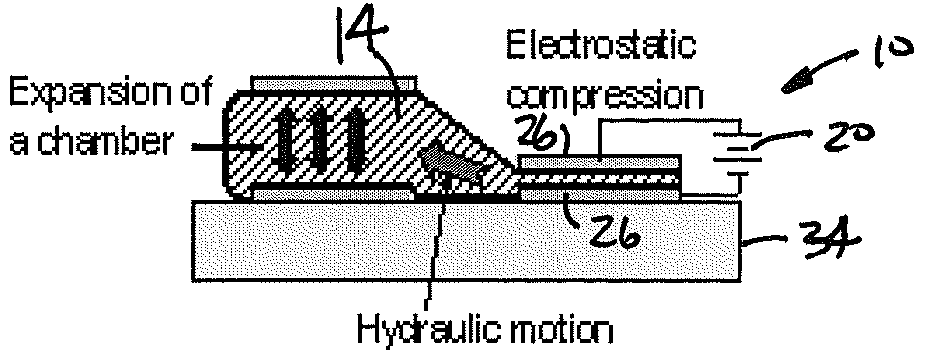

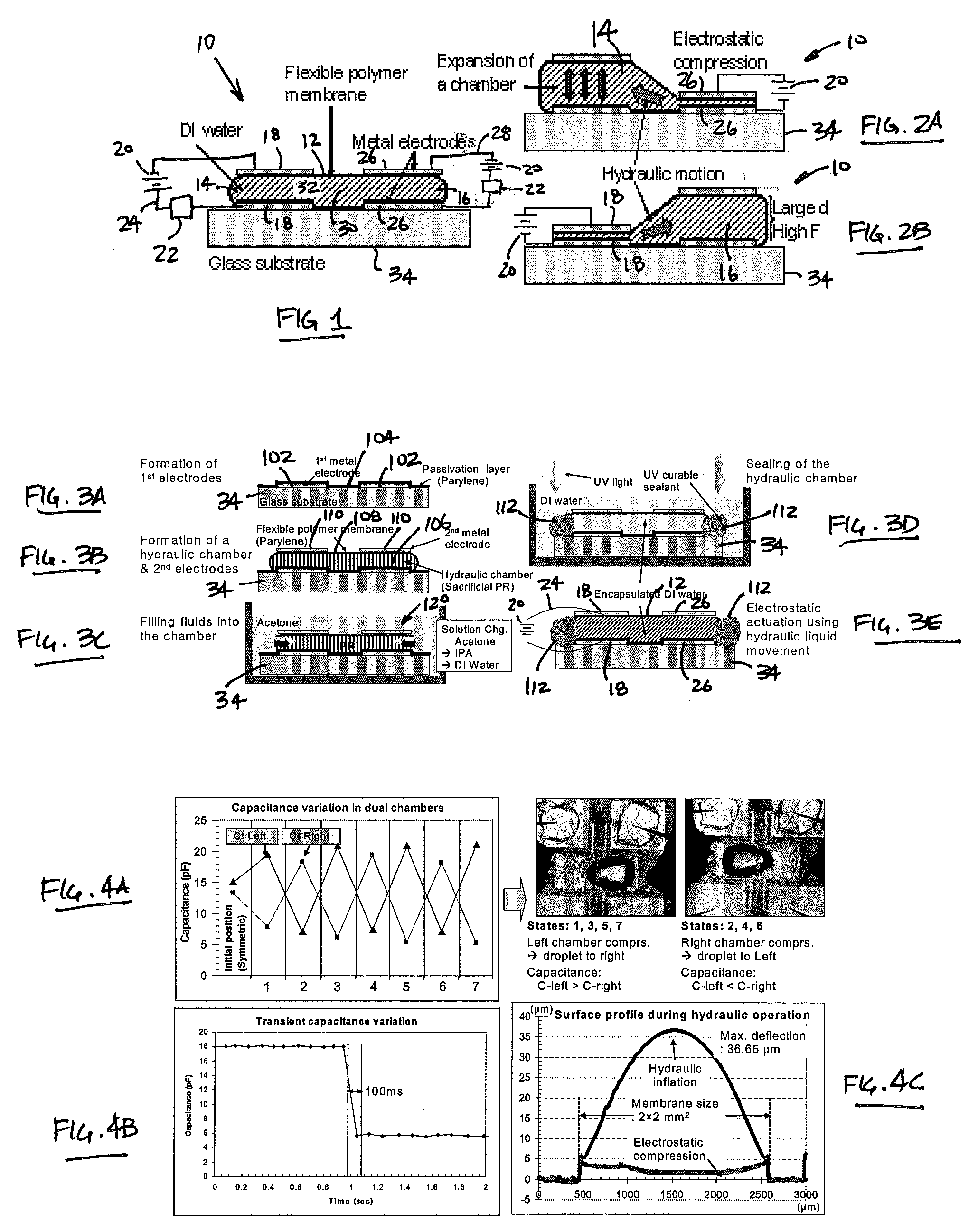

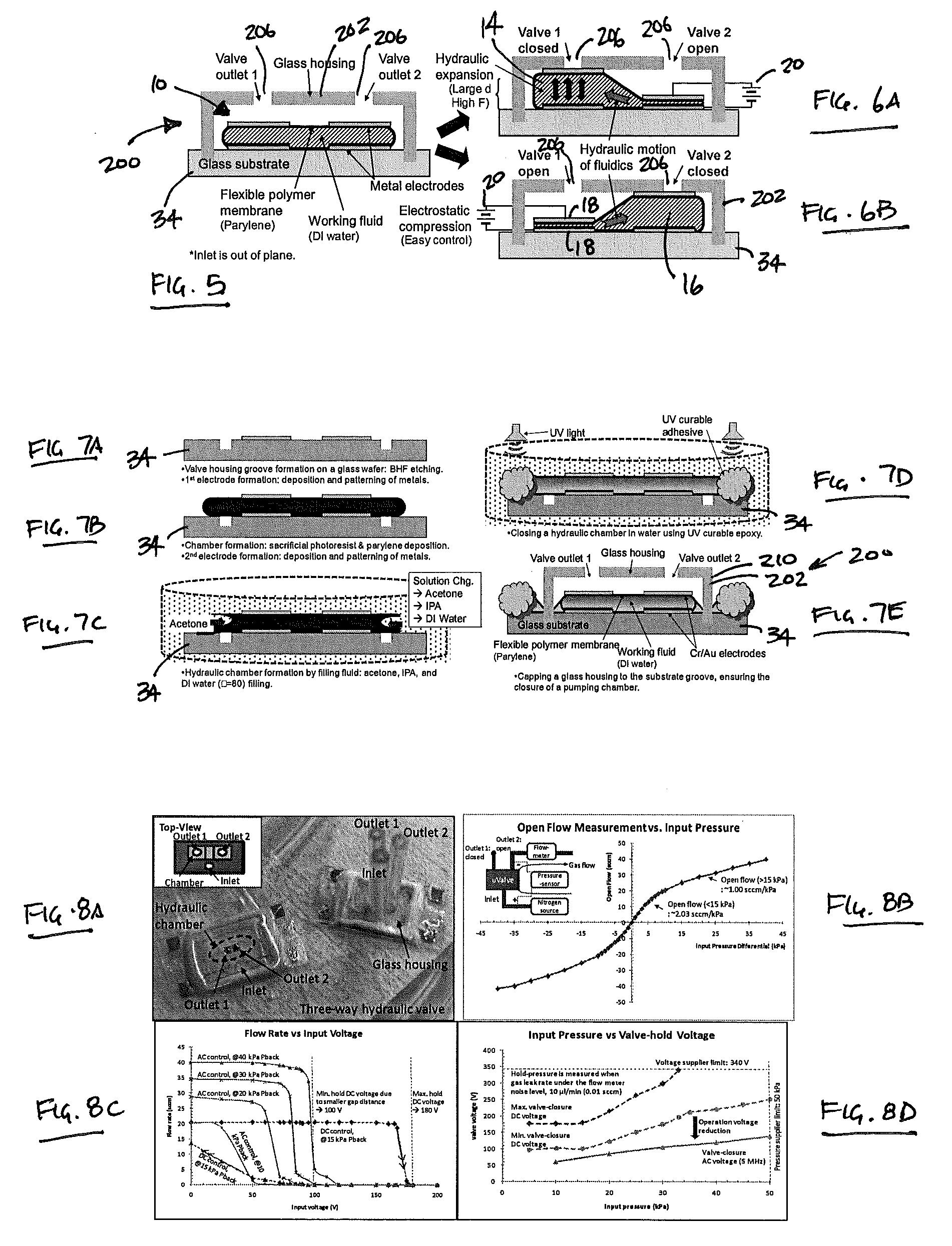

Liquid-gap electrostatic hydraulic micro actuators

InactiveUS20090115285A1Reduce voltageHigh gas conductancePiezoelectric/electrostrictive device manufacture/assemblyOperating means/releasing devices for valvesParallel plateMicro actuator

A liquid-gap electrostatic hydraulic micro actuator is provided that produces higher displacement (in and out of plane) and larger force than typical electrostatic actuators by utilizing a non-conducting liquid as its dielectric material. This new class of actuators utilizes the liquid dielectric for hydraulic amplification and force transfer. The liquid electrostatic actuator consists of two chambers each forming a parallel-plate capacitor, filled with a non-conducting incompressible liquid. One chamber is compressed by pulling down a flexible membrane using electrostatic actuation, thus forcing the liquid under it to transfer into the other chamber. Such movement causes the other chamber's membrane to expand out of plane.

