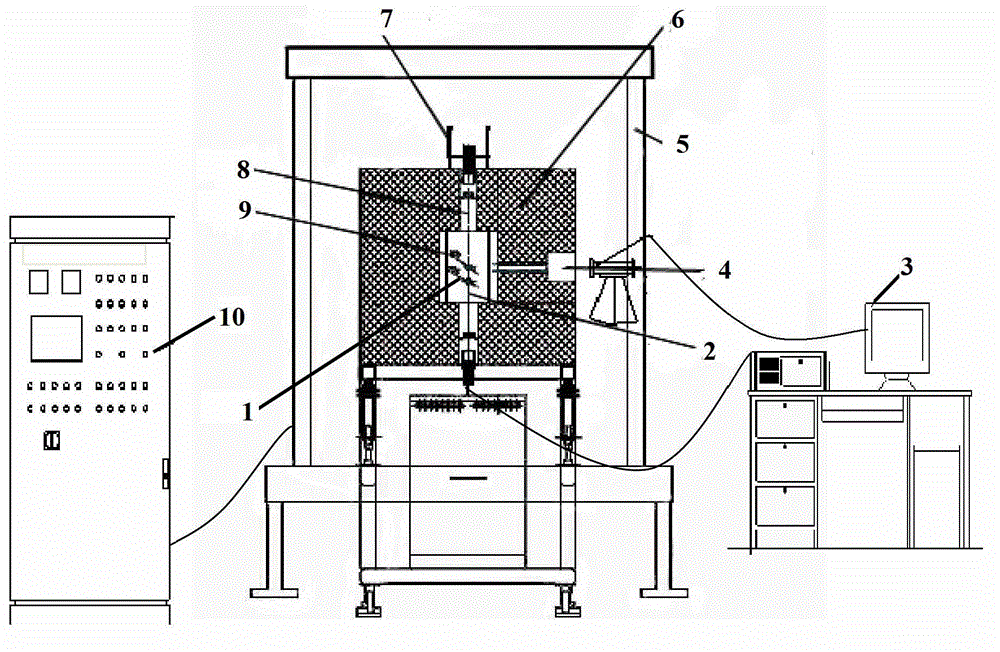

Device and method for testing mechanical property in ultrahigh temperature oxidation environment

A testing device and an oxidizing environment technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., can solve the test temperature Inaccurate testing, poor repeatability of experiments, lack of non-contact deformation testing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: Measuring the tensile strength of a certain ultra-high temperature ceramic material

[0080] The specific experimental operation steps are:

