Proportional multi-way valve with steering load feedback

A proportional multi-way valve and load feedback technology, which is applied in the field of multi-way hydraulic valves, can solve problems such as poor controllability of operating speed, out-of-control actual operation, waste of output power, etc., and achieve improved control performance, sensitive action, and improved operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

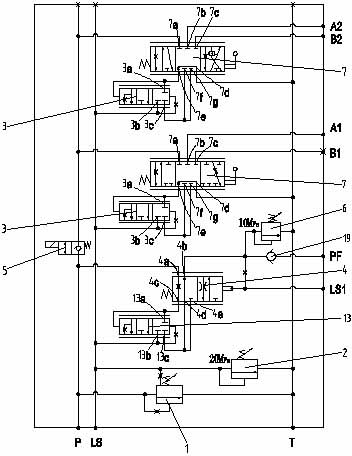

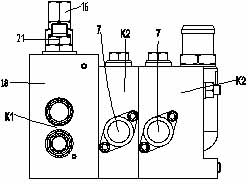

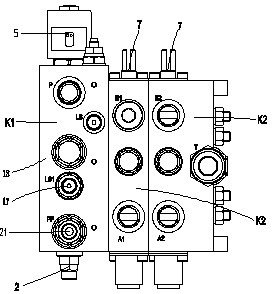

[0030] Such as Figure 1 to Figure 8 As shown, the icon numbers are as follows: three-way flow spool 1, main relief valve 2, second pressure compensation valve 3, control valve one port 3a, control valve two port 3b, control valve three port 3c, steering spool 4, turn Valve oil inlet 4a, rotary valve oil return port 4b, rotary valve one outlet 4c, rotary valve two outlet 4d, rotary valve three outlet 4e, first throttle groove 41, second throttle groove 42, third throttle groove 43. Two-position two-way solenoid valve 5, steering relief valve 6, unit control spool 7, control valve oil inlet 7a, control valve first output port 7b, control valve second output port 7c, control valve oil return port 7d, Control valve one port 7e, control valve two port 7f, control valve three port 7g, control chamber 71, fastening nut 8, adjustment seat 9, spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com