Owner:RGT UNIV OF MICHIGAN

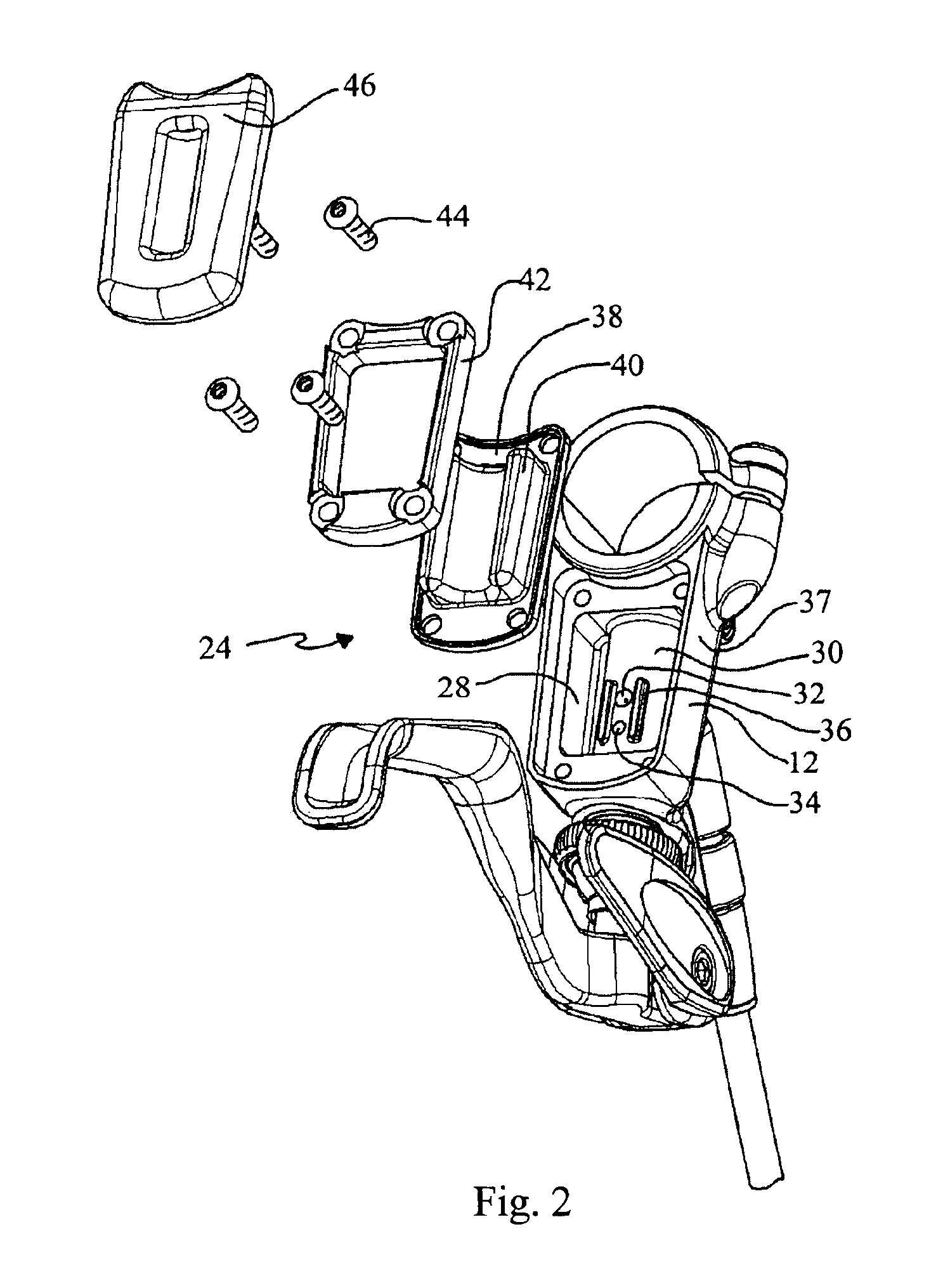

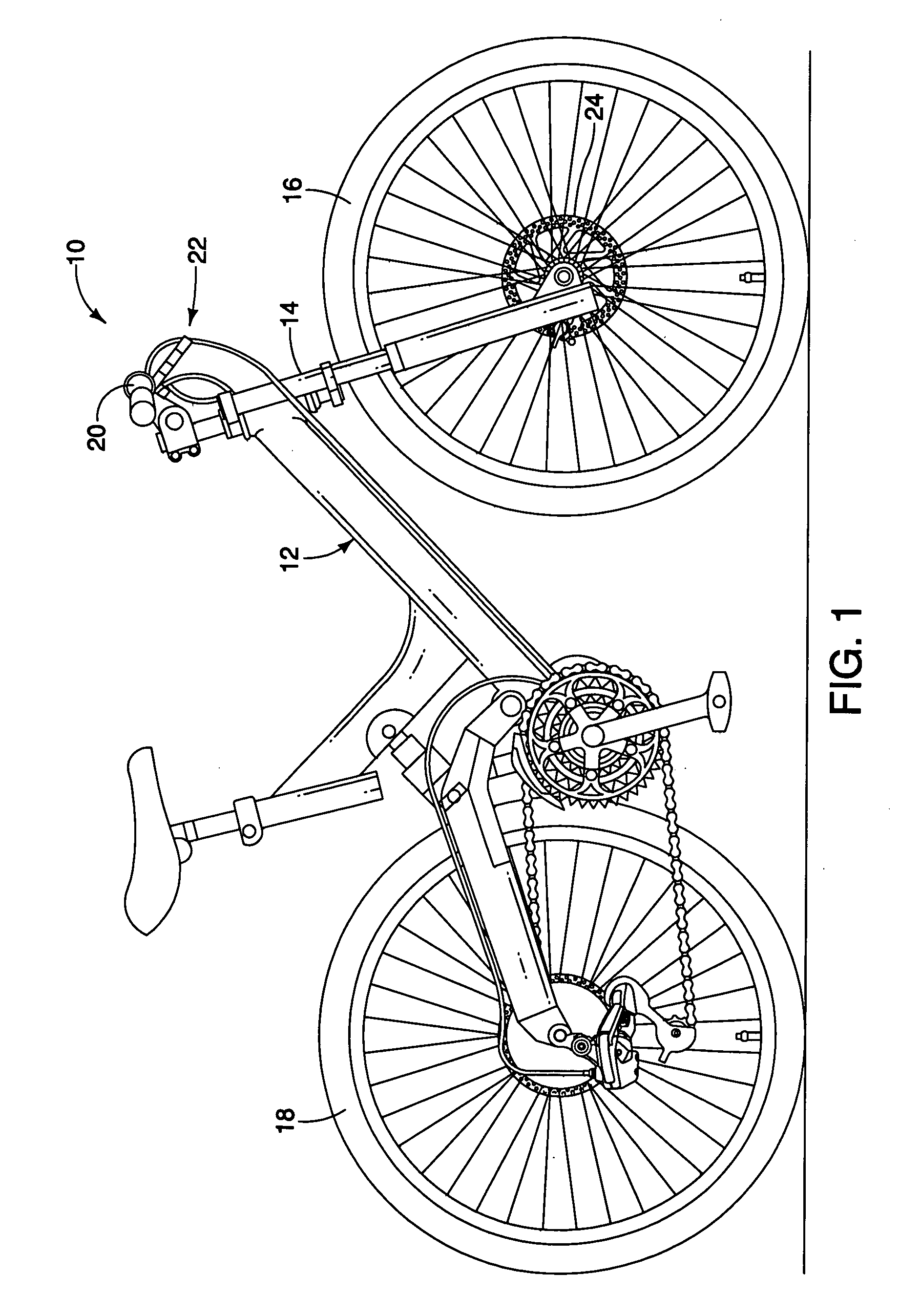

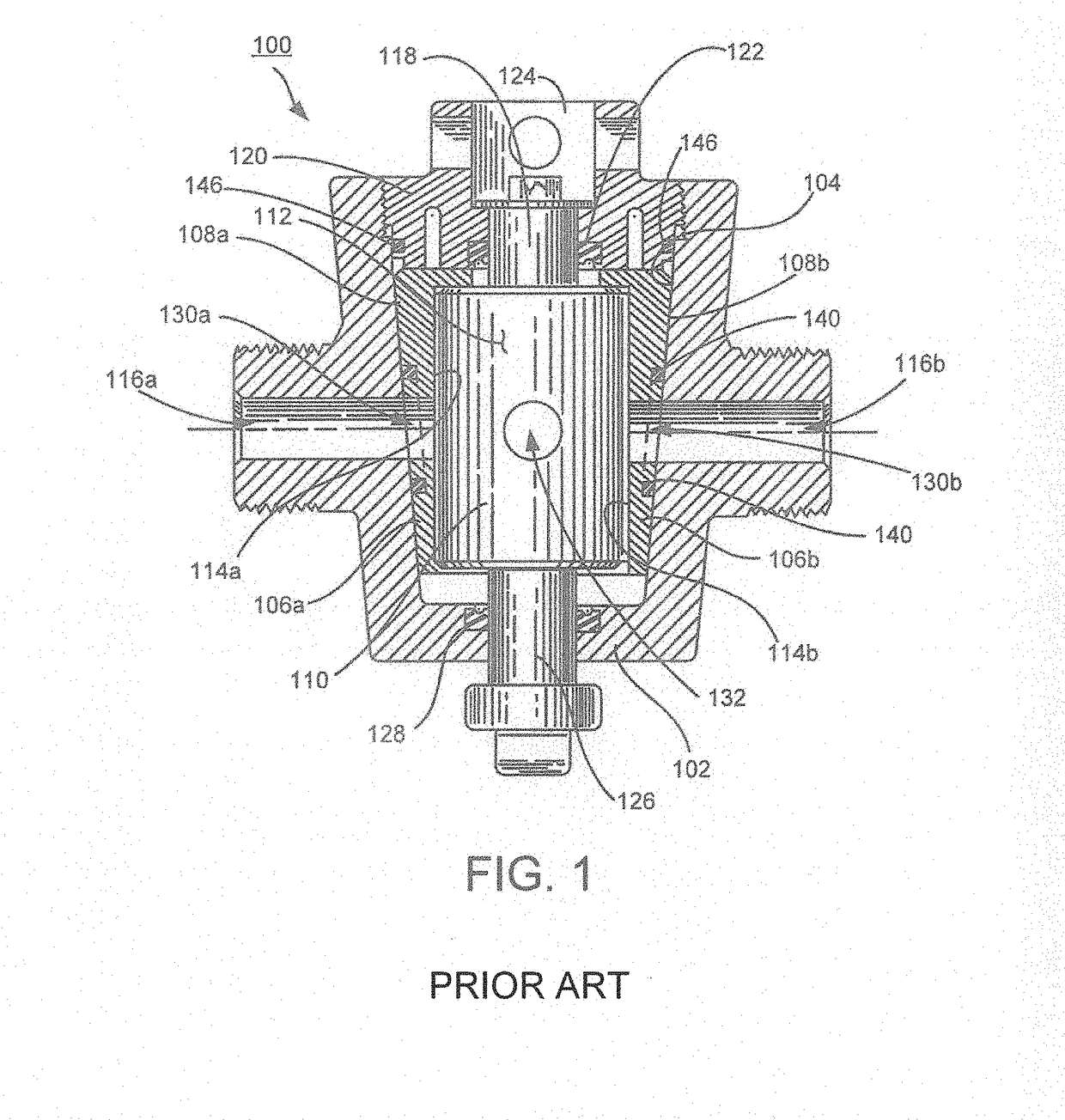

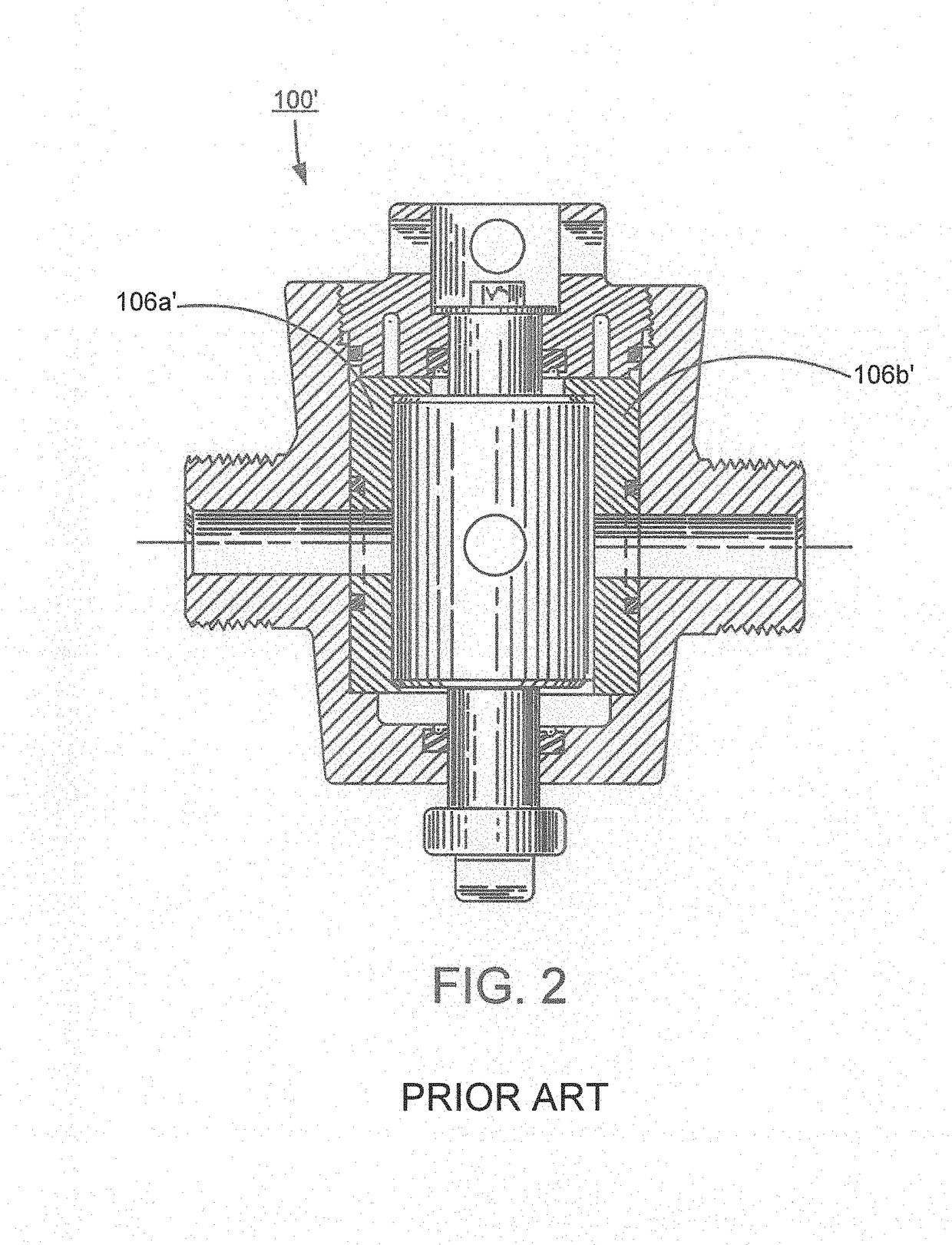

Bicycle hydraulic brake accentuate device

ActiveUS20070283692A1Improved master piston movement responseImproved brake responseRotary clutchesTelemotorsRest positionMaster cylinder

A bicycle hydraulic brake actuation device includes a hydraulic master cylinder housing having a bore and a push rod guide surface, a master piston and a radial seal received in the bore, a push rod and a lever. The push rod is supported by the push rod guide surface for sliding movement within the hydraulic master cylinder housing. The push rod is configured to move the master piston and the radial seal from a neutral position to a braking position. The lever is pivotally attached to the housing for pivotal movement between an at rest position and a brake actuation position. The lever is also configured and arranged to move the push rod and the master piston from the neutral position toward the braking position as the lever is pivoted between the at rest position and the brake actuation position.