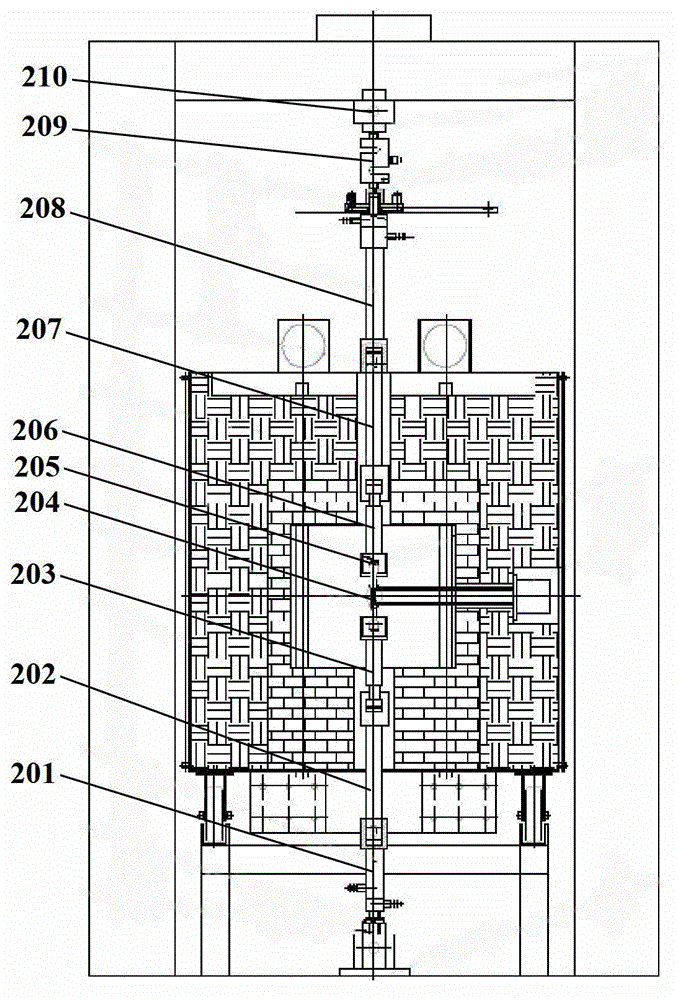

[0081] (1) Take a test sample. The shape and size of the sample refer to the American ASTM C1295 standard. The gauge length of the sample is 30mm, and the cross-section within the gauge length is 5.97mm×2.98mm. On the upper and lower chucks connected by rods (such as figure 2 As shown), give the sample a small pre-tightening force (﹤20N) to keep it in the vertical direction; insert the ultra-high temperature extension into the furnace body, and the gauge length section of the ejector rod is in contact with the pre-sample; adjust the power supply, The heating process in the furnace is controlled by an ultra-high temperature ceramic heating element, and the temperature of the sample in the furnace is measured by an infrared thermometer to 1650 degrees, and then kept for 5 minutes;

[0082] (2) The loading bar loads ...

Embodiment 2

[0083] Example 2: Measuring the flexural strength of an ultra-high temperature ceramic material supporting a certain military product

[0084] The specific experimental operation steps are:

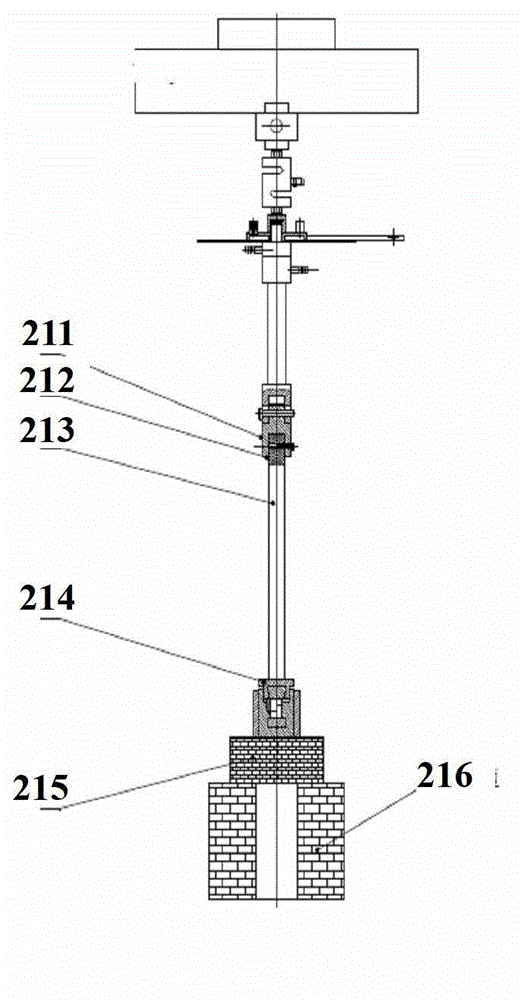

[0085] (1) Take a test sample, measure its size as 2.98mm×3.97mm×40.2mm, place the sample on the roller rod fixed on the fixture support (such as image 3 As shown), the span between the lower rollers is 20mm; adjust the power supply, heat the furnace through the ultra-high temperature ceramic heating element, use the infrared temperature measuring device to measure the temperature of the sample in the furnace to 1800 degrees, and keep it for 5 minutes;

[0086] (2) The upper roller loads the sample at the center of the sample at a speed of 0.5 mm / min until the sample breaks, and records the load-displacement curve (such as Figure 5 Shown), the corresponding critical load when the sample breaks is 154N; the calculated cantilever beam bending strength is 131MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com