Owner:SHIMANO INC

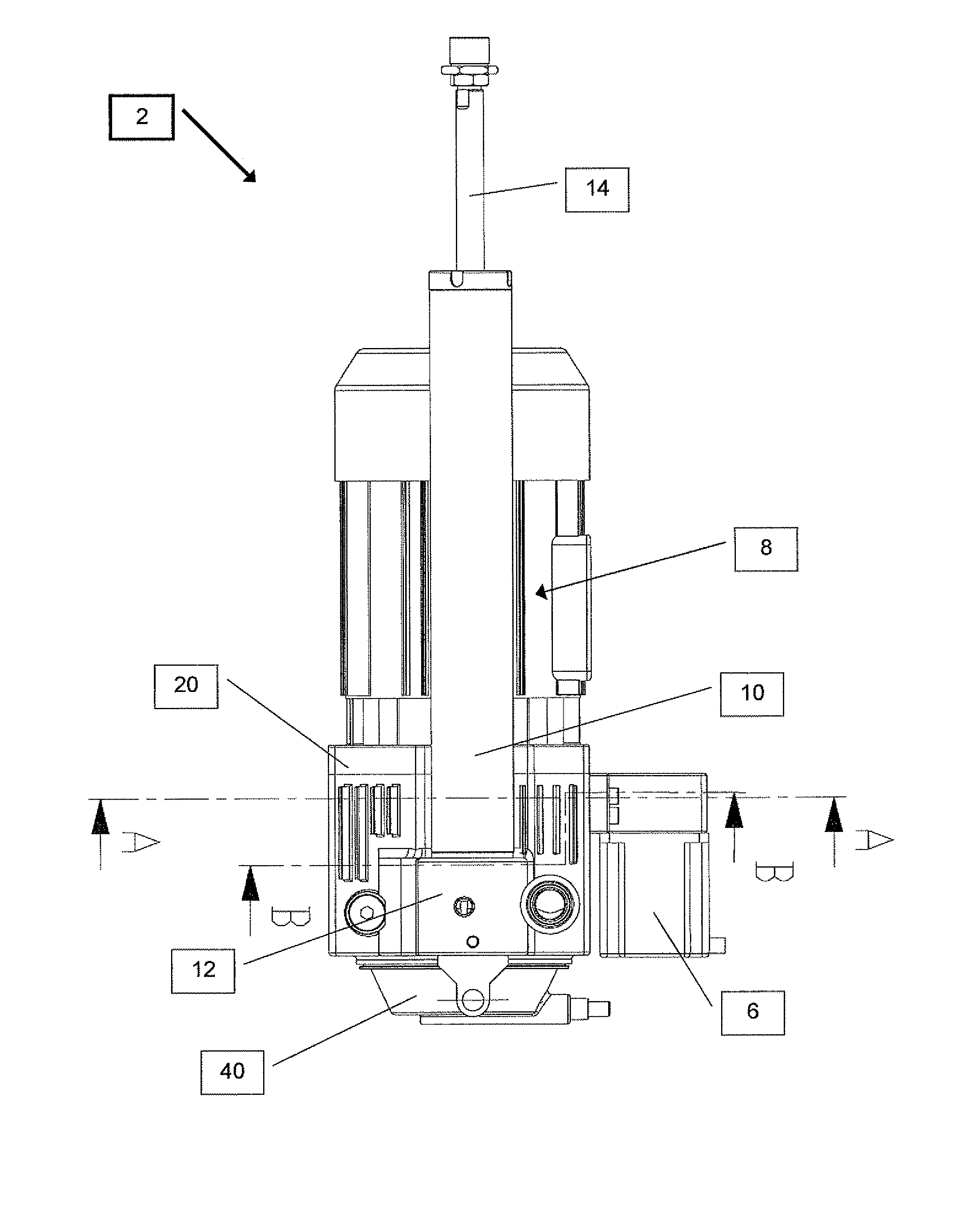

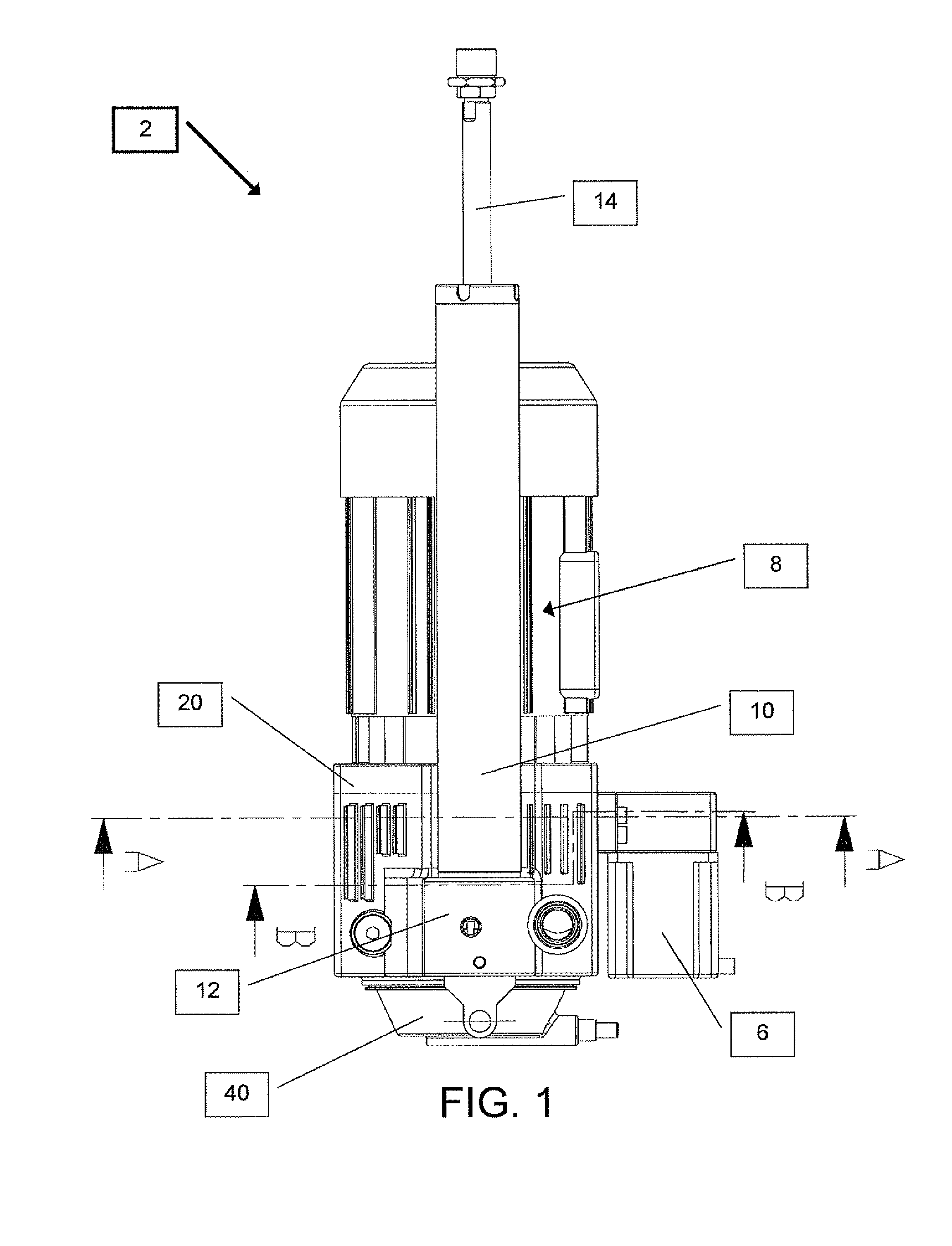

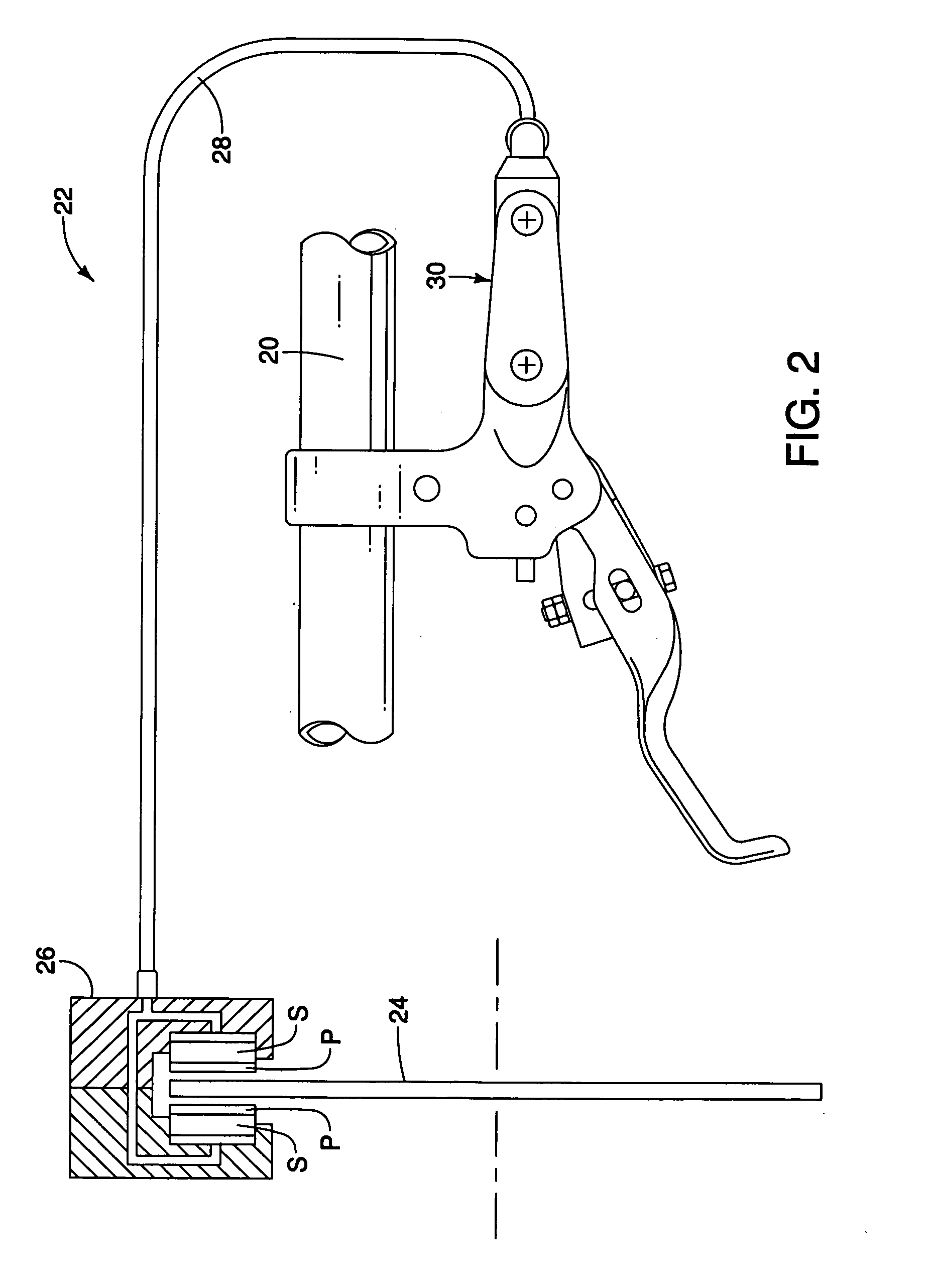

Hydraulic Brake Master Cylinder

A hydraulic brake master cylinder is provided that is compact and light in weight. The master cylinder has a reservoir shape that provides increased reservoir expansion volume. The master cylinder also provides gear shifter operation clearance and a comfortable lever that allows easy adjustment without the use of tools. The lever has defined increments of adjustment which make it easy to use. The invention also includes a method of bleeding air from the system without requiring reorientation of the master cylinder. The retention methods for the various lever embodiments shown allow for easy and inexpensive retention of the lever and also provide for reduced overall weight and cost.

Owner:HAYES BICYCLE GROUP

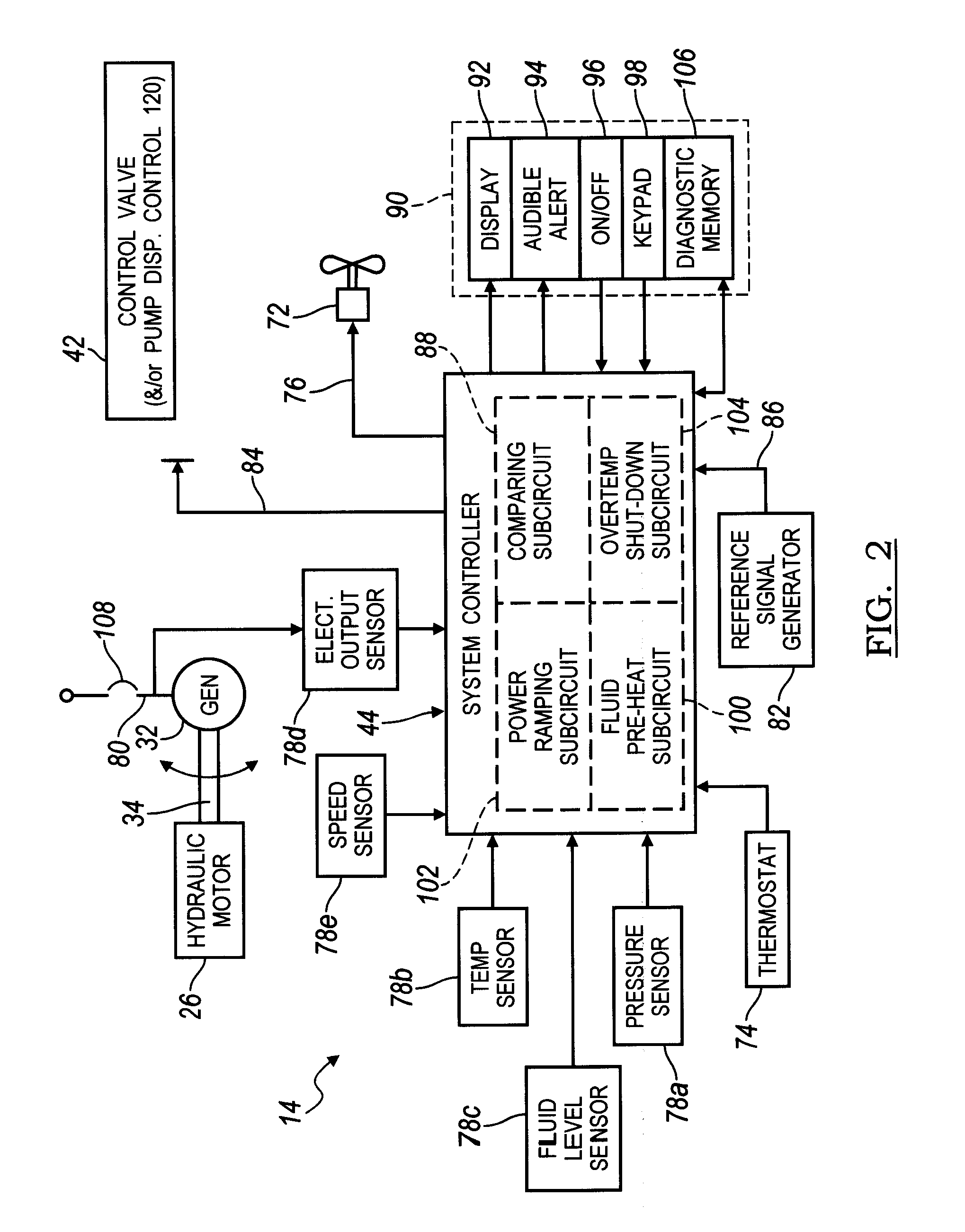

Electronic control for a hydraulically driven auxiliary power source

ActiveUS8269360B2Extend system lifeLow costGenerator circuit arrangements controlFluid couplingsHydraulic motorHydraulic pump

A hydraulic system includes a variable displacement hydraulic pump connectable to a power source, a hydraulic motor, a fluid circuit, a pump displacement control, and a controller. The pump has an inlet for receiving fluid, an outlet for discharging pressurized fluid, and a pump displacement input. The motor has an inlet for receiving pressurized fluid and an outlet for discharging spent fluid. The fluid circuit includes a supply conduit for conducting fluid discharged by the pump to the motor and a return conduit for returning fluid discharged by the motor to the pump. The pump displacement control cooperates with the pump displacement input to vary pump displacement. The controller communicates with the pump displacement control to control the pump output such that the motor is driven at a constant speed to thereby drive a generator connected to the motor at a constant speed despite speed fluctuations of the power source.

Owner:UUSI

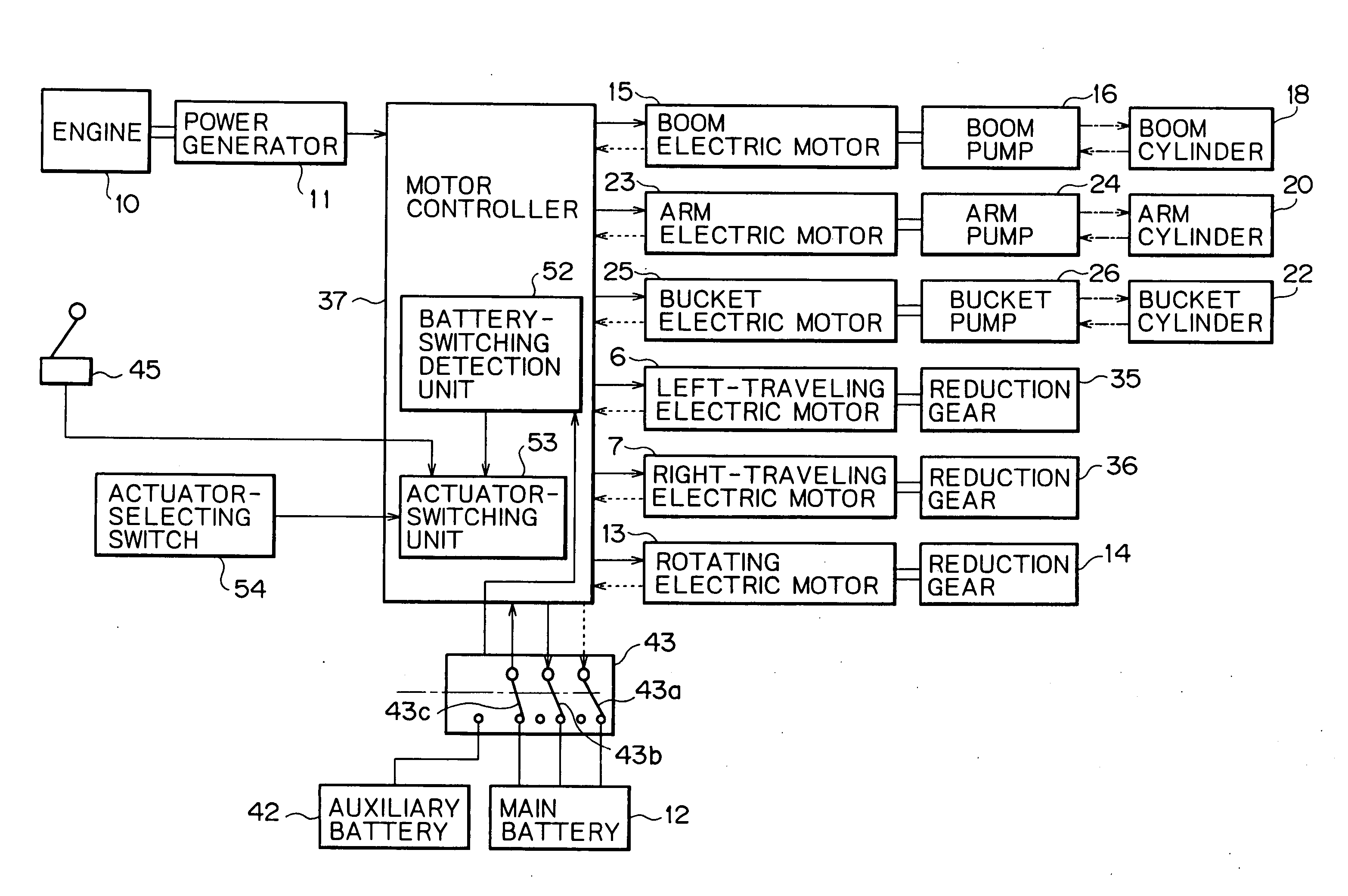

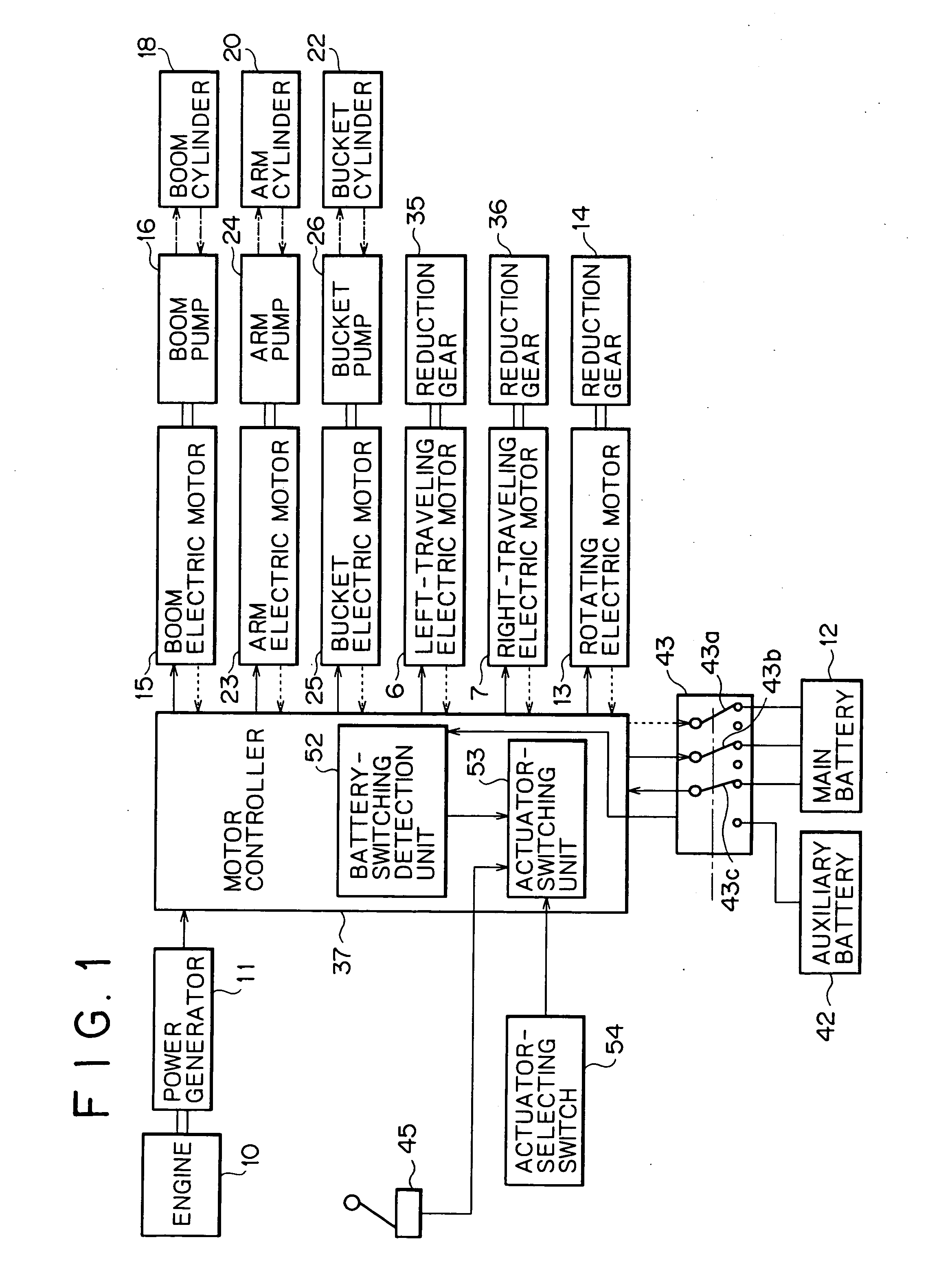

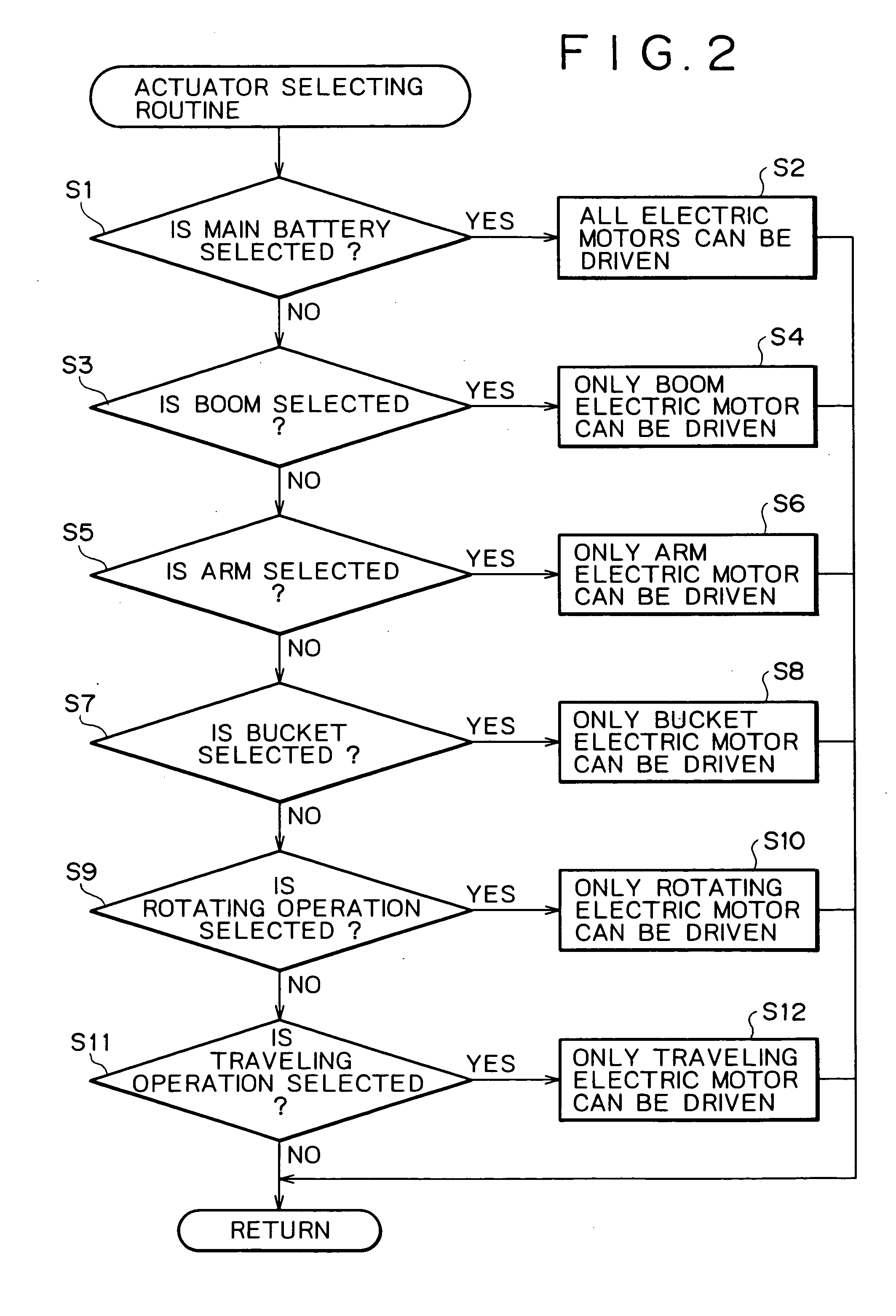

Hybride construction machine having auxiliary battery and control apparatus thereof

InactiveUS20050001606A1Improve reliabilityExcessive chargingAuxillary drivesServomotorsElectrical batteryEngineering

A hybrid construction machine according to the present invention is constructed to drive electric motors (6, 7, 13, 15, 23, 25) by means of power of a power generator (11) to be driven by an engine (10), power of an auxiliary battery (42) and power of a main battery (12) charged with power of the power generator (11). The hybrid construction machine has a switch (43) for switching to drive the electric motors (6, 7, 13, 15, 23, 25) by means of power of at least one of the power generator (11) and the main battery (12) when operating normally and to drive the electric motors (6, 7, 13, 15, 23, 25) by means of power of the auxiliary battery (42) when operating emergency such that the electric motors (6, 7, 13, 15, 23, 25) can not be driven by means of the normal power.

Owner:KOBELCO CONSTR MASCH CO LTD

Hydraulic inerter mechanism

InactiveUS20090139225A1Improve correspondenceLow costFluid couplingsTelemotorsHydraulic motorHydraulic cylinder

The invention provides a hydraulic inerter mechanism, including: a hydraulic cylinder; a hydraulic motor connected to the hydraulic cylinder, with an output shaft thereon for converting the motion of the hydraulic cylinder from rectilinear motion to rotary motion; and an inertia body disposed on the output shaft. In operation, an external force applied to the inerter mechanism causes displacement of the piston, thereby pushing working fluid inside the hydraulic cylinder to generate a pressure difference between an inlet and an outlet of a hydraulic motor. The differential pressure consequently drives the hydraulic motor to rotate, and then the output shaft further drives the inertia body to rotate, thereby attaining inerter characteristics.

Owner:NAT TAIWAN UNIV

Hybrid hydraulic system and work machine using same

A hydraulic system and work machine are provided, the hydraulic system including at least one hydraulic cylinder with a first port and a second port connected by a first fluid passage. A first pump, which is a bi-directional hydraulic pump is positioned within the first fluid passage, and a second pump is positioned in parallel with the first pump and disposed within a second fluid passage. An accumulator fluidly connects with the second fluid passage.

Owner:CATERPILLAR INC

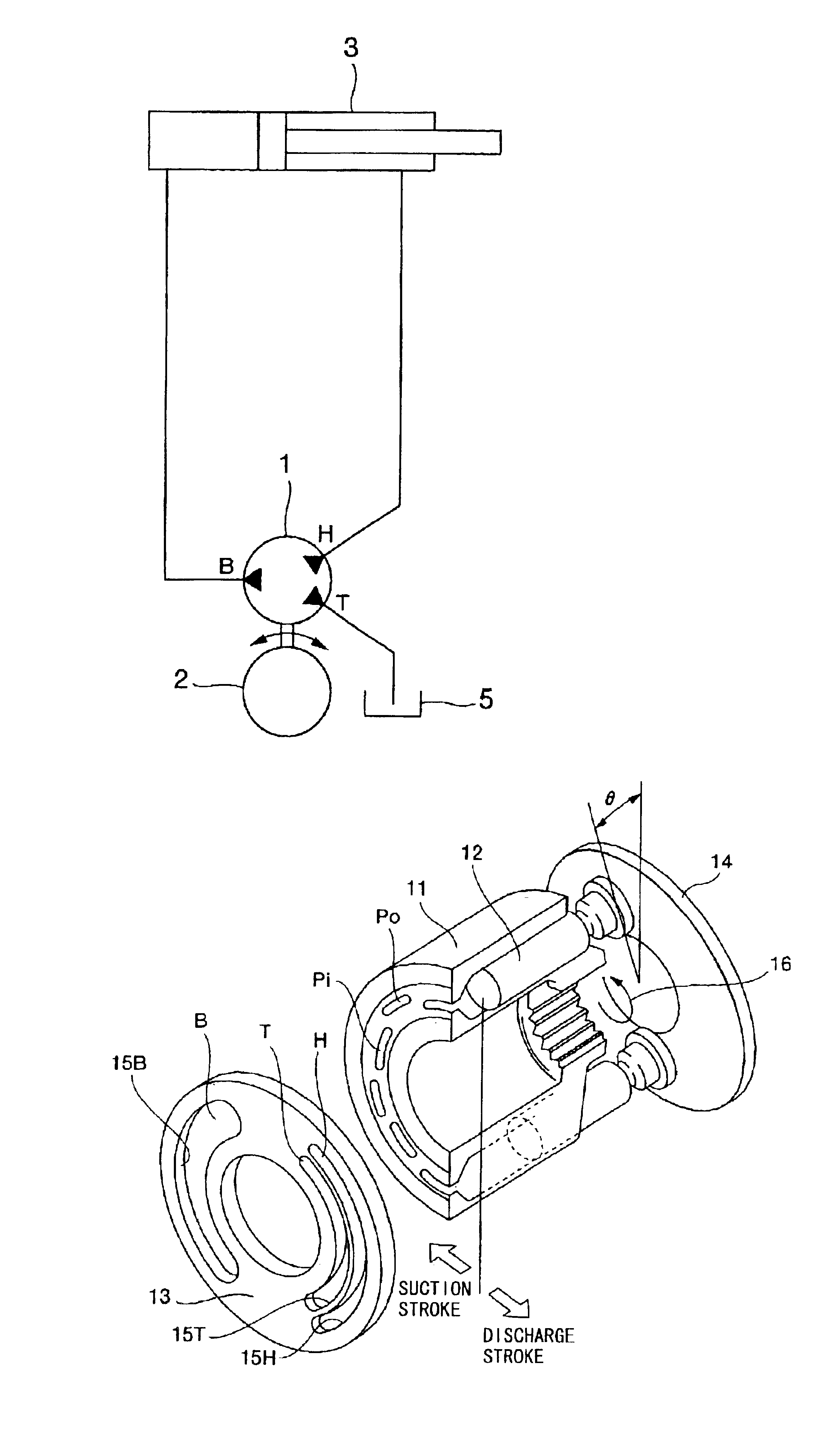

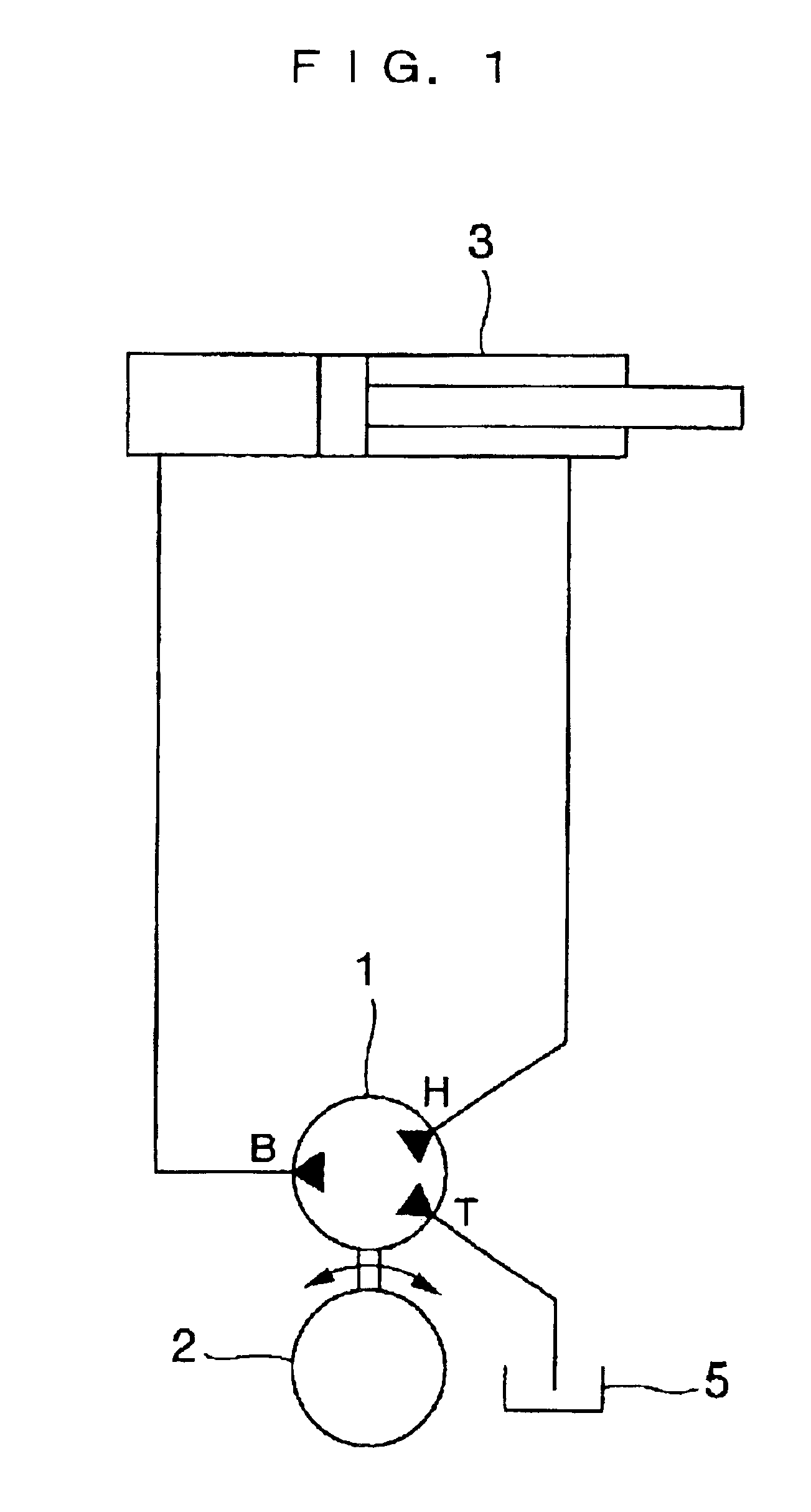

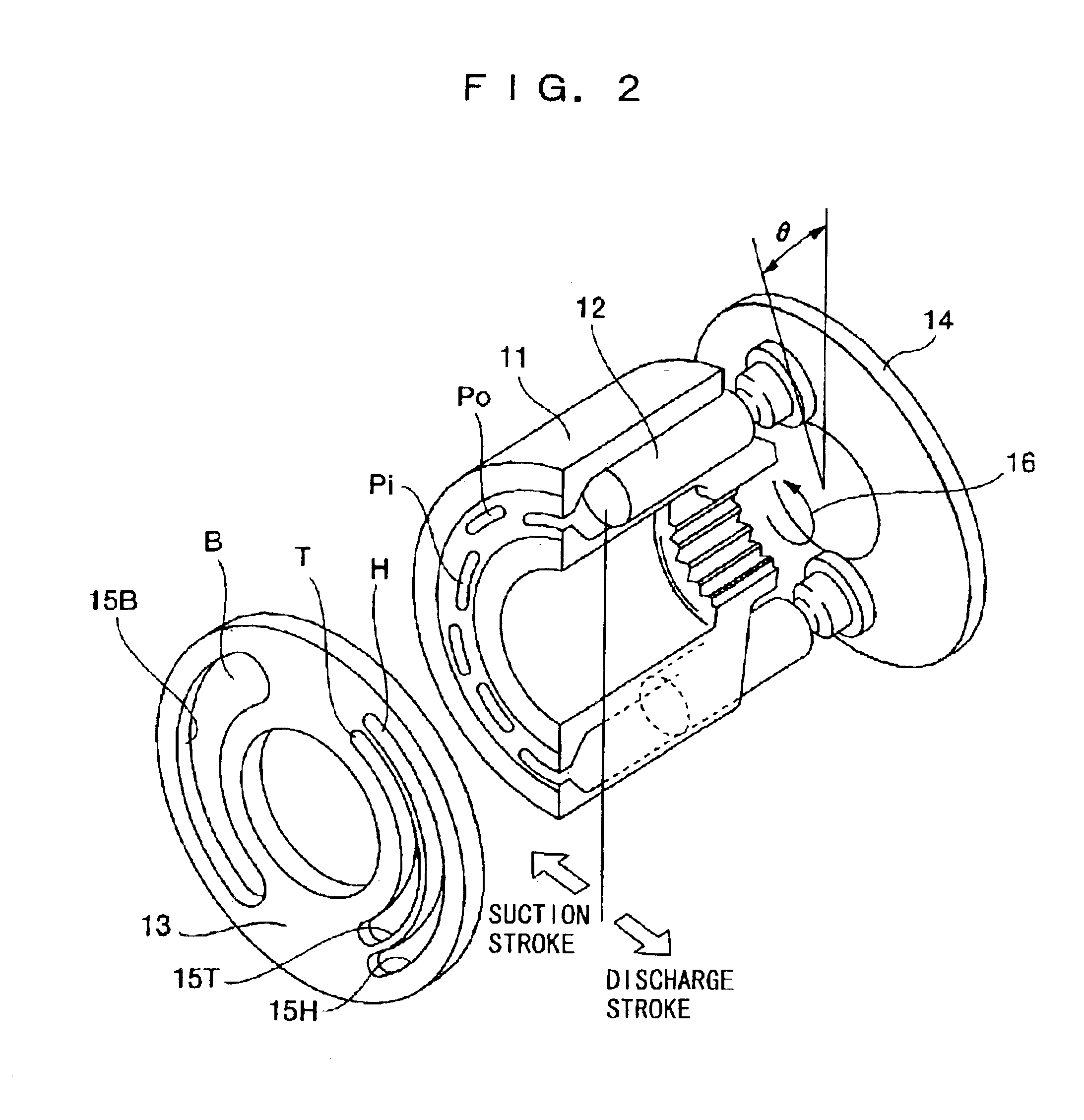

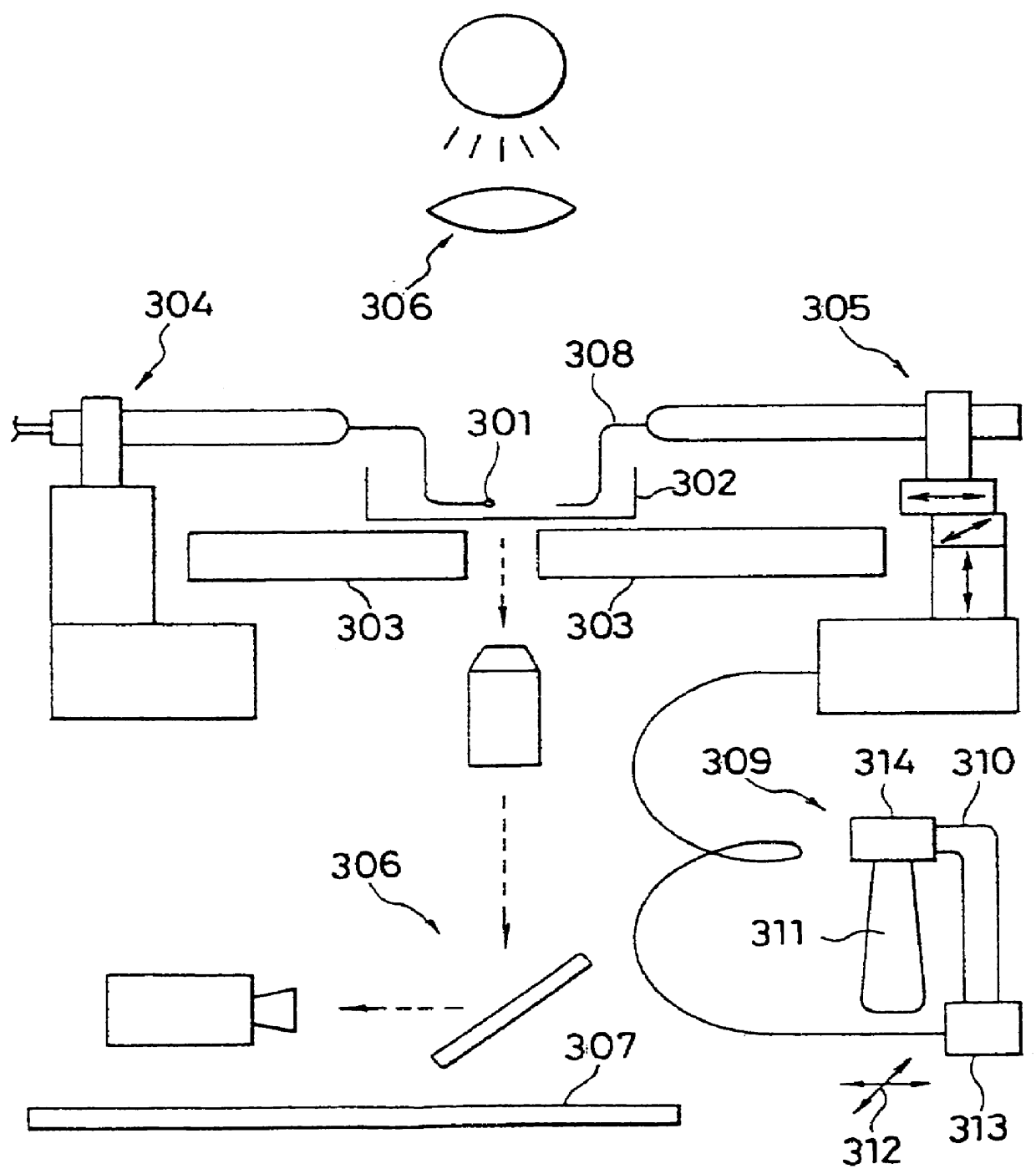

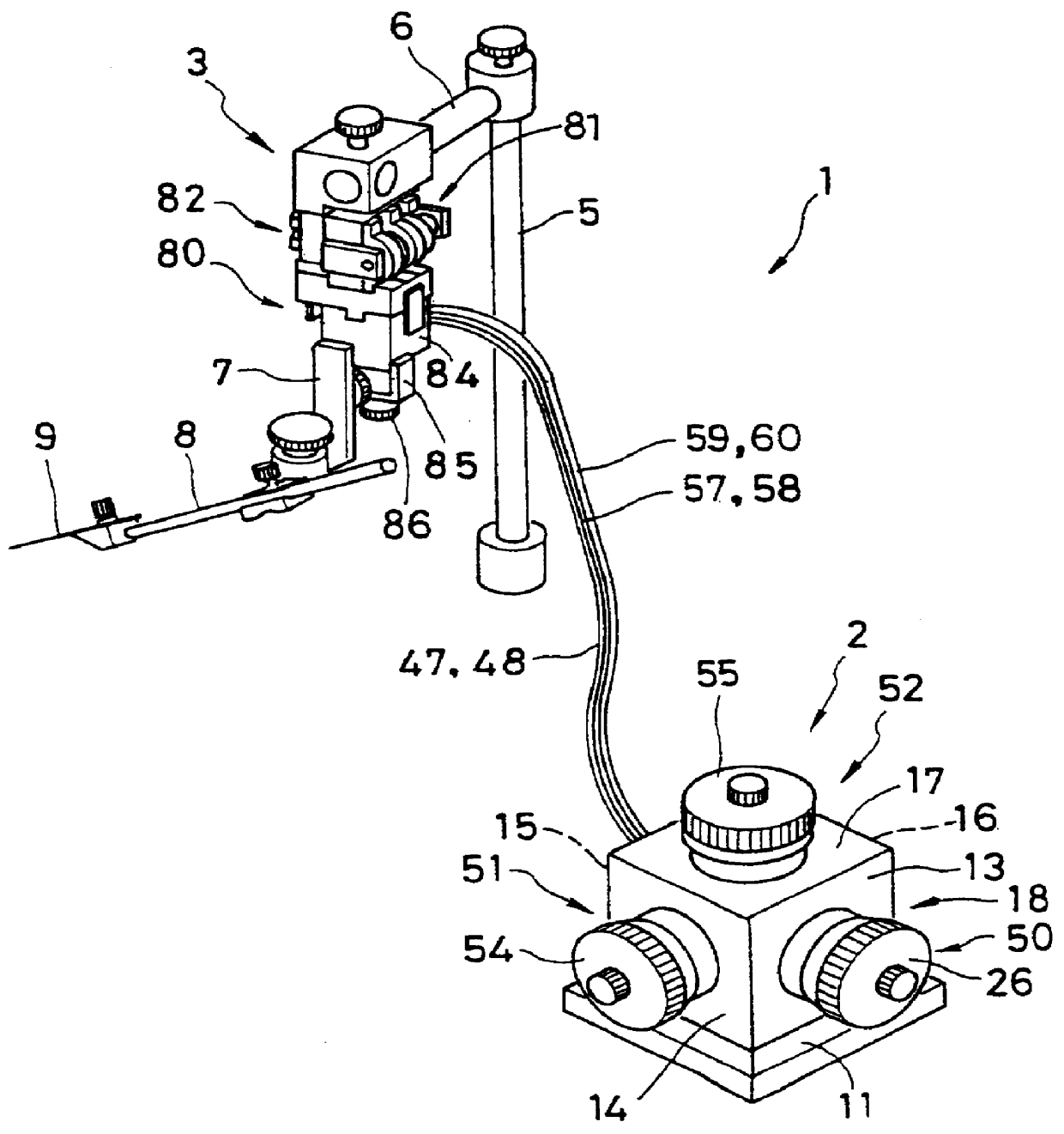

Hydraulically-operated micromanipulator apparatus

A hydraulically-operated micromanipulator apparatus is disclosed. The micromanipulator apparatus comprises: a micromanipulator fine control unit including an operating-side piston finely movable with respect to an operating-side hydraulic cylinder and fine control means, either the operating-side piston or the operating-side hydraulic cylinder being stationarily retained, while the rest being finely operable by the fine control means; a hydraulically-operated micromanipulator including an actuating-side piston finely movable with respect to an actuating-side hydraulic cylinder and a fine displacement member, the actuating-side hydraulic cylinder being connected to said operating-side hydraulic cylinder through a hose, either the actuating-side piston or the actuating-side hydraulic cylinder being stationarily retained, while the rest being attached to the fine displacement member; and compensating means for compensating a pressure change of the hydraulic fluid between said operating-side hydraulic cylinder and said actuating-side hydraulic cylinder when ambient temperature changes.

Owner:NARISHIGE

Sealing High Pressure Flow Devices

Apparatus and method contemplating a high pressure fluid end assembly having a body defining a body bore and defining a recess in the body intersecting the body bore. A closure is joined to the body and forms a sealing surface. A seal is mounted to the body in the recess and configured to extend from the recess beyond the body bore to seal against the sealing surface formed by the closure.

Owner:KERR MACHINE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com